KMA199

Programmable angle sensor

Rev. 2 — 7 December 2011

Product data sheet

1. Product profile

1.1 General description

The KMA199 is a magnetic angle sensor system. The MagnetoResistive (MR) sensor

bridges and the mixed signal Integrated Circuit (IC) are integrated into a single package.

This angular measurement system KMA199 is pre-programmed, pre-calibrated and

therefore, ready to use.

The KMA199 allows user specific adjustments of angular range, zero angle and clamping

voltages. The settings are stored permanently in an Electrically Erasable Programmable

Read-Only Memory (EEPROM).

1.2 Features and benefits

High precision sensor for magnetic

angular measurement

Automotive qualified in accordance with

AEC-Q100

Programmable user adjustments,

including zero angle and angular range

Fail-safe EEPROM

Independent from the magnetic field

strength above 35 kA/m

User-programmable 32-bit identifier

Ready to use

Ratiometric analog output voltage

Single package sensor system

High temperature range up to 160 C

Built-in transient protection

Programming via One-Wire Interface

(OWI)

Magnet-loss and power-loss detection

Factory calibrated

�KMA199

NXP Semiconductors

Programmable angle sensor

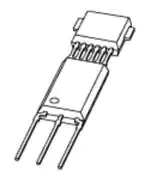

2. Pinning information

Table 1.

Pinning

Pin

Symbol

Description

1

VDD

supply voltage

2

GND

ground

3

OUT/DATA

analog output or data interface

Simplified outline

1

2

3

3. Ordering information

Table 2.

Ordering information

Type number

KMA199

KMA199

Product data sheet

Package

Name

Description

Version

-

plastic single-ended multi-chip package;

6 interconnections; 3 in-line leads

SOT880

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

2 of 36

�xxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx x xxxxxxxxxxxxxx xxxxxxxxxx xxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxx

xxxxx xxxxxx xx xxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxxxxxx xxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxx xxxxxxxxxxxxxx xxxxxx xx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxxxx x x

VDDS

VDDS

REGULATOR

VDDA

REGULATOR

VDDD

REGULATOR

LOGIC

VDD

POWER-ON

RESET

NXP Semiconductors

Vref

Iref

4. Functional diagram

KMA199

Product data sheet

VDDE

VSSE

VSSE

Rev. 2 — 7 December 2011

All information provided in this document is subject to legal disclaimers.

POWER

LOST

Cblock

VSINP

MUX

AMPLIFIER

VSINN

2

2

VCOSP

A

D

D

A

OUTPUT

BUFFER

VO

OUT/

DATA

VCOSN

VSSS

TP0

TP1

TEST CONTROL

Q_PUMP

POWER

LOST

TP2

ARRAY

EEPROM

DIGITAL FILTER

OFFSET

AND

CORRECTION

AVERAGING

CORDIC

ALGORITHM

OFFSET

CALCULATION

ANGULAR

RANGE

ADJUSTMENT

ONE-WIRE

INTERFACE

OSC

DIGITAL BLOCKS (LOGIC)

VSSE

magnetoresistive

sensor bridges

008aaa233

KMA199

Functional diagram of KMA199

internal

protection

diodes

Programmable angle sensor

3 of 36

© NXP B.V. 2011. All rights reserved.

Fig 1.

signal conditioning integrated circuit

GND

�KMA199

NXP Semiconductors

Programmable angle sensor

5. Functional description

The KMA199 amplifies two orthogonal differential signals which are delivered by MR

sensor bridges and converts them into the digital domain. The angle is calculated using

the COordinate Rotation DIgital Computer (CORDIC) algorithm. After a digital-to-analog

conversion the analog signal is provided to the output. Thus, the output is a linear

representation of the angular value. Zero angle, clamping voltages and angular range are

programmable. In addition, two 16-bit registers are available for customer purposes, like

sample identification.

The KMA199 comprises a Cyclic Redundancy Check (CRC) and an Error Detection and

Correction (EDC) supervision, as well as a magnet-loss detection to ensure a fail-safe

operation. A power-loss detection circuit pulls the analog output to the remaining supply

line, if either the supply voltage or the ground line is interrupted.

After multiplexing the two MR Wheatstone bridge signals and their successive

amplification, the signal is converted into the digital domain by an Analog-to-Digital

Converter (ADC). Further processing is done within an on-chip state machine. This

includes offset cancellation, calculation of the mechanical angle using the CORDIC

algorithm, as well as zero angle and angular range adjustment. The internal

Digital-to-Analog Converter (DAC) and the analog output stage are used for conversion of

the angle information into an analog output voltage, which is ratiometric to the supply

voltage.

The configuration parameters are stored in an user-programmable EEPROM. The OWI

(accessible using pin OUT/DATA) is used for accessing the memory.

5.1 Angular measurement directions

The differential signals of the MR sensor bridges depend only on the direction of the

external magnetic field strength Hext, which is applied parallel to the plane of the sensor.

In order to obtain a correct output signal, the minimum saturation field strength has to be

exceeded.

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

4 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

α

Hext

001aag741

Fig 2.

Angular measurement directions

Since the Anisotropic MR (AMR) effect is periodic over 180, the sensor output is also

180-periodic, where the angle is calculated relative to a freely programmable zero angle.

The dashed line indicates the mechanical zero degree position.

6. Analog output

The KMA199 provides one analog output signal on pin OUT/DATA. The measured angle

is converted linearly into a value, which is ratiometric to the supply voltage VDD. Either a

positive or a negative slope is provided for this purpose.

The following table describes the analog output behavior for a positive slope. If for

example, a magnetic field angle, above the programmed maximum angle max, but below

the clamp switch angle sw(CL) is applied to the sensor, then analog output is set to the

upper clamping voltage. If the magnetic field angle is larger than the clamp switch angle,

the analog output switches from upper to lower clamping voltage. In the case of a

negative slope, the clamping voltages are changed.

Table 3.

Analog output behavior for a positive slope

Magnetic field angle

Analog output

max < < sw(CL)

V(CL)u

sw(CL) < < ref + 180

V(CL)l

The analog output voltage range codes both angular and diagnostic information. A valid

angle value is between the upper and lower clamping voltage. If the analog output is in the

diagnostic range, that is below 4 %VDD or above 96 %VDD, an error condition has been

detected. The analog output repeats every 180.

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

5 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

VO

(%VDD)

αrng

V(CL)u

V(CL)I

0

αref

α (deg)

αmax

180

αsw(CL)

αref + 180°

001aag811

max = ref + rng

Fig 3.

Characteristic of the analog output

7. Diagnostic features

The KMA199 provides four diagnostic features:

7.1 EEPROM CRC and EDC supervision

The KMA199 system includes a supervision of the programmed data. At power-on, a CRC

of the EEPROM is performed. Furthermore the EEPROM is protected against bit errors.

Every 16-bit data word is saved internally as a 22-bit word for this purpose. The protection

logic corrects any single-bit error in a data word, while the sensor continues in normal

operation mode. Multiple bit errors per word will be detected and switches the device into

diagnostic mode.

7.2 Magnet-loss detection

If the applied magnetic field strength is not sufficient, the KMA199 raises a diagnostic

condition. In order to enter the diagnostic mode, due to EEPROM CRC or magnet-loss

detection, the device can be programmed into active diagnostic mode, where the output is

driven below 4 %VDD or above 96 %VDD.

7.3 Power-loss detection

The power-loss detection circuits enable the detection of an interrupted supply or ground

line of the KMA199. In the case of a power-loss condition, two internal switches in sensor

are closed, connecting the pin of the analog output with the supply voltage and the ground

pins.

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

6 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

KMA199

VDD

ZO(pl)

OUT/DATA

ZO(pl)

GND

008aaa234

Fig 4. Equivalent output circuit in case of a power-loss condition

Table 4 shows the resulting output voltage depending on the error case and the load

resistance.

Table 4.

Power-loss behavior

Load resistance

Supply voltage lost

Ground lost

RL > 5 k

VO 4 %VDD

VO 96 %VDD

7.4 Low supply voltage detection

If the supply voltage is below the switch-off threshold voltage, a status bit is set.

Table 5 describes the behavior of the analog output at different supply voltages.

Table 5.

Supply voltage behavior

Voltage range

Description

Analog output

0 V to 1.5 V

the output drives an active LOW, but the

switches of the power-loss detection circuits

are not fully opened and set the output to a

level between ground and half the supply

voltage

actively driven output to a

voltage level between ground

and half the supply voltage

1.5 V to VPOR

all modules begin to work and the power-on

reset is active

diagnostics at LOW level

VPOR to Vth(on) or

Vth(off)

all modules begin to work and the digital part is EEPROM defined diagnostic

initialized

level

Vth(on) or Vth(off) to analog output is switched on after power-on

4.5 V

time and represents the measured angle

4.5 V to 5.5 V

KMA199

Product data sheet

analog output of the

measured angle without the

specified accuracy

normal operation where the sensor works with analog output of the

the specified accuracy

measured angle

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

7 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

8. Limiting values

Table 6.

Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol

Parameter

VDD

supply voltage

Conditions

tinit < 200 h

Min

Max

Unit

0.3

+5.7

V

V

[1]

-

6.0

[2]

0.3

VDD + 0.3 V

-

150

mA

VO

output voltage

Ir

reverse current

Tamb

ambient temperature

40

+160

C

Tamb(pr)

programming ambient temperature

10

70

C

Tstg

storage temperature

40

+125

C

Tamb = 50 C

17

-

year

Tamb(pr) = 70 C

100

-

cycle

Min

Typ

Max

Unit

4.5

5.0

5.5

V

40

-

+160 C

Tamb < 70 C

EEPROM

tret(D)

data retention time

Nendu(W_ER) write or erase endurance

[1]

Time until sensor environment is initialized.

[2]

The maximum value of the output voltage is 5.7 V.

9. Recommended operating conditions

Table 7.

Operating conditions

In a homogenous magnetic field.

Symbol

Parameter

VDD

supply voltage

Tamb

ambient temperature

Conditions

[1]

Tamb(pr)

programming ambient temperature

10

-

70

C

CL

load capacitance

[2]

0

-

22

nF

Cblock

blocking capacitance

[3]

75

-

nF

RL

load resistance

[4]

5

-

k

Hext

external magnetic field strength

35

-

-

kA/m

[1]

Normal operating mode.

[2]

Between ground and analog output, as close as possible to the package for improved electromagnetic

immunity.

[3]

Between ground and supply voltage, as close as possible to the package and with a low equivalent series

resistance.

[4]

Power-loss detection is only possible with a load resistance within the specified range connected to the

supply or ground line.

10. Thermal characteristics

Table 8.

KMA199

Product data sheet

Thermal characteristics

Symbol

Parameter

Rth(j-a)

thermal resistance from junction to

ambient

Conditions

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

Typ

Unit

120

K/W

© NXP B.V. 2011. All rights reserved.

8 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

11. Characteristics

Table 9.

Supply current

Characteristics are valid for the operating conditions, as specified in Section 9.

Symbol

Parameter

Conditions

[1][2]

supply current

IDD

[1]

Normal operating mode.

[2]

Without load current at the analog output.

Min

Typ

Max

Unit

5

-

10

mA

Table 10. Power-on reset

Characteristics are valid for the operating conditions, as specified in Section 9.

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

Vth(on)

switch-on threshold

voltage

analog output switches on, if

VDD > Vth(on)

4.00

4.30

4.45

V

Vth(off)

switch-off threshold

voltage

analog output switches off, if

VDD < Vth(off)

-

4.20

4.30

V

Vhys

hysteresis voltage

Vhys = Vth(on) Vth(off)

0.1

-

0.4

V

VPOR

power-on reset voltage

IC is initialized

2.4

-

3.3

V

Table 11. System performance

Characteristics are valid for the operating conditions, as specified in Section 9.

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

[1]

res

angle resolution

-

-

0.04

deg

max

maximum angle

programmable angular range

for V(CL)u V(CL)l 80 %VDD

[2]

5

-

180

deg

ref

reference angle

programmable zero angle

[2]

0

-

180

deg

VO(nom)

nominal output voltage

at full supply operating range

5

-

95

%VDD

VO(udr)

upper diagnostic range

output voltage

[3]

96

-

100

%VDD

VO(ldr)

lower diagnostic range

output voltage

[3]

0

-

4

%VDD

V(CL)u

upper clamping voltage

[4]

40

-

95

%VDD

V(CL)l

lower clamping voltage

[4]

5

-

30.5

%VDD

V(CL)

clamping voltage variation

deviation from programmed

value

0.3

-

+0.3

%VDD

IO

output current

normal operation mode;

operating as sink or source

-

-

2

mA

Vn(o)(RMS)

RMS output noise voltage

equivalent power noise

lin

temp

linearity error

temperature drift error

KMA199

Product data sheet

[5]

-

0.4

2.5

mV

temperature range

40 C to +160 C

[5][6]

1.2

-

+1.2

deg

temperature range

40 C to +140 C

[5][6]

1

-

+1

deg

temperature range

40 C to +160 C

[1][5][6]

-

-

0.8

deg

temperature range

40 C to +140 C

[1][5][6]

-

-

0.65

deg

[7]

[7]

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

9 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

Table 11. System performance …continued

Characteristics are valid for the operating conditions, as specified in Section 9.

Symbol

tempRT

hys

lin

ang

Parameter

temperature drift error at

room temperature

hysteresis error

microlinearity error

angular error

mang

slope of angular error

ZO(pl)

power-loss output

impedance

Conditions

Min

Typ

Max

Unit

temperature range

40 C to +160 C

[6][7][8]

-

-

0.65

deg

temperature range

40 C to +140 C

[6][7][8]

-

-

0.55

deg

referred to input

[5][6]

-

-

0.09

deg

referred to input

[5][6]

0.1

-

+0.1

deg

temperature range

40 C to +160 C

[5][6][9]

1.35

-

+1.35

deg

temperature range

40 C to +140 C

[5][6][9]

1.1

-

+1.1

deg

[5][6][9]

-

-

0.04

deg/deg

-

-

210

impedance to remaining

supply line in case of lost

supply voltage or lost ground

[1]

At a nominal output voltage between 5 %VDD and 95 %VDD and a maximum angle of max = 180.

[2]

In steps of resolution < 0.022.

[3]

Activation is dependent on the programmed diagnostic mode.

[4]

In steps of 0.02 %VDD.

[5]

At a low-pass filtered analog output with a cut-off frequency of 0.7 kHz.

[6]

Definition of errors is given in Section 12.

[7]

Based on a 3 standard deviation.

[8]

Room temperature is given for an ambient temperature of 25 C.

[9]

Graph of angular error is shown in Figure 5.

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

10 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

1.40

1.35

|Δφang|

(deg)

1.10

(1)

(2)

0.75

0.65

0

−20

−16

−12.25

−1 0 1

12.25

20

16

α1 − α0 (deg)

001aal765

(1) 40 C to +160 C.

(2) 40 C to +140 C.

Fig 5.

Envelope curve for the magnitude of angular error

Table 12. Dynamics

Characteristics are valid for the operating conditions, as specified in Section 9.

Symbol

Parameter

Conditions

ton

turn-on time

fupd

update frequency

ts

settling time

tcmd(ent)

enter command mode time after power on

[1]

until first valid result

after an ideal mechanical

angle step of 45, until 90 %

of the final value is reached;

CL = 5 nF

Min

[1]

Typ

Max

Unit

-

-

5

ms

2

3.125

-

kHz

-

-

1.8

ms

16

-

26

ms

Min

Typ

Max

Unit

After reaching the power-on threshold voltage.

Table 13. Digital interface

Characteristics are valid for the operating conditions, as specified in Section 9.

Symbol

Parameter

VIH

HIGH-level input voltage

80

-

-

%VDD

VIL

LOW-level input voltage

-

-

20

%VDD

VOH

HIGH-level output voltage

IO = 2 mA

80

-

-

%VDD

VOL

LOW-level output voltage

IO = 2 mA

-

-

20

%VDD

Iod

overdrive current

absolute value for overdriving

the output buffer

-

-

20

mA

tstart

start time

LOW level before rising edge

5

-

-

s

KMA199

Product data sheet

Conditions

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

11 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

Table 13. Digital interface …continued

Characteristics are valid for the operating conditions, as specified in Section 9.

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

tstop

stop time

HIGH level before falling edge

5

-

-

s

Tbit

bit period

minimum period may be

limited by the load

capacitance

10

-

100

s

Tbit

bit period deviation

deviation between received

clock and sent clock

0.8Tbit

1Tbit

1.2Tbit

s

tw0

pulse width 0

0.175Tbit

0.25Tbit

0.375Tbit

s

tw1

pulse width 1

0.625Tbit

0.75Tbit

0.825Tbit

s

tto

time-out time

digital communication reset

guaranteed after maximum tto

-

-

220

s

ttko(slv)

slave takeover time

duration of LOW level for

slave takeover

1

-

5

s

ttko(mas)

master takeover time

duration of LOW level for

master takeover

0Tbit

-

0.5Tbit

s

tprog

programming time

for a single EEPROM address

20

-

-

ms

tcp

charge pump time

waiting time after enabling the

EEPROM charge pump clock

1

-

-

ms

12. Definition of errors

12.1 General

Angular measurement errors by the KMA199 result from linearity errors, temperature drift

errors and hysteresis errors. Figure 6 shows the output signal of an ideal sensor, where

the measured angle meas corresponds ideally to the magnetic field angle . This curve

will further be denoted as angle reference line ref() with a slope of 0.5 %VDD/deg.

φmeas

(deg)

φref(α)

180

α (deg)

001aag812

Fig 6. Definition of the reference line

The angular range is set to max = 180 and the clamping voltages are programmed to

V(CL)l = 5 %VDD and V(CL)u = 95 %VDD for a valid definition of errors.

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

12 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

12.2 Hysteresis error

The hysteresis error hys is defined as the maximum difference between the angles,

given by the device output when performing a positive (clockwise) rotation and negative

(counter clockwise) rotation over an angular range of 180, measured at a constant

temperature.

φmeas

(deg)

Δφhys

180

α (deg)

001aag813

Fig 7. Definition of the hysteresis error

Equation 1 gives the mathematical description for the hysteresis value hys:

hys() = meas( 180 ) – meas( 0 )

(1)

12.3 Linearity error

The KMA199 output signal deviation from a best straight line BSL, with the same slope as

the reference line, is defined as linearity error. The magnetic field angle is varied at fixed

temperatures for measurement of this linearity error. The output signal deviation from the

best straight line at the given temperature is the linearity error lin. It is a function of the

magnetic field angle and the temperature of the device Tamb.

φmeas

(deg)

φBSL(α, Tamb)

φref(α)

Δφlin(α, Tamb)

180

α (deg)

001aag814

Fig 8. Definition of the linearity error

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

13 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

12.4 Microlinearity error

The microlinearity error lin is the device output deviation from 1, if the magnetic field

angle is changed by = 1.

φmeas

(deg)

φref(α)

Δφmeas = 1° + Δφμlin(α)

Δα = 1°

α (deg)

001aag815

Fig 9. Definition of the microlinearity error

12.5 Temperature drift error

The temperature drift temp is defined as the envelope over the deviation of the angle

versus the temperature range. It is considered as the pure thermal effect.

φmeas

(deg)

Ty

Tx

Δφtemp

180

α (deg)

001aag816

Fig 10. Definition of the temperature drift error

Equation 2 gives the mathematical description for temperature drift value temp:

temp() = meas( , T x) – meas( , T y)

(2)

with:

Tx: temperature for maximum meas at angle

Ty: temperature for minimum meas at angle

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

14 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

The deviation from the value at room temperature tempRT describes the temperature

drift of the angle, compared to the value, which the sensor provides at room temperature:

temp

RT( ,

T amb) = meas( , T amb) – meas( , T RT)

(3)

with:

TRT: room temperature (25 C)

12.6 Angular error

The angular error ang is the error of angle difference measured by the sensor, if the

mechanical angle deviates from 0 to 1. Here 0 and 1 are arbitrary angles within the

angular range. The angle measurement at 0 is the initially programmed reference angle,

programmed by the customer at room temperature and zero hour upon production. The

angle measurement at 1 is made at any temperature within the ambient temperature

range:

ang = meas( 1 , T amb) – meas( 0 , T RT) – 1 – 0

(4)

with:

0, 1: arbitrary mechanical angles within the angular range

meas(0, TRT): programmed angle at 0, TRT = 25 C and zero hour upon production

meas(1, Tamb): angle measured by the sensor at 1 and any temperature within Tamb

This error comprises non-linearity and temperature drift related to the room temperature.

|Δφang|

mang

|Δφang(peak)|

|Δφμlin + Δφtemp|RT|

−α*

α0 − 1° α0 + 1°

α0

+α*

α1

001aal766

Fig 11. Definition of the angular error

Figure 11 shows the envelope curve for the magnitude of angular error |ang| versus 1

for all angles 0 and all temperatures Tamb within the ambient temperature range. |ang|

has its minimum, if 1 is in the range of 1 around 0. Here only the microlinearity error

lin and the temperature drift related to the room temperature |tempRT| occurs. If 1

deviates from 0 by more than 1 in either direction, |ang| can increase with a gradient

defined by slope mang.

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

15 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

Angular error can be expressed by Equation 5 to Equation 8:

for |1 0| 1

ang = lin + temp

(5)

RT

for 1 < |1 0| < *

ang = lin + temp

RT

+ m ang 1 – 0 – 1

(6)

RT

(7)

for |1 0| *

ang =

lin 2 + temp

2

with:

ang(peak) – lin + temp RT

= ----------------------------------------------------------------------------------- + 0 + 1

m ang

(8)

13. Programming

13.1 General description

The KMA199 provides an OWI to enable programming of the device which uses

pin OUT/DATA bidirectionally.

In general the device runs in analog output mode, the normal operating mode. This mode

is configured by the embedded programming data and is started after a power-on reset

once time ton has elapsed. In this mode, the magnetic field angle is converted into the

corresponding output voltage.

Command mode has to be entered to enable programming. In this mode, the customer

can adjust all required parameters (for example zero angle and angular range) to meet the

application requirements. After enabling the internal charge pump and waiting for tcp the

data is stored in the EEPROM. After changing the contents of the EEPROM, the

checksum must be recalculated and written (see Section 13.4).

In order to enter the command mode, a specific command sequence must be send after a

power-on reset and during the time slot tcmd(ent). The external source used to send the

command sequence must overdrive the output buffer of the KMA199 (I > Iod).

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

16 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

During communication, the KMA199 is always the slave and the external programming

hardware is the master. Figure 12 illustrates the structure of the OWI data format.

write

IDLE

START COMMAND DATA BYTE 1 DATA BYTE 2 STOP

IDLE

read

IDLE

START COMMAND HANDOVER DATA BYTE 1 DATA BYTE 2 TAKEOVER STOP IDLE

001aag742

Fig 12. OWI data format

The master provides the start condition, which is a rising edge after a LOW level. Then a

command byte which can be either a read or a write command is send. Depending on the

command, the master or the slave has to send the data immediately after the command

sequence. In the case of a read command, an additional handover or takeover bit is

inserted before and after the data bytes. Each communication must be closed with a stop

condition driven by the master. If the slave does not receive a rising edge for a time longer

than tto, a time-out condition occurs. The bus is reset to the idle state and waits for a start

condition and a new command. This can be used to synchronize the device regardless of

the previous state.

All communication is based on this structure (see Figure 12), even for entering the

command mode. In this case a special write command is required, followed by the

command sequence (two data bytes). The customer can access the EEPROM, CTRL1,

TESTCTRL0 and SIGNATURE registers (described in Section 13.5). Only a power-on

reset will leave the command mode. A more detailed description of the programming is

given in the next sections.

13.2 Timing characteristics

As described in the previous section, a start and stop condition is necessary for

communication. The LOW-level duration before the rising edge of the start condition is

defined as tstart. The HIGH-level duration after the rising edge of the stop condition is

defined as tstop. These parameters, together with all other timing characteristics are

shown in Table 13.

tstart

tstop

001aag817

Fig 13. OWI start and stop condition

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

17 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

Figure 14 shows the coding of a single bit with a HIGH level of VIH and a LOW level of VIL.

Here the pulse width t1 or t0 represents a logic 1 or a logic 0 of a full bit period Tbit,

respectively.

bit = 0

bit = 1

Tbit

0.175

Tbit

0.375

0.625

tw0

0.825

tw1

0.25

0.75

001aag818

Fig 14. OWI timing

13.3 Sending and receiving data

The master has to control the communication during sending or receiving data.

The command byte defines the region, address and type of command requested by the

master. In case of a read command, an additional handover or takeover bit must be

inserted before and after the two data bytes (see Figure 12). However the OWI is a serial

data transmission, whereas the Most Significant Byte (MSB) must be send at first.

Table 14.

Format of a command byte

7

6

5

4

3

2

1

0

CMD7

CMD6

CMD5

CMD4

CMD3

CMD2

CMD1

CMD0

Table 15.

Command byte bit description

Bit

Symbol

Description

7 to 5

CMD[7:5]

region bits

000 = 16-bit EEPROM

001 to 011 = reserved

100 = 16-bit register

101 to 111 = reserved

4 to 1

CMD[4:1]

address bits

0

CMD0

read/write

0 = write

1 = read

A more detailed description of all customer accessible registers is given in Section 13.5.

Both default value and the complete command including the address and write or read

request are also listed.

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

18 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

13.3.1 Write access

To write data to the EEPROM, the internal charge pump must be enabled by setting the

bits EEP_CP_CLOCK_EN and EEP_WRITE_EN and waiting for tcp. The following

procedure must be performed:

•

•

•

•

Start condition: The master drives a rising edge after a LOW level

Command: The master sends a write command (CMD0 = 0)

Data: The master sends two data bytes

Stop condition: The master drives a rising edge after a LOW level

Figure 15 shows the write access of the digital interface. The signal OWI represents the

data on the bus from the master or slave. The signals master output enable and slave

output enable just symbolize if the master or the slave output is enabled or disabled,

respectively.

START

CMD7

CMD0

WDATA15

WDATA0

STOP

IDLE

master

output

enable

OWI

(2)

slave

output

enable

(1)

001aag743

(1) Missing rising edges generate a time-out condition and the written data is ignored.

(2) If the master does not drive the bus, the bus is defined by the bus-pull.

Fig 15. OWI write access

Note: As already mentioned in Section 13.1, the command mode has to be entered using

the write procedure. If command mode is not entered, digital communication is not

possible and the sensor operates in normal operating mode. After changing an address,

the time tprog must elapse before changing another address. Finally the checksum must

be recalculated and written, after changing the contents of the EEPROM

(see Section 13.4).

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

19 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

13.3.2 Read access

To read data from the sensor, the following procedure must be performed:

• Start condition: The master drives a rising edge after a LOW level

• Command: The master sends a read command (CMD0 = 1)

• Handover: The master sends a handover bit, that is a logic 0 and disables the output

after a three-quarter bit period

• Takeover: The slave drives a LOW level after the falling edge for ttko(slv)

• Data: The slave sends two data bytes

• Handover: The slave sends a handover bit, that is a logic 0 and disables the output

after a three-quarter bit period

• Takeover: The master drives a LOW level after the falling edge for ttko(mas)

• Stop condition: The master drives a rising edge after a LOW level

Figure 16 shows the read access of the digital interface. The signal OWI represents the

data on the bus from the master or slave. The signals master output enable and slave

output enable just symbolize if the master or the slave output is enabled or disabled,

respectively.

START

CMD7

CMD0

HANDSHAKE

RDATA15

RDATA0

HANDSHAKE

STOP

IDLE

master

output

enable

(3)

OWI

(5)

(1)

slave

output

enable

(2)

(2)

(4)

001aag744

(1) Duration of LOW level for slave takeover ttko(slv).

(2) There is an overlap in the output enables of master and slave, because both drive a LOW level.

However this ensures the independency from having a pull-up or pull-down on the bus. In addition

it improves the ElectroMagnetic Compatibility (EMC) robustness, because all levels are actively

driven.

(3) Duration of LOW level for master takeover ttko(mas).

(4) If the master does not take over and a pull-up exists, the stop condition is generated by the pull-up.

Otherwise a time-out is generated if there is a pull-down and the slave waits for a rising edge as

start condition.

(5) If the master does not drive the bus, the bus is defined by the bus-pull.

Fig 16. OWI read access

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

20 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

13.3.3 Entering the command mode

After a power-on reset, the sensor provides a time slot tcmd(ent) for entering the command

mode. A specific command sequence has to be send (see Figure 17). If command mode

is not entered, the sensor starts in the normal operating mode. However the signature can

be written by the master, if the sensor switches to diagnostic mode.

During the command mode sequence, the analog output is enabled. The external

programming hardware has to overdrive the output with the current Iod. If command mode

is activated, the analog output is disabled and pin OUT/DATA operates as a digital

interface.

tcmd(ent)

VDD

OWI

START

94h

command

9Bh

A4h

STOP

signature

001aag819

Fig 17. OWI command mode procedure

13.4 Cyclic redundancy check

As already mentioned in Section 7, there is an 8-bit checksum for the EEPROM data.

To calculate this value, the CRC needs to be generated with the MSB of the EEPROM

data word at first over all corresponding addresses in increasing order.

All addresses from 0h to Fh have to be read out for calculating the checksum. The Least

Significant Byte (LSB) of address Fh which contains the previous checksum must be

overwritten with 0h before the calculation can be started.

Finally, the internal charge pump has to be enabled for programming by setting the bits

EEP_CP_CLOCK_EN and EEP_WRITE_EN (see Table 16) and waiting for tcp.

The generator polynomial for the calculation of the checksum is:

8

2

G(x) = x + x + x + 1

(9)

With a start value of FFh and the data bits are XOR at the x8 point.

KMA199

Product data sheet

All information provided in this document is subject to legal disclaimers.

Rev. 2 — 7 December 2011

© NXP B.V. 2011. All rights reserved.

21 of 36

�KMA199

NXP Semiconductors

Programmable angle sensor

13.4.1 Software example in C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

#include

// calc_crc accepts unsigned 16-bit data in data

int calc_crc(int crc, unsigned int data)

{

const int gpoly = 0x107; // generator polynomial

int i;

//index variable

for (i = 15; i >= 0; i--)

{

crc