Order

Now

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

Reference

Design

LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

LM25180 42-VIN PSR Flyback DC/DC Converter with 65-V, 1.5-A Integrated Power MOSFET

1 Features

2 Applications

•

•

•

•

•

•

1

•

•

•

•

Designed for reliable and rugged applications

– Wide input voltage range of 4.5 V to 42 V with

operation down to 3.5 V after start-up

– Robust solution with only one component

crossing the isolation barrier

– ±1.5% total output regulation accuracy

– Optional VOUT temperature compensation

– 6-ms internal or programmable soft start

– Input UVLO and thermal shutdown protection

– Hiccup-mode overcurrent fault protection

– –40°C to +150°C junction temperature range

Integration reduces solution size and cost

– Integrated 65-V, 0.4-Ω power MOSFET

– No opto-coupler or transformer auxiliary

winding required for VOUT regulation

– Internal loop compensation

High-efficiency PSR flyback operation

– Quasi-resonant MOSFET turn-off in BCM

– Low input quiescent current

– External bias option for improved efficiency

– Single- and multi-output implementations

Ultra-low conducted and radiated EMI signatures

– Soft switching avoids diode reverse recovery

– Optimized for CISPR 32 EMI requirements

Create a custom regulator design using

WEBENCH® Power Designer

Isolated field transmitters and field actuators

Multi-output rails for analog input modules

Motor drives: IGBT and SiC gate drive supplies

Building automation HVAC systems

Isolated bias supplies

3 Description

The LM25180 is a primary-side regulated (PSR)

flyback converter with high efficiency over a wide

input voltage range of 4.5 V to 42 V. The isolated

output voltage is sampled from the primary-side

flyback voltage, eliminating the need for an

optocoupler, voltage reference, or third winding from

the transformer for output voltage regulation.

The high level of integration results in a simple,

reliable and high-density design with only one

component crossing the isolation barrier. Boundary

conduction mode (BCM) switching enables a compact

magnetic solution and better than ±1.5% load and

line regulation performance. An integrated 65-V

power MOSFET provides output power up to 7 W

with enhanced headroom for line transients.

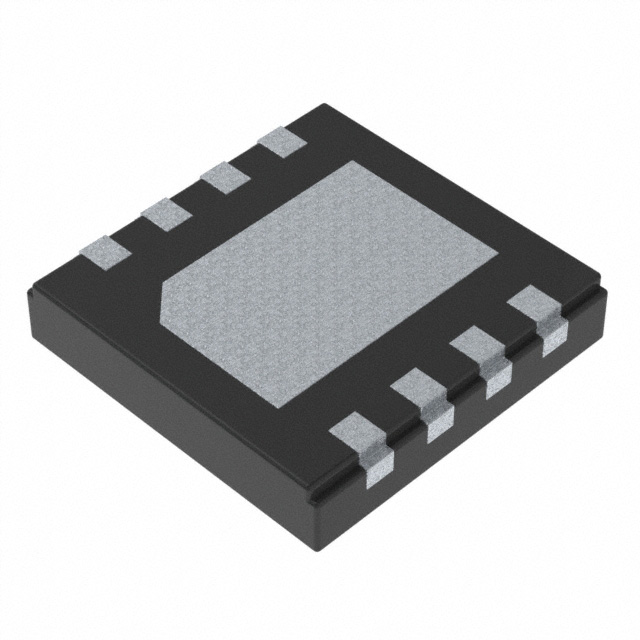

The LM25180 flyback converter is available in a 8pin, 4-mm × 4-mm, thermally-enhanced WSON

package with 0.8-mm pin pitch.

Device Information(1)

PART NUMBER

LM25180

T1

DZ

3:1

DF

VIN

SW

EN/UVLO

RFB

LM25180

GND

DFLY

90

VOUT = 5 V

85

158 k:

FB

Efficiency (%)

CIN

Typical Efficiency, VOUT = 5 V

COUT

100 F

2.2 F

BODY SIZE (NOM)

4.00 mm × 4.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Typical Application

VIN = 4.5 V...42 V

PACKAGE

WSON (8)

80

75

70

RSET

RSET

SS/BIAS

VIN = 12V

VIN = 24V

VIN = 36V

65

12.1 k:

TC

60

0

0.2

0.4

0.6

0.8

Output Current (A)

1

1.2

1.4

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

Table of Contents

1

2

3

4

5

6

7

8

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Description (continued).........................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

2

3

4

7.1

7.2

7.3

7.4

7.5

7.6

4

4

4

4

5

6

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Typical Characteristics ..............................................

Detailed Description .............................................. 9

8.1 Overview ................................................................... 9

8.2 Functional Block Diagram ......................................... 9

8.3 Feature Description................................................... 9

8.4 Device Functional Modes........................................ 15

9

Application and Implementation ........................ 16

9.1 Application Information............................................ 16

9.2 Typical Applications ................................................ 16

10 Power Supply Recommendations ..................... 32

11 Layout................................................................... 33

11.1 Layout Guidelines ................................................. 33

11.2 Layout Examples................................................... 34

12 Device and Documentation Support ................. 35

12.1

12.2

12.3

12.4

12.5

12.6

12.7

Device Support......................................................

Documentation Support ........................................

Receiving Notification of Documentation Updates

Support Resources ...............................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

35

36

36

36

36

37

37

13 Mechanical, Packaging, and Orderable

Information ........................................................... 37

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (July 2019) to Revision B

Page

•

Added EMI bullet in Features ................................................................................................................................................. 1

•

Added magnetic components in Table 3 ............................................................................................................................. 17

•

Added expressions for UVLO turn-on/off voltage thresholds in Typical Applications .......................................................... 20

•

Updated Layout Examples .................................................................................................................................................. 34

•

Added PSR flyback converter family in Device and Documentation Support ...................................................................... 35

•

Updated Documentation Support ......................................................................................................................................... 36

Changes from Original (November 2018) to Revision A

Page

•

Changed EC table specs for current limit............................................................................................................................... 4

•

Added note about failsafe current limit ................................................................................................................................. 14

5 Description (continued)

The LM25180 flyback converter simplifies implementation of isolated DC/DC supplies with optional features to

optimize performance for the target end equipment. The output voltage is set by one resistor, while an optional

resistor improves output voltage accuracy by negating the thermal coefficient of the flyback diode voltage drop.

Additional features include an internally-fixed or externally-programmable soft start, optional bias supply

connection for higher efficiency, precision enable input with hysteresis for adjustable line UVLO, hiccup-mode

overload protection, and thermal shutdown protection with automatic recovery.

2

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

6 Pin Configuration and Functions

NGU Package

8-Pin WSON With Wettable Flanks

Top View

SW

1

8

GND

FB

2

7

RSET

VIN

3

6

TC

EN/UVLO

4

5

SS/BIAS

Pin Functions

PIN

NO.

NAME

I/O (1)

DESCRIPTION

1

SW

P

Switch node that is internally connected to the drain of the N-channel power MOSFET. Connect

to the primary-side switching terminal of the flyback transformer.

2

FB

I

Primary side feedback pin. Connect a resistor from FB to SW. The ratio of the FB resistor to the

resistor at the RSET pin sets the output voltage.

3

VIN

P/I

Input supply connection. Source for internal bias regulators and input voltage sensing pin.

Connect directly to the input supply of the converter with short, low impedance paths.

4

EN/UVLO

I

Enable input and undervoltage lockout (UVLO) programming pin. If the EN/UVLO voltage is

below 1.1 V, the converter is in shutdown mode with all functions disabled. If the EN/UVLO

voltage is greater than 1.1 V and below 1.5 V, the converter is in standby mode with the internal

regulator operational and no switching. If the EN/UVLO voltage is above 1.5 V, the start-up

sequence begins.

5

SS/BIAS

I

Soft start or bias input. Connect a capacitor from SS/BIAS to GND to adjust the output start-up

time and input inrush current. If SS/BIAS is left open, the internal 6-ms soft-start timer is

activated. Connect an external supply to SS/BIAS to supply bias to the internal voltage regulator

and enable internal soft start.

6

TC

I

Temperature compensation pin. Tie a resistor from TC to RSET to compensate for the

temperature coefficient of the forward voltage drop of the secondary diode, thus improving

regulation at the secondary-side output.

7

RSET

I

Reference resistor tied to GND to set the reference current for FB. Connect a 12.1-kΩ resistor

from RSET to GND.

8

GND

G

Analog and power ground. Ground connection of internal control circuits and power MOSFET.

-

DAP

G

Die attach pad. Connect to PCB ground plane.

(1)

P = Power, G = Ground, I = Input, O = Output

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

3

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

7 Specifications

7.1 Absolute Maximum Ratings

Over the recommended operating junction temperature range of –40°C to 150°C (unless otherwise noted)

Input voltage

Output voltage

MIN

MAX

VIN to GND

–0.3

45

EN/UVLO to GND

–0.3

45

TC to GND

–0.3

6

SS/BIAS to GND

–0.3

14

FB to GND

–0.3

45.3

FB to VIN

–0.3

0.3

RSET to GND

–0.3

3

SW to GND

–1.5

70

SW to GND (20-ns transient)

–3

UNIT

V

V

Operating junction temperature, TJ

–40

150

°C

Storage temperature, Tstg

–55

150

°C

7.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS001, all pins (1)

HBM ESD Classification Level 2

±2000

Charged device model (CDM), per JEDEC specification

JESD22-C101, all pins (2)

CDM ESD Classification Level C4B

±500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

7.3 Recommended Operating Conditions

Over the recommended operating junction temperature range of –40°C to 150°C (unless otherwise noted)

MIN

VIN

Input voltage after turn on

VSW

NOM

MAX

4.5

UNIT

42

V

SW voltage

65

V

VEN/UVLO

EN/UVLO voltage

42

V

VSS/BIAS

SS/BIAS voltage

13

V

TJ

Operating junction temperature

150

°C

–40

7.4 Thermal Information

LM25180

THERMAL METRIC (1)

NGU (WSON)

UNIT

8 PINS

RΘJA

Junction-to-ambient thermal resistance

41.3

°C/W

RΘJC(top)

Junction-to-case (top) thermal resistance

34.7

°C/W

RΘJB

Junction-to-board thermal resistance

19.1

°C/W

ΨJT

Junction-to-top characterization parameter

0.3

°C/W

ΨJB

Junction-to-board characterization parameter

19.2

°C/W

RΘJC(bot)

Junction-to-case (bottom) thermal resistance

3.2

°C/W

(1)

4

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

7.5 Electrical Characteristics

Typical values correspond to TJ = 25°C. Minimum and maximum limits aaply over the full –40°C to 150°C junction

temperature range unless otherwise indicated. VIN = 24 V and VEN/UVLO = 2 V unless otherwise stated.

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

SUPPLY CURRENT

ISHUTDOWN

VIN shutdown current

VEN/UVLO = 0 V

IACTIVE

VIN active current

VEN/UVLO = 2.5 V, VRSET = 1.8 V

IACTIVE-BIAS

VIN current with BIAS connected

VSS/BIAS = 6 V

VSD-FALLING

Shutdown threshold

VEN/UVLO falling

3

µA

260

350

µA

25

40

µA

0.3

V

ENABLE AND INPUT UVLO

VSD-RISING

Standby threshold

VEN/UVLO rising

0.8

1

V

VUV-RISING

Enable threshold

VEN/UVLO rising

1.45

1.5

1.53

V

VUV-HYST

Enable voltage hysteresis

VEN/UVLO falling

0.04

0.05

IUV-HYST

Enable current hysteresis

VEN/UVLO = 1.6 V

4.2

5

5.5

µA

IRSET

RSET current

RRSET = 12.1 kΩ

VRSET

RSET regulation voltage

RRSET = 12.1 kΩ

1.191

1.21

VFB-VIN1

FB to VIN voltage

IFB = 80 µA

VFB-VIN2

FB to VIN voltage

IFB = 120 µA

V

FEEDBACK

100

µA

1.224

–40

V

mV

40

mV

SWITCHING FREQUENCY

FSW-MIN

Minimum switching frequency

12

kHz

FSW-MAX

Maximum switching frequency

350

kHz

tON-MIN

Minimum switch on-time

140

ns

DIODE THERMAL COMPENSATION

VTC

TC voltage

ITC = ±10 µA, TJ = 25°C

1.2

1.27

V

ISW = 100 mA

0.4

Ω

POWER SWITCHES

RDS(on)

MOSFET on-state resistance

SOFT-START AND BIAS

ISS

SS ext capacitor charging current

5

µA

tSS

Internal SS time

6

ms

VBIAS-UVLO-

BIAS enable voltage

VSS/BIAS rising

5.5

BIAS UVLO hysteresis

VSS/BIAS falling

190

RISE

VBIAS-UVLOHYST

5.75

V

mV

CURRENT LIMIT

ISW-PEAK

Peak current limit threshold

1.23

1.5

1.73

A

THERMAL SHUTDOWN

TSD

Thermal shutdown threshold

TSD-HYS

Thermal shutdown hysteresis

TJ rising

175

°C

6

°C

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

5

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

7.6 Typical Characteristics

VIN = 24 V, VEN/UVLO = 2 V (unless otherwise stated).

90

5.2

5.15

85

Output Voltage (V)

Efficiency (%)

5.1

80

75

70

5.05

5

4.95

4.9

VIN = 12V

VIN = 24V

VIN = 36V

65

VIN = 12V

VIN = 24V

VIN = 36V

4.85

60

4.8

0

0.2

0.4

0.6

0.8

Output Current (A)

1

1.2

1.4

0

0.2

0.4

0.6

0.8

1

Output Current (A)

1.2

1.4

1.6

See Figure 23

See Figure 23

Figure 1. Efficiency versus Load

Figure 2. Output Voltage versus Load

SW 20V/DIV

VDFLY 5V/DIV

1 Ps/DIV

1 Ps/DIV

See Figure 23

See Figure 23

IOUT = 1 A

IOUT = 1 A

Figure 4. Flyback Diode Switching Waveform in BCM

Figure 3. Primary-side Switching Waveform in BCM

Shutdown Quiescent Current (PA)

18

VOUT 1V/DIV

VIN 10V/DIV

IOUT 500mA/DIV

2 ms/DIV

15

12

9

6

3

0

-50

See Figure 23

Figure 5. Start-up Characteristic

6

VIN = 12 V

VIN = 24 V

VIN = 42 V

-25

0

25

50

75

100

Junction Temperature (qC)

125

150

D001

Figure 6. Shutdown Quiescent Current versus Temperature

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

Typical Characteristics (continued)

VIN = 24 V, VEN/UVLO = 2 V (unless otherwise stated).

35

Active Quiescent Current (PA)

Active Quiescent Current (PA)

290

280

270

260

250

VIN = 12 V

VIN = 24 V

VIN = 42 V

240

-50

-25

0

25

50

75

100

Junction Temperature (qC)

125

30

25

20

VIN = 12 V

VIN = 24 V

VIN = 42 V

15

-50

150

-25

0

D002

25

50

75

100

Junction Temperature (qC)

125

150

D003

VSS/BIAS = 6 V

Figure 8. Active Quiescent Current with BIAS versus

Temperature

102

104

101

102

RSET Current (PA)

RSET Current (PA)

Figure 7. Active Quiescent Current versus Temperature

100

100

98

99

96

-50

98

0

6

12

18

24

Input Voltage (V)

30

36

42

-25

Figure 9. RSET Current versus Input Voltage

125

150

D005

EN/UVLO Threshold Voltage (V)

1.54

1.6

TC Voltage (V)

25

50

75

100

Junction Temperature (qC)

Figure 10. RSET Current versus Temperature

1.8

1.4

1.2

1

0.8

-50

0

D004

-25

0

25

50

75

100

Junction Temperature (qC)

125

150

1.52

1.5

1.48

1.46

1.44

1.42

VEN/UVLO Rising

VEN/UVLO Falling

1.4

-50

D006

Figure 11. TC Voltage versus Temperature

-25

0

25

50

75

100

Junction Temperature (qC)

125

150

D007

Figure 12. EN/UVLO Threshold Voltages versus

Temperature

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

7

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

Typical Characteristics (continued)

5.3

0.8

5.2

0.7

Switch RDS(on) (:)

EN/UVLO Hysteresis Current (PA)

VIN = 24 V, VEN/UVLO = 2 V (unless otherwise stated).

5.1

5

4.9

4.8

0.6

0.5

0.4

0.3

4.7

-50

-25

0

25

50

75

100

Junction Temperature (qC)

125

0.2

-50

150

160

1.5

155

1.2

BCM

FFM

0.6

0.3

-25

0

25

50

75

100

Junction Temperature (qC)

125

125

150

D009

150

145

140

130

-50

150

-25

0

D010

Figure 15. Switch Peak Current Limits versus Temperature

25

50

75

100

Junction Temperature (qC)

125

150

D011

Figure 16. Minimum Switch On-Time versus Temperature

380

Max. Switching Frequency (kHz)

13

Min. Switching Frequency (kHz)

25

50

75

100

Junction Temperature (qC)

135

0

-50

12.5

12

11.5

11

-50

-25

0

25

50

75

100

Junction Temperature (qC)

125

150

370

360

350

340

330

320

-50

D012

Figure 17. Minimum Switching Frequency versus

Temperature

8

0

Figure 14. MOSFET RDS(on) versus Temperature

1.8

Minimum on-time (ns)

Peak Current Limit (A)

Figure 13. EN/UVLO Hysteresis Current versus Temperature

0.9

-25

D008

-25

0

25

50

75

100

Junction Temperature (qC)

125

150

D013

Figure 18. Maximum Switching Frequency versus

Temperature

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

8 Detailed Description

8.1 Overview

The LM25180 primary-side regulated (PSR) flyback converter is a high-density, cost-effective solution for

industrial systems requiring less than 7 W of isolated DC/DC power. This compact, easy-to-use flyback converter

with low IQ can be applied over a wide input voltage range from 4.5 V to 42 V, with operation down to 3.5 V after

start-up. Innovative frequency and current amplitude modulation enables high conversion efficiency across the

entire load and line range. Primary-side regulation of the isolated output voltage using sampled values of the

primary winding voltage eliminates the need for an opto-coupler or an auxiliary transformer winding for feedback.

Regulation performance that rivals that of traditional opto-coupler solutions is achieved without the associated

cost, solution size, and reliability concerns. The LM25180 converter services a wide range of applications

including IGBT-based motor drives, factory automation, and medical equipment.

8.2 Functional Block Diagram

VIN

NP : NS

CIN

EN/UVLO

DZ

LM25180

5 PA

DFLY

BIAS

REGULATOR

Standby

1.5 V

1.45 V

VOUT

COUT

SS/BIAS

VDD

VIN

VDD UVLO

Shutdown

DF

SAMPLED

FEEDBACK

1.1 V

VIN

THERMAL

SHUTDOWN

FB

65-V Power

MOSFET

RSET

gm

COMP

SW

VDD

VREF

TRIMMED

REFERENCE

RTC

CONTROL

LOGIC

RSET

FB

ILIM

TC

1.5 A

TC

REGULATION

VDD

GND

RFB

SS/BIAS

Internal SS

CSS

8.3 Feature Description

8.3.1 Integrated Power MOSFET

The LM25180 is a flyback dc/dc converter with integrated 65-V, 1.5-A N-channel power MOSFET. During the

MOSFET on-time, the transformer primary current increases from zero with slope VIN / LMAG (where LMAG is the

transformer primary-referred magnetizing inductance) while the output capacitor supplies the load current. When

the high-side MOSFET is turned off by the control logic, the SW voltage VSW swings up to approximately VIN +

(NPS × VOUT), where NPS = NP/NS is the primary-to-secondary turns ratio of the transformer. The magnetizing

current flows in the secondary side through the flyback diode, charging the output capacitor and supplying

current to the load. Duty cycle D is defined as tON / tSW, where tON is the MOSFET conduction time and tSW is the

switching period.

Figure 19 shows a typical schematic of the LM25180 PSR flyback circuit. Components denoted in red are

optional depending on the application requirements.

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

9

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

Feature Description (continued)

T1

DFLY

VIN

VOUT

DCLAMP

COUT

RUV1

CIN

EN/UVLO

RUV2

SW

RFB

LM25180

GND

NP : NS

DF

VIN

DOUT

FB

RSET

SS/BIAS

CSS

RTC

RSET

TC

Figure 19. LM25180 Flyback Converter Schematic (Optional Components in Red)

8.3.2 PSR Flyback Modes of Operation

The LM25180 uses a variable-frequency, peak current-mode (VFPCM) control architecture with three possible

modes of operation as illustrated in Figure 20.

Frequency

foldback mode

(FFM)

Discontinuous conduction mode (DCM)

Boundary conduction mode (BCM)

400

Switching Frquency (kHz)

350

300

250

200

150

100

50

0

0

20

40

60

80

100

% Total Rated Output Power

Figure 20. Three Modes of Operation Illustrated by Variation of Switching Frequency With Load

10

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

Feature Description (continued)

The LM25180 operates in boundary conduction mode (BCM) at heavy loads. The power MOSFET turns on when

the current in the secondary winding reaches zero, and the MOSFET turns off when the peak primary current

reaches the level dictated by the output of the internal error amplifier. As the load is decreased, the frequency

increases in order to maintain BCM operation. The duty cycle of the flyback converter is given Equation 1, where

VD is the forward voltage drop of the flyback diode as its current approaches zero.

VOUT

D

VIN

VD ˜ NPS

VOUT

VD ˜ NPS

(1)

The output power in BCM is given by Equation 2, where the applicable switching frequency and peak primary

current in BCM are specified by Equation 3 and Equation 4, respectively.

LMAG ˜ IPRI-PK(BCM)

POUT(BCM)

FSW(BCM)

2

˜ FSW(BCM)

2

(2)

1

§L

IPRI-PK(BCM) ˜ ¨ MAG

¨ VIN

©

IPRI-PK(BCM)

2 ˜ VOUT

LMAG

NPS ˜ VOUT

VD

·

¸¸

¹

(3)

VD ˜ IOUT

VIN ˜ D

(4)

As the load decreases, the LM25180 clamps the maximum switching frequency to 350 kHz, and the converter

enters discontinuous conduction mode (DCM). The power delivered to the output in DCM is proportional to the

peak primary current squared as given by Equation 5 and Equation 6. Thus, as the load decreases, the peak

current reduces to maintain regulation at 350-kHz switching frequency.

POUT(DCM)

IPRI-PK(DCM)

DDCM

LMAG ˜ IPRI-PK(DCM)

2

2

˜ FSW(DCM)

(5)

2 ˜ IOUT ˜ VOUT

VD

LMAG ˜ FSW(DCM)

(6)

LMAG ˜ IPRI-PK(DCM) ˜ FSW(DCM)

VIN

(7)

At even lighter loads, the primary-side peak current set by the internal error amplifier decreases to a minimum

level of 0.3 A, or 20% of its 1.5-A peak value, and the MOSFET off-time extends to maintain the output load

requirement. The system operates in frequency foldback mode (FFM), and the switching frequency decreases as

the load current is reduced. Other than a fault condition, the lowest frequency of operation of the LM25180 is 12

kHz, which sets a minimum load requirement of approximately 0.5% full load.

8.3.3 Setting the Output Voltage

To minimize output voltage regulation error, the LM25180 senses the reflected secondary voltage when the

secondary current reaches zero. The feedback (FB) resistor, which is connected between SW and FB as shown

in Figure 19, is determined using Equation 8, where RSET is nominally 12.1 kΩ.

RFB

VOUT

VD ˜ NPS ˜

RSET

VREF

(8)

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

11

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

Feature Description (continued)

8.3.3.1 Diode Thermal Compensation

The LM25180 employs a unique thermal compensation circuit that adjusts the feedback setpoint based on the

thermal coefficient of the flyback diode's forward voltage drop. Even though the output voltage is measured when

the secondary current is effectively zero, there is still a non-zero forward voltage drop associated with the flyback

diode. Select the thermal compensation resistor using Equation 9.

RTC ¬ªk: ¼º

RFB ¬ªk: ¼º

NPS

˜

3

TCDiode ¬ªmV qC ¼º

(9)

The temperature coefficient of the diode voltage drop may not be explicitly provided in the diode datasheet, so

the effective value can be estimated based on the measured output voltage shift over temperature when the TC

resistor is not installed.

8.3.4 Control Loop Error Amplifier

The inputs of the error amplifier include a level-shifted version of the FB voltage and an internal 1.21-V reference

set by the resistor at RSET. A type-II internal compensation network stabilizes the converter. In BCM operation

when the output voltage is in regulation, an on-time interval is initiated when the secondary current reaches zero.

The power MOSFET is subsequently turned off when an amplified version of the peak primary current exceeds

the error amplifier output.

8.3.5 Precision Enable

The precision EN/UVLO input supports adjustable input undervoltage lockout (UVLO) with hysteresis for

application specific power-up and power-down requirements. EN/UVLO connects to a comparator with a 1.5-V

reference voltage and 50-mV hysteresis. An external logic signal can be used to drive the EN/UVLO input to

toggle the output on and off for system sequencing or protection. The simplest way to enable the LM25180 is to

connect EN/UVLO directly to VIN. This allows the LM25180 to start up when VIN is within its valid operating

range. However, many applications benefit from using a resistor divider RUV1 and RUV2 as shown in Figure 21 to

establish a precision UVLO level.

LM25180

VCC

VIN

5 A

RUV1

EN/UVLO

+

RUV2

1.5 V

1.45 V

UVLO

Comparator

Figure 21. Programmable Input Voltage UVLO With Hysteresis

Use Equation 10 and Equation 11 to calculate the input UVLO voltages turn-on and turn-off voltages,

respectively, where VUV-RISING and VUV-FALLING are the UVLO comparator thresholds and IUV-HYST is the hysteresis

current.

VIN(on)

12

§

RUV1 ·

VUV-RISING ¨ 1

¸

© RUV2 ¹

(10)

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

Feature Description (continued)

VIN(off)

§

RUV1 ·

VUV-FALLING ¨ 1

¸ IUV-HYST ˜ RUV1

© RUV2 ¹

(11)

The LM25180 also provides a low-IQ shutdown mode when the EN/UVLO voltage is pulled below a base-emitter

voltage drop (approximately 0.6 V at room temperature). If the EN/UVLO voltage is below this hard shutdown

threshold, the internal LDO regulator powers off, and the internal bias-supply rail collapses, shutting down the

bias currents of the LM25180. The LM25180 operates in standby mode when the EN/UVLO voltage is between

the hard shutdown and precision-enable thresholds.

8.3.6 Configurable Soft Start

The LM25180 has a flexible and easy-to-use soft-start control pin, SS/BIAS. The soft-start feature prevents

inrush current impacting the LM25180 and the input supply when power is first applied. This is achieved by

controlling the voltage at the output of the internal error amplifier. Soft start is achieved by slowly ramping up the

target regulation voltage when the device is first enabled or powered up. Selectable and adjustable start-up

timing options include a 6-ms internally-fixed soft start and an externally-programmable soft start.

The simplest way to use the LM25180 is to leave SS/BIAS open. The LM25180 employs an internal soft-start

control ramp and starts up to the regulated output voltage in 6 ms.

However, in applications with a large amount of output capacitance, higher VOUT or other special requirements,

the soft-start time can be extended by connecting an external capacitor CSS from SS/BIAS to GND. A longer softstart time further reduces the supply current needed to charge the output capacitors while sourcing the required

load current. When the EN/UVLO voltage exceeds the UVLO rising threshold and a delay of 20 µs expires, an

internal current source ISS of 5 µA charges CSS and generates a ramp to control the primary current amplitude.

Calculate the soft-start capacitance for a desired soft-start time, tSS, using Equation 12.

CSS ª¬nF º¼

5 ˜ t SS ª¬ms º¼

(12)

CSS is discharged by an internal FET when switching is disabled by EN/UVLO or thermal shutdown.

8.3.7 External Bias Supply

DFLY

T1

VIN

VOUT

DCLAMP

COUT

RUV1

CIN

DF

VIN

EN/UVLO

RUV2

RSET

NP : NS

SW

RFB

LM25180

GND

FB

DBIAS1

SS/BIAS

DBIAS2

RSET

TC

DOUT

12 V

CBIAS

22 nF

NP : NAUX

Figure 22. External Bias Supply Using Transformer Auxiliary Winding

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

13

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

Feature Description (continued)

The LM25180 has an external bias supply feature that reduces input quiescent current and increases efficiency.

When the voltage at SS/BIAS exceeds a rising threshold of 5.5 V, bias power for the internal LDO regulator can

be derived from an external voltage source or from a transformer auxiliary winding as shown in Figure 22. With a

bias supply connected, the LM25180 then uses its internal soft-start ramp to control the primary current during

start-up.

When using a transformer auxiliary winding for bias power, the total leakage current related to diodes DBIAS1 and

DBIAS2 in Figure 22 should be less than 1 µA across the full operating temperature range.

8.3.8 Minimum On-Time and Off-Time

When the internal power MOSFET is turned off, the leakage inductance of the transformer resonates with the

SW node parasitic capacitance. The resultant ringing behavior can be excessive with large transformer leakage

inductance and may corrupt the secondary zero-current detection. In order to prevent such a situation, a

minimum switch off-time, designated as tOFF-MIN, of maximum 450 ns is set internally to ensure proper

functionality. This sets a lower limit for the transformer magnetizing inductance as discussed in the Detailed

Design Procedure.

Furthermore, noise effects as a result of power MOSFET turn-on can impact the internal current sense circuit

measurement. To mitigate this effect, the LM25180 provides a blanking time after the MOSFET turns on. This

blanking time forces a minimum on-time, tON-MIN, of 140 ns.

8.3.9 Overcurrent Protection

In case of an overcurrent condition on the isolated output(s), the output voltage drops lower than the regulation

level since the maximum power delivered is limited by the peak current capability on the primary side. The peak

primary current is maintained at 1.5 A (plus an amount related to the 100-ns propagation delay of the current limit

comparator) until the output decreases to the secondary diode voltage drop to impact the reflected signal on the

primary side. At this point, the LM25180 assumes the output cannot be recovered and re-calibrates its switching

frequency to 9 kHz until the overload condition is removed. The LM25180 responds with similar behavior to an

output short circuit condition.

For a given input voltage, Equation 13 gives the maximum output current prior to the engagement of overcurrent

protection. The typical threshold value for ISW-PEAK from the Specifications is 1.5 A.

IOUT(max)

K

˜

ISW-PEAK

2 § VOUT

¨

© VIN

1 ·

¸

NPS ¹

(13)

A failsafe current limit set at 2.4 A, or 1.6 times the nominal peak current limit, provides redundant fault protection

in case of transformer short circuit or saturation effects. This initiates a 7.5-ms hiccup interval after eight

overcurrent events.

8.3.10 Thermal Shutdown

Thermal shutdown is an integrated self-protection to limit junction temperature and prevent damage related to

overheating. Thermal shutdown turns off the device when the junction temperature exceeds 175°C to prevent

further power dissipation and temperature rise. Junction temperature decreases after shutdown, and the restarts

when the junction temperature falls to 169°C.

14

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

8.4 Device Functional Modes

8.4.1 Shutdown Mode

EN/UVLO facilitates ON and OFF control for the LM25180. When VEN/UVLO is below approximately 0.6 V, the

device is in shutdown mode. Both the internal LDO and the switching regulator are off. The quiescent current in

shutdown mode drops to 3 μA at VIN = 24 V. The LM25180 also employs internal bias rail undervoltage

protection. If the internal bias supply voltage is below its UV threshold, the converter remains off.

8.4.2 Standby Mode

The internal bias rail LDO regulator has a lower enable threshold than the converter itself. When VEN/UVLO is

above 0.6 V and below the precision-enable threshold (1.5 V typically), the internal LDO is on and regulating.

The precision enable circuitry is turned on once the internal VCC is above its UV threshold. The switching action

and voltage regulation are not enabled until VEN/UVLO rises above the precision enable threshold.

8.4.3 Active Mode

The LM25180 is in active mode when VEN/UVLO is above the precision-enable threshold and the internal bias rail

is above its UV threshold. The LM25180 operates in one of three modes depending on the load current

requirement:

1. Boundary conduction mode (BCM) at heavy loads.

2. Discontinuous conduction mode (DCM) at medium loads.

3. Frequency foldback mode (FFM) at light loads.

Refer to PSR Flyback Modes of Operation for more detail.

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

15

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

9.1 Application Information

The LM25180 requires only a few external components to convert from a wide range of supply voltages to one or

more isolated output rails. To expedite and streamline the process of designing of a LM25180-based converter, a

comprehensive LM25180 quick-start calculator is available for download to assist the designer with component

selection for a given application. WEBENCH® online software is also available to generate complete designs,

leveraging iterative design procedures and access to comprehensive component databases. The following

sections discuss the design procedure for both single- and dual-output implementations using specific circuit

design examples.

As mentioned previously, the LM25180 also integrates several optional features to meet system design

requirements, including precision enable, input UVLO, programmable soft start, output voltage thermal

compensation, and external bias supply connection. Each application incorporates these features as needed for

a more comprehensive design.

The application circuits detailed in Typical Applications show LM25180 configuration options suitable for several

application use cases. Refer to the LM5180EVM-S05 and LM5180EVM-DUAL EVM user's guides for more detail.

9.2 Typical Applications

For step-by-step design procedures, circuit schematics, bill of materials, PCB files, simulation and test results of LM25180-powered

implementations, refer to the TI reference designs library.

9.2.1 Design 1: Wide VIN, Low IQ PSR Flyback Converter Rated at 5 V, 1 A

The schematic diagram of a 5-V, 1-A PSR flyback converter is given in Figure 23.

VIN = 10 V...36 V

DFLY

T1

VOUT = 5 V

IOUT = 1 A

DCLAMP

24 V

RUV1

COUT

100 F

536 k:

CIN

10 F

EN/UVLO

RUV2

100 k:

SW

RFB

158 k:

LM25180

GND

SS/BIAS

FB

RSET

CSS

47 nF

3:1

30 PH

DF

VIN

DOUT

5.6 V

RTC

RSET

130 k:

12.1 k:

TC

Figure 23. Schematic for Design 1 With VIN(nom) = 24 V, VOUT = 5 V, IOUT = 1 A

16

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

9.2.1.1 Design Requirements

The required input, output, and performance parameters for this application example are shown in Table 1.

Table 1. Design Parameters

DESIGN PARAMETER

VALUE

Input voltage range

10 V to 36 V

Input UVLO thresholds

9.5 V on, 6.5 V off

Output voltage

5V

Rated load current, VIN = 24 V

1A

Output voltage regulation

±1.5%

Output voltage ripple

< 100 mV

The target full-load efficiency is 86% based on a nominal input voltage of 24 V and an isolated output voltage of

5 V. The LM25180 is chosen to deliver a fixed 5-V output voltage set by resistor RFB connected between the SW

and FB pins. The input voltage turn-on and turn-off thresholds are established by RUV1 and RUV2. The required

components are listed in Table 2. Transformers for other single-output designs are listed in Table 3.

Table 2. List of Components for Design 1

REF DES

QTY

SPECIFICATION

VENDOR

PART NUMBER

CIN

1

10 µF, 50 V, X7R, 1210, ceramic

Taiyo Yuden

UMK325AB7106KM-T

Murata

GRM32EC70J107ME15

Taiyo Yuden

JMK325AC7107MM-P

TDK

C3225X5R0J107M250AC

100 µF, 6.3 V, X7S, 1210, ceramic

COUT

1

100 µF, 6.3 V, X5R, 1210, ceramic

Würth Electronik

885012109004

CSS

1

47 nF, 16 V, X7R, 0402

Std

Std

DCLAMP

1

Zener, 24 V, 1 W, PowerDI-123

DFLZ24-7

Diodes Inc.

DF

1

Switching diode, 75 V, 0.25 A, SOD-323

CMDD4448

Central Semi

DFLY

1

Schottky diode, 40 V, 2 A, SOD-123

FSV340FP

ONsemi

DOUT

1

Zener, 5.6 V, 5%, SOD-523

BZX585-C5V6

Nexperia

RFB

1

158 kΩ, 1%, 0402

Std

Std

RSET

1

12.1 kΩ, 1%, 0402

Std

Std

RTC

1

130 kΩ, 1%, 0402

Std

Std

RUV1

1

536 kΩ, 1%, 0603

Std

Std

RUV2

1

100 kΩ, 1%, 0402

Std

Std

Coilcraft

YA8779-BL

Würth Electronik

750317605

30 µH, 2.6 A, turns ratio 3 : 1, 12.5 × 15.5 mm

Sumida

12387-T151

40 µH, 2 A, turns ratio 3 : 1, 13.3 × 15.2 mm

Würth Electronik

750313974

LM25180 PSR flyback converter, VSON-8

Texas Instruments

LM25180NGUR

30 µH, 2 A, turns ratio 3 : 1, 9.3 × 10.2 mm

T1

U1

1

1

Table 3. Magnetic Components for Other Single-Output Designs

OUTPUT VOLTAGE RANGE

TURNS RATIO

LMAG, ISAT

DIMENSIONS

VENDOR

PART NUMBER

4 V to 8 V

2:1

8 V to 11 V

1.5 : 1

12 V to 18 V

1:1

18 V to 36 V

1:2

YA9036-AL

36 V to 55 V

1:3

YA9037-AL

YA9033-AL

YA9034-AL

30 µH, 2 A

9.3 × 10.2 × 10.6 mm

Coilcraft

YA9035-AL

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

17

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

9.2.1.2 Detailed Design Procedure

9.2.1.2.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the LM25180 device with WEBENCH® Power Designer.

1. Start by entering the input voltage (VIN), output voltage (VOUT), and output current (IOUT) requirements.

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

9.2.1.2.2 Custom Design With Excel Quickstart Tool

Select components based on the converter specifications using the LM25180 quick-start calculator.

9.2.1.2.3 Flyback Transformer – T1

Choose a turns ratio based on an approximate 60% max duty cycle at minimum input voltage using Equation 14,

rounding up or down as needed.

NPS

VIN(min)

DMAX

˜

1 DMAX VOUT VD

0.6

10 V

˜

1 0.6 5 V + 0.3 V

3

(14)

Select a magnetizing inductance based on the minimum off-time constraint using Equation 15. Choose a value of

30 µH to allow some margin for this application. Specify a saturation current of 2 A, above the maximum switch

current specification of the LM25180.

LMAG t

VOUT

VD ˜ NPS ˜ t OFF-MIN

ISW-PEAK(FFM)

5 V + 0.3 V ˜ 3 ˜ 450ns

0.3 A

24 +

(15)

Note that a higher magnetizing inductance provides a larger operating range for BCM and FFM, but the leakage

inductance may increase based on a higher number of primary turns, NP. The primary and secondary winding

RMS currents are given by Equation 16 and Equation 17, respectively.

IPRI-RMS

D

˜ IPRI-PK

3

(16)

2 ˜ IOUT ˜ IPRI-PK ˜ NPS

3

ISEC-RMS

(17)

Find the maximum output current for a given turns ratio using Equation 18, where the typical value for ISW-PEAK is

the 1.5-A switch current peak threshold. Iterate by increasing the turns ratio if the output current capability is too

low at minimum input voltage.

IOUT(max)

18

K

˜

ISW-PEAK

2 § VOUT

¨

© VIN

1 ·

¸

NPS ¹

0.85

1.5 A

˜

2 § 5V 1·

¨

¸

© VIN 3 ¹

-°0.85 A at VIN 12 V

®

°¯1.2 A at VIN 24 V

Submit Documentation Feedback

(18)

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

9.2.1.2.4 Flyback Diode – DFLY

The flyback diode reverse voltage is given by Equation 19.

VD-REV t

VIN(max)

NPS

36 V

3

VOUT

5V

17 V

(19)

Select a 40-V, 3-A Schottky diode for this application to account for inevitable diode voltage overshoot and

ringing related to the resonance of transformer leakage inductance and diode parasitic capacitance. Connect an

appropriate RC snubber circuit (for example, 100 Ω and 22 pF) across the flyback diode if needed, particularly if

the transformer leakage inductance is high. Also, choose a flyback diode with current rating that aligns with the

maximum peak secondary winding current of NPS*ISW-PEAK. As mentioned in Layout, place adequate copper at

the cathode of the diode to improve its thermal performance and prevent overheating during high ambient

temperature or overload conditions. Beware of the high leakage current typical of a Schottky diode at elevated

operating temperatures.

9.2.1.2.5 Zener Clamp Circuit – DF, DCLAMP

Connect a diode-Zener clamping circuit across the primary winding to limit the peak switch-node voltage after

MOSFET turn-off below the maximum level of 65 V, as given by Equation 20.

VDZ(clamp)

VSW(max)

VIN(max)

(20)

Choosing the zener, DCLAMP, with clamp voltage of approximately 1.5 times the reflected output voltage, as

specified by Equation 21, provides a balance between the maximum switch voltage excursion and the leakage

inductance demagnetization time.

VDZ(clamp)

1.5 ˜ NPS ˜ VOUT

VD

1.5 ˜ 3 ˜ 5 V 0.3 V | 24 V

(21)

Select an ultra-fast switching diode or Schottky diode for DF with rated voltage greater than the maximum input

voltage and with low forward recovery voltage drop.

9.2.1.2.6 Output Capacitor – COUT

The output capacitor determines the voltage ripple at the converter output, limits the voltage excursion during a

load transient, and sets the dominant pole of the converter's small-signal response. For a flyback converter

specifically, the output capacitor supplies the load current when the main switch is on, and therefore the output

voltage ripple is a function of load current and duty cycle.

Select an output capacitance using Equation 22 to limit the ripple voltage amplitude to less than 1% of the output

voltage at minimum input voltage and maximum load.

2

COUT t

LMAG ˜ ISW-PEAK

2 ˜ 'VOUT ˜ VOUT

§1 D ·

˜¨

¸

© 2 ¹

2

30 + ˜

2

§ 1 0.6 ·

˜

2 ˜ 50mV ˜ 5 V ¨© 2 ¸¹

$

2

86 )

(22)

Select a 100-µF, 6.3-V capacitor in 1210 case size with X5R or better dielectric. Equation 23 gives the output

capacitor RMS ripple current.

ICOUT-RMS

IOUT ˜

2 ˜ NPS ˜ IPRI-PK

3 ˜ IOUT

1

(23)

9.2.1.2.7 Input Capacitor – CIN

Select an input capacitance using Equation 24 to limit the ripple voltage amplitude to less than 5% of the input

voltage when operating at nominal input voltage.

CIN

§ D·

IPRI-PK ˜ D ˜ ¨ 1

2 ¸¹

©

t

2 ˜ FSW ˜ 'VIN

2

(24)

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

19

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

Substituting the input current at full load, switching frequency, peak primary current and peak-to-peak ripple

specification gives CIN greater than 2 μF. Mindful of the voltage coefficient of ceramic capacitors, select a 10-µF,

50-V ceramic input capacitor with X7R dielectric in 1210 case size. Equation 25 gives the input capacitor RMS

ripple current.

D ˜ IPRI-PK

4

1

˜

2

3 ˜D

ICIN-RMS

(25)

9.2.1.2.8 Feedback Resistor – RFB

Select a feedback resistor, designated RFB, of 158 kΩ based on the secondary winding voltage at the end of the

flyback conduction interval (the sum of the 5-V output voltage and the Schottky diode forward voltage drop)

reflected by the transformer turns ratio of 3 : 1. The forward voltage drop of the flyback diode is 0.3 V as its

current approaches zero.

RFB

VOUT

VD ˜ NPS

5 V 0.3 V ˜ 3

0.1 mA

158 k:

0.1 mA

(26)

9.2.1.2.9 Thermal Compensation Resistor – RTC

Select a resistor for output voltage thermal compensation, designated RTC, based on Equation 27.

RTC ª¬k: º¼

RFB ª¬k: º¼

NPS

˜

3

TCDiode ª¬mV qC º¼

158 3

˜

3 1.2

130 k:

(27)

9.2.1.2.10 UVLO Resistors – RUV1, RUV2

Given VIN(on) and VIN(off) as the input voltage turn-on and turn-off thresholds of 9.5 V and 6.5 V, respectively,

select the upper and lower UVLO resistors using the following expressions:

VIN(on) ˜

RUV1

RUV2

RUV1 ˜

VUV-FALLING

VUV-RISING

IUV-HYST

VIN(off)

VUV-RISING

VIN(on) VUV-RISING

9.5 V ˜

536 k: ˜

1.45 V

1.5 V

5 $

6.5 V

536k:

(28)

1.5 V

9.5 V 1.5 V

100 k:

(29)

Calculate the actual input voltage turn-on and turn-off thresholds as follows:

VIN(on)

VIN(off)

§

RUV1 ·

VUV-RISING ¨ 1

¸

R

UV2 ¹

©

§

536 k: ·

1.5 V ¨ 1

¸

100k: ¹

©

§

RUV1 ·

VUV-FALLING ¨ 1

¸ IUV-HYST ˜ RUV1

© RUV2 ¹

9.54 V

(30)

§ 536k: ·

1.45 V ¨ 1

¸ 5 $˜

© 100k: ¹

N:

9

(31)

9.2.1.2.11 Soft-Start Capacitor – CSS

Connect an external soft-start capacitor for a specific soft-start time. In this example, select a soft-start

capacitance of 47 nF based on Equation 12 to achieve a soft-start time of 9 ms.

For technical solutions, industry trends, and insights for designing and managing power supplies, please refer to TI's

Power Management technical articles.

20

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

9.2.1.3 Application Curves

Unless otherwise stated, application performance curves were taken at TA = 25°C.

100

90

90

85

Efficiency (%)

Efficiency (%)

80

80

75

70

70

60

50

VIN = 12V

VIN = 24V

VIN = 36V

65

30

0.001

60

0

0.2

0.4

0.6

0.8

Output Current (A)

1

1.2

VIN = 12V

VIN = 24V

VIN = 36V

40

1.4

0.01

0.1

Output Current (A)

1

2

1

2

Figure 25. Efficiency (Log Scale)

Figure 24. Efficiency (Linear Scale)

5.2

5.2

5.15

5.1

Output Voltage (V)

Output Voltage (V)

5.1

5.05

5

4.95

5

4.9

4.9

VIN = 12V

VIN = 24V

VIN = 36V

VIN = 12V

VIN = 24V

VIN = 36V

4.85

4.8

0

0.2

0.4

0.6

0.8

1

Output Current (A)

1.2

1.4

1.6

4.8

0.001

0.01

0.1

Output Current (A)

Figure 27. Load Regulation (Log Scale)

Figure 26. Load Regulation (Linear Scale)

EN 1V/DIV

VOUT 1V/DIV

VOUT 1V/DIV

IOUT 500mA/DIV

IOUT 500mA/DIV

VIN 10V/DIV

2 ms/DIV

2 ms/DIV

VIN stepped to 24 V

5-Ω Load

VIN = 24 V

Figure 28. Start-up Characteristic

5-Ω Load

Figure 29. Enable ON Characteristic

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

21

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

SW 20V/DIV

VDFLY 5V/DIV

1 Ps/DIV

1 Ps/DIV

VIN = 24 V

IOUT = 1 A

VIN = 24 V

IOUT = 1 A

Figure 31. Flyback Diode Voltage

Figure 30. Switch Voltage

Average detector

Peak detector

Peak detector

Average detector

Start 150 kHz

VIN = 24 V

IOUT = 0.85 A

Stop 30 MHz

150 kHz to 30 MHz

LIN = 4.7 µH

CIN = 10 µF

Figure 32. CISPR 25 Class 5 Conducted EMI Plot

22

Start 30 MHz

VIN = 24 V

IOUT = 0.85 A

Stop 108 MHz

30 MHz to 108 MHz

LIN = 4.7 µH

CIN = 10 µF

Figure 33. CISPR 25 Class 5 Conducted EMI Plot

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

9.2.2 Design 2: PSR Flyback Converter With Dual Outputs of 15 V and –7.7 V at 200 mA

The schematic diagram of a dual-output flyback converter intended for isolated IGBT and SiC MOSFET gate

drive power supply applications is given in Figure 34.

VIN = 9.5 V...36 V

T1

DFLY1

VOUT1 = 15 V

IOUT1 = 0.2 A

DCLAMP

24 V

RUV1

340 k:

CIN

DF

VIN

10 F

DOUT1

18 V

1 : 1 : 0.52

30 PH

SW

EN/UVLO

RUV2

68.1 k:

COUT1

22 F

COUT2

47 F

RFB

LM25180

154 k:

VOUT2 = ±7.7 V

FB

GND

IOUT2 = ±0.2 A

DFLY2

RSET

SS/BIAS

DOUT2

8.2 V

RTC

RSET

200 k:

12.1 k:

TC

Figure 34. Schematic for Design 2 With VIN(nom) = 24 V, VOUT1 = 15 V, VOUT2 = –7.7 V, IOUT = 200 mA

9.2.2.1 Design Requirements

The required input, output, and performance parameters for this application example are shown in Table 4.

Table 4. Design Parameters

DESIGN PARAMETER

VALUE

Input voltage range (steady state)

9.5 V to 36 V

Output 1 voltage and current

15 V, 0.2 A

Output 2 voltage and current

–7.7 V, –0.2 A

Input UVLO thresholds

9 V on, 7 V off

Output voltage regulation

±2%

The target full-load efficiency of this LM25180 design is 88% based on a nominal input voltage of 24 V and

isolated output voltages of 15 V and –7.7 V sharing a common return. The selected flyback converter

components are cited in Table 5, including multi-winding flyback transformer, input and output capacitors,

rectifying diodes and flyback converter IC.

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

23

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

Table 5. List of Components for Design 2

REF DES

QTY

SPECIFICATION

VENDOR

PART NUMBER

CIN

1

10 µF, 50 V, X7R, 1210, ceramic

Taiyo Yuden

UMK325AB7106KM-T

TDK

C3225X7R1E226M

COUT1

1

22 µF, 25 V, X7R, 1210, ceramic

Murata

GRM32ER71E226KE15L

Taiyo Yuden

TMK325B7226MM-TR

TDK

C3225X7R1A476M

Murata

GRM32ER71A476ME15L

Taiyo Yuden

LMK325B7476MM-TR

COUT2

1

47 µF, 10 V, X7R, 1210, ceramic

DFLY1

1

Schottky diode, 100 V, 1 A, PowerDI-123

DFLS1100-7

Diodes Inc.

DFLY2

1

Schottky diode, 60 V, 1 A, PowerDI-123

DFLS160-7

Diodes Inc.

DCLAMP

1

Zener, 24 V, 1 W, PowerDI-123

DFLZ24-7

Diodes Inc.

DF

1

Switching diode, 75 V, 0.3 A, SOD323

1N4148WS

Diodes Inc.

DOUT1

1

Zener, 18 V, 5%, SOD523

BZX585-C18

Nexperia

DOUT2

1

Zener, 8.2 V, 2%, SOD523

BZX585-B8V2

Nexperia

RFB

1

154 kΩ, 1%, 0402

Std

Std

RSET

1

12.1 kΩ, 1%, 0402

Std

Std

RTC

1

200 kΩ, 1%, 0402

Std

Std

RUV1

1

340 kΩ, 1%, 0603

Std

Std

RUV2

1

68.1 kΩ, 1%, 0402

Std

Std

T1

1

30 µH, 2 A, turns ratio 1 : 1: 0.52, 9 × 10 mm, SMT

Coilcraft

YA8916-BLD

Würth Electronik

750317595

U1

1

LM25180 PSR flyback converter, VSON-8

Texas Instruments

LM25180NGUR

9.2.2.2 Detailed Design Procedure

Using the LM25180 quick-start calculator, components are selected based on the flyback converter

specifications.

9.2.2.2.1 Flyback Transformer – T1

Set the turns ratio of the transformer secondary windings using Equation 32, where NS1 and NS2 are the number

of secondary turns for the respective outputs.

NS2

NS1

VOUT2

VOUT1

VD2

VD1

7.7 V 0.4 V

15 V 0.6 V

0.52

(32)

Choose a primary-secondary turns ratio of 1 : 1 for the 15-V output based on an approximate 60% duty cycle at

minimum input voltage using Equation 33. The transformer turns ratio for both outputs is thus specified as 1 : 1 :

0.52.

NPS

VIN(min)

DMAX

˜

1 DMAX VOUT VD

0.6

9.5 V

˜

|1

1 0.6 15 V + 0.4 V

(33)

Select a magnetizing inductance based on the minimum off-time constraint using Equation 34. Choose a value of

30 µH and a saturation current of 2 A for this application.

LMAG t

VOUT

VD ˜ NPS ˜ t OFF-MIN

ISW-PEAK(FFM)

15 V + 0.35 V ˜ 1˜ 450ns

0.3 A

23 +

(34)

Find the maximum output current for a given turns ratio, assuming the outputs are symmetrically loaded, using

Equation 35.

24

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

IOUT(max)

K

ISW-PEAK

˜

2 § VOUT

¨

© VIN

0.9

1.5 A

˜

2 § 22.7 V

1

¨¨

1 1.52

© VIN

1 ·

¸

NPS ¹

·

¸¸

¹

-°0.2A at VIN 12 V

®

°¯0.27 A at VIN 24 V

(35)

9.2.2.2.2 Flyback Diodes – DFLY1 and DFLY2

The flyback diode reverse voltages for the positive and negative outputs are given respectively by Equation 36

and Equation 25.

VD1-REV t

VD2-REV t

VIN(max)

NPS

VIN(max)

NPS

36 V

1

VOUT1

VOUT2

15 V

51V

(36)

36 V ˜ 0.52 7.7 V

26.4 V

(37)

Choose 100-V, 1-A and 60-V, 1-A Schottky diodes for the positive and negative outputs, respectively, to allow

some margin for inevitable voltage overshoot and ringing related to leakage inductance and diode capacitance. If

needed, use a diode RC snubber circuit, for example 100 Ω and 22 pF, to mitigate such overshoot and ringing.

9.2.2.2.3 Input Capacitor – CIN

The input capacitor, CIN, filters the primary-side triangular current waveform. To prevent large ripple voltage, use

a low-ESR ceramic input capacitor sized according to Equation 24 for the RMS ripple current given by

Equation 25. In this design example, choose a 10-µF, 50-V ceramic input capacitor with X7R dielectric and 1210

footprint.

9.2.2.2.4 Feedback Resistor – RFB

Install a 154-kΩ resistor from SW to FB based on an output voltage setpoint of 15 V (plus a flyback diode voltage

drop) reflected to the primary by a transformer turns ratio of unity.

RFB

VOUT

VD ˜ NPS

0.1 mA

15 V

0.3 V ˜ 1

154 k:

0.1 mA

(38)

9.2.2.2.5 UVLO Resistors – RUV1, RUV2

Given VIN(on) and VIN(off) as the input voltage turn-on and turn-off thresholds of 9 V and 7 V, respectively, select

the upper and lower UVLO resistors using Equation 39 and Equation 40.

VIN(on) ˜

RUV1

RUV2

RUV1 ˜

VUV-FALLING

VUV-RISING

IUV-HYST

VIN(off)

VUV-RISING

VIN(on) VUV-RISING

9 V˜

1.45 V

1.5 V

5 $

340 k: ˜

7V

1.5 V

9 V 1.5 V

340k:

(39)

68 k:

(40)

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

25

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

9.2.2.3 Application Curves

100

100

95

90

90

80

Efficiency (%)

Efficiency (%)

85

80

75

70

65

70

60

50

60

VIN = 12V

VIN = 24V

VIN = 36V

55

VIN = 12V

VIN = 24V

VIN = 36V

40

50

30

0

50

100

150

200

Output Current (mA)

250

300

1

10

Output Current (mA)

Figure 35. Efficiency (Linear Scale)

300

Figure 36. Efficiency (Log Scale)

24

23.4

VIN = 12V

VIN = 24V

VIN = 36V

23.2

23

22.8

22.6

22.4

VIN = 12V

VIN = 24V

VIN = 36V

23.6

Output Voltage (V)

Output Voltage (V)

100

23.2

22.8

22.4

22.2

22

22

0

50

100

150

200

250

Output Current (mA)

300

350

400

1

10

Output Current (mA)

Total of VOUT1 and VOUT2

100

400

Total of VOUT1 and VOUT2

Figure 37. Load Regulation (Linear Scale)

Figure 38. Load Regulation (Log Scale)

EN 1V/DIV

VIN 10V/DIV

VOUT1 5V/DIV

VOUT1 5V/DIV

IOUT1 100mA/DIV

IOUT1 50mA/DIV

VOUT2 5V/DIV

VOUT2 5V/DIV

2 ms/DIV

2 ms/DIV

VIN stepped to 24 V

75 Ω and 40 Ω Loads

VIN = 24 V

Figure 39. Start-Up Characteristic

26

Submit Documentation Feedback

75 Ω and 40 Ω Loads

Figure 40. ENABLE ON Characteristic

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

VDFLY1 20V/DIV

SW 20V/DIV

VDFLY2 20V/DIV

1 Ps/DIV

1 Ps/DIV

VIN = 24 V

VIN = 24 V

Figure 41. Switch Voltage, Full Load

Figure 42. Flyback Diode Voltages, Full Load

VOUT1 1V/DIV

VOUT1 1V/DIV

IOUT1 100mA/DIV

IOUT1 100mA/DIV

IOUT2 100mA/DIV

IOUT2 100mA/DIV

VOUT2 0.5V/DIV

VIN = 24 V

VOUT2 0.5V/DIV

200 Ps/DIV

IOUT1 = 200 mA

Figure 43. Output 1 Load Transient, 50 mA to 200 mA

200 Ps/DIV

VIN = 24 V

IOUT2 = 200 mA

Figure 44. Output 2 Load Transient, 50 mA to 200 mA

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

27

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

9.2.3 Design 3: PSR Flyback Converter With Stacked Dual Outputs of 24 V and 5 V

The schematic diagram of a dual-output flyback converter with high-voltage secondary stacked on the lowvoltage secondary winding is given in Figure 45. This configuration reduces the number of turns for the highvoltage output, resulting in lower secondary-to-secondary leakage inductance for improved output voltage cross

regulation.

VIN = 8.5 V...42 V

T1

CIN

EN/UVLO

RUV2

34 k:

COUT1

10 F

DOUT1

27 V

1 : 1.5 : 0.4

30 PH

DF

VIN

VOUT1 = 24 V

IOUT1 = 0.1 A

DCLAMP

22 V

RUV1

147 k:

10 F

DFLY1

SW

DFLY2

VOUT2 = 5 V

RFB

LM25180

GND

130 k:

IOUT2 = 0.3 A

COUT2

47 F

FB

RSET

SS/BIAS

RTC

RSET

301 k:

12.1 k:

DOUT2

5.6 V

TC

Figure 45. Schematic for Design 3 With VIN(nom) = 24 V, VOUT1 = 24 V, VOUT2 = 5 V

9.2.3.1 Design Requirements

The required input, output, and performance parameters for this application example are shown in Table 6.

Table 6. Design Parameters

DESIGN PARAMETER

VALUE

Input voltage range (steady state)

8.5 V to 42 V

Output 1 voltage and current

24 V, 0.1 A

Output 2 voltage and current

5 V, 0.3 A

Input UVLO thresholds

8 V on, 7 V off

Output voltage regulation

±2%

The target full-load efficiency of this LM25180 design is 88% based on a nominal input voltage of 24 V and

isolated output voltages of 24 V and 5 V. The selected flyback converter components are cited in Table 7,

including multi-winding flyback transformer, input and output capacitors, rectifying diodes, and converter IC.

28

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

�LM25180

www.ti.com

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

Table 7. List of Components for Design 3

REF DES

QTY

CIN, COUT1 2

SPECIFICATION

VENDOR

PART NUMBER

10 µF, 50 V, X7R, 1210, ceramic

Taiyo Yuden

UMK325AB7106MM-T

10 µF, 50 V, X7S, 1210, ceramic

TDK

C3225X7R1H106M

COUT2

1

47 µF, 10 V, X7R, 1210, ceramic

Murata

GRM32ER71A476ME15L

DFLY1

1

Switching diode, fast recovery, 200 V, 1 A, SOD-123

DFLU1200

Diodes Inc.

DFLY2

1

Schottky diode, 40 V, 1 A, SOD-123

B140HW

Diodes Inc.

DCLAMP

1

Zener, 22 V, 1 W, PowerDI-123

DFLZ22-7

Diodes Inc.

DF

1

Switching diode, 75 V, 0.25 A, SOD-323

CMDD4448

Central Semi

DOUT1

1

Zener, 27 V, 2%, SOD-523

BZX585-B27

Nexperia

DOUT2

1

Zener, 5.6 V, 2%, SOD-523

BZX585-B5V6

Nexperia

RFB

1

130 kΩ, 1%, 0402

Std

Std

RSET

1

12.1 kΩ, 1%, 0402

Std

Std

RTC

1

301 kΩ, 1%, 0402

Std

Std

RUV1

1

147 kΩ, 1%, 0603

Std

Std

RUV2

1

34 kΩ, 1%, 0402

Std

Std

30 µH, 2 A, turns ratio 1 : 1.5 : 0.4, 9 × 10 mm, SMT

Coilcraft

YA8864-BLD

Coilcraft

YA8916-BLD

Würth Electronik

750317595

Texas Instruments

LM25180NGUR

T1

1

U1

30 µH, 2 A, turns ratio 1 : 1 : 0.55, 9 × 10 mm, SMT

1

LM25180 PSR flyback converter, VSON-8

9.2.3.2 Detailed Design Procedure

Components are selected based on the converter specifications using the LM25180 quick-start calculator. The

design procedure is similar to that outlined for Designs 1 and 2 previously.

9.2.3.2.1 Flyback Transformer – T1

The 24-V output is DC stacked on top of the 5-V output as they share a common return connection. This enables

lower secondary-to-secondary leakage inductance for better cross regulation and also reduced rectifier diode

reverse voltage stress. Choose a primary-secondary turns ratio for the effective 19-V secondary based on an

approximate 60% max duty cycle at minimum input voltage using Equation 41.

NPS1

VIN(min)

DMAX

˜

1 DMAX VOUT VD

NP

NS1

0.6

8.5 V

˜

1 0.6 19 V + 0.6 V

0.65

(41)

Set the turns ratio of the transformer secondary windings using Equation 42. The transformer turns ratio for both

outputs is thus specified as 1 : 1.5 : 0.4.

NS2

NS1

VOUT2

VOUT1

VD2

VD1

5 V 0.3 V

19 V 0.6 V

0.27

(42)

Select a magnetizing inductance based on the minimum off-time constraint using Equation 43. Choose a value of

30 µH and a saturation current of minimum 2 A for this application.

LMAG t

VOUT1

VD1 ˜ NPS1 ˜ t OFF-MIN

19 V + 0.6 V ˜ 1 1.5 ˜ 450ns

ISW-PEAK(FFM)

0.3 A

19.4 +

(43)

9.2.3.2.2 Feedback Resistor – RFB

Install a 130-kΩ resistor from SW to FB based on the secondary winding voltage (the sum of the 5-V output

voltage and the Schottky diode forward voltage drop) reflected by the relevant transformer turns ratio, which in

this design is 1 : 0.4 or 2.5 : 1.

RFB

VOUT

VD ˜ NPS

0.1 mA

5 V 0.25 V ˜ 2.5

0.1 mA

130 k:

(44)

Submit Documentation Feedback

Copyright © 2018–2020, Texas Instruments Incorporated

Product Folder Links: LM25180

29

�LM25180

SNVSB79B – NOVEMBER 2018 – REVISED MAY 2020

www.ti.com

9.2.3.2.3 UVLO Resistors – RUV1, RUV2

Given VIN(on) and VIN(off) as the input voltage turn-on and turn-off thresholds of 8 V and 7 V, respectively, select

the upper and lower UVLO resistors using the following expressions:

VIN(on) ˜

RUV1

RUV2

RUV1 ˜

VUV-FALLING

VUV-RISING

IUV-HYST

VIN(off)

VUV-RISING

VIN(on) VUV-RISING

8 V˜

1.45 V

1.5 V

5 $

147 k: ˜

7V

147k:

(45)

1.5 V

8 V 1.5 V

34 k:

(46)

Calculate the actual input voltage turn-on and turn-off thresholds as follows:

VIN(on)

VIN(off)

§

RUV1 ·

VUV-RISING ¨ 1

¸

© RUV2 ¹

§ 147 k: ·

1.5 V ¨ 1

¸

34k: ¹

©

§

RUV1 ·

VUV-FALLING ¨ 1

¸ IUV-HYST ˜ RUV1

© RUV2 ¹

7.985 V

(47)

§ 147k: ·

1.45 V ¨ 1

¸ 5 $˜

34k: ¹

©

N:

9

(48)

9.2.3.3 Application Curves

100

95

90

Efficiency (%)

VIN 10V/DIV

85

VOUT1 10V/DIV

80

75

IOUT2 100mA/DIV

70

65

VIN = 24V

VIN = 42V

VOUT2 5V/DIV

60

0

20

40

60

80

Total Output Power (% Full Load)

100

2 ms/DIV

VIN ramped to 24 V