EtronTech

EM68B16CWQK

32M x 16 bit DDRII Synchronous DRAM (SDRAM)

Advance (Rev. 1.1, Jun. /2018)

Features

Overview

The EM68B16C is a high-speed CMOS DoubleData-Rate-Two (DDR2), synchronous dynamic randomaccess memory (SDRAM) containing 512 Mbits in a 16bit wide data I/Os. It is internally configured as a quad

bank DRAM, 4 banks x 8Mb addresses x 16 I/Os.

The device is designed to comply with DDR2 DRAM

key features such as posted CAS# with additive latency,

Write latency = Read latency -1, Off-Chip Driver (OCD)

impedance adjustment, and On Die Termination(ODT).

All of the control and address inputs are synchronized

with a pair of externally supplied differential clocks. Inputs

are latched at the cross point of differential clocks (CK

rising and CK# falling). All I/Os are synchronized with a

pair of bidirectional strobes (DQS and DQS#) in a source

synchronous fashion. The address bus is used to convey

row, column, and bank address information in RAS #, CAS#

multiplexing style. Accesses begin with the registration

of a Bank Activate command, and then it is followed by

a Read or Write command. Read and write accesses to

the DDR2 SDRAM are 4 or 8-bit burst oriented; accesses

start at a selected location and continue for a programmed

number of locations in a programmed sequence. Operating

the four memory banks in an interleaved fashion allows

random access operation to occur at a higher rate than

is possible with standard DRAMs. An auto precharge

function may be enabled to provide a self-timed row

precharge that is initiated at the end of the burst sequence.

A sequential and gapless data rate is possible depending

on burst length, CAS latency, and speed grade of the

device.

JEDEC Standard Compliant

JEDEC Standard 1.8V I/O (SSTL_18-compatible)

Power supplies: VDD & VDDQ = +1.8V 0.1V

Operating temperature: TC = -40~95°C (Industrial)

Supports JEDEC clock jitter specification

Fully synchronous operation

Fast clock rate: 333/400/533MHz

Differential Clock, CK & CK#

Bidirectional single/differential data strobe

- DQS & DQS#

4 internal banks for concurrent operation

4-bit prefetch architecture

Internal pipeline architecture

Precharge & active power down

Programmable Mode & Extended Mode registers

Posted CAS# additive latency (AL): 0, 1, 2, 3, 4, 5, 6

WRITE latency = READ latency - 1 tCK

Burst lengths: 4 or 8

Burst type: Sequential / Interleave

DLL enable/disable

Off-Chip Driver (OCD)

- Impedance Adjustment

- Adjustable data-output drive strength

On-die termination (ODT)

RoHS compliant

Auto Refresh and Self Refresh

Average refresh period

- 8192 cycles/64ms (7.8us at -40°C ≦ TC ≦ +85°C)

- 8192 cycles/32ms (3.9us at +85°C ≦ TC ≦ +95°C)

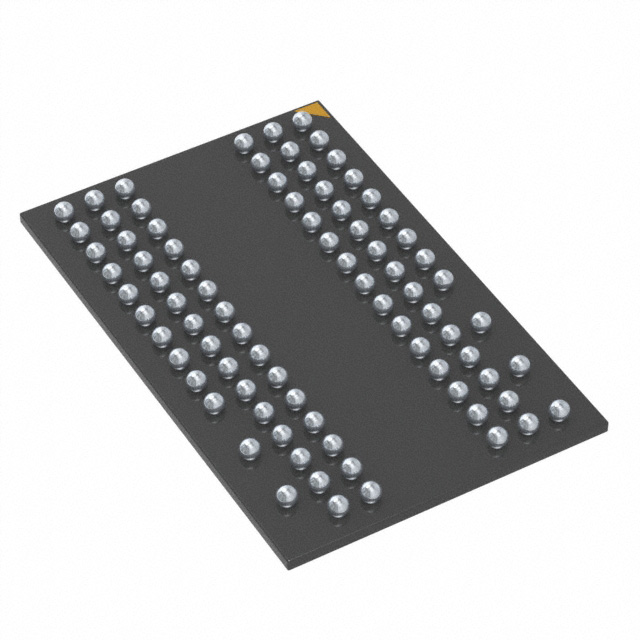

84-ball 8x12.5x1.2mm (max) FBGA

- Pb and Halogen Free

Table 1. Ordering Information

Part Number

Clock Frequency

EM68B16CWQK-18IH

533MHz

EM68B16CWQK-25IH

400MHz

EM68B16CWQK-3IH

333MHz

WQ: indicates 8x12.5x1.2mm (max) FBGA package

K: indicates Generation Code

Data Rate

Power Supply

Package

1066Mbps/pin

800Mbps/pin

667Mbps/pin

VDD 1.8V, VDDQ 1.8V

VDD 1.8V, VDDQ 1.8V

VDD 1.8V, VDDQ 1.8V

FBGA

FBGA

FBGA

I: indicates Industrial Grade

H: indicates Pb and Halogen Free

Etron Technology, Inc.

No. 6, Technology Rd. V, Hsinchu Science Park, Hsinchu, Taiwan 30078, R.O.C.

TEL: (886)-3-5782345

FAX: (886)-3-5778671

Etron Technology, Inc. reserves the right to change products or specification without notice.

�EtronTech

EM68B16CWQK

Table 2. Speed Grade Information

Speed Grade

Clock Frequency

CAS Latency

tRCD (ns)

tRP (ns)

DDR2-1066

533MHz

7

13.125

13.125

DDR2-800

400MHz

5

12.5

12.5

DDR2-667

333MHz

5

15

15

Figure 1. Ball Assignment (FBGA Top View)

1

2

3

A

VDD

NC

B

DQ14

C

…

7

8

9

VSS

VSSQ

UDQS#

VDDQ

VSSQ

UDM

UDQS.

VSSQ

DQ15

VDDQ

DQ9

VDDQ

VDDQ

DQ8

VDDQ

D

DQ12

VSSQ

DQ11

DQ10

VSSQ

DQ13

E

VDD

NC

VSS

VSSQ

LDQS#

VDDQ

F

DQ6

VSSQ

LDM

LDQS

VSSQ

DQ7

G

VDDQ

DQ1

VDDQ

VDDQ

DQ0

VDDQ

H

DQ4

VSSQ

DQ3

DQ2

VSSQ

DQ5

J

VDDL

VREF

VSS

VSSDL

CK

VDD

CKE

WE#

RAS#

CK#

ODT

BA0

BA1

CAS#

CS#

A10

A1

A2

A0

A3

A5

A6

A4

A7

A9

A11

A8

A12

NC

NC

NC

K

L

NC

M

N

VSS

P

R

Rev. 1.1

VDD

2

VDD

VSS

Jun. /2018

�EtronTech

EM68B16CWQK

Figure 2. Block Diagram

CK

CK#

DLL

CLOCK

BUFFER

Row

Decoder

CKE

COMMAND

DECODER

A10/AP

COLUMN

COUNTER

MODE

REGISTER

8M x 16

CELL ARRAY

(BANK #1)

Column Decoder

ADDRESS

BUFFER

REFRESH

COUNTER

LDQS

LDQS#

UDQS

UDQS#

Column Decoder

Row

Decoder

A0~A9

A11

A12

BA0

BA1

CONTROL

SIGNAL

GENERATOR

Row

Decoder

CS#

RAS#

CAS#

WE#

8M x 16

CELL ARRAY

(BANK #0)

DATA

STROBE

BUFFER

DQ0

8M x 16

CELL ARRAY

(BANK #2)

Column Decoder

DQ

Buffer

ODT LDM

UDM

Rev. 1.1

3

Row

Decoder

~

DQ15

8M x 16

CELL ARRAY

(BANK #3)

Column Decoder

Jun. /2018

�EtronTech

EM68B16CWQK

Figure 3. State Diagram

CKEL

OCD

calibration

Setting

MR,

EMR(1)

EMR(2)

EMR(3)

Initialization

Sequence

Self

Refreshing

SR F H

C KE

PR

Idle

All banks

precharged

(E)MRS

REF

CK

E

CK L

EH

ACT

Refreshing

CK

EL

Precharge

Power

Down

Activating

CKEL

CKEL

CK

Active

Power

Down

EL

Automatic Sequence

Cammand Sequence

C KE

C KE H

L

Bank

Active

WR

W

RA

WR

RD

RD

RD

A

CKEH = CKE HIGH, exit Power Down,exit Self Refresh

Reading

RD

WR

Writing

ACT = Activate

WR(A) = Write (with Autoprecharge)

RDA

RD(A) = Read (with Autoprecharge)

PR(A) = Precharge (All)

A

WR

RDA

WRA

CKEL = CKE LOW, enter Power Down

(E)MRS = (Extended) Mode Register Set

SRF = Enter Self Refresh

Writing

With

Autoprecharge

Reading

With

Autoprecharge

PR, PRA

PR, PRA

PR, PRA

REF = Refresh

Precharging

Note: Use caution with this diagram. It is indented to provide a floorplan of the possible state transitions and the commands to control

them, not all details. In particular situations involving more than one bank, enabling/disabling on-die termination, Power Down

entry/exit, timing restrictions during state transitions, among other things, are not captured in full detail.

Rev. 1.1

4

Jun. /2018

�EtronTech

EM68B16CWQK

Ball Descriptions

Table 3. Ball Details

Symbol

Type

Description

CK, CK#

Input

Differential Clock: CK, CK# are driven by the system clock. All SDRAM input signals are

sampled on the crossing of positive edge of CK and negative edge of CK#. Output (Read)

data is referenced to the crossings of CK and CK# (both directions of crossing).

CKE

Input

Clock Enable: CKE activates (HIGH) and deactivates (LOW) the CK signal. If CKE goes

LOW synchronously with clock, the internal clock is suspended from the next clock cycle

and the state of output and burst address is frozen as long as the CKE remains LOW.

When all banks are in the idle state, deactivating the clock controls the entry to the Power

Down and Self Refresh modes.

BA0, BA1

Input

Bank Address: BA0 and BA1 define to which bank the BankActivate, Read, Write, or

BankPrecharge command is being applied.

A0-A12

Input

Address Inputs: A0-A12 are sampled during the BankActivate command (row address A0

-A12) and Read/Write command (column address A0-A9 with A10 defining Auto Precharge).

CS#

Input

Chip Select: CS# enables (sampled LOW) and disables (sampled HIGH) the command

decoder. All commands are masked when CS# is sampled HIGH. CS# provides for external

bank selection on systems with multiple banks. It is considered part of the command code.

RAS#

Input

Row Address Strobe: The RAS# signal defines the operation commands in conjunction

with the CAS# and WE# signals and is latched at the crossing of positive edges of CK and

negative edge of CK#. When RAS# and CS# are asserted "LOW" and CAS# is asserted

"HIGH" either the BankActivate command or the Precharge command is selected by the

WE# signal. When the WE# is asserted "HIGH" the BankActivate command is selected

and the bank designated by BA is turned on to the active state. When the WE# is asserted

"LOW" the Precharge command is selected and the bank designated by BA is switched to

the idle state after the precharge operation.

CAS#

Input

Column Address Strobe: The CAS# signal defines the operation commands in conjunction

with the RAS# and WE# signals and is latched at the crossing of positive edges of CK and

negative edge of CK#. When RAS# is held "HIGH" and CS# is asserted "LOW" the column

access is started by asserting CAS# "LOW". Then, the Read or Write command is selected

by asserting WE# “HIGH" or “LOW".

WE#

Input

Write Enable: The WE# signal defines the operation commands in conjunction with the

RAS# and CAS# signals and is latched at the crossing of positive edges of CK and negative

edge of CK#. The WE# input is used to select the BankActivate or Precharge command

and Read or Write command.

LDQS,

Input /

LDQS#

Output

Bidirectional Data Strobe: Specifies timing for Input and Output data. Read Data Strobe

is edge triggered. Write Data Strobe provides a setup and hold time for data and DQM.

LDQS is for DQ0~7, UDQS is for DQ8~15. The data strobes LDOS and UDQS may be

used in single ended mode or paired with LDQS# and UDQS# to provide differential pair

signaling to the system during both reads and writes.A control bit at EMR(1)[A10] enables

or disables all complementary data strobe signals.

UDQS

UDQS#

LDM, UDM

Input

DQ0-DQ15

Input /

Output

ODT

Input

VDD

Supply

Power Supply: +1.8V 0.1V.

VSS

Supply

Ground

Rev. 1.1

Data Input Mask: Input data is masked when DM is sampled HIGH during a write cycle.

LDM masks DQ0-DQ7, UDM masks DQ8-DQ15.

Data I/O: Bi-directional data bus.

On Die Termination: ODT enables internal termination resistance. It is applied to each

DQ, LDQS/LDQS#, UDQS/UDQS#, LDM, and UDM signal. The ODT pin is ignored if the

EMR (1) is programmed to disable ODT.

5

Jun. /2018

�EtronTech

EM68B16CWQK

VDDL

Supply

DLL Power Supply: +1.8V 0.1V.

VSSDL

Supply

DLL Ground

VDDQ

Supply

DQ Power: +1.8V 0.1V.

VSSQ

Supply

DQ Ground

VREF

Supply

Reference Voltage for Inputs: +0.5 x VDDQ

NC

-

Rev. 1.1

No Connect: These pins should be left unconnected.

6

Jun. /2018

�EtronTech

EM68B16CWQK

Operation Mode

The following tables provide a quick reference of available DDR2 SDRAM commands, including CKE power-down

modes and bank-to-bank commands.

Table 4. Truth Table (Note (1), (2))

Command

State

CKEn-1 CKEn DM BA0,1 A10 A0-9, 11-12 CS# RAS# CAS# WE#

Idle(3)

H

H

X

V

Row address

L

L

H

H

Single Bank Precharge

Any

H

H

X

V

L

X

L

L

H

L

All Banks Precharge

Any

H

H

X

X

H

X

L

L

H

L

Write

Active(3)

H

H

X

V

L

L

H

L

L

Write with AutoPrecharge

Active(3)

H

H

X

V

H

Column

address

(A0 – A9)

L

H

L

L

Read

Active(3)

H

H

X

V

L

L

H

L

H

Read and Autoprecharge

Active(3)

H

H

X

V

H

Column

address

(A0 – A9)

L

H

L

H

(Extended) Mode Register Set

Idle

H

H

X

V

L

L

L

L

No-Operation

Any

H

X

X

X

X

X

L

H

H

H

Device Deselect

Any

H

X

X

X

X

X

H

X

X

X

Refresh

Idle

H

H

X

X

X

X

L

L

L

H

SelfRefresh Entry

Idle

H

L

X

X

X

X

L

L

L

H

SelfRefresh Exit

Idle

L

H

X

X

X

X

H

X

X

X

L

H

H

H

Power Down Mode Entry

Idle

H

L

X

X

X

X

H

X

X

X

L

H

H

H

Power Down Mode Exit

Any

L

H

X

X

X

X

H

X

X

X

L

H

H

H

Data Input Mask Disable

Active

H

X

L

X

X

X

X

X

X

X

Data Input Mask

Active

H

X

H

X

X

X

X

NOTE 1: V=Valid data, X=Don't Care, L=Low level, H=High level

NOTE 2: CKEn signal is input level when commands are provided.

CKEn-1 signal is input level one clock cycle before the commands are provided.

NOTE 3: These are states of bank designated by BA signal.

NOTE 4: LDM and UDM can be enabled respectively.

X

X

X

BankActivate

Enable(4)

Rev. 1.1

7

OP code

Jun. /2018

�EtronTech

EM68B16CWQK

Functional Description

Read and write accesses to the DDR2 SDRAM are burst oriented; accesses start at a selected location and continue

for a burst length of four or eight in a programmed sequence. Accesses begin with the registration of an Active

command, which is then followed by a Read or Write command. The address bits registered coincident with the

active command are used to select the bank and row to be accessed (BA0, BA1 select the bank; A0-A12 select the

row). The address bits registered coincident with the Read or Write command are used to select the starting column

location for the burst access and to determine if the auto precharge command is to be issued.

Prior to normal operation, the DDR2 SDRAM must be initialized. The following sections provide detailed information

covering device initialization, register definition, command descriptions, and device operation.

Power-up and Initialization

DDR2 SDRAMs must be powered up and initialized in a predefined manner. Operational procedures other than

those specified may result in undefined operation.

The following sequence is required for POWER UP and Initialization.

*1

1. Apply power and attempt to maintain CKE below 0.2 x VDDQ and ODT at a low state (all other inputs may be

undefined.) The VDD voltage ramp time must be no greater than 200ms from when VDD ramps from 300mV to

VDDmin; and during the VDD voltage ramp, |VDD-VDDQ| ≦ 0.3V

- VDD, VDDL and VDDQ are driven from a single power converter output, AND

- VTT is limited to 0.95 V max, AND

- VREF tracks VDDQ/2.

or

- Apply VDD before or at the same time as VDDL.

- Apply VDDL before or at the same time as VDDQ.

- Apply VDDQ before or at the same time as VTT & VREF.

At least one of these two sets of conditions must be met.

2. Start clock and maintain stable condition.

3. For the minimum of 200s after stable power and clock (CK, CK#), then apply NOP or deselect and take CKE HIGH.

4. Wait minimum of 400ns then issue precharge all command. NOP or deselect applied during 400ns period.

5. Issue EMRS(2) command. (To issue EMRS (2) command, provide “LOW” to BA0, “HIGH” to BA1.)

6. Issue EMRS (3) command. (To issue EMRS (3) command, provide “HIGH” to BA0 and BA1.)

7. Issue EMRS to enable DLL. (To issue "DLL Enable" command, provide "LOW" to A0, "HIGH" to BA0 and "LOW"

to BA1.)

8. Issue a Mode Register Set command for “DLL reset”. (To issue DLL reset command, provide "HIGH" to A8 and

"LOW" to BA0-1)

9. Issue precharge all command.

10. Issue 2 or more auto-refresh commands.

11. Issue a mode register set command with LOW to A8 to initialize device operation. (i.e. to program operating

parameters without resetting the DLL.)

12. At least 200 clocks after step 8, execute OCD Calibration (Off Chip Driver impedance adjustment).If OCD

calibration is not used, EMRS OCD Default command (A9=A8=A7=HIGH) followed by EMRS OCD calibration

Mode Exit command (A9=A8=A7=LOW) must be issued with other operating parameters of EMRS.

13. The DDR2 SDRAM is now ready for normal operation.

NOTE 1: To guarantee ODT off, VREF must be valid and a LOW level must be applied to the ODT pin.

Rev. 1.1

8

Jun. /2018

�EtronTech

EM68B16CWQK

Mode Register Set (MRS)

The mode register stores the data for controlling the various operating modes of DDR2 SDRAM. It controls CAS

latency, burst length, burst sequence, test mode, DLL reset, WR, and various vendor specific options to make DDR2

SDRAM useful for various applications.The default value of the mode register is not defined, therefore the mode

register must be programmed during initialization for proper operation. The mode register is written by asserting

LOW on CS#, RAS#, CAS#, WE#, BA0 and BA1, while controlling the state of address pins A0 - A12. The DDR2

SDRAM should be in all bank precharge state with CKE already HIGH prior to writing into the mode register.The

mode register set command cycle time (tMRD) is required to complete the write operation to the mode register. The

mode register contents can be changed using the same command and clock cycle requirements during normal

operation as long as all bank are in the precharge state.The mode register is divided into various fields depending on

functionality.

- Burst Length Field (A2, A1, A0): This field specifies the data length of column access and selects the Burst Length.

- Addressing Mode Select Field (A3): The Addressing Mode can be Interleave Mode or Sequential Mode. Both

Sequential Mode and Interleave Mode support burst length of 4 and 8.

- CAS Latency Field (A6, A5, A4): This field specifies the number of clock cycles from the assertion of the Read

command to the first read data. The minimum whole value of CAS Latency

depends on the frequency of CK. The minimum whole value satisfying the following

formula must be programmed into this field. tCAC(min) ≦ CAS Latency X tCK

- Test Mode field (A7); DLL Reset Mode field (A8): These two bits must be programmed to "00" in normal operation.

- (BA0, BA1): Bank addresses to define MRS selection.

Table 5. Mode Register Bitmap

BA1 BA0 A12

0

0

PD

A11

A10

WR

A9

A8 DLL Reset

0

No

1

Yes

A12 Active power down exit time

0

Fast exit (use tXARD)

1

Slow exit (use tXARDS)

BA1 BA0 MRS Mode

0

0

MR

0

1

EMR(1)

1

0

EMR(2)

1

1

EMR(3)

A8

DLL

A7

0

1

A7

TM

A6

A5

A4

CAS Latency

Mode

Normal

Test

A3

BT

A3

0

1

A2

A1

A0

Burst Length

Burst Type

Sequential

Interleave

Address Field

Mode Register

A2

0

0

A1

1

1

A0

0

1

BL

4

8

A4

0

1

0

1

0

1

0

1

CAS Latency

Reserved

Reserved

Reserved

3

4

5

6

7

*1

Write recovery for autoprecharge

A11

A10

A9

WR(cycles)

0

0

0

Reserved

0

0

1

2

0

1

0

3

0

1

1

4

1

0

0

5

1

0

1

6

1

1

0

7

1

1

1

8

A6

0

0

0

0

1

1

1

1

A5

0

0

1

1

0

0

1

1

NOTE 1: For DDR2-667/800/1066, WR min is determined by tCK (avg) max and WR max is determined by t CK(avg) min. WR

[cycles] = RU {tWR[ns]/tCK(avg)[ns]}, where RU stands for round up. The mode register must be programmed to this

value.This is also used with tRP to determine tDAL.

Rev. 1.1

9

Jun. /2018

�EtronTech

EM68B16CWQK

Extended Mode Register Set (EMRS)

EMR(1)

The extended mode register(1) stores the data for enabling or disabling the DLL, output driver strength, ODT value

selection and additive latency. The default value of the extended mode register is not defined, therefore the

extended mode register must be written after power-up for proper operation. The extended mode register is written

by asserting LOW on CS#, RAS#, CAS#, WE#, BA1 and HIGH on BA0, while controlling the states of address pins

A0 ~ A12. The DDR2 SDRAM should be in all bank precharge with CKE already HIGH prior to writing into the

extended mode register. The mode register set command cycle time (t MRD) must be satisfied to complete the write

operation to the extended mode register. Mode register contents can be changed using the same command and

clock cycle requirements during normal operation as long as all banks are in the precharge state. A0 is used for DLL

enable or disable. A1 is used for enabling a half strength data-output driver. A3~A5 determine the additive latency,

A2 and A6 are used for ODT value selection, A7~A9 are used for OCD control, A10 is used for DQS# disable.

- DLL Enable/Disable: The DLL must be enabled for normal operation. DLL enable is required during power up

initialization, and upon returning to normal operation after having the DLL disabled. The DLL is

automatically disabled when entering self refresh operation and is automatically re-enabled

upon exit of self refresh operation. Any time the DLL is enabled (and subsequently reset), 200

clock cycles must occur before a Read command can be issued to allow time for the internal

clock to be synchronized with the external clock. Failing to wait for synchronization to occur

may result in a violation of the tAC or tDQSCK parameters.

Table 6. Extended Mode Register EMR (1) Bitmap

BA1 BA0 A12 A11 A10 A9

A8

A7

0

1

Qoff

0 DQS# OCD program

BA1 BA0

0

0

0

1

1

0

1

1

A9

0

0

0

1

1

A10

0

1

MRS mode

MR

EMR(1)

EMR(2)

EMR(3)

A8

0

0

1

0

1

DQS#

Enable

Disable

A7

0

1

0

0

1

A6

Rtt

A5

A4

A3

Additive Latency

A6

0

0

1

1

A2

0

1

0

1

Rtt(NOMINAL)

ODT Disable

75Ω

150Ω

50Ω

OCD Calibration Program

OCD Calibration mode exit; maintain setting

Drive(1)

Drive(0)

*1

Adjust mode

*2

OCD Calibration default

A12

0

1

*3

Qoff

Output buffer enabled

Output buffer disabled

A2

A1

A0 Address Field

Rtt D.I.C DLL Extended Mode Register

A0

0

1

DLL Enable

Enable

Disable

A1

Output Driver

Impedance Control

0

1

Full strength

Reduced strength

A5 A4 A3

0

0

0

0

0

1

0

1

0

0

1

1

1

0

0

1

0

1

1

1

0

1

1

1

Additive Latency

0

1

2

3

4

5

6

Reserved

NOTE 1: When Adjust mode is issued, AL from previously set value must be applied.

NOTE 2: After setting to default, OCD calibration mode needs to be exited by setting A9-A7 to 000.

NOTE 3: Output disabled – DQs, DQSs, DQSs#.This feature is intended to be used during IDD characterization of read current.

Rev. 1.1

10

Jun. /2018

�EtronTech

EM68B16CWQK

EMR(2)

The extended mode register (2) controls refresh related features. The default value of the extended mode register (2)

is not defined, therefore the extended mode register (2) must be written after power-up for proper operation. The

extended mode register(2) is written by asserting LOW on CS#, RAS#, CAS#, WE#, HIGH on BA1 and LOW on

BA0, while controlling the states of address pins A0 ~ A12. The DDR2 SDRAM should be in all bank precharge with

CKE already HIGH prior to writing into the extended mode register (2). The mode register set command cycle time

(tMRD) must be satisfied to complete the write operation to the extended mode register (2). Mode register contents

can be changed using the same command and clock cycle requirements during normal operation as long as all

banks are in the precharge state.

Table 7. Extended Mode Register EMR (2) Bitmap

BA1 BA0 A12 A11 A10

*1

1

0

0

A7

0

1

BA1

0

0

1

1

BA0

0

1

0

1

A9

A8

A7

A6

A5

SRF

0

A4

*1

A3

*4

DCC

A2

A1

A2

0

0

0

0

1

1

1

1

A1

0

0

1

1

0

0

1

1

A0

0

1

0

1

0

1

0

1

A3

0

1

Address Field

Extended Mode egister(2)

PASR

High Temperature Self-Refresh Rate Enable

Disable

*2

Enable

MRS mode

MR

EMR(1)

EMR(2)

EMR(3)

A0

*3

DCC Enable

Disable

Enable

*4

Partial Array Self Refresh for 4 Banks

Full array

Half Array (BA[1:0]=00&01)

Quarter Array (BA[1:0]=00)

Not defined

3/4 array (BA[1:0]=01,10&11)

Half array (BA[1:0]=10&11)

Quarter array (BA[1:0]=11)

Not defined

NOTE 1: The rest bits in EMRS(2) are reserved for future use and all bits in EMRS(2) except A0-A2, A7, BA0 and BA1 must be

programmed to 0 when setting the extended mode register(2) during initialization.

NOTE 2: Due to the migration nature, user needs to ensure the DRAM part supports higher than 85 °C Tcase temperature selfrefresh entry. If the high temperature self-refresh mode is supported then controller can set the EMRS2[A7] bit to

enable the self-refresh rate in case of higher than 85 °C temperature self-refresh operation.

NOTE 3: If PASR (Partial Array Self Refresh) is enabled, data located in areas of the array beyond the specified location will be

lost if self refresh is entered. Data integrity will be maintained if t REF conditions are met and no Self Refresh command

is issued.

NOTE 4: DCC (Duty Cycle Corrector) implemented, user may be given the controllability of DCC thru EMR (2) [A3] bit.

Rev. 1.1

11

Jun. /2018

�EtronTech

EM68B16CWQK

EMR(3)

No function is defined in extended mode register(3).The default value of the extended mode register(3) is not

defined, therefore the extended mode register(3) must be programmed during initialization for proper operation.

Table 8. Extended Mode Register EMR (3) Bitmap

BA1 BA0 A12 A11 A10

1

1

A9

A8

A7

A6

*1

0

A5

A4

A3

A2

A1

A0

Address Field

Extended Mode Register(3)

NOTE 1: All bits in EMR (3) except BA0 and BA1 are reserved for future use and must be set to 0 when programming the EMR (3).

Rev. 1.1

12

Jun. /2018

�EtronTech

EM68B16CWQK

Off-chip drive (OCD) impedance adjustment

DDR2 SDRAM supports driver calibration feature and the following flow chart is an example of sequence.Every

calibration mode command should be followed by “OCD calibration mode exit” before any other command being

issued.All MR should be programmed before entering OCD impedance adjustment and ODT (On Die Termination)

should be carefully controlled depending on system environment.

Figure 4. OCD impedance adjustment sequence

Before entering OCD impedance adjustment, all MR should be programmed and

ODT should be carefully controlled depending on system environment

Start

EMRS:OCD calibration mode exit

EMRS:Drive(1)

DQ &DQS HIGH;DQS# LOW

Test

EMRS:Drive(0)

DQ &DQS LOW;DQS# HIGH

ALL OK

ALL OK

Test

EMRS:OCD calibration mode exit

EMRS:OCD calibration mode exit

EMRS:Enter Adjust Mode

EMRS:Enter Adjust Mode

BL=4 code input to all DQs

Inc, Dec, or NOP

BL=4 code input to all DQs

Inc, Dec, or NOP

EMRS:OCD calibration mode exit

EMRS:OCD calibration mode exit

EMRS:OCD calibration mode exit

End

Rev. 1.1

13

Jun. /2018

�EtronTech

EM68B16CWQK

- Extended mode register for OCD impedance adjustment

OCD impedance adjustment can be done using the following EMRS mode. In drive mode all outputs are driven out

by DDR2 SDRAM. In Drive (1) mode, all DQ, DQS signals are driven HIGH and all DQS# signals are driven LOW. In

Drive (0) mode, all DQ, DQS signals are driven LOW and all DQS# signals are drive HIGH. In adjust mode, BL = 4

of operation code data must be used. In case of OCD calibration default, output driver characteristics have a

nominal impedance value of 18 Ohms during nominal temperature and voltage conditions. Output driver

characteristics for OCD calibration default are specified in the following table. OCD applies only to normal full

strength output drive setting defined by EMRS and if half strength is set, OCD default driver characteristics are not

applicable. When OCD calibration adjust mode is used, OCD default output driver characteristics are not applicable.

After OCD calibration is completed or driver strength is set to default, subsequent EMRS commands not intended to

adjust OCD characteristics must specify A7~A9 as ’000’ in order to maintain the default or calibrated value.

Table 9. OCD drive mode program

A9

A8

A7

operation

0

0

0

1

1

0

0

1

0

1

0

1

0

0

1

OCD calibration mode exit

Drive(1) DQ, DQS, HIGH and DQS# LOW

Drive(0) DQ, DQS, LOW and DQS# HIGH

Adjust mode

OCD calibration default

- OCD impedance adjust

To adjust output driver impedance, controllers must issue the ADJUST EMRS command along with a 4bit burst

code to DDR2 SDRAM as in the following table. For this operation, Burst Length has to be set to BL = 4 via MRS

command before activating OCD and controllers must drive this burst code to all DQs at the same time. DT0 in the

following table means all DQ bits at bit time 0, DT1 at bit time 1, and so forth. The driver output impedance is

adjusted for all DDR2 SDRAM DQs simultaneously and after OCD calibration, all DQs of a given DDR2 SDRAM will

be adjusted to the same driver strength setting.

The maximum step count for adjustment is 16 and when the limit is reached, further increment or decrement code

has no effect. The default setting maybe any step within the 16 step range. When Adjust mode command is issued,

AL from previously set value must be applied.

Table 10. OCD adjust mode program

4bit burst code inputs to all DQs

DT0

DT1

DT2

DT3

0

0

0

0

0

0

0

1

0

0

1

0

0

1

0

0

1

0

0

0

0

1

0

1

0

1

1

0

1

0

0

1

1

0

1

0

Other Combinations

Rev. 1.1

Pull-up driver strength

NOP

Increase by 1 step

Decrease by 1 step

NOP

NOP

Increase by 1 step

Decrease by 1 step

Increase by 1 step

Decrease by 1 step

14

Operation

Pull-down driver strength

NOP

NOP

NOP

Increase by 1 step

Decrease by 1 step

Increase by 1 step

Increase by 1 step

Decrease by 1 step

Decrease by 1 step

Reserved

Jun. /2018

�EtronTech

EM68B16CWQK

ODT (On Die Termination)

On Die Termination (ODT) is a feature that allows a DRAM to turn on/off termination resistance for each DQ,

UDQS/UDQS#, LDQS/LDQS#, UDM, and LDM signal via the ODT control pin. The ODT feature is designed to

improve signal integrity of the memory channel by allowing the DRAM controller to independently turn on/off

termination resistance for any or all DRAM devices.

The ODT function is supported for ACTIVE and STANDBY modes. It is turned off and not supported in SELF

REFRESH mode.

Figure 5. Functional representation of ODT

VDDQ

VDDQ

VDDQ

SW1

SW2

SW3

Rval1

Rval2

Rval3

DRAM

Input

Buffer

Input

pin

Rval1

SW1

VSSQ

Rval2

SW2

VSSQ

Rval3

SW3

VSSQ

Switch (sw1, sw2, sw3) is enabled by ODT pin.

Selection among sw1, sw2, and sw3 is determined by “Rtt (nominal)” in EMR.

Termination included on all DQs, DM, DQS, and DQS# pins

Table 11. ODT DC Electrical Characteristics

Parameter/Condition

Symbol

Min.

Nom.

Max.

Unit Note

Rtt effective impedance value for EMRS(A6,A2)=0,1;75Ω

Rtt1(eff)

60

75

90

Ω

Rtt effective impedance value for EMRS(A6,A2)=1,0;150Ω Rtt2(eff)

120

150

180

Ω

Rtt effective impedance value for EMRS(A6,A2)=1,1;50Ω

Rtt3(eff)

40

50

60

Ω

Rtt mismatch tolerance between any pull-up/pull-down pair Rtt(mis)

-6

6

%

NOTE 1: Measurement Definition for Rtt(eff): Apply VIH (ac) and VIL (ac) to test pin separately, then measure

current I (VIH (ac)) and I (VIL (ac)) respectively.

Rtt(eff)=

1

1

1

2

VIH (ac ) VIL (ac )

I(VIH (ac))-I(VIL (ac))

NOTE 2: Measurement Definition for Rtt (mis): Measure voltage (VM) at test pin (midpoint) with no load.

2xVM

Rtt(mis)=

1 100%

VDDQ

Rev. 1.1

15

Jun. /2018

�EtronTech

EM68B16CWQK

Bank activate command

The Bank Activate command is issued by holding CAS# and WE# HIGH with CS# and RAS# LOW at the rising edge

of the clock. The bank addresses BA0 and BA1 are used to select the desired bank. The row addresses A0 through

A12 are used to determine which row to activate in the selected bank. The Bank Activate command must be applied

before any Read or Write operation can be executed. Immediately after the bank active command, the DDR2

SDRAM can accept a read or write command (with or without Auto-Precharge) on the following clock cycle. If a R/W

command is issued to a bank that has not satisfied the t RCDmin specification, then additive latency must be

programmed into the device to delay the R/W command which is internally issued to the device. The additive latency

value must be chosen to assure tRCDmin is satisfied. Additive latencies of 0, 1, 2, 3, 4, and 5 are supported. Once a

bank has been activated it must be precharged before another Bank Activate command can be applied to the same

bank. The bank active and precharge times are defined as tRAS and tRP, respectively. The minimum time interval

between successive Bank Activate commands to the same bank is determined (tRC). The minimum time interval

between Bank Active commands is tRRD

Read and Write access modes

After a bank has been activated, a Read or Write cycle can be executed. This is accomplished by setting RAS#

HIGH, CS# and CAS# LOW at the clock’s rising edge. WE# must also be defined at this time to determine whether

the access cycle is a Read operation (WE# HIGH) or a Write operation (WE# LOW). The DDR2 SDRAM provides a

fast column access operation. A single Read or Write Command will initiate a serial Read or Write operation on

successive clock cycles. The boundary of the burst cycle is strictly restricted to specific segments of the page length.

Any system or application incorporating random access memory products should be properly designed, tested, and

qualified to ensure proper use or access of such memory products. Disproportionate, excessive, and/or repeated

access to a particular address or addresses may result in reduction of product life.

Posted CAS#

Posted CAS# operation is supported to make command and data bus efficient for sustainable bandwidths in DDR2

SDRAM. In this operation, the DDR2 SDRAM allows a CAS# Read or Write command to be issued immediately

after the RAS bank activate command (or any time during the RAS# -CAS#-delay time, tRCD, period). The command

is held for the time of the Additive Latency (AL) before it is issued inside the device. The Read Latency (RL) is

controlled by the sum of AL and the CAS latency (CL). Therefore if a user chooses to issue a R/W command before

the tRCDmin, then AL (greater than 0) must be written into the EMR(1). The Write Latency (WL) is always defined as

RL - 1 (Read Latency -1) where Read Latency is defined as the sum of additive latency plus CAS latency

(RL=AL+CL). Read or Write operations using AL allow seamless bursts (refer to seamless operation timing diagram

examples in Read burst and Write burst section)

Burst Mode Operation

Burst mode operation is used to provide a constant flow of data to memory locations (Write cycle), or from memory

locations (Read cycle). The parameters that define how the burst mode will operate are burst sequence and burst

length. The DDR2 SDRAM supports 4 bit and 8 bit burst modes only. For 8 bit burst mode, full interleave address

ordering is supported, however, sequential address ordering is nibble based for ease of implementation. The burst

length is programmable and defined by the addresses A0 ~ A2 of the MRS. The burst type, either sequential or

interleaved, is programmable and defined by the address bit 3 (A3) of the MRS. Seamless burst Read or Write

operations are supported. Interruption of a burst Read or Write operation is prohibited, when burst length = 4 is

programmed. For burst interruption of a Read or Write burst when burst length = 8 is used, see the “Burst

Interruption“ section of this datasheet. A Burst Stop command is not supported on DDR2 SDRAM devices.

Rev. 1.1

16

Jun. /2018

�EtronTech

EM68B16CWQK

Table 12. Burst Definition, Addressing Sequence of Sequential and Interleave Mode

Burst Length

4

8

Start Address

A2

A1

A0

X

0

0

X

0

1

X

1

0

X

1

1

0

0

0

0

0

1

0

1

0

0

1

1

1

0

0

1

0

1

1

1

0

1

1

1

Sequential

Interleave

0, 1, 2, 3

1, 2, 3, 0

2, 3, 0, 1

3, 0, 1, 2

0, 1, 2, 3, 4, 5, 6, 7

1, 2, 3, 0, 5, 6, 7, 4

2, 3, 0, 1, 6, 7, 4, 5

3, 0, 1, 2, 7, 4, 5, 6

4, 5, 6, 7, 0, 1, 2, 3

5, 6, 7, 4, 1, 2, 3, 0

6, 7, 4, 5, 2, 3, 0, 1

7, 4, 5, 6, 3, 0, 1, 2

0, 1, 2, 3

1, 0, 3, 2

2, 3, 0, 1

3, 2, 1, 0

0, 1, 2, 3, 4, 5, 6, 7

1, 0, 3, 2, 5, 4, 7, 6

2, 3, 0, 1, 6, 7, 4, 5

3, 2, 1, 0, 7, 6, 5, 4

4, 5, 6, 7, 0, 1, 2, 3

5, 4, 7, 6, 1, 0, 3, 2

6, 7, 4, 5, 2, 3, 0, 1

7, 6, 5, 4, 3, 2, 1, 0

Burst read command

The Burst Read command is initiated by having CS# and CAS# LOW while holding RAS# and WE# HIGH at the

rising edge of the clock. The address inputs determine the starting column address for the burst. The delay from the

start of the command to when the data from the first cell appears on the outputs is equal to the value of the Read

Latency (RL). The data strobe output (DQS) is driven LOW 1 clock cycle before valid data (DQ) is driven onto the

data bus. The first bit of the burst is synchronized with the rising edge of the data strobe (DQS). Each subsequent

data-out appears on the DQ pin in phase with the DQS signal in a source synchronous manner. The RL is equal to

an additive latency (AL) plus CAS Latency (CL). The CL is defined by the Mode Register Set (MRS), similar to the

existing SDR and DDR SDRAMs. The AL is defined by the Extended Mode Register Set (1) (EMRS (1)).

DDR2 SDRAM pin timings are specified for either single ended mode or differential mode depending on the setting

of the EMRS “Enable DQS” mode bit; timing advantages of differential mode are realized in system design. The

method by which the DDR2 SDRAM pin timings are measured is mode dependent. In single ended mode, timing

relationships are measured relative to the rising or falling edges of DQS crossing at VREF. In differential mode,

these timing relationships are measured relative to the cross point of DQS and its complement, DQS#. This

distinction in timing methods is guaranteed by design and characterization. Note that when differential data strobe

mode is disabled via the EMRS, the complementary pin, DQS#, must be tied externally to VSS through a 20 Ω to

10KΩ resistor to insure proper operation.

Burst write operation

The Burst Write command is initiated by having CS#, CAS# and WE# LOW while holding RAS# HIGH at the rising

edge of the clock. The address inputs determine the starting column address. Write latency (WL) is defined by a

Read latency (RL) minus one and is equal to (AL + CL -1);and is the number of clocks of delay that are required

from the time the Write command is registered to the clock edge associated to the first DQS strobe. A data strobe

signal (DQS) should be driven LOW (preamble) one clock prior to the WL. The first data bit of the burst cycle must

be applied to the DQ pins at the first rising edge of the DQS following the preamble. The tDQSS specification must

be satisfied for each positive DQS transition to its associated clock edge during write cycles.

The subsequent burst bit data are issued on successive edges of the DQS until the burst length is completed, which

is 4 or 8 bit burst. When the burst has finished, any additional data supplied to the DQ pins will be ignored. The DQ

Signal is ignored after the burst write operation is complete. The time from the completion of the burst Write to bank

precharge is the write recovery time (WR). DDR2 SDRAM pin timings are specified for either single ended mode or

differential mode depending on the setting of the EMRS “Enable DQS” mode bit; timing advantages of differential

mode are realized in system design. The method by which the DDR2 SDRAM pin timings are measured is mode

dependent.

In single ended mode, timing relationships are measured relative to the rising or falling edges of DQS crossing at the

specified AC/DC levels. In differential mode, these timing relationships are measured relative to the cross point of

DQS and its complement, DQS#. This distinction in timing methods is guaranteed by design and characterization.

Note that when differential data strobe mode is disabled via the EMRS, the complementary pin, DQS#, must be tied

externally to VSS through a 20Ω to 10KΩ resistor to insure proper operation.

Rev. 1.1

17

Jun. /2018

�EtronTech

EM68B16CWQK

Write data mask

One Write data mask (DM) pin for each 8 data bits (DQ) will be supported on DDR2 SDRAMs, Consistent with the

implementation on DDR SDRAMs. It has identical timings on Write operations as the data bits, and though

used

in a uni-directional manner, is internally loaded identically to data bits to insure matched system timing. DM is not

used during read cycles.

Precharge operation

The Precharge command is used to precharge or close a bank that has been activated. The Precharge Command is

triggered when CS#, RAS# and WE# are LOW and CAS# is HIGH at the rising edge of the clock. The Precharge

Command can be used to precharge each bank independently or all banks simultaneously. Three address bits A10,

BA1, and BA0 are used to define which bank to precharge when the command is issued.

Table 13. Bank Selection for Precharge by address bits

A10

BA1

BA0

Precharged Bank(s)

LOW

LOW

LOW

LOW

HIGH

LOW

LOW

HIGH

HIGH

DON’T CARE

LOW

HIGH

LOW

HIGH

DON’T CARE

Bank 0 only

Bank 1 only

Bank 2 only

Bank 3 only

ALL Banks

Burst read operation followed by precharge

Minimum Read to precharge command spacing to the same bank = AL + BL/2 + max (RTP, 2) - 2 clocks. For the

earliest possible precharge, the precharge command may be issued on the rising edge which “Additive latency (AL)

+ BL/2 clocks” after a Read command. A new bank active (command) may be issued to the same bank after the

RAS# precharge time (tRP). A precharge command cannot be issued until tRAS is satisfied.

The minimum Read to Precharge spacing has also to satisfy a minimum analog time from the rising clock edge that

initiates the last 4-bit prefetch of a Read to Precharge command. This time is called tRTP (Read to Precharge). For

BL = 4 this is the time from the actual read (AL after the Read command) to Precharge command. For BL = 8 this is

the time from AL + 2 clocks after the Read to the Precharge command.

Burst Write operation followed by precharge

Minimum Write to Precharge command spacing to the same bank = WL + BL/2 + tWR. For write cycles, a delay

must be satisfied from the completion of the last burst write cycle until the Precharge command can be issued. This

delay is known as a write recovery time (tWR) referenced from the completion of the burst write to the Precharge

command. No Precharge command should be issued prior to the tWR delay, as DDR2 SDRAM does not support

any burst interrupt by a Precharge command. tWR is an analog timing parameter and is not the programmed value

for tWR in the MRS.

Auto precharge operation

Before a new row in an active bank can be opened, the active bank must be precharged using either the Precharge

Command or the auto-precharge function. When a Read or a Write Command is given to the DDR2 SDRAM, the

CAS# timing accepts one extra address, column address A10, to allow the active bank to automatically begin

precharge at the earliest possible moment during the burst read or write cycle. If A10 is LOW when the READ or

WRITE Command is issued, then normal Read or Write burst operation is executed and the bank remains active at

the completion of the burst sequence. If A10 is HIGH when the Read or Write Command is issued, then the autoprecharge function is engaged. During auto-precharge, a Read Command will execute as normal with the exception

that the active bank will begin to precharge on the rising edge which is CAS latency (CL) clock cycles before the end

of the read burst. Auto-precharge also be implemented during Write commands. The precharge operation engaged

by the Auto precharge command will not begin until the last data of the burst write sequence is properly stored in the

memory array. This feature allows the precharge operation to be partially or completely hidden during burst Read

cycles (dependent upon CAS latency) thus improving system performance for random data access. The RAS#

lockout circuit internally delays the Precharge operation until the array restore operation has been completed (tRAS

satisfied) so that the auto precharge command may be issued with any Read or Write command.

Rev. 1.1

18

Jun. /2018

�EtronTech

EM68B16CWQK

Burst read with auto precharge

If A10 is HIGH when a Read Command is issued, the Read with Auto-Precharge function is engaged. The DDR2

SDRAM starts an Auto-Precharge operation on the rising edge which is (AL + BL/2) cycles later from the Read with

AP command if tRAS(min) and tRTP are satisfied. If tRAS(min) is not satisfied at the edge, the start point of AutoPrecharge operation will be delayed until tRAS(min) is satisfied. If tRTP(min) is not satisfied at the edge, the start

point of Auto-precharge operation will be delayed until tRTP(min) is satisfied.

In case the internal precharge is pushed out by tRTP, tRP starts at the point where the internal precharge happens

(not at the next rising clock edge after this event). So for BL = 4 the minimum time from Read with Auto-Precharge

to the next Activate command becomes AL + tRTP + tRP. For BL = 8 the time from Read with Auto-Precharge to the

next Activate command is AL + 2 + tRTP + tRP. Note that both parameters tRTP and tRP have to be rounded up to

the next integer value. In any event internal precharge does not start earlier than two clocks after the last 4-bit

prefetch.

A new bank active (command) may be issued to the same bank if the following two conditions are satisfied simultaneously:

(1) The RAS# precharge time (tRP) has been satisfied from the clock at which the Auto-Precharge begins.

(2) The RAS# cycle time (tRC) from the previous bank activation has been satisfied.

Burst write with auto precharge

If A10 is HIGH when a Write Command is issued, the Write with Auto-Precharge function is engaged. The DDR2

SDRAM automatically begins precharge operation after the completion of the burst write plus Write recovery time

(tWR). The bank undergoing auto-precharge from the completion of the write burst may be reactivated if the

following two conditions are satisfied.

(1) The data-in to bank activate delay time (WR + tRP) has been satisfied.

(2) The RAS# cycle time (tRC) from the previous bank activation has been satisfied.

Table 14. Precharge & Auto Precharge Clarification

Minimum Delay between “From

Unit Notes

Command” to “To Command”

Precharge (to same Bank as Read)

AL+BL/2+max(RTP,2)-2

Read

tCK

1,2

Precharge All

AL+BL/2+max(RTP,2)-2

Precharge (to same Bank as Read w/AP)

AL+BL/2+max(RTP,2)-2

Read w/AP

tCK

1,2

Precharge All

AL+BL/2+max(RTP,2)-2

Precharge (to same Bank as Write)

WL+BL/2+tWR

Write

tCK

2

Precharge All

WL+BL/2+tWR

Precharge (to same Bank as Write w/AP)

WL+BL/2+tWR

Write w/AP

tCK

2

Precharge All

WL+BL/2+tWR

Precharge (to same Bank as Precharge)

1

Precharge

tCK

2

Precharge All

1

Precharge

1

Precharge All

tCK

2

Precharge All

1

NOTE 1: RTP [cycles] =RU {tRTP [ns]/tCK (avg) [ns]}, where RU stands for round up.

NOTE 2: For a given bank, the precharge period should be counted from the latest precharge command, either one

bank precharge or precharge all, issued to that bank.The prechrage period is satisfied after t RP or tRP

all(=tRP for 4 bank device) depending on the latest precharge command issued to that bank.

From Command

Rev. 1.1

To Command

19

Jun. /2018

�EtronTech

EM68B16CWQK

Refresh command

When CS#, RAS# and CAS# are held LOW and WE# HIGH at the rising edge of the clock, the chip enters the

Refresh mode (REF). All banks of the DDR2 SDRAM must be precharged and idle for a minimum of the Precharge

time (tRP) before the Refresh command (REF) can be applied. An address counter, internal to the device, supplies

the bank address during the refresh cycle. No control of the external address bus is required once this cycle has

started.

When the refresh cycle has completed, all banks of the DDR2 SDRAM will be in the precharged (idle) state. A delay

between the Refresh command (REF) and the next Activate command or subsequent Refresh command must be

greater than or equal to the Refresh cycle time (tRFC).To allow for improved efficiency in scheduling and switching

between tasks, some flexibility in the absolute refresh interval is provided. A maximum of eight Refresh commands

can be posted to any given DDR2 SDRAM, meaning that the maximum absolute interval between any Refresh

command and the next Refresh command is 9 * tREFI.

Self refresh operation

The Self Refresh command can be used to retain data in the DDR2 SDRAM, even if the rest of the system is

powered down. When in the Self Refresh mode, the DDR2 SDRAM retains data without external clocking. The

DDR2 SDRAM device has a built-in timer to accommodate Self Refresh operation. The Self Refresh Command is

defined by having CS#, RAS#, CAS# and CKE# held LOW with WE# HIGH at the rising edge of the clock. ODT

must be turned off before issuing Self Refresh command, by either driving ODT pin LOW or using EMRS command.

Once the Command is registered, CKE must be held LOW to keep the device in Self Refresh mode. The DLL is

automatically disabled upon entering Self Refresh and is automatically enabled upon exiting Self Refresh. When the

DDR2 SDRAM has entered Self Refresh mode all of the external signals except CKE, are “don’t care”. For proper

Self Refresh operation all power supply pins (VDD, VDDQ, VDDL and VREF) must be at valid levels. The DRAM

initiates a minimum of one refresh command internally within tCKE period once it enters Self Refresh mode. The

clock is internally disabled during Self Refresh Operation to save power. The minimum time that the DDR2 SDRAM

must remain in Self Refresh mode is tCKE. The user may change the external clock frequency or halt the external

clock one clock after Self Refresh entry is registered, however, the clock must be restarted and stable before the

device can exit Self Refresh operation.

The procedure for exiting Self Refresh requires a sequence of commands. First, the clock must be stable prior to

CKE going back HIGH. Once Self Refresh Exit is registered, a delay of at least tXSNR must be satisfied before a

valid command can be issued to the device to allow for any internal refresh in progress. CKE must remain HIGH for

the entire Self Refresh exit period tXSRD for proper operation except for Self Refresh re-entry. Upon exit from Self

Refresh, the DDR2 SDRAM can be put back into Self Refresh mode after waiting at least tXSNR period and issuing

one refresh command(refresh period of tRFC). NOP or deselect commands must be registered on each positive

clock edge during the Self Refresh exit interval tXSNR. ODT should be turned off during tXSRD.

The use of Self Refresh mode introduces the possibility that an internally timed refresh event can be missed when

CKE is raised for exit from Self Refresh mode. Upon exit from Self Refresh, the DDR2 SDRAM requires a minimum

of one extra auto refresh command before it is put back into Self Refresh mode.

Rev. 1.1

20

Jun. /2018

�EtronTech

EM68B16CWQK

Power-Down

Power-down is synchronously entered when CKE is registered LOW along with NOP or Deselect command. No read

or write operation may be in progress when CKE goes LOW. These operations are any of the following: read burst or

write burst and recovery. CKE is allowed to go LOW while any of other operations such as row activation, precharge

or autoprecharge, mode register or extended mode register command time, or autorefresh is in progress.

The DLL should be in a locked state when power-down is entered. Otherwise DLL should be reset after exiting

power-down mode for proper read operation.

If power-down occurs when all banks are precharged, this mode is referred to as Precharge Power-down; if powerdown occurs when there is a row active in any bank, this mode is referred to as Active Power-down. For Active

Power-down two different power saving modes can be selected within the MRS register, address bit A12. When A12

is set to “LOW” this mode is referred as “standard active power-down mode” and a fast power-down exit timing

defined by the tXARD timing parameter can be used. When A12 is set to “HIGH” this mode is referred as a power

saving “LOW power active power-down mode”. This mode takes longer to exit from the power-down mode and the

tXARDS timing parameter has to be satisfied. Entering power-down deactivates the input and output buffers,

excluding CK, CK#, ODT and CKE. Also the DLL is disabled upon entering precharge power-down or slow exit

active power-down, but the DLL is kept enabled during fast exit active power-down. In power-down mode, CKE LOW

and a stable clock signal must be maintained at the inputs of the DDR2 SDRAM, and all other input signals are

“Don’t Care”. Power-down duration is limited by 9 times tREFI of the device.

The power-down state is synchronously exited when CKE is registered HIGH (along with a NOP or Deselect

command). A valid, executable command can be applied with power-down exit latency, tXP, tXARD or tXARDS,

after CKE goes HIGH. Power-down exit latencies are defined in the AC spec table of this data sheet.

Asynchronous CKE LOW Event

DRAM requires CKE to be maintained “HIGH” for all valid operations as defined in this datasheet. If CKE

asynchronously drops “LOW” during any valid peration DRAM is not guaranteed to preserve the contents of array. If

this event occurs, memory controller must satisfy DRAM timing specification tDelay efore turning off the clocks.

Stable clocks must exist at the input of DRAM before CKE is raised “HIGH” again. DRAM must be fully re-initialized.

DRAM is ready for normal operation after the initialization sequence.

Input clock frequency change during precharge power down

DDR2 SDRAM input clock frequency can be changed under following condition: DDR2 SDRAM is in precharged

power down mode. ODT must be turned off and CKE must be at logic LOW level. A minimum of 2 clocks must be

waited after CKE goes LOW before clock frequency may change. SDRAM input clock frequency is allowed to

change only within minimum and maximum operating frequency specified for the particular speed grade. During

input clock frequency change, ODT and CKE must be held at stable LOW levels. Once input clock frequency is

changed, stable new clocks must be provided to DRAM before precharge power down may be exited and DLL must

be RESET via EMRS after precharge power down exit. Depending on new clock frequency an additional MRS

command may need to be issued to appropriately set the WR, CL etc. During DLL re-lock period, ODT must remain

off. After the DLL lock time, the DRAM is ready to operate with new clock frequency.

No operation command

The No Operation Command should be used in cases when the DDR2 SDRAM is in an idle or a wait state. The

purpose of the No Operation Command (NOP) is to prevent the DDR2 SDRAM from registering any unwanted

commands between operations. A No Operation Command is registered when CS# is LOW with RAS#, CAS#, and

WE# held HIGH at the rising edge of the clock. A No Operation Command will not terminate a previous operation

that is still executing, such as a burst read or write cycle.

Deselect command

The Deselect Command performs the same function as a No Operation Command. Deselect Command occurs

when CS# is brought HIGH at the rising edge of the clock, the RAS#, CAS#, and WE# signals become don’t cares.

Rev. 1.1

21

Jun. /2018

�EtronTech

EM68B16CWQK

Table 15. Absolute Maximum DC Ratings

Symbol

Parameter

Values

Unit Note

VDD

Voltage on VDD pin relative to Vss

-1.0 ~ 2.3

V

1,3

VDDQ Voltage on VDDQ pin relative to Vss

-0.5 ~ 2.3

V

1,3

VDDL Voltage on VDDL pin relative to Vss

-0.5 ~ 2.3

V

1,3

VIN, VOUT Voltage on any pin relative to Vss

-0.5 ~ 2.3

V

1,4

TSTG Storage temperature

-55 ~ 100

C

1,2

°

NOTE 1: Stress greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to the

devices. This is a stress rating only and functional operation of the device at these or any other conditions

above those indicated in the operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect reliability.

NOTE 2: Storage temperature is the case temperature on the center/top side of the DRAM.

NOTE 3: When VDD and VDDQ and VDDL are less than 500mV, Vref may be equal to or less than 300mV.

NOTE 4: Voltage on any input or I/O may not exceed voltage on VDDQ.

Table 16. Operating Temperature Condition

Symbol

Parameter

Values

Unit Note

-40 ~ 95

1,2

TOPER Operating temperature (Industrial)

°C

NOTE 1: Operating Temperature is the case surface temperature on the center/top side of the DRAM.

NOTE 2: The operation temperature range are the temperature where all DRAM specification will be supported.

Outside of this temperature range, even if it is still within the limit of stress condition, some deviation on

portion of operation specification may be required. During operation, the DRAM case temperature must be

maintained between 0 - 85°C under all other specification parameter. However, in some applications, it is

desirable to operate the DRAM up to 95°C case temperature. Therefore, two spec options may exist.

a) Supporting 0 - 85°C with full JEDEC AC & DC specifications. This is the minimum requirements for all

operating temperature options.

b) This is an optional feature and not required. Supporting 0 - 85°C and being able to extend to 95°C with

doubling auto-refresh commands in frequency to a 32 ms period ( tREFI = 3.9 us). Supporting higher

temperature Self-Refresh entry via the control of EMRS (2) bit A7.

c) During operation, the DRAM case temperature must be maintained between -40 - 95 °C for Industrial

grade under all specification parameters.

Table 17. Recommended DC Operating Conditions

Symbol

Parameter

Min.

Typ.

Max.

Unit Note

VDD

Power supply voltage

1.7

1.8

1.9

V

1

VDDL

Power supply voltage for DLL

1.7

1.8

1.9

V

5

VDDQ

Power supply voltage for I/O Buffer

1.7

1.8

1.9

V

1,5

VREF

Input reference voltage

0.49 x VDDQ

0.5 x VDDQ

0.51 x VDDQ

mV

2,3

VTT

Termination voltage

VREF - 0.04

VREF

VREF + 0.04

V

4

NOTE 1: There is no specific device VDD supply voltage requirement for SSTL_18 compliance. However under all

conditions VDDQ must be less than or equal to VDD.

NOTE 2: The value of VREF may be selected by the user to provide optimum noise margin in the system. Typically

the value of VREF is expected to be about 0.5 x VDDQ of the transmitting device and VREF is expected to track

variations in VDDQ.

NOTE 3: Peak to peak ac noise on VREF may not exceed ±2 % VREF (dc).

NOTE 4: VTT of transmitting device must track VREF of receiving device.

NOTE 5: VDDQ tracks with VDD, VDDL tracks with VDD. AC parameters are measured with VDD, VDDQ and VDDL tied together.

Rev. 1.1

22

Jun. /2018

�EtronTech

EM68B16CWQK

Table 18. Input logic level

Symbol

Parameter

-18I

-25I/3I

Unit Note

Min.

Max.

Min.

Max.

VREF + 0.125

VDDQ + 0.3

VREF + 0.125

VDDQ + 0.3

V

VIL (DC) DC Input Low Voltage

-0.3

VREF - 0.125

-0.3

VREF - 0.125

V

VIH (AC) AC Input High Voltage

VREF + 0.2

-

VREF + 0.2

VDDQ + Vpeak

V

VIL (AC) AC Input Low Voltage

-

VREF - 0.2

VSSQ - Vpeak

VREF - 0.2

V

VID (AC) AC Differential Voltage

0.5

VDDQ + 0.6

0.5

VDDQ

V

VIH (DC) DC Input logic High Voltage

1

0.5 x VDDQ

0.5 x VDDQ

0.5 x VDDQ

0.5 x VDDQ

VIX (AC) AC Differential cross point Voltage

V

2

- 0.175

+ 0.175

- 0.175

+ 0.175

NOTE 1: VID(AC) specifies the input differential voltage |VTR -VCP| required for switching, where VTR is the true input

signal (such as CK, DQS, LDQS or UDQS) and VCP is the complementary input signal (such as CK, DQS,

LDQS or UDQS). The minimum value is equal to VIH (AC) - VIL (AC).

NOTE 2: The typical value of VIX (AC) is expected to be about 0.5 x VDDQ of the transmitting device and VIX (AC) is

expected to track variations in VDDQ. VIX (AC) indicates the voltage at which differential input signals must

cross.

NOTE 3: Refer to Overshoot/undershoot specification for Vpeak value: maximum peak amplitude allowed for overshoot

and undershoot.

Table 19. AC Input test conditions

Symbol

Parameter

Values

Unit Note

VREF

Input reference voltage

0.5 x VDDQ

V

1

VSWING(max) Input signal maximum peak to peak swing

1.0

V

1

Slew Rate Input signal minimum slew rate

1.0

V/ns 2, 3

NOTE 1: Input waveform timing is referenced to the input signal crossing through the VIH /IL (ac) level applied to the

device under test.

NOTE 2: The input signal minimum slew rate is to be maintained over the range from VREF to VIH(ac) min for rising

edges and the range from VREF to VIL (ac) max for falling edges.

NOTE 3: AC timings are referenced with input waveforms switching from VIL (ac) to VIH (ac) on the positive transitions

and VIH (ac) to VIL (ac) on the negative transitions.

Table 20. Differential AC output parameters

Symbol

Value

Parameter

Min.

Max.

Unit Note

Vox(ac) AC Differential Cross Point Voltage

0.5 x VDDQ - 0.125 0.5 x VDDQ + 0.125

V

1

NOTE 1: The typical value of VOX (ac) is expected to be about 0.5 x VDDQ of the transmitting device and VOX (ac) is

expected to track variations in VDDQ. VOX (ac) indicates the voltage at which differential output signals must

cross.

Rev. 1.1

23

Jun. /2018

�EtronTech

EM68B16CWQK

Table 21. AC overshoot/undershoot specification for address and control pins

(A0-A12, BA0-BA1, CS#, RAS#, CAS#, WE#, CKE, ODT)

Parameter

-18I

-25I

-3I

Unit

Maximum peak amplitude allowed for overshoot area

0.5

0.5

0.5

V

Maximum peak amplitude allowed for undershoot area

0.5

0.5

0.5

V

Maximum overshoot area above VDD

0.5

0.66

0.8

V-ns

Maximum undershoot area below VSS

0.5

0.66

0.8

V-ns

Figure 6. AC overshoot and undershoot definition for address and control pins

Maximum

Amplitude

Volts (V)

Overshoot

Area

VDD

VSS

Maximum

Amplitude

Undershoot

Area

Time (ns)

Table 22. AC overshoot/undershoot specification for clock, data, strobe, and mask pins

(DQ, UDQS, LDQS, UDQS#, LDQS#, DM, CK, CK#)

Parameter

Maximum peak amplitude allowed for overshoot area

-18I

-25I

-3I

Unit

0.5

0.5

0.5

V

Maximum peak amplitude allowed for undershoot area

0.5

0.5

0.5

V

Maximum overshoot area above VDD

0.19

0.23

0.23

V-ns

Maximum undershoot area below VSS

0.19

0.23

0.23

V-ns

Figure 7. AC overshoot and undershoot definition for clock, data, strobe, and mask pins

Maximum

Amplitude

Volts (V)

Overshoot

Area

VDDQ

VSSQ

Maximum

Amplitude

Undershoot

Area

Time (ns)

Rev. 1.1

24

Jun. /2018

�EtronTech

EM68B16CWQK

Table 23. Output AC test conditions

Symbol

VOTR

Parameter

Value

Output timing measurement reference level

Unit Note

0.5 x VDDQ

V

1

NOTE 1: The VDDQ of the device under test is referenced.

Table 24. Output DC current drive

Symbol

IOH(dc)

Parameter

Output minimum source DC current

Values

Unit Note

-13.4

mA 1, 3, 4

IOL(dc)

Output minimum sink DC current

13.4

mA 2, 3, 4

NOTE 1: VDDQ = 1.7 V; VOUT = 1420 mV. (VOUT - VDDQ) /IOH must be less than 21 Ω for values of VOUT between VDDQ

and VDDQ - 280 mV.

NOTE 2: VDDQ = 1.7 V; VOUT = 280 mV. VOUT/IOL must be less than 21 Ω for values of VOUT between 0 V and 280 mV.

NOTE 3: The dc value of VREF applied to the receiving device is set to VTT

NOTE 4: The values of IOH (dc) and IOL (dc) are based on the conditions given in Notes 1 and 2. They are used to

test device drive current capability to ensure VIH min plus a noise margin and VIL max minus a noise

margin are delivered to an SSTL_18 receiver. The actual current values are derived by shifting the desired

driver operating point (see JEDEC standard: Section 3.3 of JESD8-15A) along a 21 Ω load line to define a

convenient driver current for measurement.

Table 25. Capacitance (VDD = 1.8V, TOPER = 25 C)

Symbol

DDR2-1066/800

Parameter

Min.

Max.

CIN1

Input Capacitance : Command and Address

1.0

1.75

CIN2

Input Capacitance (CK, CK#)

1.0

2.0

CI/O

DM, DQ, DQS Input/Output Capacitance

2.5

3.5

DCIO

Delta Input/Output Capacitance: DM, DQ, DQS

0.5

DCI1

Delta Input Capacitance: Command and Address

0.25

DCI2

Delta Input Capacitance: CK, CK#

0.25

NOTE 1: These parameters are periodically sampled and are not 100% tested.

Rev. 1.1

25

DDR2-667

Min.

Max.

1.0

1.0

2.5

-

2.0

2.0

3.5

0.5

0.25

0.25

Unit

pF

pF

pF

pF

pF

pF

Jun. /2018

�EtronTech

EM68B16CWQK

Table 26. IDD specification parameters and test conditions (VDD = 1.8V 0.1V, TOPER = -40~95 C)

Parameter & Test Condition

Operating one bank active-precharge current:

tCK =tCK (min), tRC = tRC (min), tRAS = tRAS(min); CKE is HIGH, CS# is HIGH

between valid commands; Address bus inputs are SWITCHING; Data bus

inputs are SWITCHING

Operating one bank active-read-precharge current:

IOUT = 0mA; BL = 4, CL = CL (min), AL = 0; tCK = tCK (min),tRC = tRC (min), tRAS

= tRAS(min), tRCD = tRCD (min);CKE is HIGH, CS# is HIGH between valid

commands;Address bus inputs are switching; Data pattern is same as IDD4W

Precharge power-down current:

All banks idle;tCK =tCK (min); CKE is LOW; Other control and address bus

inputs are STABLE; Data bus inputs are FLOATING

Precharge quiet standby current:

All banks idle; tCK =tCK (min); CKE is HIGH, CS# is HIGH; Other control and

address bus inputs are STABLE; Data bus inputs are FLOATING

Precharge standby current:

All banks idle; tCK = tCK (min); CKE is HIGH, CS# is HIGH; Other control and

address bus inputs are SWITCHING; Data bus inputs are SWITCHING

Active power-down current:

MRS(A12)=0

All banks open; tCK =tCK (min); CKE is LOW; Other control and

address bus inputs are STABLE; Data bus inputs are FLOATING MRS(A12)=1

Active standby current:

All banks open; tCK = tCK(min), tRAS = tRAS (max), tRP = tRP (min); CKE is HIGH,

CS# is HIGH between valid commands; Other control and address bus inputs

are SWITCHING; Data bus inputs are SWITCHING

Operating burst write current:

All banks open,continuous burst writes; BL = 4, CL = CL (min), AL = 0; tCK=

tCK (min), tRAS = tRAS (max), tRP = tRP (min); CKE is HIGH, CS# is HIGH

between valid commands; Address bus inputs are switching; Data bus inputs

are switching

Operating burst read current:

All banks open, continuous burst reads, IOUT = 0mA; BL = 4, CL = CL (min),

AL = 0; tCK = tCK (min), tRAS = tRAS (max), tRP = tRP (min); CKE is HIGH, CS# is

HIGH between valid commands; Address bus inputs are SWITCHING; Data

pattern is same as IDD4W

Burst refresh current:

tCK = tCK (min); refresh command at every tRFC (min) interval; CKE is HIGH,

CS# is HIGH between valid commands; Other control and address bus inputs

are SWITCHING; Data bus inputs are SWITCHING

Self refresh current:

CK and CK# at 0V; CKE ≤ 0.2V;Other control and address bus inputs are

FLOATING; Data bus inputs are FLOATING

Operating bank interleave read current:

All bank interleaving reads, IOUT= 0mA; BL = 4, CL = CL (min), AL =tRCD (min)

- 1 x tCK (min); tCK = tCK (min), tRC = tRC (min), tRRD = tRRD (min), tRCD = tRCD

(min); CKE is HIGH, CS# is HIGH between valid commands; Address bus

inputs are STABLE during DESELECTs. Data pattern is same as IDD4R

-18I

-25I

Max.

-3I

Unit

IDD0

70

65

60

mA

IDD1

80

75

70

mA

IDD2P

10

10

10

mA

IDD2Q

35

35

35

mA

IDD2N

35

35

35

mA

25

25

25

mA

20

20

20

mA

IDD3N

50

45

40

mA

IDD4W

120

100

90

mA

IDD4R

115

95

85

mA

IDD5

105

100

95

mA

IDD6

10

10

10

mA

IDD7

185

170

155

mA

Symbol

IDD3P

NOTE 1: IDD specifications are tested after the device is properly initialized.

NOTE 2: Input slew rate is specified by AC Parametric Test Condition.

NOTE 3: IDD parameters are specified with ODT disabled.