TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

4.5-V TO 20-V INPUT, 3-A OUTPUT SYNCHRONOUS PWM SWITCHES

WITH INTEGRATED FET (SWIFT™)

FEATURES

1

SIMPLIFIED SCHEMATIC

• 100-mΩ, 4.5-A Peak MOSFET Switch for High

Efficiency at 3-A Continuous Output Current

• Use External Low-Side MOSFET or Diode

• Fixed-Output Versions – 1.2 V/1.5 V/1.8 V/

2.5 V/3.3 V/5 V

• Internally Compensated for Low Parts Count

• Synchronize to External Clock

• 180° Out-of-Phase Synchronization

• Wide Pulse Width Modulation (PWM)

Frequency – Fixed 250 kHz,

500 kHz, or Adjustable 250 kHz to 700 kHz

• Internal Slow Start

• Load Protected by Peak Current Limit and

Thermal Shutdown

• Adjustable Undervoltage Lockout

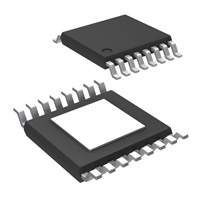

• 16-Pin PowerPAD™ Thin Shrink Small-Outline

Package (TSSOP) (PWP)

2

Input

Voltage

TPS54356

VIN

SYNC

PWRGD

ENA

BOOT

BIAS

PH

Output

Voltage

LSG

PGND

VSENSE

PWRPAD

EFFICIENCY

vs

OUTPUT CURRENT

100

VI = 6 V

95

VI = 12 V

APPLICATIONS

•

•

•

•

Industrial and Commercial Low-Power

Systems

LCD Monitors and TVs

Computer Peripherals

Point-of-Load Regulation for High

Performance DSPs, FPGAs, ASICs, and

Microprocessors

SUPPORTS DEFENSE, AEROSPACE,

AND MEDICAL APPLICATIONS

•

•

•

•

•

•

•

(1)

Efficiency − %

90

85

80

75

70

65

60

VI= 12 V

VO= 3.3 V

fs = 500 kHz

55

50

0

1

2

3

4

IO − Output Current − A

Controlled Baseline

One Assembly/Test Site

One Fabrication Site

Available in Military (–55°C/125°C)

Temperature Range (1)

Extended Product Life Cycle

Extended Product-Change Notification

Product Traceability

Additional temperature ranges are available - contact factory

1

2

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

SWIFT, PowerPAD are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2007–2009, Texas Instruments Incorporated

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

DESCRIPTION/ORDERING INFORMATION

The TPS5435x is a medium-output-current synchronous buck PWM converter with an integrated high-side

MOSFET and a gate driver for an optional low-side external MOSFET. Features include a high-performance

voltage error amplifier that enables maximum performance under transient conditions. The TPS5435x has an

undervoltage lockout (UVLO) circuit to prevent start-up until the input voltage reaches a preset value, an internal

slow-start circuit to limit in-rush currents, and a power-good (PWRGD) output to indicate valid output conditions.

The synchronization feature is configurable as either an input or an output for easy 180° out-of-phase

synchronization.

The TPS5435x devices are available in a thermally enhanced 16-pin PowerPAD™ Thin Shrink Small-Outline

Package (TSSOP). TI provides evaluation modules and the SWIFT™ Designer software tool to aid in quickly

achieving high-performance power-supply designs to meet aggressive equipment development cycles.

2

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

ORDERING INFORMATION

–55°C to 125°C

OUTPUT VOLTAGE

PART NUMBER

Plastic HTSSOP – PWP

1.2 V

TPS54352MPWPREP (2)

TBD

Plastic HTSSOP – PWP

1.5 V

TPS54353MPWPREP (2)

TBD

Plastic HTSSOP – PWP

1.8 V

TPS54354MPWPREP

Plastic HTSSOP – PWP

2.5 V

TPS54355MPWPREP (2)

Plastic HTSSOP – PWP

3.3 V

TPS54356MPWPREP

Plastic HTSSOP – PWP

(1)

(2)

PACKAGE

MARKING

PACKAGE (1)

TJ

5V

TPS54357MPWPREP

PMDM

TBD

PMEM

(2)

TBD

The PWP package also is available taped and reeled. Add an R suffix to the device type (i.e., TPS5435xPWPR).

Product preview

Absolute Maximum Ratings (1)

over operating free-air temperature range (unless otherwise noted)

UNIT

VIN

Input voltage range, VI

Output voltage range, VO

Source current, IO

VSENSE

–0.3 V to 8 V

UVLO

–0.3 V to 8 V

SYNC

–0.3 V to 4 V

ENA

–0.3 V to 4 V

BOOT

VI(PH) + 8 V

VBIAS

–0.3 V to 8.5 V

LSG

–0.3 V to 8.5 V

SYNC

–0.3 V to 4 V

RT

–0.3 V to 4 V

PWRGD

–0.3 V to 6 V

COMP

–0.3 V to 4 V

PH

–1.5 V to 22 V

PH

Internally Limited (A)

LSG (steady-state current)

10 mA

COMP, VBIAS

3 mA

SYNC

Sink current, IS

Voltage differential

–0.3 V to 21.5 V

5 mA

LSG (steady-state current)

100 mA

PH (steady-state current)

500 mA

COMP

3 mA

ENA, PWRGD

10 mA

AGND to PGND

±0.3 V

Operating virtual junction temperature range, TJ

–55°C to 150°C

Storage temperature range, Tstg

–65°C to 150°C

Lead temperature 1,6 mm (1/16 in) from case for 10 s

(1)

260°C

Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

3

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

Electrostatic Discharge (ESD) Protection

MIN

MAX

UNIT

Human-Body Model (HBM)

600

V

Charged-Device Model (CDM)

1.5

kV

Recommended Operating Conditions

TPS54352-6

Input voltage range, VI

TPS54357

Operating junction temperature, TJ

MIN

MAX

4.5

20

6.65

20

–55

125

UNIT

V

°C

Electrical Characteristics

TJ = –55°C to 125°C, VIN = 4.5 V to 20 V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

Supply Current

IQ

VIN

Quiescent current

Operating current, PH pin open,

No external low side MOSFET, RT = Hi-Z

5

Shutdown, ENA = 0 V

1

Start threshold

voltage

TPS54352-6

Stop threshold

voltage

TPS54352-6

3.69

3.97

TPS54357

5.45

5.8

Hysteresis

TPS54357

mA

4.32

4.48

6.4

6.65

TPS54352-6

350

TPS54357

600

V

V

mV

Output Voltage

TPS54352

TPS54353

TPS54354

VO

Output voltage

TPS54355

TPS54356

TPS54357

TJ = 25°C, IO = 100 mA to 3 A

1.88

1.2

1.212

IO = 100 mA to 3 A

1.176

1.2

1.224

TJ = 25°C, IO = 100 mA to 3 A

1.485

1.5

1.515

1.47

1.5

1.53

TJ = 25°C, IO = 100 mA to 3 A

1.782

1.8

1.818

IO = 100 mA to 3 A

1.764

1.8

1.836

TJ = 25°C, IO = 100 mA to 3 A

2.475

2.5

2.525

2.45

2.5

2.55

TJ = 25°C, VIN = 5.5 V to 20 V,

IO = 100 mA to 3 A

3.267

3.3

3.333

VIN = 5.5 V to 20 V, IO = 100 mA to 3 A

3.234

3.3

3.366

4.95

5

5.05

4.9

5

5.1

1.2

1.25

IO = 100 mA to 3 A

IO = 100 mA to 3 A

TJ = 25°C, VIN = 7.5 V to 20 V,

IO = 100 mA to 3 A

VIN = 7.5 V to 20 V, IO = 100 mA to 3 A

V

Under Voltage Lockout (UVLO)

Start threshold voltage

UVLO

Stop threshold voltage

1.02

Hysteresis

V

1.1

V

100

mV

Bias Voltage (VBIAS)

VBIAS

Output voltage

IVBIAS = 5 mA, VIN ≥ 12 V

7.5

7.8

8

IVBIAS = 5 mA, VIN = 4.5 V

4.4

4.47

4.5

RT grounded

200

250

300

RT open

400

500

600

RT = 100 kΩ (1% resistor to AGND)

425

500

575

V

Oscillator (RT)

Internally set PWM switching frequency

Externally set PWM switching frequency

4

Submit Documentation Feedback

kHz

kHz

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

Electrical Characteristics (continued)

TJ = –55°C to 125°C, VIN = 4.5 V to 20 V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

Falling-Edge-Triggered Bidirectional Sync System (SYNC)

SYNC out low-to-high rise time

(10%/90%) (1)

25 pF to ground

200

500

ns

SYNC out high-to-low fall time

(90%/10%) (1)

25 pF to ground

5

10

ns

Falling-edge delay time (1)

Delay from rising edge to rising edge of PH

pins, See Figure 19

180

°

RT = 100 kΩ

100

ns

Delay

RT = 100 kΩ

(falling-edge SYNC to rising-edge PH) (1)

360

ns

Minimum input pulse width

(1)

SYNC out high-level voltage

50-kΩ resistor to ground, No pullup resistor

2.5

V

SYNC out low-level voltage

0.6

SYNC in low-level threshold

0.8

V

SYNC in high-level threshold

SYNC in frequency range (1)

2.3

Percentage of programmed frequency

V

–10%

10%

225

770

V

kHz

Feed-Forward Modulator (Internal Signal)

Modulator gain

VIN = 12 V, TJ = 25°C

8

Modulator gain variation

±25%

Minimum controllable ON time (1)

Maximum duty factor (1)

180

VIN = 4.5 V

80%

ns

86%

VSENSE

Input bias current, VSENSE

µA

1

Enable (ENA)

Disable low-level input voltage

TPS54352

TPS54353

Internal

slow-start time

(10% to 90%)

TPS54354

TPS54355

TPS54356

TPS54357

0.5

fs = 250 kHz, RT = ground (1)

3.2

fs = 500 kHz, RT = Hi-Z (1)

1.6

fs = 250 kHz, RT = ground (1)

4

fs = 500 kHz, RT = Hi-Z (1)

2

fs = 250 kHz, RT = ground

4.6

fs = 500 kHz, RT = Hi-Z (1)

2.3

fs = 250 kHz, RT = ground (1)

4.4

fs = 500 kHz, RT = Hi-Z (1)

2.2

fs = 250 kHz, RT = ground (1)

5.9

fs = 500 kHz, RT = Hi-Z (1)

2.9

fs = 250 kHz, RT = ground (1)

5.4

fs = 500 kHz, RT = Hi-Z

(1)

Pullup current source

Pulldown MOSFET

(1)

V

ms

2.7

1.8

5

II(ENA) = 1 mA

0.1

Rising voltage

97%

10

µA

V

Power Good (PWRGD)

Power-good threshold

Rising-edge delay (1)

PWRGD

(1)

fs = 250 kHz

4

fs = 500 kHz

2

Output saturation voltage

Isink = 1 mA, VIN > 4.5 V

0.05

Output saturation voltage

Isink = 100 µA, VIN = 0 V

0.76

Open-drain leakage current

Voltage on PWRGD = 6 V

ms

V

V

3

µA

Specified by design, not production tested

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

5

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

Electrical Characteristics (continued)

TJ = –55°C to 125°C, VIN = 4.5 V to 20 V (unless otherwise noted)

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

3.3

4.5

6.5

UNIT

Current Limit

Current limit

Current-limit hiccup time

VIN = 12 V

(2)

fs = 500 kHz

A

4.5

ms

165

°C

7

°C

15

ns

ns

Thermal Shutdown

Thermal-shutdown trip point (2)

Thermal-shutdown hysteresis

(2)

Low-Side MOSFET Driver (LSG)

Turn-on rise time, (10/90%) (2)

VIN = 4.5 V, Capacitive load = 1000 pF

Deadtime

VIN = 12 V

60

VIN = 4.5 V sink/source

7.5

VIN = 12 V sink/source

5

Driver ON resistance

Ω

Output Power MOSFETS (PH)

Phase-node voltage when disabled

Voltage drop, low-side FET and diode

rDS(ON)

(2)

(3)

6

High-side power MOSFET switch (3)

DC coinditions and no load, ENA = 0 V

0.5

V

VIN = 4.5 V, Idc = 100 mA

1.13

1.42

VIN = 12 V, Idc = 100 mA

1.08

1.38

VIN = 4.5 V, BOOT-PH = 4.5 V, IO = 0.5 A

150

300

VIN = 12 V, BOOT-PH = 8V, IO = 0.5 A

100

200

V

mΩ

Specified by design, not production tested

Resistance from VIN to PH pins

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

PIN ASSIGNMENTS

PWP PACKAGE

(TOP VIEW)

VIN

VIN

UVLO

PWRGD

RT

SYNC

ENA

COMP

1

2

3

4

5

6

7

8

THERMAL

PAD

16

15

14

13

12

11

10

9

BOOT

PH

PH

LSG

VBIAS

PGND

AGND

VSENSE

NOTE: If there is not a pin 1 indicator, turn device to enable

reading the symbol from left to right. Pin 1 is at the lower

left corner of the device.

TERMINAL FUNCTIONS

TERMINAL

DESCRIPTION

NO.

NAME

1, 2

VIN

Input supply voltage, 4.5 V to 20 V. Must bypass with a low ESR 10-µF ceramic capacitor. Place cap as

close to device as possible; see Figure 23 for an example.

3

UVLO

Undervoltage lockout. Connecting an external resistive voltage divider from VIN to the pin overrides the

internal default VIN start and stop thresholds.

4

PWRGD

Power good output. Open-drain output. A low on the pin indicates that the output is less than the desired

output voltage. There is an internal rising-edge filter on the output of the PWRGD comparator.

5

RT

Frequency setting. Connect a resistor from RT to AGND to set the switching frequency. Connecting the RT

pin to ground or floating will set the frequency to an internally preselected frequency.

SYNC

Bidirectional synchronization I/O. SYNC is an output when the RT pin is floating or connected low. The

output is a falling-edge signal out of phase with the rising edge of PH. SYNC may be used as an input to

synchronize to a system clock by connecting to a falling edge signal when an RT resistor is used. See 180°

Out of Phase Synchronization operation in the Application Information section. In all cases, a 10-kΩ resistor

must be tied to the SYNC pin in parallel with ground. For information on how to extend slow start, see the

Enable (ENA) and Internal Slow Start section.

6

7

ENA

8

COMP

Enable. Below 0.5 V, the device stops switching. Float pin to enable.

9

VSENSE

10

AGND

Analog ground. Internally connected to the sensitive analog ground circuitry. Connect to PGND and

PowerPAD package.

11

PGND

Power ground. Noisy internal ground. Return currents from the LSG driver output return through the PGND

pin. Connect to AGND and PowerPAD package.

12

VBIAS

Internal 8-V bias voltage. A 1-µF ceramic bypass capacitance is required on the VBIAS pin.

13

LSG

Error amplifier output. Do not connect anything to this pin.

Feedback

Gate drive for optional low-side MOSFET. Connect gate of n-channel MOSFET for a higher efficiency

synchronous buck converter configuration. Otherwise, leave open and connect Schottky diode from ground

to PH pins.

14, 15

PH

16

BOOT

Phase node. Connect to external L-C filter.

Bootstrap capacitor for high-side gate driver. Connect a 0.1-µF ceramic capacitor from BOOT to PH pins.

PowerPAD

PGND and AGND pins must be connected to the exposed pad for proper operation. See Figure 23 for an

example PCB layout.

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

7

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

FUNCTIONAL BLOCK DIAGRAM

BOOT

VIN

PH

320 kΩ

Hiccup

UVLO

UVLO

125 kΩ(1)

SYNC

Current Limit

1.2V

2x Oscillator

RT

Bias + Drive

Regulator

PWM Ramp

(FeedFoward)

Z3

VBIAS

PWM

Comparator

COMP

S

Q

Adaptive Deadtime

and

Control Logic

Z1

Z4

VSENSE

VBIAS2

Z2

R

Error

Amplifier

LSG

Z5

Thermal

Shutdown

Reference

System

PWRGD

UVLO

5 µA

VSENSE

97% Ref

ENA

Hiccup

Timer

VBIAS

UVLO

Rising

Edge

Delay

Hiccup

TPS5435x

(1) 75

POWERPAD

kΩ for the TPS54357

VBIAS

PGND

AGND

DETAILED DESCRIPTION

Undervoltage Lockout (UVLO)

The UVLO system has an internal voltage divider from VIN to AGND. The defaults for the start/stop values are

labeled VIN and are given in Table 1. The internal UVLO threshold can be overridden by placing an external

resistor divider from VIN to ground. The internal divider values are approximately 320 kΩ for the high-side

resistor and 125 kΩ for the low-side resistor. The divider ratio (and, therefore, the default start/stop values) is

quite accurate, but the absolute values of the internal resistors may vary as much as 15%. If high accuracy is

required for an externally adjusted UVLO threshold, select lower-value external resistors to set the UVLO

threshold. Using a 1-kΩ resistor for the low-side resistor (R2 see Figure 1) is recommended. Under no

circumstances should the UVLO pin be connected directly to VIN.

Table 1. Start/Stop Voltage Threshold

VIN (default)

START VOLTAGE THRESHOLD

STOP VOLTAGE THRESHOLD

TPS54352-6

4.49

3.69

TPS54357

6.65

5.45

1.24

1.02

UVLO

The equations for selecting the UVLO resistors are:

VIN(start)

1 kW

R1 +

* 1 kW

1.24 V

(R1 ) 1 kW)

1.02 V

VIN(stop) +

1 kW

8

Submit Documentation Feedback

(1)

(2)

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

Input

Voltage

Supply

R2

(1) 75

320 kΩ

R1

1 kΩ

125 kΩ (1)

kΩ for the TPS54357

Figure 1. Circuit Using External UVLO Function

For applications that require an UVLO threshold greater than 4.49 V (6.6 V for TPS54357), external resistors

may be implemented (see Figure 1) to adjust the start-voltage threshold. For example, an application needing a

UVLO start voltage of approximately 7.8 V using equation 1, R1 is calculated to the nearest standard resistor

value of 5.36 kΩ. Using equation 2, the input voltage stop threshold is calculated as 6.48 V.

Enable (ENA) and Internal Slow Start

The TPS5435x has an internal digital slow start that ramps the reference voltage to its final value in 1150

switching cycles. The internal slow-start time (10% to 90%) is approximated by the following expression:

1.15k

T

(ms) +

SS_INTERNAL

ƒs (kHz) n

Use n in Table 2.

(3)

Table 2. Slow-Start Characteristics

DEVICE

n

TPS54352

1.485

TPS54353

1.2

TPS54354

1

TPS54355

1.084

TPS54356

0.818

TPS54357

0.900

Once the TPS5435x device is in normal regulation, the ENA pin is high. If ENA is pulled below the stop threshold

of 0.5 V, switching stops and the internal slow start resets. If an application requires the TPS5435x to be

disabled, use open-drain or open-collector output logic to interface to ENA (see Figure 2). ENA has an internal

pullup current source. Do not use external pullup resistors.

5 µA

Disabled

RSS

CSS

Enabled

Figure 2. Interfacing to the ENA Pin

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

9

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

Extending Slow-Start Time

In applications that use large values of output capacitance, there may be a need to extend the slow-start time to

prevent the startup current from tripping the current limit. The current-limit circuit is designed to disable the

high-side MOSFET and reset the internal voltage reference for a short amount of time when the high-side

MOSFET current exceeds the current-limit threshold. If the output capacitance and load current cause the startup

current to exceed the current-limit threshold, the power-supply output will not reach the desired output voltage.

To extend the slow-start time and to reduce the startup current, an external resistor and capacitor can be added

to the ENA pin. The slow-start capacitance is calculated using the following equation:

CSS (µF) = 5.55 10−3

n

Tss (ms)

Use n in Table 2.

(4)

The RSS resistor must be 2 kΩ and the slow-start capacitor must be less than 0.47 µF.

Switching Frequency (RT)

The TPS5435x has an internal oscillator that operates at twice the PWM switching frequency. The internal

oscillator frequency is controlled by the RT pin. Grounding RT sets the PWM switching frequency to a default

frequency of 250 kHz. Floating RT sets the PWM switching frequency to 500 kHz.

Connecting a resistor from RT to AGND sets the frequency according to the following equation (also see

Figure 30).

46000

RT (kW) +

ƒ s (kHz) * 35.9

(5)

RT controls the SYNC pin functions. If RT is floating or grounded, SYNC is an output. If the switching frequency

has been programmed using a resistor from RT to AGND, SYNC functions as an input.

The internal voltage-ramp charging current increases linearly with the set frequency and keeps the feed-forward

modulator constant (Km = 8), regardless of the frequency set point.

Table 3.

SWITCHING FREQUENCY

SYNC PIN

RT PIN

250 kHz, internally set

Generates SYNC output signal

AGND

500 kHz, internally set

Generates SYNC output signal

Float

Externally set from 250 kHz to 700 kHz

Terminate to quiet ground

with 10-kΩ resistor

R = 215 kΩ to 69 kΩ

Synchronization signal

Set RT resistor equal to 90% to 110% of external

synchronization frequency. When using a dual setup (see

Figure 27 for example), if the master 35x device RT pin is

left floating, use a 110-kΩ resistor to tie the slave RT pin

to ground. Conversely, if the master 35x device RT pin is

grounded, use a 237-kΩ resistor to tie the slave RT pin to

ground.

Externally synchronized frequency

180° Out-of-Phase Synchronization (SYNC)

The SYNC pin is configurable as an input or as an output, as noted in the previous section. When operating as

an input, SYNC is a falling-edge-triggered signal (see Figure 3, Figure 4, and Figure 19). When operating as an

output, the signal's falling edge is approximately 180° out of phase with the rising edge of the PH pins. Thus, two

TPS5435x devices operating in a system can share an input capacitor and draw ripple current at twice the

frequency of a single unit.

When operating the two TPS5435x devices 180° out of phase, the total RMS input current is reduced, thus,

reducing the amount of input capacitance needed and increasing efficiency.

When synchronizing a TPS5435x to an external signal, the timing resistor on the RT pin must be set so that the

oscillator is programmed to run at 90% to 110% of the synchronization frequency.

10

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

VI(SYNC)

VO(PH)

Figure 3. SYNC Input Waveform

Internal Oscillator

VO(PH)

VO(SYNC)

Figure 4. SYNC Output Waveform

Power Good (PWRGD)

The VSENSE pin is compared to an internal reference signal if the VSENSE is greater than 97% and no other

faults are present. The PWRGD pin presents a high impedance. A low on PWRGD indicates a fault. PWRGD

has been designed to provide a weak pulldown and indicates a fault even when the device is unpowered. If the

TPS5435x has power and has any fault flag set, the TPS5435x indicates the power is not good by driving the

PWRGD pin low. The following events, singly or in combination, indicate power is not good:

• VSENSE pin out of bounds

• Overcurrent

• Thermal shutdown

• UVLO undervoltage

• Input voltage not present (weak pulldown)

• Slow starting

• VBIAS voltage is low.

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

11

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

Once the PWRGD pin presents a high impedance (i.e., power is good), a VSENSE pin out-of-bounds condition

forces PWRGD low (i.e., power is bad) after a time delay. This time delay is a function of the switching frequency

and is calculated using equation 6:

T

+ 1000 ms

delay

ƒs (kHz)

(6)

Bias Voltage (VBIAS)

The VBIAS regulator provides a stable supply for the internal analog circuits and the low-side gate driver. Up to 1

mA of current can be drawn for use in an external application circuit. The VBIAS pin must have a bypass

capacitor value of 1 µF. X7R- or X5R-grade dielectric ceramic capacitors are recommended because of their

stable characteristics over temperature.

Bootstrap Voltage (BOOT)

The BOOT capacitor obtains its charge cycle by cycle from the VBIAS capacitor. A capacitor from the BOOT pin

to the PH pins is required for operation. The bootstrap connection for the high-side driver must have a bypass

capacitor of 0.1 µF.

Error Amplifier

The VSENSE pin is the error amplifier inverting input. The error amplifier is a true voltage amplifier, with 1.5 mA

of drive capability with a minimum of 60 dB of open-loop voltage gain and a unity-gain bandwidth of 2 MHz.

Voltage Reference

The voltage-reference system produces a precision reference signal by scaling the output of a

temperature-stable bandgap circuit. During production testing, the bandgap and scaling circuits are trimmed to

produce 0.891 V at the output of the error amplifier, with the amplifier connected as a voltage follower. The trim

procedure improves the regulation, since it cancels offset errors in the scaling and error-amplifier circuits.

PWM Control and Feed Forward

Signals from the error-amplifier output, oscillator, and current-limit circuit are processed by the PWM control

logic. Referring to the internal block diagram, the control logic includes the PWM comparator, PWM latch, and

the adaptive dead-time control logic. During steady-state operation below the current-limit threshold, the PWM

comparator output and oscillator pulse train alternately reset and set the PWM latch.

Once the PWM latch is reset, the low-side driver and integrated pulldown MOSFET remain on for a minimum

duration set by the oscillator pulse width. During this period, the PWM ramp discharges rapidly to the valley

voltage. When the ramp begins to charge back up, the low-side driver turns off and the high-side FET turns on.

The peak PWM ramp voltage varies inversely with input voltage to maintain a constant modulator and

power-stage gain of 8 V.

As the PWM ramp voltage exceeds the error-amplifier output voltage, the PWM comparator resets the latch, thus

turning off the high-side FET and turning on the low-side FET. The low-side driver remains on until the next

oscillator pulse discharges the PWM ramp.

During transient conditions, the error-amplifier output can be below the PWM ramp valley voltage or above the

PWM peak voltage. If the error amplifier is high, the PWM latch is never reset and the high-side FET remains on

until the oscillator pulse signals the control logic to turn the high-side FET off and the internal low-side FET and

driver on. The device operates at its maximum duty cycle until the output voltage rises to the regulation set point,

setting VSENSE to approximately the same voltage as the internal voltage reference. If the error-amplifier output

is low, the PWM latch is reset continually and the high-side FET does not turn on. The internal low-side FET and

low-side driver remain on until the VSENSE voltage decreases to a range that allows the PWM comparator to

change states. The TPS5435x is capable of sinking current through the external low-side FET until the output

voltage reaches the regulation set point.

The minimum on time is designed to be 180 ns. During the internal slow-start interval, the internal reference

ramps from 0 V to 0.891 V. During the initial slow-start interval, the internal reference voltage is very small,

resulting in skipped pulses because the minimum on time causes the actual output voltage to be slightly greater

than the preset output voltage, until the internal reference ramps up.

12

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

Deadtime Control

Adaptive dead-time control prevents shoot-through current from flowing in the integrated high-side MOSFET and

the external low-side MOSFET during the switching transitions by actively controlling the turn-on times of the

drivers. The high-side driver does not turn on until the voltage at the gate of the low-side MOSFET is below 1 V.

The low-side driver does not turn on until the voltage at the gate of the high-side MOSFET is below 1 V.

Low-Side Gate Driver (LSG)

LSG is the output of the low-side gate driver. The 100-mA MOSFET driver is capable of providing gate drive for

most popular MOSFETs suitable for this application. Use the SWIFT Designer Software Tool to find the most

appropriate MOSFET for the application. Connect the LSG pin directly to the gate of the low-side MOSFET. Do

not use a gate resistor, as the resulting turn-on time may be too slow.

Integrated Pulldown MOSFET

The TPS5435x has a diode-MOSFET pair from PH to PGND. The integrated MOSFET is designed for light-load

continuous-conduction-mode operation when only an external Schottky diode is used. The combination of

devices keeps the inductor current continuous under conditions where the load current drops below the inductor's

critical current. Care should be taken in the selection of inductor in applications using only a low-side Schottky

diode. Since the inductor ripple current flows through the integrated low-side MOSFET at light loads, the

inductance value should be selected to limit the peak current to less than 0.3 A during the high-side FET turn-off

time. The minimum value of inductance is calculated using the following equation:

ǒ1 * VO

Ǔ

VI

VO

L(H) +

ƒs

0.6

(7)

Thermal Shutdown

The device uses the thermal shutdown to turn off the MOSFET drivers and controller if the junction temperature

exceeds 165°C. The device is restarted automatically when the junction temperature decreases to 7°C below the

thermal shutdown trip point and starts up under control of the slow-start circuit.

Overcurrent Protection

Overcurrent protection is implemented by sensing the drain-to-source voltage across the high-side MOSFET and

compared to a voltage level that represents the overcurrent threshold limit. If the drain-to-source voltage exceeds

the overcurrent threshold limit for more than 100 ns, the ENA pin is pulled low, the high-side MOSFET is

disabled, and the internal digital slow-start is reset to 0 V. ENA is held low for approximately the time that is

calculated by the following equation:

T

(ms) + 2250

HICCUP

ƒs (kHz)

(8)

Once the hiccup time is complete, ENA is released and the converter initiates the internal slow start.

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

13

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

TYPICAL CHARACTERISTICS

Conditions are VI = 12 V, VO = 3.3 V, fs = 500 kHz, IO = 3 A, TA = 25°C (unless otherwise noted).

Gain

0

0

−10

−30

−20

−60

−30

−90

−120

See Figure 25

−50

−60

100

1k

10 k

−150

−180

1M

100 k

VI = 12 V

0.1

VI = 6 V

0

−0.2

See Figure 25

0

0.5

1

0

−0.02

IO = 0 A

−0.04

−0.06

1.5

2

2.5

3

3.5

−0.1

4

See Figure 25

6

10

8

12

14

16

18

20

22

VI − Input Voltage − V

Figure 6.

INPUT RIPPLE VOLTAGE

Figure 7.

OUTPUT RIPPLE VOLTAGE

VI(RIPPLE) = 100 mV/div (ac coupled)

VO(RIPPLE) = 10 mV/div (ac coupled)

VI = 6 V

95

IO = 1.5 A

0.02

IO − Output Current − A

Figure 1

Figure 5.

EFFICIENCY

vs

OUTPUT CURRENT

IO = 3 A

0.04

−0.08

−0.3

f − Frequency − Hz

100

VI = 18 V

−0.1

0.06

VI = 12 V

Amplitude

90

85

80

V(PH) = 5 V/div

Amplitude

−40

0.2

Output Voltage Change − %

30

Output Voltage Change − %

60

Phase − Degrees

90

20

10

0.08

120

Phase

30

Efficiency − %

0.1

150

40

G − Gain − dB

0.3

180

50

LINE REGULATION

LOAD REGULATION

MEASURED LOOP RESPONSE

60

V(PH) = 5 V/div

VI = 18 V

75

70

65

See Figure 25

60

See Figure 25

50

0

1

See Figure 25

Time − 1 µs/div

55

2

3

Time − 1 µs/div

4

IO − Output Current − A

Figure 8.

GATE DRIVE VOLTAGE

See Figure 25

Figure 11.

Submit Documentation Feedback

VI = 5 V/div

VO= 2 V/div

V(PWRGD)= 2 V/div

See Figure 25

See Figure 25

Time − 1 µs/div

14

I(PH) = 1 A/div

Power Up Response − mV

V(PH) = 5 V/div

Figure 10.

POWER UP

VO = 50 mV/div (ac coupled)

Load Transient Response − mV

Amplitude

V(LSG) = 5 V/div

Figure 9.

LOAD TRANSIENT RESPONSE

Time − 200 µs/div

Figure 12.

Time − 2 ms/div

Figure 13.

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

TYPICAL CHARACTERISTICS (continued)

Conditions are VI = 12 V, VO = 3.3 V, fs = 500 kHz, IO = 3 A, TA = 25°C (unless otherwise noted).

EFFICIENCY

vs

OUTPUT CURRENT

100

VI = 5 V/div

CONTINUOUS CONDUCTION MODE

V(PH) = 5 V/div

Continuous Conduction Mode

Power Down Waveforms − V

POWER DOWN

VI = 6 V

95

VI = 12 V

90

85

Efficiency − %

VO= 2 V/div

V(PWRGD)= 2 V/div

VI = 18 V

80

75

70

I(L1) = 200 mA/div

65

See Figure 25

See Figure 26

60

Time − 1 µs/div

55

Time − 2 ms/div

See Figure 26

50

0

1

2

3

4

IO − Output Current − A

Figure 14.

LIGHT LOAD CONDUCTION

Figure 15.

SEQUENCING WAVEFORMS

Figure 16.

INPUT RIPPLE CANCELLATION

V(PH1) = 10 V/div

VO1(3.3)= 2 V/div

V(PWRGD1)= 2 V/div

V(PH2) = 10 V/div

VI = 50 mV/div (ac coupled)

VO2 (1.8)= 2 V/div

See Figure 26

Time − 1 µs/div

50

40

120

40

120

30

90

30

90

20

60

90

20

60

10

0

Gain

30

0

0

−60

−90

−30

−90

−120

−40

−120

−40

−150

−50

−60

−150

−180

1M

−50

−40

100 k

30

0

−30

−30

10 k

0

60

Gain

10

−30

−60

1k

0

20

−20

−20

−60

100

30

150

−60

−30

See Figure 28

Gain

10

180

Phase

−10

−10

−50

G − Gain − dB

30

Phase − Degrees

120

Phase

G − Gain − dB

60

150

50

Phase

Figure 19.

MEASURED LOOP RESPONSE

330-mF OSCON

180

60

150

40

G − Gain − dB

Figure 18.

MEASURED LOOP RESPONSE

2 y 180-mF SP CAPACITORS

180

50

Time − 1 µs/div

Time − 2 ms/div

Figure 17.

MEASURED LOOP RESPONSE

100-mF POSCAP

Phase − Degrees

60

See Figure 27

See Figure 27

−10

−30

−20

−90

−180

1M

f − Frequency − Hz

Figure 20.

Copyright © 2007–2009, Texas Instruments Incorporated

See Figure 29

100

1k

10 k

100 k

f − Frequency − Hz

Figure 21.

Phase − Degrees

I(L1) = 200 mA/div

Input Ripple Cancellation − V

VI = 10 V/div

Sequencing Waveforms − V

Light Load Conduction

V(PH) = 5 V/div

−120

See Figure 30

−60

100

1k

−150

10 k

100 k

−180

1M

f − Frequency − Hz

Figure 22.

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

15

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

LAYOUT INFORMATION

Figure 23. TPS5435x PCB Layout

PCB Layout

The VIN pins should be connected together on the printed circuit board (PCB) and bypassed with a low-ESR

ceramic bypass capacitor. Care should be taken to minimize the loop area formed by the bypass capacitor

connections, the VIN pins, and the TPS5435x ground pins. The minimum recommended bypass capacitance is

10-µF ceramic with a X5R or X7R dielectric, and the optimum placement is closest to the VIN pins and the

AGND and PGND pins. See Figure 23 for an example of a board layout. The AGND and PGND pins should be

tied to the PCB ground plane at the pins of the IC. The source of the low-side MOSFET and the anode of the

Schottky diode should be connected directly to the PCB ground plane. The PH pins should be tied together and

routed to the drain of the low-side MOSFET or to the cathode of the external Schottky diode. Since the PH

connection is the switching node, the MOSFET (or diode) should be located very close to the PH pins, and the

area of the PCB conductor minimized to prevent excessive capacitive coupling. The recommended conductor

width from pins 14 and 15 is 0.050 in to 0.075 in of 1-oz copper. The length of the copper land pattern should be

no more than 0.2 in.

For operation at full-rated load, the analog ground plane must provide adequate heat dissipating area. A 3-in ×

3-in plane of copper is recommended, though not mandatory, dependent on ambient temperature and airflow.

Most applications have larger areas of internal ground plane available, and the PowerPAD package should be

connected to the largest area available. Additional areas on the bottom or top layers also help dissipate heat,

and any area available should be used when 3 A or greater operation is desired. Connection from the exposed

area of the PowerPAD package to the analog ground-plane layer should be made using 0.013-in diameter vias to

avoid solder wicking through the vias. Four vias should be in the PowerPAD area, with four additional vias

outside the pad area and underneath the package. Additional vias beyond those recommended to enhance

thermal performance should be included in areas not under the device package.

16

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

�0.0130

8 PL

Minimum recommended exposed copper

area for PowerPAD package . 5-mil

stencils may require 10-% larger area.

Minimum recommended thermal vias:

4 � 0.013 diameter inside PowerPAD area and

4 � 0.013 diameter under device as shown.

Additional 0.018 diameter vias may be used if

top-side analog ground area is extended.

0.0150

0.06

0.0371

0.0400

0.1970

0.1942

0.0570

0.0400

0.0400

0.0256

Minimum recommended

top-side analog ground area.

0.1700

0.1340

0.0690

0.0400

Connect pin 10 AGND

and pin 11 PGND to

analog ground plane in

this area for optimum

performance.

Figure 24. Thermal Considerations for PowerPAD™ Layout

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

17

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

APPLICATION INFORMATION

Figure 25 shows the schematic for a typical TPS54356 application. The TPS54356 can provide up to 3-A output

current at a nominal output voltage of 3.3 V. For proper thermal performance, the exposed PowerPAD package

underneath the device must be soldered down to the printed circuit board.

+

+

Figure 25. Application Circuit, 12 V to 3.3 V

Design Procedure

The following design procedure can be used to select component values for the TPS54356. Alternately, the

SWIFT Designer Software may be used to generate a complete design. The SWIFT Designer Software uses an

iterative design procedure and accesses a comprehensive database of components when generating a design.

This section presents a simplified discussion of the design process.

To begin the design process, a few parameters must be decided upon. The designer needs to know the

following:

• Input voltage range

• Output voltage

• Input ripple voltage

• Output ripple voltage

• Output current rating

• Operating frequency

For this design example, use the following as the input parameters:

DESIGN PARAMETER

EXAMPLE VALUE

Input voltage range

6 V to 18 V

Output voltage

3.3 V

Input ripple voltage

300 mV

Output ripple voltage

10 mV

Output current rating

3A

Operating frequency

500 kHz

Switching Frequency

The switching frequency is set using the RT pin. Grounding RT sets the PWM switching frequency to a default

frequency of 250 kHz. Floating RT sets the PWM switching frequency to 500 kHz. By connecting a resistor from

RT to AGND, any frequency in the range of 250 kHz to 700 kHz can be set. Use equation 9 to determine the

proper value of RT.

46000

RT (kW) +

ƒ s (kHz) * 35.9

(9)

In this example circuit, RT is not connected and the switching frequency is set at 500 kHz.

18

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

Input Capacitors

The TPS54356 requires an input decoupling capacitor and, depending on the application, a bulk input capacitor.

The minimum value for the decoupling capacitor, C9, is 10 µF. A high-quality ceramic type X5R or X7R is

recommended. The voltage rating should be greater than the maximum input voltage. Additionally, some bulk

capacitance may be needed, especially if the TPS54356 circuit is not located within about 2 in from the input

voltage source. The value for this capacitor is not critical, but it also should be rated to handle the maximum

input voltage including ripple voltage and should filter the output so that input ripple voltage is acceptable.

This input ripple voltage can be approximated by equation 10:

I OUT(MAX) 0.25

DV IN +

) (I OUT(MAX) ESR (MAX))

CBULK ƒ sw

(10)

Where:

IOUT(MAX) = Maximum load current

ƒSW= Switching frequency

CBULK = Bulk capacitor value

and ESRMAX = Maximum series resistance of the bulk capacitor

The maximum RMS ripple current also needs to be checked. For worst-case conditions, this can be

approximated by equation 11:

I

OUT(MAX)

I

+

CIN

2

(11)

In this case, the input ripple voltage is 140 mV and the RMS ripple current is 1.5 A. The maximum voltage across

the input capacitors is VIN max plus delta VIN/2. The chosen bulk and bypass capacitors are each rated for 25 V

and the combined ripple current capacity is greater than 3 A, both providing ample margin. It is very important

that the maximum ratings for voltage and current are not exceeded under any circumstance.

Output Filter Components

Inductor Selection

To calculate the minimum value of the output inductor, use equation 12:

V

L

(MIN)

+

V

OUT

IN(MAX)

ǒVIN(MAX) * VOUTǓ

K

I

IND

OUT

ƒ sw

(12)

KIND is a coefficient that represents the amount of inductor ripple current relative to the maximum output current.

For designs using low ESR output capacitors such as ceramics, use KIND = 0.3. When using higher ESR output

capacitors, KIND = 0.2 yields better results.

For this design example, use KIND = 0.1 to keep the inductor ripple current small. The minimum inductor value is

calculated to be 17.96 µH. The next-highest standard value is 22 µH, which is used in this design.

For the output filter inductor, it is important that the RMS current and saturation current ratings not be exceeded.

The RMS inductor current can be derived from equation 13:

I L(RMS) +

Ǹ

I 2OUT(MAX) ) 1

12

ǒ

V OUT

V IN(MAX)

Copyright © 2007–2009, Texas Instruments Incorporated

ǒV IN(MAX) * V OUTǓ

L OUT

ƒ sw

Ǔ

2

0.8

(13)

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

19

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

and the peak inductor current can be determined using equation 14:

I L(PK) + I OUT(MAX) )

ǒVIN(MAX) * VOUTǓ

V OUT

1.6

V IN(MAX)

L OUT

ƒ sw

(14)

For this design, the RMS inductor current is 3.007 A and the peak inductor current is 3.15 A. The chosen

inductor is a Coiltronics DR127-220 22 µH. It has a saturation current rating of 7.57 A and a RMS current rating

of 4 A, easily meeting these requirements. A lesser-rated inductor could be used if less margin is desired. In

general, inductor values for use with the TPS54356 are in the range of 6.8 µH to 47 µH.

Capacitor Requirements

The important design factors for the output capacitor are dc voltage rating, ripple current rating, and equivalent

series resistance (ESR). The dc voltage and ripple current ratings cannot be exceeded. The ESR is important

because, along with the inductor current, it determines the amount of output ripple voltage. The actual value of

the output capacitor is not critical, but some practical limits do exist.

Consider the relationship between the desired closed-loop crossover frequency of the design and LC corner

frequency of the output filter. In general, it is desirable to keep the closed-loop crossover frequency at less than

one-fifth of the switching frequency. With high switching frequencies such as the 500-kHz frequency of this

design, internal circuit limitations of the TPS54356 limit the practical maximum crossover frequency to about 70

kHz. Additionally, the capacitor type and value must be chosen to work with the internal compensation network of

the TPS5435x family of dc/dc converters. To allow for adequate phase gain in the compensation network, the LC

corner frequency should be approximately one decade or so below the closed-loop crossover frequency. This

limits the minimum capacitor value for the output filter to:

C

OUT(MIN)

+

1

LOUT

(2pƒK )

2

CO

(15)

Where K is the frequency multiplier for the spread between fLC and fCO. K should be between 5 and 15, typically

10, for one decade difference. For a desired crossover of 20 kHz and a 22-µH inductor, the minimum value for

the output capacitor is 288 µF. The selected output capacitor must be rated for a voltage greater than the desired

output voltage, plus one-half the ripple voltage. Any derating amount also must be included. The maximum RMS

ripple current in the output capacitor is given by equation 16:

I COUT(RMS) + 1

Ǹ12

ȡVOUT ǒVIN(MAX) * VOUTǓȣ

ȧ VIN(MAX) LOUT ƒsw ȧ

Ȣ

Ȥ

(16)

The calculated RMS ripple current is 156 mA in the output capacitors.

Choosing Capacitor Value

For this design example, a relatively large aluminum electrolytic capacitor is combined with a smaller-value

ceramic capacitor. This combination provides a stable high-performance design at a relatively low cost. Also, by

carefully choosing the capacitor values and ESRs, the design can be tailored to complement the internal

compensation poles and zeros of the TPS54356.

These preconfigured poles and zeroes, internal to the TPS54356, limit the range of output filter configurations. A

variety of capacitor values and types of dielectric are supported. There are a number of different ways to

calculate the output filter capacitor value and ESR to work with the internal compensation network. This

procedure outlines a relatively simple procedure that produces good results with an output filter consisting of a

high-ESR dielectric capacitor in parallel with a low-ESR ceramic capacitor. SWIFT Designer Software is used for

designs with unusually high closed-loop crossover frequencies, low value, low-ESR output capacitors such as

ceramics, or if the designer is unsure about the design procedure.

20

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

The TPS54356 contains a compensation network with the following nominal characteristics:

ƒINT = 1.7 kHz

ƒZ1 = 2.5 kHz

ƒZ2 = 4.8 kHz

ƒP1 = 95 kHz

ƒP2 = 125 kHz

For a stable design, the closed-loop crossover frequency should be set less than one-fifth of the switching

frequency, and the phase margin at crossover must be greater than 45 degrees. The general procedure outlined

here produces results consistent with these requirements, without going into great detail about the theory of loop

compensation.

In this case, the output filter LC corner frequency should be selected to be near the first compensation zero

frequency, as described by equation 17:

1

ƒ

+

^ƒ

LC

Z1

2p L

C2

OUT

(17)

Ǹ

Placement of the LC corner frequency at fZ1 is not critical; it only needs to be close. For the design example,

fLC = 2 kHz.

Solving for C2 using equation 18:

C2 ^ 2 2 1

4p ƒ

L

Z1 OUT

(18)

The desired value for C2 is calculated as 184 µF. A close standard value of 330 µF is chosen, with a resulting

LC corner frequency of 1.9 kHz. As shown, this value is not critical as long as it results in a corner frequency in

the vicinity of fZ1.

Next, when using a large ceramic capacitor in parallel with a high-ESR electrolytic capacitor, there is a pole in

the output filter that should be at fZ2, as shown in equation 19:

1

ƒ

+

+ƒ

P(ESR)

Z2

2pR

C5

(C2ESR)

(19)

Now, the actual C2 capacitor must be selected based on the ESR and the value of capacitor C5, so that the

above equation is satisfied. In this example, the R(C2ESR)C5 product should be 3.18 × 10–5. From the available

capacitors, by choosing a Panasonic EEVFKOJ331XP aluminum electrolytic capacitor with a nominal ESR of

0.34 Ω yields a calculated value for C5 of 98 µF. The closest standard value is 100 µF. As the actual ESR of the

capacitor can vary by a large amount, this value also is not critical.

The closed-loop crossover frequency should be greater than fLC and less than one-fifth of the switching

frequency. Also, the crossover frequency should not exceed 70 kHz, as the error amplifier may not provide the

desired gain. As stated previously, closed loop-crossover frequencies between 5 and 15 times fLC work well. For

this design, the crossover frequency can be estimated by:

ƒ

+ 1.125 10 *3 ƒ

ƒ

CO

P(ESR)

LC

(20)

This simplified equation is valid for this design because the output filter capacitors are mixed technology.

Compare this result to the actual measured loop response plot of Figure 5. The measured closed-loop crossover

frequency of 19.95 kHz differs from the calculated value because the actual output filter capacitor component

parameters differed slightly from the specified data-sheet values.

Capacitor ESR and Output Ripple

The amount of output ripple voltage, as specified in the initial design parameters, is determined by the maximum

ESR of the output capacitor and the input ripple current. The output ripple voltage is the inductor ripple current

times the ESR of the output filter, so the maximum specified ESR as listed in the capacitor data sheet is given by

equation 21:

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

21

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

ESR (MAX) +

ǒ

VIN(MAX)

LOUT

V OUT

ǒV IN(MAX)

ƒsw

Ǔ

0.8

* VOUTǓ

DV p*p(MAX)

(21)

and the maximum ESR required is 33 mΩ. In this design, the aluminum electrolytic capacitor has an ESR of

0.340 mΩ, but it is in parallel with an ultra-low ESR ceramic capacitor of 2 mΩ maximum. The measured output

ripple voltage for this design is approximately 4 mVp-p, as shown in Figure 10.

Bias AND Bootstrap Capacitors

Every TPS54356 design requires a bootstrap capacitor, C3, and a bias capacitor, C4. The bootstrap capacitor

must be 0.1 µF. The bootstrap capacitor is located between the PH pins and BOOT pin. The bias capacitor is

connected between the VBIAS pin and AGND. The value should be 1 µF. Both capacitors should be high-quality

ceramic types with X7R or X5R grade dielectric for temperature stability. They should be placed as close to the

device connection pins as possible.

Low-Side FET

The TPS54356 is designed to operate using an external low-side FET, and the LSG pin provides the gate drive

output. Connect the drain to the PH pin, the source to PGND, and the gate to LSG. The TPS54356 gate drive

circuitry is designed to accommodate most common n-channel FETs that are suitable for this application. The

SWIFT Designer Software can be used to calculate all the design parameters for low-side FET selection. There

are some simplified guidelines that can be applied that produce an acceptable solution in most designs.

The selected FET must meet the absolute maximum ratings for the application:

• Drain-source voltage (VDSS) must be higher than the maximum voltage at the PH pin, which is

VINMAX + 0.5 V.

• Gate-source voltage (VGSS) must be greater than 8 V.

• Drain current (ld) must be greater than 1.1 × IOUTMAX.

• Drain-source on resistance (RDSON) should be as small as possible; less than 30 mΩ is desirable. Lower

values for RDSON result in designs with higher efficiencies. It is important to note that the low-side FET on

time typically is longer than the high-side FET on time, so attention paid to low-side FET parameters can

make a marked improvement in overall efficiency.

• Total gate charge (Qg) must be less than 50 nC. Again, lower Qg characteristics result in higher efficiencies.

• Additionally, check that the device chosen is capable of dissipating the power losses.

For this design, a Fairchild FDR6674A 30-V n-channel MOSFET is used as the low-side FET. This particular FET

is designed specifically to be used as a low-side synchronous rectifier.

Power Good

The TPS54356 is provided with a power-good (PWRGD) output pin. This output is an open-drain output and is

intended to be pulled up to a 3.3-V or 5-V logic supply. A 10-kΩ pullup resistor works well in this application. The

absolute maximum voltage is 6 V, so care must be taken not to connect this pullup resistor to VIN if the

maximum input voltage exceeds 6 V.

Snubber Circuit

R10 and C11 of the application schematic in Figure 25 comprise a snubber circuit. The snubber is included to

reduce overshoot and ringing on the phase node when the internal high-side FET turns on. Since the frequency

and amplitude of the ringing depends to a large degree on parasitic effects, it is best to choose these component

values, based on actual measurements of any design layout. See literature number SLUP100 for more detailed

information on snubber design.

Figure 26 shows an application where a clamp diode is used in place of the low-side FET. The TPS54352-7

incorporates an integrated pulldown FET so that the circuit remains operating in continuous mode during light

load operation. A 3-A 40-V Schottky diode, such as the Motorola MBRS340T3 or equivalent, is recommended.

See Figure 15, Figure 16, and Figure 17 for efficiency data and switching waveforms for this circuit.

22

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

+

+

Figure 26. Power Supply With Schottky Diode

Figure 27 is an example of power-supply sequencing using a TPS54356 (U1) to generate an output of 3.3 V, and

a TPS54354 (U2) to generate a 1.8-V output. These output voltages are typical I/O and core voltages for

microprocessors and FPGAs. In the circuit, the 3.3-V supply is designed to power up first.

+

+

Pull up to

3.3 V or 5 V

+

+

Figure 27. Power Supply With Sequencing

The PWRGD pin of U1 is tied to the ENA pin of U2 so that the 1.8-V supply starts to ramp up after the 3.3-V

supply is within regulation. Figure 18 shows these start-up sequence waveforms.

Since the RT pin of U1 is floating, the SYNC pin is an output. This synchronization signal is fed the SYNC pin of

U2. RT of U2 has a 110-kΩ resistor to ground, and SYNC for this device acts as an input. The 1.8-V supply

operates synchronously with the 3.3-V supply, and their switching node rising edges are approximately 180

degrees out of phase, allowing for a reduction in the input voltage ripple. See Figure 19 for this waveform.

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

23

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

Alternate Output Filter Designs

The previous design procedure example demonstrated a technique to design a 3.3-V power supply using both

aluminum electrolytic and ceramic output filter capacitors. Other types of output filter capacitors are supported by

the TPS5435x family of dc/dc converters. Figure 26, Figure 27, and Figure 28 show designs using other popular

capacitor types.

In Figure 28, the TPS54356 is shown with a single 100-µF 6-V POSCAP as the output filter capacitor. C10 is a

high-frequency bypass capacitor and does not enter into the design equations. The design procedure is similar to

the previous example, except in the design of the output filter. In the previous example, the output filter LC corner

was set at the first zero in the compensation network, while the second compensation zero was used to

counteract the output filter pole caused by the interaction of the C2 capacitor ESR with C5. In this design

example, the output LC corner frequency is to be set at the second zero frequency (fZ2) of the internal

compensation network, approximately 5 kHz, while the first zero is used to provide phase boost prior to the LC

corner frequency.

+

+

Figure 28. 3.3-V Power Supply With Sanyo POSCAP Output Filter Capacitor

Inductor Selection

Using equation 12 and a KIND 0.2, the minimum inductor value required is 8.98 µH. The closest standard value,

10 µH, is selected. RMS and peak inductor currents are the same as calculated previously.

Capacitor Selection

With the inductor set at 10 µH and a desired corner frequency of 5 kHz, the output capacitor value is given by:

1

1

C2 +

+

+ 101 mF

4

p 2 5000 2 10 *5

4p 2ƒ Z2 2 Lout

Use 100 µF as the closest standard value.

Calculating the RMS ripple current in the output capacitor using equation 16 yields 156 mA. The POSCAP

6TPC100M capacitor selected is rated for 1700 mA. See the closed-loop response curve for this design in

Figure 20.

+

+

+

Figure 29. 3.3-V Power Supply With Panasonic SP Output Filter Capacitors

24

Submit Documentation Feedback

Copyright © 2007–2009, Texas Instruments Incorporated

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

www.ti.com ....................................................................................................................................................... SLVS684A – JANUARY 2007 – REVISED JULY 2009

In Figure 29, the TPS54356 is shown with two 180-mF 4-V special polymer dielectric output filter capacitors (C2

and C5). C10 is a high-frequency bypass capacitor and does not enter into the design equations. In the previous

example, the output LC corner frequency is to be set at the second zero frequency fZ2 of the internal

compensation network, approximately 5 kHz, while the first zero is used to provide phase boost prior to the LC

corner frequency. The special polymer electrolytic capacitors used in this design require that the closed-loop

crossover frequency be lowered due to the significantly lower ESR of this type of capacitor.

Inductor Selection

The inductor is the same 10-µH value as the previous example.

Capacitor Selection

To lower the closed-loop crossover, it is necessary to reduce the LC corner frequency below 5 kHz. Using a

target value of 2500 Hz, the output capacitor value is given by:

1

1

C2 +

+

+ 405 mF

4

p 2 2500 2 10 *5

4p 2ƒ Z2 2 Lout

Use 2 × 180 µF = 360 µF as a combination of standard values that is close to 405 µF.

The RMS ripple current in the output capacitor is the same as before. The selected capacitors are each 3.3 A.

See the closed-loop response curve for this design in Figure 21.

In Figure 30, the TPS54356 is shown with a Sanyo OSCON output filter capacitor (C2). C10 is a high-frequency

bypass capacitor and does not enter into the design equations. This design is identical to the previous example,

except that a single OSCON capacitor of 330 µF is used for the calculated value of 405 µF. Compare the

closed-loop response for this design in Figure 22 to the closed-loop response in Figure 21. Note that there is only

a slight difference in the response and the general similarity in both the gain and phase plots. This is the

expected result for these two similar output filters.

+

+

Figure 30. 3.3-V Power Supply With Sanyo OSCON Output Filter Capacitor

Many other additional output filter designs are possible. Use the SWIFT Designer Software to generate other

designs or follow the general design procedures illustrated in this application section.

Copyright © 2007–2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TPS54352-EP TPS54353-EP TPS54354-EP TPS54355-EP TPS54356-EP TPS54357-EP

25

�TPS54352-EP, TPS54353-EP, TPS54354-EP

TPS54355-EP, TPS54356-EP, TPS54357-EP

SLVS684A – JANUARY 2007 – REVISED JULY 2009 ....................................................................................................................................................... www.ti.com

MAXIMUM SWITCHING FREQUENCY

vs

INPUT VOLTAGE

RT RESISTANCE

vs

SWITCHING FREQUENCY

TPS54357

TPS54356

6.0

TPS54355

400

TPS54354

300

TPS54353

TPS54352

200

VI − Input Voltage − V

500

175

150

125

100

100

IO > 0.5 A

Stop

5.0

4.5

TPS54352−6

Start

75

4.0

50

200

3.5

−50 −25

300

400

500

600

700

Switching Frequency − kHz

0

25

50

75

100 125 150

TA − Free-Air Temperature − 5C

Figure 31.

Figure 32.

Figure 33.

ENABLED SUPPLY CURRENT

vs

INPUT VOLTAGE

DISABLED SUPPLY CURRENT

vs

INPUT VOLTAGE

BIAS VOLTAGE

vs

INPUT VOLTAGE

1.3

TJ = 25°C

fS = 500 kHz

8.0

TJ = 25°C

TJ = 25°C

8

7

6

5

4

7.5

VBIAS − Bias Voltage − V

Disabled Supply Current − mA

9

TPS54357

5.5

Stop

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

10

1.2

1.1

1.0

7.0

6.5

6.0

5.5

5.0

4.5

3

0.9

0

5

10

15

20

4.0

25

0

5

10

15

20

0

25

5

10

15

VI − Input Voltage − V

VI − Input Voltage − V

VI − Input Voltage − V

Figure 34.

Figure 35.

Figure 36.

POWER-GOOD THRESHOLD

vs

JUNCTION TEMPERATURE

INTERNAL VOLTAGE REFERENCE

vs

JUNCTION TEMPERATURE

CURRENT LIMIT

vs

INPUT VOLTAGE

98.0

Vref − Internal Voltage Reference − V

97.5

97.0

96.5

96.0

−50 −25

0

25

50

75

100 125 150

TJ − Junction Temperature − 5C

Figure 37.

Submit Documentation Feedback

20

25

6.0

0.8912

TJ = 25°C

VIN = 12 V

0.8910

5.5

0.8908

Current Limit − A

Enabled Supply Current − mA

200

Start

VI − Input Voltage − V

PWRGD − Power Good Threshold − %

6.5

600

0

26

225

700

RT Resistance − kW

Maximum Switching Frequency − kHz

800

VIN(UVLO) START AND STOP

vs

FREE-AIR TEMPERATURE

0.8906

0.8904

0.8902

5.0

4.5

0.8900

0.8898

−50 −25

4.0

0

25

50

75

100 125 150

TJ − Junction Temperature − 5C

Figure 38.

5.0

7.5

10.0

12.5

15.0

17.5

20.0

VI − Input Voltage − V

Figure 39.

Copyright © 2007–2009, Texas Instruments Incorporated