MP3312

2.7V-5.5V Input , 38V OVP,

Dual-Channel White LED Driver

DESCRIPTION

FEATURES

The MP3312 is a dual-channel step-up WLED

driver with integrated 40V MOSFET, and

supports 2.7V to 5.5V power supply input. It uses

peak current mode to regulate the LED current

which is set by external resistor.

The MP3312 employs 1.2MHz fixed switching

frequency. It features supporting both PWM input

analog dimming and digital analog dimming to

accurately regulate the dimming current.

The MP3312 integrates current source to

balance LED current, which leads good ILED

matching and accuracy performance.

In addition, the MP3312 has LED open and short

protection, cycle by cycle current limit protection,

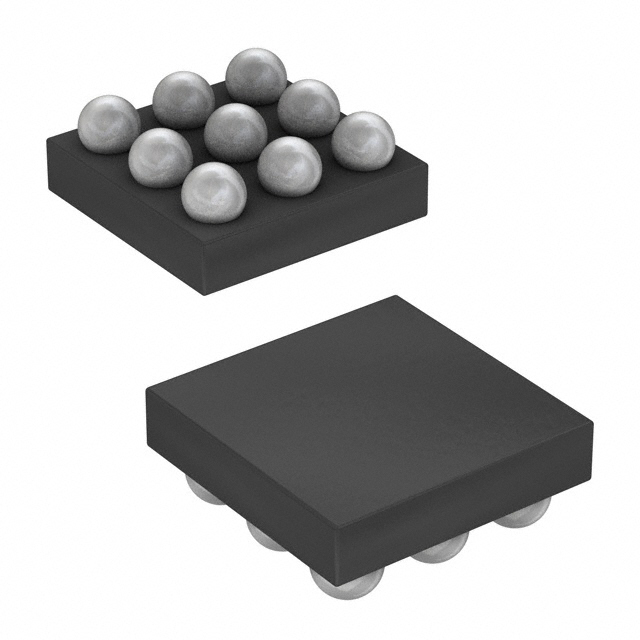

and thermal shutdown protection. It is available in

tiny WLCSP1.35x1.35-9 package.

2.7V~5.5V Input Voltage

1.2MHz Switching Frequency

Dual Channels Support up to 30mA/String

1% Current Matching Between LED Channels

+/-2% Current Accuracy

38V OVP Protection

PWM Input Analog Dimming Mode

5kHz to100kHz PWM Input Analog Dimming

1-Wire Interface for Digital Dimming

9-bit Dimming Resolution

Internal Soft Start to Reduce Inrush Current

Available in WLCSP1.35x1.35-9 Package

APPLICATIONS

Feature Phone and Smart Phones

Tablets

GPS Receivers

2.5ms shuts down the

IC.

C2

VIN

Power supply input pin. Connect a ceramic capacitor nearby this pin to bypass the IC.

C3

SW

Drain connection of the internal N-CH power MOSFET.

MP3312 Rev. 1.1

12/7/2020

LED2 current sink pin.

LED1 current sink pin.

PWM signal input pin. 5kHz to 100kHz PWM Signal is recommended to this pin to do the

analog current dimming. Low logic for >20ms shuts down the IC.

Internal error amplifier output pin. Connect a capacitor to compensate the system.

GND pin.

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

7

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

FUNCTIONAL BLOCK DIAGRAM

L1

D1

VOUT

VIN

C2

C1

SW

VIN

OVP

Shutdown

OSC

PWM

Control

EN

EN

Detection

PWM

RAMP

Analog

Dimming

VREF

EA

PWM

Comparator

LED1

COMP

Feedback

Control

Min.

Max.

R2

C3

GND

Short

Protection

Current Control

LED2

ISET

EN

R1

Figure 1— Functional Block Diagram

MP3312 Rev. 1.1

12/7/2020

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

8

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

OPERATION

The MP3312 employs the fixed switching

frequency, peak current mode control

architecture and 2 regulated current sinks to

power the LED array. The operation of the

MP3312 can be understood by referring to the

below function block diagram.

System Startup

Either pulling EN or PWM to high enables the

IC operation while pulling EN to GND

for >2.5ms or pulling PWM to GND for >20ms

shuts down the IC.

When enabled, the MP3312 checks the

topology connection first. The MP3312 also

checks other safety limits, including UVLO and

over-temperature protection (OTP). If all the

protections pass, the chip then starts boosting

the step-up converter with an internal soft-start.

It is recommended that the enable signal occurs

after the establishment of the input voltage and

PWM dimming signal during the start-up

sequence to avoid large inrush current.

Switching Operation

At the start of each oscillator cycle the main low

side FET (M1) is turned on through the control

circuitry. To prevent sub-harmonic oscillation at

duty cycle greater than 50 percent, a stabilizing

ramp is added to the output of the current

sense amplifier and the result is fed into the

positive input of the PWM generation

comparator. When this voltage equals the

output voltage of the error amplifier the main

power FET is turned off. Then the inductor

current flows through the free-wheeling diode,

which forces the inductor current to decrease.

The output voltage of the internal error amplifier

is an amplified signal of the difference between

the reference voltage and the feedback voltage.

The converter automatically chooses the lowest

active LEDX pin voltage to provide a highenough bus voltage to power all the LED arrays.

If the feedback voltage drops below the

reference, the output of the error amplifier

increases. It results in more current flowing

through the MOSFET, thus increasing the

MP3312 Rev. 1.1

12/7/2020

power delivered to the output. This forms a

closed loop that regulates the output voltage.

Dimming Control

MP3312 supports analog dimming and 1-wire

digital set dimming mode to regulate the WLED

current.

To do analog dimming, apply a PWM signal to

PWM pin by adjusting the LED current

amplitude. The internal filter is integrated and

the PWM signal with 5k~100kHz range is

supported. Internal dimming signal duty

detection circuit automatically changes the

internal reference lineally to regulate the current.

In addition, the EN pin supports 1-wire interface

to do current dimming control. The 1-wire

description and protocol details are as follow.

1-wire Interface

1-wire interface is based on master-slave

structure which is designed for digital dimming.

The EN pin is multipurpose as single port to

receive LED brightness data. The rate to detect

the bit can automatically range from

1.39kBit/sec to 50kBit/sec.

The command sent to chip (slave) contains 24

bits, 9-bit dimming data, 8-bit device address

and RFA bit are included. Chip detects the bit in

series and it transmits the LSB first and MSB

finally.

The control bits description is as below and

Figure 2 shows the command bytes structure in

detail.

D0-D8 are the dimming data bits which

achieve 9-bit dimming resolution

Bit9 and bit11-bit15 is reserved. Set to 0

RFA bit indicates master needs Request of

Acknowledge or not.

Device address byte is DA0-DA7. The

device address byte is set to 0x8F.

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

9

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

Address Byte

Data Byte

Data in

Start

D0

D1

D2

D3

D4

D5

D6

D7

D8

Bit9

0

RFA

bit11-bit15

(00000)

MSB

DA0 DA1 DA2 DA3 DA4 DA5 DA6 DA7

1

1

1

1

0

0

0

1

E0S

LSB

Figure 2—1-wire command structure

1-wire interface defines logic 0 and logic 1 by

comparing the time of the signal low level and

high level, 1 cycle means 1 logic bit. The bit

detection starts with a falling edge on the EN

pin and ends with the next falling edge. Shown

as Figure 3

Low logic (logic 0): tLOW≥3* tHIGH

1. Pulling VIN and PWM to high.

High logic (logic 1): tHIGH≥3* tLOW

2. Pulling data line from low to high for tDELAY (1wire detection delay time, 100us) and this

rising edge is the start of 1-wire detection

window.

tLOW

tHIGH

tHIGH

tLOW

The EN pin needs to distinguish EN signal and

digital dimming signal when set up boost driver.

Chip only receives 1-wire signal when EN pin

signal matches 1-wire protocol during 1ms 1wire detection window. 1-wire dimming

sequence is described as below, and shown in

Figure 4.

3. After 1-wire detection delay time, pulling data

line to low for more than tDETECTION (1-wire

detection time, 260us). Then pulling data

line to high.

Logic “1”

Logic “0”

Figure 3—1-Wire Bit Definition

4. The sum of 1-wire detection delay time and

1-wire detection time should be less than tWIN.

(The time of 1-wire detection window,1ms).

PWM

Detection

Window

Programming

Code

Programming

Code

Detection

Window

Interval

time

Programming

Code

EN

Detection

Time

Detection

Delay

ILED

Start Up Delay

Ramp

Up

Ramp Up

Shut Down

Delay

Figure 4—1-Wire Dimming Sequence

MP3312 Rev. 1.1

12/7/2020

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

10

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

In addition, before chip starts to receive each

command with first falling edge, data line should

keep high level for tSTART (min. 2us) time. which

The transmission of each command is completed

with low level for tEOS (min. 2us).Shown in Figure

5.

The ACK signal feedback to master or not is

dependent on RFA bit. If ACK is needed, the

master should have an open-drain output, and

data line should be pulled high by master with a

resistor load.

There is a counter (typical: 2MHz/13bits) to

measure the time of the high/low level in 1-Wire

interface. The counter keeps work in the interval

time between 2 commands, and it will recount

after time out in single level. For preventing the

mis-trigger, the counter of the interval time

should result at the value larger than 5, otherwise

the first bit of the next command will be missed. If

bit-missed happens, the bit-malposition will

happen in later communication process, and it

will cause 1-Wire communication fail (1-Wire

digital set dimming fail) since for the wrong

address byte. Increasing the tEOS will do help for

MP3312 to recover from communication failure

(when tEOS=300us, the communication fail will

recover soon)

tSTART

tEOS

Address Bits

Data Bits

Static High

Static High

Data In

D0

D8

Bit9

RFA=0

Bit15

DA0

DA7

Figure 5— Data-line Timing when RFA=0

tSTART

Data In

tACKval

Address Bits

Data Bits

Static High

Static High

D0

D8

Bit9

RFA=1

Bit15

DA0

DA7

tACK

ACK signal is “ture”.

Data line is pulled down by

slave

Data out

(ACK signal is “ true”)

Date line needs be pulled

high by master with

resistor load to detect ACK

signal

Data out

(ACK signal is “false”)

ACK signal is “false”.

Data line is not pulled down

by slave

Figure 6—Data-line Timing when RFA=1

If RFA=0, No ACK signal feedback. After all 24

bits data is transferred, data line keeps low for

MP3312 Rev. 1.1

12/7/2020

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

11

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

tEOS (min. 2us) delay, and then it is pulled to static

high. Shown as Figure 5.

If RFA=1, ACK signal feedback to master. After

all 24 bits data is transferred, the data line keeps

low for tACKval (max. 2us) time ,then data line

should be released to output high impedance and

master is ready to detect the ACK signal from

slave . After tACKval, if ACK “false” (1-wire data is

not received successfully), the data line will be

pulled to high directly. After tACKval, if ACK “ture”

(1-wire data is received successfully), data line

will be continuously pulled to low VACKL (max.

0.4V) by slave for tACK (max. 512us) time. The

master reads this low logic, it means chip

received 1-wire data successfully. Then the data

line is pulled to static high. Shown as Figure 6.

MP3312 has a 9-bit DAC for digital dimming

control and the dimming resolution is 1/511. The

default code value of D0 (LSB)-D8(MSB) is

“111111111” when the device is first enabled.

The LED current is dependent on the internal

register value D0-D8 according to below formula:

ILED ILEDfull

Unused LED Channel

In some cases, if one LED current channel is not

used, connect the corresponding LEDx to GND

to remove it from the control loop.

Short String Protection

The MP3312 monitors the LEDX pin voltage to

judge if the short string occurs. If one string is

short, the respective LEDX pin will be pulled up

to the boost output and tolerate high voltage

stress. If the LEDX pin voltage is higher than 5 V

and LED current is larger than 8% full-scale

setting current, the short string condition is

detected and if such condition lasts longer than

8ms, the fault string current source is disabled till

VIN and EN is reset for enable again.

Thermal Shutdown Protection

To prevent the IC operate at exceedingly high

temperature, thermal shutdown is implemented in

this chip by detecting the silicon die temperature.

When the die temperature exceeds the upper

threshold 150℃, the IC shutdowns and recovers

to normal operation when die temperature drops

below lower threshold. Typically, the hysteresis

value is 25°C.

code

511

ILEDfull is the full scale output current set by RISET

to ISET pin. Code is the DEC value of resolution

bit (D0-D8).

Cycle-by-Cycle Current Limit Protection

MP3312 provides cycle-by-cycle current limit

protection to avoid any damage due to too large

current rating. During startup, the current limit is

clamped to 1A for around 6ms to avoid output

overshoot and inrush current. After that, the

current limit returns back to normal 1.8A.

Open String Protection

Open string protection is achieved by detecting

the VOUT pin. If the LED string is open, the

feedback voltage is lower than the reference

voltage, thus the COMP rises up and keeps

charge the output capacitor until VOUT pin hits

the protection point VOVP. Then the IC stops

switching and shuts down till VIN and EN is reset

for enable again.

MP3312 Rev. 1.1

12/7/2020

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

12

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

APPLICATION INFORMATION

Setting the LED Current

The full scale LED current can be set through the

current setting resistor on the FB pin.

ILED(mA)

VISET (V)

* 1020

RISET (k)

For VISET=1.232V, RISET=63.4kΩ, the LED current

is set to 20mA. Please do not leave ISET pin

open.

Selecting the Input Capacitor

The input capacitor reduces the surge current

drawn from the input supply and the switching

noise from the device. The input capacitor

impedance at the switching frequency should be

much less than the input source impedance to

prevent the high-frequency switching current

from passing through to the input. Use ceramic

capacitors with X5R or X7R dielectrics for their

low ESR and small temperature coefficients. For

most applications, a 1uF~4.7μF ceramic

capacitor is ok.

Selecting the Inductor

The MP3312 requires an inductor to supply a

higher output voltage while being driven by the

input voltage. A larger value inductor results in

less ripple current, resulting in lower peak

inductor current and reducing stress on the

internal N-channel MOSFET. However, the larger

value inductor has a larger physical size, higher

series resistance, and lower saturation current.

Choose an inductor that does not saturate under

the worst-case load conditions. Select the

minimum inductor value to ensure that the boost

converter works in continuous conduction mode

with high efficiency and good EMI performance.

Calculate the required inductance value using the

equation:

η VOUT D (1 D)

2 fSW ILOAD

2

L

D 1

VIN

VOUT

Where VIN and VOUT are the input and output

voltages, fSW is the switching frequency, ILOAD is

the total LED load current, and η is the efficiency.

The switching current is used for the peak current

MP3312 Rev. 1.1

12/7/2020

mode control. In order to avoid hitting the current

limit, the worst-case inductor peak current should

be less than 80% of the current-limit ILIM.

Generally, a 4.7uH~10uH inductor is ok to cover

most of the applications. Note that the system

efficiency is dependent on the DC resistance of

inductor, and larger DC resistance causes larger

power loss.

Selecting the Output Capacitor

The output capacitor keeps the output voltage

ripple small and ensures feedback loop stability.

The output capacitor impedance must be low at

the switching frequency. Ceramic capacitors with

X7R dielectrics are recommended for their low

ESR characteristics. Care must be taken that

ceramic capacitance is also dependent on the

voltage rating; DC bias voltage and the value can

loss as much as 50% of its capacitance at its

rated voltage rating. Please leave enough

voltage rating margin when select the component.

In addition, too low capacitance will cause the

loop instability. For most applications, a

1μF~4.7μF ceramic capacitor is ok.

Selecting the External Schottky Diode

To optimize the efficiency, a high-speed and low

reverse recovery current schottky diode is

recommended. Make sure the diode’s average

and peak current rating exceeds the output

average LED current and the peak inductor

current. In addition, the diode’s break-down

voltage rating should be large than the maximum

voltage across the diode. Usually, unexpected

high frequency spike voltage can be seen across

the diode when the diode turns off. So, leaving

some voltage rating margin is always needed to

guarantee normal long term operation when

selecting a diode.

Layout Considerations

Careful attention must be paid to the PCB board

layout and components placement. Proper layout

of the high frequency switching path is critical to

prevent noise and electromagnetic interference

problems. The loop of MP3312’s internal low side

MOSFET, schottky diode, and output capacitor is

flowing with high frequency ripple current, it must

be minimized. So the input and output capacitor

should be placed to IC as close as possible.

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

13

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

TYPICAL APPLICATION CIRCUITS

L1

VIN

GND

D1

4.7uH

C2

1uF

C1

1uF

SW

IN

EN

PWM

EN

MP3312

PWM

LED1

LED2

COMP

ISET

C3

330nF

GND

R1

63.4k

Figure 7— Typical Application for dual string 6LEDs, 20mA/string

MP3312 Rev. 1.1

12/7/2020

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

14

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

PACKAGE INFORMATION

WLCSP1.35X1.35-9

PIN 1 ID

PIN 1 ID

MARKING

PIN 1 ID INDEX

AREA

BOTTOM VIEW

TOP VIEW

SIDE VIEW

NOTE:

1) ALL DIMENSIONS ARE IN MILLIMETERS.

2) BALL COPLANARITY SHALL BE 0.05

MILLIMETER MAX.

3) JEDEC REFERENCE IS MO-211,

VARIATION BC.

4) DRAWING IS NOT TO SCALE.

RECOMMENDED LAND PATTERN

MP3312 Rev. 1.1

12/7/2020

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

15

�MP3312 - 2.7V-5.5V INPUT, 38V OVP, DUAL-CHANNEL WHITE LED DRIVER

Revision History

Revision #

Revision date

1.1

12/7/2020

Description

add the explanation on the failure issue of 1-wire

communication

Pages

Updated

11

NOTICE: The information in this document is subject to change without notice. Please contact MPS for current specifications.

Users should warrant and guarantee that third party Intellectual Property rights are not infringed upon when integrating MPS

products into any application. MPS will not assume any legal responsibility for any said applications.

MP3312 Rev. 1.1

12/7/2020

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2020 MPS. All Rights Reserved.

16

�