Sample &

Buy

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

LM3555 Synchronous Boost Converter With 500-mA High-Side

LED Driver and Dual-Mode Control Interface

1 Features

3 Description

•

The LM3555 is a 2-MHz fixed-frequency, currentmode synchronous boost converter designed to drive

either a single flash LED at 500 mA or two series

flash LEDs at 400 mA. A high-voltage current source

allows the LEDs to be terminated to the GND plane

eliminating the need for an additional return trace

back to the device.

1

•

•

•

•

•

•

•

•

•

•

•

High-Voltage High-Side Current Source Allows for

Grounded Cathode LED Operation

Synchronous Boost Converter

Peak Converter Efficiency > 90%

Accurate and Programmable LED Current

Ranging From 60 mA to 500 mA

Adaptive LED Current Range Based on LED

Configuration

Dedicated Indicator Current Source

Dedicated Torch and Strobe Pins

Dual Mode Control (General Purpose or I2C)

Broken Inductor Detection

Output Overvoltage Protection

Output and LED Short-Circuit Protection

400-kHz I2C-Compatible Interface

A dual-mode control interface allows the user to

configure the LM3555 with a general-purpose

interface using two enable pins for control or an I2C

allowing a higher level of control. Both interfaces

allow access to the indicator, assist light, and flash

modes. A dedicated STROBE pin provides a direct

interface to trigger the flash event, while an external

TORCH pin provides an additional method for

enabling the LEDs in a constant current mode.

The LM3555 can adaptively scale the maximum flash

level delivered to the LEDs based upon the flash

configuration, whether it be a single LED or two LEDs

in series.

2 Applications

Camera Phone LED Flash

Eight protection features are available on the LM3555

ranging from overvoltage protection to broken

inductor detection. The LM3555 has four selectable

inductor current limits to help the user select an

inductor that is appropriate for the design.

Device Information(1)

PART NUMBER

LM3555

PACKAGE

DSBGA (12)

BODY SIZE (MAX)

2.09 mm × 1.565 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Typical Application

2.2 µH

CIN

10 µF

SW

VIN

VOUT

+

VBAT

COUT

10 µF

STROBE

TORCH

I2C/EN

VLED

LM3555

SCL/EN1

SDA/EN2

PGND

SGND

IND

Copyright © 2016, Texas Instruments Incorporated

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

Table of Contents

1

2

3

4

5

6

7

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

6.7

4

4

4

5

5

7

8

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

Control Interface Timing Requirements ....................

Typical Characteristics ..............................................

Detailed Description ............................................ 15

7.1

7.2

7.3

7.4

Overview .................................................................

Functional Block Diagram .......................................

Feature Description.................................................

Device Functional Modes........................................

15

15

16

19

7.5 Programming........................................................... 22

7.6 Register Maps ......................................................... 24

8

Application and Implementation ........................ 27

8.1 Application Information............................................ 27

8.2 Typical Application ................................................. 27

9 Power Supply Recommendations...................... 30

10 Layout................................................................... 31

10.1 Layout Guidelines ................................................. 31

10.2 Layout Example .................................................... 31

11 Device and Documentation Support ................. 32

11.1

11.2

11.3

11.4

11.5

11.6

Device Support......................................................

Documentation Support ........................................

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

32

32

32

32

32

32

12 Mechanical, Packaging, and Orderable

Information ........................................................... 32

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision F (November 2013) to Revision G

Page

•

Added Device Information and Pin Configuration and Functions sections, ESD Ratings Thermal Information tables,

Feature Description, Device Functional Modes, Application and Implementation, Power Supply Recommendations,

Layout, Device and Documentation Support, and Mechanical, Packaging, and Orderable Information sections ................. 1

•

Changed RθJA value; add rest of Thermal Information ........................................................................................................... 5

Changes from Revision E (November 2011) to Revision F

•

2

Page

Changed layout of National Data Sheet to TI format ........................................................................................................... 31

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

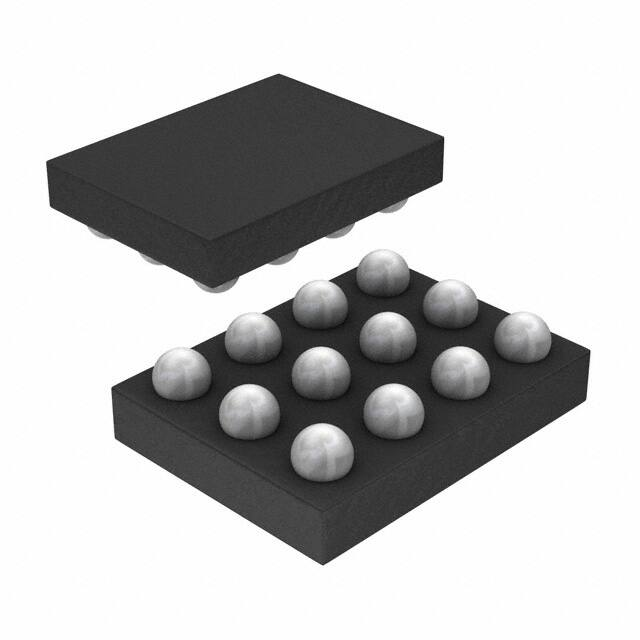

5 Pin Configuration and Functions

YZR Package

12-Pin DSBGA

Top View

YZR Package

12-Pin DSBGA

Bottom View

A1

A2

A3

A3

A2

A1

B1

B2

B3

B3

B2

B1

C1

C2

C3

C3

C2

C1

D1

D2

D3

D3

D2

D1

Pin Functions

PIN

I/O

DESCRIPTION

NUMBER

NAME

A1

PGND

—

Power ground

A2

SGND

—

Signal ground

A3

VIN

I

B1

SW

—

B2

TORCH

I

Torch pin. Driving this pin high enables torch mode.

B3

IND

O

Red indicator LED current source. Connect to RED LED anode

C1

VOUT

O

Boost output. Connect output bypass capacitor very close to this pin

C2

STROBE

I/O

Strobe signal input pin to synchronize flash pulse in I2C mode. This signal usually comes

from the camera processor. In simple logic mode this pin, when tied to a voltage rail

through a pullup resistor indicates the number of LEDs in the system.

C3

I2C / EN

I

I2C / EN-logic selection. High = I2C mode, Low = simple logic mode.

D1

VLED

O

LED current source. Connect to the anode of the flash LED. One or two LEDs can be

connected in series.

D2

SDA / EN2

I/O

EN2 signal pin in simple logic mode. I2C data signal in I2C mode.

D3

SCL / EN1

I

EN1 signal pin in simple logic mode. I2C clock signal in I2C mode.

Input voltage pin of the device. Connect input bypass capacitor very close to this pin.

Inductor connection

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

3

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1) (2) (3)

MIN

MAX

UNIT

VIN

−0.3

6

V

TORCH, IND, STROBE, I2C/EN, SDA/EN2, SCL/EN1

−0.3

(VIN + 0.3 V) w/ 6 V

maximum

V

12

V

10

V

SW

VOUT, VLED

Continuous power dissipation (4)

Internally limited

Junction temperature, TJ-MAX

Maximum lead temperature (soldering)

See

Storage temperature, Tstg

(1)

(2)

(3)

(4)

(5)

150

°C

150

°C

(5)

–55

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

All voltages are with respect to the potential at the GND pin.

If Military/Aerospace specified devices are required, contact the Texas Instruments Sales Office/ Distributors for availability and

specifications.

Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ=150°C (typical) and

disengages at TJ=135°C (typical). Thermal shutdown is specified by design.

For detailed soldering specifications and information, please refer to AN-1112 DSBGA Wafer Level Chip Scale Package (SNVA009).

6.2 ESD Ratings

V(ESD)

(1)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001 (1)

VALUE

UNIT

±2500

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted) (1) (2)

MIN

MAX

2.5

5.5

V

Junction temperature, TJ

−30

125

°C

Ambient temperature, TA (3)

−30

85

°C

Input voltage

(1)

(2)

(3)

4

UNIT

Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Recommended Operating Ratings are

conditions under which operation of the device is specified. Operating Ratings do not imply specified performance limits. For specified

performance limits and associated test conditions, see the Electrical Characteristics tables.

All voltages are with respect to the potential at the GND pin.

In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may

have to be de-rated. Maximum ambient temperature (TA-MAX) is dependent on the maximum operating junction temperature (TJ-MAX-OP =

125°C), the maximum power dissipation of the device in the application (PD-MAX), and the junction-to-ambient thermal resistance of the

part/package in the application (RθJA), as given by the following equation: TA-MAX = TJ-MAX-OP – (RθJA × PD-MAX).

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

6.4 Thermal Information

LM3555

THERMAL METRIC (1)

YZR (DSBGA)

UNIT

12 PINS

RθJA

Junction-to-ambient thermal resistance

92.9

°C/W

RθJC(top)

RθJB

Junction-to-case (top) thermal resistance

0.6

°C/W

Junction-to-board thermal resistance

16.1

°C/W

ψJT

Junction-to-top characterization parameter

2.8

°C/W

ψJB

Junction-to-board characterization parameter

16.1

°C/W

(1)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report, SPRA953.

6.5 Electrical Characteristics

Unless otherwise specified: typical limits are for TA = 25°C; minimum and maximum limits apply over the full operating

ambient temperature range (−30°C ≤ TA ≤ +85°C); VIN = 3.6 V. (1) (2)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

50.7

(–15.5%)

60

67.2

(12%)

69.8

(–12.8%)

80

86.4

(8%)

304

(–5%)

320

336

(5%)

475

(–5%)

500

535

(7%)

–20.4%

2.5 mA

33.6%

–20.4%

5 mA

33.8%

–20.3%

7.5 mA

33.7%

–20.2%

10 mA

33.4%

300

350

9.5

9.96

UNIT

CURRENT AND VOLTAGE SPECIFICATIONS

ILED-OUT

IIND-OUT

Flash LED accuracy

Indicator LED current

accuracy

2.7 V ≤ VIN ≤ 5.5 V

VOUT = 6.5 V,

VLED = 6.2 V

2.7 V ≤ VIN ≤ 5.5 V, VIND = 2 V (indicator mode)

mA (%)

VCSH

Current source

headroom voltage

2.7 V ≤ VIN ≤ 5.5 V

VOVP

Overvoltage Protection

Range

2.7 V ≤ VIN ≤ 5.5 V

VOUT

Output voltage range

(VLED × NLED) + VCSH

ISD

Shutdown current

2.7 V ≤ VIN ≤ 5.5 V

ISB

Standby current

2.7 V ≤ VIN ≤ 5.5 V

1.1

IQ

Operating quiescent

current

2.7 V ≤ VIN ≤ 5.5 V, device switching

3.5

mA

VREF

Reference Voltage for

LED Detection

VIN = 3.6 V (No Offset)

4.35

V

VIND

Indicator Fault Voltages

UVLO

Undervoltage lockout

Falling VIN

2.35

2.4

2.43

UVLOHYST

UVLO hysteresis

Rising VIN

60

70

85

(1)

(2)

Trip point (rising)

9.22

Hysteresis

0.4

Upper range

8.5

Lower range

2.8

IND OVP

V

V

0.75

µA

4.3

µA

2.571

IND Short

mV

0.842

V

V

mV

Minimum (MIN) and maximum (MAX) limits are specified by design, test, or statistical analysis. Typical (TYP) numbers are not specified,

but do represent the most likely norm. Unless otherwise specified, conditions for typical specifications are: VIN = 3.6 V and TA = 25°C.

Switching disabled.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

5

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

Electrical Characteristics (continued)

Unless otherwise specified: typical limits are for TA = 25°C; minimum and maximum limits apply over the full operating

ambient temperature range (−30°C ≤ TA ≤ +85°C); VIN = 3.6 V.(1)(2)

PARAMETER

ILIM

Peak current limit

TEST CONDITIONS

2.7 V ≤ VIN ≤ 5.5 V

(3)

MIN

TYP

MAX

Current limit register

value = 00

1.183

1.250

1.55

Current limit register

value = 01

1.417

1.500

1.781

Current limit register

value = 10

1.512

1.750

2.025

Current limit register

value = 11

1.805

2

2.267

1.91

(−4.5%)

2

2.15

(7.5%)

UNIT

A

OSCILLATOR AND TIMING SPECIFICATIONS (NON-I2C INTERFACE TIMING)

ƒSW

Switching frequency

2.7 V ≤ VIN ≤ 5.5 V

tHW

Hardware flash timeout

Default timer

tRU

Current ramp-up time

ILED = 0mA to ILED = fullscale,

VOUT = 6.5 V, VLED = 6.2 V

0.6

1

msec

tRD

Current ramp down time

ILED = fullscale to ILED = 0 mA

VOUT = 6.5 V, VLED = 6.2 V

0.2

0.5

msec

tTORCH-DG

Torch deglitching time

11.7

msec

850

6.3

9

MHz

msec

CONTROL INTERFACE VOLTAGE SPECIFICATIONS

VI2C/EN

I2C/EN pin voltage

threshold

2.7 V ≤ VIN ≤ 5.5 V

VIL

Low-level threshold

voltage (SCL/EN1 and

SDA/EN2)

2.7 V ≤ VIN ≤ 5.5 V

VIH

High-level threshold

voltage (SCL/EN1 and

SDA/EN2)

2.7 V ≤ VIN ≤ 5.5 V

VOL

Low-level output

threshold limit

(SDA/EN2)

ILOAD = 3 mA

(3)

6

Simple mode

2

I C mode

0.54

1.26

0.54

1.26

V

V

V

0.4

V

TA (minimum) = 0°C to account for self-heating. Current Limit specification uses VIN (maximum) = 4 V to account for the input voltage

range where current limit could be reached based upon the maximum application specifications for output voltage and diode current.

Operation above 4 V and up to 5.5 V is allowed and must not reach current limit.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

6.6 Control Interface Timing Requirements

MIN

NOM

MAX

UNIT

250

500

µsec

TI2C-Start

I2C logic start-up time (I2C/EN going high)

ƒSCL

SCL clock frequency

tI2C

I2C hang-up time

tLOW

Low Period of SCL clock

1.3

µsec

tHIGH

High Period of SCL clock

0.6

µsec

tHD-STA

Hold Time (repeated) START condition

0.6

µsec

tSU-STA

Setup time for a repeated START condition

0.6

µsec

tHD-DAT

Data hold time

0

µsec

tSU-DAT

Data setup time

100

nsec

tR

Rise time for SCL and SDA

300

tF

Fall time for SCL and SDA

300

tSU-STO

Setup time for stop condition

0.6

µsec

tBUF

Bus free time between stop and start condition

1.3

µsec

tVD-DAT

Data valid time

0.9

µsec

tVD-ACK

Data valid acknowledge time

0.9

µsec

400

pF

CB

400

35

20 + 0.1 ×

CB

Capacitive load for each bus line

kHz

msec

nsec

nsec

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

7

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

6.7 Typical Characteristics

0.50

0.48

0.46

0.44

TA = -30°C and +25°C

0.42

0.40

0.38

0.36

0.34

TA = +85°C

0.32

0.30

0.28

0.26

0.24

0.22

0.20

0.18

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0.35

VLED = 6.75V (2 LEDs)

0.34

TA = +25°C

0.33

ILED (A)

ILED (A)

Unless otherwise specified: TA = 25°C; VIN = 3.6 V; CIN1= 10 µF, CIN2= 0.1 µF, COUT = 11 µF; L = 2.2 µH.

0.32

0.31

TA = -30°C

TA = +85°C

0.30

0.29

2.5

3.0

3.5

BRC (#)

5.0

5.5

Two Series LEDs at 320 mA

Figure 1. LED Current vs Brightness Code

1.50

Figure 2. LED Current vs Input Voltage

0.44

VLED = 6.75V (2 LEDs)

ILED = 320 mA

VLED = 6.9V (2 LEDs)

0.43

1.25

0.42

TA = -30°C

1.00

0.41

TA = +25°C

ILED (A)

IIN (A)

4.5

VIN (V)

Two Series LEDs Flash

0.75

TA = -30°C

TA = +25°C

0.40

0.39

0.50

0.38

TA = +85°C

0.25

0.00

2.5

4.0

TA = +85°C

0.37

3.0

3.5

4.0

4.5

5.0

0.36

2.5

5.5

3.0

3.5

4.0

4.5

5.0

5.5

VIN (V)

VIN (V)

Two series LEDs at 320 mA

Two series LEDs at 400 mA

Figure 3. Input Current vs Input Voltage

Figure 4. LED Current vs Input Voltage

0.20

2.00

TA = +85°C

VLED = 6.9V (2 LEDs)

ILED = 400mA

0.18

0.16

1.70

TA = -30°C, +25°C, +85°C

ITORCH (A)

0.14

IIN (A)

1.40

TA = -30°C

1.10

TA = +25°C

0.12

0.10

0.08

0.06

0.80

0.04

0.02

0.50

2.5

3.0

3.5

4.0

4.5

5.0

VIN (V) = 3.6 V, VLED (V) = 6.3 V (2 LEDs)

0.00

0

5.5

VIN (V)

2

3

4

5

BRCTORCH (#)

6

7

2 LEDs

Two Series LEDs at 400 mA

Figure 5. Input Current vs Input Voltage

8

1

Figure 6. Torch Current vs Brightness Code

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

Typical Characteristics (continued)

Unless otherwise specified: TA = 25°C; VIN = 3.6 V; CIN1= 10 µF, CIN2= 0.1 µF, COUT = 11 µF; L = 2.2 µH.

0.080

0.100

0.075

0.095

0.070

0.090

TA = -30°C

0.065

0.060

0.055

TA = +25°C

0.080

0.075

0.050

TA = -30°C

0.070

0.045

0.065

VLED (V) = 6.0 V (2 LEDs)

0.040

2.5

3.0

3.5

4.0

4.5

5.0

VLED (V) = 6.1 V (2 LEDs)

0.060

2.5

5.5

3.0

3.5

VIN (V)

4.0

VIN (V)

4.5

5.0

5.5

Two LEDs at 80 mA

Two LEDs at 60 mA

Figure 7. Torch Current vs Input Voltage

Figure 8. Torch Current vs Input Voltage

0.60

0.60

0.55

0.58

TA = -30°C and +25°C

0.50

0.54

0.40

0.52

0.35

TA = +85°C

0.30

VLED = 3.6V

0.56

0.45

ILED (A)

ILED (A)

TA = +25°C

TA = +85°C

0.085

ITORCH (A)

ITORCH (A)

TA = +85°C

TA = -30°C

TA = +25°C

0.50

0.48

0.25

0.46

0.20

0.44

0.15

0.42

0.10

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0.40

2.5

TA = +85°C

3.0

3.5

4.0

BRC (#)

4.5

5.0

5.5

VIN (V)

One LED at 500 mA

Figure 9. Single LED Flash Current vs Brightness Code

1.30

Figure 10. LED Current vs Input Voltage

0.20

VLED = 3.6V

ILED = 500 mA

0.18

1.12

0.16

ITORCH (A)

0.14

IIN (A)

0.94

TA = +25°C

0.76

TA = -30°C

TA = -30°C, +25°C, +85°C

0.12

0.10

0.08

0.06

0.58

0.04

TA = +85°C

VIN (V) = 3.6 V, VLED (V) = 3.0 V

0.02

0.40

2.5

3.0

3.5

4.0

4.5

5.0

0.00

0

5.5

1

2

3

4

5

6

7

BRCTORCH (#)

VIN (V)

One LED

One LED at 500 mA

Figure 11. Input Current vs Input Voltage

Figure 12. Torch Current vs Brightness Code

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

9

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

Typical Characteristics (continued)

Unless otherwise specified: TA = 25°C; VIN = 3.6 V; CIN1= 10 µF, CIN2= 0.1 µF, COUT = 11 µF; L = 2.2 µH.

0.080

0.100

0.075

0.095

0.090

0.070

TA = +25°C

0.065

ITORCH (A)

ITORCH (A)

TA = +85°C

0.060

0.055

TA = +85°C

0.085

0.080

0.075

TA = -30°C

0.050

TA = -30°C

0.070

0.045

0.065

VLED (V) = 3.0 V

0.040

2.5

3.0

3.5

4.0

4.5

5.0

TA = +25°C

VLED (V) = 3.0 V

0.060

2.5

5.5

3.0

3.5

VIN (V)

One LED at 60 mA

4.0

4.5

VIN (V)

5.0

5.5

One LED at 80 mA

Figure 13. Torch Current vs Input Voltage

Figure 14. Torch Current vs Input Voltage

15.0

12.5

VIND = 2.0 V, Code 3

VIND = 2.0 V, TA = 25°C

12.5

11.5

Code 3

IIND (mA)

IIND (mA)

10.0

7.5

Code 2

TA = +85°C

10.5

TA = -30°C

TA = +25°C

5.0

9.5

Code 1

2.5

Code 0

0.0

2.5

3.0

3.5

4.0

4.5

VIN (V)

5.0

8.5

2.5

5.5

5.5

ICL = 2.0A

VOUT (V) = 8.2V @ 400 mA

9.5

1.75

VLED = 2.0 V

8.5

ICL (A)

IIND (mA)

5.0

2.00

10.5

VLED = 2.4 V

1.25

4.5

ICL = 1.75A

1.50

6.5

5.5

ICL = 1.5A

ICL = 1.25A

1.00

3.5

TA = +25°C, Code 3

3.0

3.5

4.0

4.5

VIN (V)

5.0

0.75

2.5

5.5

3.1

3.7

4.3

4.9

5.5

VIN (V)

Figure 17. Indicator Current vs Input Voltage VLED

10

4.5

2.25

VLED = 1.8 V

2.5

2.5

4.0

Figure 16. Indicator Current vs Input Voltage Tri-Temp

12.5

7.5

3.5

VIN (V)

Figure 15. Indicator Current vs Input Voltage Brightness

Codes

11.5

3.0

Figure 18. Inductor Current Limit vs Input Voltage

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

Typical Characteristics (continued)

Unless otherwise specified: TA = 25°C; VIN = 3.6 V; CIN1= 10 µF, CIN2= 0.1 µF, COUT = 11 µF; L = 2.2 µH.

0.50

1.0

VOUT (V) = 8.2V

0.9

0.45

0.8

ISB (μA)

ILED (A)

0.7

0.40

0.35

ICL = 1.5A

3.0

0.4

TA = +25°C

0.2

ICL = 1.75A

TA = -30°C

0.1

ICL = 2.0A

0.25

2.5

0.5

0.3

ICL = 1.25A

0.30

TA = +85°C

0.6

3.5

4.0

4.5

5.0

0.0

2.5

5.5

3.0

3.5

4.0

4.5

5.0

5.5

VIN (V)

VIN (V)

Figure 19. LED Current vs Input Voltage In Current Limit

Figure 20. Shutdown Current vs Input Voltage

2.20

4.0

3.5

2.10

3.0

fSW (MHz)

ISB (μA)

2.5

TA = +85°C

2.0

2.00

1.5

1.90

1.0

TA = -30°C and +25°C

0.5

0.0

2.5

3.0

3.5

4.0

4.5

5.0

1.80

-30 -20 -10 0 10 20 30 40 50 60 70 80 90

5.5

VIN (V)

TA (°C)

Figure 21. Standby Current vs Input Voltage

Figure 22. Frequency vs Temperature

2.10

TA = -30°C

t (ms)

fSW (MHz)

2.05

2.00

TA = +85°C

TA = +25°C

1.95

1.90

2.5

3.0

3.5

4.0

4.5

5.0

5.5

1k

950

900

850

800

750

700

650

600

550

500

450

400

350

300

250

200

150

100

50

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

FTO (#)

VIN (V)

Figure 23. Frequency vs Input Voltage

Figure 24. Flash Timeout Time vs Flash Timeout Code

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

11

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

Typical Characteristics (continued)

Unless otherwise specified: TA = 25°C; VIN = 3.6 V; CIN1= 10 µF, CIN2= 0.1 µF, COUT = 11 µF; L = 2.2 µH.

IIN

(500 mA/DIV)

IIN

(500 mA/DIV.)

ILED

(200 mA/DIV)

ILED

(200 mA/DIV)

VOUT

(2V/DIV)

VLED

(2V/DIV)

VOUT

(2V/DIV)

VLED

(2V/DIV)

Time

(800 Ps/DIV)

Time

(100 Ps/DIV)

Two LEDs

I2C Mode

Two LEDs

I2C Mode

Figure 26. Ramp-Down

Figure 25. Start-Up

IIN

(1A/DIV)

VOUT

(5V/DIV)

VLED

(5V/DIV)

IIN

(200 mA/DIV)

ILED

(100 mA/DIV)

ILED

(100 mA/DIV)

Time

(100 Ps/DIV)

Two LEDs

I2C Mode

Time

(200 Ps/DIV)

Two LEDs

Figure 27. Ramp-Down (Zoom)

Figure 28. Start-up

IIN

(1A/DIV)

IIN

(500 mA/DIV)

VOUT

(5V/DIV)

VOUT

(5V/DIV)

VLED

(5V/DIV)

VLED

(5V/DIV)

ILED

(100 mA/DIV)

ILED

(20 mA/DIV)

Time

(200 Ps/DIV)

Two LEDs

Simple Mode

Time

(80 Ps/DIV)

Two LEDs

Figure 29. Ramp-Down

12

Simple Mode

Torch

Figure 30. Diode Detect

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

Typical Characteristics (continued)

Unless otherwise specified: TA = 25°C; VIN = 3.6 V; CIN1= 10 µF, CIN2= 0.1 µF, COUT = 11 µF; L = 2.2 µH.

IIN

(500 mA/DIV)

IIN

(500 mA/DIV)

VOUT

(2V/DIV)

VLED

(5V/DIV)

VOUT

(2V/DIV)

VLED

(2V/DIV)

ILED

(50 mA/DIV)

Time

(400 Ps/DIV)

Time

(1 ms/DIV)

Figure 31. Overvoltage Protection Fault (OVP)

Figure 32. VOUT Short to GND Fault

IIN

(500 mA/DIV)

VLED

(200 mA/DIV)

ILED

(200 mA/DIV)

VOUT

(2V/DIV)

VOUT

(2V/DIV)

VLED

(2V/DIV)

IIN

(200 mA/DIV)

Time

(80 Ps/DIV)

Time

(1 ms/DIV)

Figure 33. VLED Short to GND Fault

VIN

(2V/DIV)

Figure 34. Broken Inductor Fault

VTORCH

(1V/DIV)

VOUT

(5V/DIV)

VLED

(5V/DIV)

ILED

(20 mA/DIV)

ILED

(50 mA/DIV)

Time

(10 ms/DIV)

Time

(400 ms/DIV)

Figure 35. Undervoltage Lockout (UVLO)

Figure 36. Torch Deglitching Time

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

13

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

Typical Characteristics (continued)

Unless otherwise specified: TA = 25°C; VIN = 3.6 V; CIN1= 10 µF, CIN2= 0.1 µF, COUT = 11 µF; L = 2.2 µH.

VSTROBE

(1V/DIV)

VSTROBE

(1V/DIV)

ILED

(100 mA/DIV)

ILED

(100 mA/DIV)

Time

(100 ms/DIV)

Time

(100 ms/DIV)

Figure 37. Edge Sensitive Strobe

Figure 38. Level Sensitive Strobe With Timeout

VSTROBE

(1V/DIV)

ILED

(100 mA/DIV)

Time

(100 ms/DIV)

Figure 39. Level Sensitive Strobe Without Timeout

14

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

7 Detailed Description

7.1 Overview

The LM3555 is a high-power white-LED flash driver capable of delivering up to 500 mA of LED current into a

single LED, or up to 400 mA into two series LEDs. The device incorporates a 2-MHz constant frequency,

synchronous, current mode PWM boost converter, and a single high-side current source to regulate the LED

current over the 2.5 V to 5.5 V input voltage range. Dual control interfaces (simple ENABLE control or I2C) and

diode detection (single LED or two LEDs in series) make the LM3555 highly adaptable to a large variety of

designs.

7.2 Functional Block Diagram

TORCH

LED

Open/Short

Detect

STROBE

I2C/EN

SCL/EN1

I2C INTERFACE/

CONTROL LOGIC/

REGISTERS

FLASH CTRL

Current

Control

TIME-OUT CTRL

SDA/EN2

VREF

gm

VIN

VLED

TORCH CTRL

RC

0.3 V

-

CC

+

VOUT

SW

Driver

OVP/Short

Detect

IND

SW

PGND

SW

Driver

SWITCH

CONTROLLER

SGND

THERMAL

SHUTDOWN

OSC

2 MHz

RAMP

CURRENT

LIMT

gm

LM3555

¦

IC

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

15

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

7.3 Feature Description

7.3.1 Synchronous Boost Converter

The LM3555 operates in two modes: LED boost mode or LED pass mode. When the input voltage is above the

LED voltage plus current source headroom voltage the device turns the PFET on continuously (pass mode). In

pass mode the difference between (VIN – ILED × RON_P) and the voltage across the LEDs is dropped across the

current source. When the output voltage (VOUT) is greater than the input voltage (VIN) minus approximately

200 mV, the PWM converter switches and maintains at least 300 mV across the current source (LED boost

mode). This minimum headroom voltage ensures that the current sinks remain in regulation.

Once the LM3555 transitions from pass mode to boost mode, the device does not return to pass mode until the

device is disabled and re-enabled. At this point, the converter re-evaluates the conditions and enter the

appropriate mode.

7.3.2 High-Side Current Source

The high-side current source of the LM3555 is capable of driving one or two LEDs in series. Depending on the

configuration, the LM3555 automatically sets default diode current levels and diode current limits. For a single

LED, the flash current range is 200 mA to 500 mA in 20-mA steps with a default current equal to 500 mA. For

two LEDs in series, the flash current range is 200 mA to 400 mA in 20-mA steps with a default current equal to

320 mA.

Additionally, the high-side current source is capable of supporting assist/torch current levels (continuous current)

between 60 mA and 160 mA in 20-mA levels.

7.3.3 I2C/EN Pin

The I2C/EN pin on the LM3555 changes the control interface depending on its state. To use the LM3555 in the

simple control mode, the I2C/EN pin must be tied low. To use the LM3555 in I2C control mode, the I2C/EN pin

must be tied high. Toggling this pin between simple control mode and I2C control mode is not recommended.

7.3.4 SDA/EN2 and SCL/EN1 Pins

Depending on the state of the I2C/EN pin, the SDA/EN2 and SCL/EN1 pins function in different ways. If the

I2C/EN pin is equal to a 1, the SDA/EN2 pin functions as an I2C SDA (data) pin, and the SCL/EN1 pin functions

as an I2C SCL (clock) pin. If the I2C/EN pin is equal to a 0, the SDA/EN2 pin functions as the simple control pin

EN2, and the SCL/EN1 pin functions as the simple control pin EN1.

When using the simple control mode, the flash, torch, and indicator modes can be enabled. In simple control

mode, internal pulldown resistors on the SDA/EN2 and SCL/EN1 pins become active. In I2C control mode, these

pulldowns become disabled.

7.3.5 STROBE Pin

The STROBE pin of the LM3555 provides an external method for initiating a flash event. In most cases, the

STROBE pin is connected to an imaging module so that the image capture and flash event are synchronized.

The STROBE pin is only functional when the LM3555 is placed into I2C control mode (I2C/EN = 1) and the output

on (OEN in 0x04) and strobe signal Mode (SEN in 0x04) bits are set (1). The STROBE pin can be configured to

be an edge sensitive or level sensitive input by setting the strobe signal usage bit (SSU in 0x04. 1 = Level, 0 =

Edge). In edge sensitive mode, a rising edge transition (0 to 1) starts the flash event, and the internal flash timer

terminates the event. In level sensitive mode, a rising edge transition (0 to 1) starts the flash event and a falling

edge transition (1 to 0) or the internal flash timer, whichever occurs first, terminates the event. In I2C mode, there

is an internal pulldown resistor that becomes enabled on the STROBE pin.

In simple control mode, the STROBE pin functions as a output when a pullup resistor is connected, alerting the

user to the number of flash LEDs present in the system. If the STROBE pin is outputting a 1, two LEDs are

present, whereas a 0 indicates a single LED is present.

16

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

Feature Description (continued)

7.3.6 TORCH Pin

The TORCH pin of the LM3555, depending on the state and configuration, allows the user to enable torch/assist

mode without having to write the command through the I2C bus or through toggling the EN1 and EN2 pins. In

simple mode, the LM3555 drives 60 mA of LED current if two series LEDs are present and 80 mA is one LED is

present. In I2C mode, the external torch mode bit (TEN in register 0x04) must be set to a 1 to allow an external

torch (default value = 1). In I2C mode, the torch mode current is equal to the Assist mode current level stored in

register 0x03. The TORCH pin has an internal pulldown resistor enabled in both simple mode and I2C mode.

7.3.7 Indicator LED Pin (IND)

The indicator LED current source pin (IND) is able to drive a single red indicator LED when the anode is

connected to the LM3555 and the cathode is connected to ground. In simple logic mode, the default indicator

current is 2.5 mA, and in I2C mode, the indicator LED current can be adjusted to 2.5 mA, 5 mA, 7.5 mA, or 10

mA.

7.3.8 Internal Diode Detection

During the start-up sequence of the LM3555 an internal voltage comparator on the VLED pin monitors the

forward voltage of the LED or LEDs. This measurement occurs when the ramp-up current reaches 80 mA. If, at

this time, the diode voltage exceeds the user-selectable diode detect threshold (Register 0x02 bits VO1 and

VO0), the LM3555 assumes two series LEDs are present and limits the maximum flash current to 400 mA. The

four adjustable levels are; 00 = 4.35 V, 01 = 4.65 V, 10 = 4.05 V and 11 = 4.95 V. This detection feature can be

disabled by setting the diode detect enable bit (DEN) in the Current Set Register (address 0x03) to a 0. The DEN

bit is set to a 1 (enabled) by default.

In all cases during start-up, the diode current first ramps to 80 mA and then proceeds to the target current. If the

torch/assist current is set to 60 mA, the LM3555 first reaches 80 mA and then drop to 60 mA.

The number of LEDs present in the system is recorded in a read-only diode number (DN) bit of the fault register

(address 0x05). In simple mode, the number of LEDs present are output on the STROBE pin (0 = 1 LED, 1 = 2

LEDs).

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

17

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

Feature Description (continued)

7.3.9 Fault Protections

The LM3555 has a number of fault protection mechanisms designed to not only protect the LM3555 device itself,

but also the rest of the system. Active faults protections include:

• Overvoltage protection (VOUT)

• Short-Circuit protection (VOUT and VLED)

• Overtemperature protection

• Flash timeout

• Indicator LED protection (open and short)

• Broken inductor protection

In the event that any of these faults occur, the LM3555 sets a flag in the Fault Register (Address 0x05) and

places the device into standby or shutdown. In simple control mode, normal operation cannot resume until the

fault has been fixed and until EN1 and EN2 are driven low 0. In I2C control mode, normal operation cannot

resume until the fault has be fixed and until an I2C read of the faults register (0x05) has completed. The act of

reading the fault register clears the fault bits.

7.3.9.1 Output Overvoltage Protection (OVP)

An OVP fault is triggered when the output voltage of the LM3555 reaches a value greater than 9.5 V (typical).

The OVP condition is cleared when the output voltage (VOUT) is able to operate below 9.5 V. An output capacitor

or an LED that has become an open circuit can cause an OVP event to occur. This fault is reported to the OVP

fault bit in the Fault Register (bit7 in address 0x05).

7.3.9.2 Output and LED Short-Circuit Protection (SCP)

An SCP fault is triggered when the output voltage (VOUT) and/or the VLED pin does not reach 0.8 V in 0.5 ms.

The short circuit condition is cleared when the output (VOUT) is allowed to reach its steady state target and

when the LED voltage rises above 0.8 V. A shorted output capacitor or a shorted LED could cause this fault to

occur. This fault is reported to the SC fault bit in the Fault Register (bit6 in address 0x05).

7.3.9.3 Overtemperature Protection (OTP)

An OTP fault is triggered when the diode junction temperature of the LM3555 reaches an internal temperature of

around 150°C. The OTP condition is cleared when the junction temperature falls below 140°C. A printed circuit

board (PCB) with poor thermal dissipation properties and very high ambient temperatures (greater that 85°C)

could cause this fault to occur. Refer to AN-1112 DSBGA Wafer Level Chip Scale Package (SNVA009) for more

information regarding proper PCB layout. This fault is reported to the OTP fault bit in the Fault Register (bit5 in

address 0x05).

7.3.9.4 Flash Timeout (FTP)

An FTP fault is triggered any time the flash pulse duration reaches the flash timeout duration. In I2C control

mode, the FTP fault is triggered whenever a flash is initiated through the Control Register (OEN and OM1/OM0

bits) or through an edge-sensitive strobe event. A FTP fault could occur in simple control Mode if the controller

tied to EN1 and EN2 pins cannot toggle the pins low at the desired pulse rate. This same condition could occur

with a level-sensitive strobe event controlled by a camera module. This fault is reported to the TO fault bit in the

Fault Register (bit4 in address 0x05). A FTP fault is the only reported fault that does not need to be cleared

before any additional LED event can occur.

7.3.9.5 Indicator Fault (IF)

An IF fault is triggered when the voltage on the IND pin is greater than 2.571 V or less than 0.842 V. This fault

indicates that there is either an open or a short present on the IND pin. The short-circuit condition is cleared

when the IND pin is allowed to operate between 0.842 V and 2.571 V. A shorted or open indicator LED could

cause this fault to occur. This fault is reported to the IF fault bit in the Fault Register (bit2 in address 0x05).

18

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

Feature Description (continued)

7.3.9.6 Broken Inductor Fault (IP)

An IP fault is triggered when the LM3555 detects that the inductance of the inductor has dropped below an

acceptable value. This fault indicates that the inductor has been damaged. An inductor that has had its ferrite

material damaged could cause this fault to occur. This fault is reported to the IP fault bit in the Fault Register

(bit1 in address 0x05).

7.3.10 Undervoltage Lockout (UVLO)

The LM3555 has a UVLO feature that disables the operation of the device in the event that the input voltage falls

below 2.4 V (typical). In simple control mode, the input voltage must increase to at least 2.47 V (typical), and the

EN1 and EN2 pins must be toggled low (0) before normal operation can resume.

In I2C control mode, the output enable bit in the Control Register (Address 0x04) is set to a 0 in the event of a

UVLO occurrence. The input voltage must rise to at least 2.47 V before the LM3555 becomes fully functional

again.

A UVLO event does not disturb the state of the other registers of the LM3555.

7.3.11 Power-On Reset (POR)

A POR circuit is present on the LM3555 for use in I2C control mode. The POR circuit ensures that the device

starts in a known OFF state and that the registers used in the I2C control interface are initialized to the proper

start-up values once the input voltage reaches a voltage greater than 1.8 V (typical). An input voltage lower than

1.8 V not only places the device into UVLO, but also clears all of the LM3555 registers.

7.4 Device Functional Modes

7.4.1 Single LED Operation

In single LED operation, the LED flash current is allowed to reach the maximum level of 500 mA. By default, the

assist/torch current is set to 80 mA, and the flash current is set to 500 mA.

For input voltages that are higher than the LED forward voltage, the LM3555 operates in a pass mode. As VIN

drops, the LM3555 first transitions from pass mode to the minimum duty-cycle boost mode. In this mode, the

output voltage (VOUT) increases to a level higher than needed to maintain current regulation through the current

source. If VIN continues to decrease, the LM3555 transitions again, this time from minimum duty-cycle boost

mode to standard boost mode. Standard boost mode adjusts the converters duty cycle to maintain 300 mV

across the current source of the device.

Once the LM3555 transitions from pass mode to either boost mode, the device stays in one of those boost

modes until the device is disabled or timed-out and then restarted.

7.4.2 Dual LED Operation

In dual LED operation, the LED flash current is allowed to reach a maximum level of 400 mA. By default, the

assist/torch current is set to 60 mA, and the flash current is set to 320 mA.

During dual LED operation, the output voltage is always greater than the input voltage (assuming standard white

flash LEDs are used), forcing the LM3555 to be in boost mode over the entire input voltage range.

7.4.3 Torch or Assist (Continuous Current) Operation

There are two different continuous current modes on the LM3555: torch and assist.

Torch mode is enabled through the use of the dedicated TORCH pin using both simple and I2C modes (1 =

Torch, 0 = Standby (I2C mode) or shutdown (simple mode). In I2C control mode, the TORCH pin functionality can

be enabled and disabled through by setting the value of the TEN bit in the Control Register (Address 0x04). TEN

= 1 allows an external torch while TEN = 0 does not.

Assist mode is enabled in simple control mode by driving EN1 low (0) and by driving EN2 high (1). In I2C control

mode, assist mode is enabled by setting the output mode bits (OM1 and OM0) to 10 and setting the output

enable bit (OEN) to a 1 in the Control Register (0x04). Assist mode remains active in I2C mode until the OEM bit

is set to 0 or until a flash event occurs.

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

19

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

Device Functional Modes (continued)

The LM3555 can drive one or two LEDs at continuous current levels ranging from 60 mA to 160 mA in 20-mA

steps. In simple control mode, the torch and assist current levels are equal to 60 mA for two LEDs or 80 mA for a

single LED. In I2C mode, the current is set in the Current Set Register (Address 0x30, AC2-AC0 bits).

7.4.4 Flash (Pulsed Current) Operation

A flash event using the LM3555 can be initiated though the dedicated control interface in both simple and I2C

modes, and through the use of the STROBE pin in I2C mode.

By driving both EN1 and EN2 high (1) in simple mode, the device enters flash mode and remains there until the

control pins are driven low (0), or a timeout event occurs. In simple mode, the flash current is equal to 500 mA

when driving a single LED and 320 mA when two LEDs are present. The default time-out duration is 850 ms.

When placed into I2C Control mode, a flash event is initiated when the output mode bits (OM1 and OM0) are set

to 11, and the output enable bit (OEN) is set to a 1 in the Control Register (0x04). In I2C mode, the flash event

remains active as long as the OEN bit is set to a 1 and terminates upon a timeout event. The safety timer

duration can be set in 50 ms intervals ranging from 100 ms to 850 ms by writing the desired value to the FT3FT0 bits in the Indicator and Timer Register (Address 0x02).

The STROBE pin provides added system flexibility because it allows an additional external device (camera

module, GPU, and so forth) to trigger a flash event. To initiate a strobe event in I2C control mode, the strobe

signal mode (SEN) bit and the output enable (OEN) bits in the Control Register (Address 0x04) must first be set

to 1's.

Following the setting of the SEN and OEN bits, the user must chose to have an edge-sensitive or level-sensitive

strobe event. Writing a 1 to the strobe signal usage (SSU) bit in the Control Register (Address 0x04), the

LM3555 is configured to be level sensitive, while writing a 0 configures the device to be edge sensitive. In both

cases, the strobe flash event is started upon the STROBE pin being driven high.

In an edge-sensitive event, the flash duration stays active until the flash duration timer lapses regardless of the

state of the STROBE pin. If a level-sensitive strobe is used, the flash event remains active as long as the

STROBE pin is held high and as long as the flash duration time has not lapsed.

In I2C control mode, the end of a flash event, whether initiated through the Control Register or STROBE pin,

forces the OEN bit to a 0 and places the LM3555 back into the standby state.

7.4.5 Indicator Operation

Indicator mode is enabled in simple control mode by driving EN1 high (1) and by driving EN2 high (0). In I2C

control mode, Indicator mode is enabled by setting the output mode bits (OM1 and OM0) to 01 and setting the

Output Enable bit (OEN) to a 1 in the Control Register (0x04). Indicator mode remains active in I2C mode until

the OEM bit is set to 0 or until a torch or flash event occurs.

In simple control mode, the indicator LED current is fixed to 2.5 mA, while in I2C control mode, the indicator

current is adjustable to 2.5 mA, 5 mA, 7.5 mA, or 10 mA by changing the values of the IC1 and IC0 bits in the

Indicator and Timer Register (Address 0x02).

7.4.6 Simple Control State Diagram

Flash

Assist Light

Shutdown

Red

Indicator

20

External

Torch

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

Device Functional Modes (continued)

Table 1. Simple Mode Truth Table (1)

(1)

EN1

EN2

TORCH

MODE

0

0

0

shutdown

0

0

1

external torch

0

1

X

assist light

1

0

X

indicator

1

1

X

flash

I2C/EN = 0

Internal

Flash

Strobe Flash

Edge

Strobe Flash

Level

Shutdown

Standby

Output On

External

Torch

Red

Indicator

Assist Light

External

Torch

Figure 40. I2C Control State Diagram

Table 2. I2C Mode Truth Table (1)

(1)

OEN

OM1

OM0

TEN

SEN

TORCH

STROBE

MODE

0

0

0

0

X

X

X

standby

0

0

0

1

X

0

X

standby

0

0

0

1

X

1

X

external torch

0

0

1

X

X

X

X

atandby

0

1

0

X

X

X

X

atandby

0

1

1

X

X

X

X

atandby

1

0

0

X

X

0

X

atandby

1

0

0

X

X

1

X

external torch

1

0

1

X

X

X

X

indicator

1

1

0

X

X

X

X

assist

1

1

1

X

0

X

X

internal flash

1

1

1

X

1

X

0

atandby

1

1

1

X

1

X

1

strobe flash

I2C/EN = 1, SCL and SDA = X

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

21

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

7.5 Programming

7.5.1 I2C-Compatible Interface

7.5.1.1 Data Validity

The data on SDA line must be stable during the HIGH period of the clock signal (SCL). In other words, the state

of the data line can only be changed when CLK is LOW.

SCL

SDA

data

change

allowed

data

valid

data

change

allowed

data

valid

data

change

allowed

Figure 41. Data Validity Diagram

A pullup resistor between VIO and SDA must be greater than (VIO – VOL) / 3 mA to meet the VOL requirement on

SDA. Using a larger pullup resistor results in lower switching current with slower edges, while using a smaller

pullup results in higher switching currents with faster edges.

7.5.1.2 Start and Stop Conditions

START and STOP conditions classify the beginning and the end of the I2C session. A START condition is

defined as SDA signal transitioning from HIGH to LOW while SCL line is HIGH. A STOP condition is defined as

the SDA transitioning from LOW to HIGH while SCL is HIGH. The I2C master always generates START and

STOP conditions. The I2C bus is considered to be busy after a START condition and free after a STOP condition.

During data transmission, the I2C master can generate repeated START conditions. First START and repeated

START conditions are equivalent, function-wise. The data on SDA line must be stable during the HIGH period of

the clock signal (SCL). In other words, the state of the data line can only be changed when CLK is LOW.

SDA

SCL

S

P

START condition

STOP condition

Figure 42. Start and Stop Conditions

7.5.1.3 Transferring Data

Every byte put on the SDA line must be eight bits long, with the most significant bit (MSB) being transferred first.

Each byte of data has to be followed by an acknowledge bit. The acknowledge related clock pulse is generated

by the master. The master releases the SDA line (HIGH) during the acknowledge clock pulse. The LM3555 pulls

down the SDA line during the 9th clock pulse, signifying an acknowledge. The LM3555 generates an

acknowledge after each byte has been received.

After the START condition, the I2C master sends a chip address. This address is seven bits long followed by an

eighth bit which is a data direction bit (R/W). The LM3555 address is 30h. For the eighth bit, a 0 indicates a

WRITE and a 1 indicates a READ. The second byte selects the register to which the data is written. The third

byte contains data to write to the selected register.

22

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

Programming (continued)

ack from slave

ack from slave

start

msb Chip Address lsb

w

ack

msb Register Add lsb

ack

start

Id = 30h

w

ack

addr = 04h

ack

ack from slave

msb

DATA

lsb

ack

stop

ack

stop

SCL

SDIO

data = 08h

w = write (SDA = 0); ack = acknowledge (SDA pulled down by the slave): id = chip address, 30h for LM3555

Figure 43. Write Cycle

7.5.1.4 I2C-Compatible Chip Address

The chip address for LM3555 is 0110000, or 30hex.

MSB

LSB

ADR6

bit7

ADR5

bit6

ADR4

bit5

ADR3

bit4

ADR2

bit3

ADR1

bit2

ADR0

bit1

0

1

1

0

0

0

0

R/W

bit0

2

I C Slave Address (chip address)

Figure 44. Device Address

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

23

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

7.6 Register Maps

7.6.1 Internal Registers of LM3555

REGISTER

INTERNAL HEX ADDRESS

POWER ON VALUE

Version Control Register

0x01

0000 1100

Indicator and Timer Register

0x02

0000 1111

Current Set Register

0x03

0110 1001

Control Register

0x04

1011 0100

Fault Register

0x05

0000 1000

7.6.2 Register Definitions

Definition:

RF3 RF2 RF1 RF0 DR3 DR2 DR1 DR0

Default:

0

0

0

0

0110 0110 0110 0110

ARF3–RF0: unused

DR3–DR0: design revision = 1100

Figure 45. Version Control Register, Address: 0x01

Definition:

IC1 IC0 VO1 VO0 FT3 FT2 FT1 FT0

Default:

0

0

0

0

1

1

1

1

IC1–IC0: indicator LED current control bits

VO1-VO0: VREF offset adjustment bits. used for diode detection.

FT3-FT0: software flash timer duration control bits

Figure 46. Indicator and Timer Register, Address: 0x02

Table 3. Indicator Currents

IC1

IC0

INDICATOR LED CURRENT

0

0

2.5 mA

0

1

5 mA

1

0

7.5 mA

1

1

10.0 mA

Table 4. Offset Voltages

VREFVOLTAGE

(OFFSET FROM 4.35 V)

VO1

VO0

0

0

4.35 V (+0 V)

0

1

4.65 V (+0.3 V)

1

0

4.05 V (−0.3 V)

1

1

4.95 V (+0.6 V)

Table 5. Flash Timeout Duration

24

FT3

FT2

FT1

FT0

FLASH TIMEOUT DURATION

0

0

0

0

100 ms

0

0

0

1

150 ms

0

0

1

0

200 ms

0

0

1

1

250 ms

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

Table 5. Flash Timeout Duration (continued)

FT3

FT2

FT1

FT0

FLASH TIMEOUT DURATION

0

1

0

0

300 ms

0

1

0

1

350 ms

0

1

1

0

400 ms

0

1

1

1

450 ms

1

0

0

0

500 ms

1

0

0

1

550 ms

1

0

1

0

600 ms

1

0

1

1

650 ms

1

1

0

0

700 ms

1

1

0

1

750 ms

1

1

1

0

800 ms

1

1

1

1

850 ms

Definition: FC3 FC2 FC1 FC0 DEN AC2 AC1 AC0

Default:

0

1

1

0

1

0

0

1

FC3-FC0: flash current control bits

DEN: diode detection enable bit. 1 = en, 0 = disabled. default = 1 (enabled)

AC2-AC0: assist light current control bits

Figure 47. Current Set Register, Address: 0x03

Table 6. Flash Current Levels

FC3

FC2

FC1

FC0

FLASH CURRENT LEVEL

0

0

0

0

200 mA

0

0

0

1

220 mA

0

0

1

0

240 mA

0

0

1

1

260 mA

0

1

0

0

280 mA

0

1

0

1

300 mA

0

1

1

0

320 mA (2 LEDs)

0

1

1

1

340 mA

1

0

0

0

360 mA

1

0

0

1

380 mA

1

0

1

0

400 mA (2 LED maximum)

1

0

1

1

420 mA

1

1

0

0

440 mA

1

1

0

1

460 mA

1

1

1

0

480 mA

1

1

1

1

500 mA (1LED)

Table 7. Assist Light Current Levels

AC2

AC1

AC0

ASSIST CURRENT LEVEL

0

0

0

60 mA

0

0

1

60 mA (2 LEDs)

0

1

0

60 mA

0

1

1

80 mA (1 LED)

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

25

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

Table 7. Assist Light Current Levels (continued)

AC2

AC1

AC0

ASSIST CURRENT LEVEL

1

0

0

100 mA

1

0

1

120 mA

1

1

0

140 mA

1

1

1

160 mA

Definition: IL1

Default:

1

IL0 SSU TEN OEN SEN OM1 OM0

0

1

1

0

1

0

0

IL1-IL0: peak inductor current limit bits

SSU: strobe signal usage. 0 = edge sensitive, 1 = level sensitive. 1 = default

TEN: external torch mode enable. 0 = not allowed, 1 = allowed. 1 = default

OEN: output enable. 0 = output disabled, 1 = output enabled. 0 = default

SEN: strobe signal mode. 0 = disabled, 1 = enabled. 1 = default

OM1-OM0: output mode select bits

Figure 48. Control Register, Address: 0x04

Table 8. Peak Inductor Current Limit Levels

IL1

IL0

PEAK INDUCTOR CURRENT LIMIT

0

0

1.25 A

0

1

1.5 A

1

0

1.75 A

1

1

2A

Table 9. Output Modes

OM1

OM0

OUTPUT MODE

0

0

external torch

0

1

indicator

1

0

assist light

1

1

flash

Definition: OVP SC OTP TO DN

Default:

0

0

0

0

X

IF

IP RFU

0

0

0

OVP: overvoltage protection fault. 1 = fault, 0 = no fault

SC: short-circuit fault: 1 = Fault, 0 = no fault

OTP: overtemperature protection fault. 1 = fault, 0 = no fault

TO: flash timeout fault. 1 = fault, 0 = no fault

DN: number of LEDs. 1 = 2 LEDs, 0 = 1 LED. (This bit is R/W). 1 = fault, 0 = no fault

IF: indicator LED fault. 1 = fault, 0 = no fault

IP: inductor peak current limit fault (broken inductor fault). 1 = fault, 0 = no fault

RFU: not used

Figure 49. Fault and Info Register, Address: 0x05

26

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component

specification, and TI does not warrant its accuracy or completeness. TI’s customers are

responsible for determining suitability of components for their purposes. Customers should

validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LM3555 is a white-LED driver for LED camera flash applications. The dual high-side current sources allow

for grounded cathode LEDs. The LM3555 can adaptively scale the maximum flash level delivered to the LEDs

based upon the flash configuration, whether it be a single LED or two LEDs in series.

8.2 Typical Application

2.2 µH

CIN

10 µF

SW

VIN

VOUT

+

VBAT

COUT

10 µF

STROBE

TORCH

I2C/EN

VLED

LM3555

SCL/EN1

SDA/EN2

PGND

SGND

IND

Copyright © 2016, Texas Instruments Incorporated

Figure 50. LM3555 Typical Application

8.2.1 Design Requirements

For typical white-LED driver applications, use the parameters listed in Table 10.

Table 10. Design Parameters

DESIGN PARAMETER

EXAMPLE VALUE

Input voltage range

2.5 V to 5.5 V

Number of LEDs

1 or 2 LEDs in Series

Output current range

60 mA to 500mA

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

27

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

8.2.2 Detailed Design Procedure

8.2.2.1 Inductor Current Limit

To prevent damage to the inductor of the LM3555 and to limit the power drawn by the LM3555 during a flash

event, an inductor current limit circuit is present. The LM3555 monitors the current through the inductor during

the charge phase of the boost cycle. In the event that the inductor current reaches the current limit, the NFET of

the converter terminates the charge phase for that cycle. The process repeats itself until the flash event has

ended or until the input voltage increases to the point where the peak current is no longer reached. Hitting the

peak inductor current limit does not disable the part. It does, however, limit the output power delivery to the

LEDs.

In simple control mode, the peak inductor current limit is set to 1.75 A. In I2C control mode, the inductor current

limit can be set to 1.25 A, 1.5 A, 1.75 A, and 2 A depending on the values of the IL1 and IL0 bits in the Control

Register (address 0x04). The peak inductor current limit value can be used to help size the inductor to the

appropriate saturation current level. For more information on inductor sizing, please refer to the Inductor

Selection.

8.2.2.2 Inductor Selection

The LM3555 is designed to use a 2.2-µH inductor. When the device is boosting (VOUT > VIN) the inductor is one

of the biggest sources of efficiency loss in the circuit. Therefore, choosing an inductor with the lowest possible

series resistance is important. Additionally, the saturation rating of the inductor must be greater than the

maximum operating peak current of the LM3555. This prevents excess efficiency loss that can occur with

inductors that operate in saturation and prevents over heating of the inductor and possible damage. For proper

inductor operation and circuit performance ensure that the inductor saturation and the peak current limit setting of

the LM3555 (1.25 A, 1.5 A, 1.75 A, or 2 A) is greater than IPEAK. IPEAK can be calculated by:

IPEAK =

I LOAD VOUT

V x (VOUT - VIN)

x

+ 'IL where 'IL = IN

K

VIN

2 x f SW x L x VOUT

(1)

Table 11. Recommended Inductors

MANUFACTURER

PART NUMBER

L / ISAT

Toko

FDSE312-2R2M

2.2 µH / 2.3 A

Coilcraft

LPS4012-222ML

2.2 µH / 2.3 A

TDK

VLF4014ST-2R2M1R9

2.2 µH / 2 A

8.2.2.3 Capacitor Selection

The LM3555 requires 2 external capacitors for proper operation (TI recommends CIN = 10 µF (4.7 µF minimum)

and COUT = 10 µF ). TI also recommends placing an additional 0.1-µF input capacitor placed right next to the VIN

pin. Surface-mount multi-layer ceramic capacitors are recommended. These capacitors are small, inexpensive

and have very low equivalent series resistance (ESR < 20 mΩ typical). Tantalum capacitors, OS-CON

capacitors, and aluminum electrolytic capacitors are not recommended for use with the LM3555 due to their high

ESR, as compared to ceramic capacitors.

For most applications, ceramic capacitors with X7R or X5R temperature characteristic are preferred for use with

the LM3555. These capacitors have tight capacitance tolerance (as good as ±10%) and hold their value over

temperature (X7R: ±15% over −55°C to +125°C; X5R: ±15% over −55°C to 85°C).

Capacitors with Y5V or Z5U temperature characteristic are generally not recommended for use with the LM3555.

Capacitors with these temperature characteristics typically have wide capacitance tolerance (80%, −20%) and

vary significantly over temperature (Y5V: 22%, –82% over −30°C to +85°C range; Z5U: 22%, –56% over 10°C to

85°C range). Under some conditions, a nominal 1-µF Y5V or Z5U capacitor could have a capacitance of only 0.1

µF. Such detrimental deviation is likely to cause Y5V and Z5U capacitors to fail to meet the minimum

capacitance requirements of the LM3555.

The recommended voltage rating for the input capacitor is 10 V (minimum = 6.3 V). The recommended output

capacitor voltage rating is 16 V (minimum = 10 V). The recommended value takes into account the DC bias

capacitance losses, while the minimum rating takes into account the OVP trip levels.

28

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

8.2.3 Application Curves

100

100

TA = -30°C

90

80

80

äLED (%)

äLED (%)

TA = -30°C

90

TA = +85°C

TA = +25°C

70

TA = +85°C

70

TA = +25°C

60

60

VLED (@ 320 mA) = 6.75V (2 LEDs)

50

2.5

3.0

3.5

4.0

4.5

5.0

VLED (@ 400 mA) = 6.9V (2 LEDs)

50

2.5

5.5

3.0

3.5

4.0

VIN (V)

5.0

5.5

VIN (V)

Two Series LEDs at 320 mA

Two Series LEDs at 400 mA

Figure 51. LED Efficiency vs Input Voltage

Figure 52. LED Efficiency vs Input Voltage

100

100

TA = -30°C

90

90

TA = -30°C

80

80

äLED (%)

äLED (%)

4.5

70

TA = +85°C

60

TA = +25°C

70

TA = +85°C

TA = +25°C

60

50

50

VLED (V) = 6.0V (2 LEDs)

40

2.5

3.0

3.5

4.0

4.5

5.0

40

2.5

5.5

VLED (V) = 6.1V (2 LEDs)

3.0

3.5

VIN (V)

4.0

4.5

5.0

5.5

VIN (V)

Two LEDs at 60 mA

Two LEDs at 80 mA

Figure 53. LED Efficiency vs Input Voltage

Figure 54. LED Efficiency vs Input Voltage

100

100

VLED (@ 500 mA) = 3.6V

TA = -30°C

90

90

TA = +25°C

äLED (%)

äLED (%)

80

80

70

TA = +85°C

TA = -30°C

70

60

TA = +25°C

60

50

TA = +85°C

50

2.5

3.0

3.5

4.0

4.5

5.0

40

2.5

5.5

3.0

3.5

VLED (V) = 3.0V

4.0

4.5

5.0

5.5

VIN (V)

VIN (V)

One LED at 60 mA

One LED at 500 mA

Figure 55. LED Efficiency vs Input Voltage

Figure 56. LED Efficiency vs Input Voltage

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

29

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

100

90

TA = +25°C

80

äLED (%)

TA = -30°C

70

60

50

TA = +85°C

VLED (V) = 3.0V

40

2.5

3.0

3.5

4.0

4.5

5.0

5.5

VIN (V)

One LED at 80 mA

Figure 57. LED Efficiency vs Input Voltage

9 Power Supply Recommendations

The LM3555 is designed to operate from an input supply range of 2.5 V to 5.5 V. This input supply must be well

regulated and provide the peak current required by the LED configuration and inductor selected.

30

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

�LM3555

www.ti.com

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

10 Layout

10.1 Layout Guidelines

The DSBGA is a chip-scale package with good thermal properties. For more detailed instructions on handling

and mounting DSBGA packages, refer to AN-1112 DSBGA Wafer Level Chip Scale Package (SNVA009).

The high switching frequencies and large peak currents make the PCB layout a critical part of the design. The

proceeding steps must be followed to ensure stable operation and proper current source regulation.

1. Connect the inductor as close to the SW pin as possible. This reduces the inductance and resistance of the

switching node which minimizes ringing and excess voltage drops.

2. Connect the return terminals of the input capacitor and the output capacitor as close to the two ground pins

(PGND and SGND) as possible and through low impedance traces.

3. Bypass VIN with a 10-µF ceramic capacitor and an additional 0.1-µF ceramic capacitor. Connect the positive

terminal of this capacitor as close to VIN as possible.

4. Connect COUT as close to the VOUT pin as possible. This reduces the inductance and resistance of the output

bypass node which minimizes ringing and voltage drops. This improves efficiency and decreases the noise

injected into the current sources.

10.2 Layout Example

CIN1

4.45 mm

CIN2

L1

COUT

LM3555

7.0 mm

Figure 58. LM3555 Layout

Submit Documentation Feedback

Copyright © 2008–2016, Texas Instruments Incorporated

Product Folder Links: LM3555

31

�LM3555

SNVS594G – DECEMBER 2008 – REVISED APRIL 2016

www.ti.com

11 Device and Documentation Support

11.1 Device Support

11.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

11.2 Documentation Support

11.2.1 Related Documentation

For additional information, see the following:

AN-1112 DSBGA Wafer Level Chip Scale Package (SNVA009)

11.3 Community Resources