MLX90364LVS-ADD-203-RE 数据手册

MLX90364 Triaxis® Position Sensor

Datasheet

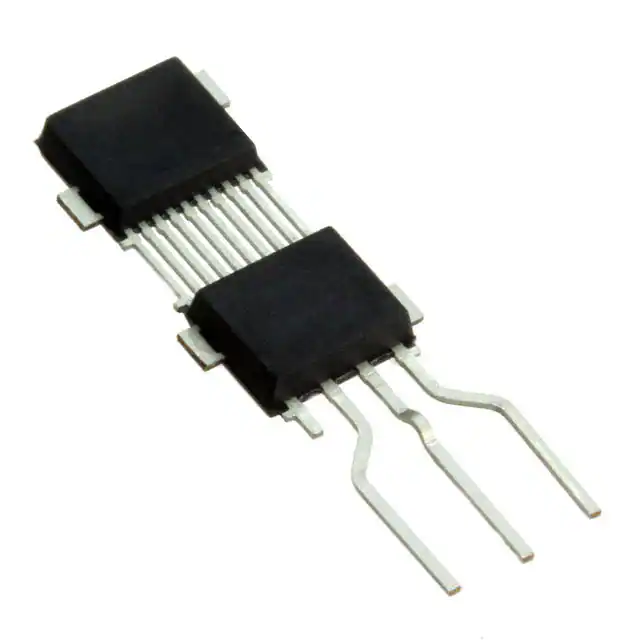

Absolute Rotary & Linear Position Sensor IC

Robust Dual Mold Package (DMP-4) feat. up to

4 Decoupling Capacitors (ESD/EMC)

Reliable NoPCB Module Integration

Triaxis Hall Technology

Simple Magnetic Design

Programmable Transfer Characteristic (MultiPoints – Piece-Wise-Linear)

Selectable Output Mode: Analog (Ratiometric)

– Pulse Width Modulation (PWM)

12 bit Resolution - 10 bit Thermal Accuracy

Open/Short Diagnostics

On Board Diagnostics

Over-Voltage Protection

Under-Voltage Detection

48 bit ID Number option

Automotive Temperature Range

AEC-Q100 & AEC-Q200 Qualified

DMP-4 RoHS Compliant

Output Thermal Offset correction

DMP-4

Applications

Absolute Rotary Position Sensor

Absolute Linear Position Sensor

EGR Valve Position Sensor

Turbo Actuator

Throttle Position Sensor

Clutch, Shift & Fork Position Sensor

Ride Height Position Sensor

Float Level Sensor

Description

The MLX90364 Triaxis® Position Sensor Assembly

is a high accuracy linear and angular position

sensor which eliminates need for inclusion of a

printed circuit board (PCB) within sensing

modules.

This device is based on a Dual Mold Package

(DMP-4) construction, which integrates a Triaxis

position sensing die together with the decoupling

capacitors necessary to meet the strenuous ESD

and EMC requirements. No PCB is needed.

The Triaxis position sensing die is nothing but the

one used for the MLX90365 in conventional

surface-mount packages (SOIC-8 and TSSOP-16).

Similarly to other Triaxis products, the MLX90364

is sensitive to the flux density applied

orthogonally and parallel to the IC surface i.e. the

3 components of the flux density applied to the IC

(i.e. BX, BY and BZ). This allows the MLX90364 with

the correct magnetic circuit to decode the

absolute position of any moving magnet (e.g.

rotary position from 0 to 360 Degrees or linear

displacement, stroke).

MLX90364 reports a programmable ratiometric

analog output signal compatible with any resistive

potentiometer or programmable linear Hall

sensor. Through programming, the MLX90364

provides also a digital PWM (Pulse Width

Modulation) output characteristic.

VDD

VDIG

Prot.

2V5

Reg

DSP

Triaxis®

VX

VY

VZ

EEPROM

RAM

MUX

Features and Benefits

G

ADC

Output Stage

12 bit Analog

µC

OUT

12 bit PWM

ROM - Firmware

VSS

�MLX90364 Triaxis® Position Sensor

Datasheet

Contents

Features and Benefits................................................................................................................................... 1

Applications .................................................................................................................................................. 1

Description ................................................................................................................................................... 1

1. Ordering Information ............................................................................................................................... 5

2. Functional Diagram .................................................................................................................................. 8

3. Glossary of Terms ..................................................................................................................................... 8

4. Pinout ....................................................................................................................................................... 9

5. Absolute Maximum Ratings ...................................................................................................................... 9

6. Electrical Specification ............................................................................................................................ 10

7. Timing Specification................................................................................................................................ 13

7.1. ANALOG OUTPUT ........................................................................................................................... 13

7.2. PWM OUTPUT ................................................................................................................................ 14

8. Accuracy Specification ............................................................................................................................ 15

8.1. Magnetic Accuracy ......................................................................................................................... 15

8.1.1. Normal Magnetic range: 20 mT ≤ B < 70 mT........................................................................... 15

8.1.2. Extended Range #1 : 15 mT ≤ B < 20 mT ................................................................................ 16

8.1.3. Extended Range #2: 10 mT ≤ B < 15 mT ................................................................................. 16

8.2. ANALOG OUTPUT ........................................................................................................................... 17

8.3. PWM OUTPUT ................................................................................................................................ 18

9. Magnetic Specification ........................................................................................................................... 20

10. CPU & Memory Specification ............................................................................................................... 20

11. Traceability Information ....................................................................................................................... 21

12. End-User Programmable Items ............................................................................................................ 21

13. Description of End-User Programmable Items ..................................................................................... 23

13.1. Output modes .............................................................................................................................. 23

13.1.1. OUT mode .............................................................................................................................. 23

13.1.2. Analog Output Mode ............................................................................................................. 24

13.1.3. PWM Output Mode ............................................................................................................... 24

13.2. Output Transfer Characteristic .................................................................................................... 25

13.2.1. Enable scaling Parameter (only for LNR type 4 pts) .............................................................. 26

13.2.2. CLOCKWISE Parameter .......................................................................................................... 26

REVISION 007 – OCT 2018

390109036401

Page 2 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

13.2.3. Discontinuity Point (or Zero Degree Point) ........................................................................... 26

13.2.4. 4-Pts LNR Parameters ............................................................................................................ 26

13.2.5. 17-Pts LNR Parameters .......................................................................................................... 27

13.2.6. CLAMPING Parameters .......................................................................................................... 28

13.2.7. Thermal Output Offset correction (AxE version only) ........................................................... 28

13.3. Identification ................................................................................................................................ 29

13.4. Lock .............................................................................................................................................. 29

13.5. Sensor Front-End ......................................................................................................................... 30

13.5.1. MAPXYZ .................................................................................................................................. 30

13.5.2. SMISM, k and SEL_k Parameters ........................................................................................... 30

13.5.3. GAINMIN and GAINMAX Parameters .................................................................................... 31

13.6. Filter ............................................................................................................................................. 31

13.6.1. Hysteresis Filter ...................................................................................................................... 31

13.6.2. FIR Filters ................................................................................................................................ 31

13.7. Programmable Diagnostic Settings.............................................................................................. 32

13.7.1. DIAG mode ............................................................................................................................. 32

13.7.2. DIAG Level .............................................................................................................................. 32

13.7.3. Field Strength Diagnostic ....................................................................................................... 32

13.7.4. PWM Diagnostic ..................................................................................................................... 33

13.7.5. Diagnostic Features................................................................................................................ 33

13.8. EEPROM endurance ..................................................................................................................... 33

14. Self Diagnostic ...................................................................................................................................... 34

15. Built-in Capacitors and Recommended Application Diagrams ............................................................. 38

16. Standard information regarding manufacturability of Melexis products with different soldering

processes ............................................................................................................................................... 39

17. ESD Precautions.................................................................................................................................... 39

18. Package Information............................................................................................................................. 40

18.1. DMP-4 Package ............................................................................................................................ 40

18.1.1. DMP-4 - Package Outline Dimensions (POD) – Straight Leads.............................................. 40

18.1.2. DMP-4 - Package Outline Dimensions (POD) – STD1 2.54 .................................................... 41

18.1.3. DMP-4 - Package Outline Dimensions (POD) – STD2 2.54 .................................................... 41

18.1.4. DMP-4 - Package Outline Dimensions (POD) – STD4 2.54 .................................................... 42

18.1.5. DMP-4 - Marking .................................................................................................................... 42

REVISION 007 – OCT 2018

390109036401

Page 3 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

18.1.6. DMP-4 - Sensitive Spot Positioning ....................................................................................... 43

18.1.7. DMP-4 - Angle detection ....................................................................................................... 44

19. Disclaimer ............................................................................................................................................. 45

20. Contact ................................................................................................................................................. 45

REVISION 007 – OCT 2018

390109036401

Page 4 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

1. Ordering Information

Product Code

Packing

Comment

Form

Temperature

Package

Option Code

MLX90364

L

VS

ADB-200

RE/RX

Not recommended for new design

MLX90364

L

VS

ADB-201

RE/RX

Not recommended for new design

MLX90364

L

VS

ADB-203

RE/RX

Not recommended for new design

MLX90364

L

VS

ADB-208

RE/RX

Not recommended for new design

MLX90364

L

VS

ADB-250

RE/RX

Not recommended for new design

MLX90364

L

VS

ADB-251

RE/RX

Not recommended for new design

MLX90364

L

VS

ADB-253

RE/RX

Not recommended for new design

MLX90364

L

VS

ADB-258

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-200

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-201

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-203

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-208

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-250

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-251

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-253

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-258

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-300

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-301

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-303

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-308

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-400

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-401

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-403

RE/RX

Not recommended for new design

MLX90364

L

VS

ADD-408

RE/RX

Not recommended for new design

MLX90364

L

VS

ADE-200

RE/RX

Not recommended for new design

MLX90364

L

VS

ADE-201

RE/RX

Not recommended for new design

MLX90364

L

VS

ADE-203

RE/RX

Not recommended for new design

REVISION 007 – OCT 2018

390109036401

Page 5 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

Product Code

Packing

Comment

Form

Temperature

Package

Option Code

MLX90364

L

VS

ADE-208

RE/RX

MLX90364

L

VS

AED-200

RE/RX

MLX90364

L

VS

AED-201

RE/RX

MLX90364

L

VS

AED-203

RE/RX

MLX90364

L

VS

AED-208

RE/RX

MLX90364

L

VS

AED-250

RE/RX

MLX90364

L

VS

AED-251

RE/RX

MLX90364

L

VS

AED-253

RE/RX

MLX90364

L

VS

AED-258

RE/RX

MLX90364

L

VS

AED-300

RE/RX

MLX90364

L

VS

AED-301

RE/RX

MLX90364

L

VS

AED-303

RE/RX

MLX90364

L

VS

AED-308

RE/RX

MLX90364

L

VS

AED-400

RE/RX

MLX90364

L

VS

AED-401

RE/RX

MLX90364

L

VS

AED-403

RE/RX

MLX90364

L

VS

AED-408

RE/RX

MLX90364

L

VS

AEE-200

RE/RX

MLX90364

L

VS

AEE-201

RE/RX

MLX90364

L

VS

AEE-203

RE/RX

MLX90364

L

VS

AEE-208

RE/RX

REVISION 007 – OCT 2018

390109036401

Not recommended for new design

Not recommended for new design

Not recommended for new design

Not recommended for new design

Not recommended for new design

Not recommended for new design

Page 6 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

Legend:

Temperature Code:

L: from -40 Deg.C to 150 Deg.C

Package Code:

“VS” for DMP-4

Option Code:

Axx-xxx: die version

ADx-xxx: not recommended for new design

AED-xxx: standard version

AEE-xxx: standard version with thermal offset correction

xxx-123:

12: Capacitances configuration see section 15.1

3: Trim-and-Form for DMP-4

Packing Form:

0: Standard straight leads. See section 18.1.1

1: Trim-and-Form STD1 2.54. See section 18.1.2 (not recommended for new

design, prefer STD4 2.54)

3: Trim-and-Form STD2 2.54. See section 18.1.3

8: Trim-and-Form STD4 2.54. See section 18.1.4

RE for Reel (face-up)

RX for Reel (face down)

SP Sample Pack

Ordering Example:

REVISION 007 – OCT 2018

390109036401

MLX90364LVS-AED-201-RE

Page 7 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

2. Functional Diagram

VDD

VDIG

Prot.

2V5

Reg

DSP

VX

VY

VZ

RAM

MUX

Triaxis

®

G

ADC

EEPROM

Output Stage

12 bit Analog

µC

OUT

12 bit PWM

ROM - Firmware

VSS

Figure 1 – Block Diagram

3. Glossary of Terms

Gauss (G),

Tesla (T)

TC

NC

ADC

LSB

MSB

DNL

INL

RISC

ASP

DSP

ATAN

IMC

Units for the magnetic flux density - 1 mT

= 10 G

Temperature Coefficient (in ppm/Deg.C.)

Not Connected

Analog-to-Digital Converter

Least Significant Bit

Most Significant Bit

Differential Non-Linearity

Integral Non-Linearity

Reduced Instruction Set Computer

Analog Signal Processing

Digital Signal Processing

Trigonometric function: arctangent (or

inverse tangent)

Integrated Magneto-Concentrator (IMC®)

CoRDiC

EMC

FE

RE

FW

HW

PWM

%DC

MT3V

MT4V

LSD

PP

Coordinate Rotation Digital Computer

(i.e. iterative rectangular-to-polar

transform)

Electro-Magnetic Compatibility

Falling Edge

Rising Edge

Firmware

Hardware

Pulse Width Modulation

Ratio Ton / Tperiod where Ton is the high

state duration and Tperiod is the duration

of 1 pwm period

More Than 3V Condition

More Than 4V Condition

Low Side Driver = Open drain N

Push-Pull

Table 1 – Glossary of Terms

REVISION 007 – OCT 2018

390109036401

Page 8 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

4. Pinout

PIN

Pin Name

1

VSS (Ground)

2

VDD

3

OUT

4

VSS (Ground)

5. Absolute Maximum Ratings

Parameter

Value

Supply Voltage, VDD (overvoltage)

+ 24 V

Reverse Voltage Protection

− 12 V (breakdown at -14 V)

Positive Output Voltage

+ 18 V (breakdown at 24 V)

Output Current (IOUT)

+ 30 mA (in breakdown)

Reverse Output Voltage

− 0.3 V

Reverse Output Current

− 50 mA (in breakdown)

Operating Ambient Temperature Range, TA

− 40 … + 150 Deg.C

Storage Temperature Range, TS

− 40 … + 150 Deg.C

Magnetic Flux Density

±1T

Exceeding the absolute maximum ratings may cause permanent damage. Exposure to absolute maximumrated conditions for extended periods may affect device reliability. These max ratings are guaranteed by

mean of a qualification test where the device is supplied at 24V for 48h, the Output voltage is supplied at

18V for 48h and the device is reversely supplied at -12V for 1h.

REVISION 007 – OCT 2018

390109036401

Page 9 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

6. Electrical Specification

DC Operating Parameters at Nominal Supply Voltage (unless otherwise specified) and for TA as specified by

the Temperature suffix (L).

Parameter

Symbol

Nominal Supply Voltage

(1)

Supply Current

IDD

Ipeak

Isurge Current(4)

Isurge

Power-On reset

Hysteresis

Min

Typ

Max

Units

4.5

5

5.5

V

Power saving Enabled

6

10(2)

Power saving Disabled

8

12

Peak current in PWM mode 7

30

40

mA

20

mA

2.5

V

200

mV

4.2

V

200

mV

6.6

V

200

mV

Vout = 0 V

15

mA

Vout = 5 V

15

mA

Vout = 18 V (TA = 25 Deg.C)

18

mA

VDD

Supply Current (PWM

mode) (3)

Power-On reset (rising)

Test Conditions

HPOR_LH

Refer to internal voltage Vdig

2

2.25

HPOR_Hyst

50

MT4V LH

3.8

Start-up Hysteresis

MT4V Hyst

50

PTC Entry Level (rising)

MT7V_LH

5.8

MT7V_Hyst

50

Start-up Level (rising)

PTC Entry Level

Hysteresis

Output Short Circuit

Current

ISHORT

Output Load Analog

RL

Output Load PWM

RL_PWM

Pull-down to Ground

Pull-up to 5V

4.0

6.2

mA

4.7(5)

10

kΩ

(5)

10

kΩ

4.7

Pull-down to Ground

1

kΩ

Pull-up to 5V

1

kΩ

1

For the dual version, the supply current is multiplied by 2.

To reach 10mA, the power saving option should be enabled. This option switches off and on internal blocks dynamically. It can be

disabled in case of extreme emission requirements or if an analog output is required with a resistor on either supply or output line.

3

This current is due to the charge of output capacitors in PWM push-pull mode.

4

The specified value is valid during early start-up time only; the current might dynamically exceed the specified value, shortly,

during the Start-up phase.

5

The minimum specified value is mandatory to reach passive diagnostic output levels. A minimum 1k load resistor can be used

otherwise.

2

REVISION 007 – OCT 2018

390109036401

Page 10 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

Parameter

Analog Saturation Output

Level

Symbol

Vsat_lo

Vsat_hi

Digital Saturation Level

Open drain Output

Vo_min

(RL_PWM to VPU(6))

Active Diagnostic Output

Level

Dsat_lo

Digital Saturation Output

Level

Dsat_hi

Test Conditions

Min

Typ

Max

Pull-up load RL ≥ 10 kΩ to 5 V

0.5

2

Pull-up load RL ≥ 5 kΩ to 18V

2

3

Pull-down load RL ≥ 5 kΩ

95

97

Pull-down load RL ≥ 10 kΩ

97.5

98.5

Pull-up load RL_PWM ≤ 1 kΩ to 5V

98

Pull-up load RL_PWM ≤ 1 kΩ to 14V

95

Pull-up load RL_PWM ≤ 1 kΩ to 18V

90

Pull-up load RL_PWM ≤ 5.6 kΩ to 5V

96

Pull-up load RL_PWM ≤ 5.6 kΩ to 14V

85

Pull-up load RL_PWM ≤ 5.6 kΩ to 18V

73

Units

%VDD

%VDD

%VPU(6)

Pull-up load RL ≥ 10 kΩ to 5V

0.5

2

Pull-up load RL ≥ 5 kΩ to 18V

2

3

Pull-down load RL ≥ 5 kΩ

95

97

Pull-down load RL ≥ 10 kΩ

97.5

98.5

%VDD

%VDD

Broken VSS &

BVSSPD

Passive Diagnostic

Output Level

BVSSPU

(Broken Track Diagnostic)

(7)

BVDDPD

BVDDPU

Digital output Ron

Clamped Output Level

Ron

Pull-down load RL ≥ 5 kΩ

95

Pull-down load RL ≥ 10 kΩ

97.5

Broken VSS &

Pull-up load RL ≥ 1kΩ

99.5

Broken VDD &

%VDD

100

0

Pull-down load RL ≥ 1kΩ

Broken VDD &

Pull-up load RL ≥ 5kΩ

%VDD

0.5

%VDD

2

%VDD

Diag_Low

15

30

Diag_Hi

120

300

Ω

Clamp_lo

Programmable

0

100

%VDD (8)

Clamp_hi

Programmable

0

100

%VDD (8)

6

VPU being the pull-up voltage connected externally to the output through the pull-up resistor

For detailed information on diagnostics, see also section Self Diagnostic

8

Clamping levels need to be considered vs the saturation of the output stage (see Vsat_lo and Vsat_hi)

7

REVISION 007 – OCT 2018

390109036401

Page 11 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

As an illustration of the previous table, the MLX90364 fits the typical classification of the output span

described on the Figure 2.

100 %

90 %

96 %

92 %

88 %

Diagnostic Band (High)

Clamping High

80 %

Output Level

70 %

60 %

Linear Range

50 %

40 %

30 %

20 %

10 %

0%

12 %

8%

4%

Clamping Low

Diagnostic Band (Low)

Figure 2 – Example of Output Span Classification for typical application

REVISION 007 – OCT 2018

390109036401

Page 12 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

7. Timing Specification

7.1. ANALOG OUTPUT

DC Operating Parameters at Nominal Supply Voltage (unless otherwise specified) and for TA as specified by

the Temperature suffix (L).

Parameter

Main Clock Frequency

Symbol

Ck

Main Clock Frequency Thermal

Drift

∆TCk

Refresh Rate

tper

Test Conditions

Min

Typ

Max

Units

12.6

13.3

14

MHz

± 3%

CkNOM

290

305

μs

657(10)

896

Filter=1

876

1195

Filter=2

1095

1494

118

121.5

All contributors (trimming

accuracy, supply voltage, thermal

and ageing)

275

Filter=0(9)

Step Response Time

Ts

Watchdog

Twd

Phase Shift

PS

Filter=0

Start-up Cycle

Tsu

Analog OUT Slew-rate excluded

Analog OUT Slew-rate

9

114.5

Analog Mode 1

0.16

37

ms

Deg/Hz

5

25

μs

ms

V/ms

See section 13.6 for details concerning Filter parameter

This represents a theoretical average response time

10

REVISION 007 – OCT 2018

390109036401

Page 13 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

7.2. PWM OUTPUT

DC Operating Parameters at Nominal Supply Voltage VDD

specified by the Temperature suffix (L).

Parameter

Symbol

FPWM

PWM Frequency

=

VPU (unless otherwise specified) and for TA as

Test Conditions

Max

Units

1000

Hz

Initial Tolerance (25 Deg.C)

± 2%

FPWM

After EOL tuning (25 Deg.C)

± 1%

FPWM

Thermal/Lifetime drift

± 3%

FPWM

Programmable Range

(PWM Output Enabled)

Min

Typ

100

PWM OUT Slew-rate excluded

Start-up Cycle

Tsu

100Hz

11.8

13

250Hz

5.8

7

1000Hz

5.8

7

80

130

μs

27

50

μs

27

50

μs

27

50

μs

ms

LOW SIDE DRIVER – Mode 5

Digital Output Rise Time

RL = 1 kΩ PU

PUSH-PULL – Mode 7

RL = 1 kΩ PU

LOW SIDE DRIVER – Mode

Digital Output Fall Time

RL = 1 kΩ PU

PUSH-PULL – Mode 7

RL = 1 kΩ PU

REVISION 007 – OCT 2018

390109036401

Page 14 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

8. Accuracy Specification

8.1. Magnetic Accuracy

8.1.1. Normal Magnetic range: 20 mT ≤ B < 70 mT

DC Operating Parameters at Nominal Supply Voltage (unless otherwise specified) and for TA as specified by

the Temperature suffix (L).

Parameter

Symbol

Thermal Offset Drift #1(11)

at the DSP input (excl. DAC

and output stage)

Thermal Drift of Sensitivity

Mismatch(12)

Min

Max

Units

TA from -40 to 125 Deg.C

-60

+60

LSB15

TA from -40 to 150 Deg.C

-90

+90

LSB15

XY axis

- 0.5

+ 0.5

-1

+1

TA = 25 Deg.C – XY axis

-0.3

0.3

TA = 25 Deg.C – XZ axis

-2

2

TA = 25 Deg.C – YZ axis

-2

2

XZ (YZ) axis

Magnetic Angle phase error

Thermal Drift of Magnetic

Angle phase error

XY – Intrinsic Linearity

Error(13)

Test Conditions

XY axis, XZ (YZ) axis

Typ

0.01

Le

TA = 25 Deg.C – factory trim.

“SMISM”

XZ - Intrinsic Linearity

Error(13)

Le

TA = 25 Deg.C – “k” trimmed for

XZ

-2.5

YZ - Intrinsic Linearity

Error(13)

Le

TA = 25 Deg.C – “k” trimmed for

YZ

-2.5

-1

%

Deg.

Deg.

1

Deg.

±1.25

+2.5

Deg.

±1.25

+2.5

Deg.

11

For instance, in case of a rotary position sensor application, Thermal Offset Drift #1 equal ± 60LSB15 yields to max. ± 0.3 Deg.

angular error for the computed angular information (output of the DSP). This is only valid if k = 1.

12

For instance, in case of a rotary position sensor application, Thermal Drift of Sensitivity Mismatch equal ± 0.5% yields to max. ±

0.15 Deg. angular error for the computed angular information (output of the DSP). See “MLX90364 Front-End Application Note” for

more details.

13

The Intrinsic Linearity Error refers to the IC itself (offset, sensitivity mismatch, orthogonality) taking into account an ideal rotating

field for BX and BY. Once associated to a practical magnetic construction and the associated mechanical and magnetic tolerances,

the output linearity error increases. However, it can be improved with the multi-point end-user calibration. The intrinsic Linearity

Error for Magnetic angle ∠XZ and ∠YZ can be reduced through the programming of the k factor.

REVISION 007 – OCT 2018

390109036401

Page 15 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

Parameter

Symbol

(14)

Noise pk-pk

Test Conditions

Min

Typ

Max

Filter = 0, 40mT

0.10

0.2

Filter = 1 (recommended), 30mT

0.10

0.2

Filter = 2, 20mT

0.10

0.2

Units

Deg.

8.1.2. Extended Range #1 : 15 mT ≤ B < 20 mT

DC Operating Parameters at nominal supply voltage (unless otherwise specified) and for TA as specified by

the Temperature suffix (L).

Parameter

Symbol

Test Conditions

Min

Offset on Raw Signals X,Y,Z

X0,Y0,Z0

TA = 25 Deg.C.

Thermal Offset Drift #1

Typ

Max

Units

-120

+120

LSB15

at the DSP input (excl. DAC

and output stage)

TA from -40 to 125 Deg.C

-120

+120

TA from -40 to 150 Deg.C

-180

+180

Noise pk-pk

Filter 0

75

LSB15

LSB15

In case of the use of the MLX90364 in those extended ranges, Melexis recommends validating the headroom

of the internal diagnostic and if necessary to disable the diagnostic mode related to the amplitude of the

flux strength and/or amplification factor of the device.

8.1.3. Extended Range #2: 10 mT ≤ B < 15 mT

DC Operating Parameters at nominal supply voltage (unless otherwise specified) and for TA as specified by

the Temperature suffix (L).

Parameter

Symbol

Test Conditions

Min

Offset on Raw Signals X,Y,Z

X0,Y0,Z0

TA = 25 Deg.C.

Thermal Offset Drift #1

Typ

Max

Units

-180

+180

LSB15

at the DSP input (excl. DAC

and output stage)

TA from -40 to 125 Deg.C

-180

+180

TA from -40 to 150 Deg.C

-270

+270

Noise pk-pk

Filter 0

112

LSB15

LSB15

In case of the use of the MLX90364 in those extended ranges, Melexis recommends to validate the

headroom of the internal diagnostic and if necessary to disable the diagnostic mode related to the

amplitude of the flux strength and/or amplification factor of the device.

14

Noise pk-pk (peak-to-peak) is here intended as 6 times the Noise standard Deviation. The application diagram used is described in

the recommended wiring. For detailed information, refer to section Filter in application mode (Section 13.6).

REVISION 007 – OCT 2018

390109036401

Page 16 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

8.2. ANALOG OUTPUT

DC Operating Parameters at nominal supply voltage (unless otherwise specified) and for TA as specified by

the Temperature suffix (L).

Parameter

ADC Resolution on the raw

signals sine and cosine(15)

Symbol

Test Conditions

Min

RADC

-0.2

(DAC and Output Stage)

12b DAC (Theoretical, Noise

free)

RDAC

INL (before EOL calibration)

DNL

Output stage Noise

Ratiometry Error

15

Max

15

Thermal Offset Drift #2

Analog Output Resolution

Typ

bits

+0.2

0.05

Clamped Output

%VDD

%VDD/

LSB12

0.025

-4

Units

+4

LSB12

1

3

LSB12

0.05

0.075

%VDD

4.5V ≤ VDD ≤ 5.5V

-0.05

+0.05

LT4V ≤ VDD ≤ MT7V

-0.1

+0.1

%VDD

16 bits corresponds to 15 bits + sign. Internal computation is performed using 16 bits.

REVISION 007 – OCT 2018

390109036401

Page 17 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

8.3. PWM OUTPUT

DC Operating Parameters at nominal supply voltage (unless otherwise specified) and for TA as specified by

the Temperature suffix (L).

Parameter

Symbol

PWM Output

Resolution

RPWM

Test Conditions

12 bits

Min

Typ

Max

Units

%DC/

0.025

LSB

LOW SIDE DRIVER – Mode5

±0.075

%DC

±0.075

%DC

±0.05

±0.2

Hz

±0.05

±0.2

Hz

100Hz, RL = 1 kΩ PU

±0.02

±0.03

%DC

200Hz, RL = 1 kΩ PU

±0.02

±0.03

%DC

100Hz, RL = 1 kΩ PU

±0.02

±0.03

%DC

200Hz, RL = 1 kΩ PU

±0.02

±0.03

%DC

200Hz, RL = 1 kΩ PU

PWM % DC Jitter

(16)

±0.015

JDC

PUSH-PULL – Mode7

200Hz, RL = 1 kΩ PU

LOW SIDE DRIVER – Mode5

100-1000 Hz, RL = 1 kΩ PU

PWM Freq Jitter

(16)

JPWM

PUSH-PULL – Mode7

100-1000 Hz, RL = 1 kΩ PU

LOW SIDE DRIVER – Mode5

PWM % DC thermal

drift

16

PUSH-PULL – Mode7

Jitter is defined by ± 3 σ for 1000 successive acquisitions with clamped output.

REVISION 007 – OCT 2018

390109036401

Page 18 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

%Duty Cycle = TON / TPWM

%DC Jitter = JDC = JON / TPWM

Output (V)

TPWM

TON

Jitter on TON

= JON

Jitter on TPWM

= JPWM

Time (s)

Parameter

PWM TON, TPWM

Symbol

TON

TPWM

Duty Cycle

Trigger level = 50 % Vpush-pull

10% and 90% of amplitude

Rise time, Fall time

Jitter

Test Conditions

JON

JPWM

% DC

± 3 σ for 1000 successive acquisitions

TON / TPWM

Figure 3 – MLX90364 PWM measurement conditions.

REVISION 007 – OCT 2018

390109036401

Page 19 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

9. Magnetic Specification

DC Operating Parameters at Nominal Supply Voltage (unless otherwise specified) and for TA as specified by

the Temperature suffix (L).

Parameter

Symbol

Test Conditions

Magnetic Flux Density

BX, BY(17)

√[ BX 2 + BY 2 ]

Magnetic Flux Density

BZ

Magnetic Flux Norm

√[ BX2 + BY2 + (Bz/kmin)2 ]

Norm

Min

GainIMCXY

1.2

IMC Gain in Z (20)

GainIMCZ

1.1

Magnet Temperature

Coefficient

k

GainIMCXY / GainIMCZ

TCm

Max

Units

70(18)

mT

126

mT

20(19)

IMC Gain in X and Y (20)

k factor

Typ

1

mT

1.4

1.8

1.3

1.2

1.5

-2400

0

ppm/Deg.C

10. CPU & Memory Specification

The DSP is based on a 16 bit RISC µController. This CPU provides 2.5 Mips while running at 10 MHz.

Parameter

Symbol

Test Conditions

Min

Typ

Max

Units

ROM

10

KB

RAM

384

B

EEPROM

128

B

17

The condition must be fulfilled for at least one field BX or BY.

Above 70 mT, the IMC® starts saturating yielding to an increase of the linearity error.

19

Below 20 mT, the performances slightly degrade due to a reduction of the signal-to-noise ratio, signal-to-offset ratio.

20

This is the magnetic gain linked to the Integrated Magneto Concentrator structure. This is the overall variation. Within one lot,

the part to part variation is typically ± 10% versus the average value of the IMC gain of that lot.

18

REVISION 007 – OCT 2018

390109036401

Page 20 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

11. Traceability Information

Every device contains a unique ID that is programmed by Melexis in the EEPROM. Melexis strongly

recommends storing this value during the EOL (End-Of-Line) programming to ensure full traceability of the

final product.

These parameters shall never be erased during the EOL programming.

Default

Values

# bit

Melexis identification reference

MLX

16

MELEXISID2

Melexis identification reference

MLX

16

MELEXISID3

Melexis identification reference

MLX

16

Parameter

Comments

MELEXISID1

12. End-User Programmable Items

Parameter

Comments

Standard

# bit

OUT mode

Define the output stage mode

1

3

DIAG mode

Diagnostic mode

7

3

DIAG Level

Diagnostic Level

0

1

MAPXYZ

Mapping fields for output angle

0

2

CLAMP_HIGH

Clamping High

50%

16

CLAMP_LOW

Clamping Low

50%

16

FILTER

Filter mode selection

0

2

SMISM

Sensitivity mismatch factor X,Y

MLX

15

k

Sensitivity mismatch factor X (Y) , Z

MLX

15

SEL_k

Affected signal component by k: B1 or B2 (in

combination of MAPXYZ)

0

1

GAINMIN

Low threshold for virtual gain

00h

8

GAINMAX

High threshold for virtual gain

28h

8

GAINSATURATION

Gain Saturates on GAINMIN and GAINMAX

0h

1

FIELDTHRESH_Low

Field limit under which a fault is reported

10mT

8

FIELDTHRESH_High

Field limit above which a fault is reported

FFh

8

PWM

PWM function

0h

1

REVISION 007 – OCT 2018

390109036401

Page 21 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

Parameter

Comments

Standard

# bit

PWMPOL

PWM polarity

0h

1

PWMT

PWM Frequency (trimmed at 200Hz)

MLX

8

DC_FAULT

PWM Duty Cycle if Fault

1h

8

DC_FTL

PWM Duty Cycle if Field Strength Too Low

1h

8

DC_WEAK

PWM Duty Cycle if Weak Magnet

1h

8

WEAKMAGTHRESH

Weak Magnet threshold Byte (1LSB = 1mT)

0h

8

DP

Discontinuity point

0h

15

CW

Clock Wise

0h

1

FHYST

Hysteresis filter

0h

8

4POINTS

Selection of correction method 4 or 17 pts

1h

1

LNR_S0

4pts – Initial Slope

0 %/deg

16

LNR_A_X

4pts – AX Coordinate

0 deg

16

LNR_A_Y

4pts – AY Coordinate

10 %

16

LNR_A_S

4pts – AS Coordinate

0.22%/deg

16

LNR_B_X

4pts – BX Coordinate

360 deg

16

LNR_B_Y

4pts – BY Coordinate

100%

16

LNR_B_S

4pts – BS Coordinate

0 %/deg

16

LNR_C_X

4pts – CX Coordinate

360 deg

16

LNR_C_Y

4pts – CY Coordinate

100%

16

LNR_C_S

4pts – CS Coordinate

0 %/deg

16

LNR_D_X

4pts – DX Coordinate

360 deg

16

LNR_D_Y

4pts – DY Coordinate

100%

16

LNR_D_S

4pts – DS Coordinate

0 %/deg

16

W

17pts – Output angle range

0h

4

USERID1

Cust. ID reference

Bin1

16

203h(ADB)

USERID2

Cust. ID reference

204h(AxD)

16

205h(AxE)

USERID3

Cust. ID reference

MLX

16

LNR_Yn (n = 0, 1, 2 …, 16)

17pts – Y-coordinate points

N/A

16

REVISION 007 – OCT 2018

390109036401

Page 22 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

Parameter

Comments

Standard

# bit

DIAG Settings

16 Bit Diagnostics enabling

FDFFh

16

CRC_DISABLE

Enable EERPOM CRC check ( 3131h= disable)

0h

16

MEMLOCK (AxD and AxE version

only)

Write-protects USER/MLX EEPROM param.

0h

2

ANGLEOFSSLOPECOLD (AxE version

only)

Temperature coefficient offset at cold

temperatures

0h

8

ANGLEOFSSLOPEHOT (AxE version

only)

Temperature coefficient offset at hot

temperatures

0h

8

Melexis strongly recommends checking the User Identification data (Parameters USERID) during EOL

programming.

13. Description of End-User Programmable Items

13.1. Output modes

13.1.1. OUT mode

Defines the Output Stage mode in application.

Output mode[2:0]

Type

Descriptions

Comments

0

Disable

Output HiZ

Not recommended

1

Analog

Analog Rail-to-Rail

Analog

5

Digital

open drain NMOS

PWM

6

Digital

open drain PMOS

PWM

7

Digital

Push-Pull

PWM

REVISION 007 – OCT 2018

390109036401

Page 23 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

13.1.2. Analog Output Mode

The Analog Output Mode is a rail-to-rail and ratiometric output with a push-pull output stage configuration

allows the use of a pull-up or pull-down resistor.

13.1.3. PWM Output Mode

If PWM output mode is selected, the output signal is a digital signal with Pulse Width Modulation (PWM).

The PWM polarity is selected by the PWMPOL parameter:

PWMPOL = 1 for a low level at 100%

PWMPOL = 0 for a high level at 100%

The PWM frequency is selected by the PWMT parameter. The following table provides typical code for

different target PWM frequency and for both low and high speed modes.

PWM F (Hz)

PWMT (LSB)

@13.3MHz

PWM res. (μs)

PWM res. (%)

PWM res. (bit)

100

44333

0.240

0.0024

15

250

17733

0.240

0.006

14

500

8866

0.240

0.012

13

Notes:

A more accurate trimming can be performed to take into account initial tolerance of the main clock.

The PWM frequency is subjected to the same tolerances as the main clock (see ∆TCk).

REVISION 007 – OCT 2018

390109036401

Page 24 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

13.2. Output Transfer Characteristic

There are 2 different possibilities to define the transfer function (LNR):

With 4 arbitrary points (defined on X and Y coordinates) and 5 slopes

With 17 equidistant points for which only the Y coordinates are defined.

Parameter

LNR type

Value

CLOCKWISE

Both

DP

Both

0 … 359.9999

Deg.

Only 4 pts

0 … 359.9999

Deg.

Only 4 pts

0 … 100

%

Only 4 pts

-17 … 0 … 17

%/Deg.

Only 17 pts

-50 … + 150

%

W

Only 17 pts

65.5 … 360

Deg.

CLAMP_LOW

Both

0 … 100

%

CLAMP_HIGH

Both

0 … 100

%

ANGLEOFSSLOPECOLD (Only AxE)

Both

0..255

LSB

ANGLEOFSSLOPEHOT (Only AxE)

Both

0..255

LSB

0 CounterClockWise

1 ClockWise

Unit

LSB

LNR_A_X

LNR_B_X

LNR_C_X

LNR_D_X

LNR_A_Y

LNR_B_Y

LNR_C_Y

LNR_D_Y

LNR_S0

LNR_A_S

LNR_B_S

LNR_C_S

LNR_D_S

LNR_Y0

LNR_Y1

…

LNR_Y16

REVISION 007 – OCT 2018

390109036401

Page 25 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

13.2.1. Enable scaling Parameter (only for LNR type 4 pts)

This parameter enables to scale LNR_x_Y from -50% - 150% according to the following formula

(Scaled Out)%VDD = 2 x Out%VDD – 50%

13.2.2. CLOCKWISE Parameter

The CLOCKWISE parameter defines the magnet rotation direction.

•

CCW is the defined by the 1-2-3-4 pin order direction for the Dual Mold Package.

•

CW is defined by the reverse direction: 4-3-2-1 pin order direction for the Dual Mold Package.

Refer to the drawing in the sensitive spot positioning sections (Section 18.1.6).

13.2.3. Discontinuity Point (or Zero Degree Point)

The Discontinuity Point defines the 0 Deg. point on the circle. The discontinuity point places the origin at any

location of the trigonometric circle. The DP is used as reference for all the angular measurements.

360°

0°

The placement of the discontinuity

point (0 point) is programmable.

Figure 4 - Discontinuity Point Positioning

13.2.4. 4-Pts LNR Parameters

The LNR parameters, together with the clamping values, fully define the relation (the transfer function)

between the digital angle and the output signal.

The shape of the MLX90364 transfer function from the digital angle value to the output voltage is described

by the drawing below. Six segments can be programmed but the clamping levels are necessarily flat.

Two, three, or even six calibration points are then available, reducing the overall non-linearity of the IC by

almost an order of magnitude each time. Three to six calibration points will be preferred by customers

looking for excellent non-linearity figures. Two-point calibrations will be preferred by customers looking for

a cheaper calibration set-up and shorter calibration time.

REVISION 007 – OCT 2018

390109036401

Page 26 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

100%

CLAMPHIGH

Clamping High

D

LNR_D_Y

C

LNR_C_Y

B

LNR_B_Y

A

LNR_A_Y

Slope LNR_C_S

Slope LNR_B_S

Slope

LNR_A_S

Slope

LNR_S0

CLAMPLOW

0%

LNR_A_X

0 (Deg.)

Slope LNR_D_S

Clamping Low

LNR_B_X

LNR_C_X

LNR_D_X

360 (Deg.)

Figure 5 - 4-Pts LNR Parameters

13.2.5. 17-Pts LNR Parameters

The LNR parameters, together with the clamping values, fully define the relation (the transfer function)

between the digital angle and the output signal.

The shape of the MLX90364 transfer function from the digital angle value to the output voltage is described

by the drawing below. In the 17-Pts mode, the output transfer characteristic is Piece-Wise-Linear (PWL).

LNR_Y16

100%

CLAMPHIGH

Clamping High

LNR_Y15

...

LNR_Y14

LNR_Y2

LNR_Y1

CLAMPLOW

0%

0 (Deg.)

LNR_Y0

Clamping Low

Δx

Δx

...

Δx

Δx

360 (Deg.)

(360-W)/2

(360-W)/2

W = range from 65.5 Deg. up to 360 Deg.

360 - W

Figure 6 - Input range from 65.5 Deg. up to 360 Deg.

All the Y-coordinates can be programmed from -50% up to +150% to allow clamping in the middle of one

segment (like on the Figure 6), but the output value is limited to CLAMPLOW and CLAMPHIGH values.

Between two consecutive points, the output characteristic is interpolated.

REVISION 007 – OCT 2018

390109036401

Page 27 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

The parameter W determines the input range on which the 17 points (16 segments) are uniformly spread:

W

Range

Δx

W

Range

Δx

0 (0000b)

360.0 Deg.

22.5 Deg.

8

180.0 Deg.

11.3 Deg.

1

320.0 Deg.

20.0 Deg.

9

144.0 Deg.

9.0 Deg.

2

288.0 Deg.

18.0 Deg.

10

120.0 Deg.

7.5 Deg.

3

261.8 Deg.

16.4 Deg.

11

102.9 Deg.

6.4 Deg.

4

240.0 Deg.

15.0 Deg.

12

90.0 Deg.

5.6 Deg.

5

221.5 Deg.

13.8 Deg.

13

80.0 Deg.

5.0 Deg.

6

205.7 Deg.

12.9 Deg.

14

72.0 Deg.

4.5 Deg.

7

192.0 Deg.

12.0 Deg.

15 (1111b)

65.5 Deg.

4.1 Deg.

Outside of the selected range, the output will remain in clamping levels.

13.2.6. CLAMPING Parameters

The clamping levels are two independent values to limit the output voltage range. The CLAMPLOW

parameter adjusts the minimum output voltage level. The CLAMPHIGH parameter sets the maximum output

voltage level. Both parameters have 16 bits of adjustment and are available for both LNR modes. In analog

mode, the resolution will be limited by the D/A converter (12 bits) to 0.024%VDD. In PWM mode, the

resolution will be 0.024%DC.

13.2.7. Thermal Output Offset correction (AxE version only)

On the version AxE, the two parameters ANGLEOFSSLOPEHOT and ANGLEOFSSLOPECOLD, defined in the

section 12, enable to add, to the output an offset depending on the measured temperature depicted in the

Figure 7.

Thermal

compensation

offset

+5.62%

full span

ANGLEOFSSLOPEHOT

0

Temperature

(degree)

ANGLEOFSSLOPECOLD

-3.37%

full span

-40

35

160

Figure 7 - Input range from -40 Deg.C up to 160 Deg.C

REVISION 007 – OCT 2018

390109036401

Page 28 of 45

�MLX90364 Triaxis® Position Sensor

Datasheet

The thermal offset is added before the clamping (see section 13.2.6). The span of this offset is +5.63/-3.37% of

the full output scale. The added thermal offset varies with temperature see the equation below and the

thermal coefficient is defined separately before (used coefficient ANGLEOFSSLOPECOLD) and after 35Deg.C

(used coefficient ANGLEOFSSLOPEHOT).

If temperature is higher than 35 Deg.C then:

output