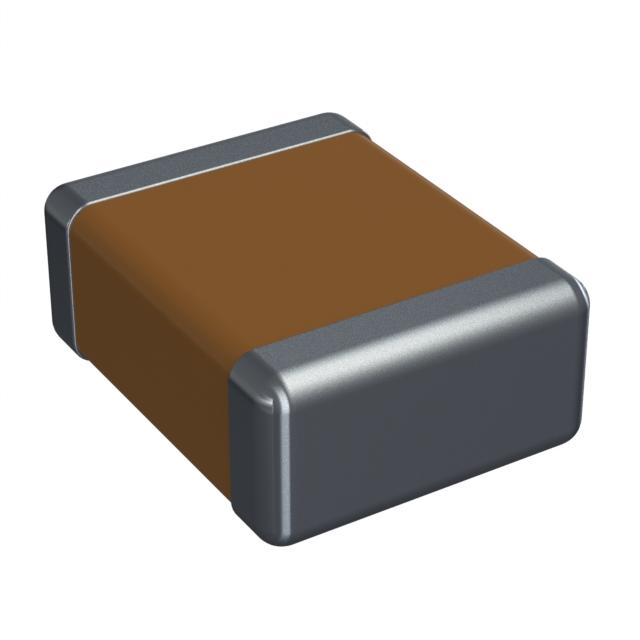

X7R Dielectric, KGM Series

General Specifications

The X7R dielectric is the most popular of the intermediate EIA class II materials due to its relative temperature stability.

While the capacitance change is non-linear, temperature variation is within ±15% from - 55°C to + 125°C.

Capacitance for X7R varies under the influence of electrical operating conditions such as voltage and frequency. X7R

dielectric chip usage covers a broad spectrum of industrial applications where known changes in capacitance due to

applied voltages are acceptable.

SpiCAT is an additional online resource that KAVX offers to help create engineering simulations. Please visit spicat.

kyocera-avx.com for more information.

HOW TO ORDER

KGM

03

A

R7

1E

101

M

N

Series

General Purpose

Tin/Nickel Finish

Size

02= 01005 32= 1210

03= 0201

43= 1812

05= 0402

44= 1825

15= 0603

55= 2220

21= 0805

56= 2225

31= 1206

Thickness

See Cap Chart

Dielectric

R7 = X7R

Voltage

0G = 4.0V

1H = 50V

0J = 6.3V

2A = 100V

1A = 10V

2D = 200V

1C = 16V

2E = 250V

1E = 25V

2H = 500V

Capacitance

Code Code (in pF)

2 Significant Digits +

Number of zeros

eg. 106 = 10µF

103 = 10nF

Capacitance

Tolerance

J* = +/- 5%

K = +/- 10%

M = +/- 20%

Packaging

See Table Below

PACKAGING CODES

Code

EIA (inch)

IEC(mm)

7" Paper

02

01005

0402

H

7" Embossed

13" Paper

03

0201

0603

H

05

0402

1005

H

N

15

0603

1608

T

M

*≤1μF only, contact

factory for additional

values

13"Embossed

N

21

0805

2012

T

U

M

L

31

1206

3216

T

U

M

L

32

1210

3225

U

L

43

1812

4532

V

S

44

1825

4564

V

S

55

2220

5750

V

S

56

2225

5763

V

S

*Note: The thickness determines if packaging is paper or embossed.

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or available

online at www.kyocera-avx.com/disclaimer/ by reference and should be reviewed in full before placing any order.

TDS-SMDMLCC-0038 | Rev 5

– surface mount ceramic capacitor products –

1

�X7R Dielectric, KGM Series

Specifications and Test Methods

Parameter/Test

Operating Temperature Range

Capacitance

X7R Specification Limits

-55ºC to +125ºC

Within specified tolerance

Dissipation Factor / Tanδ

Refer to https://spicat.kyocera-avx.com for

individual part number specification

Insulation Resistance

Dielectric Strength

Bending Strength

Solderability

Appearance

Capacitance Variation

Dissipation Factor / Tanδ

Resistance to

Solder Heat

Insulation Resistance

Withstanding Voltage /

Dielectric Strength

Appearance

Capacitance Variation

Dissipation Factor

Thermal Shock

Insulation Resistance

Withstanding Voltage /

Dielectric Strength

Appearance

Capacitance Variation

Dissipation Factor / Tanδ

Load Life

Insulation Resistance

Appearance

Capacitance Variation

Dissipation Factor / Tanδ

Load

Humidity

Insulation Resistance

Appearance

Termination Strength

Appearance

Capacitance

Vibration

Tanδ

Heat Treatment

Measuring Conditions (Complies with JIS C5101 / IEC60384)

Temperature Cycle Chamber

Measure after heat treatment

Capacitance Frequency Volt

C≤10µF

Frequency : 1kHz±10%

Volt : 1.0±0.2Vrms *0.5±0.2Vrms

C>10µF

Frequency : 120Hz±10%

Volt : 0.5±0.2Vrms

The charge and discharge current of the capacitor must not exceed 50mA.

Apply the rated voltage for 1 minute, and measure it in normal temperaRefer to https://spicat.kyocera-avx.com for

ture and humidity. The charge and discharge current of the capacitor must

individual part number specifiction

not exceed 50mA.

Charge device with 250% of rated voltage for 1-5 seconds, w/charge and

No breakdown or visual defects

discharge current limited to 50 mA (max)

Note: Charge device with 150% of rated voltage for 500V devices.

No significant damage with 1mm bending

Glass epoxy PCB: Fulcrum spacing: 90mm, duration time 10 seconds.

Soaking condition

Solder coverage : 95% min.

Sn-3Ag-0.5Cu 245±5℃ 3±0.5 sec.

No problem observed

Take the initial value after heat treatment.

Soak the sample in 260℃±5℃ solder for 10±0.5 seconds and place in nor≤ ±7.5%

mal temperature and humidity, and measure after heat treatment.

Within specification

(Pre-heating conditions)

Within specification

Order

Temperature

Time

1

80 to 100℃

2 minutes

2

150 to 200℃

2 minutes

Resist without problem

The charge and discharge current of the capacitor must not exceed 50mA

for IR and withstanding voltage measurement.

No visual defects

Take the initial value after heat treatment.

(Cycle)

≤ ±7.5%

Room temperature (3 min.)―>

Within specification

Lowest operation temperature (30 min.)―>

Within specification

Room temperature (3 min.)―>

Highest operation temperature(30 min.)

After 5 cycles, measure after heat treatment.

Resist without problem

The charge and discharge current of the capacitor must not exceed 50mA

for IR and withstanding voltage measurement.

No visual defects

Take the initial value after heat treatment.

After applying *1.5 the rated voltage at the highest operation

≤ ±12.5%

temperature for 1000+12/ −0 hours, and measure the sample after heat

≤ Initial Value x 2.0 (See Above)

treatment in normal temperature and humidity.

The charge and discharge current of the capacitor must not exceed

Over 1000MΩ or 50MΩ · µF, whichever is less.

50mA for IR measurement.

*Exceptions Listed Below

*Apply 1.0 times when the rated voltage is 4V or less. Applied voltages

for respective products are indicated in the chart below.

No visual defects

Take the initial value after heat treatment.

After applying rated voltage for 500+12/ −0 hours in the condition of

≤ ±12.5%

40℃ ± 2℃ and 90 to 95%RH, and place in normal temperature and

Within specification

humid- ity, then measure the sample after heat treatment.

Over 1000MΩ or 50MΩ · µF, whichever is less.

The charge and discharge current of the capacitor must not exceed

*Exceptions Listed Below

50mA for IR measurement.

No problem observed

Microscope

Apply a sideward force of 500g (5N) to a PCB-mounted sample. note :

No problem observed

2N for 0201 size, and 1N for 01005 size.

No problem observed

Take the initial value after heat treatment.

Vibration frequency: 10 to 55 (Hz)

Within tolerance

Amplitude: 1.5mm

Sweeping condition: 10 ―> 55 ―> 10Hz/ 1 minute in X, Y and Z

Within tolerance

directions: 2 hours each, 6 hours in total, and place in normal temperature

and humidity, then measure the sample after heat treatment.

Expose sample in the temperature of 150+0/ −10℃ for 1 hour and leave the sample in normal temperature and humidity for

24±2 hours.

Voltage to be applied in the High Temperature Load (Applied voltage is the multiple of the rated voltage)

Rated Voltage

×1.0

Products

16V

KGM21AR71C475

Insulation Resistance : Over 10MΩ・μF

R7

2

05

15

21

31

KGM05AR70J474

KGM15AR71E105

KGM21AR71C475

KGM31AR71E106, KGM31AR71H475

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or available

online at www.kyocera-avx.com/disclaimer/ by reference and should be reviewed in full before placing any order.

TDS-SMDMLCC-0038 | Rev 5

– surface mount ceramic capacitor products –

�X7R Dielectric, KGM Series

Capacitance Range

SIZE

Soldering

Packaging

(L) Length

W) Width

(t) Terminal

mm

(in.)

mm

(in.)

mm

(in.)

WVDC

Cap

(pF)

100 101

01005

Reflow Only

All Paper

0.40 ± 0.02

(0.016 ± 0.0008)

0.20 ± 0.02

(0.008 ± 0.0008)

0.10± 0.04

(0.004 ± 0.0016)

16

6.3

A

A

150 151

A

220 221

A

330 331

A

470 471

A

680 681

A

1000 102

A

1500 152

A

2200 222

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

3300 332

3900 392

4700 472

5600 562

6800 682

Cap

0.010 103

(μF)

0.012 123

0201

Reflow Only

All Paper

0.60 ± 0.03

(0.024 ± 0.001)

0.30 ± 0.03

(0.011 ± 0.001)

0.15 ± 0.05

(0.006 ± 0.002)

0.015 153

0.018 183

A

0.022 223

0.027 273

0.033 333

0.039 393

0.047 473

0.068 683

0.082 823

A

0.1 104

0.12 124

0.15 154

0.22 224

0.33 334

0.47 474

0.68 684

1.0 105

2.2 225

4.7 475

0402

Reflow/Wave

All Paper

1.00 ± 0.10

(0.040 ± 0.004)

0.50 ± 0.10

(0.020 ± 0.004)

0.25 ± 0.15

(0.010 ± 0.006)

0603

Reflow/Wave

Paper/Embossed

1.60 ± 0.15

(0.063 ± 0.006)

0.81 ± 0.15

(0.032 ± 0.006)

0.35 ± 0.15

(0.014 ± 0.006)

0805

Reflow/Wave

Paper/Embossed

2.01 ± 0.20

(0.079 ± 0.008)

1.25 ± 0.20

(0.049 ± 0.008)

0.50 ± 0.25

(0.020 ± 0.010)

10 16 25 50 6.3 10 16 25 50 100 6.3 10 16 25 50 100 200

A A A A A A A A A A A A A A A A B

A A A A A A A A A A A A A A A A B

A A A A A A A A A A A A A A A A B

A A A A A A A A A A A A A A A A B

A A A A A A A A A A A A A A A A B

A A A A A A A A A A A A A A A A B

A A A A A A A A A A A A A A A A B

A A A

A A A A A A A A A A A A B

A A A

A A A A A A A A A A A A B

A A A

A A A A A A A A A A A A B

A A A

A A A A A A A A A A A A B

A A A

A A A A A A A A A A A A B

A A A

A A A A A A A A A A A A B

A A A

A A A A A A A A A A A A B

A A A

A A A A A A A A A A A A B

A A A A A

A A A A A A B

A A A A A

A A A A A B B

A A A A A

A A A A A B B

A A

A A A A A

A A A A A B B

A A A A A

A A A A B B

A A A A A

A A A B B B

A A A A A

A A A B B B

A A A A A

A A A B B B

A A A A C

A A A B B B

A A A A C

A A A B B B

A A A A C

A A A B B B

A A A B B

A A A A

A A A B B

A A A A

A B B B B

B B B B B

A A

B B B B B

B B B

A A

B B B B C

B B C

C

10 106

1206

Reflow/Wave

Paper/Embossed

3.20 ± 0.30

(0.126 ± 0.012)

1.60 ± 0.30

(0.063 ± 0.012)

0.50 ± 0.25

(0.020 ± 0.010)

250 6.3 10 16 25 50 100 200

B

B

B

N N N N N N

B

N N N N N N

B

N N N N N N

B

N N N N N N

B

N N N N N N

B

N N N N N N

B

N N N N N N

B

N N N N N A

B

N N N N N A

B

N N N N N A

B

N N N N N A

B

N N N N N A

B

N N N N N A

B

N N N N N A

B

N N N N A A

B

N N N N A A

B

N N N N A A

N N N N A A

N N N N A A

N N N N A A

N N N N A A

N N N N A A

N N N N A A

N N N N A A

N N N E A

E

E

E

E A

A A A A A

A A A A A

A A A A A

A A A A A

A A A A A

A A A A

A A A

A A A

250 500

B

B

N B

N B

N B

N B

N B

N B

N B

A A

A A

A A

A A

A A

A A

A A

A A

A A

A A

A

A

A

A

22 226

6.3 10 16 25 50 100 200 250 500

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

V

V

V

H

H

H

H

H

H

A

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

V

V

V

H

H

H

H

H

H

A

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

V

V

V

H

H

H

H

H

A

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

M

M

M

H

H

H

H

A

A

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

M

M

P

H

H

H

H

A

H

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

D

D

D

D

A

A

A

A

H

H

H

T

T

T

T

T

T

T

T

T

T

T

T

D

D

D

D

D

D

A

A

A

A

A

A

A

A

A

T

T

T

T

T

T

T

T

T

T

T

T

D

D

D

D

D

D

A

A

A

A

A

A

A

A

A

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

A

A

A

A

A

47 476

100 107

6.3 10 16 25 50 6.3 10 16 25 50 100 6.3 10 16 25 50 100 200 250 6.3 10 16 25 50 100 200 250 500 6.3 10 16 25 50 100 200 250 500

WVDC

16

SIZE

01005

0201

0402

Case Size

01005 (KGM 02)

0201 (KGM03)

Thickness Letter

Max Thickness (mm)

Carrier Tape

Packaging Code 7"reel

Packaging Code 13"reel

A

0.22

PAPER

H

n/a

A

0.33

PAPER

H

N

0603

0402 (KGM05)

0603 (KGM15)

0805

1206

0805 (KGM21)

A

C

A

B

C

N

0.55

0.70

0.90

0.95

1.00

1.00

PAPER

PAPER PAPER PAPER PAPER

H

H

T

T

T

T

N

N

M

M

M

M

PAPER

E

1.35

EMB

U

L

A

1.45

EMB

U

L

1206 (KGM31)

B

0.94

PAPER

T

M

V

1.22

EMB

U

L

M

1.25

EMB

U

L

T

P

D

1.35

1.40

1.45

EMB

EMB

EMB

U

U

U

L

L

L

EMBOSSED (EMB)

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or available

online at www.kyocera-avx.com/disclaimer/ by reference and should be reviewed in full before placing any order.

TDS-SMDMLCC-0038 | Rev 5

– surface mount ceramic capacitor products –

A

1.80

EMB

U

L

H

1.90

EMB

U

L

3

�X7R Dielectric, KGM Series

Capacitance Range

SIZE

Soldering

Packaging

mm

(in.)

mm

W) Width

(in.)

mm

(t) Terminal

(in.)

WVDC

Cap 100 101

(pF) 150 151

220 221

330 331

470 471

680 681

1000 102

1500 152

2200 222

3300 332

3900 392

4700 472

5600 562

6800 682

Cap 0.010 103

(μF) 0.012 123

0.015 153

0.018 183

0.022 223

0.027 273

0.033 333

0.039 393

0.047 473

0.068 683

0.082 823

0.100 104

0.120 124

0.150 154

0.220 224

0.330 334

0.470 474

0.680 684

1.000 105

2.200 225

4.700 475

10 106

22 226

47 476

100 107

WVDC

SIZE

(L) Length

1210

Reflow Only

Paper/Embossed

3.30 ± 0.4

(0.130± 0.016)

2.50 ± 0.30

(0.098 ± 0.012)

0.50 ± 0.25

(0.020 ± 0.010)

25

50

100

10

16

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

E

E

E

E

E

E

L

L

L

L

L

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

E

E

E

E

E

E

L

L

L

A

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

E

E

E

E

E

E

L

L

L

L

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

E

E

E

E

E

E

L

L

A

10

16

25

50

1210

Case Size

Thickness Letter

Max Thickness (mm)

Carrier Tape

Packaging Code 7"reel

Packaging Code 13"reel

4

200

500

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

E

E

H

L

L

L

L

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

E

E

E

E

E

H

H

H

H

L

L

L

L

L

D

D

D

D

D

D

D

E

E

E

E

E

E

E

E

E

E

H

H

H

H

P

P

P

100

200

500

16

1812

Reflow Only

All Embossed

4.50 ± 0.40

(0.177 ± 0.016)

3.20 ± 0.40

(0.126 ± 0.016)

0.61 ± 0.36

(0.024 ± 0.014)

25

50

100

200

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

F

F

F

J

J

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

F

F

F

J

J

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

F

F

F

J

J

16

25

50

100

1812

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

F

F

F

J

J

1210 (KGM 32)

R

1.05

EMB

U

L

D

1.4

EMB

U

L

E

1.45

EMB

U

L

H

1.8

EMB

U

L

P

2.2

EMB

U

L

500

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

F

F

F

F

J

J

A

A

A

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

F

F

F

J

J

J

J

J

200

500

1825

Reflow Only

All Embossed

4.50 ± 0.40

(0.177 ± 0.016)

6.40 ± 0.40

(0.252 ± 0.016)

0.61 ± 0.36

(0.024 ± 0.014)

50

100

200

500

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

F

50

1812 (KGM 43)

A

2.70

EMB

U

L

L

2.80

EMB

U

L

A

1.4

EMB

V

S

B

F

J

1.45

2.21

2.80

EMB

EMB

EMB

V

V

V

S

S

S

EMBOSSED(EMB)

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

F

F

25

2220

Reflow Only

All Embossed

5.70 ± 0.50

(0.224 ± 0.020)

5.00 ± 0.40

(0.197 ± 0.016)

0.64 ± 0.39

(0.025 ± 0.015)

50

100

200

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

C

D

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

C

D

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

D

H

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

C

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

G

500

25

50

100

2220

200

500

50

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

F

100

200

1825

1825 (KGM 44)

C

2.21

EMB

V

S

F

2.80

EMB

V

S

2220 (KGM 55)

Z

2.21

EMB

V

S

C

2.80

EMB

V

S

D

3.3

EMB

V

S

TDS-SMDMLCC-0038 | Rev 5

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

G

G

D

2.21

EMB

V

S

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

G

100

200

2225

2225 (KGM56)

H

3.4

EMB

V

S

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or available

online at www.kyocera-avx.com/disclaimer/ by reference and should be reviewed in full before placing any order.

– surface mount ceramic capacitor products –

500

2225

Reflow Only

All Embossed

5.70 ± 0.40

(0.224 ± 0.016)

6.30 ± 0.40

(0.248 ± 0.016)

0.64 ± 0.39

(0.025 ± 0.015)

50

100

200

500

G

2.80

EMB

V

S

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

G

500

�

很抱歉,暂时无法提供与“KGM32ER72H472KU”相匹配的价格&库存,您可以联系我们找货

免费人工找货