LM5170

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

LM5170 Multiphase Bidirectional Current Controller

1 Features

2 Applications

•

•

•

•

•

•

•

•

•

Functional Safety-Capable

– Documentation available to aid functional safety

system design

Suited for high power industrial dual battery

system

– 100-V HV-port and 65-V LV-port max ratings

– 1% Accurate bidirectional current regulation

– 1% Accurate channel current monitoring

– 5-A Peak half-bridge gate drivers

– Support multi-phase operation with stackability

– Diode emulation prevents negative current

Programmability and flexibility

– Programmable or adaptive dead-time control

– Programmable oscillator frequency with

optional synchronization to external clock

– Dual channel enable control inputs

– Analog and PWM current controls

– Programmable peak current limit

– Programmable soft-start timer

– Phase adding or dropping using EN2

Integrated protection features

– HV and LV port over-voltage protection

– MOSFET failure detect at start-up and circuit

breaker control

– Thermal shutdown

Battery tester

Bi-directional battery management system

Backup battery powered converters

Stackable buck or boost converters

Negative to positive voltage converter

3 Description

The LM5170 controller provides the essential high

voltage and precision elements of a dual-channel

bidirectional converter. It regulates the average

current flowing between the high voltage and low

voltage ports in the direction designated by the

DIR input signal. The current regulation level is

programmed through analog or digital PWM inputs.

Dual-channel differential current sense amplifiers and

dedicated channel current monitors achieve typical

current accuracy of 1%. Robust 5-A half-bridge

gate drivers are capable of driving parallel MOSFET

switches delivering 500 W or more per channel.

The diode emulation mode of the synchronous

rectifiers prevents negative currents but also enables

discontinuous mode operation for improved efficiency

with light loads. Versatile protection features include

cycle-by-cycle current limiting, overvoltage protection

at both HV and LV ports, MOSFET failure detection,

and overtemperature protection.

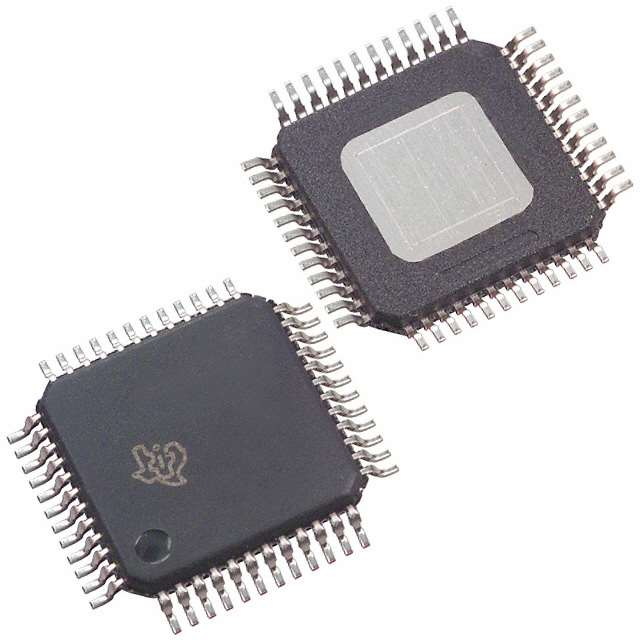

Device Information(1)

(1)

PART NUMBER

PACKAGE

BODY SIZE (NOM)

LM5170

TQFP (48)

7.00 mm × 7.00 mm

For all available packages, see the orderable addendum at

the end of the data sheet.

LV-Port

(12 V)

HV-Port

(48 V)

+10 V Bias

HO1 SW1 LO1

PGND

VCC

CSA1

VIN

CSB1

VINX

IOUT1

RAMP1

OVPA

IOUT2

IPK

OSC

RAMP2

SYNCOUT

AGND

ISETD

OVPB

SYNCIN

ISETA

DIR

EN1

CSB2

EN2

CSA2

HO2

SW2 LO2

GND

Simplified Application Circuit

Channel Current Tracking ISETA Command

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Description (continued).................................................. 2

6 Pin Configuration and Functions...................................3

7 Specifications.................................................................. 6

7.1 Absolute Maximum Ratings........................................ 6

7.2 ESD Ratings............................................................... 6

7.3 Recommended Operating Conditions.........................6

7.4 Thermal Information....................................................7

7.5 Electrical Characteristics.............................................7

7.6 Typical Characteristics.............................................. 11

8 Detailed Description......................................................14

8.1 Overview................................................................... 14

8.2 Functional Block Diagram......................................... 15

8.3 Feature Description...................................................16

8.4 Device Functional Modes..........................................32

8.5 Programming............................................................ 36

9 Application and Implementation.................................. 39

9.1 Application Information............................................. 39

9.2 Typical Application.................................................... 47

10 Power Supply Recommendations..............................59

11 Layout........................................................................... 60

11.1 Layout Guidelines................................................... 60

11.2 Layout Examples.....................................................61

12 Device and Documentation Support..........................64

12.1 Device Support....................................................... 64

12.2 Receiving Notification of Documentation Updates..64

12.3 Support Resources................................................. 64

12.4 Trademarks............................................................. 64

12.5 Electrostatic Discharge Caution..............................64

12.6 Glossary..................................................................64

13 Mechanical, Packaging, and Orderable

Information.................................................................... 64

4 Revision History

Changes from Revision A (June 2020) to Revision B (August 2021)

Page

• Updated the numbering format for tables, figures and cross-references throughout the document ..................1

Changes from Revision * (November 2019) to Revision A (June 2020)

Page

• Added functional safety bullet to the Section 1 ..................................................................................................1

5 Description (continued)

An innovative average current mode control scheme maintains constant loop gain, allowing a single R-C network

to compensate both buck and boost conversion. The oscillator is adjustable up to 500 kHz and can synchronize

to an external clock. Multiphase parallel operation is achieved by connecting two LM5170 controllers for 3or 4-phase operation, or by synchronizing multiple controllers to phase-shifted clocks for a higher number of

phases. A low state on the UVLO pin disables the LM5170 in a low current shutdown mode.

2

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

DT

OSC

AGND

ISETA

DIR

EN2

ISETD

SYNCOUT

SYNCIN

EN1

IOUT2

IOUT1

48

47

46

45

44

43

42

41

40

39

38

37

6 Pin Configuration and Functions

NC

7

30

IPK

RAMP2

8

29

OPT

OVPA

9

28

RAMP1

UVLO

10

27

nFAULT

COMP2

11

26

COMP1

SS

12

25

OVPB

24

VCCA

SW1

31

23

6

HB1

VIN

22

NC

HO1

32

21

5

NC

NC

20

BRKS

LO1

33

19

4

VCC

VINX

18

BRKG

PGND

34

17

3

LO2

NC

16

CSB1

NC

35

15

2

HO2

CSB2

14

CSA1

HB2

36

13

1

SW2

CSA2

Figure 6-1. 48-Pin TQFP, PHP Package (Top View)

Table 6-1. Pin Functions

PIN

I/O(1)

DESCRIPTION

CSA2

I

2

CSB2

I

CH-2 differential current sense inputs. The CSA2 pin connects to the CH-2 power inductor. The CSB2 pin

connects to the circuit breaker or directly to the LV-Port if the circuit breaker is not used. The CH-2 current sense

resistor is placed between these two pins.

3

NC

—

No connect

NO.

NAME

1

4

VINX

O

Internally connected to VIN the pin through a cutoff switch. When the controller is shut down, VINX is

disconnected from VIN, opening the current leakage path. When the controller is enabled, VINX is connected

to VIN and serves as the pullup supply for the RC ramp generators at the RAMP1 and RAMP2 pins. VINX also

pulls up the OVPA pin through an internal 3-MΩ resistor.

5

NC

—

No connect

6

VIN

I

7

NC

—

The input pin connecting to the HV-Port line voltage. It supplies the BRKG pin through an internal 330-µA

current source.

No connect

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

3

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

Table 6-1. Pin Functions (continued)

PIN

DESCRIPTION

NAME

8

RAMP2

I

The inverting input of the CH-2 PWM comparator. An external RC circuit tied between VINX, RAMP2, and

AGND forms the ramp generator, producing a ramp signal proportional to the HV-Port voltage, thus achieving

a voltage feedforward function. The RAMP2 capacitor voltage is reset to AGND at the end of every switching

cycle.

9

OVPA

I

Connected to the non-inverting input of the HV-Port overvoltage comparator. An internal 3-MΩ pullup resistor

and an external resistor across the OVPA and AGND pins form a divider that senses the HV-Port voltage. When

the OVPA pin voltage is above the 1.185-V threshold, the SS capacitor is discharged and held low until the

overvoltage condition is removed.

10

ULVO

I

The UVLO pin serves as the master enable pin. When UVLO is pulled below 1.25 V, the entire LM5170 is in a

low quiescent current shutdown mode. When UVLO is pulled above 1.25 V but below 2.5 V, the LM5170 enters

the initialization stage where the nFAULT pin is first pulled up to 5 V, while the rest of the LM5170 is kept in

the OFF state. When UVLO is pulled above the 2.5 V, the LM5170 enters a MOSFET failure detection stage. If

no failure is detected, the circuit breaker gate driver (BRKS and BRKG) turns on, and the LM5170 enables the

oscillator and RAMP generator, and stands by until the EN1 and EN2 commands enable the channel.

11

COMP2

O

The output of the CH-2 transconductance (gm) error amplifier and the non-inverting input of the CH-2 PWM

comparator. A loop compensation network must be connected to this pin.

12

SS

I

The soft-start programming pin. An external capacitor and an internal 25-μA current source set the ramp rate of

the COMP pins voltage during soft start. If CH-2 is enabled after CH-1 completes soft start, the CH-2 turnon is

not controlled by the SS pin.

13

SW2

I

CH-2 switch node. Connect to the CH-2 high-side MOSFET source, the low-side MOSFET drain, and the

bootstrap capacitor return terminal.

CH-2 high-side gate driver bootstrap supply input

14

HB2

P

15

HO2

I/O

CH-2 high-side gate driver output

16

NC

—

No connect

17

LO2

I/O

CH-2 low-side gate driver output

18

PGND

G

Power ground connection pin for the low-side gate drivers and external VCC bias supply

19

VCC

I/P

VCC bias supply pin, powering the drivers. An external bias supply between 9 V to 12 V must be applied across

the VCC and PGND pins.

20

LO1

I/O

CH-1 low-side gate driver output

21

NC

—

No connect

22

HO1

I/O

CH-1 high-side gate driver output

23

HB1

P

CH-1 high-side gate driver bootstrap supply input

24

SW1

I

CH-1 switch node. Connect to the CH-1 high-side MOSFET source, the low-side MOSFET drain, and the

bootstrap capacitor return terminal.

25

OVPB

I

Connected to the non-inverting input of the LV-Port overvoltage comparator. An internal 1-MΩ pullup resistor

and an external resistor across the OVPB and AGND pins form the divider that senses the LV-Port voltage.

When the converter operates in boost mode, the OVPB pin status is ignored. In buck mode, when the OVPB

pin voltage is above the 1.185-V threshold, the SS capacitor is discharged and held low until the overvoltage

condition is removed.

26

COMP1

O

Output of the CH-1 transconductance (gm) error amplifier and the non-inverting input of the CH-1 PWM

comparator. A loop compensation network must be connected to this pin.

I/O

Fault flag pin or external shutdown pin. When a MOSFET drain-to-source short circuit failure is detected before

start-up, the nFAULT pin is internally pulled low to report the short-circuit failure. The LM5170 remains in a

disabled state. The nFAULT pin can also be externally pulled low to shut down the LM5170, serving as a forced

shutdown pin. In forced shutdown, all gate drivers turn off and nFAULT is latched low until the UVLO pin is

pulled below 1.25 V to release the latch and initiate a new start-up.

27

4

I/O(1)

NO.

nFAULT

28

RAMP1

I

The inverting input of the CH-1 PWM comparator. An external RC circuit tied between VINX, RAMP1, and

AGND forms the ramp generator, producing a ramp signal proportional to the HV-Port voltage. This achieves

a voltage feedforward function. The RAMP1 capacitor voltage is reset to AGND at the end of every switching

cycle.

29

OPT

I

Multiphase configuration pin. Tied to either VCCA or AGND, the OPT pin sets the phase lag of the SYNCOUT

signal corresponding to 4-phase or 3-phase operation, respectively.

30

IPK

I

A resistor connected between IPK and AGND sets the threshold for the cycle-by-cycle current limit comparator.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

Table 6-1. Pin Functions (continued)

PIN

I/O(1)

DESCRIPTION

NO.

NAME

31

VCCA

I/P

Analog bias supply pin. Connect VCCA to VCC through an external 25-Ω resistor. A low-pass filter capacitor is

required from the VCCA pin to AGND.

32

NC

—

No connect

33

BRKS

O

Connect to the common source of the circuit breaker MOSFET pair. When the circuit breaker function is

disabled, simply connect to AGND through a 20-kΩ resistor.

34

BRKG

O

Connect to the gate pins of the circuit breaker MOSFET pair. Once the LM5170 is enabled, an internal 330-µA

current source starts to charge the circuit breaker MOSFET gates. The BRKG to BRKS voltage is internally

clamped at 12 V.

35

CSB1

I

36

CSA1

I

37

IOUT1

O

CH-1 inductor current monitor pin. A current source proportional to the CH-1 inductor current flows out of this

pin. Placing a terminating resistor and filter capacitor from IOUT1 to AGND produces a DC voltage representing

the CH-1 DC current level. An internal 25-µA offset DC current source at the IOUT1 pin raises the active signal

to be above the ground noise, thus improving the monitor noise immunity.

38

IOUT2

O

CH-2 inductor current monitor pin. A current proportional to the CH-2 inductor current flows out of this pin.

Placing a terminating resistor and filter capacitor from IOUT2 to AGND produces a DC voltage representing the

CH-2 DC current level. An internal 25-µA offset DC current source at the IOUT2 pin raises the active signal

above the ground noise, thus improving the monitor noise immunity.

39

EN1

I

CH-1 enable pin. Pulling EN1 above 2.4 V turns off the SS pulldown and allows CH-1 to begin a soft-start

sequence. Pulling EN1 below 1 V discharges the SS capacitor and holds it low. The high- and low-side gate

drivers of both channels are held in the low state when SS is discharged.

40

SYNCIN

I

Input for an external clock that overrides the free-running internal oscillator. The SYNCIN pin can be left open or

grounded when it is not used.

CH-1 differential current sense inputs. The CSA1 pin connects to the CH-1 power inductor. The CSB1 pin

connects to the circuit breaker or directly to the LV-Port if the circuit breaker is not used. The CH-1 current sense

resistor is placed between these two current sense pins. An internal 1-MΩ resistor is connected between the

CSB1 and OVPB pins through an internal cutoff switch. During operation, the cutoff switch is closed and this

internal resistor pulls up the OVPB pins. In shutdown mode, the internal resistor is disconnected by the cutoff

switch.

41

SYNCOUT

O

Clock output pin and fault check mode selector. SYNCOUT is connected to the downstream LM5170 in a 3- or

4-phase configuration. It also functions as a circuit breaker selection pin during start-up. Placing a 10-kΩ resistor

from the SYNCOUT to AGND pin disables the fault check feature. If no resistor is connected from SYNCOUT to

AGND, the fault check is enabled.

42

ISETD

I

The PWM current programming pin. The inductor DC current level is proportional to the PWM duty cycle. Use

either ISETA or ISETD but not both for channel current programming. When ISETD is not used, short ISETD to

AGND.

43

EN2

I

CH-2 enable pin. Pulling EN2 above 2.4 V enables CH-2. Pulling EN2 below 1 V shuts down the HO2 and LO2

drivers.

Direction command input. Pulling DIR above 2 V sets the converter to buck mode, which commands the current

to flow from the HV-Port to LV-Port. Pulling DIR below 1 V sets the converter to boost mode, which commands

the current to flow from the LV-Port to HV-Port. If the DIR pin is left open, the LM5170 detects an invalid

command and disables both channels with the MOSFET gate drivers in the low state.

44

DIR

I

45

ISETA

I, O

46

AGND

G

Analog ground reference. AGND must connect to PGND externally through a single point connection to improve

the LM5170 noise immunity.

47

OSC

I

The internal oscillator frequency is programmed by a resistor between OSC and AGND.

48

DT

I

A resistor connected between DT and AGND sets the dead time between the high-side and low-side driver

outputs. Tie the DT pin to VCCA to activate the internal adaptive dead time control.

—

EP

—

(1)

The analog current programming pin. The inductor DC current is proportional to the ISETA voltage. Use either

ISETA or ISETD but not both for channel current programming. When ISETA is not used, connect a 100-pF to

0.1-µF capacitor from ISETA to AGND.

Exposed pad of the package. No internal electrical connections. Must be soldered to the large ground plane to

reduce thermal resistance.

Note: G = Ground, I = Input, O = Output, P = Power

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

5

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

7 Specifications

7.1 Absolute Maximum Ratings

Over operating free-air temperature range (unless otherwise noted)(1) (2)

VIN, VINX, to AGND

MIN

MAX

–0.3

95

VIN, VINX, to AGND 50-ns Transient

100

VIN to VINX

–0.3

95

VIN to VINX 50-ns Transient

100

SW1, SW2 to PGND

–5

95

SW1, SW2 to PGND (20-ns Transient)

Voltage

UNIT

100

SW1, SW2 to PGND (50-ns Transient)

–16

HB1 to SW1, HB2 to SW2

–0.3

14

HO1 to SW1, HO2 to SW2

–0.3

HB + 0.3

HO1 to SW1, HO2 to SW2 (20-ns Transient)

–1.5

LO1, LO2 to PGND

–0.3

LO1, LO2 to PGND (20-ns Transient)

–1.5

BRKG, BRKS, to PGND

–0.3

65

–5

65

CSA1 to CSB1, CSA2 to CSB2

–0.3

0.3

BRKG to BRKS

–0.3

14

EN1, EN2, DIR, IOUT1, IOUT2, IPK, ISETA, ISETD, nFAULT,

OSC, OVPA, OVPB, SYNCIN, SYNCOUT, UVLO, to AGND

–0.3

7

PGND to AGND

–0.3

0.3

VCC to PGND, VCCA, DT, OPT, COMP1, COMP2, RAMP1,

RAMP2, SS, to AGND

–0.3

14

CSA1, CSB1, CSA2, CSB2 to PGND

V

VCC + 0.3

TJ

Operating junction temperature

–40

150

°C

Tstg

Storage temperature

–55

150

°C

(1)

(2)

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress

ratings only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

For soldering specs, see www.ti.com/packaging.

7.2 ESD Ratings

VALUE

V(ESD)

(1)

(2)

Electrostatic discharge

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001, all pins(1)

±2000

Charged-device model (CDM), per JEDEC specification JESD22C101, all pins(2)

±500

UNIT

V

JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

7.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)(1)

MIN

VIN, HV-Port

LV-Port

VVCC

6

NOM

MAX

Buck mode

6

85

Boost mode

6

85

Buck mode

Boost mode

External voltage applied to VCC

Submit Document Feedback

0

60

3(2)

60

9

12

UNIT

V

V

V

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

over operating free-air temperature range (unless otherwise noted)(1)

MIN

TJ

Operating junction temperature

FOSC

Oscillator frequency

FEX_CLK

Synchronization to external clock frequency (minimal 50 kHz)

tDT

Programmable dead time

MAX

UNIT

125

°C

50

500

kHz

0.8 × FOSC

1.2 × FOSC

kHz

ISETD PWM frequency

SYNCIN pulse width

(1)

(2)

NOM

–40

15

200

ns

1

1000

kHz

100

500

ns

Recommended Operating Conditions are conditions under which the device is intended to be functional. For specifications and test

conditions, see the Electrical Characteristics.

Minimum input voltage in boost mode can be lower than 3 V after start-up, but is limited by the minimum off-time.

7.4 Thermal Information

LM5170

THERMAL METRIC(1)

UNIT

PHP (TQFP)

48 PINS

RθJA

Junction-to-ambient thermal resistance

25.1

°C/W

RθJC(top)

Junction-to-case (top) thermal resistance

15.6

°C/W

RθJB

Junction-to-board thermal resistance

8.5

°C/W

ψJT

Junction-to-top characterization parameter

0.2

°C/W

ψJB

Junction-to-board characterization parameter

8.5

°C/W

RθJC(bot)

Junction-to-case (bottom) thermal resistance

1.1

°C/W

(1)

For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

7.5 Electrical Characteristics

FOSC = 100 kHz; VVCC = 10 V; VVIN = VHV-Port = 48 V and VLV-Port = 12 V, unless otherwise stated.(1)

PARAMETER

TEST CONDITIONS

MIN(3)

TYP(2)

MAX(3)

UNIT

VIN SUPPLY (VIN, VINX)

ISHUTDOWN

VIN pin current in shutdown mode

VUVLO = 0 V

ISTANDBY

VIN pin current, no switching

VVCC > 9 V, VUVLO > 2.5 V, VEN1 = VEN2

=0V

VIN to VINX disconnect switch

VUVLO < 1 V or VVCC < 7.5 V

VIN to VINX disconnect switch

VUVLO > 2.6 V, VVCC > 9 V

20

1

µA

mA

5

MΩ

100

Ω

VCC AND VCCA BIAS SUPPLIES

VCCUVLO

VCC undervoltage detection

VVCC falling

7.6

8

8.3

V

VCCHYS

VCC UVLO hysteresis

VVCC rising

8.1

8.5

8.9

V

IVCC_SD

VCC sink current in shutdown mode

VUVLO = 0 V

30

µA

IVCC_SB

VCC sink current in standby: no switching

VUVLO > 2.6 V, VEN1 = VEN2 = 0 V

10

mA

MASTER ON/OFF CONTROL (UVLO)

VUVLO_TH

UVLO release threshold

UVLO voltage rising

2.4

2.5

2.6

V

IHYS

UVLO hysteresis current

UVLO source current when VUVLO > 2.6

V

21

25

29

µA

VSD

UVLO shutdown threshold (IC shutdown)

UVLO voltage falling

1

1.25

1.5

V

UVLO shutdown release

UVLO voltage rising above VSD

0.15

0.25

0.35

UVLO glitch filter time

UVLO voltage falling

tUVLO

UVLO internal pulldown current

V

2.5

µs

1

µA

CHANNEL ENABLE INPUTS EN1 AND EN2

VIL

Enable input low state

Disabled the driver outputs

VIH

Enable input high state

Enable the driver outputs

Internal pulldown impedance

EN1, EN2 internal pulldown resistor

1

2

V

V

100

kΩ

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

7

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

FOSC = 100 kHz; VVCC = 10 V; VVIN = VHV-Port = 48 V and VLV-Port = 12 V, unless otherwise stated.(1)

PARAMETER

TEST CONDITIONS

MIN(3)

EN glitch filter time (the rising and falling edges)

TYP(2)

MAX(3)

2

UNIT

µs

DIRECTION COMMAND (DIR)

VDIR

Command for current flowing from LV-Port to

HV-Port (boost mode 12 V to 48 V)

Actively pulled low by external circuit

Command for current flowing from HV-Port to

LV-Port (buck mode 48 V to 12 V)

Actively pulled high by external circuit

Standby (invalid DIR command)

DIR neither active high nor active low

1.5

V

DIR glitch filter

Both rising and falling edges

10

µs

1

2

V

V

ISET INPUT (ISETA, ISETD)

Regulated DC current sense voltage to ISETA

voltage

GISETA

|VCSA – VCSB| = 50 mV

19.7

ISETA internal pulldown resistor

GISETD

Conversion ratio of ISETA voltage to ISETD

duty cycle

VISETD _LO

ISETD PWM signal low-state voltage

VISETD _HI

ISETD PWM signal high-state voltage

20

20.3

170

ISETD frequency = 10 kHz, Duty = 100%

30.63

31.25

mV/V

kΩ

31.88

1

2

mV / %

V

V

ISETD internal pulldown resistor

100

kΩ

ISETD internal decoder filter resistor (tied to

ISETA pin)

100

kΩ

OUTPUT CURRENT MONITOR (IOUT1, IOUT2)

GIOUT_BK1

IOUT1 and IOUT2 versus channel current sense

|VCSA – VCSB| = 50 mV, VDIR > 2 V

voltage, in buck mode

4.9

5

5.1

μA/mV

GIOUT_BST1

IOUT1 and IOUT2 versus channel current sense

|VCSA – VCSB| = 50 mV, VDIR < 1 V

voltage, in boost mode

4.9

5

5.1

μA/mV

GIOUT_BK2

IOUT1 and IOUT2 versus channel current sense |VCSA – VCSB| = 10 mV, VDIR > 2 V, TJ =

voltage, in buck mode

25°C

4.91

5.18

5.43

μA/mV

GIOUT_BST2

IOUT1 and IOUT2 versus channel current sense |VCSA – VCSB| = 10 mV, VDIR < 1 V, TJ =

voltage, in boost mode

25°C

4.47

4.77

5.1

μA/mV

22

25

28

µA

IOUT1 and IOUT2 DC offset currents

|VCSA – VCSB| = 0 mV

CURRENT SENSE AMPLIFIER (BOTH CHANNELS)

GCS_BK1

Amplifier output to current sense voltage in buck

|VCSA – VCSB| = 50 mV, VDIR > 2 V

mode

49.25

50

50.75

V/V

GCS_BST1

Amplifier output to current sense voltage in

boost mode

49.25

50

50.75

V/V

GCS_BK2

Amplifier output to current sense voltage in buck |VCSA – VCSB| = 10 mV, VDIR > 2 V, TJ =

mode

25°C

49

52

55

V/V

GCS_BST2

Amplifier output to current sense voltage in

boost mode

45

48

51

V/V

BWCS

Amplifier bandwidth

|VCSA – VCSB| = 50 mV, VDIR < 1 V

|VCSA – VCSB| = 10 mV, VDIR < 1 V, TJ =

25°C

10

MHz

1

mA/V

2

mA

TRANSCONDUCTION AMPLIFIER (COMP1, COMP2)

Gm

Transconductance

ICOMP

Output source current limit

VISETA = 2.5 V, |VCSA – VCSB| = 10 mV

Output sink current limit

VISETA = 0 V, |VCSA – VCSB| = 50 mV

BWgm

–2

mA

4

MHz

COMP to output delay

50

ns

COMP to PWM offset

1

Amplifier bandwidth

PWM COMPARATOR

TOFF(min)

Minimum OFF time

150

200

V

250

ns

15

Ω

RAMP GENERATOR (RAMP1 AND RAMP2)

RAMP discharge device RDS(on)

Threshold voltage for valid ramp signal

0.6

V

PEAK CURRENT LIMIT (IPK)

IPK internal current source

8

24.375

Submit Document Feedback

25

25.625

µA

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

FOSC = 100 kHz; VVCC = 10 V; VVIN = VHV-Port = 48 V and VLV-Port = 12 V, unless otherwise stated.(1)

PARAMETER

TEST CONDITIONS

MIN(3)

TYP(2)

MAX(3)

UNIT

IPKBuck

Current sense voltage versus cycle-by-cycle

limit threshold voltage given at IPK pin, in buck

mode

RIPK = 40 kΩ, VDIR > 2 V

35.8

46

58.9

mV/V

IPKBoost

Current sense voltage versus cycle-by-cycle

limit threshold voltage given at IPK pin, in boost

mode

RIPK = 40 kΩ, VDIR < 1 V

38.5

48

62.25

mV/V

OVP voltage rising

1.15

1.185

1.22

V

OVERVOLTAGE PROTECTION (OVPA, OVPB)

OVP threshold

OVPHYS

OVP hysteresis (falling edge)

100

OVPA and OVPB glitch filter

mV

5

µs

ROVPA

Internal OVPA pullup resistor

VINX to OVPA impedance

3

MΩ

ROVPB

Internal OVPB pullup resistor

CSB1 to OVPB impedance, VUVLO > 2.6

V

1

MΩ

OSCILLATOR (OSC)

VOSC

Oscillator frequency 1

ROSC = 40 kΩ, SYNCIN open

90

100

110

kHz

Oscillator frequency 2

ROSC = 10 kΩ, SYNCIN open

335

375

410

kHz

OSC pin DC voltage

1.25

V

SYNCIN

VSYNIH

SYNCIN input threshold for high state

2

V

VSYNIL SYNC SYNCIN input threshold for low state

1

V

Internal pulldown impedance

VSYNCIN = 2.5 V

100

kΩ

Delay to establish synchronization

0.8 × FOSC < FSYNCIN < 1.2 × FOSC

200

µs

SYNCOUT

VSYNOH

SYNCOUT high state

VSYNOL

SYNCOUT low state

Sourcing current when SYNCOUT in high state

2.5

0.4

VSYNCOUT = 2.5 V

SYNCOUT pulse width

SYNCOUT phase delay configurations

RSYNCOUT

Circuit breaker signature

V

1

240

300

VOPT > 2 V

90

VOPT < 1 V

120

Use circuit breaker function and fault

detection at start-up

OPEN

Do not use circuit breaker function or

disable fault detection at start-up

10

V

mA

370

ns

Degree

kΩ

BOOTSTRAP (HB1, HB2)

VHB-UV

Bootstrap undervoltage threshold

VHB-UV-HYS

Hysteresis

IHB-LK

Bootstrap quiescent current

(VHB – VSW) voltage rising

5.7

6.5

7.3

0.5

VHB – VSW = 10 V, VHO – VSW = 0 V

V

V

50

µA

HIGH-SIDE GATE DRIVERS (HO1, HO2)

VOLH

HO low-state output voltage

IHO = 100 mA

VOHH

HO high-state output voltage

IHO = –100 mA, VOHH = VHB – VHO

HO rise time (10% to 90% pulse magnitude)

0.1

V

0.15

V

CLD = 1000 pF

5

ns

HO fall time (90% to 10% pulse magnitude)

CLD = 1000 pF

4

ns

IOHH

HO peak source current

VHB – VSW = 10 V

4

A

IOLH

HO peak sink current

VHB – VSW = 10 V

5

A

0.1

V

LOW-SIDE GATE DRIVERS (LO1, LO2)

VOLL

LO low-state output voltage

ILO = 100 mA

VOHL

LO high-state output voltage

ILO = –100 mA, VOHL = VVCC – VLO

0.15

V

LO rise time (10% to 90% pulse magnitude)

CLD = 1000 pF

5

ns

LO fall time (90% to 10% pulse magnitude)

CLD = 1000 pF

4

ns

IOHL

LO peak source current

4

A

IOLL

LO peak sink current

5

A

INTERLEAVE PHASE DELAY FROM CH-2 To CH-1 (OPT)

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

9

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

FOSC = 100 kHz; VVCC = 10 V; VVIN = VHV-Port = 48 V and VLV-Port = 12 V, unless otherwise stated.(1)

PARAMETER

VOPTL

OPT input low state

VOPTH

OPT input high state

HO2 on-time rising edge versus HO1 on-time

rising edge, or LO2 on-time rising edge versus

LO1 on-time rising edge

TEST CONDITIONS

MIN(3)

TYP(2)

MAX(3)

1

2

V

V

VOPT > 2 V for 2, 4, 6, and 8 phases

175

180

185

VOPT < 1 V for 3 phases

235

240

245

Internal pulldown impedance

UNIT

Degrees

1

MΩ

DEAD TIME (DT)

tDT

LO falling edge to HO rising edge delay

RDT = 7.5 kΩ

40

ns

tDT

HO falling edge to LO rising edge delay

RDT = 7.5 kΩ

40

ns

VDT

DC voltage level for programming

1.25

V

VDT

DC voltage for adaptive dead time scheme only

(short DT to VCCA)

VCCA

V

VADPT

HO-SW or LO-GND voltage threshold to enable

cross output for adaptive dead time scheme

VVCC > 9 V, (VHB – VSW) > 8 V, HO or LO

voltage falling

1.5

V

tADPT

LO falling edge to HO rising edge delay

VDT = VVCC

36

ns

tADPT

HO falling edge to LO rising edge delay

VDT = VVCC

41

ns

25

µA

1

V

30

Ω

0.23

V

SOFT START (SS)

ISS

SS charging current source

VSS = 0 V

VSS-OFFS

SS to PWM comparator offset

SS – PWM comparator noninverting

input

RSS

SS discharge device RDS(on)

VSS = 2 V

VSS_LOW

SS discharge completion threshold

Once it is discharged by internal logic

DIODE EMULATION

Current zero cross threshold

Current sense voltage

0

mV

CKT BREAKER CONTROL (BRKG, BRKS)

IBRKG

Sourcing current

nFAULT = 5 V, VVIN = 24 V, VBRKS = 12

V

VBRK-CLP

Voltage clamp

nFAULT= 5 V, VVIN = 48 V, VBRKS = 12 V

RBRK-SINK

Sinking capability

nFAULT = 0 V

VREADY

BRKG to BRKS voltage threshold to indicate

readiness for operation

Rising edge

IBRKG-LEAK

BRKG leakage current

nFAULT= 5 V, VVIN – VBRKS = 0 V,

VBRKG – VBRKS = 10 V

275

330

9

6.5

375

14.5

µA

V

20

Ω

8.5

V

20

µA

FAULT ALARM (nFAULT)

In normal operation, no fault

4

Internal pull-up impedance for normal operation

5

V

30

kΩ

Internal pull-down FET RDS(on) after fault

detected

External pull-down voltage threshold for IC

shutdown

tFAULT

External pul-ldown glitch filter

td1_FAULT

Delay time of nFAULT pull-down below 1 V to

(VBRKG – VBRKS) < 1.5 V

td2_FAULT

Start-up fault detection duration

125

Ω

1

V

2

VUVLO > 2.6 V, VVCC > 9 V

µs

5

µs

3

ms

THERMAL SHUTDOWN

TSD

Thermal shutdown

TSD-HYS

Thermal shutdown hysteresis

(1)

(2)

(3)

10

175

°C

25

°C

All minimum and maximum limits are specified by correlating the electrical characteristics to process and temperature variations and

applying statistical process control.

Typical values correspond to TJ = 25°C.

Minimum and maximum limits apply over the –40°C to 125°C junction temperature range.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

7.6 Typical Characteristics

VVIN = 48 V, VVCC = 10 V, VUVLO = 3.3 V, TJ = 25°C, unless otherwise stated.

18

VCCA Quiescent Current (PA)

VIN Quiescent Current (PA)

20

15

10

5

±

ƒ&

25°C

16

14

12

10

8

150°C

±

0

10

20

30

40

50

60

Input Voltage (V)

70

80

90

4

100

6

150°C

7.9

8.6

VCC UVLO Threshold (V)

8.8

7.85

7.8

7.75

7.7

0

25

50

75

100

Junction Temperature (°C)

125

8.2

8

Falling

Rising

7.6

-50

150

Figure 7-3. VCCA Standby Current vs Temperature

-25

0

25

50

75

100

Junction Temperature (°C)

125

150

Figure 7-4. VCC UVLO Threshold vs Temperature

105

IOUT1/2 Current Source Gain (PA/mV)

6

104

103

102

101

100

99

98

-50

8.4

7.8

-25

14

Figure 7-2. VCCA Shutdown IQ

7.95

7.65

-50

12

VUVLO = 0 V

Figure 7-1. VIN Shutdown IQ

VCCA Standby Current (mA)

25°C

8

10

VCCA Voltage (V)

VUVLO = 0 V

Oscillator Frequency (kHz)

ƒ&

6

0

IOUT1 Gain

IOUT2 Gain

5.8

5.6

5.4

5.2

5

4.8

4.6

4.4

4.2

4

-25

0

25

50

75

100

Junction Temperature (°C)

125

150

0

10

20

30

40

50

60

70

Current Sense Voltage (mV)

80

90

100

D001

ROSC = 40.2 kΩ

Figure 7-5. Oscillator Frequency vs Temperature

Figure 7-6. IOUT1 and IOUT2 Current Monitor

Accuracy vs VCS

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

11

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

50.75

Current Sense Voltage (mV)

Current Sense Voltage, V CS (mV)

100

80

60

40

20

1

2

3

Current Setting, VISETA (V)

4

50.25

50

49.75

49.5

49.25

-50

0

0

50.5

5

-25

0

25

50

75

100

Junction Temperature (°C)

125

150

VISETA = 2.5 V

Figure 7-7. Regulated VCS Voltage vs ISETA

Voltage

Figure 7-8. Regulated VCS Voltage vs Temperature

280

600

278

IOUT1, IOUT2 (PA)

IOUT1, IOUT2 (PA)

500

400

300

200

IOUT1 (PA)

IOUT2 (PA)

IOUT1

IOUT2

0

0

20

40

60

Current Sense Voltage (mV)

80

270

-50

100

0

25

50

75

100

Junction Temperature (°C)

125

150

VCS = 50 mV

Figure 7-10. IOUT1 and IOUT2 Current Monitor vs

Temperature

25.2

OVP Rising Threshold Voltage (V)

1.19

25.1

25

24.9

24.8

24.7

24.6

24.5

-50

-25

D001

Figure 7-9. IOUT1 and IOUT2 Current Monitor vs

VCS Voltage

Source Current (PA)

274

272

100

-25

0

25

50

75

100

Junction Temperature (°C)

125

150

Figure 7-11. IPK Current Source vs Temperature

12

276

1.188

1.186

1.184

1.182

1.18

-50

-25

0

25

50

75

100

Junction Temperature (°C)

125

150

Figure 7-12. OVP Reference Voltage vs

Temperature

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

1.01

OVPB Pull-up Resisitance (M:)

OVPA Pull-up Resisitance (M:)

3.1

3.05

3

2.95

2.9

-50

-25

0

25

50

75

100

Junction Temperature (°C)

125

1.005

1

0.995

0.99

-50

150

-25

0

25

50

75

100

Junction Temperature (°C)

125

150

Figure 7-14. OVPB Pullup Resistance vs

Temperature

Figure 7-13. OVPA Pullup Resistance vs

Temperature

140

80

Adaptive Deadtime (ns)

Programmed Deadtime (ns)

120

100

80

60

40

20

60

40

20

HO to LO

LO to HO

RDT = 25 k:

RDT = 7.5 k:

0

-50

-25

0

25

50

75

100

Junction Temperature (°C)

125

0

-50

150

-25

0

FSW = 100 kΩ

Circuit Breaker Gate Current (PA)

450

VBRKS (V)

12

VBRKG

150

Figure 7-16. Adaptive Dead Time vs Temperature

14

6

125

VDT = VVCC

Figure 7-15. Programmed Dead Time vs

Temperature

10

25

50

75

100

Junction Temperature (°C)

8

4

2

0

0

10

20

VVIN

30

VCS1B (V)

40

50

Figure 7-17. [VBRKG – VBRKS] vs [VVIN – VBRKG]

Voltage

390

330

270

210

-50

-25

0

25

50

75

100

Junction Temperature (°C)

125

150

Figure 7-18. Circuit Breaker Gate Current vs

Temperature

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

13

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

8 Detailed Description

8.1 Overview

The LM5170 is a high-performance, dual-channel bidirectional current controller intended to manage current

transfer between a Higher Voltage Port (HV-Port) and Lower Voltage Port (LV-Port). It integrates essential analog

functions that enable the design of high-power converters with a minimal number of external components. The

device regulates DC current in the direction designated by the DIR pin input signal. The current regulation

level is programmed by the analog signal applied at the ISETA pin or the digital PWM signal at the ISETD pin.

Independent enable signals activate each channel of the dual controller.

The dual-channel differential current sense amplifiers and dedicated channel current monitors achieve typical

accuracy of 1%. The robust 5-A half-bridge gate drivers are capable of controlling parallel MOSFET switches,

delivering 500 W or more per channel. The diode emulation mode of the buck or boost synchronous rectifiers

enables discontinuous mode operation for improved efficiency under light load conditions and prevents negative

current. Versatile protection features include:

• Cycle-by-cycle peak current limit

• Overvoltage protection of both 48-V and 12-V battery rails

• Detection and protection of MOSFET switch failures

• Overtemperature protection

The LM5170 uses average current mode control, simplifying compensation by eliminating the right-half plane

zero in boost operating mode and maintaining a constant loop gain regardless of the operating voltages and load

level. The free-running oscillator is adjustable up to 500 kHz and can be synchronized to an external clock within

±20% of the free running oscillator frequency. Stackable multiphase parallel operation is achieved by connecting

two LM5170 controllers in parallel for 3- or 4-phase operation. It can also be done by synchronizing multiple

LM5170 controllers to external multiphase clocks for a higher number of phases. The UVLO pin provides master

ON and OFF control that disables the LM5170 in a low-quiescent current shutdown state when the pin is held

low.

Definition of IC Operation Modes:

• Shutdown Mode: When the UVLO pin is < 1.25 V, VCC < 8 V, or nFAULT < 1.25 V, the LM5170 is in

shutdown mode with all gate drivers in the low state, all internal logic reset, and the VINX pin disconnected

from the VIN pin. When UVLO < 1.25 V, the IC draws < 20 µA through the VIN and VCC pins.

• Initialization Mode: When the UVLO pin is > 1.5 V but < 2.5 V, VCC > 8.5 V, and nFAULT > 2 V, the LM5170

establishes proper internal logic states and prepares for circuit operation.

• Standby Mode: When the UVLO pin is > 2.5 V, VCC > 8.5 V, and nFAULT > 2 V, the LM5170 first

performs fault detection for 2 to 3 ms. During this time, the external power MOSFETs are each checked for

drain-to-source short-circuit conditions. If a fault is detected, the LM5170 returns to shutdown mode and is

latched in shutdown until reset through the UVLO or VCC pins. If no failure is detected, the LM5170 is ready

to operate. The circuit breaker MOSFETs are turned on and the oscillator and ramp generators are activated,

but the four gate drive outputs remain off until the EN1 or EN2 initiate the power delivery mode.

• Power Delivery Mode: When the UVLO pin > 2.5 V, VCC > 8.5 V, nFAULT > 2 V, EN1 or EN2 > 2 V, DIR

is valid (> 2 V or < 1 V), and ISETA > 0 V, the SS capacitor is released and the LM5170 regulates the DC

current at the level set at the ISETA pin.

14

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

8.2 Functional Block Diagram

OPT

OSC

SYNCOUT

SYNCIN

VIN

VIN

SD

VINX

UVLO

+

-

1.5V

VCCUV

ENABLE

nFAULT

CONTROL

LOGIC

RESET

+

-

1.5V

BIAS

REGULATORS

1.185V

25µA

2.5V

VCCA

2.5V

CLK2

VINX

SD

300uA

DIR_GOOD

DIR

VALIDATION

DIR

3.125V

CLK1

OSCILLATOR AND

PHASE SPLITTER

DIR

ISETA

VIN

FLIP

DETECT

ISET

100K

SS

DISABLE1

100K

DEAD TIME

CONTROL

3 MEG

DT

OVER

TEMP

VDT

+

-

+

-

8.5V

+

-

1.185V

CSB1

DIR 0

OVP

OVPA

VCC

FLIP

DETECT

DIR

SD

VINX

VCC

1 MEG

OVPB

1

1.185V

PK LIMIT

PROGRAM

VIPK

VCC_UV

25uA

COMMON CONTROL

AGND

DIR

CSB1

CSB1

Gm=1 mA/V

IOUT1

+

-

-

ISET

+

SS1

+

COMP1

+

-

PEAK

LIMIT

PWM

COMP

PEAK

HOLD

DIODE

EMULATION

+

-

CSA1

-

RAMP1

CLK1

CS AMP

A=50

ERR AMP

1V

OVP

0.6V

SD

EN1

CLK1

S

Q

R

Q

DISABLE1

EN1

VIPK

HB1

DISABLE1

VDT

ZERO

CROSS

DIR

1-D1

D1

DELAY

LOGIC

LEVEL

SHIFT

HO1

SW1

ADPT

LOGIC

VDT

VCC

DELAY

LOGIC

DISABLE1

CH-2 CONTROL

100uA/V

25uA

LO1

DIR

CSB2

Gm=1 mA/V

IOUT2

+

-

-

ISET

+

SS2

+

+

-

PEAK

LIMIT

PWM

COMP

PEAK

HOLD

DIODE

EMULATION

+

-

CSA2

-

RAMP2

CLK2

CS AMP

A=50

ERR AMP

1V

COMP2

IPK

PGND

CH-1 CONTROL

100uA/V

25uA

OVP

0.6V

SD

EN1

CLK2

EN2

BRKS

25uA

SS1

SS2

FAILURE

DETECT

12V

SD

3.125V

ISETD

BRKG

CIRCUIT

BREAKER

CONTROL

S

DISABLE2

R

VIPK

HB2

DISABLE2

VDT

ZERO

CROSS

DIR

LEVEL

SHIFT

Q

1-D2

Q D2

VDT

DISABLE2

DELAY

LOGIC

ADPT

LOGIC

DELAY

LOGIC

HO2

SW2

VCC

LO2

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

15

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

8.3 Feature Description

8.3.1 Bias Supply (VCC, VCCA)

The LM5170 requires an external bias supply of 9 V to 12 V at the VCC and VCCA pins to function. If an

external supply voltage is greater than 12 V, a 10-V LDO or switching regulator must be used to produce 10 V

for VCC and VCCA. Figure 8-1 shows typical connections of the bias supply. The VCC voltage is directly fed to

the low-side MOSFET drivers. A 1-µF to 2.2-µF ceramic capacitor must be placed between the VCC and PGND

pins to bypass the driver switching currents. The VCCA pin serves as the bias supply input for the internal logic

and analog circuits for which the ground reference is the AGND pin. VCCA must be connected to VCC through a

25-Ω to 50-Ω external resistor. A 0.1-µF to 1-µF bypass capacitor must be placed between the VCCA and AGND

pins to filter out possible switching noise.

The internal VCC undervoltage (UV) detection circuit monitors the VCC voltage. When the VCC voltage falls

below 8 V on the falling edge, the LM5170 is held in shutdown state. For normal operation, the VCC and VCCA

voltages must be greater than 8.5 V on a rising edge.

25

Ext > 12 Vdc

Ext

9~12 Vdc

Driver

VCCA

Analog

Circuit

CVCCA

AGND

10 V

VCC

VCC

UV

LDO

CVCC

PGND

Figure 8-1. VCC Bias Supply Connections

8.3.2 Undervoltage Lockout (UVLO) and Master Enable or Disable

The UVLO pin serves as the master enable or disable pin. To use the UVLO pin to program undervoltage lockout

control for the HV-port, LV-port, or VCC rail, see Section 8.5.2.

There are two UVLO voltage thresholds. When the pin voltage is externally pulled below 1.25 V, the LM5170 is

in shutdown mode, where the following occurs:

• All gate drivers are in the OFF state

• All internal logic resets

• The VINX pin is disconnected from the VIN pin

• The IC draws less than 20 µA through the VIN, VCC, and VCCA pins

When the VCC voltage is above the 8.5 V and the UVLO pin voltage is pulled higher than 1.5 V but lower than

2.5 V, the LM5170 is in initialization mode where the nFAULT pin is pulled up to approximately 5 V, but the rest of

the LM5170 remain off.

When the UVLO pin is pulled higher than 2.5 V, which is the UVLO release threshold and the master enable

threshold, the LM5170 starts the MOSFET failure detection in a period of 2 to 3 ms (see Section 8.3.16). If no

failure is detected, the BRKG pin starts to source a 330-µA current to charge the gates of the breaker MOSFETs.

When the BRKG to BRKS voltage is above 8.5 V, the LM5170 enters standby mode. In standby mode, the

VINX pin is internally connected to the VIN pin through an internal cutoff switch (see Figure 8-2). Additionally,

the internal 1-MΩ OVPB pullup resistor is connected to the CSB1 pin through another internal cutoff switch (see

Figure 8-18). The oscillator and the RAMP1 and RAMP2 generators start to operate, the SYNCOUT pin starts

to send clock pulses at the oscillator frequency, and the LM5170 is ready to operate. The LO1, LO2, HO1, and

HO2 drivers remain off until the EN1, EN2, and DIR inputs command them to operate.

When a MOSFET gate-to-source short-circuit failure is detected, the LM5170 is latched off. The latch can only

be reset by pulling the VCC pin below 8 V or by pulling the UVLO pin below 1.25 V. For details, see Section

8.3.16.

16

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

8.3.3 High Voltage Input (VIN, VINX)

Figure 8-2 shows the external and internal configuration for the VIN and VINX pins. Both are rated at 100 Vdc.

The VIN pin must be directly connected either to the voltage rail of the HV-Port, or through a small RC filter

consisting of 10- to 20-Ω resistor and 0.1-µF to 1-µF bypass capacitor. The VIN pin supplies the internal 330-µA

current source supplying the BRKG pin.

A cutoff switch connects and disconnects the VIN and VINX pins. When the UVLO pin voltage is greater than

2.5 V, and when the VCC voltage is greater than 8.5 V, the switch is closed and the VINX and VIN pins are

connected.

The VINX pin serves as the supply pin for the RAMP generators (see Figure 8-2 and Section 8.3.9 for details).

It is also the high-side terminal of the internal 3-MegΩ pullup resistor for the OVPA pin (see Section 8.3.17 for

details). Moreover, it serves as the HV-Port voltage sense for internal circuit use during operation.

HV-Port (48 V)

VIN

VINX

VINX

3 Meg

RAMP1

OVPA

+

OVP

COMP

RAMP2

1.185 V

±

AGND

Figure 8-2. VIN and VINX Pins Configuration

8.3.4 Current Sense Amplifier

Each channel of the LM5170 has an independent bidirectional, high accuracy, and high-speed differential current

sense amplifier. The differential current sense polarity is determined by the DIR command. The amplifier gain

is 50, so that a smaller current sense resistor can be used to reduce power dissipation. The amplified current

sense signal is used to perform the following functions:

• Applied to the inverting input of the error amplifier for current loop regulation

• Used to reconstruct the channel current monitor signal at the IOUT1 and IOUT2 pins

• Monitored by the cycle-by-cycle peak current limit comparator for instantaneous overcurrent protection

• Sensed by the current zero cross detector to operate the synchronous rectifiers in diode emulation mode

The current sense resistor Rcs must be selected for 50-mV current sense voltage when the channel DC current

reaches the rated level. The CS1A, CS1B, CS2A, and CS2B pins must be Kelvin connected for accurate

sensing.

It is very important that the current sense resistors are non-inductive. Otherwise, the sensed current signals are

distorted even if the parasitic inductance is only a few nH. Such inductance may not affect the current regulation

during continuous conduction mode, but it does affect current zero cross detection, hence the performance of

diode emulation mode under light load. As a consequence, the synchronous rectifier gate pulse is truncated

much earlier than the inductor current zero crossing. This causes the body diode of the synchronous rectifier to

conduct unnecessarily for a longer time. See Section 8.3.15 for details.

If the selected current sense resistor has parasitic inductance. See Section 9.1 for methods to compensate for

this condition and achieve optimal performance.

8.3.5 Control Commands

8.3.5.1 Channel Enable Commands (EN1, EN2)

These pins are two-state function pins. Always use CH-1 if only single-channel operation is required. Note that

CH-2 can only be enabled when CH-1 is also enabled.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

17

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

1. When the EN1 pin voltage is pulled above 2 V (logic state of 1), the HO1 and LO1 outputs are enabled

through soft start.

2. When the EN1 pin voltage is pulled below 1 V (logic state of 0), CH-1 controller is disabled and both HO1

and LO1 outputs are turned off.

3. Similar behaviors for EN2, HO2, and LO2 of CH-2, except that the EN2 pin does not affect the SS pin. Refer

to Section 8.3.10 for details.

4. When the EN1 and EN2 pins are left open, an internal 100-kΩ pulldown resistor sets them to the low state.

5. The built-in 2-µs glitch filters prevent errant operation due to the noise on the EN1 and EN2 signals.

8.3.5.2 Direction Command (DIR)

This pin is a triple function pin.

1. When the DIR pin is actively pulled above 2 V (logic state of 1), the LM5170 operates in buck mode, and

current flows from the HV-Port to the LV-Port.

2. When the DIR pin is actively pulled below 1 V (logic state of 0), the LM5170 operates in boost mode, and

current flows from the LV-Port to the HV-Port.

3. When the DIR pin is in the third state that is different from the previous two, it is considered an invalid

command and the LM5170 remains in standby mode regardless of the EN1 and EN2 states. This tri-state

function prevents faulty operation when losing the DIR signal connection to the MCU.

4. When DIR changes state between 1 and 0 dynamically during operation, the transition causes the SS pin

to discharge first to below 0.23 V. Then, the SS pin pulldown is released and the LM5170 goes through a

new soft-start process to produce the current in the new direction. This eliminates surge current during the

direction change.

5. The built-in 10-µs glitch filter prevents errant operation by noise on the DIR signal.

8.3.5.3 Channel Current Setting Commands (ISETA or ISETD)

The LM5170 accepts the current setting command in the form of either an analog voltage or a PWM signal.

The analog voltage uses the ISETA pin, and the PWM signal uses the ISETD pin. There is an internal ISETD

decoder that converts the PWM duty ratio at the ISETD pin to an analog voltage at the ISETA pin. Owing to

possible ground noise impact, TI recommends to remove EN1 signal to achieve no load (0 A).

Figure 8-3 and Figure 8-4 show the pin configurations for current programming with an analog voltage or a PWM

signal. The channel DC current is expressed in terms of resulted differential current sense voltage VCS_dc. When

ISETA is used, the ISETD pin can be left open or connected to AGND. When ISETD is used, place ceramic

capacitor CISETA between the ISETA pin and AGND. CISETA and the internal 100 kΩ at the output of the ISETD

decoder forms a low-pass RC filter to attenuate the ripple voltage on ISETA. However, the RC filter delays the

ISETD dynamic change to be reflected on ISETA. To limit the delay to not exceed Tdelay_ISETD, the time constant

of the RC filter must satisfy Equation 1.

100 k: u CISETA d

Tdelay_ISETD

(1)

4

Therefore, the maximum CISETA must be determined by Equation 2:

CISETA d

Tdelay_ISETD

4 u 100 k:

(2)

On the other hand, the time constant of the RC filter must be big enough for effective filtering. To attenuate the

ripple by 40 dB, the RC filter corner frequency must be at least two decade below FISETD, that is, Equation 3

1

d 0.01u FISETD

2S u 100 k: u CISETA

(3)

Therefore the minimum ISETD signal frequency must be determined by Equation 4:

18

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

FISETD t

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

1

400

t

2S u 1 k: u CISETA 2S u Tdelay_ISETD

(4)

Current Level

Command

ISETA

+

ISETD

±

AGND

VCS_dc (mV)

For instance, if ISETA is required to settle down to the steady-state in 1 ms following an ISETD duty ratio step

change, namely Tdelay_ISETD < 1 ms, select CISETA < 2.5 nF, and FISETD > 64 kHz. If Tdelay_ISETD < 0.1 ms, then

CISETA < 250 pF and FISETD > 640 kHz. Note that the feedback loop property causes additional delay for the

actual current to settle to the new regulation level.

60.0

50.0

0

2.5

0

ISETA (V)

3.0

Figure 8-3. Pin Configurations for Current Setting Using an Analog Voltage Signal

VCS_dc (mV)

Current Level

Command

ISETD

FISETD=1~1000 kHz

ISETA

CISETA

100 pF~100 nF

62.5

50.0

AGND

0

0%

80% 100%

ISETD Duty (%)

Figure 8-4. Pin Configurations for Current Setting Using a PWM Signal

The ISETA pin is directly connected to the non-inverting input of the error amplifier. By ISETA programming, the

channel DC current is determined by Equation 5:

VCS dc

0.02 u VISETA

(5)

Or by Equation 6:

I_channel_dc

VCS_dc_

(6)

Rcs

Or by Equation 7:

I_channel_dc

0.02 u VISETA

Rcs

(7)

where

•

Rcs is the channel current sensing resistor value

When using ISETD, the produced VISETA by the internal decoder is equal to the product of the effective duty

ratio of the ISETD PWM signal (DISETD) and the 3.125-V internal reference voltage. The channel current is

determined by Equation 8:

IVISETA

3.125 V u DISETD

(8)

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

19

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

Or by Equation 9:

VCS dc

0.0625 V u DISETD

(9)

Or by Equation 10:

I_channel_dc

0.0625 V u DISETD

Rcs

(10)

8.3.6 Channel Current Monitor (IOUT1, IOUT2)

The LM5170 monitors the real time inductor current in each channel at the IOUT1 and IOUT2 pins. The channel

current is converted to a small current source scaled by the factors seen in Equation 11 and Equation 12:

IOUT1

IOUT2

VCSI

200 :

25 PA

VCS2

200 :

25 PA

(11)

(12)

where

•

•

VCS1 and VCS2 are the real time current sense voltage of CH-1 and CH-2, respectively

25 µA is a DC offset current superimposed on to the IOUT signals (refer to Figure 8-5)

The DC offset current is introduced to raise the no-load signal above the possible ground noise floor. Since the

monitor signal is in the form of current, an accurate reading can be obtained across a termination resistor even

if the resistor is located far from the LM5170 but close to the MCU, thus rejecting potential ground differences

between the LM5170 and the MCU. Figure 8-6 shows a typical channel current monitor through a 9.09-KΩ

termination resistor and a 10-nF to 100-nF ceramic capacitor in parallel. The RC network converts the current

monitor signal into a DC voltage proportional to the channel DC current. For example, when the current sense

voltage DC component is 50 mVdc, namely VCS_dc = 50 mV, the termination RC network produces a DC voltage

of 2.5 V. Note that the maximum IOUT pin voltage is internally clamped to approximately 4 V.

IOUT (µA)

275

25

0

50

0

V_CS (mV)

Figure 8-5. Channel Monitor Current Source Versus Current Sense Voltage

To MCU

Monitor

IOUT2

9.09 k

IOUT1

10 ~100 nF

9.09 k

10 ~100 nF

AGND

Ground

Impedance

Figure 8-6. Channel Current Monitor

20

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

8.3.7 Cycle-by-Cycle Peak Current Limit (IPK)

The internal 25-µA current source and a single external resistor RIPK establish a voltage at the IPK pin to

program the cycle-by-cycle current limit threshold. To set the inductor peak current limit value to IPK, RIPK must

satisfy Equation 13:

RIPK

Rcs u IPK

1.1PA

(13)

IPK must be greater than the inductor peak current at full load, and lower than the rated saturation current of the

inductor, Isat.

When the IPK pin voltage is greater than 4.5 V, either from a very large RIPK value or the pin being open or some

other reason, an internal monitor circuit shuts down the switching. This prevents the LM5170 from operating with

erroneous peak current limit threshold.

8.3.8 Error Amplifier

Each channel of the LM5170 has an independent gm error amplifier. The output of the error amplifier is

connected to the COMP pin, allowing the loop compensation network to be applied between the COMP pins and

AGND.

The LM5170 control loop is the inner current loop of the bidirectional converter system, of which the outer

voltage loop can either be controlled by an MCU, a DSP, an FPGA, and so forth, or by an analog circuit. Since

the LM5170 employs the averaged current mode control scheme, the inner loop is basically a first order system.

As seen in Figure 8-7, a Type-II compensation network consisting of RCOMP, CCOMP, and CHF is adequate to

stabilize the LM5170 inner current loop. Refer to Section 9.1 for details of the compensation network selection

criteria.

8.3.9 Ramp Generator

Refer to Figure 8-7 for the following:

• Circuit block diagram for the ramp generator

• gm error amplifier

• PWM comparator

• Soft-start control circuit

The VINX pin serves as the supply pin for the ramp generator. Each ramp generator consists of an external RC

circuit (RRAMP and CRAMP) and an internal pulldown switch controlled by the clock signal.

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

21

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

HV-Port (48 V)

VIN

Shutdown

VINX

RRAMP1

RAMP1

CLK1

CRAMP1

±

PWM

1V

COMP1

To Driver Logic

+

RCOMP1

25 µA

Gm AMP

SS

CHF1

±

CCOMP1

From Current

Sense Amp

Gm

CSS

+

AGND

ISET

COMP2

RRAMP2

To CH2 PWM

RAMP2

CLK2

CRAMP2

Figure 8-7. Error Amplifier, Ramp Generator, Soft Start, and PWM Comparator

When the LM5170 is enabled, CRAMP1/2 is charged by the VINX pin through RRAMP1/2 at the beginning of each

switching cycle. The internal pulldown FET discharges CRAMP1/2 at the end of the cycle within a 200-ns internal.

Then the pulldown is released, and CRAMP1/2 repeats the charging and discharging cycles. In general, the RAMP

RC time constant is much greater than the period of a switching cycle. Therefore, the RAMP pin voltages are

sawtooth signals with a slope proportional to the HV-Port voltage. This way, the RAMP signals convey the line

voltage info. Being directly used by the PWM comparators to determine the instantaneous switching duty cycles,

the RAMP signals fulfill the line voltage feedforward function and enable the LM5170 to have a fast response to

line transients.

Note

TI recommends you to select appropriate RRAMP and CRAMP values by the following equation such that

the RAMP pins reach the peak value of approximately 5 V each cycle when VIN is at 48 V.

RRAMP

Fsw

9.6

u CRAMP

(14)

For instance, if Fsw = 100 kHz and CRAMP1 = CRAMP2 = 1 nF, a resistor of approximately 96 kΩ must be selected

for RRAMP1 and RRAMP2.

22

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

Because CRAMP1/2 must be fully discharged every cycle through the 15-Ω channel resistor of the pulldown FET

within the 150-ns minimum discharging interval, CRAMP1/2 must be limited to be less than 2.5 nF nominal at room

temperature.

There is also a valid RAMP signal detection circuit for each channel to prevent the channel from errantly running

into the maximum duty cycle if RAMP goes away. It detects the peak voltage of the RAMP signal. If the peak

voltage is less than 0.6 V in consecutive cycles, it is considered an invalid RAMP and the channel stops

switching by turning both HO and LO off until the RAMP signal recovers. This 0.6-V voltage threshold defines the

minimum operating voltage of the HV-Port to be approximately 5.76 V.

8.3.10 Soft Start

The soft-start feature helps the converter to gradually reach the steady-state operating point, thus reducing

start-up stresses and surge currents. With the LM5170, there are two ways to implement the soft start.

8.3.10.1 Soft-Start Control by the SS Pin

Place a ceramic capacitor CSS between the SS pin and AGND to program the soft-start time. When the EN1

voltage is < 1 V, an internal pulldown switch holds the SS pin at AGND. When the EN1 pin voltage is > 2 V, the

SS pulldown is released, and CSS is charged up slowly by the internal 25-µA current source. See Figure 8-7. The

slow ramping SS voltage clamps the COMP1 and COMP2 pins through two separate clamp circuits. Once the

SS voltage exceeds the 1-V offset voltage, the PWM duty cycle starts to increase gradually from zero.

When EN1 is pulled below 1 V, CSS is discharged by the internal pulldown FET. Once this pulldown FET is

turned on, it remains on until the SS voltage falls below 0.23 V, which is the threshold voltage indicating the

completion of SS discharge.

Note that the EN2 pin does not affect the SS pin. When EN1 and EN2 are enabled together, the CH-2 output

follows CH-1 by going through the same soft-start process. If EN2 is enabled at a later time and CH-1 has

already completed soft start, CH-2 is not affected by the SS pin. This allows the CH-2 current to ramp up quickly

to supply the increased load current. However, when SS is pulled low, both CH-1 and CH-2 are affected at the

same time.

8.3.10.2 Soft Start by MCU Through the ISET Pin

The MCU can control the soft start by gradually ramping up the ISETA voltage or the ISETD PWM duty ratio,

whichever is applicable. When ISETA or ISETD is used to control the soft start, CSS must be properly selected to

a value such that it does not interfere with the ISETA/D soft start.

8.3.10.3 The SS Pin as the Restart Timer

The SS pin also fulfills the function of a restart timer in an OVP event or following a DIR command change:

1. Restart timer in OVP: When OVPA or OVPB catches an overvoltage event (refer to Section 8.3.17), CSS

is discharged immediately by the internal pulldown FET. This FET remains ON as long as the overvoltage

condition persists. When the overvoltage condition is removed and after the SS voltage is discharged to

below 0.23 V, the SS pulldown is released, setting off a new soft-start cycle. The circuit can run in retry or

hiccup mode if the overvoltage condition reappears. The retry frequency is determined by the SS capacitor

as well as the nature of the overvoltage condition.

2. Restart timer: When DIR dynamically flips its state from 0 to 1, or 1 to 0 during operation, CSS is first

discharged to 0.23 V by the internal pulldown FET. Then, the pulldown is released to set off a new softstart cycle to gradually build up the channel current in the new direction. In this way, the channel current

overshoot is eliminated.

8.3.11 Gate Drive Outputs, Dead Time Programming, and Adaptive Dead Time (HO1, HO2, LO1, LO2, DT)

Each channel of the LM5170 has a robust 5-A (peak) half bridge driver to drive external N-channel power

MOSFETs. As shown in Figure 8-8, the low-side drive is directly powered by VCC, and the high-side driver

by the bootstrap capacitor CBT. During the on-time of the low-side driver, the SW pin is pulled down to PGND

and CBT is charged by VCC through the boot diode DBT. TI recommends selecting a 0.1-µF or larger ceramic

capacitor for CBT, and an ultra-fast diode of 1 A and 100-V ratings for DBT. TI also strongly recommends you add

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Product Folder Links: LM5170

23

�LM5170

www.ti.com

SNVSBJ0B – DECEMBER 2019 – REVISED AUGUST 2021

a 2-Ω to 5-Ω resistor (RBT) in series with DBT to limit the surge charging current and improve the noise immunity

of the high-side driver.

RBT

DBT

2Ÿ

HB

VCC

Driver

HO

CBT

SW

External

10-V Supply

VCCA

AGND

Internal

Logic

Circuit

Driver

LO

PGND

Figure 8-8. Bootstrap Circuit for High-Side Bias Supply

During start-up in buck mode, CBT may not be charged initially. The LM5170 then holds off the high-side driver

outputs (HO1 and HO2) and sends LO pulses of 200-ns width in consecutive cycles to pre-charge CBT. When

the boot voltage is greater than the 6.5-V boot UV threshold, the high-side drivers output PWM signals at the

HO1 and HO2 pins for normal switching action.

During start-up in boost mode, CBT is naturally charged by the normal turnon of the low-side MOSFET, therefore,

there is no such 200-ns pre-charge pulse at the LO pins.

To prevent shoot-through between the high-side and low-side power MOSFETs on the same half bridge leg, two