MLX90374 - Triaxis® Position Processor

Datasheet

Features and Benefits

Triaxis Hall Technology

On Chip Signal Processing for Robust

Absolute Position Sensing

ISO26262 ASIL-C Safety

Element out of Context

AEC-Q100 Qualified

Programmable Measurement Range

Programmable Linear Transfer Characteristic

(4 or 8 Multi-points or 16 or 32 PWL)

PWM Redundant Dual Output

SENT and Programmable Switch Dual Output

SAE J2716 APR2016 SENT

Enhanced serial data communication

48 bits ID Number option

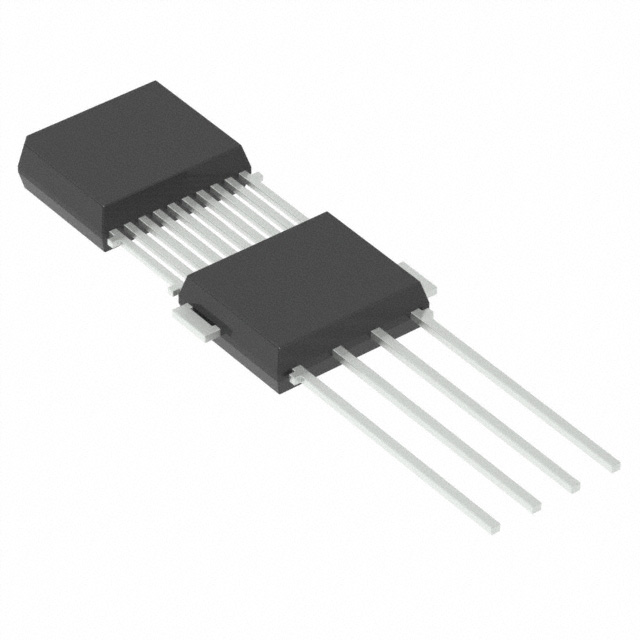

Single Die - SOIC-8 Package (RoHS)

PCB-less DMP-4 Package (RoHS)

Robustness against stray-field

SOIC-8

DMP-4

Application Examples

Absolute Rotary Position Sensor

Pedal Position Sensor

Throttle Position Sensor

Ride Height Position Sensor

Absolute Linear Position Sensor

Steering Wheel Position Sensor

Float-Level Sensor

Non-Contacting Potentiometer

REVISION 4 - 20 MAR 2019

3901090374

Description

The MLX90374 is a monolithic magnetic position

processor IC. It consists of a Triaxis® Hall magnetic

front end, an analog to digital signal conditioner, a

DSP for advanced signal processing and a dual

output stage driver.

The MLX90374 is sensitive to the three

components of the magnetic flux density applied to

the IC (i.e. Bx, By and Bz). This allows the MLX90374

with the correct magnetic circuit to decode the

absolute position of any moving magnet (e.g.

rotary position from 0 to 360 Degrees or linear

displacement, see fig. 2). It enables the design of

non-contacting position sensors that are

frequently required for both automotive and

industrial applications.

The MLX90374 provides either a dual PWM output

or a combination of SENT plus a programmable

switch function. In dual PWM output mode, the

circuit offers a wide panel of configurations from

fully redundant signals to individually configurable

outputs, including the choice between several

error reporting modes. In SENT mode, the circuit

delivers enhanced serial messages consisting of

error codes, and user-defined values.

�MLX90374 - Triaxis® Position Processor

Datasheet

Ordering Information

Temp.

Package

Option Code

Packing

Form

MLX90374

G

DC

ABB-200

RE

Linear position Strayfield Immune

MLX90374

G

DC

ABB-300

RE

Angular Rotary / Linear position

MLX90374

G

VS

ABB-200

RE/RX

Linear position Strayfield Immune

MLX90374

G

VS

ABB-207

RE/RX

Linear position Strayfield Immune

MLX90374

G

VS

ABB-300

RE/RX

Angular Rotary / Linear position

MLX90374

G

VS

ABB-307

RE/RX

Angular Rotary / Linear position

MLX90374

G

DC

ABC-100

RE

Angular Rotary Strayfield Immune

MLX90374

G

DC

ABC-200

RE

Linear position Strayfield Immune

MLX90374

G

DC

ABC-300

RE

Angular Rotary / Linear position

MLX90374

G

VS

ABC-100

RE/RX

Angular Rotary Strayfield Immune

MLX90374

G

VS

ABC-107

RE/RX

Angular Rotary Strayfield Immune

MLX90374

G

VS

ABC-200

RE/RX

Linear position Strayfield Immune

MLX90374

G

VS

ABC-207

RE/RX

Linear position Strayfield Immune

MLX90374

G

VS

ABC-300

RE/RX

Angular Rotary / Linear position

MLX90374

G

VS

ABC-307

RE/RX

Angular Rotary / Linear position

Product

Definition

Table 1 - Ordering Codes

Temperature Code:

G: from -40°C to 160°C

Package Code:

DC : SOIC-8 package (see 17.1)

VS : DMP-4 package (PCB-less dual mold, see 17.6)

Option Code - Chip revision ABC-123 : Chip Revision

ABB : Not recommended for new designs (1)

ABC : Standard preferred revision (1)

Option Code - Application

ABC-123 : 1-Application - Magnetic configuration

1: Angular Rotary Strayfield Immune

2: Linear position Strayfield Immune

3: Legacy / Angular Rotary / Linear position

ABC is preferred product revision to be selected for new designs. ABB remains in production during the entire product lifecycle

but does not include all the features of the ABC revision.

1

REVISION 4 - 20 MAR 2019

3901090374

Page 2 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Option Code - SW &

DMP-4 configuration

ABC-123: 2-SW and DMP-4 package configuration

For SOIC-8 (code DC) packages

0: 2x PWM / SENT 3µs mode

For DMP-4 (code VS) package (see section 14.2)

0 : 2x PWM / SENT 3 µs mode (C1, C4 = 10nF)

Option Code - Trim & Form ABC-123: 3 - DMP-4 Trim & Form configuration

0: Standard straight leads. See section 17.5

7: Trim and Form STD3 2.00 See section 17.6

Packing Form:

-RE : Tape & Reel

VS:2500 pcs/reel

DC:3000 pcs/reel

-RX : Tape & Reel, similar to RE with parts face-down (VS package only)

Ordering Example:

MLX90374GVS-ABC-307-RX

For a legacy version in DMP-4 package with trim and form STD3 2.00,

delivered in Reel face down.

Table 2 - Ordering Codes Information

REVISION 4 - 20 MAR 2019

3901090374

Page 3 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Contents

Features and Benefits ............................................................................................................ 1

Application Examples............................................................................................................. 1

Description............................................................................................................................ 1

Ordering Information ............................................................................................................ 2

1. Functional Diagram and Application Modes ........................................................................ 6

2. Glossary of Terms .............................................................................................................. 7

3. Pin Definitions and Descriptions ......................................................................................... 8

3.1. Pin Definition for SOIC-8 package .................................................................................. 8

3.2. Pin Definition for DMP ................................................................................................... 8

4. Absolute Maximum Ratings ................................................................................................ 9

5. General Electrical Specifications ....................................................................................... 10

6. Timing Specification ......................................................................................................... 12

6.1. General Timing Specifications ..................................................................................... 12

6.2. Timing Modes .............................................................................................................. 12

6.3. Timing Definitions ........................................................................................................ 14

6.4. PWM timing specifications .......................................................................................... 16

6.5. SENT timing specifications ........................................................................................... 17

7. Magnetic Field Specifications ........................................................................................... 20

7.1. Rotary Stray-field Immune Mode (-100 code) ............................................................. 20

7.2. Linear Stray-field Immune ........................................................................................... 21

7.3. Standard/Legacy Mode ................................................................................................ 22

8. Accuracy Specifications .................................................................................................... 24

8.1. Definition ..................................................................................................................... 24

8.2. Rotary Stray-field Immune (-100 code) ....................................................................... 25

8.3. Linear Stray-field Immune Mode (-200 code) ............................................................. 26

8.4. Standard/Legacy Mode (-300 code) ............................................................................ 27

9. Memory Specifications..................................................................................................... 28

10. Digital output protocol ................................................................................................... 29

10.1. PWM (pulse width modulation)................................................................................. 29

10.2. Single Edge Nibble Transmission (SENT) SAE J2716 .................................................. 30

11. End-User Programmable Items ....................................................................................... 38

11.1. End User Identification Items .................................................................................... 44

12. Description of End-User Programmable Items ................................................................ 45

REVISION 4 - 20 MAR 2019

3901090374

Page 4 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

12.1. Sensor Front-End ....................................................................................................... 45

12.2. Sensor DSP Configuration .......................................................................................... 46

12.3. Selection of Output modes ........................................................................................ 56

12.4. Programmable Diagnostics Settings .......................................................................... 59

13. Functional Safety ........................................................................................................... 62

13.1. Safety Manual ............................................................................................................ 62

13.2. Safety Mechanisms .................................................................................................... 62

14. Recommended Application Diagrams ............................................................................. 66

14.1. Wiring with the MLX90374 in SOIC-8 Package .......................................................... 66

14.2. Wiring with the MLX90374 in DMP-4 Package (built-in capacitors) .......................... 67

15. Standard information regarding manufacturability of Melexis products with different

soldering processes ......................................................................................................... 68

16. ESD Precautions ............................................................................................................. 68

17. Package Information ...................................................................................................... 69

17.1. SOIC-8 - Package Dimensions .................................................................................... 69

17.2. SOIC-8 - Pinout and Marking ..................................................................................... 69

17.3. SOIC-8 - Sensitive spot positioning ............................................................................ 70

17.4. SOIC-8 - Angle detection ........................................................................................... 71

17.5. DMP-4 - Package Outline Dimensions (POD) STD1 1.27 ............................................ 72

17.6. DMP-4 - Package Outline Dimensions (POD) STD3 2.00 ............................................ 73

17.7. DMP-4 - Marking ....................................................................................................... 74

17.8. DMP-4 - Sensitive Spot Positioning ........................................................................... 74

17.9. DMP-4 - Angle detection MLX90374 DMP-4 ............................................................. 76

17.10. Packages Thermal Performances ............................................................................. 76

18. Contact ......................................................................................................................... 77

19. Disclaimer ..................................................................................................................... 77

REVISION 4 - 20 MAR 2019

3901090374

Page 5 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

1. Functional Diagram and Application Modes

fig. 1 - MLX93074 Block diagram

Rotary Strayfield Immune

Angular Rotary

Linear Position

fig. 2 - Application Modes

REVISION 4 - 20 MAR 2019

3901090374

Page 6 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

2. Glossary of Terms

Name

Description

ADC

Analog-to-Digital Converter

AoU

Assumption of Use

ASP

Analog Signal Processing

AWD

Absolute Watchdog

CPU

Central Processing Unit

CRC

Cyclic Redundancy Check

%DC

Duty Cycle of the output signal i.e. TON /(TON + TOFF)

DMP

Dual Mold Package

DP

Discontinuity Point

DCT

Diagnostic Cycle Time

DSP

Digital Signal Processing

ECC

Error Correcting Code

EMA

Exponential Moving Average

EMC

Electro-Magnetic Compatibility

EoL

End of Line

FIR

Finite Impulse Response

Gauss (G)

Alternative unit for the magnetic flux density (10G = 1mT)

HW

Hardware

IMC

Integrated Magnetic Concentrator

INL / DNL

Integral Non-Linearity / Differential Non-Linearity

IWD

Intelligent Watchdog

LSB/MSB

Least Significant Bit / Most Significant Bit

NC

Not Connected

NVRAM

Non Volatile RAM

POR

Power On Reset

PSF

Product Specific Functions

PWL

Piecewise Linear

PWM

Pulse Width Modulation

RAM

Random Access Memory

ROM

Read-Only Memory

SEooC

Safety Element out of Context

TC

Temperature Coefficient (in ppm/°C)

Tesla (T)

SI derived unit for the magnetic flux density (Vs/m2)

Table 3 - Glossary of Terms

REVISION 4 - 20 MAR 2019

3901090374

Page 7 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

3. Pin Definitions and Descriptions

3.1. Pin Definition for SOIC-8 package

Pin #

Name

Description

1

VDD

Supply

2

Input

For test or Application

3

OUT2

Second Output

4

Test

For test or application

5

OUT1

First Output

6

VSS

Digital ground

7

VDEC

Decoupling pin

8

VSS

Analog ground

Table 4 - SOIC-8 Pins definition and description

Pins Input and Test are internally grounded in application. For optimal EMC behaviour always connect the

unused pins to the electrical ground of the PCB.

3.2. Pin Definition for DMP

DMP-4 package adds a dual output PCB-less solution to the Triaxis® product family.

Pin #

Name

Description

1

OUT1

First Output

2

VSS

Ground

3

VDD

Supply

4

OUT2

Second Output

Table 5 - DMP-4 Pins definition and description

REVISION 4 - 20 MAR 2019

3901090374

Page 8 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

4. Absolute Maximum Ratings

Parameter

Supply Voltage

Reverse Voltage Protection

Symbol

Max

Unit

VDD

27

V

< 48h ; Tj < 175°C

VDD

37

V

< 60s ; TAMB < 35°C

-14

V

< 48h

VDD-rev

-20

V

< 1h

V

< 48h

V

< 48h

VOUT

Reverse Output Voltage

VOUT-rev

Positive Input pin Voltage

VInput

Reverse Input pin Voltage

VInput-rev

Operating Temperature

27

-14

VDEC

VDEC-rev

Test pin Voltage

Condition

VDD-rev

Positive Output Voltage

Internal Voltage

Min

3.6

-0.3

V

6

-3

VTEST

-0.3

TAMB

-40

V

V

3.6

VTEST-rev

V

V

V

+160

°C

+175

°C

Junction Temperature

TJ

Storage Temperature

TST

-55

+170

°C

Magnetic Flux Density

Bmax

-1

1

T

see 17.10 for package thermal

dissipation values

Table 6 - Absolute maximum ratings

Exceeding the absolute maximum ratings may cause permanent damage.

Exposure to absolute maximum ratings conditions for extended periods may affect device reliability.

REVISION 4 - 20 MAR 2019

3901090374

Page 9 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

5. General Electrical Specifications

General electrical specifications are valid for temperature range [-40;160] °C and supply voltage range

[4.5;5.5] V unless otherwise noted.

Electrical Parameter

Symbol

Min

Typ

Max

Supply Voltage

VDD

4.5

5

5.5

V

For voltage regulated mode

Supply Voltage Battery

VDD

6

12

18

V

For Battery usage (2)

Supply Current

IDD

9.0

10.5

12.6

mA

Rotary and linear stray field

applications (option code -100, 200)

Supply Current

IDD

8.0

9.0

10.5

mA

Legacy applications (option code 300)

Surge Current

Isurge

-

30

40

mA

IC Startup current (tstartup < 40µs)

Start-up Level

VDDstart

3.6

V

Minimal supply start-up voltage

PTC Entry Level (rising)

VPROV0

7.10

7.35

7.70

V

Supply overvoltage detection in 5V

applications (2)

VPROV0Hyst

400

500

600

mV

VPROV1

21.5

23.0

24.5

V

For Battery usage (2)

VPROV1Hyst

0.8

1.4

2.0

V

For Battery usage (2)

Under voltage detection

VDDUVH

3.95

4.10

4.25

V

Supply undervoltage high threshold

Under voltage detection

VDDUVL

3.75

3.90

4.05

V

Supply undervoltage low threshold

VDEC

3.2

3.3

3.4

V

Internal analog voltage

Regulated Voltage

Overvoltage detection

VDECOVH

3.65

3.75

3.85

V

High threshold

Regulated Voltage

Undervoltage detection

VDECUVL

2.70

2.85

2.92

V

Low threshold

Regulated Voltage UV /

OV detection hysteresis

VDECOVHyst

VDECUVHyst

100

150

200

mV

VDDD

1.80

1.85

1.95

V

Digital supply Overvoltage

detection

VDDDOVH

2.00

2.10

2.20

V

Digital Supply

Undervoltage detection

VDDDUVL

1.585

1.680

1.735

V

Digital Supply OV / UV

detection Hysteresis

VPORHyst

30

100

200

mV

PTC Entry Level Hysteresis

PTC Entry Level (rising)

PTC Entry Level Hysteresis

Regulated Voltage

Digital supply

Unit Condition

Power-on Reset low threshold

Table 7 - Supply System Electrical Specifications

2

Selection between 5V or battery applications is done using WARM_ACT_HIGH parameter. See chap.11

REVISION 4 - 20 MAR 2019

3901090374

Page 10 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Electrical Parameter

Symbol

Min

Typ

Max

Unit

Condition

Output Short Circuit

Current( 3)

IOUTshortPP

-25

8

-10

15

mA

mA

Push-pull modes (SENT, PWM)

VOUT = 0 V

VOUT = 5 V .. 18V

Ouput Short Circuit

Current

IOUTshortOD1

10

25

mA

VOUT = 5V

Output Short Circuit

Current

IOUTshortOD2

40

90

mA

PWM mode Open Drain only

(see 12.3.5)

RL

3

kΩ

PWM pull-up to 5V,

PWM pull-down to 0V

RL

10

-

55

kΩ

SENT pull-up

RL

1

-

100

kΩ

Open drain pull-up

VsatLoPP

0

1

2

5

%VDD

RL ≥ 10kΩ

RL ≥ 3kΩ, pull-up to 5V

VsatHiPP

98

95

99

100

%VDD

RL ≥ 10kΩ

RL ≥ 3kΩ, pull-down

VsatLoOD

0

10

%Vext

Pull-up to any external voltage

Vext ≤ 18V, IL ≤ 3.4mA

Ron

27

100

Ω

Output Load

Digital push-pull output

level

Digital open drain output

level

Digital output Ron

50

Push-pull mode

Table 8 - Output Electrical specifications

3

Output current limitation triggers after a typical delay of 3µs.

REVISION 4 - 20 MAR 2019

3901090374

Page 11 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

6. Timing Specification

Timing specifications are valid for temperature range [-40;160] °C and supply voltage range [4.5;5.5] V

unless otherwise noted.

6.1. General Timing Specifications

Parameter

Main Clock Frequency

Symbol

Min.

Typ

Max.

Unit

Condition

22.8

24

25.2

MHz

Including thermal and lifetime

drift

5

%Fck

Relative tolerances, including

thermal and lifetime drift

FCK

-5

Main Clock initial

tolerances

ΔFCK,0

23.75

24

24.25

MHz

T=35°C

Main Clock Frequency

Thermal Drift

ΔFCK,T

-2

-

2

%Fck

Relative to clock frequency at

35°C. No ageing effects.

1MHz Clock Frequency

F1M

Intelligent Watchdog

Timeout

TIWD

19

20

21

ms

FCK = 24MHz

Absolute Watchdog

Timeout

TAWD

19

20

21

ms

F1M = 1MHz

Analog Diagnostics DCT

Digital Diagnostics DCT

Fail Safe state duration

Safe Startup Time

DCTANA

1

MHz

Meas

17

Tframe

SENT Sync. Mode, NangFram=2

34

Tframe

SENT Sync. Mode, NangFram=1

20

ms

see Table 67, section 13.2

34

17

34

DCTDIG

Tangle

PWM or SENT Asynchronous

mode (6.2.1)

34

TFSS

9.8

28.4

11.0

32.0

11.9

34.6

ms

After a digital single-event fault

ABC revision

ABB revision

TSafeStup

-

11.2

12.4

ms

Only valid for ABC revision (see

6.3.1.2)

Table 9 - General Timing Specifications

6.2. Timing Modes

The MLX90374 can be configured in two continuous angle acquisition modes described in the following

sections.

6.2.1. Continuous Asynchronous Acquisition Mode

In this mode, the sensor continuously acquire angle at a fixed rate that is asynchronous with regards to the

output. The acquisition rate is defined by the variable T_ADC_SEQ parameter which defines the angle

measurement period TangleMeas. This mode is used in PWM and SENT without pause. Even though PWM is

periodic, asynchronous mode is better suited and enables complete filtering options for PWM signals that

are often slow compared to the sensor internal measurement sequence.

REVISION 4 - 20 MAR 2019

3901090374

Page 12 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

fig. 3 - Continuous Asynchronous Timing Mode

Parameter

Symbol

Angle acquisition time

TangleAcq

Internal Angle

Measurement Period

TangleMeas

528

588

-

μs

Typical is default factory

settings (no user control)

NTframe

282

-

-

ticks

Do not modify for

asynchronous mode (see

chap.11, T_FRAME)

SENT Frame Tick Count

Min.

Typ

Max.

330

Unit

Condition

μs

Table 10 - Continuous Asynchronous Timing Mode

6.2.2. Continuous Synchronous Acquisition Mode

In continuous synchronous timing mode, the sensor acquires angles based on the output frequency. As a

consequence, the output should have a fixed frame frequency. This mode is used only with constant SENT

frame length (SENT with pause). The length of the SENT frame is defined by the parameter T_FRAME in

number of ticks. The user has the choice to select either one or two angle acquisitions and DSP calculations

per frame.

fig. 4 - Continuous Synchronous Timing Mode

REVISION 4 - 20 MAR 2019

3901090374

Page 13 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Following table describes the frame length of synchronous acquisition mode with regards to T_FRAME

parameter value (see chap. 11). Minimal values represent MLX90374 best achievable performance. Typical

values are default or recommended values. Maximal values are limited by the SAE J2716 standard and not

displayed in this table. For a chosen timing configuration, one has to consider the main clock relative

tolerances listed in Table 9 to get a tolerance on the frame duration.

Parameter

Symbol

SENT Frame Tick Count

(Normal SENT)

NTframe

310(4)

320

-

ticks

For tick time of 3μs (Normal

SENT) and two angles per frame

SENT Frame Tick Count

(Normal SENT)

NTframe

282(4)

304 5

-

ticks

For tick time of 3μs (Normal

SENT) and one angle per frame

SENT Frame Tick Count

(Fast SENT)

NTframe

320(4)

330

-

ticks

For tick time of 1.5μs (Fast SENT)

and one angle per frame

SENT Frame Period

(Normal SENT)

Tframe

930(4)

960

-

μs

3μs tick time with pause and two

angles per frame (FCK = 24MHz)

SENT Frame Period (Fast)

Tframe

480(4)

495

-

μs

1.5μs tick time with pause, one

angle per frame (FCK = 24MHz)

NangFram

1

2

Number of angles per

frame

Min

Typ

Max

Unit

Condition

set by TWO_ANGLE_FRAME

parameter

Table 11 - SENT Synchronous Timing Mode Configuration

6.3. Timing Definitions

6.3.1. Startup Time

VDDstart

Supply Voltage

SENT output

Tinit

High-Z

Tstup

Null Frame

Null Frame

Null Frame

Valid Angle

Valid Angle

Tstup3

Tstup2

Tstup1

Output

Ready

PWM output

High-Z (no drive)

First Sync

Pulse

First Valid Angle

fig. 5 - Startup Time Definition

Minimal timings are only confirmed to work in a specific configuration and may lead to noise degradation. Melexis

recommends typical configuration (factory settings) for safe operation with any end user configuration.

4

5

This timing optimizes the startup time (see Table 14)

REVISION 4 - 20 MAR 2019

3901090374

Page 14 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

6.3.1.1. Normal Startup

A typical startup in SENT consists of two main phases. During the first one, the circuit performs its

initialisation until being able to start acquiring angles and transmitting SENT frames. This first phase lasts

Tinit milliseconds. After that time, the IC starts transmitting SENT initialisation frames, also called null

frames, their content being mainly zeros. During the second phase, the sensor acquires angles until the

amplification chain gain settles. The overall startup time Tstup is the time between power up and complete

transmission of the first valid angle.

6.3.1.2. Safe Startup

When COLD_SAFE_STARTUP_EN is set (see chap.11, End-User Programmable Items), the circuit performs

a full diagnostic cycle before starting the transmission of an angle. This sequence lasts TSafeStup milliseconds

(see Table 9 - General Timing Specifications). After Tinit, the circuit start sending null SENT frames until the

full diagnostic sequence is complete.

6.3.1.3. Startup phase in PWM mode

In PWM mode, startup is defined by three values, T stup[1..3]. The first value is reached when the output is

ready and starts to drive a voltage. The second value T2 is the start of the first value angle transmission and

the third one T3 the moment the first angle has been transmitted.

6.3.2. Latency (average)

Latency is the average lag between the movement of the detected object (magnet) and the response of

the sensor output. This value is representative of the time constant of the system for regulation

calculations.

fig. 6 - Definition of Latency

6.3.3. Step Response (worst case)

Step response is defined as the delay between a change of position of the magnet and the 100% settling

time of the sensor output with full angle accuracy with regards to filtering. Worst case is happening when

REVISION 4 - 20 MAR 2019

3901090374

Page 15 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

the movement of the magnet occurs just after a measurement sequence has begun. Step response

therefore consists of the sum of:

δmag,measSeq, the delay between magnetic change and start of next measurement sequence

TmeasSeq, the measurement sequence length

δmeasSeq,frameStart, the delay between end of measurement sequence and start of next frame

Tframe, the frame length

For worst case, the measurement sequence length is considered for δmag,measSeq. This gives:

TwcStep = 2TmeasSeq + δmeasSeq,frameStart + Tframe

Magnetic step

(input change)

End of SENT/PWM Frame

Output response to

the magnetic step

partial response

Complete response

Measurement

sequence

SENT w

pause

Step Response

PWM

fig. 7 - Step Response Definition

6.4. PWM timing specifications

Parameter

Symbol

Min

Typ

Max

Unit

FPWM

100

1000

2000

Hz

PWM Frequency Initial

Tolerances

ΔFPWM,0

-1.5

1.5

%FPWM

PWM Frequency Thermal

Drift

ΔFPWM,T

-2.0

2.0

%FPWM

PWM Frequency Drift

ΔFPWM

-5.0

5.0

%FPWM

PWM startup Time (up to

output ready)

Tstup1

PWM startup Time (up to

first sync. Edge)

Tstup2

PWM Frequency

REVISION 4 - 20 MAR 2019

3901090374

6.60

7.10

7.60

Condition

T=35°C, can be trimmed at EOL

Over temperature and lifetime

ms

16.6

ms

Tstup1 + TPWM

Page 16 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Parameter

Symbol

Min

Typ

Max

Unit

Tstup3

7.60

8.60

26.6

ms

Tstup1 + 2* TPWM (6)

Rise Time PWM

trise

1.0

4.8

12.0

μs

Fall Time PWM

tfall

1.0

4.8

12.0

μs

typ. with SENT_SEL_SR_RISE/FALL

= 4 (see 10.2.6). Measured

between 1.1V and 3.8V

PWM startup Time (up to

first data received)

Condition

Table 12 - PWM timing specifications

6.5. SENT timing specifications

Timing specifications are valid for a given configuration of the SENT frame and tick time (see 10.2.9).

Parameter

Symbol

Min

Typ

Max

Unit

Condition

1.5

3

6

μs

1.5μs = Fast SENT

3μs = Normal SENT (default)

6μs = Slow SENT

-

2.95

3.10

ms

Until initialisation frame starts

SENT edge rise Time

4.5

6.2

7.5

μs

SENT edge fall Time

3.9

4.8

5.2

μs

for SENT_SEL_SR_RISE/FALL =4

(see 10.2.6)

Tick time

SENT startup time (up to

first sync pulse)

Tinit

691

415

Slow Message cycle length

ms

Extended sequence ( 40 frames )

Short sequence (24 frames )

Table 13 - SENT General Timing Specifications

Parameter

Symbol

Min

Typ

Max

Unit

Condition

For SENT with pause (synchronous), 3μs tick time, 2 angles per SENT frame, T_FRAME = 310

SENT startup time

Tstup

-

6.48

-

ms

Until first valid angle received

Average Latency

Tlatcy

-

1.73

2.19

-

ms

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

TwcStep

-

-

2.98

3.91

ms

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

Step Response (worst

case)

For SENT with pause (synchronous), 3μs tick time, 2 angles per SENT frame, T_FRAME = 320

SENT startup time

Tstup

-

6.60

-

ms

Until first valid angle received

Average Latency

Tlatcy

-

1.77

2.25

-

ms

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

TwcStep

-

-

3.12

4.08

ms

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

Step Response (worst

case)

6

First frame transmitted has no synchronization edge; therefore the second frame transmitted is the first complete one.

7

See section 12.2.3 for details concerning Filter parameter

REVISION 4 - 20 MAR 2019

3901090374

Page 17 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Parameter

Symbol

Min

Typ

Max

Unit

Condition

For SENT with pause (synchronous), 3μs tick time, 1 angle per SENT frame, T_FRAME = 282

SENT startup time

Tstup

-

6.99

-

ms

Until first valid angle received

Average Latency

Tlatcy

-

1.33

-

ms

Filter = 0 (no filter)

TwcStep

-

-

2.32

ms

Filter = 0 (no filter)

Step Response (worst

case)

For SENT with pause (synchronous), 3μs tick time, 1 angle per SENT frame, T_FRAME = 304

SENT startup time

Tstup

-

6.41

-

ms

Until first valid angle received

Average Latency

Tlatcy

-

1.54

-

ms

Filter = 0 (no filter)

TwcStep

-

-

2.60

ms

Filter = 0 (no filter)

Step Response (worst

case)

Table 14 - Synchronous SENT Mode Timing Specifications for 3us tick time

Parameter

Symbol

Min

Typ

Max

Unit

Condition

For SENT with pause (synchronous), 1.5μs tick time, 1 angle per SENT frame, T_FRAME = 320

SENT startup time

Average Latency

Step Response (worst

case)

Tstup

Tlatcy

TwcStep

6.12

6.23

-

0.98

1.15

1.31

-

-

1.58

1.89

2.20

-

-

ms

Until first valid angle received

ms

Filter = 0 (no filter)

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

ms

Filter = 0 (no filter)

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

For SENT with pause (synchronous), 1.5μs tick time, 1 angle per SENT frame, T_FRAME = 330

SENT startup time

Average Latency

Step Response (worst

case)

Tstup

Tlatcy

TwcStep

6.12

6.23

-

1.05

1.21

1.37

-

-

1.63

1.95

2.27

-

-

ms

Until first valid angle received

ms

Filter = 0 (no filter)

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

ms

Filter = 0 (no filter)

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

Table 15 - Synchronous SENT Mode Timing Specifications for 1.5us tick time

REVISION 4 - 20 MAR 2019

3901090374

Page 18 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Parameter

Symbol

Min

Typ

Max

Unit

Condition

For SENT without pause (asynchronous), 3μs tick time(8)

SENT startup time

Average Latency

Step Response (worst

case)

Tstup

6.25

6.42

6.39

6.56

Tlatcy

1.40

1.67

2.20

1.40

1.70

2.30

-

-

2.76

3.29

4.35

2.83

3.43

4.63

TwcStep

6.51

6.68

ms

Until first valid angle received

with SENT_INIT_GM = 1

ms

Filter = 0 (no filter)

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

ms

Filter = 0 (no filter)

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

For SENT without pause (asynchronous), 1.5μs tick time(8)

SENT startup time

Average Latency

Step Response (worst

case)

Tstup

6.42

6.50

Tlatcy

0.91

1.17

1.70

0.91

1.21

1.81

-

-

1.71

2.19

3.15

2.01

2.61

3.81

TwcStep

6.56

ms

Until first valid angle received

ms

Filter = 0 (no filter)

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

ms

Filter = 0 (no filter)

Filter = 1 (FIR11)

Filter = 2 (FIR1111) (7)

Table 16 - Asynchronous SENT Mode Timing Specifications

8 In asynchronous mode, the latency is defined as an average delay with regards to all possible variations. For worst case, refer

to step response (worst case) values

REVISION 4 - 20 MAR 2019

3901090374

Page 19 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

7. Magnetic Field Specifications

Magnetic Field specifications are valid for temperature range [-40;160] °C unless otherwise noted.

7.1. Rotary Stray-field Immune Mode (-100 code)

Parameter

Symbol

Min

Typ

Max

-

-

Unit

Condition

Number of magnetic poles

NP

Magnetic Flux Density in XY plane

BX, BY ( 10)

25(11)

mT

�𝐵𝐵𝑋𝑋2 + 𝐵𝐵𝑌𝑌2

Magnetic Flux Density in Z

BZ

100

mT

(this is not the useful signal)

1

0

mT

mm

Magnetic in-plane gradient

of in-plane field component

Magnet Temperature

Coefficient

∆𝐵𝐵𝑋𝑋𝑋𝑋

∆𝑋𝑋𝑋𝑋

4

( 9)

3.8

10

TCm

-2400

0.075

0.1

0.125

Field too Low Threshold(13)

∆𝐵𝐵𝑋𝑋𝑋𝑋

∆𝑋𝑋𝑋𝑋

BTH_LOW

0.8

1.2

( 14)

Field too High Threshold(13)

BTH_HIGH

70

100(15)

102(15)

Field Strength Resolution(12)

ppm

°C

mT

mm LSB

mT

mm

mT

mm

(this is not the useful signal)

2

2

��𝑑𝑑𝐵𝐵𝑋𝑋 − 𝑑𝑑𝐵𝐵𝑌𝑌 � + �𝑑𝑑𝐵𝐵𝑋𝑋 + 𝑑𝑑𝐵𝐵𝑌𝑌 �

𝑑𝑑𝑑𝑑

𝑑𝑑𝑑𝑑

𝑑𝑑𝑑𝑑

𝑑𝑑𝑑𝑑

2

this is the useful signal (see fig. 8)

Magnetic field gradient norm

(12bits data)

Typ is recommended value to be

set by user

Typ is recommended value to be

set by user

Table 17 - Magnetic specification for rotary stray-field immune

Nominal performances apply when the useful signal ∆𝐵𝐵𝑋𝑋𝑋𝑋 /∆𝑋𝑋𝑋𝑋 is above the typical specified limit. Under

this value, limited performances apply. See 8.2 for accuracy specifications.

9

Due to 4 poles magnet usage, maximum angle measurement range is limited to 180°

10

The condition must be fulfilled for all combinations of Bx and By.

11

Above this limit, the IMC® starts to saturate, yielding to an increase of the linearity error.

12

Only valid with default MAGNET_SREL_T[1..7] configuration

13

Typ. value is set by default for NVRAM rev.9 and shall be set by user for rev.8 (see Table 43, USER_ID1 and Table 42)

Higher values of Field too Low threshold are not recommended by Melexis and shall only been set in accordance with the

magnetic design and taking a sufficient safety margin to prevent false positive.

14

15

Due to the saturation effect of the IMC, the FieldTooHigh monitor detects only defects in the sensors

REVISION 4 - 20 MAR 2019

3901090374

Page 20 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Temperature (°C)

160

-40

Limited

Performances

Nominal

Performances

Typical magnet

characteristics

3.8 5.7

10

∆B XY mT

∆XY mm

fig. 8 - Minimum useful signal definition for rotary stray-field immune application

7.2. Linear Stray-field Immune (-200 code)

Parameter

Symbol

Min

Typ

Max

2

-

Unit

Condition

Number of magnetic poles

NP

Magnetic Flux Density in X

BX

80(16)

mT

BY ≤ 20mT

BX, BY ( 17)

70(18)

mT

BZ

100

mT

�𝐵𝐵𝑋𝑋2 + 𝐵𝐵𝑌𝑌2 , BY >20mT

Magnetic Flux Density in X-Y

Magnetic Flux Density in Z

Magnetic gradient of X-Z

field components

Distance between the two

IMC®

∆𝐵𝐵𝑋𝑋𝑋𝑋

∆𝑋𝑋

GIMC

Magnet Temperature

Coefficient

TCm

∆𝐵𝐵𝑋𝑋𝑋𝑋

∆𝑋𝑋

mT

mm

6( 19)

1.91

∆𝑋𝑋

IMC gain

Field Strength Resolution(12)

3

Linear movement

mm

∆𝐵𝐵𝑍𝑍 2 (20)

�

𝐺𝐺𝐼𝐼𝐼𝐼𝐼𝐼 ∆𝑋𝑋

∆𝑋𝑋

1

see chapter 17 for magnetic

center definitions

see (20)

1.19

-2400

2

��∆𝐵𝐵𝑋𝑋 � + �

0

0.037

0.05

0.063

Field too Low Threshold(13)

BTH_LOW

0.2

1.2

( 21)

Field too High Threshold(13)

BTH_HIGH

35

50

51

ppm

°C

mT

Magnetic field gradient norm

mm LSB expressed in 12bits words

mT

mm

mT

mm

Typ is recommended value to

be set by user

Typ is recommended value to

be set by user

Table 18 - Magnetic specifications for linear stray-field application

16

Above 80 mT, with BY field in the mentioned limits, the IMC® starts saturating yielding to an increase of the linearity error.

17

The condition must be fulfilled for all combinations of BX and BY.

18

Above 70 mT, the IMC® starts saturating yielding to an increase of the linearity error.

19

Below 6 mT/mm, the performances are degraded due to a reduction of the signal-to-noise ratio, signal-to-offset ratio.

IMC has better performance for concentrating in-plane (X-Y) field components, resulting in a better magnetic sensitivity. A

correction factor, called IMC gain has to be applied to the Z field component to account for this difference.

20

Higher values of Field too Low threshold are not recommended by Melexis and shall only been set in accordance with the

magnetic design and taking a sufficient safety margin to prevent false positive.

21

REVISION 4 - 20 MAR 2019

3901090374

Page 21 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Nominal performances apply when the useful signal ∆Bxz/∆X and temperature range are inside the values

defined in the following figure (fig. 9). At higher temperature or lower field gradients, the accuracy of

MLX90374 is degraded and Limited Performances, described in section 8.3.2, apply.

160

Limited

Performances

135

Temperature (°C)

Limited

Performances

Typical magnet

characteristics

3

Nominal

Performances

6

∆BXZ mT

∆X mm

-40

fig. 9 - Minimum useful signal definition for linear stray-field immune application

7.3. Standard/Legacy Mode (-300 code)

Parameter

Symbol

Min.

Typ.

Max.

Number of magnetic poles

NP

-

2

-

Magnetic Flux Density in XY plane

BX, BY(17)

Magnetic Flux Density in Z

BZ

Useful Magnetic Flux

Density Norm

Unit

Condition

70

mT

100

mT

�𝐵𝐵𝑋𝑋2 + 𝐵𝐵𝑌𝑌2

in absolute value

�𝐵𝐵𝑋𝑋2 + 𝐵𝐵𝑌𝑌2 (X-y mode)

BNorm

10(22)

20

mT

�𝐵𝐵𝑋𝑋2 + �

1

𝐺𝐺𝐼𝐼𝐼𝐼𝐼𝐼

2

𝐵𝐵𝑍𝑍 � (X-Z mode)

2

1

𝐵𝐵 �

𝐺𝐺𝐼𝐼𝐼𝐼𝐼𝐼 𝑍𝑍

�𝐵𝐵𝑌𝑌2 + �

(Y-Z mode)

see 12.1.1 for sensing mode

description.

IMC gain

GIMC

Magnet Temperature

Coefficient

TCm

22

1.19

-2400

see

0

23

ppm

°C

Below 10 mT the performances are degraded due to a reduction of the signal-to-noise ratio, signal-to-offset ratio

23 IMC

has better performance for concentrating in-plane (X-Y) field components, resulting in a better overall magnetic

sensitivity. A correction factor, called IMC gain has to be applied to the Z field component to account for this difference.

REVISION 4 - 20 MAR 2019

3901090374

Page 22 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Parameter

Symbol

Min.

Typ.

Max.

BNorm

0.075

0.100

0.125

Field Too Low Threshold(25)

BTH_LOW

0.4

4.0

Field Too High Threshold(25)

BTH_HIGH

70

100(27)

Field Strength

Resolution(24)

Unit

Condition

Magnetic field gradient norm

expressed in 12bits words

( 26)

mT

LSB

mT

Typ is recommended value to

be set by user

100(27)

mT

Typ is recommended value to

be set by user

Table 19 - Magnetic specifications for Standard application

Nominal performances apply when the useful signal BNorm is above the typical specified limit. Under this

value, limited performances apply. See 8.4 for accuracy specifications.

160

Temperature (°C)

Limited

Performances

-40

Nominal

Performances

Typical magnet

characteristic

10

15

20

Norm (mT)

fig. 10 - Minimum useful signal definition for Standard/Legacy application

24

Only valid with default MAGNET_SREL_T[1..7] configuration

25

Typ. value is set by default for NVRAM rev.9 and shall be set by user for rev.8 (see Table 43, USER_ID1 and Table 42)

Higher values of Field too Low threshold are not recommended by Melexis and shall only been set in accordance with the

magnetic design and taking a sufficient safety margin to prevent false positive.

26

27

Due to the saturation effect of the IMC, the FieldTooHigh monitor detects only defects in the sensors

REVISION 4 - 20 MAR 2019

3901090374

Page 23 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

8. Accuracy Specifications

Accuracy specifications are valid for temperature range [-40;160] °C and supply voltage range [4.5 - 5.5] V

unless otherwise noted.

8.1. Definition

This section defines several parameters, which will be used for the magnetic specifications.

rv

Cu

d

ur

re

lC

su

ea

ea

Id

M

Output (%DC, Deg)

ve

e

8.1.1. Intrinsic Linearity Error

Noise (pk-pk)

Intrinsic Linearity Error

(LE)

±3σ

Input (Deg.)

fig. 11 - Sensor accuracy definition

Illustration of fig. 11 depicts the intrinsic linearity error in new parts. The Intrinsic Linearity Error refers to

the IC itself (offset, sensitivity mismatch, orthogonality) taking into account an ideal magnetic field. Once

associated to a practical magnetic construction and the associated mechanical and magnetic tolerances,

the output linearity error increases. However, it can be improved with the multi-point end-user calibration

(see 12.2.6). As a consequence, this error is not critical in application because it is calibrated away.

8.1.2. Total Angle Drift

After calibration, the output angle of the sensor might still change due to temperature change, aging, etc.

This is defined as the total drift 𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇 :

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇 = max{𝜃𝜃(𝜃𝜃𝐼𝐼𝐼𝐼 , 𝑇𝑇, 𝑡𝑡) − 𝜃𝜃(𝜃𝜃𝐼𝐼𝐼𝐼 , 𝑇𝑇𝑅𝑅𝑅𝑅 , 𝑡𝑡0 )}

where 𝜃𝜃𝐼𝐼𝐼𝐼 is the input angle, 𝑇𝑇 is the temperature, 𝑇𝑇𝑅𝑅𝑅𝑅 is the room temperature, and 𝑡𝑡 is the elapsed

lifetime after calibration. 𝑡𝑡0 represents the status at the start of the operating life. Note the total drift 𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇

is always defined with respect to angle at room temperature. In this datasheet, 𝑇𝑇𝑅𝑅𝑅𝑅 is typically defined at

35°C, unless stated otherwise. The total drift is valid for all angles along the full mechanical stroke.

REVISION 4 - 20 MAR 2019

3901090374

Page 24 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

8.2. Rotary Stray-field Immune (-100 code)

8.2.1. Nominal Performance

Valid before EoL calibration and for all applications under nominal performances conditions described in

section 7.1 (fig. 8) and chapter 5.

Parameter

XY - Intrinsic Linearity Error

Symbol

Min

LE_XY

-1

Typ

Noise (28)

XY - Total Drift (30)

Hysteresis

Output Stray Field Immunity

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑋𝑋𝑋𝑋

-0.85

Max

Unit

1

Deg.

0.2

0.4

Deg.

Filter = 2

Filter = 0 ( 29)

0.85

Deg.

Relative to 35°C

0.1

Deg.

0.6

∂θFF

Condition

Deg.

with 10mT/mm useful gradient

field and 4kA/m stray-field (31)

Table 20 - Rotary stray-field immune magnetic performances

8.2.2. Limited Performances

Valid before EoL calibration and for all applications under limited performances conditions described in

section 7.1 (fig. 8) and chapter 5.

Parameter

XY - Intrinsic Maximum Error

Noise

Symbol

Min

LE

-1

Typ

(28)

XY - Total Drift (30)

-0.85

Hysteresis

0.1

Max

Unit

1

Deg.

Condition

0.7

0.5

0.35

Deg.

Filter = 0

Filter = 1

Filter = 2

0.85

Deg.

Relative to 35°C

Deg.

Table 21 - Rotary stray-field immune limited magnetic performances

28

±3σ

29

See section 12.2.3 for details concerning Filter parameter

Verification done on new and aged devices in an ideal magnetic field gradient (see 8.1.2). An additional application-specific

error arises from the non-ideal magnet and mechanical tolerance drift.

30

31 Tested in accordance with ISO 11452-8:2015, at 30°C, with stray-field strength of 4kA/m from any direction. This error scales

linearly with both the useful field and the disturbing field.

REVISION 4 - 20 MAR 2019

3901090374

Page 25 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

8.3. Linear Stray-field Immune Mode (-200 code)

8.3.1. Nominal Performances

Valid before EoL calibration and for all applications under nominal conditions described in section 7.2 (fig.

9) and chapter 5.

Parameter

Symbol

Min

Typ

Max

Unit

LE_XZ

-2.5

±1.25

2.5

Deg.

0.10

0.15

-

0.20

0.30

0.25

Deg.

Filter = 1, 6mT/mm

Filter = 0, 6mT/mm

Filter = 0, 6mT/mm, Tmax=125°C

0.8

Deg.

Compared to 35°C, 6mT/mm

gradient field

0.10

Deg.

0.8

Deg.

XZ - Intrinsic Maximum Error

Noise

(28)

XZ - Total Drift (30)

Hysteresis

Output Stray Field Immunity

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑋𝑋𝑋𝑋

∂θFF

-0.8

Condition

For 6mT/mm gradient field and

4kA/m stray-field (31)

Table 22 - Linear stray-field immune magnetic performances

8.3.2. Limited Performances

Valid before EoL calibration and for all applications under limited performances conditions described in

section 7.2 (fig. 9) and chapter 5.

Parameter

XZ - Intrinsic Maximum Error

Noise

Symbol

Min

Typ

Max

Unit

LE

-4

±2

4

Deg.

0.20

0.25

-

0.40

0.65

0.45

Deg.

Filter = 1, 3mT/mm

Filter = 0, 3mT/mm

Filter = 0, 3mT/mm, Tmax=125°C

1.4

Deg.

Compared to 35°C, 3mT/mm

0.25

Deg.

3mT/mm

(28)

XZ - Total Drift (30)

Hysteresis

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑋𝑋𝑋𝑋

-1.4

Condition

Table 23 - Linear stray-field immune limited magnetic performances

REVISION 4 - 20 MAR 2019

3901090374

Page 26 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

8.4. Standard/Legacy Mode (-300 code)

8.4.1. Nominal Performances

Valid before EoL calibration and for all applications under nominal conditions described in section 7.3 (fig.

10) and chapter 5.

Parameter

Symbol

Min

XY - Intrinsic Linearity Error

LE_XY

-1

XZ - Intrinsic Linearity Error

LE_XZ

-2.5

YZ - Intrinsic Linearity Error

LE_YZ

-2.5

Noise (32)

XY - Total Drift

(33)

XZ - Total Drift

(33)

YZ - Totla Drift

(33)

Hysteresis

Typ

Max

Unit

Condition

1

Deg.

±1.25

2.5

Deg.

±1.25

2.5

Deg.

0.05

0.1

0.05

0.1

0.2

0.1

Deg.

Filter = 0, 40mT

Filter = 0, 20mT

Filter = 2

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑋𝑋𝑋𝑋

-0.45

0.45

Deg.

Relative to 35°C

-0.6

0.6

Deg.

Relative to 35°C

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑌𝑌𝑌𝑌

-0.6

0.6

Deg.

Relative to 35°C

0.1

Deg.

20mT

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑋𝑋𝑋𝑋

0.05

Table 24 - Standard Mode Nominal Magnetic Performances

8.4.2. Limited Performances

Valid before EoL calibration and for all applications under limited performances conditions described in

section 7.3 (fig. 10) and chapter 5.

Parameter

Symbol

Min

XY - Intrinsic Linearity Error

LE_XY

-1

XZ - Intrinsic Linearity Error

LE_XZ

-2.5

YZ - Intrinsic Linearity Error

LE_YZ

-2.5

Noise

(32)

XY - Total Drift

(33)

XZ - Total Drift

(33)

YZ - Total Drift

(33)

Hysteresis

Typ

Max

Unit

Condition

1

Deg.

±1.25

2.5

Deg.

±1.25

2.5

Deg.

0.2

0.14

0.1

0.4

0.28

0.2

Deg.

Filter = 0

Filter = 1

Filter = 2

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑋𝑋𝑋𝑋

-0.6

0.6

Deg.

Relative to 35°C

-0.8

0.8

Deg.

Relative to 35°C

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑌𝑌𝑌𝑌

-0.8

0.8

Deg.

Relative to 35°C

0.2

Deg.

10mT

𝜕𝜕𝜕𝜕𝑇𝑇𝑇𝑇_𝑋𝑋𝑋𝑋

0.1

Table 25 - Standard Mode Limited Magnetic Performances

32

±3σ

Verification done on new and aged devices in an ideal magnetic field (see 8.1.2). An additional application-specific error arises

from the non-ideal magnet and mechanical tolerance drift.

33

REVISION 4 - 20 MAR 2019

3901090374

Page 27 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

9. Memory Specifications

Parameter

Symbol

ROM

ROMsize

32

kB

RAM

RAMsize

1024

B

NVRAMsize

256

B

NVRAM

Min

Typ

Max

Unit

Note

1 bit parity check (single error

detection)

1 bit parity check (single error

detection)

6 bits ECC (single error correction,

double error detection)

Table 26 - Memory Specifications

REVISION 4 - 20 MAR 2019

3901090374

Page 28 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

10. Digital output protocol

10.1. PWM (pulse width modulation)

10.1.1. Definition

%Duty Cycle = TON / TPWM

%DC Jitter = JDC = JON / JPWM

TPWM

Output (V)

TON

Jitter on TON

= JON

Jitter on TPWM

= JPWM

Time (s)

fig. 12 - PWM Signal definition

Parameter

PWM period

Rise time, Fall time

Jitter

Duty Cycle

Symbol

TPWM

trise, tfall

JON

JPWM

DC

Test Conditions

Trigger level = 50% VDD

Between 20% and 80% of VDD, see Table 12 for values

±3σ for 1000 successive acquisitions with clamped output

TON / TPWM

Table 27 - PWM Signal definition

10.1.2. PWM performances

Parameter

PWM Output Resolution

Symbol

Rpwm

PWM %DC Jitter

JDC

PWM Period Jitter

Jpwm

PWM %DC thermal drift

Min

-

Typ

Max

Unit

Condition

0.024

0.051

%DC/LSB

0.03

%DC

Push-Pull, 2kHz,

CL=10nF, RLPU =4.7kΩ

-

300

ns

Push-Pull, 2kHz,

CL=10nF, RLPU=4.7kΩ

0.02

0.05

%DC

Push-Pull, 2kHz,

CL=10nF, RLPU=4.7kΩ

2kHz. Worst case error for

160°C

Table 28 - PWM Signal Specifications

REVISION 4 - 20 MAR 2019

3901090374

Page 29 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

10.2. Single Edge Nibble Transmission (SENT) SAE J2716

The MLX90374 can be configured to provide a digital output signal compliant with SAE J2716 Revised

APR2016.

10.2.1. Sensor message definition

The MLX90374 repeatedly transmits a sequence of pulses, corresponding with a sequence of nibbles (4

bits), with the following sequence:

Calibration/Synchronization pulse period 56 clock ticks to determine the time base of the SENT

frame

One 4 bits Status and Serial Communication nibble pulse

A sequence of one up to six 4 bits data nibble pulses representing the values of the signal(s) to be

transmitted. The number of nibbles will be fixed for each application of the encoding scheme (i.e.

Singe Secure sensor format A.3, Throttle positions sensor A.1)

One 4 bits Checksum nibble pulse

One optional pause pulse

See also SAE J2716 APR2016 for general SENT specification.

fig. 13 - SENT message encoding example for two 12bits signals

REVISION 4 - 20 MAR 2019

3901090374

Page 30 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

10.2.2. Sensor message frame contents

The MLX90374 SENT transmits a sequence of data nibbles, according to the following configurations:

Description

Symbol

SENT

Min

SENTrev

Clock tick time

Typ

Max

2010

tickTime

1

3

Number of data nibbles

Xdn

3

6

Frame duration (no pause

pulse)

Npp

154

Frame duration with pause

pulse

Ppc

282

Sensor type

A.1

A.3

320

Unit

Description

SENT revision. Supports

enhanced serial channel

messages (2016)

2016

Main use cases :

Fast SENT, 1.5µs tick time

Normal SENT, 3µs tick time

Slow SENT, 6µs tick time

(see section 6.5)

12

µs

270

ticks

6 data nibbles

922

ticks

Valid for 3µs tick time

Dual Throttle Position sensors

Single Secure sensors

Table 29 - SENT Protocol Frame Definition

10.2.3. Single secure sensor A.3

The MLX90374 SENT transmits a sequence of data nibbles; according single secure sensor format defined

in SAE J2716 appendix A.3.The frame contains 12-bit angular value, a 8 bits rolling counter and an inverted

copy of the most significant nibble of angular value. This format is activated when SENT_SS bit is set to 1

(see Table 42, #137)

SM

[1:0]

S

[1:0]

Ch 1

[11:8]

Ch 1

[7:4]

12 bit angle data

Ch 1

[3:0]

COUNT

[7:4]

COUNT

[3:0]

~Ch 1

[11:8]

CRC

8 bit rolling counter

fig. 14 - A.3 Single Secure Sensor Frame Format

Shorthand Description

Tick

time

Data

nibbles

Pause

Pulse

Serial

message

Data

format

SENT2010-03.0us-6dn-ppc(366.0)-esp-A.3

3 us

6

Y

Enhanced

A.3

SENT2010-03.0us-6dn-ppc(366.0)-nsp-A.3

3 us

6

Y

None

A.3

SENT2010-03.0us-6dn-npp-nsp-A.3

3 us

6

N

None

A.3

SENT2010-##-#us-#dn-###()-###-A.3

1..12

6

Y/N

En/None

A.3

Table 30 - A.3 Single Secure Sensor Shorthand examples

REVISION 4 - 20 MAR 2019

3901090374

Page 31 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

10.2.4. Dual Throttle position sensor A.1

The MLX90374 SENT transmits a sequence of data nibbles; according dual throttle positions sensor defined

in SAE J2716 appendix A.1.The frame contains two 12-bit angular values.

SM

[1:0]

S

[1:0]

Ch 1

[7:4]

Ch 1

[11:8]

Ch 1

[3:0]

Ch2

[3:0]

Ch2

[7:4]

12 bit angle data

Ch2

[11:8]

CRC

12 bit angle data

fig. 15 - A.1 Dual Throttle Position Sensor Frame Format

Shorthand Description

Tick

time

Data

nibbles

Pause

Pulse

Serial

message

Data

format

SENT2010-03.0us-6dn-ppc(366.0)-esp-A.1

3 us

6

Y

Enhanced

A.1

SENT2010-03.0us-6dn-ppc(366.0)-nsp-A.1

3 us

6

Y

None

A.1

SENT2010-03.0us-6dn-npp-nsp-A.1

3 us

6

N

None

A.1

SENT2010-##-#us-#dn-###()-###-A.1

1..12

6

Y/N

En/None

A.1

Table 31 - A.1 Dual Throttle Position Sensor Shorthand Examples

Second fast channel configuration:

SENT_FAST_CHANNEL_2

CH2 configuration (ABB revision)

CH2 configuration (ABC revision)

0

Temperature sensor (SP ID 0x23)

Temperature sensor (SP ID 0x23)

1

0xFF9(d4089) - CH1

Second Output (see 12.3)

2

RAM data (RAMPROBE_PTR)

RAM data (RAMPROBE_PTR)

3

0xFFF(d4095) - CH1

0xFFF(d4095) - CH1

Table 32 - A.1 Dual Throttle Position Sensor Fast Channel 2 configuration

10.2.5. Start-up behaviour

The circuit will start to send initialisation frames once digital start-up is done but angle measurement

initialisation sequence is not yet complete. These initialisation frames content can be chosen by user with

the following option:

SENT_INIT_GM

Initialisation frame value

Comments

0

0x000

SAE compliant

1

0xFFF

OEM requirement

Table 33 - Initialisation Frame Content Definition

REVISION 4 - 20 MAR 2019

3901090374

Page 32 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

10.2.6. SENT Output Timing configuration

SENT_TICK_TIME

Tick time configuration

Description

0

3 µs

Standard SENT

1

0.5 µs

Not recommended

2

1 µs

Not recommended

3

1.5 µs

Fast SENT

4

2.0 µs

Not recommended

5

2.5 µs

Not recommended

6

6 µs

Slow SENT

7

12 µs

Not recommended

Table 34 - SENT Tick Time Configuration

SENT_SEL_SR_FALL

Fall time (Tfall)

SENT_SEL_SR_RISE

Rise Time (Trise)

0

No slew rate control

0

No slew rate control

1

0.7 µs

1

0.9 µs

2

1.2 µs

2

1.6 µs

3

1.9 µs

3

3.0 µs

4

4.8 µs

4

6.2 µs

5

9.6 µs

5

12 µs

6

19 µs

6

24 µs

7

24 µs

7

30 µs

Table 35 - SENT Rise and Fall Times Configuration

3.8V

1.1V

Tfall

SENT_SLOPE_TRIM[3..0]

Trise

SENT_SLOPE_TRIM[7..4]

fig. 16 - SENT Rise and Fall Times configuration

REVISION 4 - 20 MAR 2019

3901090374

Page 33 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

NIBBLE_PULSE_CONFIG

High/low time configuration

2

Fixed low time (5 ticks)

3

Fixed high time (6 ticks)(34)

Table 36 - SENT Nibble configuration (high/low times)

10.2.7. Serial message channel (slow channel)

Serial data is transmitted serial in bit number 3 and 2 of the status and communication nibble. A serial

message frame stretches over 18 consecutive SENT data messages from the transmitter. All 18 frames must

be successfully received (no errors, calibration pulse variation, data nibble CRC error, etc.) for the serial

value to be received.

Enhanced format with 12-bits data and 8-bits message ID is used (SAE J2716 APR2016 5.2.4.2, fig. 5.2.4.22). According to the standard, SM[0] contains a 6bits CRC followed by a 12-bits data. Message content is

defined by a 8-bit message ID transmitted in the SM[1] channel. Correspondence between ID and message

content is defined in the tables below (Table 37, Table 38 and Table 39).

SM

[1:0]

S

[1:0]

Status Nibble =

Ch 1

[11:8]

2 bit serial message

2 bit status

fig. 17 - SENT Status Nibble and Serial Message

By default, the short sequence consisting of a cycle of 24 data is transmitted (Table 37). An extended

sequence can be used through configuration of SENT_SLOW_EXTENDED (Table 38). Additionally, the norm

of the B field detected by the sensor can be returned at the end of the sequence by setting

SENT_SLOW_BFIELD (Table 39).

#

8bit ID

Item

Source data

1

0x01

Diagnostic error code

Current status code from RAM

2

0x06

SENT standard revision

SENT_REV from NVRAM

3

0x01

Diagnostic error code

Current status code from RAM

4

0x05

Manufacturer code

SENT_MAN_CODE from NVRAM

5

0x01

Diagnostic error code

Current status code from RAM

6

0x03

Channel 1 / 2 Sensor type

SENT_SENSOR_TYPE from NVRAM

7

0x01

Diagnostic error code

Current status code from RAM

8

0x07

Fast channel 1: X1

SENT_CHANNEL_X1 from NVRAM

9

0x01

Diagnostic error code

Current status code from RAM

34 When using fixed high time in normal SENT mode, Melexis recommends lowering SENT_SEL_SR_RISE to 3 or setting

ABE_OUT_MODE to 2 to two to avoid potential timing degradation on short nibbles.

REVISION 4 - 20 MAR 2019

3901090374

Page 34 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

#

8bit ID

Item

Source data

10

0x08

Fast channel 1: X2

SENT_CHANNEL_X2 from NVRAM

11

0x01

Diagnostic error code

Current status code from RAM

12

0x09

Fast channel 1: Y1

SENT_CHANNEL_Y1 from NVRAM

13

0x01

Diagnostic error code

Current status code from RAM

14

0x0A

Fast channel 1: Y2

SENT_CHANNEL_Y2 from NVRAM

15

0x01

Diagnostic error code

Current status code from RAM

16

0x23

(Internal) temperature

Current temperature from RAM

17

0x01

Diagnostic error code

Current status code from RAM

18

0x29

Sensor ID #1

SENT_SENSOR_ID1 from NVRAM

19

0x01

Diagnostic error code

Current status code from RAM

20

0x2A

Sensor ID #2

SENT_SENSOR_ID2 from NVRAM

21

0x01

Diagnostic error code

Current status code from RAM

22

0x2B

Sensor ID #3

SENT_SENSOR_ID3 from NVRAM

23

0x01

Diagnostic error code

Current status code from RAM

24

0x2C

Sensor ID #4

SENT_SENSOR_ID4 from NVRAM

Table 37 - SENT Slow Channel Standard Data Sequence

#

8bit ID

Item

Source data

25

0x01

Diagnostic error code

Current status code from RAM

26

0x90

OEM Code #1

SENT_OEM_CODE1 from NVRAM

27

0x01

Diagnostic error code

Current status code from RAM

28

0x91

OEM Code #2

SENT_OEM_CODE2 from NVRAM

29

0x01

Diagnostic error code

Current status code from RAM

30

0x92

OEM Code #3

SENT_OEM_CODE3 from NVRAM

31

0x01

Diagnostic error code

Current status code from RAM

32

0x93

OEM Code #4

SENT_OEM_CODE4 from NVRAM

33

0x01

Diagnostic error code

Current status code from RAM

34

0x94

OEM Code #5

SENT_OEM_CODE5 from NVRAM

35

0x01

Diagnostic error code

Current status code from RAM

36

0x95

OEM Code #5

SENT_OEM_CODE6 from NVRAM

37

0x01

Diagnostic error code

Current status code from RAM

38

0x96

OEM Code #5

SENT_OEM_CODE7 from NVRAM

39

0x01

Diagnostic error code

Current status code from RAM

40

0x97

OEM Code #8

SENT_OEM_CODE8 from NVRAM

Table 38 - SENT Slow Channel Extended Data Sequence

REVISION 4 - 20 MAR 2019

3901090374

Page 35 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

#

8bit ID

Item

source data

25

0x80

Field Strength

Bfield_norm from RAM

(standard sequence)

41

0x80

Field Strength

Bfield_norm from RAM

(extended sequence)

Table 39 - SENT Slow Channel Magnetic Field Norm ID and position

For Field Strength encoding, see chapter 7, Magnetic Field Specifications, under the section corresponding

to the selected application.

10.2.8. Serial Message Error Code

The list of error and status messages transmitted in the 12-bit Serial Message data field when Serial

Message 8-bit ID is 0x01, is given in the Table 40. The error is one-hot encoded and therefore each bit is

linked to one or several monitor. Only the first error detected is reported and serial message error code

will not be updated until all the errors have disappeared. This mechanism ensures only one error at a time

takes control of the error debouncing counter (see 12.4.2).

The MSB acts as an error Flag when SENT_DIAG_STRICT is set. This bit will be high only when an error is

present. For compatibility with previous Triaxis®, this bit can be kept high even if no error is present

(SENT_DIAG_STRICT = 0).

Bit Nb

12 Bit Data (hex)

Diagnostic

Comments

-

0x000 / 0x800

No error

Programmable (SENT_DIAG_STRICT, see Table

42, no 151)

0

0x801

GainOOS

Gain out of spec (see GAIN_MIN, GAIN_MAX)

1

0x802

FieldTooLow

Fieldstrength below defined low threshold (see

Table 42, no 103)

2

0x804

FieldTooHigh

Fieldstrength above defined high threshold (see

Table 42, no 104)

3

0x808

ADCclip

ADC is saturated, either low or high

4

0x810

ADC_test

ADC wrong conversion

5

0x820

Analog Supply Monitors

Detects VDDA (VDEC) over and under voltage or

VDD under voltage

6

0x840

Digital Supply Monitors

Detects VDDD (1.8V internal digital supply)

overvoltage

7

0x880

RoughOffset

Hall Element offset monitor

8

0x900

Over/Under Temp

Temperature sensor monitor (see 12.4.3)

9

0xA00

HE_Bias / Analog Front

End

Hall Element biasing issue / Analog front end

self-test ( 35)

35

Only available on MLX90374 ABC version (not on ABB)

REVISION 4 - 20 MAR 2019

3901090374

Page 36 of 77

�MLX90374 - Triaxis® Position Processor

Datasheet

Bit Nb

12 Bit Data (hex)

Diagnostic

Comments

10

0xC00

Suply Bias Current

Current biasing system monitor

11

0x800

Extra Error Flag

set to one if any error present (only when

SENT_DIAG_STRICT = 1). Otherwise, always high.

Table 40 - SENT Serial Message Error Code

10.2.9. SENT configuration shorthand definition

Shorthand description

SENT SAE J2716 Rev

Clock Tick length [μs]

Number of data Nibbles

Pause Pulse Option

Format

Req

90374 programmable setting

SENT

xxxx

2007

2008

2010

2016

CRC_2007

0

> 2007

1

2007

0.5 5 V)

0

1

WARM_TRIGGER_LONG

174

Add delay to enter PTC mode (MT7V)

0

1

Magnet Relative sensitivity at temperature Tx (36)

255

8

SENSOR FRONT-END

MAGNET_SREL_T[1..7]

7..13

GAINMIN

14

Low threshold for virtual gain

01

8

GAINMAX

15

High threshold for virtual gain

63

8

GAINSATURATION

26

Gain Saturates on GAINMIX and GAINMAX

0

1

Mapping fields for output angle

SENSING_MODE

18

Rotary stray field Immune -- order code 100

0

Linear position stray field Immune -- order code 200

4

Linear position / Angular Rotary -- order code 300

DSP_NB_CONV(37)

19

EN_USER_FE_TRIMMING

125

B_OFS_1

B_OFS_2

Number of phase spinning within ADC sequence

3

1-3

0(37)

2

Enable Additional Virtual Offset

0

1

161

Virtual Offset on component B1 (Warning! if used

overwrites USERID[2] and USERID[3])

0

16

163

Virtual Offset on component B2 (Warning! if used

overwrites USERID[4] and USERID[5])

0

16

0=4 phase spinning

DSP – FILTERING

FILTER

21

Filter mode selection

1

2

HYST

16

Hysteresis threshold for EMA (IIR) filter

0

8

DENOISING_FILTER_ALPHA_SEL

95

Select the alpha parameter of the EMA (IIR) filter

0

2

DSP – ANGLE MAPPING FUNCTIONS

CW

20

Set rotation to clockwise

0

1

DP

27

Discontinuity point

0

16

WORK_RANGE_GAIN

217

Re-scaling before the piece-wise linearization step

16

8

0

3

0

1

WORKING_RANGE

23

4POINTS

22

17, 32pts - Output angle range

(= limited selection of WORK_RANGE_GAIN)

Select LNR method 4 pts