DRV8426

SLOSE55B – MAY 2020 – REVISED MAY 2021

DRV8426 Stepper Driver With Integrated Current Sense, 1/256 Microstepping,

STEP/DIR Interface and smart tune Technology

1 Features

•

•

•

•

•

•

•

•

•

•

•

•

•

PWM microstepping stepper motor driver

– Simple STEP/DIR interface

– Up to 1/256 microstepping indexer

Integrated current sense functionality

– No sense resistors required

– ±5% full-scale current accuracy

Smart tune decay technology, fixed slow, and

mixed decay options

4.5 to 33-V Operating supply voltage range

Low RDS(ON):

– 900 mΩ HS + LS at 24 V, 25°C

High current capacity per bridge

– 2.5 A peak, 1.5 A full-scale, 1.1 A rms

Pin to pin compatible with – DRV8424/25: 33-V, 330/550 mΩ HS + LS

– DRV8436: 48-V, 900 mΩ HS + LS

– DRV8434: 48-V, 330 mΩ HS + LS

Configurable off-time PWM chopping

– 7-μs, 16-μs, 24-μs, or 32-μs.

Supports 1.8-V, 3.3-V, 5.0-V logic inputs

Low-current sleep mode (2 μA)

Spread spectrum clocking for low electromagnetic

interference (EMI)

Small package and footprint

Protection features

– VM undervoltage lockout (UVLO)

– Charge pump undervoltage (CPUV)

– Overcurrent protection (OCP)

– Thermal shutdown (OTSD)

– Fault condition output (nFAULT)

of driving up to 1.5-A full-scale output current

(dependent on PCB design).

The DRV8426 uses an internal current sense

architecture to eliminate the need for two external

power sense resistors, saving PCB area and

system cost. The device uses an internal PWM

current regulation scheme selectable between smart

tune, slow and mixed decay options. Smart tune

automatically adjusts for optimal current regulation,

compensates for motor variation and aging effects

and reduces audible noise from the motor.

A simple STEP/DIR interface allows an external

controller to manage the direction and step rate of

the stepper motor. The device can be configured

in full-step to 1/256 microstepping. A low-power

sleep mode is provided using a dedicated nSLEEP

pin. Protection features are provided for supply

undervoltage, charge pump faults, overcurrent, short

circuits, and overtemperature. Fault conditions are

indicated by the nFAULT pin.

Device Information(1)

(1)

PART NUMBER

PACKAGE

BODY SIZE (NOM)

DRV8426PWPR

HTSSOP (28)

9.7 mm x 4.4 mm

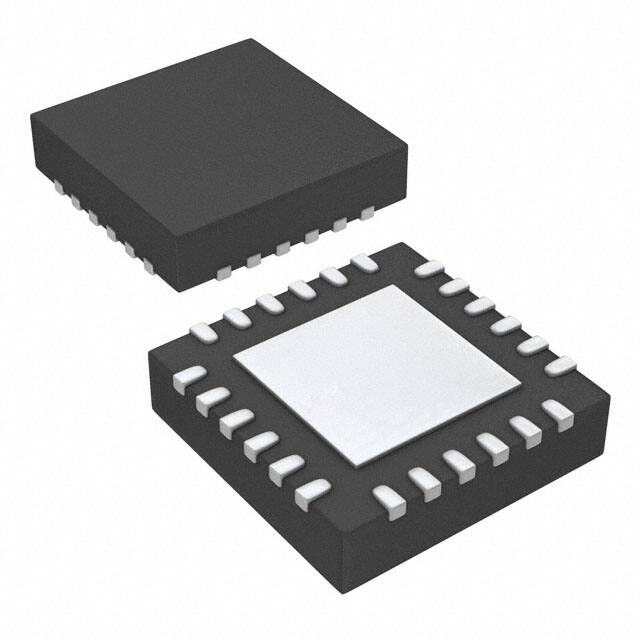

DRV8426RGER

VQFN (24)

4.0 mm x 4.0 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

2 Applications

•

•

•

•

•

•

•

•

•

Printers and scanners

3D printers

ATM and money handling machines

Textile and sewing machines

Stage lighting equipment

CCTV, security and dome cameras

Office and home automation

Factory automation and robotics

Medical applications

Simplified Schematic

3 Description

The DRV8426 is a stepper motor driver for industrial

and consumer applications. The device is fully

integrated with two N-channel power MOSFET

H-bridge drivers, a microstepping indexer, and

integrated current sensing. The DRV8426 is capable

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

6 Specifications.................................................................. 6

6.1 Absolute Maximum Ratings........................................ 6

6.2 ESD Ratings............................................................... 6

6.3 Recommended Operating Conditions.........................7

6.4 Thermal Information....................................................7

6.5 Electrical Characteristics.............................................8

6.6 Indexer Timing Requirements..................................... 9

6.7 Typical Characteristics.............................................. 10

7 Detailed Description......................................................13

7.1 Overview................................................................... 13

7.2 Functional Block Diagram......................................... 14

7.3 Feature Description...................................................14

7.4 Device Functional Modes..........................................32

8 Application and Implementation.................................. 34

8.1 Application Information............................................. 34

8.2 Typical Application.................................................... 34

9 Power Supply Recommendations................................39

9.1 Bulk Capacitance...................................................... 39

10 Layout...........................................................................40

10.1 Layout Guidelines................................................... 40

11 Device and Documentation Support..........................41

11.1 Receiving Notification of Documentation Updates.. 41

11.2 Community Resources............................................41

11.3 Trademarks............................................................. 41

12 Mechanical, Packaging, and Orderable

Information.................................................................... 42

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (October 2020) to Revision B (May 2021)

Page

• Fixed typo in Description ................................................................................................................................... 1

• Fixed Typo in Table 7-4 ....................................................................................................................................16

• Removed duplicate package drawings............................................................................................................. 42

Changes from Revision * (May 2020) to Revision A (October 2020)

Page

• Changed Device Status to "Production Data".....................................................................................................1

2

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

5 Pin Configuration and Functions

Figure 5-1. PWP PowerPAD™ Package 28-Pin HTSSOP Top View

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

3

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Figure 5-2. RGE Package 24-Pin VQFN with Exposed Thermal PAD Top View

Table 5-1. Pin Functions

PIN

NAME

AOUT1

4

NO.

HTSSOP

VQFN

4, 5

3

I/O

TYPE

DESCRIPTION

O

Output

Winding A output. Connect to stepper motor winding.

AOUT2

6, 7

4

O

Output

Winding A output. Connect to stepper motor winding.

PGND

3, 12

2, 7

—

Power

Power ground. Connect to system ground.

BOUT2

8, 9

5

O

Output

Winding B output. Connect to stepper motor winding

BOUT1

10, 11

6

O

Output

Winding B output. Connect to stepper motor winding

CPH

28

23

CPL

27

22

—

Power

Charge pump switching node. Connect a X7R, 0.022-µF, VM-rated

ceramic capacitor from CPH to CPL.

DIR

24

19

I

Input

Direction input. Logic level sets the direction of stepping; internal

pulldown resistor.

ENABLE

25

20

I

Input

Logic low to disable device outputs; logic high to enable; internal pullup

to DVDD. Also determines the type of OCP and OTSD response.

DVDD

15

10

O

Power

Logic supply voltage. Connect a X7R, 0.47-μF to 1-μF, 6.3-V or 10-V

rated ceramic capacitor to GND.

GND

14

9

—

Power

Device ground. Connect to system ground.

VREF

17

12

I

Input

Current set reference input. Maximum value 3.3 V for DRV8426. DVDD

can be used to provide VREF through a resistor divider.

M0

18

13

M1

22

17

I

Input

Microstepping mode-setting pins. Sets the step mode; internal pulldown

resistor.

DECAY0

21

16

DECAY1

20

15

I

Input

Decay-mode setting pins. Sets the decay mode (see the Section 7.3.6

section).

STEP

23

18

I

Input

Step input. A rising edge causes the indexer to advance one step;

internal pulldown resistor.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Table 5-1. Pin Functions (continued)

PIN

NAME

NO.

I/O

TYPE

DESCRIPTION

HTSSOP

VQFN

VCP

1

24

—

Power

Charge pump output. Connect a X7R, 0.22-μF, 16-V ceramic capacitor

to VM.

VM

2, 13

1, 8

—

Power

Power supply. Connect to motor supply voltage and bypass to PGND

with two 0.01-µF ceramic capacitors (one for each pin) plus a bulk

capacitor rated for VM.

TOFF

19

14

I

Input

Sets the Decay mode off time during current chopping; four level pin.

Also sets the ripple current in smart tune ripple control mode.

nFAULT

16

11

O

Open Drain

Fault indication. Pulled logic low with fault condition; open-drain output

requires an external pullup resistor.

nSLEEP

26

21

I

Input

Sleep mode input. Logic high to enable device; logic low to enter lowpower sleep mode; internal pulldown resistor. An nSLEEP low pulse

clears faults.

-

-

-

-

PAD

Thermal pad. Connect to system ground.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

5

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)(1)

MIN

MAX

Power supply voltage (VM)

–0.3

35

V

Charge pump voltage (VCP, CPH)

–0.3

VVM + 7

V

Charge pump negative switching pin (CPL)

–0.3

VVM

V

nSLEEP pin voltage (nSLEEP)

–0.3

VVM

V

Internal regulator voltage (DVDD)

–0.3

5.75

V

Control pin voltage (STEP, DIR, ENABLE, nFAULT, DECAY0, DECAY1, TOFF, M0, M1)

–0.3

5.75

Open drain output current (nFAULT)

0

10

Reference input pin voltage (VREF)

UNIT

V

mA

–0.3

5.75

V

Continuous phase node pin voltage (AOUT1, AOUT2, BOUT1, BOUT2)

–1

VVM + 1

V

Transient 100 ns phase node pin voltage (AOUT1, AOUT2, BOUT1, BOUT2)

–3

VVM + 3

V

Peak drive current (AOUT1, AOUT2, BOUT1, BOUT2)

Internally Limited

Operating ambient temperature, TA

–40

A

125

°C

Operating junction temperature, TJ

–40

150

°C

Storage temperature, Tstg

–65

150

°C

(1)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress

ratings only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

6.2 ESD Ratings

VALUE

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

V(ESD)

6

Electrostatic

discharge

Charged-device model (CDM), per JEDEC specification JESD22C101

Submit Document Feedback

UNIT

±2000

Corner pins for PWP (1,

14, 15, and 28)

±750

Other pins

±500

V

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

VVM

Supply voltage range for normal (DC) operation

VI

Logic level input voltage

MAX

UNIT

4.5

33

V

0

5.5

V

VVREF

VREF voltage

0.05

3.3

ƒSTEP

Applied STEP signal (STEP)

0

500(1)

kHz

V

IFS

Motor full-scale current (xOUTx)

0

1.5(2)

A

Irms

Motor RMS current (xOUTx)

0

1.1(2)

A

TA

Operating ambient temperature

–40

125

°C

TJ

Operating junction temperature

–40

150

°C

(1)

(2)

STEP input can operate up to 500 kHz, but system bandwidth is limited by the motor load

Power dissipation and thermal limits must be observed

6.4 Thermal Information

THERMAL METRIC(1)

RθJA

RGE (VQFN)

28 PINS

24 PINS

UNIT

33.0

43.0

°C/W

RθJC(top) Junction-to-case (top) thermal resistance

28.0

35.0

°C/W

RθJB

Junction-to-board thermal resistance

12.9

19.9

°C/W

ψJT

Junction-to-top characterization parameter

0.7

1.0

°C/W

ψJB

Junction-to-board characterization parameter

12.8

19.8

°C/W

RθJC(bot) Junction-to-case (bottom) thermal resistance

4.9

6.7

°C/W

(1)

Junction-to-ambient thermal resistance

PWP (HTSSOP)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

7

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

6.5 Electrical Characteristics

Typical values are at TA = 25°C and VVM = 24 V. All limits are over recommended operating conditions, unless otherwise

noted.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

5

6.5

mA

2

4

μA

40

μs

POWER SUPPLIES (VM, DVDD)

IVM

VM operating supply current

IVMQ

VM sleep mode supply current nSLEEP = 0

ENABLE = 1, nSLEEP = 1, No motor load

tSLEEP

Sleep time

nSLEEP = 0 to sleep-mode

tRESET

nSLEEP reset pulse

nSLEEP low to clear fault

120

μs

20

tWAKE

Wake-up time

nSLEEP = 1 to output transition

0.8

1.2

ms

tON

Turn-on time

VM > UVLO to output transition

0.8

1.2

ms

tEN

Enable time

ENABLE = 0/1 to output transition

5

μs

VDVDD

Internal regulator voltage

5.25

V

No external load, 6 V < VVM < 33 V

No external load, VVM = 4.5 V

4.75

5

4.2

4.35

V

VVM + 5

V

CHARGE PUMP (VCP, CPH, CPL)

VCP

VCP operating voltage

6 V < VVM < 33 V

f(CP)

Charge pump switching

frequency

VVM > UVLO; nSLEEP = 1

360

kHz

LOGIC-LEVEL INPUTS (STEP, DIR, nSLEEP)

VIL

Input logic-low voltage

VIH

Input logic-high voltage

VHYS

Input logic hysteresis

IIL

Input logic-low current

VIN = 0 V

IIH

Input logic-high current

VIN = 5 V

0

0.6

V

1.5

5.5

V

150

–1

mV

1

μA

100

μA

0.6

V

2.2

V

TRI-LEVEL INPUTS (M0, DECAY0, DECAY1, ENABLE)

VI1

Input logic-low voltage

Tied to GND

VI2

Input Hi-Z voltage

Hi-Z

1.8

0

VI3

Input logic-high voltage

Tied to DVDD

2.7

IO

Output pull-up current

2

5.5

10

V

μA

QUAD-LEVEL INPUTS (M1, TOFF)

VI1

Input logic-low voltage

Tied to GND

1

1.25

1.4

V

Input Hi-Z voltage

Hi-Z

1.8

2

2.2

V

VI4

Input logic-high voltage

Tied to DVDD

2.7

IIL

Output pull-up current

VI2

330kΩ ± 5% to GND

VI3

0

0.6

5.5

10

V

V

μA

CONTROL OUTPUTS (nFAULT)

VOL

Output logic-low voltage

IOH

Output logic-high leakage

IO = 5 mA

–1

0.5

V

1

μA

550

mΩ

MOTOR DRIVER OUTPUTS (AOUT1, AOUT2, BOUT1, BOUT2)

TJ = 25 °C, IO = -1 A

RDS(ONH)

RDS(ONL)

tSR

8

High-side FET on resistance

Low-side FET on resistance

Output slew rate

450

TJ = 125 °C, IO = -1 A

700

850

mΩ

TJ = 150 °C, IO = -1 A

780

950

mΩ

TJ = 25 °C, IO = 1 A

450

550

mΩ

TJ = 125 °C, IO = 1 A

700

850

mΩ

TJ = 150 °C, IO = 1 A

780

950

mΩ

VVM = 24 V, IO = 1 A, Between 10% and

90%

240

Submit Document Feedback

V/µs

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Typical values are at TA = 25°C and VVM = 24 V. All limits are over recommended operating conditions, unless otherwise

noted.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

2.09

2.2

2.31

V/A

8.25

μA

PWM CURRENT CONTROL (VREF)

KV

Transimpedance gain

VREF = 3.3 V

IVREF

VREF Leakage Current

VREF = 3.3 V

tOFF

PWM off-time

ΔITRIP

Current trip accuracy

IO,CH

AOUT and BOUT current

matching

TOFF = 0

7

TOFF = 1

16

TOFF = Hi-Z

24

TOFF = 330 kΩ to GND

32

μs

IO = 1.5 A, 10% to 20% current setting

–15

15

IO = 1.5 A, 20% to 67% current setting

–10

10

IO = 1.5 A, 68% to 100% current setting

–5

5

–2.5

2.5

IO = 1.5 A

%

%

PROTECTION CIRCUITS

VM falling, UVLO falling

4.1

4.25

4.35

VM rising, UVLO rising

4.2

4.35

4.45

VUVLO

VM UVLO lockout

VUVLO,HYS

Undervoltage hysteresis

Rising to falling threshold

VCPUV

Charge pump undervoltage

VCP falling

IOCP

Overcurrent protection

Current through any FET

tOCP

Overcurrent deglitch time

tRETRY

Overcurrent retry time

TOTSD

Thermal shutdown

Die temperature TJ

THYS_OTSD

Thermal shutdown hysteresis

Die temperature TJ

100

mV

VVM + 2

V

1.8

μs

2.5

A

4

150

V

ms

165

180

20

°C

°C

6.6 Indexer Timing Requirements

Typical limits are at TJ = 25°C and VVM = 24 V. Over recommended operating conditions unless otherwise noted.

NO.

(1)

MIN

MAX

UNIT

500(1)

kHz

1

ƒSTEP

Step frequency

2

tWH(STEP)

Pulse duration, STEP high

970

3

tWL(STEP)

Pulse duration, STEP low

970

ns

4

tSU(DIR, Mx)

Setup time, DIR or MODEx to STEP rising

200

ns

5

tH(DIR, Mx)

Hold time, STEP rising to DIR or MODEx change

200

ns

ns

STEP input can operate up to 500 kHz, but system bandwidth is limited by the motor load.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

9

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Figure 6-1. STEP and DIR Timing Diagram

6.7 Typical Characteristics

Figure 6-2. Sleep Current over Supply Voltage

10

Figure 6-3. Sleep Current over Temperature

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Figure 6-4. Operating Current over Supply Voltage

Figure 6-5. Operating Current over Temperature

Figure 6-6. Low-Side RDS(ON) over Supply Voltage

Figure 6-7. Low-Side RDS(ON) over Temperature

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

11

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Figure 6-8. High-Side RDS(ON) over Supply Voltage

12

Figure 6-9. High-Side RDS(ON) over Temperature

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7 Detailed Description

7.1 Overview

The DRV8426 is an integrated motor-driver solution for bipolar stepper motors. The device provides the

maximum integration by integrating two N-channel power MOSFET H-bridges, current sense resistors and

regulation circuitry, and a microstepping indexer. The DRV8426 is pin-to-pin compatible with the DRV8424/25,

DRV8436, and the DRV8434. The DRV8426 is capable of supporting wide supply voltage of 4.5 to 33 V. The

device provides an output current up to 2.5-A peak, 1.5-A full-scale, or 1.1-A root mean square (rms). The actual

full-scale and rms current depends on the ambient temperature, supply voltage, and PCB thermal capability.

The DRV8426 uses an integrated current-sense architecture which eliminates the need for two external power

sense resistors, hence saving significant board space, BOM cost, design efforts and reduces significant power

consumption. This architecture removes the power dissipated in the sense resistors by using a current mirror

approach and using the internal power MOSFETs for current sensing. The current regulation set point is adjusted

by the voltage at the VREF pin.

A simple STEP/DIR interface allows for an external controller to manage the direction and step rate of the

stepper motor. The internal microstepping indexer can execute high-accuracy micro-stepping without requiring

the external controller to manage the winding current level. The indexer is capable of full step, half step, and 1/4,

1/8, 1/16, 1/32, 1/64, 1/128, and 1/256 microstepping. High microstepping contributes to significant audible noise

reduction and smooth motion. In addition to a standard half stepping mode, a noncircular half stepping mode is

available for increased torque output at higher motor RPM.

Stepper motor drivers need to re-circulate the winding current by implementing several types of decay modes,

like slow decay, mixed decay and fast decay. The DRV8426 comes with smart tune decay modes. The smart

tune is an innovative decay mechanism that automatically adjusts for optimal current regulation performance

agnostic of voltage, motor speed, variation and aging effects. Smart tune Ripple Control uses a variable off-time,

ripple current control scheme to minimize distortion of the motor winding current. Smart tune Dynamic Decay

uses a fixed off-time, dynamic fast decay percentage scheme to minimize distortion of the motor winding current

while minimizing frequency content and significantly reducing design efforts. Along with this seamless, effortless

automatic smart tune, DRV8426 also provides the traditional decay modes like slow-mixed and mixed decay as

well.

A low-power sleep mode is included which allows the system to save power when not actively driving the motor.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

13

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.2 Functional Block Diagram

Figure 7-1.

7.3 Feature Description

Table 7-1 lists the recommended external components for the DRV8426 device.

14

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Table 7-1. DRV8426 External Components

COMPONENT

PIN 1

PIN 2

CVM1

VM

PGND

CVM2

VM

PGND

CCP

VCP

VM

RECOMMENDED

Two X7R, 0.01-µF, VM-rated ceramic capacitors

Bulk, VM-rated capacitor

X7R, 0.22-µF, 16-V ceramic capacitor

CSW

CPH

CPL

X7R, 0.022-µF, VM-rated ceramic capacitor

CDVDD

DVDD

GND

X7R, 0.47-µF to 1-µF, 6.3-V ceramic capacitor

RnFAULT

VCC (1)

nFAULT

RREF1

VREF

VCC

RREF2 (Optional)

VREF

GND

(1)

>4.7-kΩ resistor

Resistor to limit chopping current. It is recommended that the value of parallel

combination of RREF1 and RREF2 should be less than 50-kΩ.

VCC is not a pin on the DRV8426 device, but a VCC supply voltage pullup is required for open-drain output nFAULT; nFAULT may be

pulled up to DVDD.

7.3.1 Stepper Motor Driver Current Ratings

Stepper motor drivers can be classified using three different numbers to describe the output current: peak, RMS,

and full-scale.

7.3.1.1 Peak Current Rating

The peak current in a stepper driver is limited by the overcurrent protection trip threshold IOCP. The peak current

describes any transient duration current pulse, for example when charging capacitance, when the overall duty

cycle is very low. In general the minimum value of IOCP specifies the peak current rating of the stepper motor

driver. For the DRV8426 device, the peak current rating is 2.5A per bridge.

7.3.1.2 RMS Current Rating

The RMS (average) current is determined by the thermal considerations of the IC. The RMS current is calculated

based on the RDS(ON), rise and fall time, PWM frequency, device quiescent current, and package thermal

performance in a typical system at 25°C. The actual operating RMS current may be higher or lower depending

on heatsinking and ambient temperature. For the DRV8426 device, the RMS current rating is 1.1 A per bridge.

7.3.1.3 Full-Scale Current Rating

The full-scale current describes the top of the sinusoid current waveform while microstepping. Because the

sinusoid amplitude is related to the RMS current, the full-scale current is also determined by the thermal

considerations of the device. The full-scale current rating is approximately √2 × IRMS for a sinusoidal current

waveform, and IRMS for a square wave current waveform (full step).

Full-scale current

Output Current

RMS current

AOUT

BOUT

Step Input

Figure 7-2. Full-Scale and RMS Current

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

15

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.2 PWM Motor Drivers

The DRV8426 device has drivers for two full H-bridges to drive the two windings of a bipolar stepper motor.

Figure 7-3 shows a block diagram of the circuitry.

Figure 7-3. PWM Motor Driver Block Diagram

7.3.3 Microstepping Indexer

Built-in indexer logic in the DRV8426 device allows a number of different step modes. The M0 and M1 pins are

used to configure the step mode as shown in Table 7-2. The settings can be changed on the fly.

Table 7-2. Microstepping Indexer Settings

16

MODE0

MODE1

STEP MODE

0

0

Full step (2-phase excitation) with 100%

current

0

330kΩ to

GND

Full step (2-phase excitation) with 71%

current

1

0

Non-circular 1/2 step

Hi-Z

0

1/2 step

0

1

1/4 step

1

1

1/8 step

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Table 7-2. Microstepping Indexer Settings

(continued)

MODE0

MODE1

STEP MODE

Hi-Z

1

1/16 step

0

Hi-Z

1/32 step

Hi-Z

330kΩ to

GND

1/64 step

Hi-Z

Hi-Z

1/128 step

1

Hi-Z

1/256 step

Table 7-3 shows the relative current and step directions for full-step (71% current), 1/2 step, 1/4 step and 1/8

step operation. Higher microstepping resolutions follow the same pattern. The AOUT current is the sine of the

electrical angle and the BOUT current is the cosine of the electrical angle. Positive current is defined as current

flowing from the xOUT1 pin to the xOUT2 pin while driving.

At each rising edge of the STEP input the indexer travels to the next state in the table. The direction is shown

with the DIR pin logic high. If the DIR pin is logic low, the sequence is reversed.

Note

If the step mode is changed on the fly while stepping, the indexer advances to the next valid state for

the new step mode setting at the rising edge of STEP.

The initial excitation state is an electrical angle of 45°, corresponding to 71% of full-scale current in both coils.

This state is entered after power-up, after exiting logic undervoltage lockout, or after exiting sleep mode.

Table 7-3. Relative Current and Step Directions

1/8 STEP

1/4 STEP

1/2 STEP

1

1

1

FULL

STEP

71%

2

3

2

4

5

3

2

1

6

7

4

8

9

5

3

10

11

6

12

13

7

4

2

14

15

8

16

17

9

5

18

19

10

20

21

11

6

22

3

AOUT CURRENT

(% FULL-SCALE)

BOUT CURRENT

(% FULL-SCALE)

ELECTRICAL

ANGLE (DEGREES)

0%

100%

0.00

20%

98%

11.25

38%

92%

22.50

56%

83%

33.75

71%

71%

45.00

83%

56%

56.25

92%

38%

67.50

98%

20%

78.75

100%

0%

90.00

98%

-20%

101.25

92%

-38%

112.50

83%

-56%

123.75

71%

-71%

135.00

56%

-83%

146.25

38%

-92%

157.50

20%

-98%

168.75

0%

-100%

180.00

-20%

-98%

191.25

-38%

-92%

202.50

-56%

-83%

213.75

-71%

-71%

225.00

-83%

-56%

236.25

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

17

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Table 7-3. Relative Current and Step Directions (continued)

1/8 STEP

1/4 STEP

23

12

FULL

STEP

71%

1/2 STEP

24

25

13

7

26

27

14

28

29

15

8

4

30

31

16

32

AOUT CURRENT

(% FULL-SCALE)

BOUT CURRENT

(% FULL-SCALE)

ELECTRICAL

ANGLE (DEGREES)

-92%

-38%

247.50

-98%

-20%

258.75

-100%

0%

270.00

-98%

20%

281.25

-92%

38%

292.50

-83%

56%

303.75

-71%

71%

315.00

-56%

83%

326.25

-38%

92%

337.50

-20%

98%

348.75

Table 7-4 shows the full step operation with 100% full-scale current. This stepping mode consumes more power

than full-step mode with 71% current, but provides a higher torque at high motor RPM.

Table 7-4. Full Step with 100% Current

FULL

STEP

100%

AOUT CURRENT

(% FULL-SCALE)

BOUT CURRENT

(% FULL-SCALE)

ELECTRICAL ANGLE

(DEGREES)

1

100

100

45

2

100

-100

135

3

-100

-100

225

4

-100

100

315

Table 7-5 shows the noncircular 1/2–step operation. This stepping mode consumes more power than circular

1/2-step operation, but provides a higher torque at high motor RPM.

Table 7-5. Non-Circular 1/2-Stepping Current

NON-CIRCULAR 1/2-STEP

AOUT CURRENT

(% FULL-SCALE)

BOUT CURRENT

(% FULL-SCALE)

ELECTRICAL ANGLE

(DEGREES)

1

0

100

0

2

100

100

45

3

100

0

90

4

100

–100

135

5

0

–100

180

6

–100

–100

225

7

–100

0

270

8

–100

100

315

7.3.4 Controlling VREF with an MCU DAC

In some cases, the full-scale output current may need to be changed between many different values, depending

on motor speed and loading. The voltage of the VREF pin can be adjusted in the system to change the full-scale

current.

In this mode of operation, as the DAC voltage increases, the full-scale regulation current increases as well. For

proper operation, the output of the DAC should not rise above 3.3V for DRV8426.

18

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Figure 7-4. Controlling VREF with a DAC Resource

The VREF pin can also be adjusted using a PWM signal and low-pass filter.

Figure 7-5. Controlling VREF With a PWM Resource

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

19

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.5 Current Regulation

The current through the motor windings is regulated by an adjustable, off-time PWM current-regulation circuit.

When an H-bridge is enabled, current rises through the winding at a rate dependent on the DC voltage,

inductance of the winding, and the magnitude of the back EMF present. When the current hits the current

regulation threshold, the bridge enters a decay mode for a period of time determined by the TOFF pin setting to

decrease the current. After the off-time expires, the bridge is re-enabled, starting another PWM cycle.

Figure 7-6. Current Chopping Waveform

The PWM regulation current is set by a comparator which monitors the voltage across the current sense

MOSFETs in parallel with the low-side power MOSFETs. The current sense MOSFETs are biased with a

reference current that is the output of a current-mode sine-weighted DAC whose full-scale reference current is

set by the voltage at the VREF pin.

The full-scale regulation current (IFS) can be calculated as IFS (A) = VREF (V) / KV (V/A) = VREF (V) / 2.2 (V/A).

20

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.6 Decay Modes

During PWM current chopping, the H-bridge is enabled to drive through the motor winding until the PWM current

chopping threshold is reached. This is shown in Figure 7-7, Item 1.

Once the chopping current threshold is reached, the H-bridge can operate in two different states, fast decay or

slow decay. In fast decay mode, once the PWM chopping current level has been reached, the H-bridge reverses

state to allow winding current to flow in a reverse direction. The opposite FETs are turned on; as the winding

current approaches zero, the bridge is disabled to prevent any reverse current flow. Fast decay mode is shown

in Figure 7-7, item 2. In slow decay mode, winding current is re-circulated by enabling both of the low-side FETs

in the bridge. This is shown in Figure 7-7, Item 3.

Figure 7-7. Decay Modes

The decay mode of the DRV8426 is selected by the DECAY0 and DECAY1 pins as shown in Table 7-6. If

DECAY1 pin is Hi-Z, irrespective of the DECAY0 pin voltage, the decay mode will be smart tune dynamic decay.

The decay modes can be changed on the fly. After a decay mode change, the new decay mode is applied after a

10 µs de-glitch time.

Table 7-6. Decay Mode Settings

DECAY0

DECAY1

INCREASING STEPS

DECREASING

STEPS

0

0

Smart tune Dynamic

Decay

Smart tune Dynamic

Decay

0

1

Smart tune Ripple

Control

Smart tune Ripple

Control

1

0

Mixed decay: 30%

fast

Mixed decay: 30%

fast

1

1

Slow decay

Mixed decay: 30%

fast

Hi-Z

0

Mixed decay: 60%

fast

Mixed decay: 60%

fast

Hi-Z

1

Slow decay

Slow decay

Figure 7-8 defines increasing and decreasing current. For the slow-mixed decay mode, the decay mode is

set as slow during increasing current steps and mixed decay during decreasing current steps. In full step and

noncircular 1/2-step operation, the decay mode corresponding to decreasing steps is always used.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

21

�DRV8426

www.ti.com

AOUT Current

SLOSE55B – MAY 2020 – REVISED MAY 2021

Increasing

Decreasing

Increasing

Decreasing

STEP Input

BOUT Current

AOUT Current

Decreasing

Increasing

Increasing

Decreasing

STEP Input

Figure 7-8. Definition of Increasing and Decreasing Steps

22

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.6.1 Slow Decay for Increasing and Decreasing Current

Increasing Phase Current (A)

ITRIP

tBLANK

tOFF

tBLANK

tOFF

tDRIVE

Decreasing Phase Current (A)

tDRIVE

ITRIP

tBLANK

tOFF

tDRIVE

tBLANK

tDRIVE

tOFF

tBLANK

tDRIVE

Figure 7-9. Slow/Slow Decay Mode

During slow decay, both of the low-side FETs of the H-bridge are turned on, allowing the current to be

recirculated.

Slow decay exhibits the least current ripple of the decay modes for a given tOFF. However on decreasing current

steps, slow decay will take a long time to settle to the new ITRIP level because the current decreases very

slowly.

In cases where current is held for a long time (no input in the STEP pin) or at very low stepping speeds, slow

decay may not properly regulate current because no back-EMF is present across the motor windings. In this

state, motor current can rise very quickly, and may require a large off-time. In some cases this may cause a loss

of current regulation, and a more aggressive decay mode is recommended.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

23

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.6.2 Slow Decay for Increasing Current, Mixed Decay for Decreasing Current

Increasing Phase Current (A)

ITRIP

tBLANK

tOFF

tBLANK

tOFF

tDRIVE

Decreasing Phase Current (A)

tDRIVE

tBLANK

tDRIVE

ITRIP

tBLANK

tFAST

tDRIVE

tBLANK

tOFF

tFAST

tDRIVE

tOFF

Figure 7-10. Slow-Mixed Decay Mode

Mixed decay begins as fast decay for a time, followed by slow decay for the remainder of the tOFF time. In this

mode, mixed decay only occurs during decreasing current. Slow decay is used for increasing current.

This mode exhibits the same current ripple as slow decay for increasing current, because for increasing current,

only slow decay is used. For decreasing current, the ripple is larger than slow decay, but smaller than fast decay.

On decreasing current steps, mixed decay settles to the new ITRIP level faster than slow decay.

24

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.6.3 Mixed Decay for Increasing and Decreasing Current

Increasing Phase Current (A)

ITRIP

tOFF

tBLANK

tOFF

tDRIVE

Decreasing Phase Current (A)

tDRIVE

tBLANK

tDRIVE

ITRIP

tBLANK

tDRIVE

tFAST

tBLANK

tOFF

tFAST

tDRIVE

tOFF

Figure 7-11. Mixed-Mixed Decay Mode

Mixed decay begins as fast decay for a time, followed by slow decay for the remainder of tOFF. In this mode,

mixed decay occurs for both increasing and decreasing current steps.

This mode exhibits ripple larger than slow decay, but smaller than fast decay. On decreasing current steps,

mixed decay settles to the new ITRIP level faster than slow decay.

In cases where current is held for a long time (no input in the STEP pin) or at very low stepping speeds, slow

decay may not properly regulate current because no back-EMF is present across the motor windings. In this

state, motor current can rise very quickly, and requires an excessively large off-time. Increasing or decreasing

mixed decay mode allows the current level to stay in regulation when no back-EMF is present across the motor

windings.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

25

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.6.4 Smart tune Dynamic Decay

The smart tune current regulation schemes are advanced current-regulation control methods compared to

traditional fixed off-time current regulation schemes. Smart tune current regulation schemes help the stepper

motor driver adjust the decay scheme based on operating factors such as the ones listed as follows:

•

•

•

•

•

•

•

Motor winding resistance and inductance

Motor aging effects

Motor dynamic speed and load

Motor supply voltage variation

Motor back-EMF difference on rising and falling steps

Step transitions

Low-current versus high-current dI/dt

The device provides two different smart tune current regulation modes, named smart tune Dynamic Decay and

smart tune Ripple Control.

Increasing Phase Current (A)

ITRIP

tBLANK

tBLANK

tOFF

tBLANK

tOFF

tDRIVE

tDRIVE

tDRIVE

Decreasing Phase Current (A)

ITRIP

tBLANK

tOFF

tDRIVE

tBLANK

tDRIVE

tBLANK

tOFF

tFAST

tDRIVE

tFAST

Figure 7-12. Smart tune Dynamic Decay Mode

Smart tune Dynamic Decay greatly simplifies the decay mode selection by automatically configuring the decay

mode between slow, mixed, and fast decay. In mixed decay, smart tune dynamically adjusts the fast decay

percentage of the total mixed decay time. This feature eliminates motor tuning by automatically determining the

best decay setting that results in the lowest ripple for the motor.

The decay mode setting is optimized iteratively each PWM cycle. If the motor current overshoots the target trip

level, then the decay mode becomes more aggressive (add fast decay percentage) on the next cycle to prevent

regulation loss. If a long drive time must occur to reach the target trip level, the decay mode becomes less

aggressive (remove fast decay percentage) on the next cycle to operate with less ripple and more efficiently. On

falling steps, smart tune Dynamic Decay automatically switches to fast decay to reach the next step quickly.

Smart tune Dynamic Decay is optimal for applications that require minimal current ripple but want to maintain a

fixed frequency in the current regulation scheme.

26

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.6.5 Smart tune Ripple Control

Increasing Phase Current (A)

ITRIP

IVALLEY

tBLANK

tBLANK

tOFF

tBLANK

tOFF

tDRIVE

Decreasing Phase Current (A)

tDRIVE

tBLANK

tOFF

tDRIVE

tDRIVE

ITRIP

IVALLEY

tBLANK

tOFF

tBLANK

tOFF

tBLANK

tDRIVE

tDRIVE

tOFF

tDRIVE

Figure 7-13. Smart tune Ripple Control Decay Mode

Smart tune Ripple Control operates by setting an IVALLEY level alongside the ITRIP level. When the current level

reaches ITRIP, instead of entering slow decay until the t OFF time expires, the driver enters slow decay until I VALLEY

is reached. Slow decay operates similar to mode 1 in which both low-side MOSFETs are turned on allowing the

current to recirculate. In this mode, tOFF varies depending on the current level and operating conditions.

The ripple current in this decay mode is programmed by the TOFF pin. The ripple current is dependent on the

ITRIP of a particular microstep level.

Table 7-7. Current Ripple Settings

TOFF

Current Ripple at a specific microstep level

0

11mA + 1% of ITRIP

1

11mA + 2% of ITRIP

Hi-Z

11mA + 4% of ITRIP

330kΩ to GND

11mA + 6% of ITRIP

The ripple control method allows much tighter regulation of the current level increasing motor efficiency and

system performance. Smart tune Ripple Control can be used in systems that can tolerate a variable off-time

regulation scheme to achieve small current ripple in the current regulation. Select a low ripple current setting to

ensure that the PWM frequency is not in the audible range. However, higher values of ripple current reduces the

PWM frequency and therefore the switching loss.

7.3.6.6 PWM OFF Time

The TOFF pin configures the PWM OFF time for all decay modes except smart tune ripple control, as shown in

Table 7-6. The OFF time settings can be changed on the fly. After a OFF time setting change, the new OFF time

is applied after a 10 µs de-glitch time.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

27

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Table 7-8. OFF Time Settings

TOFF

OFF Time

0

7 µs

1

16 µs

Hi-Z

24 µs

330kΩ to GND

32 µs

7.3.6.7 Blanking time

After the current is enabled (start of drive phase) in an H-bridge, the current sense comparator is ignored for a

period of time (tBLANK) before enabling the current-sense circuitry. The blanking time also sets the minimum drive

time of the PWM. The blanking time is approximately 1 µs.

7.3.7 Charge Pump

A charge pump is integrated to supply a high-side N-channel MOSFET gate-drive voltage. The charge pump

requires a capacitor between the VM and VCP pins to act as the storage capacitor. Additionally a ceramic

capacitor is required between the CPH and CPL pins to act as the flying capacitor.

Figure 7-14. Charge Pump Block Diagram

28

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.8 Linear Voltage Regulators

A linear voltage regulator is integrated in the DRV8426 device. The DVDD regulator can be used to provide a

reference voltage. DVDD can supply a maximum of 2mA load. For proper operation, bypass the DVDD pin to

GND using a ceramic capacitor.

The DVDD output is nominally 5-V. When the DVDD LDO current load exceeds 2mA, the output voltage drops

significantly.

Figure 7-15. Linear Voltage Regulator Block Diagram

If a digital input must be tied permanently high (that is, Mx, DECAYx or TOFF), tying the input to the DVDD pin

instead of an external regulator is preferred. This method saves power when the VM pin is not applied or in

sleep mode: the DVDD regulator is disabled and current does not flow through the input pulldown resistors. For

reference, logic level inputs have a typical pulldown of 200 kΩ.

The nSLEEP pin cannot be tied to DVDD, else the device will never exit sleep mode.

7.3.9 Logic Level, tri-level and quad-level Pin Diagrams

Figure 7-16 shows the input structure for M0, DECAY0, DECAY1 and ENABLE pins.

Figure 7-16. Tri-Level Input Pin Diagram

Figure 7-16 shows the input structure for M1 and TOFF pins.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

29

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Figure 7-17. Quad-Level Input Pin Diagram

Figure 7-18 shows the input structure for STEP, DIR and nSLEEP pins.

Figure 7-18. Logic-Level Input Pin Diagram

7.3.10 nFAULT Pin

The nFAULT pin has an open-drain output and should be pulled up to a 5-V, 3.3-V or 1.8-V supply. When a

fault is detected, the nFAULT pin will be logic low. nFAULT pin will be high after power-up. For a 5-V pullup, the

nFAULT pin can be tied to the DVDD pin with a resistor. For a 3.3-V or 1.8-V pullup, an external supply must be

used.

Output

nFAULT

Figure 7-19. nFAULT Pin

7.3.11 Protection Circuits

The DRV8426 device is fully protected against supply undervoltage, charge pump undervoltage, output

overcurrent, and device overtemperature events.

7.3.11.1 VM Undervoltage Lockout (UVLO)

If at any time the voltage on the VM pin falls below the UVLO-threshold voltage for the voltage supply, all

the outputs are disabled, and the nFAULT pin is driven low. The charge pump is disabled in this condition.

Normal operation resumes (motor-driver operation and nFAULT released) when the VM undervoltage condition

is removed.

30

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

7.3.11.2 VCP Undervoltage Lockout (CPUV)

If at any time the voltage on the VCP pin falls below the CPUV voltage, all the outputs are disabled, and the

nFAULT pin is driven low. The charge pump remains active during this condition. Normal operation resumes

(motor-driver operation and nFAULT released) when the VCP undervoltage condition is removed.

7.3.11.3 Overcurrent Protection (OCP)

An analog current-limit circuit on each FET limits the current through the FET by removing the gate drive. If this

current limit persists for longer than the tOCP time, the FETs in both H-bridges are disabled and the nFAULT pin is

driven low. The charge pump remains active during this condition. The overcurrent protection can operate in two

different modes: latched shutdown and automatic retry. The operating modes can be changed on the fly.

7.3.11.3.1 Latched Shutdown

The ENABLE pin of the DRV8426 has to be made Hi-Z to select latched shutdown mode. In this mode, after

an OCP event, the outputs are disabled and the nFAULT pin is driven low. Once the OCP condition is removed,

normal operation resumes after applying an nSLEEP reset pulse or a power cycling.

7.3.11.3.2 Automatic Retry

The ENABLE pin of the DRV8424/25 has to be HIGH (>2.7V) to select automatic retry mode. In this mode,

after an OCP event the outputs are disabled and the nFAULT pin is driven low. Normal operation resumes

automatically (motor-driver operation and nFAULT released) after the tRETRY time has elapsed and the fault

condition is removed.

7.3.11.4 Thermal Shutdown (OTSD)

If the die temperature exceeds the thermal shutdown limit (TOTSD) all MOSFETs in the H-bridge are disabled,

and the nFAULT pin is driven low. The charge pump is disabled during this condition. The thermal shutdown

protection can operate in two different modes: latched shutdown and automatic retry. The operating modes can

be changed on the fly.

7.3.11.4.1 Latched Shutdown

The ENABLE pin of the DRV8426 has to be made Hi-Z to select latched shutdown mode. In this mode, after an

OTSD event, the relevant outputs are disabled and the nFAULT pin is driven low. After the junction temperature

falls below the overtemperature threshold limit minus the hysteresis (TOTSD – THYS_OTSD), normal operation

resumes after applying an nSLEEP reset pulse or a power cycling.

7.3.11.4.2 Automatic Retry

The ENABLE pin of the DRV8424/25 has to be HIGH (>2.7V) to select automatic retry mode. In this mode, after

a OTSD event all the outputs are disabled and the nFAULT pin is driven low. Normal operation resumes (motordriver operation and the nFAULT line released) when the junction temperature falls below the overtemperature

threshold limit minus the hysteresis (TOTSD – THYS_OTSD).

7.3.11.5 Fault Condition Summary

Table 7-9. Fault Condition Summary

FAULT

CONDITION

CONFIGU

RATION

ERROR

REPORT

H-BRIDGE CHARGE

PUMP

INDEXER

LOGIC

RECOVERY

VM undervoltage

(UVLO)

VM < VUVLO

—

nFAULT

Disabled

Disabled

Disabled

Reset

(VDVDD <

3.9 V)

Automatic: VM >

VUVLO

VCP undervoltage

(CPUV)

VCP < VCPUV

—

nFAULT

Disabled

Operating

Operating

Operating

VCP > VCPUV

ENABLE =

Hi-Z

nFAULT

Disabled

Operating

Operating

Operating

Latched

ENABLE =

1

nFAULT

Disabled

Operating

Operating

Operating

Automatic retry:

tRETRY

Overcurrent (OCP)

IOUT > IOCP

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

31

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Table 7-9. Fault Condition Summary (continued)

FAULT

CONDITION

Thermal Shutdown

(OTSD)

CONFIGU

RATION

TJ > TTSD

ERROR

REPORT

H-BRIDGE CHARGE

PUMP

INDEXER

LOGIC

RECOVERY

ENABLE =

Hi-Z

nFAULT

Disabled

Disabled

Operating

Operating

Latched

ENABLE =

1

nFAULT

Disabled

Disabled

Operating

Operating

Automatic: TJ <

TOTSD - THYS_OTSD

7.4 Device Functional Modes

7.4.1 Sleep Mode (nSLEEP = 0)

The DRV8426 device state is managed by the nSLEEP pin. When the nSLEEP pin is low, the DRV8426 device

enters a low-power sleep mode. In sleep mode, all the internal MOSFETs are disabled and the charge pump is

disabled. The tSLEEP time must elapse after a falling edge on the nSLEEP pin before the device enters sleep

mode. The DRV8426 device is brought out of sleep automatically if the nSLEEP pin is brought high. The tWAKE

time must elapse before the device is ready for inputs.

7.4.2 Disable Mode (nSLEEP = 1, ENABLE = 0)

The ENABLE pin is used to enable or disable the DRV8426 device. When the ENABLE pin is low, the output

drivers are disabled in the Hi-Z state.

7.4.3 Operating Mode (nSLEEP = 1, ENABLE = Hi-Z/1)

When the nSLEEP pin is high, the ENABLE pin is Hi-Z or 1, and VM > UVLO, the device enters the active mode.

The tWAKE time must elapse before the device is ready for inputs.

7.4.4 nSLEEP Reset Pulse

A latched fault can be cleared through a quick nSLEEP pulse. This pulse width must be greater than 20 µs and

shorter than 40 µs. If nSLEEP is low for longer than 40 µs but less than 120 µs, the faults are cleared and the

device may or may not shutdown, as shown in the timing diagram (see Figure 7-20). This reset pulse does not

affect the status of the charge pump or other functional blocks.

Figure 7-20. nSLEEP Reset Pulse

7.4.5 Functional Modes Summary

Table 7-10 lists a summary of the functional modes.

Table 7-10. Functional Modes Summary

CONDITION

CONFIGURA

TION

H-BRIDGE

DVDD

Regulator

CHARGE PUMP

INDEXER

Logic

Sleep mode

4.5 V < VM < 33 V

nSLEEP pin =

0

Disabled

Disabled

Disabled

Disabled

Disabled

Operating

4.5 V < VM < 33 V

nSLEEP pin =

1

ENABLE pin =

1 or Hi-Z

Operating

Operating

Operating

Operating

Operating

32

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Table 7-10. Functional Modes Summary (continued)

CONDITION

Disabled

CONFIGURA

TION

4.5 V < VM < 33 V

nSLEEP pin =

1

ENABLE pin =

0

H-BRIDGE

Disabled

DVDD

Regulator

Operating

CHARGE PUMP

Operating

INDEXER

Operating

Logic

Operating

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

33

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

8 Application and Implementation

Note

Information in the following applications sections is not part of the TI component specification, and

TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining

suitability of components for their purposes. Customers should validate and test their design

implementation to confirm system functionality.

8.1 Application Information

The DRV8426 is used in bipolar stepper control.

8.2 Typical Application

The following design procedure can be used to configure the DRV8426 device.

Figure 8-1. Typical Application Schematic (1/8 microstepping, smart tune Ripple Control Decay, HTSSOP

package)

34

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

Figure 8-2. Typical Application Schematic (1/8 microstepping, smart tune Ripple Control Decay, VQFN

package)

8.2.1 Design Requirements

Table 8-1 lists the design input parameters for a typical application.

Table 8-1. Design Parameters

DESIGN PARAMETER

REFERENCE

EXAMPLE VALUE

Supply voltage

VM

Motor winding resistance

RL

2.4 Ω/phase

Motor winding inductance

LL

5.8 mH/phase

θstep

1.8°/step

nm

1/8 step

v

18.75 rpm

IFS

1A

Motor full step angle

Target microstepping level

Target motor speed

Target full-scale current

24 V

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

35

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

8.2.2 Detailed Design Procedure

8.2.2.1 Stepper Motor Speed

The first step in configuring the DRV8426 device requires the desired motor speed and microstepping level. If

the target application requires a constant speed, then a square wave with frequency ƒstep must be applied to the

STEP pin. If the target motor speed is too high, the motor does not spin. Make sure that the motor can support

the target speed. Use Equation 1 to calculate ƒstep for a desired motor speed (v), microstepping level (nm), and

motor full step angle (θstep)

¦step VWHSV V

v (rpm) u 360 (q / rot)

Tstep (q / step) u nm (steps / microstep) u 60 (s / min)

(1)

The value of θstep can be found in the stepper motor data sheet, or written on the motor. For example, the

motor in this application is required to rotate at 1.8°/step for a target of 18.75 rpm at 1/8 microstep mode. Using

Equation 1, ƒstep can be calculated as 500 Hz.

The microstepping level is set by the M0 and M1 pins and can be any of the settings listed in Table 8-2. Higher

microstepping results in a smoother motor motion and less audible noise, but requires a higher ƒstep to achieve

the same motor speed.

Table 8-2. Microstepping Indexer Settings

MODE0

MODE1

STEP MODE

0

0

Full step (2-phase excitation) with 100%

current

0

330kΩ to

GND

Full step (2-phase excitation) with 71%

current

1

0

Non-circular 1/2 step

Hi-Z

0

1/2 step

0

1

1/4 step

1

1

1/8 step

Hi-Z

1

1/16 step

0

Hi-Z

1/32 step

Hi-Z

330kΩ to

GND

1/64 step

Hi-Z

Hi-Z

1/128 step

1

Hi-Z

1/256 step

8.2.2.2 Current Regulation

In a stepper motor, the full-scale current (IFS) is the maximum current driven through either winding. This quantity

depends on the VREF voltage. The maximum allowable voltage on the VREF pin is 3.3V for DRV8426. DVDD

can be used to provide VREF through a resistor divider. During stepping, IFS defines the current chopping

threshold (ITRIP) for the maximum current step. IFS (A) = VREF (V) / 2.2 (V/A)

8.2.2.3 Decay Modes

The DRV8426 device supports six different decay modes, as shown in Table 7-6. When a motor winding current

has hit the current chopping threshold (ITRIP), the DRV8426 places the winding in one of the six decay modes for

tOFF. After tOFF, a new drive phase starts.

36

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

8.2.3 Thermal Application

This section presents the power dissipation calculation and junction temperature estimation of the device.

8.2.3.1 Power Dissipation

The total power dissipation constitutes of three main components - conduction loss (PCOND), switching loss

(PSW) and power loss due to quiescent current consumption (PQ).

8.2.3.1.1 Conduction Loss

The current path for a motor connected in full-bridge is through the high-side FET of one half-bridge and

low-side FET of the other half-bridge. The conduction loss (PCOND) depends on the motor rms current (IRMS) and

high-side (RDS(ONH)) and low-side (RDS(ONL)) on-state resistances as shown in Equation 2.

PCOND = 2 x (IRMS)2 x (RDS(ONH) + RDS(ONL))

(2)

The conduction loss for the typical application shown in Table 8-2 is calculated in Equation 3.

PCOND = 2 x (IRMS)2 x (RDS(ONH) + RDS(ONL)) = 2 x (1-A / √2)2 x (0.45-Ω + 0.45-Ω) = 0.9-W

(3)

Note

This power calculation is highly dependent on the device temperature which significantly effects

the high-side and low-side on-resistance of the FETs. For more accurate calculation, consider the

dependency of on-resistance of FETs with device temperature.

8.2.3.1.2 Switching Loss

The power loss due to the PWM switching frequency depends on the slew rate (tSR), supply voltage, motor RMS

current and the PWM switching frequency. The switching losses in each H-bridge during rise-time and fall-time

are calculated as shown in Equation 4 and Equation 5.

PSW_RISE = 0.5 x VVM x IRMS x tRISE_PWM x fPWM

(4)

PSW_FALL = 0.5 x VVM x IRMS x tFALL_PWM x fPWM

(5)

Both tRISE_PWM and tFALL_PWM can be approximated as VVM/ tSR. After substituting the values of various

parameters, and assuming 30-kHz PWM frequency, the switching losses in each H-bridge are calculated as

shown below PSW_RISE = 0.5 x 24-V x (1-A / √2) x (24-V / 240 V/µs) x 30-kHz = 0.025-W

(6)

PSW_FALL = 0.5 x 24-V x (1-A / √2) x (24-V / 240 V/µs) x 30-kHz = 0.025-W

(7)

The total switching loss for the stepper motor driver (PSW) is calculated as twice the sum of rise-time (PSW_RISE)

switching loss and fall-time (PSW_FALL) switching loss as shown below PSW = 2 x (PSW_RISE + PSW_FALL) = 2 x (0.025-W + 0.025-W) = 0.1-W

(8)

Note

The rise-time (tRISE) and the fall-time (tFALL) are calculated based on typical values of the slew rate

(tSR). This parameter is expected to change based on the supply-voltage, temperature and device to

device variation.

The switching loss is directly proportional to the PWM switching frequency. The PWM frequency in an

application will depend on the supply voltage, inductance of the motor coil, back emf voltage and OFF

time or the ripple current (for smart tune ripple control decay mode).

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

37

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

8.2.3.1.3 Power Dissipation Due to Quiescent Current

The power dissipation due to the quiescent current consumed by the power supply is calculated as shown below

PQ = VVM x IVM

(9)

Substituting the values, quiescent power loss can be calculated as shown below PQ = 24-V x 5-mA = 0.12-W

(10)

Note

The quiescent power loss is calculated using the typical operating supply current (IVM) which is

dependent on supply-voltage, temperature and device to device variation.

8.2.3.1.4 Total Power Dissipation

The total power dissipation (PTOT) is calculated as the sum of conduction loss, switching loss and the quiescent

power loss as shown in Equation 11.

PTOT = PCOND + PSW + PQ = 0.9-W + 0.1-W + 0.12-W = 1.12-W

(11)

8.2.3.2 Device Junction Temperature Estimation

For an ambient temperature of TA and total power dissipation (PTOT), the junction temperature (TJ) is calculated

as TJ = TA + (PTOT x RθJA)

Considering a JEDEC standard 4-layer PCB, the junction-to-ambient thermal resistance (RθJA) is 33 °C/W for the

HTSSOP package and 43 °C/W for the VQFN package.

Assuming 25°C ambient temperature, the junction temperature for the HTSSOP package is calculated as shown

below TJ = 25°C + (1.12-W x 33°C/W) = 61.96 °C

(12)

The junction temperature for the VQFN package is calculated as shown below TJ = 25°C + (1.12-W x 43°C/W) = 73.16 °C

38

(13)

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

9 Power Supply Recommendations

The DRV8426 device is designed to operate from an input voltage supply (VM) range from 4.5 V to 33 V. A

0.01-µF ceramic capacitor rated for VM must be placed at each VM pin as close to the DRV8426 device as

possible. In addition, a bulk capacitor must be included on VM.

9.1 Bulk Capacitance

Having appropriate local bulk capacitance is an important factor in motor drive system design. It is generally

beneficial to have more bulk capacitance, while the disadvantages are increased cost and physical size.

The amount of local capacitance needed depends on a variety of factors, including:

•

•

•

•

•

•

The highest current required by the motor system

The power supply’s capacitance and ability to source current

The amount of parasitic inductance between the power supply and motor system

The acceptable voltage ripple

The type of motor used (brushed DC, brushless DC, stepper)

The motor braking method

The inductance between the power supply and motor drive system will limit the rate current can change from the

power supply. If the local bulk capacitance is too small, the system will respond to excessive current demands

or dumps from the motor with a change in voltage. When adequate bulk capacitance is used, the motor voltage

remains stable and high current can be quickly supplied.

The data sheet generally provides a recommended value, but system-level testing is required to determine the

appropriate sized bulk capacitor.

The voltage rating for bulk capacitors should be higher than the operating voltage, to provide margin for cases

when the motor transfers energy to the supply.

Power Supply

Parasitic Wire

Inductance

Motor Drive System

VM

+

±

+

Motor

Driver

GND

Local

Bulk Capacitor

IC Bypass

Capacitor

Copyright © 2016, Texas Instruments Incorporated

Figure 9-1. Example Setup of Motor Drive System With External Power Supply

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

39

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

10 Layout

10.1 Layout Guidelines

The VM pin should be bypassed to PGND using a low-ESR ceramic bypass capacitor with a recommended

value of 0.01 µF rated for VM. This capacitor should be placed as close to the VM pin as possible with a thick

trace or ground plane connection to the device PGND pin.

The VM pin must be bypassed to PGND using a bulk capacitor rated for VM. This component can be an

electrolytic capacitor.

A low-ESR ceramic capacitor must be placed in between the CPL and CPH pins. A value of 0.022 µF rated for

VM is recommended. Place this component as close to the pins as possible.

A low-ESR ceramic capacitor must be placed in between the VM and VCP pins. A value of 0.22 µF rated for 16

V is recommended. Place this component as close to the pins as possible.

Bypass the DVDD pin to ground with a low-ESR ceramic capacitor. A value of 0.47 µF rated for 6.3 V is

recommended. Place this bypassing capacitor as close to the pin as possible.

The thermal PAD must be connected to system ground.

40

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

11 Device and Documentation Support

11.1 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper

right corner, click on Alert me to register and receive a weekly digest of any product information that has

changed. For change details, review the revision history included in any revised document.

11.2 Community Resources

11.3 Trademarks

All trademarks are the property of their respective owners.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

41

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

42

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

PACKAGE OUTLINE

PWP0028M

TM

PowerPAD TSSOP - 1.2 mm max height

SCALE 2.000

SMALL OUTLINE PACKAGE

C

6.6

TYP

6.2

A

0.1 C

PIN 1 INDEX

AREA

SEATING

PLANE

26X 0.65

28

1

2X

9.8

9.6

NOTE 3

8.45

14

15

0.30

0.19

0.1

C A B

28X

4.5

4.3

B

SEE DETAIL A

(0.15) TYP

2X 0.82 MAX

NOTE 5

14

15

2X 0.825 MAX

NOTE 5

0.25

GAGE PLANE

1.2 MAX

4.05

3.53

THERMAL

PAD

0 -8

0.15

0.05

0.75

0.50

DETAIL A

A 20

TYPICAL

28

1

3.10

2.58

4224480/A 08/2018

PowerPAD is a trademark of Texas Instruments.

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

3. This dimension does not include mold flash, protrusions, or gate burrs. Mold flash, protrusions, or gate burrs shall not

exceed 0.15 mm per side.

4. Reference JEDEC registration MO-153.

5. Features may differ or may not be present.

www.ti.com

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: DRV8426

43

�DRV8426

www.ti.com

SLOSE55B – MAY 2020 – REVISED MAY 2021

EXAMPLE BOARD LAYOUT

PWP0028M

TM

PowerPAD TSSOP - 1.2 mm max height

SMALL OUTLINE PACKAGE

(3.4)

NOTE 9

(3.1)

METAL COVERED

BY SOLDER MASK

SYMM

28X (1.5)

1

28X (0.45)

28

SEE DETAILS

(R0.05) TYP

26X (0.65)

(4.05)

(0.6)

SYMM

(9.7)

NOTE 9

SOLDER MASK

DEFINED PAD

(1.2) TYP

( 0.2) TYP

VIA

15

14

(1.2) TYP

(5.8)

LAND PATTERN EXAMPLE

EXPOSED METAL SHOWN

SCALE: 8X

SOLDER MASK

OPENING

METAL UNDER

SOLDER MASK

METAL

SOLDER MASK

OPENING

EXPOSED METAL

EXPOSED METAL

0.05 MIN

ALL AROUND

0.05 MAX

ALL AROUND

NON-SOLDER MASK

DEFINED

(PREFERRED)

SOLDER MASK

DEFINED

SOLDER MASK DETAILS

15.000

4224480/A 08/2018

NOTES: (continued)

6. Publication IPC-7351 may have alternate designs.

7. Solder mask tolerances between and around signal pads can vary based on board fabrication site.

8. This package is designed to be soldered to a thermal pad on the board. For more information, see Texas Instruments literature

numbers SLMA002 (www.ti.com/lit/slma002) and SLMA004 (www.ti.com/lit/slma004).

9. Size of metal pad may vary due to creepage requirement.

10. Vias are optional depending on application, refer to device data sheet. It is recommended that vias under paste be filled, plugged

or tented.

www.ti.com