Sample &

Buy

Product

Folder

Support &

Community

Tools &

Software

Technical

Documents

LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

LM3559 Synchronous Boost Flash Driver With Dual 900-mA High-Side Current Sources

(1.8-A Total Flash Current)

1 Features

3 Description

•

The LM3559 is a 2-MHz fixed-frequency synchronous

boost converter with two 900-mA constant current

drivers for high-current white LEDs. The dual highside current sources allow for grounded cathode LED

operation and can be tied together for providing flash

currents of up to 1.8 A. An adaptive regulation

method ensures the current for each LED remains in

regulation and maximizes efficiency.

1

•

•

•

•

•

•

•

•

•

•

•

•

•

Dual High-Side Current Sources Allow for

Grounded Cathode LED Operation

Accurate and Programmable LED Current from

28.125 mA to 1.8 A

Optimized Flash Current During Low Battery

Conditions

Independent LED Current Source Programmability

Four Operating Modes: Torch, Flash, Privacy

Indicate, and Message Indicator

4-Bit Analog-to-Digital (ADC) for VLED Monitoring

Battery Voltage Sensing and Current Scale-Back

LED Sensing and Current Scale-Back

Hardware Flash and Torch Enable

Active-Low Hardware Reset

Dual Synchronization Inputs for RF Power

Amplifier Pulse Events

LED and Output Disconnect During Shutdown

Open and Short LED Detection

400-kHz I2C-Compatible Interface

2 Applications

•

•

The LM3559 is controlled via an I2C-compatible

interface. Features include: an internal 4-bit ADC to

monitor the LED voltage, independent LED current

control, a hardware flash enable allowing a logic input

to trigger the flash pulse, dual TX inputs which force

the flash pulse into a low-current torch mode allowing

for synchronization to RF power amplifier events or

other

high-current

conditions,

an

integrated

comparator designed to monitor an NTC thermistor

and provide an interrupt to the LED current, an input

voltage monitor to monitor low battery conditions, and

a flash current scale-back feature that actively

monitors the battery voltage and optimizes the flash

current during low battery-voltage conditions.

Additionally, an active high HWEN input provides a

hardware shutdown during system software failures.

The 2-MHz switching frequency, overvoltage

protection, and adjustable current limit allow for the

use of tiny, low-profile (1-µH or 2.2-µH) inductors and

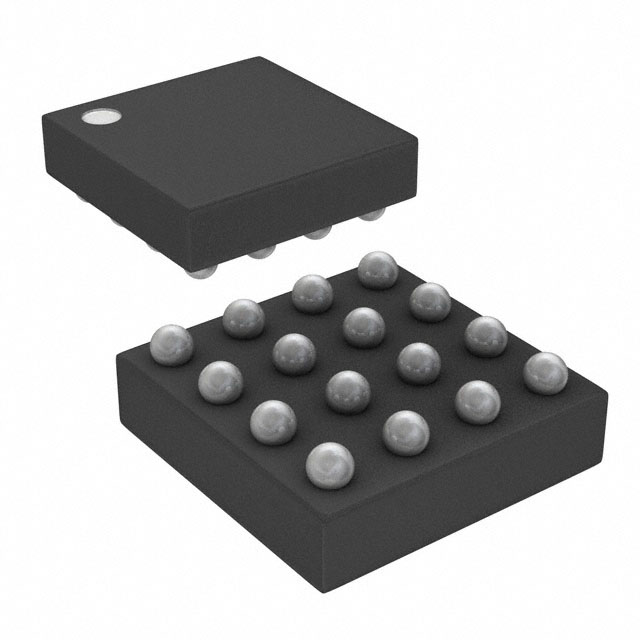

(10-µF) ceramic capacitors. The device is available in

a ultra-small 16-pin DSBGA package (total solution

size < 26 mm2) and operates over the –40°C to

+85°C temperature range.

Camera Phone LED Flash

White LED Biasing

Simplified Schematic

SW

2.5 V to 5.5 V

IN

Device Information(1)

OUT

PART NUMBER

PACKAGE

LM3559

LM3559

LED1

SDA

Flash

LEDs

LED2

D2

STROBE

TX1/TORCH/GPIO1

TX2/INT/GPIO2

GND

D1

LED Efficiency vs VIN Dual LEDs

95.0

LEDI/NTC

Optional Indicator

LED or LED

Thermal Sensing

Circuit

Copyright © 2016, Texas Instruments Incorporated

1.96 mm × 1.96 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

ILED = 450 mA

90.0

85.0

Led Efficiency (%)

HWEN

SCL

BODY SIZE (NOM)

DSBGA (16)

ILED = 337.5 mA

80.0

75.0

70.0

ILED=281.25 mA

65.0

60.0

55.0 ILED = 393.75 mA

50.0

45.0

40.0

2.5

3.0

3.5

4.0

Vin (V)

4.5

5.0

(Flash Brightness Codes 0x88 - 0xAA)

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Table of Contents

1

2

3

4

5

6

7

8

Features ..................................................................

Applications ...........................................................

Description .............................................................

Revision History.....................................................

Pin Configuration and Functions .........................

Specifications.........................................................

1

1

1

2

3

4

6.1

6.2

6.3

6.4

6.5

6.6

4

4

4

4

5

6

Absolute Maximum Ratings ......................................

ESD Ratings..............................................................

Recommended Operating Conditions.......................

Thermal Information ..................................................

Electrical Characteristics...........................................

I2C Timing Requirements (SCL, SDA)......................

Typical Characteristics.......................................... 7

Detailed Description ............................................ 11

8.1

8.2

8.3

8.4

Overview .................................................................

Functional Block Diagram .......................................

Feature Description.................................................

Device Functional Modes........................................

11

12

13

20

8.5 Programming........................................................... 25

8.6 Register Maps ......................................................... 27

9

Application and Implementation ........................ 36

9.1 Application Information............................................ 36

9.2 Typical Applications ................................................ 36

10 Power Supply Recommendations ..................... 41

11 Layout................................................................... 42

11.1 Layout Guidelines ................................................. 42

11.2 Layout Example .................................................... 43

12 Device and Documentation Support ................. 44

12.1

12.2

12.3

12.4

12.5

12.6

12.7

Device Support......................................................

Documentation Support ........................................

Receiving Notification of Documentation Updates

Community Resources..........................................

Trademarks ...........................................................

Electrostatic Discharge Caution ............................

Glossary ................................................................

44

44

44

44

44

44

44

13 Mechanical, Packaging, and Orderable

Information ........................................................... 44

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision A (May 2013) to Revision B

Page

•

Added Device Information and Pin Configuration and Functions sections, ESD Ratings and Thermal Information

tables, Feature Description, Device Functional Modes, Application and Implementation, Power Supply

Recommendations, Layout, Device and Documentation Support, and Mechanical, Packaging, and Orderable

Information sections................................................................................................................................................................ 1

•

Added Thermal Information table with revised RθJA value (from "50.4°C/W" to "71.3°C/W") and additional thermal

values. ................................................................................................................................................................................... 4

Changes from Original (May 2013) to Revision A

•

2

Page

Changed layout of National Data Sheet to TI format ........................................................................................................... 42

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

5 Pin Configuration and Functions

YZR Package

16-Pin DSBGA

Top View

Top View

A1

A2

A3

A4

B1

B2

B3

B4

C1

C2

C3

C4

D1

D2

D3

D4

Pin Functions

PIN

TYPE

DESCRIPTION

NO.

NAME

A1

LED1

Power

High-side current source output for flash LED1

A2, B2

OUT

Power

Step-up DC-DC converter output. Connect a 10-µF ceramic capacitor between this

pin and GND.

A3, B3

SW

Power

Drain connection for internal NMOS and synchronous PMOS switches

A4, B4

GND

Ground

Ground

B1

LED2

Output

High-side current source output for flash LED2

C1

LEDI/NTC

Input/Output

Configureable as a high-side current source output for indicator LED or comparator

input for LED temperature sensing

C2

TX1/TORCH/GPIO1

Input/Output

Configureable as a dual-polarity RF power amplifier synchronization input, a hardware

torch mode enable, or as a general purpose logic I/O. This pin has an internal 300-kΩ

pulldown to GND.

C3

STROBE

Input

Active high hardware flash enable. Drive STROBE high to turn on the flash current

pulse. This pin has an internal 300-kΩ pulldown to GND.

C4

IN

Power

Input voltage connection. Connect IN to the input supply, and bypass to GND with a

minimum 10-µF or larger ceramic capacitor.

D1

TX2/INT/GPIO2

Input/Output

Configurable as a dual-polarity power amplifier synchronization input, an interrupt

output, or as a general purpose logic I/O. This pin has an internal 300-kΩ pulldown to

GND.

D2

SDA

Input/Output

Serial data input output. High impedance in shutdown or in power down.

D3

SCL

Input

Serial clock input. High impedance in shutdown or in power down.

D4

HWEN

Input

Logic high hardware enable. HWEN is a high impedance input and is normally

connected with an external pullup resistor to a logic high voltage.

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

3

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1)

MIN

MAX

UNIT

VIN

–0.3

6

V

VSCL, VSDA, VHWEN, VSTROBE, VTX1, VTX2, VLED1, VLED2, VLEDI/NTC

–0.3

to the lesser of (VIN + 0.3

V) with 6 V maximum

V

VSW, VOUT

–0.3

6

V

Continuous power dissipation

(2)

Internally limited

Junction temperature, TJ-MAX

Storage temperature, Tstg

(1)

(2)

–65

150

°C

150

°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ = 150°C (typical) and

disengages at TJ = 135°C (typical). Thermal shutdown is ensured by design.

6.2 ESD Ratings

V(ESD)

(1)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

VALUE

UNIT

±2000

V

(1)

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN

MAX

Input voltage, VIN

2.5

5.5

V

Junction temperature, TJ

–40

125

°C

Ambient temperature, TA (1)

–40

85

°C

(1)

UNIT

In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may

have to be derated. Maximum ambient temperature (TA-MAX) is dependent on the maximum operating junction temperature (TJ-MAX-OP =

125°C), the maximum power dissipation of the device in the application (PD-MAX), and the junction-to-ambient thermal resistance of the

part/package in the application (RθJA), as given by the following equation: TA-MAX = TJ-MAX-OP – (RθJA × PD-MAX).

6.4 Thermal Information

LM3559

THERMAL METRIC

(1)

YZR (DSBGA)

UNIT

16 PINS

RθJA

Junction-to-ambient thermal resistance (2)

71.3

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

18.4

°C/W

RθJB

Junction-to-board thermal resistance

9.8

°C/W

ψJT

Junction-to-top characterization parameter

1.7

°C/W

ψJB

Junction-to-board characterization parameter

1.7

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

9.7

°C/W

(1)

(2)

4

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report, SPRA953.

Junction-to-ambient thermal resistance (RθJA) is taken from a thermal modeling result, performed under the conditions and guidelines

set forth in the JEDEC standard JESD51-7. The test board is a 4-layer FR-4 board measuring 102 mm × 76 mm × 1.6 mm with a 2 × 1

array of thermal vias. The ground plane on the board is 50 mm × 50 mm. Thickness of copper layers are 36 µm/18 µm/18 µm/36 µm

(1.5 oz/1oz/1oz/1.5 oz). Ambient temperature in simulation is 22°C, still air. Power dissipation is 1 W.

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

6.5 Electrical Characteristics

Unless otherwise specified, VIN = 3.6 V, VHWEN = VIN, TA = 25°C. (1)

PARAMETER

(2)

TEST CONDITIONS

MIN

TYP

MAX

900-mA flash current setting, per

current source

–7%

1800

7%

900-mA flash current setting, per

current source

–40°C ≤ TA ≤ 85°C

–4%

1800

4%

UNIT

CURRENT SOURCE SPECIFICATIONS

Current source

accuracy

ILED

ILED1 + ILED2, 3 V

≤ VIN ≤ 4.2 V,

VOUT = 4.5 V

28.125-mA torch current, per

current source

–40°C ≤ TA ≤ 85°C

VOUT – VLED1/2

Current source

regulation voltage

VOVP

Output overvoltage

protection trip point (3)

mA

28.125-mA torch current, per

current source

–10%

ILED = 1.8 A (ILED1 + ILED2), VOUT = 4.5 V

56.2

10%

270

ON threshold

mV

5

ON threshold, –40°C ≤ TA ≤ 85°C

4.925

OFF threshold

5.075

V

4.88

STEP-UP DC-DC CONVERTER SPECIFICATIONS

RPMOS

PMOS switch onresistance

IPMOS = 1A

80

mΩ

RNMOS

NMOS switch onresistance

INMOS = 1A

80

mΩ

3 V ≤ VIN ≤ 4.2 V

3 V ≤ VIN ≤ 4.2 V

–40°C ≤ TA ≤ 85°C

3 V ≤ VIN ≤ 4.2 V

Switch current limit (4)

ICL

3 V ≤ VIN ≤ 4.2 V

–40°C ≤ TA ≤ 85°C

3 V ≤ VIN ≤ 4.2 V

3 V ≤ VIN ≤ 4.2 V

–40°C ≤ TA ≤ 85°C

3 V ≤ VIN ≤ 4.2 V

3 V ≤ VIN ≤ 4.2 V

–40°C ≤ TA ≤ 85°C

IOUT_SC

ILEDI/NTC

VTRIP

(1)

(2)

(3)

(4)

Output short-circuit

current limit

Indicator current

Comparator trip

threshold

Flash Duration

Register bits

[6:5] = 00

Flash Duration

Register bits

[6:5] = 01

Flash Duration

Register bits

[6:5] = 10

Flash Duration

Register bits

[6:5] = 11

1.4

1.2

1.6

2.1

1.8

2.3

A

2.7

2.4

3

3.2

2.9

VOUT < 2.3 V

3.5

350

Register 0x12, bits[2:0] = 111, 2.7 V ≤ VIN ≤ 4.2 V

VLEDI/NTC = 2 V, –40°C ≤ TA ≤ 85°C

Register 0x12, bits[2:0] = 111, 2.7 V ≤ VIN ≤ 4.2 V

VLEDI/NTC = 2 V

18

mA

16

Configuration register 1, bit [4] = 1,

3 V ≤ VIN ≤ 4.2 V

Configuration register 1, bit [4] = 1,

3 V ≤ VIN ≤ 4.2 V, –40°C ≤ TA ≤ 85°C

mA

20

1

V

0.97

1.03

All voltages are with respect to the potential at the GND pin.

Minimum (MIN) and maximum (MAX) limits are specified by design, test, or statistical analysis. Typical (TYP) numbers represent the

most likely norm. Unless otherwise stated, conditions for typical specifications are: VIN = 3.6 V and TA = 25°C.

The typical curve for overvoltage protection (OVP) is measured in closed loop using Figure 43 . The OVP value is found by forcing an

open circuit in the LED1 and LED2 path and recording the peak value of VOUT. The value given in Electrical Characteristics is found in

an open loop configuration by ramping the voltage at OUT until the OVP comparator trips. The closed loop data can appear higher due

to the stored energy in the inductor being dumped into the output capacitor after the OVP comparator trips. Worst case is an open circuit

condition where the output voltage can continue to rise after the OVP comparator trips by approximately IIN × sqrt(L/COUT).

The typical curve for current limit is measured in closed loop using Figure 43, and increasing IOUT until the peak inductor current stops

increasing. The value given in Electrical Characteristics is measured open loop and is found by forcing current into SW until the current

limit comparator threshold is reached. Closed loop data appears higher due to the delay between the comparator trip point and the

NFET turning off. This delay allows the closed loop inductor current to ramp higher after the trip point by approximately 20 ns × VIN/L.

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

5

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Electrical Characteristics (continued)

Unless otherwise specified, VIN = 3.6 V, VHWEN = VIN, TA = 25°C.(1) (2)

PARAMETER

ƒSW

Switching frequency

Quiescent supply

current

IQ

TEST CONDITIONS

MIN

TYP

2.7 V ≤ VIN ≤ 5.5 V

MAX

2

2.7 V ≤ VIN ≤ 5.5 V, –40°C ≤ TA ≤ 85°C

1.8

2.2

UNIT

MHz

Device not switching, VOUT = 3V

650

µA

Device switching, VOUT = 4.5V

1.55

mA

Indicate mode, Indicator Register bits [2:0] = 111

VLEDI/NTC = 2 V

590

µA

Indicate mode, Indicator Register bits [2:0] = 111

VLEDI/NTC = 2 V, –40°C ≤ TA ≤ 85°C

2.7 V ≤ VIN ≤ 5.5 V, –40°C ≤ TA ≤

85°C

750

ISHDN

Shutdown supply

current

ISTBY

Standby supply

current

VIN_TH

VIN monitor threshold

VIN_FLASH_TH

VIN flash monitor

threshold

VIN Monitor Register = 0x08

tTX

Flash-to-torch LED

current settling time

TX_ Low to High

ILED1 + ILED2 = 1.8A to 112.5mA

20

Time from when ILED

hits target until VLED

data is available

ADC Delay Register bit [5] = 1

16

tD

VF_ADC

ADC threshold

2.7 V ≤ VIN ≤ 5.5 V

2.7 V ≤ VIN ≤ 5.5 V, –40°C ≤ TA ≤

85°C

HWEN = GND

1

µA

1.25

HWEN = VIN,

Enable Register

bits [1:0] = 00

2.4

VIN Monitor Register = 0x01

2.9

VIN Monitor Register = 0x01, –40°C ≤ TA ≤ 85°C

2.85

2.95

2.9

VIN Monitor Register = 0x08, –40°C ≤ TA ≤ 85°C

2.85

2.95

ADC Delay Register bit [5] = 0

ADC Delay Register bits [4:0] = 0000

250

VLED Monitor Register bits [3:0] = 1111

4.6

VLED Monitor Register bits [3:0] = 1111

–40°C ≤ TA ≤ 85°C

4.4

µA

V

V

µs

µs

4.8

V

HWEN, STROBE, TX1/TORCH/GPIO1, TX2/INT/GPIO2 VOLTAGE SPECIFICATIONS

VIL

Input logic low

2.7 V ≤ VIN ≤ 5.5 V, –40°C ≤ TA ≤ 85°C

0

0.4

V

VIH

Input logic high

2.7 V ≤ VIN ≤ 5.5 V, –40°C ≤ TA ≤ 85°C

1.2

VIN

V

RPD

Internal pulldown

resistance on TX1,

TX2, STROBE

300

kΩ

I2C-COMPATIBLE VOLTAGE SPECIFICATIONS (SCL, SDA)

VIL

Input logic low

2.7 V ≤ VIN ≤ 5.5 V, –40°C ≤ TA ≤ 85°C

VIH

Input logic high

2.7 V ≤ VIN ≤ 5.5 V

VOL

Output logic low

(SDA)

ILOAD = 3 mA

2.7 V ≤ VIN ≤ 5.5 V, –40°C ≤ TA ≤ 85°C

0

0.4

V

1.3

VIN

V

0.4

V

6.6 I2C Timing Requirements (SCL, SDA)

See (1)

MIN

1/t1

SCL(clock frequency)

t2

Data in setup time to SCL high

t3

Data out stable after SCL low

t4

t5

(1)

6

NOM

400

MAX

UNIT

kHz

100

ns

0

ns

SDA low setup time to SCL low (start)

100

ns

SDA high hold time after SCL high (stop)

100

ns

Specified by design, not production tested.

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

7 Typical Characteristics

Unless otherwise specified: VIN = 3.6 V, COUT = 10 µF, CIN = 10 µF, L = 1 µH (TOKO FDSD0312-1R0, RL = 43 mΩ),

Figure 43.

Register Bits [6:5] = 00

Register Bits [6:5] = 01

Figure 1. Closed Loop Current Limit vs VIN Flash Duration

Register Bits [6:5] = 10

Figure 2. Closed Loop Current Limit vs VIN Flash Duration

Register Bits [6:5] = 11

Figure 3. Closed Loop Current Limit vs VIN Flash Duration

Figure 4. Closed Loop Current Limit vs VIN Flash Duration

VHWEN= 0 V

Enable Register = 0x18

Figure 5. Standby Current vs VIN VHWEN = VIN

Figure 6. Shutdown Current vs VIN

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

7

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Typical Characteristics (continued)

Unless otherwise specified: VIN = 3.6 V, COUT = 10 µF, CIN = 10 µF, L = 1 µH (TOKO FDSD0312-1R0, RL = 43 mΩ),

Figure 43.

6.10

0.80

TA=-40°C

OVP Threshold (V)

I (non-Switching) (mA)

6.00

TA=85°C

0.75

0.70

0.65

TA=25°C

0.60

TA=-40°C

5.90

5.80

TA=85°C

5.70

5.60

0.55

5.50

0.50

2.5

5.40

2.5

TA=25°C

3.0

3.5

4.0

4.5

Vin (V)

5.0

5.5

Figure 7. Non-Switching Current vs VIN

4.0

4.5

Vin (V)

5.0

5.5

Figure 8. OVP Thresholds vs VIN

2.35

2.03

TA=25°C

TA=-40°C

TA=-40°C

IINDICATE (mA)

2.30

2.01

TA=85°C

1.99

TA=25°C

2.25

2.20

2.15

2.10

1.97

TA=85°C

2.05

1.95

2.5

3.5

2.40

2.05

Frequency (MHz)

3.0

3.0

3.5

4.0

4.5

Vin (V)

5.0

2.00

2.7

5.5

3.1

3.5

3.9 4.3

VIN (V)

4.7

5.1

5.5

Register Bits [2:0] = 0x00

Figure 9. Switching Frequency vs VIN

Figure 10. Indicator Currents vs VIN Indicator

6.50

18.6

TA=-40°C

18.4

6.10

TA=85°C

IINDICATE(mA)

Indicator Current (mA)

6.30

TA=25°C

5.90

18.0

17.8

5.70

5.50

2.8

TA=-40°C

TA=25°C

17.6

3.3

3.9

4.4

Vin (V)

5.0

17.4

2.5

5.5

Register Bits [2:0] = 0x02

3.0

3.5

4.0

4.5

Vin (V)

5.0

5.5

Register Bits [2:0] = 0x07

Figure 11. Indicator Current vs VIN Indicator

8

TA=85°C

18.2

Figure 12. Indicator Current vs VIN Indicator

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

Typical Characteristics (continued)

Unless otherwise specified: VIN = 3.6 V, COUT = 10 µF, CIN = 10 µF, L = 1 µH (TOKO FDSD0312-1R0, RL = 43 mΩ),

Figure 43.

1.900

Code (0xFF)

1.850

1.800

1.750

1.700

Code (0xEE)

Iled (A)

Iled (A)

1.650

1.600

1.550

Code (0xCC)

Code (0xDD)

1.500

1.450

1.400

1.350

1.300

1.250

2.5

Code (0xBB)

3.0

3.5

4.0

Vin(V)

4.5

5.0

Upper 5 Flash Brightness Codes

1.300

1.250

1.200

1.150

1.100

1.050

1.000

0.950

0.900

0.850

0.800

0.750

0.700

0.650

0.600

2.5

Code (0xAA)

Code (0x99)

Code (0x88)

Code (0x77)

3.0

3.5

4.0

Vin(V)

4.5

5.0

Middle 5 Flash Brightness Codes

Figure 13. ILED (Flash Mode) vs VIN LED1 and LED2

Connected Together

Figure 14. ILED (Flash Mode) vs VIN LED1 and LED2

Connected Together

0.480

0.285

Code (0x5B)

0.255

0.450

Code (0x76)

Code (0x7F)

0.225

0.420

Code (0x52)

Iled (A)

0.195

ILed (A)

Code (0x66)

0.390

Code (0x6B)

0.360

0.165

Code (0x49)

0.135

0.330

0.105

Code (0x64)

Code (0x00)

0.300

0.270

2.5

0.075

3.0

3.5

4.0

Vin (V)

4.5

0.045

2.5

5.0

3.0

3.5

4.0

Vin(V)

4.5

5.0

Lower 4 Torch Brightness Codes

Upper 4 Torch Brightness Codes

Figure 15. ILED (Torch Mode) vs VIN LED1 and LED2

Connected Together

Figure 16. ILED (Torch Mode) vs VIN LED1 and LED2

Connected Together

Figure 17. Strobe High-to-Flash LED Current

Figure 18. VIN Monitor Operation

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

9

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Typical Characteristics (continued)

Unless otherwise specified: VIN = 3.6 V, COUT = 10 µF, CIN = 10 µF, L = 1 µH (TOKO FDSD0312-1R0, RL = 43 mΩ),

Figure 43.

Figure 19. VIN Flash Monitor Operation

Figure 20. NTC-Mode Operation

Figure 21. AET-Mode Operation

Figure 22. HWEN Operation Device Enabled in Flash Mode

TX2 Active High

Figure 23. TX1 Interrupt (Force Torch)

10

Figure 24. TX2 Interrupt (Forced Shutdown)

(1)

The typical curve for current limit is measured in closed loop using Figure 43, and increasing IOUT until the peak

inductor current stops increasing. The value given in Electrical Characteristics is measured open loop and is found by

forcing current into SW until the current limit comparator threshold is reached. Closed loop data appears higher due to

the delay between the comparator trip point and the NFET turning off. This delay allows the closed loop inductor

current to ramp higher after the trip point by approximately 20 ns × VIN/L.

(2)

The typical curve for overvoltage protection (OVP) is measured in closed loop using Figure 43 . The OVP value is

found by forcing an open circuit in the LED1 and LED2 path and recording the peak value of VOUT. The value given in

Electrical Characteristics is found in an open loop configuration by ramping the voltage at OUT until the OVP

comparator trips. The closed loop data can appear higher due to the stored energy in the inductor being dumped into

the output capacitor after the OVP comparator trips. Worst case is an open circuit condition where the output voltage

can continue to rise after the OVP comparator trips by approximately IIN × sqrt(L/COUT).

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

8 Detailed Description

8.1 Overview

The LM3559 is a high-power white LED flash driver capable of delivering up to 1.8 A of LED current into a single

LED, or up to 900 mA into two parallel LEDs. The device incorporates a 2-MHz constant frequency, synchronous

boost converter, and two high-side current sources to regulate the LED current over the 2.5-V to 5.5-V input

voltage range.

During operation when the output voltage is greater than VIN – 150 mV, the boost converter switches and

maintains at least 270 mV across both current sources (LED1 and LED2). This minimum headroom voltage

ensures that the current sinks remain in regulation. When the input voltage rises above the LED voltage + current

source headroom voltage, the device stops switching and turns the PFET on continuously (pass mode). In pass

mode the difference between (VIN - ILED × RON_P) and the voltage across the LEDs is dropped across the current

sources.

Four hardware control pins provide control of the LM3559 device. These include a hardware flash enable

(STROBE), dual flash-interrupt inputs (TX1 and TX2) designed to interrupt the flash pulse during high-battery

current conditions, and a logic high hardware enable (HWEN) that can be pulled low to rapidly place the device

into shutdown. Additional features of the LM3559 include an internal 4-bit ADC for LED voltage monitoring, an

internal comparator for LED thermal sensing via an external NTC thermistor, a battery voltage monitor during

flash current turnon which monitors VIN and optimizes the flash current during low-battery voltage conditions, an

input voltage monitor that can force torch mode or LED shutdown of the flash current during input undervoltage

conditions, a low-power Indicator current source with programmable patterns, and a mode for utilizing the flash

LEDs as a privacy indicator.

Control of the LM3559 is done via an I2C-compatible interface. This includes adjustment of the flash and torch

current levels, adjustment of the indicator LED currents and indicator pattern, changing the flash timeout

duration, changing the switch current limit, and reading back the ADC results. Additionally, there are 8 flag bits

that indicate flash current timeout, LED overtemperature, LED failure (by sensing LED short or output OVP

condition during flash, torch, or privacy modes), device thermal shutdown, VIN undervoltage condition, tripping of

the VIN flash monitor, and the occurrence of a TX interrupt (both TX1 and TX2).

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

11

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

8.2 Functional Block Diagram

SW

Overvoltage

Comparator

2 MHz

Oscillator

VREF

+

-

IN

VIN Flash

Monitor

Threshold

VIN Monitor

Threshold

80 PŸ

VOVP

OUT

ILED1

ILED2

+

-

+

-

PWM

Control

ILEDI

Thermal

Shutdown

+150°C

LEDI/

NTC

+

-

Error

Amplifier

LED1

80 PŸ

+

+

-

Current Sense/

Current Limit

Max

VLED

1V

Slope

Compensation

SDA

SCL

LED2

VHR

Soft-Start

Control

Logic/

Registers

I 2C

Interface

ADC

4 Bits

HWEN

12

TX1/

TORCH/

GPIO1

STROBE

TX2/INT/

GPIO2

GND

Copyright © 2016, Texas Instruments Incorporated

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

8.3 Feature Description

8.3.1 Power Amplifier Synchronization (TX1)

The TX1/TORCH/GPIO1 pin has a triple function. With the Configuration Register 1 Bit [7] = 0 (default)

TX1/TORCH/GPIO1 is a power-amplifier-synchronization input. This mode is designed to reduce the flash LED

current when TX1 is pulled high (active high polarity) or low (active low polarity). When the LM3559 is engaged in

a flash event and the TX1/TORCH pin is pulled high, both LED1 and LED2 are forced into torch mode at the

programmed torch current setting. If TX1 is then pulled low before the flash pulse terminates, the LED current

returns to the previous flash current level. At the end of the flash timeout, whether the TX1/TORCH pin is high or

low, the current sources turn off.

The polarity of the TX1 input can be changed from active high to active low by writing a 0 to bit [5] of

Configuration Register 1. With this bit set to 0 the LM3559 is forced into torch mode when TX1/TORCH is pulled

low. Figure 25 details the functionality of the TX1 interrupt.

Flash Timeout

IFLASH

ITORCH

STROBE

TX1 or TX2 set

for Active High

Figure 25. TX1 or TX2 Interrupt Event

Flash Duration

IFLASH

ITORCH

STROBE

TORCH

Figure 26. Hardware-Torch Mode

8.3.2 Input Voltage Flash Monitor Fault

The VIN flash monitor flag (bit [6] of the Flags Register reads back a 1 when the input voltage flash monitor is

enabled and VIN falls below the programmed VIN flash monitor threshold. This flag must be read back in order to

resume normal operation after the LED current has been forced to the lower flash current setting.

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

13

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Feature Description (continued)

8.3.3 Independent LED Control

Bits [4:3] of the enable register provide for independent turnon and turnoff of the LED1 or LED2 current sources.

The LED current is adjusted by writing to the Torch Brightness or Flash Brightness Registers. Both the Torch

Brightness and the Flash Brightness Register provide for independent current programming for the LED currents

in either LED1 or LED2. (See Torch Brightness Register and Flash Brightness Register descriptions.)

8.3.4 Hardware Torch

With Configuration Register 1 Bit [7] = 1, TX1/TORCH is configured as a hardware-torch-mode enable. In this

mode (TORCH mode), a high at TX1/TORCH turns on the LED current at the programmed torch current setting.

The STROBE input and I2C-enabled flash takes precedence over torch mode. In hardware-torch mode, both

LED1 and LED2 current sources turn off after a flash event ,and Configuration Register 1 Bit [7] is reset to 0. In

this situation, to re-enter torch mode via hardware torch, the hardware-torch enable bit (Configuration Register 1

Bit [7]) must be reset to 1. Figure 26 details the functionality of the TX1/TORCH/GPIO1 input.

8.3.5 Fault Protections

8.3.5.1 Overvoltage Protection

The output voltage is limited to typically 5 V (5.075 V maximum). In situations such as the current source open,

the LM3559 raises the output voltage in order to keep the LED current at its target value. When VOUT reaches 5

V the overvoltage comparator trips and turns off both the internal NFET and PFET switches. When VOUT falls

below 4.88 V (typical), the LM3559 begins switching again.

8.3.5.2 Current Limit

The LM3559 features 4 selectable current limits: 1.4 A, 2.1 A, 2.7 A, and 3.2 A. These are programmable

through the I2C-compatible interface via bits [6:5] of the Flash Duration Register. When the current limit is

reached, the LM3559 stops switching for the remainder of the switching cycle.

Since the current limit is sensed in the NMOS switch there is no mechanism to limit the current when the device

operates in pass mode. In situations where there could potentially be large load currents at OUT and the LM3559

is operating in pass mode, the load current must be limited to 3 A. In boost mode or pass mode, if VOUT falls

below approximately 2.3 V the part stops switching, and the PFET operates as a current source, limiting the

current to typically 350 mA. This prevents damage to the LM3559 and prevents excessive current draw from the

battery during output short-circuit conditions.

8.3.5.3 Flash Timeout

The flash-timeout period sets the amount of time that the flash current is being sourced from current sources

LED1 and LED2. Bits [4:0] of the Flash Duration Register set the flash-timeout period. There are 32 different

flash-timeout durations in steps of 32 ms giving a flash timeout range of 32 ms to 1024 ms (see Table 5).

8.3.5.4 Indicator LED/Thermistor (LEDI/NTC)

The LEDI/NTC pin serves a dual function, either as a programmable LED message indicator driver, or as a

comparator input for negative temperature coefficient (NTC) thermistors.

8.3.5.4.1 Message Indicator Current Source (LEDI/NTC)

LEDI/NTC is configured as a message indicator current source by setting Configuration Register 1 bit [4] = 0.

The indicator current source is enabled/disabled via Enable Register bit [6]. Enable Register bit [7] programs the

message indictor for blinking mode. When the message indicator is set for blinking mode the pattern

programmed into the Indicator Register and Indicator Blinking Register is sent to the message indicator current

source.

The Indicator Blinking Register controls the following (see Table 17):

1. Number of blank periods (BLANK#. This has 16 settings. tBLANK = tACTIVE × BLANK# , where tACTIVE = tPERIOD

× PERIOD#

2. Pulse width (tPULSE) has 16 settings between 0 and 480 ms in steps of 32 ms. The pulse width is the duration

which the indicator current is at its programmed set point at the end of the ramp-up time.

14

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

Feature Description (continued)

The Indicator Register controls the following (see Table 16):

1. Indicator current level (IIND). There are 8 message indicator current levels from 2.25 mA to 18 mA in steps of

2.25 mA.

2. Number of periods (PERIOD#). This has 8 steps. A period (tPERIOD) is found by (tPERIOD = tR + tF + 2 × tPULSE).

(See Figure 27 for indicator timing).

3. Ramp times (tR or tF) for turnon and turnoff of the indicator current source. Four programmable times of 78

ms, 156 ms, 312 ms, and 624 ms are available. The ramp times apply for both ramp-up and ramp-down and

are not independently changeable.

tPERIOD

tBLANK

tPERIOD

tPULSE

tPULSE

IIND

tR

tF

tPULSE

tR

tF

tPULSE

Figure 27. Message Indicator Timing Diagram

8.3.5.4.1.1 Message Indicator Example 1 (Single Pulse With Dead Time):

As an example, to set up the message indicator for a 312-ms ramp-up and ramp-down, 192 ms pulse width, and

1 pulse followed by a 5-s delay. The indicator settings will be as follows. tR = tF = 312 ms, tWIDTH = 192 ms

(tPERIOD = 312 ms × 2 + 192 ms × 2 = 1016 ms). BLANK# setting will be: 5 s / 1016 ms × 1 (PERIOD# = 1).

Giving a BLANK# setting of 5. The resulting waveform appears as shown in Figure 28.

tPERIOD

tBLANK

(1.016s)

(5.08s)

Figure 28. Message Indicator Example 1

8.3.5.4.1.2 Message Indicator Example 2 (Multiple Pulses With Dead Time):

Another example has the same tR, tF, tPULSE, and tBLANK times as before, but this time the PERIOD# is set to 3.

Now the tACTIVE time is tPERIOD × 3 = 1016 ms × 3 = 3048 ms. This results in a blank time of tBLANK = tACTIVE ×

BLANK# = 3.048 s × 5 = 15.24 s (see Figure 29).

tACTIVE

(3.048s)

tPERIOD

(1.016s)

tPERIOD

tPERIOD

(1.016s)

(1.016s)

tBLANK

(15.24s)

Figure 29. Message Indicator Example 2

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

15

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Feature Description (continued)

8.3.5.4.1.3 Updating The Message Indicator

The best way to update the message indicator is to disable the message indicator output via the Enable Register

bit [7], write the new sequence to the Indicator Register and/or Indicator Blinking Register, and then re-enable the

message indicator. Updating the Indicator Registers on the fly can lead to long delays between pattern changes.

This is especially true if the PERIOD# or BLANK# setting is changed from a high setting to a lower setting.

8.3.6 Input Voltage (VIN ) Monitor

The LM3559 has an internal comparator at IN that monitors the input voltage and can force the LED current into

torch mode or into shutdown, if VIN falls below the programmable VIN monitor threshold. Bit 0 in the VIN Monitor

Register enables or disables this feature. Bits [2:1] of the VIN Monitor Register program the 4 adjustable

thresholds of 2.9 V, 3 V, 3.1 V, and 3.2 V. Bit 3 in Configuration Register 2 selects whether an undervoltage

event forces torch mode or forces the LEDs off. See Table 13 for additional information. When the VIN monitor is

active and VIN falls below the programmed VIN Monitor threshold, the active current sources (LED1 and/or

LED2) either turns off or is forced into the torch current setting. To reset the LED current to its previous level, VIN

must go above the VIN monitor threshold and the Flags Register must be read back. See Figure 30 for the VIN

monitor timing waveform.

To avoid noise from falsely triggering the VIN monitor, this mode incorporates a 250 µs deglitch timer. With the

VIN monitor active, VIN must go below the VIN monitor threshold (VIN_TH) and remain below it for 250 µs before

the LEDs are forced into torch mode (or shut down) and the VIN monitor flag is written.

Deglitch Time

(250 Ps)

Flash Timeout

IFLASH

LED

Current

ITORCH

Input

Voltage

VIN_MON_TH

STROBE

Figure 30. VIN Monitor Waveform

8.3.7 VIN Flash Monitor (Flash Current Rising)

A second comparator at IN is available to monitor the input voltage during the flash current turnon. Bit [3] of the

VIN Monitor Register enables/disables this feature. With this bit set to 1 the VIN flash monitor is active. Bits [5:4]

of the VIN Monitor Register program the 4 selectable thresholds of (2.9 V, 3 V, 3.1 V, and 3.2 V). The feature

operates as follows: during flash current turnon the active current sources (LED1 and/or LED2) transition through

each of the lower flash and torch current levels until the target flash current is reached. With the VIN flash monitor

active, if the input voltage falls below the VIN flash monitor threshold during the flash current turnon,the flash

current is set to the level that the current ramp had risen to at the time of the undervoltage event. The VIN flash

monitor only operates during the ramping up of the flash LED current.

The VIN flash monitor ignores the first 2 flash codes during the flash pulse turnon. As a result, if the VIN flash

monitor is enabled, and VIN were to fall below the VIN flash threshold as the LED current ramps up through either

of the first two levels, then the flash pulse would not be halted until code #3 (168.75-mA per current source).

16

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

Feature Description (continued)

To avoid noise from falsely triggering the VIN flash monitor, this mode incorporates an 8-µs deglitch timer as well

as an internal analog filter at the input of the VIN flash monitor comparator. With the VIN flash monitor active, VIN

must go below the VIN flash monitor threshold (VIN_FLASH) and remain below it for 8 µs before the flash current

ramp is halted and the VIN flash monitor flag is written.

8.3.8 Last Flash Register

Once the VIN flash monitor is tripped, the flash code that corresponded to the LED current at which the flash

current ramp was halted is written to the Last Flash Register. The Last Flash Register is a read-only register; the

lower 4 bits are available to latch the code for LED1 and the upper 4 bits to latch the code for LED2.

For example, suppose that the LM3559 device is set up for a single LED with a target flash current of 1125 mA.

The VIN flash monitor is enabled with the VIN flash monitor threshold set to 3. V (VIN Monitor Register bits [5:4] =

0, 1). When the STROBE input is brought high, the LED current begins ramping up through the torch and flash

codes at 32 µs per code. As the input current increases, the input voltage at the device IN pin begins to fall due

to the source impedance of the battery. By the time the LED current has reached 900 mA (code 0x77 or 450 mA

per current source), VIN falls below 3 V. The VIN flash monitor then stops the flash current ramp and the device

continues to proceed with the flash pulse, but at 900 mA instead of 1125 mA. Figure 31 details this sequence.

Flash Current Target = 1125 mA

Flash Current Limited to 900 mA

LED Current

0

32 Ps

VIN

VIN Flash

Monitor

Threshold

Figure 31. VIN Flash Monitor Example

8.3.9 LED Voltage Monitor

The LM3559 includes a 4-bit ADC which monitors the LED forward voltage (VLED) and stores the digitized value

in bits [3:0] of the VLED Monitor Register. The highest voltage of VLED1 or VLED2 is automatically sensed and

that becomes the sample point for the ADC. Bit 5, the ADC shutdown bit, enables or disables the ADC with the

default state set to enable (bit [5] = 0).

8.3.10 ADC Delay

The ADC Delay Register provides for a programmable delay from 250 µs to 8 ms, in steps of 250 µs. This delay

is the delay from when the EOC bit goes low to when the VLED monitor samples the LED voltage. In automatic

mode the EOC bit goes low when the Flash LED current hits its target. In manual mode the EOC bit goes low at

the end of a readback of the VLED Monitor Register (or when the manual mode bit (bit 4) is re-written with a 1).

Figure 32 and Figure 33 detail the timing of the VLED Monitor for both automatic mode and manual mode.

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

17

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Feature Description (continued)

tCONV = 16 Ps

EOC Bit

is set to 0

tDELAY

LED Voltage

(The higher of

VLED1 or VLED2)

EOC Bit

is set to 1

(Data Valid)

STROBE

(Level/Edge Bit set

to Level)

Figure 32. VLED Monitor Automatic Mode

EOC Bit

is set to 1

(Data Valid)

EOC Bit

is set to 0

tDELAY

tDELAY

tCONV = 16 Ps

I2C WRITE ACK

EOC Bit

is set to 1

(Data Valid)

EOC Bit

is set to 0

I2C READ

ACK

tCONV = 16 Ps

LED Voltage

(The higher of

VLED1 or VLED2)

Figure 33. VLED Monitor Manual Mode

8.3.11 Flags Register and Fault Indicators

Eight fault flags are available in the LM3559. These include: a flash timeout, a thermal shutdown, an LED failure

flag (LEDF), an LED thermal flag (NTC), a VIN monitor flag, and a VIN flash monitor flag. Additionally, two LED

interrupt flag bits (TX1 interrupt and TX2 interrupt) are set when the corresponding interrupt is activated. Reading

back a 1 indicates the flagged event has happened. A read of the Flags Register resets these bits.

8.3.11.1 Flash Timeout

The timeout (or TO flag, (bit [0] of the Flags Register), reads back a 1 if the LM3559 is active in flash mode and

the timeout period expires before the flash pulse is terminated. The flash pulse can be terminated before the

timeout period expires by pulling the STROBE pin low (with Enable Register bit [5] = 0), or by writing a (0,0) to

bits [1:0] of the Enable Register. The TO flag is reset to 0 by pulling HWEN low, removing power to the LM3559

device, reading the Flags Register, or when the next flash pulse is triggered.

18

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

Feature Description (continued)

8.3.11.2 Thermal Shutdown

When the die temperature of the LM3559 device reaches 150°C, the boost converter shuts down, and the NFET

and PFET turn off. Additionally, the active current source (LED1 and/or LED2) turn off. When the thermal

shutdown threshold is tripped a 1 is written to bit [1] of the Flags Register (thermal shutdown bit). The device

does not start up again until the die temperature falls to below 135°C and the Flags Register is read back, or

when the device is shut down and started up again.

8.3.11.3 LED Fault

The LED Fault flag (bit 2 of the Flags Register) reads back a 1 if the part is active in either flash or torch mode

and either LED1 or LED2 experience an open or short condition. An LED open condition is signaled if the OVP

threshold is crossed at the OUT pin while the device is in either flash or torch mode. An LED short condition is

signaled if the voltage at LED1 or LED2 goes below 500 mV while the device is in torch or flash mode. In an LED

open condition there is a 2-µs deglitch time from when the output voltage crosses the OVP threshold to when the

LED fault flag is triggered. In an LED short condition there is a 250-µs deglitch time before the LED fault flag is

set. The LED fault flag can only be reset to 0 by pulling HWEN low, doing a power-on reset of the LM3559, or by

removing the fault condition and reading back the Flags Register.

8.3.11.4 TX1 and TX2 Interrupt Flags

The TX1 and TX2 interrupt flags (bits [3] and [4]) indicate an interrupt event has occurred on the respective TX

inputs. Bit 3 reads back a 1 if TX1 is in TX mode and there has been a TX1 event since the last read of the Flags

Register. Bit 4 read back a 1 if TX2 is in TX mode and there has been a TX2 event since the last read of the

Flags Register. A read of the Flags Register automatically resets these bits. A TX event on TX1 or TX2 can be a

high-to-low transition or a low-to-high transition depending on the setting of the TX1 and TX2 polarity bits (see

Configuration Register 1 Bits [6:5]).

8.3.11.5 LED Thermal Fault (NTC Flag)

The NTC flag (bit [5] of the Flags Register) reads back a 1 if the LM3559 is active in flash or torch mode, the

device is in NTC mode, and the voltage at LEDI/NTC has fallen below VTRIP (1 V typical). When this has

happened and the LM3559 has been forced into torch mode or LED shutdown (depending on the state of

Configuration Register 2 bit [1), the Flags Register must be read, and the voltage at NTC must go above 1 V in

order to place the device back in normal operation. (See NTC Mode for more details.)

8.3.11.6 Input Voltage Monitor Fault

The VIN monitor flag (bit [7] of the Flags Register) reads back a 1 when the Input Voltage Monitor is enabled and

VIN falls below the programmed VIN monitor threshold. This flag must be read back and VIN must go above the

VIN monitor threshold in order to resume normal operation.

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

19

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

8.4 Device Functional Modes

8.4.1 Start-Up (Enabling the Device)

Turnon of the LM3559 is done through bits [1:0] of the Enable Register. Bits [1:0] enable the device in torch

mode, flash mode, or privacy Indicate mode. Additionally, bit 6 enables the message indicator at the LEDI/NTC

pin. On start-up, when VOUT is less than VIN, the internal synchronous PFET turns on as a current source and

delivers 350 mA to the output capacitor. During this time both current sources (LED1, and LED2) are off. When

the voltage across the output capacitor reaches 2.2 V the active current sources can turn on. At turnon the

current sources step through each flash and torch level until their target LED current is reached (32 µs/step).

This gives the device a controlled turnon and limits inrush current from the VIN supply.

8.4.2 Pass Mode

At turnon, when the output voltage charges up to (VIN – 150 mV), the device operates in either pass mode or

boost mode, depending upon the voltage difference between VOUT and VLED. If the voltage difference between

VOUT and VLED is less than 270 mV, the device operates in boost mode. If the difference between VOUT and VLED

is greater than 270 mV, the device operates in pass mode. In pass mode the boost converter stops switching,

and the synchronous PFET turns fully on, bringing VOUT up to VIN – IIN × RPMOS (RPMOS = 80 mΩ). In pass mode

the inductor current is not limited by the peak current limit. In this situation the output current must be limited to

3 A.

8.4.3 Flash Mode

In flash mode the LED current sources (LED1 and LED2) each provide 16 different current levels from typically

56.25 mA (total) to 1.8 A (total) in steps of 56.25 mA. The flash currents are adjusted via the Flash Brightness

Register. Flash mode is activated by writing a 1, 1 to bits [1:0] of the Enable Register or by enabling the

hardware flash input (STROBE) via bit [2] of Configuration Register 1 and then pulling the STROBE pin high

(high polarity). Once the flash sequence is activated both current sinks (LED1 and LED2) ramp up to their

programmed flash current level by stepping through all torch and flash levels (32 µs/step) until the programmed

current is reached.

Bit [5] of the Enable Register (STROBE Level/Edge bit) determines how the flash pulse terminates. With the

Level/Edge bit = 1 the flash current only terminates when it reaches the end of the flash timeout period. With the

level/edge bit = 0, flash mode can be terminated by pulling STROBE low, programming bits [1:0] of the Enable

Register with 0,0, or by allowing the flash timeout period to elapse. If the level/edge bit = 0 and STROBE is

toggled before the end of the flash timeout period the timeout period resets. Figure 34 and Figure 35 detail the

flash pulse termination for the different level/edge bit settings.

Timeout Duration

32 Ps

LED Current

STROBE

(Level/Edge Bit

set to Level)

Figure 34. LED Current for Strobe (Level Triggered, Enable Register Bit [5] = 0)

Strobe Goes Low Before the End of the Programmed Timeout Duration

20

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

Device Functional Modes (continued)

Timeout Duration

32 Ps

LED

Current

STROBE

(Level/Edge Bit

Set to Edge)

Figure 35. LED Current for Strobe (Edge Triggered, Enable Register Bit [5] = 1)

After the flash pulse terminates; either by a flash timeout, pulling STROBE low or disabling it via the I2Ccompatible interface, LED1 and LED2 turn completely off. This happens even when torch is enabled via the I2Ccompatible interface, and the flash pulse is turned on by toggling STROBE. After a flash event ends, the EN1,

EN0 bits (bits [1:0] of the Enable Register) are automatically reset with 0, 0. The exception occurs when the

privacy terminate bit is low (bit [3]) in the Privacy Register. In this case, the specific current source that is

enabled for privacy mode turns back on after the flash pulse if privacy mode had been enabled before the flash

pulse.

8.4.4 Torch Mode

In torch mode the current sources LED1 and LED2 each provide 8 different current levels (Table 3). Torch mode

is activated by setting Enable Register bits [1:0] to (1, 0). Once torch mode is enabled, the current sources ramp

up to the programmed torch current level by stepping through all of the torch currents at (32 µs/step) until the

programmed torch current level is reached.

8.4.5 Privacy-Indicate Mode

The current sources (LED1 and/or LED2) can also be used as a privacy indicator before and after flash mode.

Privacy-indicate mode is enabled by setting the Enable Register bit [1:0] to (0,1). Additionally, the Privacy

Register contains the bits to select which current source to use as the privacy indicator (either LED1, LED2, or

both), whether or not the privacy-indicate mode turns off at the end of the flash pulse, and contains the 8

intensity levels for the privacy indicator.

The intensity of the LEDs in privacy indicate mode is set by PWM’ing the lowest torch current level (28.125 mA).

Bits [2:0] of the Privacy Register allow for 8 different duty cycles of 10%, 20%, 30%, 40%, 50%, 60%, 70%, and

80%. See Table 14 for Privacy Register bit settings. Figure 36 details the timing for the privacy-indicate mode on

ILED1 or ILED2.

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

21

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Device Functional Modes (continued)

tBLINK

Duty

Cycle

tPWM

ITORCH_MIN

tBLINK set via bits [7:6] of Privacy Register

Duty cycle set via bits [2:0] of Privacy Register

tPWM set via bits[2:0] of the Privacy PWM Register

Figure 36. Privacy Indicate Timing

8.4.6 GPIO1 Mode

With bit [0] of the GPIO Register set to 1, the TX1/TORCH/GPIO1 pin is configured as a logic I/O. In this mode

the TX1/TORCH/GPIO1 pin is readable and writable as a logic input/output via bits [2:1] of the GPIO Register.

See Table 9.

8.4.7 TX2/INT/GPIO2

The TX2/INT/GPIO2 pin has a triple function. In TX2 mode (default) the TX2/INT/GPIO2 pin is an active high

flash interrupt. With GPIO Register bit [3] = 1 the TX2/INT/GPIO2 pin is configured as general purpose logic I/O.

With GPIO Register bit [6] = 1, and with the TX2/INT/GPIO2 pin configured as a GPIO2 output, the

TX2/INT/GPIO2 pin is an interrupt output.

8.4.8 TX2 Mode

In TX2 mode, when Configuration Register 1, bit [6] = 0, the TX2/INT/GPIO2 pin has active low polarity. Under

this condition when the LM3559 is engaged in a flash event and TX2 is pulled low, both LED1 and LED2 are

forced into torch mode. In TX2 mode with Configuration Register 1, bit [6] = 1 the TX2/INT/GPIO2 input has

active high polarity. Under this condition when the LM3559 is engaged in a flash event and the TX2/INT/GPIO2

pin is driven high, both LED1 and LED2 are forced into torch mode. During a flash interrupt event if the

TX2/INT/GPIO2 input is disengaged the LED current returns to the previous flash current level. During a flash

event, if TX2 is active, the LED current sources still turn off after the flash timeout. Figure 25 details the

functionality of the TX2 Interrupt.

22

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

Device Functional Modes (continued)

8.4.8.1 TX2 Shutdown

TX2 also has the capability to force shutdown. Bit [0] of Configuration Register 2 set to a 1 changes the TX2

mode from a force torch when active to a force shutdown when active. For example, if TX2/INT/GPIO2 is

configured for TX2 mode with active high polarity, and bit [0] of Configuration Register 2 is set to 1 then when

TX2 is driven high, the active current sources (LED1 and/or LED2) are forced into shutdown. Once the active

current sources are forced into shutdown by activating TX2, the current sources can only be re-enabled if TX2 is

deactivated, and the Flags Register is read back.

8.4.9 GPIO2 Mode

With Bit [3] of the GPIO Register set to 1, the TX2/INT/GPIO2 pin is configured as a logic I/O. In this mode the

TX2/INT/GPIO2 pin is readable and writeable as a logic input/output via bits [5:4] of the GPIO Register. See

Table 9.

8.4.10 Interrupt Output (INT Mode)

The TX2/INT/GPIO2 pin can be reconfigured as an active low interrupt output by setting bit [6] in the GPIO

Register to 1 and configuring TX2/INT/GPIO2 as a GPIO2 output. In this mode, TX2/INT/GPIO2 pulls low when

any of these conditions exist.

1. The LM3559 is configured for NTC mode (Configuration Register 1 bit [4] = 1) and the voltage at LEDI/NTC

has fallen below VTRIP (1 V typical).

2. The LM3559 is configured for VIN monitor mode (VIN Monitor Register bit [0] = 1) and VIN is below the

programmed VIN Monitor Threshold.

3. The LM3559 is configured for VIN flash monitor mode (VIN Monitor Register bit [3] = 1) and VIN falls below

the programmed VIN flash monitor threshold. Figure 37 shows the functionality of the TX2/INT/GPIO2 input.

Once INT is pulled low due to any of the above conditions having been met, INT only goes back high again if any

of the conditions are no longer true and the Flags Register is read.

250 Ps

Deglitch Time

Flash Timeout

IFLASH

LED Current

ITORCH

STROBE

TX2

(Interrupt Output)

LEDI/NTC

(Comparator Input)

VLEDI/NTC

(1V Typical)

Figure 37. TX2 as an Interrupt Output (During an NTC Event)

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

23

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Device Functional Modes (continued)

8.4.11 NTC Mode

Writing a 1 to the Configuration Register 1 bit [4] configures the LEDI/NTC pin for NTC mode. In this mode the

indicator current source is disabled and LEDI/NTC becomes the positive input to the NTC comparator. NTC

mode operates as a LED current interrupt that is triggered when the voltage at LEDI/NTC goes below 1 V.

Two actions can be taken when the NTC comparator is tripped. With Configuration Register 2 bit [1] set to 0 the

NTC interrupt forces the LED current from flash mode into torch mode. With Configuration Register 2 bit [1] set to

1 the NTC interrupt forces the LED current into shutdown.

Whether in NTC force torch or NTC shutdown, in order to re-enter flash mode or torch mode after an NTC event,

two things must occur. First, the NTC input must be above the 1-V threshold. Secondly, the Flags Register must

be read.

To avoid noise from falsely triggering the NTC comparator, this mode incorporates a 250-µs deglitch timer. With

NTC mode active, VLEDI/NTC must go below the trip point (VTRIP), and remain below it, for 250 µs before the LEDs

are forced into torch mode (or shut down) and the NTC flag is written.

8.4.12 Alternate External Torch (AET Mode)

Configuration Register 2 bit [2] programs the LM3559 for AET mode. With this bit set to 0 (default) TX1/TORCH

is a flash current interrupt that forces torch mode only during a flash event. For example, if TX1/TORCH goes

high while the LED current is in flash mode, the LEDs are forced into torch mode only for the duration of the

timeout counter. At the end of the timeout counter the LEDs turn off.

With the Configuration Register 2 bit [2] set to 1 the LM3559 is configured for AET mode and the operation of

TX1/TORCH becomes dependent on its occurrence relative to the STROBE input. In this mode, if TX1/TORCH

goes high first, then STROBE goes high next, the LEDs are forced into Torch mode with no timeout. In this

mode, if TX1/TORCH goes high after STROBE has gone high, then the TX1/TORCH pin operates as a normal

LED current interrupt and the LEDs turn off at the end of the timeout duration (see Figure 38.

Timeout Duration

IFLASH

LED Current

ITORCH

TX1/TORCH

STROBE

Figure 38. AET Mode Timing

8.4.13 Automatic Conversion Mode

With the ADC enabled, a conversion is performed each time a flash pulse is started. When a flash pulse is

started bit [6] of the VLED Monitor Register (end-of-conversion bit) is automatically written with a 0. At the end of

the conversion, bit [6] goes high signaling that the VLED data is valid. A read back of the VLED Monitor Register

clears the EOC bit. Figure 32 shows the VLED monitor automatic conversion.

24

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

Device Functional Modes (continued)

8.4.14 Manual Conversion Mode

The VLED monitor can be set up for manual conversion mode by setting bit [4] of the VLED Monitor Register to 1.

When this bit is set high the EOC bit (bit [6]) goes low, and a conversion is performed. When the conversion is

complete, the EOC bit goes high again. Subsequent conversions are performed in manual mode by reading back

the VLED Monitor Register, which resets the EOC bit and starts another conversion (see Figure 33).

8.5 Programming

8.5.1 I2C-Compatible Interface

8.5.1.1 START and STOP Conditions

The LM3559 is controlled via an I2C-compatible interface. START and STOP conditions classify the beginning

and end of the I2C session. A START condition is defined as SDA transitioning from HIGH to LOW while SCL is

HIGH. A STOP condition is defined as SDA transitioning from LOW to HIGH while SCL is HIGH. The I2C master

always generates the START and STOP conditions.

SDA

SCL

S

P

Start Condition

Stop Condition

Figure 39. START and STOP Sequences

The I2C bus is considered busy after a START condition and free after a STOP condition. During data

transmission the I2C master can generate repeated START conditions. A START and a repeated START

condition are equivalent function-wise. The data on SDA must be stable during the HIGH period of the clock

signal (SCL). In other words, the state of SDA can only be changed when SCL is LOW. Figure 40 shows the

SDA and SCL signal timing for the I2C-Compatible bus. See the Electrical Characteristics for timing values.

t1

SCL

t5

t4

SDA_IN

t2

SDA_OUT

t3

Figure 40. I2C-Compatible Timing

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

25

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

Programming (continued)

8.5.1.2 I2C-Compatible Chip Address

The device address for the LM3559 is 1010011 (0xA7 for read and 0xA6 for write). After the START condition,

the I2C master sends the 7-bit address followed by an eighth read or write bit (R/W). R/W = 0 indicates a WRITE

and R/W = 1 indicates a READ. The second byte following the device address selects the register address to

which the data will be written. The third byte contains the data for the selected register.

MSB

1

Bit 7

LSB

0

Bit 6

1

Bit 5

0

Bit 4

0

Bit 3

1

Bit 2

1

Bit 1

R/W

Bit 0

2

I C Slave Address (chip address)

Figure 41. Device Address

8.5.1.3 Transferring Data

Every byte on the SDA line must be eight bits long, with the most significant bit (MSB) transferred first. Each byte

of data must be followed by an acknowledge bit (ACK). The acknowledge related clock pulse (9th clock pulse) is

generated by the master. The master releases SDA (HIGH) during the 9th clock pulse (write mode). The LM3559

pulls down SDA during the 9th clock pulse, signifying an acknowledge. An acknowledge is generated after each

byte has been received.

26

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

8.6 Register Maps

Table 1. LM3559 Internal Registers

INTERNAL HEX ADDRESS

POWER-ON/RESET VALUE

Enable

REGISTER NAME

0x10

0x18

Privacy

0x11

0x58

Indicator

0x12

0x00

Indicator Blinking

0x13

0x00

Privacy PWM

0x14

0xF0

GPIO

0x20

0x80

VLED Monitor (ADC)

0x30

0x80

ADC Delay

0x31

0xC0

VIN Monitor

0x80

0xC0

Last Flash

0x81

0x00

Torch Brightness

0xA0

0x52

Flash Brightness

0xB0

0xDD

Flash Duration

0xC0

0x6F

Flags

0xD0

0x00

Configuration 1

0xE0

0x68

Configuration 2

0xF0

0xF0

Submit Documentation Feedback

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

27

�LM3559

SNVS624B – JUNE 2011 – REVISED JUNE 2016

www.ti.com

8.6.1 Enable Register

Bits [1:0] of the Enable Register controls the ON/OFF state of torch mode, flash mode, and privacy-indicate

mode. Bits [4:3] turn on/off the main current sources (LED1 and LED2). Bit [5] sets the level or edge control for

the STROBE input. Bits 7 and 6 control the indicator current source (see Table 2).

Table 2. Enable Register Descriptions

Bit 7

(EN Blink)

0 = Message

indicator

blinking

function is

disabled (1)

(default)

1 = message

indicator

blinking

function is

enabled. The

message

indicator blinks

the pattern

programmed in

the Indicator

Register and

Indicator

Blinking

Register

(1)

Bit 6

(EN Message

Indicator)

0 = Message

Indicator is

disabled

(default)

1= Message

Indicator is

enabled.

Bit 5

(STROBE

Level/Edge)

Bit 4

(LED2

Enable)

0 = (Level Sensitive)

0 = LED2 off

When STROBE goes

1 = LED2 on

high, the flash current

(default)

will turn on and remain

on for the duration the

STROBE pin is held high

or until the flash timeout

occurs, whichever

comes first. (default)

1 = (Edge Triggered)

When STROBE goes

high , the flash current

will turn on and remain

on for the duration of the

Flash timeout.

Bit 3

(LED1

Enable)

0 = LED1 off

1 = LED1 on

(default)

Bit 2

(Not Used)

N/A

Bit 1

(EN1)

Bit 0

(EN0)

Enable Bits

00 = Current sources are

shut down (default)

01 = Privacy-indicate mode

10 = Torch mode

11 = Flash mode (bits reset

at timeout)

Bit 7 enables or disables the message indicator blinking function. With this bit set to 0 and Bit 6 set to 1, the message indicator turns on

constantly at the programmed current as set in the Indicator Register, bits [2:0].

8.6.2 Torch Brightness Register

Bits [2:0] of the Torch Brightness Register set the Torch current for LED1. Bits [5:3] set the torch current for

LED2. (see Table 3).

Table 3. Torch Brightness Register Descriptions

Bit 7

(N/A)

(Not Used)

28

Bit 6

(N/A)

Bit 5

(TC2A)

Bit 4

(TC2B)

Bit 3

(TC2C)

LED2 Torch Current Select Bits

000 = 28.125 mA (56.25 mA total)

001 = 56.25 mA (112.5 mA total)

010 = 84.375 mA (168.75 mA total) default

011 = 112.5 mA (225 mA total)

100 = 140.625 mA (281.25 mA total)

101 = 168.75 mA (337.5 mA total)

110 = 196.875 mA (393.75 mA total)

111 = 225 mA (450 mA total)

Submit Documentation Feedback

Bit 2

(TC1A)

Bit 1

(TC1B)

Bit 0

(TC1C)

LED1 Torch Current Select Bits

000 = 28.125 mA (56.25 mA total)

001 = 56.25 mA (112.5 mA total)

010 = 84.375 mA (168.75 mA total) default

011 = 112.5 mA (225 mA total)

100 = 140.625 mA (281.25 mA total)

101 = 168.75 mA (337.5 mA total)

110 = 196.875 mA (393.75 mA total)

111 = 225 mA (450 mA total)

Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: LM3559

�LM3559

www.ti.com

SNVS624B – JUNE 2011 – REVISED JUNE 2016

8.6.3 Flash Brightness Register

Bits [3:0] of the Flash Brightness Register set the Flash current for LED1. Bits [7:4] set the Flash current for

LED2. (see Table 4).

Table 4. Flash Brightness Register Descriptions

Bit 7

(FC2A)

Bit 6

(FC2B)

Bit 5

(FC2C )

Bit 4

(FC2D)

LED2 Flash Current Select Bits

0000 = 56.25 mA (112.5 mA total)

0001 = 112.5 mA (225 mA total)

0010 = 168.75 mA (337.5 mA total)

0011 = 225 mA (450 mA total)

0100 = 281.25 mA (562.5 mA total)

0101 = 337.5 mA (675 mA total)

0110 = 393.75 mA (787.5 mA total)

0111 = 450 mA (900 mA total)

1000 = 506.25 mA (1012.5 mA total)

1001 = 562.5 mA (1125 mA total)

1010 = 618.75 mA (1237.5 mA total)

1011 = 675 mA (1350 mA total)

1100 = 731.25 mA (1562.5 mA total)

1101 = 787.5 mA (1575 mA total) Default

1110 = 843.75 mA (1687.5 mA total)

1111 = 900 mA (1800 mA total)

Bit 3

(FC1A )

Bit 2

(FC1B)

Bit 1

(FC1C)

Bit 0

(FC1D)

LED1 Flash Current Select Bits

0000 = 56.25 mA (112.5 mA total)

0001 = 112.5 mA (225 mA total)

0010 = 168.75 mA (337.5 mA total)

0011 = 225 mA (450 mA total)

0100 = 281.25 mA (562.5 mA total)

0101 = 337.5 mA (675 mA total)

0110 = 393.75 mA (787.5 mA total)

0111 = 450 mA (900 mA total)

1000 = 506.25 mA (1012.5 mA total)

1001 = 562.5 mA (1125 mA total)

1010 = 618.75 mA (1237.5 mA total)

1011 = 675 mA (1350 mA total)

1100 = 731.25 mA (1562.5 mA total)

1101 = 787.5 mA (1575 mA total) Default

1110 = 843.75 mA (1687.5 mA total)

1111 = 900 mA (1800 mA total)

8.6.4 Flash Duration Register

Bits [4:0] of the Flash Duration Register set the flash timeout duration. Bits [6:5] set the switch current limit (see

Table 5).

Table 5. Flash Duration Register Descriptions

Bit 7