LT1614

Inverting 600kHz

Switching Regulator

U

DESCRIPTIO

FEATURES

■

■

■

■

■

■

■

■

■

The LT ®1614 is a fixed frequency, inverting mode switching reglator that operates from an input voltage as low as

1V. Utilizing a low noise topology, the LT1614 can generate a negative output down to – 24V from a 1V to 5V input.

Fixed frequency switching ensures a clean output free

from low frequency noise. The device contains a lowbattery detector with a 200mV reference and shuts down

to less than 10µA. No load quiescent current of the LT1614

is 1mA and the internal NPN power switch handles a

500mA current with a voltage drop of just 295mV.

Better Regulation Than a Charge Pump

0.1Ω Effective Output Impedance

– 5V at 200mA from a 5V Input

600kHz Fixed Frequency Operation

Operates with VIN as Low as 1V

1mA Quiescent Current

Low Shutdown Current: 10µA

Low-Battery Detector

Low VCESAT Switch: 295mV at 500mA

U

APPLICATIO S

■

■

■

■

High frequency switching enables the use of small inductors and capacitors. Ceramic capacitors can be used in

many applications, eliminating the need for bulky tantalum types.

MR Head Bias

LCD Bias

GaAs FET Bias

Positive-to-Negative Conversion

The LT1614 is available in 8-lead MSOP or SO packages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

U

TYPICAL APPLICATIO

+

VIN

C1

33µF

100k

L2

22µH

5V to – 5V Converter Efficiency

90

VOUT

– 5V

200mA

SW

SHDN

LT1614

VC

NFB

GND

69.8k

D1

24.9k

+

VIN

5V

C2

33µF

1nF

C1, C2: AVX TAJB336M010

C3: TAIYO YUDEN EMK316BJ105MF

D1: MBR0520

L1, L2: MURATA LQH3C220

Figure 1. 5V to – 5V/200mA Converter

1614 TA01

80

EFFICIENCY (%)

C3

1µF

L1

22µH

70

60

50

40

3

100

10

30

LOAD CURRENT (mA)

300

1614 TA02

1

�LT1614

W W

W

AXI U

U

ABSOLUTE

RATI GS

(Note 1)

VIN, SHDN, LBO Voltage ......................................... 12V

SW Voltage ............................................... – 0.4V to 30V

NFB Voltage ............................................................ – 3V

VC Voltage ................................................................ 2V

LBI Voltage ............................................ 0V ≤ VLBI ≤ 1V

Current into FB Pin .............................................. ±1mA

Junction Temperature ...........................................125°C

Operating Temperature Range

LT1614C ................................................. 0°C to 70°C

LT1614I ............................................. – 40°C to 85°C

Extended Commercial

Temperature Range (Note 2) .................. – 40°C to 85°C

Storage Temperature Range ................ – 65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

U

W

U

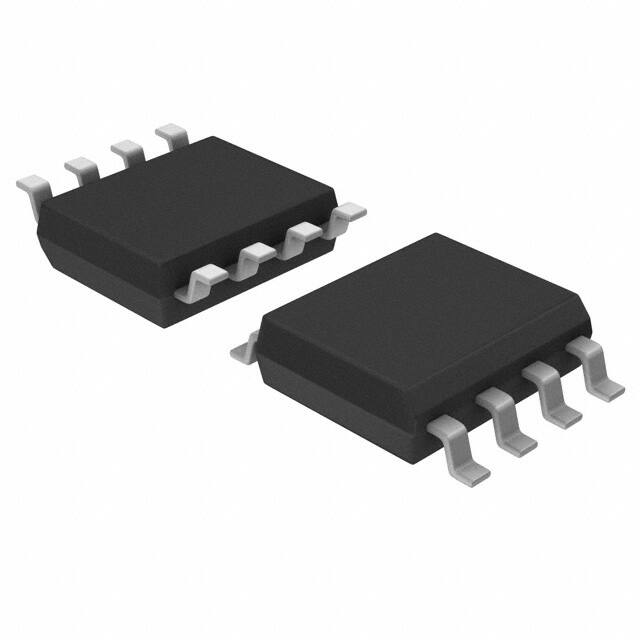

PACKAGE/ORDER I FOR ATIO

ORDER PART

NUMBER

ORDER PART

NUMBER

TOP VIEW

TOP VIEW

NFB

VC

SHDN

GND

1

2

3

4

8

7

6

5

LBO

LBI

VIN

SW

MS8 PACKAGE

8-LEAD PLASTIC MSOP

LT1614CMS8

LT1614IMS8

MS8 PART MARKING

TJMAX = 125°C, θJA = 160°C/W

LTID

LTJB

NFB 1

8

LBO

VC 2

7

LBI

SHDN 3

6

VIN

GND 4

5

SW

LT1614CS8

LT1614IS8

S8 PART MARKING

S8 PACKAGE

8-LEAD PLASTIC SO

1614

1614I

TJMAX = 125°C, θJA = 120°C/W

Consult factory for Military grade parts.

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. Commercial Grade 0°C to 70°C. VIN = 1.5V, VSHDN = VIN unless

otherwise noted.

PARAMETER

CONDITIONS

MIN

Quiescent Current

VSHDN = 0V

Feedback Voltage

NFB Pin Bias Current (Note 3)

VNFB = –1.24V

Reference Line Regulation

1V ≤ VIN ≤ 2V

2V ≤ VIN ≤ 6V

Error Amp Transconductance

2

UNITS

mA

µA

– 1.21

– 1.24

– 1.27

V

– 2.5

– 4.5

–7

µA

0.6

0.3

1.1

0.8

%/V

%/V

0.92

1

V

6

V

●

∆I = 5µA

µmhos

16

100

V/V

●

500

600

●

73

70

80

80

%

%

0.75

1.2

A

Maximum Duty Cycle

Switch Current Limit (Note 4)

2

10

●

Error Amp Voltage Gain

Switching Frequency

MAX

1

5

●

Minimum Input Voltage

Maximum Input Voltage

TYP

750

kHz

�LT1614

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. Commercial Grade 0°C to 70°C. VIN = 1.5V, VSHDN = VIN unless

otherwise noted.

PARAMETER

CONDITIONS

Switch VCESAT

Shutdown Pin Current

MIN

TYP

MAX

UNITS

ISW = 500mA (25°C, 0°C)

ISW = 500mA (70°C)

295

350

400

mV

mV

VSHDN = VIN

VSHDN = 0V

10

–5

20

– 10

µA

µA

200

210

215

mV

mV

V

LBI Threshold Voltage

●

190

185

LBO Output Low

ISINK = 10µA

0.1

0.25

LBO Leakage Current

VLBI = 250mV, VLBO = 5V

0.01

0.1

µA

LBI Input Bias Current (Note 5)

VLBI = 150mV

10

50

nA

Low-Battery Detector Gain

1MΩ Load

1000

Switch Leakage Current

VSW = 5V

0.01

3

TYP

MAX

1

5

2

10

V/V

µA

Industrial Grade – 40°C to 85°C. VIN = 1.5V, VSHDN = VIN unless otherwise noted.

PARAMETER

CONDITIONS

MIN

Quiescent Current

VSHDN = 0V

Feedback Voltage

mA

µA

●

– 1.21

– 1.24

– 1.27

V

●

–2

– 4.5

– 7.5

µA

1V ≤ VIN ≤ 2V

2V ≤ VIN ≤ 6V

0.6

0.3

1.1

0.8

%/V

%/V

– 40°C

85°C

1.1

0.8

1.25

1.0

V

V

NFB Pin Bias Current (Note 3)

VNFB = – 1.24V

Reference Line Regulation

Minimum Input Voltage

Maximum Input Voltage

Error Amp Transconductance

UNITS

6

●

∆I = 5µA

Error Amp Voltage Gain

V

16

µmhos

100

V/V

Switching Frequency

●

500

600

Maximum Duty Cycle

●

70

80

%

0.75

1.2

A

Switch Current Limit (Note 4)

750

kHz

Switch VCESAT

ISW = 500mA (– 40°C)

ISW = 500mA (85°C)

250

330

350

400

mV

mV

Shutdown Pin Current

VSHDN = VIN

VSHDN = 0V

10

–5

20

– 10

µA

µA

LBI Threshold Voltage

200

220

mV

LBO Output Low

ISINK = 10µA

0.1

0.25

V

LBO Leakage Current

VLBI = 250mV, VLBO = 5V

0.1

0.3

µA

5

30

●

180

LBI Input Bias Current (Note 5)

VLBI = 150mV

Low-Battery Detector Gain

1MΩ Load

1000

Switch Leakage Current

VSW = 5V

0.01

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT1614C is guaranteed to meet specified performance from

0°C to 70°C and is designed, characterized and expected to meet these

extended temperature limits, but is not tested at – 40°C and 85°C. The

LT1614I is guaranteed to meet the extended temperature limits.

nA

V/V

µA

3

Note 3: Bias current flows out of NFB pin.

Note 4: Switch current limit guaranteed by design and/or correlation to

static tests. Duty cycle affects current limit due to ramp generator.

Note 5: Bias current flows out of LBI pin.

3

�LT1614

U W

TYPICAL PERFOR A CE CHARACTERISTICS

Shutdown Pin Bias Current vs

Input Voltage

Quiescent Current in Shutdown

10

10

8

8

LBI Bias Current vs Temperature

16

6

4

2

LBI BIAS CURRENT (nA)

SHDN BIAS CURRENT (µA)

QUIESCENT CURRENT (µA)

14

6

4

12

10

8

6

4

2

2

0

0

1

2

3

INPUT VOLTAGE (V)

4

0

5

0

1

2

3

INPUT VOLTAGE (V)

4

1614 G01

–25

0

50

25

TEMPERATURE (°C)

75

1614 G02

Switch VCESAT vs Current

Oscillator Frequency vs

Input Voltage

210

TA = 25°C

100

1614 G03

LBI Reference vs Temperature

500

900

208

300

200

100

800

206

204

FREQUENCY (kHz)

REFERENCE VOLTAGE (mV)

400

VCESAT (mV)

0

–50

5

202

200

198

196

194

25°C

85°C

700

–40°C

600

500

192

0

0

100

500

200

300

400

SWITCH CURRENT (mA)

190

–50

600

–25

25

50

0

TEMPERATURE (°C)

75

–1.245

5

5

–1.240

VIN = 3V

1

0

–40

VIN = 5V

–20

0

20

40

TEMPERATURE (°C)

60

80

1614 G07

*Includes diode leakage

–1.235

4

VNFB (V)

NFB PIN BIAS CURRENT (µA)

QUIESCENT CURRENT (mA)

6

2

5

VNFB vs Temperature

6

3

4

1614 G06

NFB Pin Bias Current vs

Temperature

VIN = 1.25V

3

1614 G05

Quiescent Current vs

Temperature*

4

2

1

INPUT VOLTAGE (V)

1614 G04

4

400

100

3

–1.230

–1.225

2

–1.220

1

0

–50

–1.215

–25

0

25

50

TEMPERATURE (°C)

75

100

1614 G08

–1.210

–50

–25

0

25

50

TEMPERATURE (°C)

75

100

1614 G09

�LT1614

U

U

U

PIN FUNCTIONS

NFB (Pin 1): Negative Feedback Pin. Reference voltage is

– 1.24V. Connect resistive divider tap here. The suggested value for R2 is 24.9k. Set R1 and R2 according to:

R1 =

GND (Pin 4): Ground. Connect directly to local ground

plane.

SW (Pin 5): Switch Pin. Minimize trace area at this pin to

keep EMI down.

| VOUT | – 1.24

1.24

+ 4.5 • 10 – 6

R2

VIN (Pin 6): Supply Pin. Must have 1µF ceramic bypass

capacitor right at the pin, connected directly to ground.

VC (Pin 2): Compensation Pin for Error Amplifier. Connect a series RC from this pin to ground. Typical values

are 100kΩ and 1nF. Minimize trace area at VC.

LBI (Pin 7): Low-Battery Detector Input. 200mV reference. Voltage on LBI must stay between ground and

700mV. Float this pin if not used.

SHDN (Pin 3): Shutdown. Ground this pin to turn off

switcher. Must be tied to VIN (or higher voltage) to enable

switcher. Do not float the SHDN pin.

LBO (Pin 8): Low-Battery Detector Output. Open collector, can sink 10µA. A 1MΩ pull-up is recommended. Float

this pin if not used. The low-battery detector is disabled

when SHDN is low. LBO is high-Z in this state.

W

BLOCK DIAGRAM

VIN

6

VIN

R5

40k

R6

40k

+

SHDN

VC

gm

2

ERROR

AMPLIFIER

A1

+

SHUTDOWN

–

Q1

Q2

×10

LBI

–

R4

140k

NFB

LBO

8

–

200mV

A4

SW

COMPARATOR

–

1

VOUT

+

7

ENABLE

BIAS

R3

30k

RAMP

GENERATOR

R1

(EXTERNAL)

+

Σ

+

DRIVER

FF

A2

5

Q3

Q

R

+

S

+

NFB

R2

(EXTERNAL)

3

A=3

600kHz

OSCILLATOR

0.15Ω

–

4

GND

1614 BD

Figure 2. Block Diagram

5

�LT1614

U

OPERATIO

The LT1614 combines a current mode, fixed frequency

PWM architecture with a –1.23V reference to directly

regulate negative outputs. Operation can be best understood by referring to the block diagram of Figure 2. Q1 and

Q2 form a bandgap reference core whose loop is closed

around the output of the converter. The driven reference

point is the lower end of resistor R4, which normally sits

at a voltage of –1.23V. As the load current changes, the

NFB pin voltage also changes slightly, driving the output

of gm amplifier A1. Switch current is regulated directly on

a cycle-to-cycle basis by A1’s output. The flip-flop is set at

the beginning of each cycle, turning on the switch. When

the summation of a signal representing switch current and

a ramp generator (introduced to avoid subharmonic oscillations at duty factors greater than 50%) exceeds the VC

signal, comparator A2 changes stage, resetting the flipflop and turning off the switch. Output voltage decreases

(the magnitude increases) as switch current is increased.

The output, attenuated by external resistor divider R1 and

R2, appears at the NFB pin, closing the overall loop.

Frequency compensation is provided externally by a series

RC connected from the VC pin to ground. Typical values

are 100k and 1nF. Transient response can be tailored by

adjustment of these values.

As load current is decreased, the switch turns on for a

shorter period each cycle. If the load current is further

decreased, the converter will skip cycles to maintain

output voltage regulation.

C2

1µF

L1

If D2 is replaced by an inductor, as shown in Figure 4, a

higher performance solution results. This converter topology was developed by Professor S. Cuk of the California

Institute of Technology in the 1970s. A low ripple voltage

results with this topology due to inductor L2 in series with

the output. Abrupt changes in output capacitor current are

eliminated because the output inductor delivers current to

the output during both the off-time and the on-time of the

LT1614 switch. With proper layout and high quality output

capacitors, output ripple can be as low as 1mVP–P.

The operation of Cuk’s topology is shown in Figures 5

and␣ 6. During the first switching phase, the LT1614’s

switch, represented by Q1, is on. There are two current

loops in operation. The first loop begins at input capacitor

C1, flows through L1, Q1 and back to C1. The second loop

flows from output capacitor C3, through L2, C2, Q1 and

back to C3. The output current from RLOAD is supplied by

L2 and C3. The voltage at node SW is VCESAT and at node

SWX the voltage is –(VIN + |VOUT|). Q1 must conduct both

L1 and L2 current. C2 functions as a voltage level shifter,

with an approximately constant voltage of (VIN + |VOUT|)

across it.

D2

C2

1µF

L1

L2

VIN

+

D1

VIN

C1

–VOUT

LT1614

R1

SHDN

NFB

VC

10Ok

GND

VIN

GND

C3

R2

10k

1nF

1614 F03

Figure 3. Direct Regulation of Negative Output

Using Boost Converter with Charge Pump

NFB

VC

10Ok

1nF

–VOUT

R1

SHDN

C3

R2

10k

SW

LT1614

C1

SHUTDOWN

+

SHUTDOWN

D1

+

SW

+

VIN

6

The LT1614 can work in either of two topologies. The

simpler topology appends a capacitive level shift to a

boost converter, generating a negative output voltage,

which is directly regulated. The circuit schematic is detailed in Figure 3. Only one inductor is required, and the

two diodes can be in a single SOT-23 package. Output

noise is the same as in a boost converter, because current

is delivered to the output only during the time when the

LT1614’s internal switch is on.

1614 F04

Figure 4. L2 Replaces D2 to Make Low Output Ripple

Inverting Topology. Coupled or Uncoupled Inductors Can

Be Used. Follow Phasing If Coupled for Best Results

�LT1614

U

OPERATIO

When Q1 turns off during the second phase of switching,

the SWX node voltage abruptly increases to (VIN + |VOUT|).

The SW node voltage increases to VD (about 350mV). Now

current in the first loop, begining at C1, flows through L1,

C2, D1 and back to C1. Current in the second loop flows

from C3 through L2, D1 and back to C3. Load current

continues to be supplied by L2 and C3.

rents are dumped into the ground plane as drawn in

Figures 4, 5 and 6. This single layout technique can

virtually eliminate high frequency “spike” noise so often

present on switching regulator outputs.

Output ripple voltage appears as a triangular waveform

riding on VOUT. Ripple magnitude equals the ripple current

of L2 multiplied by the equivalent series resistance (ESR)

of output capacitor C3. Increasing the inductance of L1

and L2 lowers the ripple current, which leads to lower

output voltage ripple. Decreasing the ESR of C3, by using

ceramic or other low ESR type capacitors, lowers output

ripple voltage. Output ripple voltage can be reduced to

arbitrarily low levels by using large value inductors and

low ESR, high value capacitors.

An important layout issue arises due to the chopped

nature of the currents flowing in Q1 and D1. If they are both

tied directly to the ground plane before being combined,

switching noise will be introduced into the ground plane.

It is almost impossible to get rid of this noise, once present

in the ground plane. The solution is to tie D1’s cathode to

the ground pin of the LT1614 before the combined cur–(VIN + VOUT)

VCESAT

L1

SW

C2

L2

SWX

VIN

–VOUT

D1

Q1

+

C1

C3

RLOAD

+

1614 F05

Figure 5. Switch-On Phase of Inverting Converter. L1 and L2 Current Have Positive dI/dt

VIN + VOUT+ VD

L1

SW

VD

C2

L2

SWX

VIN

–VOUT

Q1

+

D1

C1

C3

RLOAD

+

1614 F06

Figure 6. Switch-Off Phase of Inverting Converter. L1 and L2 Current Have Negative dI/dt

7

�LT1614

U

OPERATIO

Transient Response

The inverting architecture of the LT1614 can generate a

very low ripple output voltage. Recently available high

value ceramic capacitors can be used successfully in

LT1614 designs. The addition of a phase lead capacitor,

CPL, reduces output perturbations due to load steps when

lower value ceramic capacitors are used and connected in

parallel with feedback resistor R1. Figure 7 shows an

LT1614 inverting converter with resistor loads RL1 and

RL2. RL1 is connected across the output, while RL2 is

switched in externally via a pulse generator. Output voltage waveforms are pictured in subsequent figures, illustrating the performance of output capacitor type.

Figure 8 shows the output voltage with a 50mA to 200mA

load step, using an AVX TAJ “B” case 33µF tantalum

capacitor at the output. Output perturbation is approximately 250mV as the load changes from 50mA to 200mA.

Steady-state ripple voltage is 40mVP–P, due to L1’s ripple

current and C3’s ESR. Figure 9 pictures the output voltage

and switch pin voltage at 500ns per division. Note the

absence of high frequency spikes at the output. This is

easily repeatable with proper layout, described in the next

section.

In Figure 10, output capacitor C3 is replaced by a ceramic

unit. These large value capacitors have ESR of 2mΩ or less

and result in very low output ripple. A 1nF capacitor, CPL,

connected across R1 reduces output perburbation due to

load step. This keeps the output voltage within 5% of

steady-state value. Figure 11 pictures the output and

switch nodes at 500ns per division. Output ripple is about

5mVP-P. Again, good layout is essential to achieve this low

noise performance.

Layout

The LT1614 switches current at high speed, mandating

careful attention to layout for best performance. You will

not get advertised performance with careless layout. Figure␣ 12

shows recommended component placement. Follow this

closely in your printed circuit layout. The cut ground

copper at D1’s cathode is essential to obtain the low noise

achieved in Figures 10 and 11’s oscillographs. Input

bypass capacitor C1 should be placed close to the LT1614

as shown. The load should connect directly to output

capacitor C2 for best load regulation. You can tie the local

ground into the system ground plane at C3’s ground

terminal.

COMPONENT SELECTION

C2

1µF

L1

22µH

VIN

5V

Inductors

L2

22µH

D1

SHDN

+

R1

69.8k

LT1614

C1

CPL

1nF

NFB

VC

GND

RC

–VOUT

SW

RL1

100Ω

C3

R2

24.9k

RL2

33Ω

+

VIN

CC

C1: AVX TAJB226M010

C2: TAIYO YUDEN LMK212BJ105MG

C3: AVX TAJB336M006 OR MURATA (SEE TEXT)

D1: MBR0520

L1, L2: MURATA LQH3C220

Figure 7. Switching RL2 Provides 50mA to 200mA

Load Step for LT1614 5V to – 5V Converter

8

1614 F07

Each of the two inductors used with the LT1614 should

have a saturation current rating (where inductance is

approximately 70% of zero current inductance) of approximately 0.4A or greater. If the device is used in

“charge pump” mode, where there is only one inductor,

then its rating should be 0.75A or greater. DCR of the

inductors should be 0.4Ω or less. 22µH inductors are

called out in the applications schematics because these

Murata units are physically small and inexpensive. Increasing the inductance will lower ripple current, increasing available output current. A coupled inductor of 33µH,

such as Coiltronics CTX33-2, will provide 290mA at – 5V

from a 5V input. Inductance can be reduced if operating

from a supply voltage below 3V. Table 1 lists several

inductors that will work with the LT1614, although this is

not an exhaustive list. There are many magnetics vendors

whose components are suitable.

�LT1614

U

OPERATIO

VOUT

100mV/DIV

AC COUPLED

ILOAD

VOUT

20mV/DIV

AC COUPLED

VSW

5V/DIV

200mA

50mA

500µs/DIV

500ns/DIV

1614 F08

Figure 8. Load Step Response of LT1614

with 33µF Tantalum Output Capacitor

Figure 9. 33µF “B” Case Tantalum Capacitor Has ESR Resulting

in 40mVP-P Voltage Ripple at Output with 200mA Load

VOUT

100mV/DIV

AC COUPLED

VOUT

10mV/DIV

AC COUPLED

200mA

VSW

5V/DIV

ILOAD

1614 F09

50mA

500µs/DIV

500ns/DIV

1614 F10

Figure 10. Replacing C3 with 22µF Ceramic Capacitor

Lowers Output Voltage Ripple. 1nF Phase-Lead Capacitor

in Parallel with R1 Lowers Transient Excursion

1614 F11

Figure 11. 22µF Ceramic Capacitor at

Output Reduces Output Ripple Voltage

C1

+

SHUTDOWN

R1

R2

RC

CC

1

8

2

7

3

6

4

5

VIN

L1

D1

+

GND

C3

C2

1614 F12

L2

VOUT

Figure 12. Suggested Component Placement. Note: Cut in Ground Copper at D1’s Cathode

9

�LT1614

U

OPERATIO

Capacitors

As described previously, ceramic capacitors can be used

with the LT1614. For lower cost applications, small tantalum units can be used. A value of 22µF is acceptable,

although larger capacitance values can be used. ESR is the

most important parameter in selecting an output capacitor. The “flying” capacitor (C2 in the schematic figures)

should be a 1µF ceramic type. An X5R or X7R dielectric

should be used to avoid capacitance decreasing severely

with applied voltage. The input bypass capacitor is less

critical, and either tantalum or ceramic can be used with

little trade-off in circuit performance. Some capacitor

types appropriate for use with the LT1614 are listed in

Table 2.

Diodes

A Schottky diode is recommended for use with the LT1614.

The Motorola MBR0520 is a very good choice. Where the

input to output voltage differential exceeds 20V, use the

MBR0530 ( a 30V diode).

Table 1. Inductor Vendors

VENDOR

PHONE

URL

PART

COMMENT

Sumida

(847) 956-0666

www.sumida.com

CLS62-22022

CD43-470

22µH Coupled

47µH

Murata

(404) 436-1300

www.murata.com

LQH3C-220

22µH, 2mm Height

Coiltronics

(407) 241-7876

www.coiltronics.com

CTX20-1

20µH Coupled, Low DCR

Table 2. Capacitor Vendors

10

VENDOR

PHONE

URL

PART

COMMENT

Taiyo Yuden

(408) 573-4150

www.t-yuden.com

Ceramic Caps

X5R Dielectric

AVX

(803) 448-9411

www.avxcorp.com

Ceramic Caps

Tantalum Caps

Murata

(404) 436-1300

www.murata.com

Ceramic Caps

�LT1614

U

U

W

U

APPLICATIONS INFORMATION

Shutdown Pin

3.3V

R1

The LT1614 has a Shutdown pin (SHDN) that must be

grounded to shut the device down or tied to a voltage equal

or greater than VIN to operate. The shutdown circuit is

shown in Figure 13.

VIN

LBI

LT1614

1M

+

LBO

R2

100k

–

200mV

INTERNAL

REFERENCE

GND

Note that allowing SHDN to float turns on both the startup current (Q2) and the shutdown current (Q3) for VIN >

2VBE. The LT1614 doesn’t know what to do in this situation

and behaves erratically. SHDN voltage above VIN is allowed. This merely reverse-biases Q3’s base emitter junction, a benign condition. The low-battery detector is disabled when SHDN is low.

VLB – 200mV

2µA

Figure 14. Setting Low-Battery Detector Trip Point

200k

VIN

2N3906

Q3

SHDN

R1 =

1614 F14

VIN

R2

400k

TO PROCESSOR

LBO

LT1614

VREF

200mV

SHUTDOWN

CURRENT

10k

200k

LBI

+

GND

10µF

1614 F15

START-UP

CURRENT

Figure 15. Accessing 200mV Reference

Q2

Q1

Figure 13. Shutdown Circuit

Low-Battery Detector

The LT1614’s low-battery detector is a simple PNP input

gain stage with an open collector NPN output. The negative input of the gain stage is tied internally to a 200mV

reference. The positive input is the LBI pin. Arrangement

as a low-battery detector is straightforward. Figure 14

details hookup. R1 and R2 need only be low enough in

value so that the bias current of the LBI pin doesn’t cause

large errors. For R2, 100k is adequate. The 200mV reference can also be accessed as shown in Figure 15. The lowbattery detect is not operative when the device is shut

down.

Coupled Inductors

The applications shown in this data sheet use two uncoupled inductors because the Murata units specified are

small and inexpensive. This topology can also be used

with a coupled inductor as shown in Figure 16. Be sure to

get the phasing right.

L1A

10µH

VIN

5V

+

VIN

C1

33µF

100k

C3

1µF

•

•

L1B

10µH

VOUT

– 5V

200mA

SW

SHDN

LT1614

VC

NFB

GND

69.8k

D1

24.9k

+

1614 F13

C2

33µF

1nF

C1, C2: AVX TAJB336M010

C3: AVX 1206CY106

D1: MBR0520

L1: COILTRONICS CTX10-1

1614 F16

Figure 16. 5V to – 5V Converter with Coupled Inductor

11

�LT1614

U

TYPICAL APPLICATIO S

5V to – 15V/80mA DC/DC Converter

C1

1µF

L1

22µH

VIN

+

100k

VOUT

–15V

80mA

SW

SHDN

LT1614

NFB

VC

22µF

L2

22µH

GND

255k

D1

+

VIN

5V

24.9k

10µF

25V

1nF

C1: 25V, Y5V

D1: MBR0520

L1, L2: MURATA LQH3C220

1614 TA05

5V to – 15V Converter Efficiency

80

EFFICIENCY (%)

75

70

65

60

55

50

1

10

LOAD CURRENT (mA)

100

1614 TA06

12

�LT1614

U

TYPICAL APPLICATIO S

3.3V to – 3.1V/200mA DC/DC Converter

C1

1µF

L1

22µH

VIN

22µF

100k

VOUT

– 3.1V

200mA

SW

SHDN

LT1614

VC

+

L2

22µH

GND

18.7k

D1

FB

22µF

+

VIN

3.3V

12.7k

1nF

C1: AVX1206CY106

D1: MBR0520

L1, L2: MURATA LQH3C220

1614 TA03

3.3V to – 3.1V Converter Efficiency

80

EFFICIENCY (%)

70

60

50

40

30

20

3

10

30

100

LOAD CURRENT (mA)

300

1614 TA04

13

�LT1614

U

PACKAGE DESCRIPTION

Dimensions in inches (millimeters) unless otherwise noted.

MS8 Package

8-Lead Plastic MSOP

(LTC DWG # 05-08-1660)

0.040 ± 0.006

(1.02 ± 0.15)

0.007

(0.18)

0.034 ± 0.004

(0.86 ± 0.102)

8

7 6

5

0° – 6° TYP

0.021 ± 0.006

(0.53 ± 0.015)

SEATING

PLANE 0.012

(0.30)

0.0256

REF

(0.65)

BSC

0.006 ± 0.004

(0.15 ± 0.102)

* DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

14

0.118 ± 0.004*

(3.00 ± 0.102)

0.118 ± 0.004**

(3.00 ± 0.102)

0.193 ± 0.006

(4.90 ± 0.15)

MSOP (MS8) 1098

1

2 3

4

�LT1614

U

PACKAGE DESCRIPTION

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

8

7

6

5

0.150 – 0.157**

(3.810 – 3.988)

0.228 – 0.244

(5.791 – 6.197)

1

0.010 – 0.020

× 45°

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

0.053 – 0.069

(1.346 – 1.752)

0°– 8° TYP

0.016 – 0.050

(0.406 – 1.270)

0.014 – 0.019

(0.355 – 0.483)

TYP

*DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

2

3

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

SO8 1298

15

�LT1614

U

TYPICAL APPLICATIO S

5V to – 5V Converter Uses All Ceramic Capacitors

C3

1µF

L1

22µH

VIN

3V TO 5V

VIN

100k

VOUT

– 5V

200mA

SW

SHDN

LT1614

VC

NFB

GND

C1

4.7µF

L2

22µH

1nF

69.8k

D1

C2

10µF

24.9k

1nF

C1: TAIYO YUDEN LMK316BJ475ML

C2: TAIYO YUDEN JMK316BJ106ML

C3: TAIYO YUDEN EMK316BJ105MF

D1: MOTOROLA MBR0520

L1, L2: MURATA LQH3C220 OR SUMIDA CD43-220

1614 TA07

Efficiency vs Load Current

80

VIN = 3V

VOUT = –5V

75

EFFICIENCY (%)

70

65

60

55

50

45

40

1

10

LOAD CURRENT (mA)

100

1614 TA08

RELATED PARTS

PART NUMBER

DESCRIPTION

COMMENTS

LTC®1174

High Efficiency Step-Down and Inverting DC/DC Converter

Selectable IPEAK = 300mA or 600mA

LT1307

Single Cell Micropower 600kHz PWM DC/DC Converter

3.3V at 75mA from 1 Cell, MSOP Package

LT1308

Single Cell High Current Micropower 600kHz Boost Converter

5V at 1A from a Single Li-Ion Cell, SO-8 Package

LT1316

Micropower Boost DC/DC Converter

Programmable Peak Current Limit, MSOP Package

LT1317

Micropower 600kHz PWM DC/DC Converter

2 Cells to 3.3V at 200mA, MSOP Package

LTC1474

Low Quiescent Current High Efficiency DC/DC Converter

IQ = 10µA, Programmable Peak Current Limit, MSOP

LT1610

1.7MHz Single Cell Micropower DC/DC Converter

5V at 200mA from 3.3V, MSOP Package

LT1611

Inverting 1.4MHz Switching Regulator in 5-Lead SOT-23

– 5V at 150mA from 5V Input, Tiny SOT-23 Package

LT1613

1.4MHz Switching Regulator in 5-Lead SOT-23

5V at 200mA from 3.3V Input, Tiny SOT-23 Package

LT1615

Micropower Constant Off-Time DC/DC Converter in 5-Lead SOT-23

20V at 12mA from 2.5V, Tiny SOT-23 Package

LT1617

Micropower Inverting DC/DC Converter in 5-Lead SOT-23

–15V at 12mA from 2.5V, Tiny SOT-23 Package

LT1930

1.2MHz Boost DC/DC Converter in 5-Lead SOT-23

5V at 480mA from 3.3V Input, VOUT Up to 34V

LT1931

1.2MHz Inverting DC/DC Converter in 5-Lead SOT-23

–5V at 350mA from 5V Input, 1mVP-P Output Ripple

16

Linear Technology Corporation

sn1614 1614fs LT/TP 1000 4K • PRINTED IN THE USA

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408)432-1900 ● FAX: (408) 434-0507 ● www.linear-tech.com

LINEAR TECHNOLOGY CORPORATION 1998

�