www.ti.com

Table of Contents

User’s Guide

TPS51218 Buck Controller Evaluation Module User's

Guide

ABSTRACT

The TPS51218EVM evaluation module (EVM) is used to evaluate the TPS51218, a small-size, single buck

controller with adaptive on-time D-CAP™ mode, providing a fixed 1.2-V output at up to 20 A from a 12-V input

bus.

Table of Contents

1 Description.............................................................................................................................................................................. 2

1.1 Typical Applications............................................................................................................................................................2

1.2 Features............................................................................................................................................................................. 2

2 Electrical Performance Specifications................................................................................................................................. 2

3 Schematic................................................................................................................................................................................3

4 Test Setup................................................................................................................................................................................4

4.1 Test Equipment.................................................................................................................................................................. 4

4.2 Recommended Test Setup.................................................................................................................................................5

5 Test Procedure........................................................................................................................................................................ 7

5.1 Line/Load Regulation and Efficiency Measurement Procedure......................................................................................... 7

5.2 List of Test Points............................................................................................................................................................... 7

5.3 Equipment Shutdown......................................................................................................................................................... 7

6 Performance Data and Typical Characteristic Curves........................................................................................................ 8

6.1 Efficiency............................................................................................................................................................................8

6.2 Load Regulation................................................................................................................................................................. 8

6.3 Transient Response........................................................................................................................................................... 9

6.4 Output Ripple................................................................................................................................................................... 10

6.5 Switch Node Voltage........................................................................................................................................................ 10

6.6 Turn-On Waveform........................................................................................................................................................... 11

6.7 Turn-Off Waveform........................................................................................................................................................... 11

6.8 Output 1.1-V Prebias Turn-On......................................................................................................................................... 12

7 EVM Assembly Drawing and PCB Layout.......................................................................................................................... 13

8 Bill of Materials..................................................................................................................................................................... 16

9 Revision History................................................................................................................................................................... 16

Trademarks

D-CAP™ are trademarks of Texas Instruments.

All trademarks are the property of their respective owners.

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

TPS51218 Buck Controller Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

1

�Description

www.ti.com

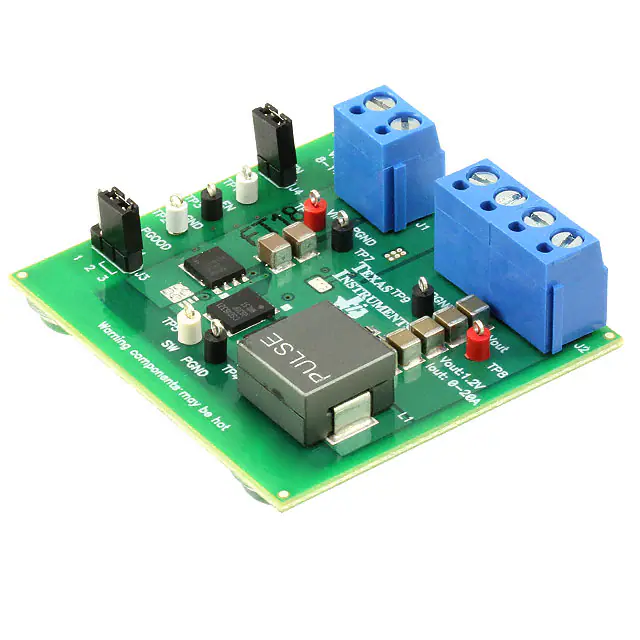

1 Description

The TPS51218EVM is designed to use a regulated 12-V bus to produce a regulated 1.2-V output at up to 20 A of

load current. The TPS51218EVM is designed to demonstrate the TPS51218 in a typical, low-voltage application

while providing a number of test points to evaluate the performance of the TPS51218.

1.1 Typical Applications

•

•

•

•

•

•

•

•

High-current system converters for server and desktop power

Switchers and routers

Embedded computers

In-vehicle infotainment PCs

POS terminals

Point-of-load modules

Graphics cards

Industrial control/factory automation PCs

1.2 Features

The TPS51218EVM features:

•

•

•

•

•

•

20-ADC steady-state current

Support prebias output voltage start-up

380-kHz switching frequency

J4 for enable function

J3 for auto-skip and forced CCM selection

Convenient test points for probing critical waveforms

2 Electrical Performance Specifications

Table 2-1. TPS51218EVM Electrical Performance Specifications

Parameter

Test Conditions

Min

Typ

Max

8

12

14

Units

INPUT CHARACTERISTICS

Voltage range

VIN

Maximum input current

VIN = 8 V, IO = 20 A

No load input current

VDC = 14 V, IO = 0 A

3.55

50

V

A

mA

OUTPUT CHARACTERISTICS

Output voltage, VOUT

Output voltage regulation

Output voltage ripple

1.2

Line regulation (VDC = 10 V–14 V)

1.0%

Load regulation (VDC = 12 V, IO = 0 A–20 A)

1.0%

VIN = 12 V, IO = 20 A

Output load current

0

Output overcurrent

V

40

mVpp

20

A

30

A

380

kHz

SYSTEMS CHARACTERISTICS

Switching frequency

Peak efficiency

VIN = 12 V, 1.2 V/10 A

90.32%

Full-load efficiency

VIN = 12 V, 1.2 V/20 A

88.64%

Operating temperature

2

25

TPS51218 Buck Controller Evaluation Module User's Guide

°C

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

�PWM

Mode

ENABLE

EN

PGND

PGOOD

GND

Not used

PWM Mode selection :

1. Jumper on pin 2 and pin 3 of J3: Setting auto - skip mode ( Default setting )

2. Jumper on pin 1 and pin 2 of J3: Setting forced CCM mode .

Enable Notes :

1. Jumper shorted on J 4 to disable the controller .( Default setting )

2. No jumper on J 4 to enable the controller .

PGND

PGND

SW

PGND

Vin

PGND

Vout

www.ti.com

Schematic

3 Schematic

Figure 3-1. TPS51218EVM Schematic

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

TPS51218 Buck Controller Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

3

�Test Setup

www.ti.com

4 Test Setup

4.1 Test Equipment

Voltage Source: The input voltage source, VIN, must be a 0-V to 14-V variable DC source capable of supplying

10 ADC. Connect VIN to J1 as shown in Figure 4-2.

Multimeters: A 0-V to 15-V voltmeter must be used to measure VIN at TP6 (VIN) and TP7 (PGND) and a 0-V

to 5-V voltmeter for VOUT measurement at TP8 (VOUT) and TP9 (PGND). A 0-A to 10-A current meter (A1) as

shown in Figure 4-2 is used for input current measurements.

Output Load: The output load must be an electronic constant resistance mode load capable of 0 ADC to 30 ADC

at 1.2 V.

Oscilloscope: A digital or analog oscilloscope can be used to measure the output ripple. The oscilloscope must

be set for the following:

•

•

•

•

•

1-MΩ impedance

20-MHz bandwidth

AC coupling

2-µs/division horizontal resolution

50-mV/division vertical resolution

Test points TP8 and TP9 can be used to measure the output ripple voltage by placing the oscilloscope probe tip

through TP8 and holding the ground barrel TP9 as shown in Figure 4-1. Using a leaded ground connection can

induce additional noise due to the large ground loop.

Metal Ground Barrel

Probe Tip

TP8

TP9

Figure 4-1. Tip and Barrel Measurement for VOUT Ripple

Fan: Some of the components in this EVM can get hot, approaching temperatures up to 60°C during operation.

A small fan capable of 200 to 400 LFM is recommended to reduce component temperatures while the EVM is

operating. The EVM must not be probed while the fan is not running.

Recommended Wire Gauge: For VIN to J1 (12-V input), the recommended wire size is 1× AWG 14 per input

connection, with the total length of wire less than four feet (2-foot input, 2-foot return). For J2 to LOAD, the

minimum recommended wire size is 2× AWG 14, with the total length of wire less than four feet (2-foot output,

2-foot return).

4

TPS51218 Buck Controller Evaluation Module User's Guide

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

�www.ti.com

Test Setup

4.2 Recommended Test Setup

DC

Source

Vin

+

-

+

-

A1

Load

V1

V2

FAN

TEXAS

INSTRUMENTS

Figure 4-2. TPS51218EVM Recommended Test Setup

Figure 4-2 shows the recommended test setup to evaluate the TPS51218EVM. Working at an ESD workstation,

ensure that any wrist straps, bootstraps, or mats are connected referencing the user to earth ground before

power is applied to the EVM.

4.2.1 Configurations

•

•

EN J4 setting

1. No jumper enables the controller.

2. A jumper shorted on J4 disables the controller (default setting).

PWM J3 setting

1. A jumper on pin 2 and pin 3 of J3 set the auto-skip mode (default setting).

2. A jumper on pin 1 and pin 2 of J3 sets a forced CCM mode.

4.2.2 Input Connections

1. Prior to connecting the DC input source VIN, it is advisable to limit the source current from VIN to 10 A

maximum. Ensure that VIN is initially set to 0 V and connected as shown in Figure 4-2.

2. Connect a voltmeter V1 at TP6 (VIN) and TP7 (PGND) to measure the input voltage.

3. Connect a current meter A1 to measure the input current.

4.2.3 Output Connections

1. Connect the load to J2, and set the load to constant resistance mode to sink 0 ADC before VIN is applied.

2. Connect a voltmeter V2 at TP8 (VOUT) and TP9 (PGND) to measure the output voltage.

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

TPS51218 Buck Controller Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

5

�Test Setup

www.ti.com

4.2.4 Other Connections

Place a fan as shown in Figure 4-2 and turn it on, making sure that air is flowing across the EVM.

6

TPS51218 Buck Controller Evaluation Module User's Guide

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

�www.ti.com

Test Procedure

5 Test Procedure

5.1 Line/Load Regulation and Efficiency Measurement Procedure

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Ensure that the load is set to constant resistance mode and to sink 0 ADC.

Ensure that the jumper provided in the EVM to short J4 is on before VIN is applied.

Ensure that the jumper provided in the EVM to short pin 2 and pin 3 of J3 is on before VIN is applied.

Increase VIN from 0 V to 12 V. Use V1 to measure the input voltage.

Remove the jumper on J4 to enable the controller.

Vary the load from 0 ADC to 20 ADC. VOUT must remain in load regulation.

Vary VIN from 8 V to 14 V. VOUT must remain in line regulation.

Put the jumper on J4 to disable the controller.

Decrease the load to 0 A.

Decrease VIN to 0 V.

5.2 List of Test Points

Table 5-1. The Functions of Each Test Points

Test Points

Name

Description

TP1

EN

Enable

TP2

PGOOD

Power Good

TP3

GND

GND

TP4

PGND

PGND

TP5

SW

Switching node

TP6

Vin

Vin

TP7

PGND

GND for Vin

TP8

Vout

Vout

TP9

PGND

PGND

5.3 Equipment Shutdown

1. Shut down the load.

2. Shut down VIN.

3. Shut down the fan.

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

TPS51218 Buck Controller Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

7

�Performance Data and Typical Characteristic Curves

www.ti.com

6 Performance Data and Typical Characteristic Curves

Figure 6-1 through Figure 6-9 present typical performance curves for the TPS51218EVM.

6.1 Efficiency

100

8 Vin auto skip

90

12 Vin auto skip

80 14 Vin auto skip

Efficiency - %

70

8 Vin forced CCM

60

50

12 Vin forced CCM

40

14 Vin forced CCM

30

20

10

0

0.001

0.01

0.1

1

IO - Output Current - A

10

100

Figure 6-1. TPS51218EVM Efficiency

6.2 Load Regulation

1.27

1.26

VO - Output Volatge - V

14 Vin forced CCM

1.25

12 Vin forced CCM

8 Vin forced CCM

1.24

1.23

1.22

14 Vin auto skip

12 Vin auto skip

8 Vin auto skip

1.21

1.2

0.001

0.01

0.1

1

IO - Output Current - A

10

100

Figure 6-2. TPS51218 Load Regulation

8

TPS51218 Buck Controller Evaluation Module User's Guide

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

�www.ti.com

Performance Data and Typical Characteristic Curves

6.3 Transient Response

TPS51218EVM Transient Response

12 Vin, 1.2 V/5A-15A Auto skip

CH1: 1.2 Voutput

CH2: Output Current

t - Time - 200 ms/div

Figure 6-3. TPS51218EVM Load Transient

TPS51218EVM Transient Response

12 Vin, 1.2 V/0A-10A Auto skip

CH1: 1.2 Voutput

CH2: Output Current

t - Time - 200 ms/div

Figure 6-4. TPS51218EVM Load Transient

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

TPS51218 Buck Controller Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

9

�Performance Data and Typical Characteristic Curves

www.ti.com

6.4 Output Ripple

TPS51218EVM Output Ripple

12 Vin, 1.2 V/20A Forced PWM

CH1: 1.2 Vout Ripple

t - Time - 2 ms/div

Figure 6-5. Output Ripple

6.5 Switch Node Voltage

TPS51218EVM Switching Node

12 Vin, 1.2 V/20A Forced PWM

CH1: SW

t - Time - 80 ns/div

Figure 6-6. Switching Node Waveform

10

TPS51218 Buck Controller Evaluation Module User's Guide

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

�www.ti.com

Performance Data and Typical Characteristic Curves

6.6 Turn-On Waveform

TPS51218EVM Enable Start up

12 Vin, 1.2 V/20A Auto skip

CH1: 12 Vin

CH2: Enable

CH3: 1.2 Vout

CH4: PGOOD

t - Time - 1 ms/div

Figure 6-7. Enable Turn-On Waveform

6.7 Turn-Off Waveform

TPS51218EVM Enable Shut down

12 Vin, 1.2 V/20A Auto skip

CH1: 12 Vin

CH2: Enable

CH3: 1.2 Vout

CH4: PDOOD

t - Time - 1 ms/div

Figure 6-8. Enable Turn-Off Waveform

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

TPS51218 Buck Controller Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

11

�Performance Data and Typical Characteristic Curves

www.ti.com

6.8 Output 1.1-V Prebias Turn-On

TPS51218EVM Enable Pre-bias start up

1.1 V output pre-bias

12 Vin, 1.2 V/0A forced PWM

CH1: 1.2 Vin

CH2: Enable

CH3: 1.2 Vout

CH4: PGOOD

t - Time - 1 ms/div

Figure 6-9. Output 1.1-V Prebias TurnOn

12

TPS51218 Buck Controller Evaluation Module User's Guide

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

�www.ti.com

EVM Assembly Drawing and PCB Layout

7 EVM Assembly Drawing and PCB Layout

Figure 7-1 through Figure 7-6 show the design of the TPS51218EVM printed-circuit board. The EVM has been

designed using a four-layer, 2-oz copper circuit board.

TEXAS

INSTRUMENTS

Figure 7-1. TPS51218EVM Top Layer Assembly Drawing, Top View

Figure 7-2. TPS51218EVM Bottom Assembly Drawing, Bottom View

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

TPS51218 Buck Controller Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

13

�EVM Assembly Drawing and PCB Layout

www.ti.com

Figure 7-3. TPS51218EVM Top Copper, Top View

Figure 7-4. TPS51218EVM Internal Layer 1

14

TPS51218 Buck Controller Evaluation Module User's Guide

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

�www.ti.com

EVM Assembly Drawing and PCB Layout

Figure 7-5. TPS51218EVM Internal Layer 2

Figure 7-6. TPS51218EVM Bottom Layer

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

TPS51218 Buck Controller Evaluation Module User's Guide

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

15

�Bill of Materials

www.ti.com

8 Bill of Materials

The EVM components are shown in Table 8-1 according to the schematic shown in Figure 3-1.

Table 8-1. Bill of Materials

QTY

REFDES

Description

MFR

Part Number

2

C9, C12

Capacitor, Ceramic, 22 µF, 16 V, X5R, 10%, 1210

Murata

GRM32ER61C226KE20L

1

C3

Capacitor, Ceramic, 1 µF, 16 V, X7R, 10%, 0603

STD

STD

2

C1, C16

Capacitor, Ceramic, 0.022 µF, 16 V, X7R, 10%, 0603

STD

STD

1

C8

Capacitor, Ceramic, 3300 pF, 25 V, X7R, 10%, 0603

STD

STD

3

C4, C5, C6

Capacitor, Ceramic, 10 µF, 16 V, X5R, 10%, 0805

STD

STD

2

C7, C17

Capacitor, Ceramic, 0.1 µF, 25 V, X7R, 10%, 0603

STD

STD

5

C10, C11, C13,

C14, C15

Capacitor, Ceramic, 100 µF, 6.3 V, X5R, 20%, 1210

Murata

GRM32ER60J107ME20L

1

L1

Inductor, SMT, 0.44 µH, 30 A, 0.0032 Ω, 0.530" × 0.510"

Pulse

PA0513.441NLT

E&E Magnetic

831-02990F

1

Q1

MOSFET, Nchan, 25 V, 21 A, 4.1 mΩ, QFN5X6mm

TI (Ciclon)

CSD16404Q5A

2

Q2, Q4

MOSFET, Nchan, 25 V, 31 A, 2.1 mΩ, QFN5X6mm

TI(Ciclon)

CSD16321Q5

3

R1, R11, R13

Resistor, Chip, 10 k, 1/16W, 1%, 0603

STD

STD

1

R10

Resistor, Chip, 7.15 k, 1/16W, 1%, 0603

STD

STD

1

R3

Resistor, Chip, 19.6 k, 1/16W, 1%, 0603

STD

STD

2

R2, R12

Resistor, Chip, 100 k, 1/16W, 1%, 0603

STD

STD

2

R6, R7

Resistor, Chip, 0, 1/16W, 1%, 0603

STD

STD

1

R4

Resistor, Chip, 3.01, 1/16W, 1%, 0603

1

R5

Resistor, Chip, 2.37, 1/16W, 1%, 0603

STD

STD

2

R8, R9

Resistor, Chip, 1, 1/16W, 5%, 0805

STD

STD

1

U2

IC, Integrated LDO with switch-over circuit, DGS10

TI

TPS51103DRC

1

U1

IC, Synchronous step-down controller, DSC10

TI

TPS51218DSC

9 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Revision * (January 2010) to Revision A (February 2022)

Page

• Updated the numbering format for tables, figures, and cross-references throughout the document. ................2

• Updated the user's guide title............................................................................................................................. 2

16

TPS51218 Buck Controller Evaluation Module User's Guide

SLVU346A – JANUARY 2010 – REVISED FEBRUARY 2022

Submit Document Feedback

Copyright © 2022 Texas Instruments Incorporated

�IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, regulatory or other requirements.

These resources are subject to change without notice. TI grants you permission to use these resources only for development of an

application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license

is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you

will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these

resources.

TI’s products are provided subject to TI’s Terms of Sale or other applicable terms available either on ti.com or provided in conjunction with

such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2022, Texas Instruments Incorporated

�