ON Semiconductor

Is Now

To learn more about onsemi™, please visit our website at

www.onsemi.com

onsemi and and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates and/or

subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of onsemi

product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent-Marking.pdf. onsemi reserves the right to make changes at any time to any products or information herein, without

notice. The information herein is provided “as-is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the information, product features, availability, functionality,

or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products and applications using onsemi products, including compliance with all laws,

regulations and safety requirements or standards, regardless of any support or applications information provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/

or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application

by customer’s technical experts. onsemi does not convey any license under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized

for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for

implantation in the human body. Should Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees,

subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal Opportunity/Affirmative

Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner. Other names and brands may be claimed as the property of others.

�CS5301

Three−Phase

Buck Controller with

Integrated Gate Drivers and

Power Good

The CS5301 is a three−phase step down controller which

incorporates all control functions required to power high performance

processors and high current power supplies. Proprietary multi−phase

architecture guarantees balanced load current distribution and reduces

overall solution cost in high current applications. Enhanced V2t

control architecture provides the fastest possible transient response,

excellent overall regulation, and ease of use.

The CS5301 multi−phase architecture reduces output voltage and

input current ripple, allowing for a significant reduction in inductor

values and a corresponding increase in inductor current slew rate. This

approach allows a considerable reduction in input and output capacitor

requirements, as well as reducing overall solution size and cost.

Features

•

•

•

•

•

•

•

•

•

•

•

•

•

•

http://onsemi.com

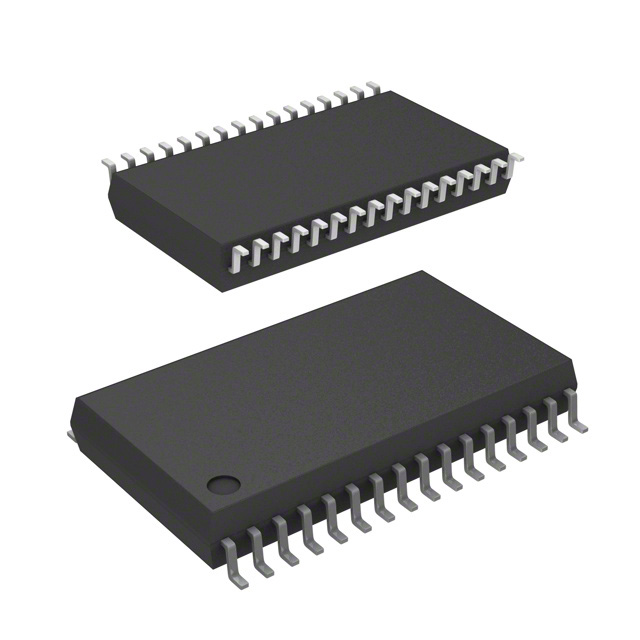

MARKING DIAGRAM

32

SO−32WB

CASE 751P

DW SUFFIX

CS5301

AWLYYWWG

1

32

A

WL

YY

WW

G

1

Enhanced V2 Control Method

5−Bit DAC with 1% Accuracy

Adjustable Output Voltage Positioning

6 On−Board Gate Drivers

200 kHz to 800 kHz Operation Set by Resistor

Current Sensed through Buck Inductors, Sense Resistors, or V−S

Control

Hiccup Mode Current Limit

Individual Current Limits for Each Phase

On−Board Current Sense Amplifiers

3.3 V, 1.0 mA Reference Output

5.0 V and/or 12 V Operation

On/Off Control (through COMP Pin)

Power Good Output

Pb−Free Package is Available*

= Assembly Location

= Wafer Lot

= Year

= Work Week

= Pb−Free Package

PIN CONNECTIONS

1

32

ROSC

VCCL

VCCL1

GATE(L)1

GND1

Gate(H)1

VCCH12

Gate(H)2

GND2

Gate(L)2

VCCL23

Gate(L)3

GND3

Gate(H)3

VCCH3

LGND

COMP

VFB

VDRP

CS1

CS2

CS3

CSREF

PWRGD

VID0

VID1

VID2

VID3

VID4

PWRGDS

ILIM

REF

ORDERING INFORMATION

Device

© Semiconductor Components Industries, LLC, 2006

February, 2006 − Rev. 12

1

Shipping †

CS5301GDW32

SO−32

22 Units/Rail

CS5301GDWR32

SO−32

1000 Tape & Reel

CS5301GDWR32G

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

Package

SO−32 1000 Tape & Reel

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

Publication Order Number:

CS5301/D

�CS5301

+12 V

+5.0 V

+12 V

D1

BAT54S

D3

BAT54S

L4

300 nH

D2

BAS16LT1

C12

1.0 nF

C1

1.0 mF

R10

10 K

C3

1.0 mF

C2

1.0 mF

+5.0 V

C11

1.0 nF

C4

R3

0.1 mF

56.2 K

C10

470 pF

R8

80.6 k

COMP

VFB

VDRP

CS1

CS2

CS3

CSREF

PWRGD

VID0

VID1

VID2

VID3

VID4

PWRGDS

ILIM

REF

CS5301

R11

10 k

+5.0 V

PWRGD

R12

20 K

VID0

VID1

VID2

Q1

CS1

L1

R4

1.0 W

C14

1.0 mF

U1

R9

19.1 k

+ C15,16

2 × 16SP180M

ROSC

VCCL

VCCL1

Gate(L)1

GND1

Gate(H)1

VCCH12

Gate(H)2

GND2

Gate(L)2

VCCL23

Gate(L)3

GND3

Gate(H)3

VCCH3

LGND

1.0 mF

Q2

C17−24

8 × 4SP560M

Q3

CS2

L2

1.0 mF

Q4

C25−32

8 × 10 mF

R1

VID3

VID4

Q5

C5

0.1 mF

3.09 k

R2

CS3

L3

R7

R5

30 k

R6

30 k

C6

.01 mF

CS1

VCORE

1.0 mF

1.40 k

Q6

30 k

C7

.01 mF

CS3

C8

.01 mF

CS2

C9

.01 mF

Q1−Q6, NTB85N03 or NTB85N03T4 by ON Semiconductor

Figure 1. Application Diagram for Intel Pentium® 4 Processor 12 V to 1.7 V, 42 A

MAXIMUM RATINGS*

Rating

Value

Unit

150

°C

−65 to +150

°C

ESD Susceptibility (Human Body Model)

2.0

kV

Thermal Resistance, Junction−to−Case, RqJC

14

°C/W

70

°C/W

230 peak

°C

Operating Junction Temperature

Storage Temperature Range

Thermal Resistance, Junction−to−Ambient, RqJA

Lead Temperature Soldering:

Reflow: (SMD styles only) (Note 1)

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously. If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

1. 60 second maximum above 183°C.

*The maximum package power dissipation must be observed.

http://onsemi.com

2

�CS5301

MAXIMUM RATINGS (continued)

Pin Name

Pin Symbol

VMAX

VMIN

ISOURCE

ISINK

VCCL

16 V

−0.3 V

N/A

70 mA DC

Power Good Sense

PWRGDS

6.0 V

−0.3 V

1.0 mA

1.0 mA

Power Good Output

PWRGD

6.0 V

−0.3 V

1.0 mA

20 mA

Return for Logic

LGND

N/A

N/A

2.0 A, 1.0 ms 200 mA DC

N/A

Power for Gate(L)1

VCCL1

16 V

−0.3 V

N/A

1.5 A, 1.0 ms 200 mA DC

Power for Gate(L)2 and Gate(L)3

VCCL23

16 V

−0.3 V

N/A

1.5 A, 1.0 ms 200 mA DC

Power for Gate(H)1 and

Gate(H)2

VCCH12

20 V

−0.3 V

N/A

1.5 A, 1.0 ms 200 mA DC

Power for Gate(H)3

VCCH3

20 V

−0.3 V

N/A

1.5 A, 1.0 ms 200 mA DC

Voltage Feedback Compensation

Network

COMP

6.0 V

−0.3 V

1.0 mA

1.0 mA

VFB

6.0 V

−0.3 V

1.0 mA

1.0 mA

Output for Adjusting Adaptive

Voltage Positioning

VDRP

6.0 V

−0.3 V

1.0 mA

1.0 mA

Frequency Resistor

ROSC

6.0 V

−0.3 V

1.0 mA

1.0 mA

Reference Output

REF

6.0 V

−0.3 V

1.0 mA

50 mA

High Side FET Drivers

GH1−3

20 V

−0.3 V DC

−2.0 V for

100 ns

1.5 A, 1.0 ms 200 mA DC

1.5 A, 1.0 ms 200 mA DC

Low Side FET Drivers

GL1−3

16 V

−0.3 V DC

−2.0 V for

100 ns

1.5 A, 1.0 ms 200 mA DC

1.5 A, 1.0 ms 200 mA DC

Return for #1 Driver

GND1

0.3 V

−0.3 V

2.0 A, 1.0 ms 200 mA DC

N/A

Return for #2 Driver

GND2

0.3 V

−0.3 V

2.0 A, 1.0 ms 200 mA DC

N/A

Return for #3 Driver

GND3

0.3 V

−0.3 V

2.0 A, 1.0 ms 200 mA DC

N/A

CS1−CS3

6.0 V

−0.3 V

1.0 mA

1.0 mA

ILIM

6.0 V

−0.3 V

1.0 mA

1.0 mA

Output Voltage

CSREF

6.0 V

−0.3 V

1.0 mA

1.0 mA

Voltage ID DAC Inputs

VID0−4

6.0 V

−0.3 V

1.0 mA

1.0 mA

Power for Logic

Voltage Feedback Input

Current Sense for Phases 1−3

Current Limit Set Point

ELECTRICAL CHARACTERISTICS (0°C < TA < 70°C; 0°C < TJ < 125°C; 4.7 V < VCCL < 14 V; 8.0 V < VCCH < 20 V;

CGATE(H) = 3.3 nF, CGATE(L) = 3.3 nF, RROSC = 53.6 k, CCOMP = 0.1 mF, CREF = 0.1 mF, DAC Code 10000, CVCC = 1.0 mF, ILIM ≥ 1.0 V;

unless otherwise specified.)

Characteristic

Test Conditions

Min

Typ

Max

Unit

± 1.0

%

Voltage Identification DAC (0 = Connected to GND; 1 = Open or Pullup to internal 3.3 V or external 5.0 V)

Accuracy (all codes)

VID code − 125 mV

Connect VFB to COMP,

Measure COMP

−

−

VID4

VID3

VID2

VID1

VID0

VID Voltage

DACOUT Voltage

−

1

1

1

1

1

−

FAULT Mode−Output Off

−

1

1

1

1

0

1.100

0.965

0.975

0.985

V

1

1

1

0

1

1.125

0.990

1.000

1.010

V

1

1

1

0

0

1.150

1.015

1.025

1.035

V

1

1

0

1

1

1.175

1.040

1.050

1.061

V

1

1

0

1

0

1.200

1.064

1.075

1.086

V

http://onsemi.com

3

�CS5301

ELECTRICAL CHARACTERISTICS (0°C < TA < 70°C; 0°C < TJ < 125°C; 4.7 V < VCCL < 14 V; 8.0 V < VCCH < 20 V;

CGATE(H) = 3.3 nF, CGATE(L) = 3.3 nF, RROSC = 53.6 k, CCOMP = 0.1 mF, CREF = 0.1 mF, DAC Code 10000, CVCC = 1.0 mF, ILIM ≥ 1.0 V;

unless otherwise specified.)

Characteristic

Test Conditions

Min

Typ

Max

Unit

Voltage Identification DAC (0 = Connected to GND; 1 = Open or Pullup to internal 3.3 V or external 5.0 V)

1

1

0

0

1

1.225

1.089

1.100

1.111

V

1

1

0

0

0

1.250

1.114

1.125

1.136

V

1

0

1

1

1

1.275

1.139

1.150

1.162

V

1

0

1

1

0

1.300

1.163

1.175

1.187

V

1

0

1

0

1

1.325

1.188

1.200

1.212

V

1

0

1

0

0

1.350

1.213

1.225

1.237

V

1

0

0

1

1

1.375

1.238

1.250

1.263

V

1

0

0

1

0

1.400

1.263

1.275

1.288

V

1

0

0

0

1

1.425

1.287

1.300

1.313

V

1

0

0

0

0

1.450

1.312

1.325

1.338

V

0

1

1

1

1

1.475

1.337

1.350

1.364

V

0

1

1

1

0

1.500

1.361

1.375

1.389

V

0

1

1

0

1

1.525

1.386

1.400

1.414

V

0

1

1

0

0

1.550

1.411

1.425

1.439

V

0

1

0

1

1

1.575

1.436

1.450

1.465

V

0

1

0

1

0

1.600

1.460

1.475

1.490

V

0

1

0

0

1

1.625

1.485

1.500

1.515

V

0

1

0

0

0

1.650

1.510

1.525

1.540

V

0

0

1

1

1

1.675

1.535

1.550

1.566

V

0

0

1

1

0

1.700

1.560

1.575

1.591

V

0

0

1

0

1

1.725

1.584

1.600

1.616

V

0

0

1

0

0

1.750

1.609

1.625

1.641

V

0

0

0

1

1

1.775

1.634

1.650

1.667

V

0

0

0

1

0

1.800

1.658

1.675

1.692

V

0

0

0

0

1

1.825

1.683

1.700

1.717

V

0

0

0

0

0

1.850

1.708

1.725

1.742

V

Input Threshold

VID4, VID3, VID2, VID1, VID0

1.00

1.25

1.50

V

Input Pullup Resistance

VID4, VID3, VID2, VID1, VID0

25

50

100

kW

3.15

3.30

3.45

V

Pullup Voltage

−

Power Good Output

Upper Threshold

Force PWRGDS

1.9 (−5%)

2.0

2.1 (+5%)

V

Lower Threshold

Force PWRGDS

0.95 × (VID

−125 mV)

or −2.6%

from nominal

PWRGD

Threshold

0.975 × (VID

−125 mV)

VID −125 mV

or +2.6%

from nominal

PWRGD

Threshold

V

0.926

0.951

0.975

V

VID4

VID3

VID2

VID1

VID0

1

1

1

1

0

−

http://onsemi.com

4

�CS5301

ELECTRICAL CHARACTERISTICS (0°C < TA < 70°C; 0°C < TJ < 125°C; 4.7 V < VCCL < 14 V; 8.0 V < VCCH < 20 V;

CGATE(H) = 3.3 nF, CGATE(L) = 3.3 nF, RROSC = 53.6 k, CCOMP = 0.1 mF, CREF = 0.1 mF, DAC Code 10000, CVCC = 1.0 mF, ILIM ≥ 1.0 V;

unless otherwise specified.)

Characteristic

Test Conditions

Min

Typ

Max

Unit

Power Good Output

1

1

1

0

1

−

0.950

0.975

1.000

V

1

1

1

0

0

−

0.974

1.000

1.025

V

1

1

0

1

1

−

0.998

1.024

1.050

V

1

1

0

1

0

−

1.021

1.048

1.075

V

1

1

0

0

1

−

1.045

1.073

1.100

V

1

1

0

0

0

−

1.069

1.097

1.125

V

1

0

1

1

1

−

1.093

1.122

1.150

V

1

0

1

1

0

−

1.116

1.146

1.175

V

1

0

1

0

1

−

1.140

1.170

1.200

V

1

0

1

0

0

−

1.164

1.195

1.225

V

1

0

0

1

1

−

1.188

1.219

1.250

V

1

0

0

1

0

−

1.211

1.243

1.275

V

1

0

0

0

1

−

1.235

1.268

1.300

V

1

0

0

0

0

−

1.259

1.292

1.325

V

0

1

1

1

1

−

1.283

1.316

1.350

V

0

1

1

1

0

−

1.306

1.341

1.375

V

0

1

1

0

1

−

1.330

1.365

1.400

V

0

1

1

0

0

−

1.354

1.389

1.425

V

0

1

0

1

1

−

1.378

1.414

1.450

V

0

1

0

1

0

−

1.401

1.438

1.475

V

0

1

0

0

1

−

1.425

1.463

1.500

V

0

1

0

0

0

−

1.449

1.487

1.525

V

0

0

1

1

1

−

1.473

1.511

1.550

V

0

0

1

1

0

−

1.496

1.536

1.575

V

0

0

1

0

1

−

1.520

1.560

1.600

V

0

0

1

0

0

−

1.544

1.584

1.625

V

0

0

0

1

1

−

1.568

1.609

1.650

V

0

0

0

1

0

−

1.591

1.633

1.675

V

0

0

0

0

1

−

1.615

1.658

1.700

V

0

0

0

0

0

−

1.639

1.682

1.725

V

Switch Leakage Current

PWRGD = 5.5 V

PWRGDS = 1.60 V

−

0.1

10.0

mA

Delay

PWRGDS low to PWRGD low

25

50

125

ms

Output Low Voltage

PWRGDS = 1.0 V

IPWRGD = 4.0 mA

−

0.15

0.40

V

http://onsemi.com

5

�CS5301

ELECTRICAL CHARACTERISTICS (0°C < TA < 70°C; 0°C < TJ < 125°C; 4.7 V < VCCL < 14 V; 8.0 V < VCCH < 20 V;

CGATE(H) = 3.3 nF, CGATE(L) = 3.3 nF, RROSC = 53.6 k, CCOMP = 0.1 mF, CREF = 0.1 mF, DAC Code 10000, CVCC = 1.0 mF, ILIM ≥ 1.0 V;

unless otherwise specified.)

Characteristic

Test Conditions

Min

Typ

Max

Unit

Voltage Feedback Error Amplifier

VFB Bias Current, (Note 2)

0.9 V < VFB < 1.8 V

5.5

6.0

6.5

mA

COMP Source Current

COMP = 0.5 V to 2.0 V;

VFB = 1.6 V; DAC = 00000

15

30

60

mA

COMP Sink Current

COMP = 0.5 V to 2.0 V;

VFB = 1.8 V; DAC = 00000

15

30

60

mA

0.20

0.27

0.34

V

−

32

−

mmho

−

2.5

−

MW

COMP Discharge Threshold Voltage

Transconductance

−

−10 mA < ICOMP < +10 mA

Output Impedance

−

Open Loop DC Gain

Note 3.

60

90

−

dB

Unity Gain Bandwidth

0.01 mF COMP Capacitor

−

400

−

kHz

−

70

−

dB

PSRR @ 1.0 kHz

−

COMP Max Voltage

VFB = 1.65 V COMP Open;

DAC = 00000

2.4

2.7

−

V

COMP Min Voltage

VFB = 1.8 V COMP Open;

DAC = 00000

−

0.1

0.2

V

−

2

5.0

10

mA

Minimum Pulse Width

Measured from CSx to GATE(H),

V(VFB) = V(CSREF) = 0 V,

V(COMP) = 0.5 V, 60 mV step

applied between VCSX and VCREF

−

350

515

ns

Channel Startup Offset

V(CS1) = V(CS2) = V(CS3) =

V(VFB) = V(CSREF) = 0 V;

Measure V(COMP) when

GATE1(H), 2(H), 3(H) switch high

0.3

0.4

0.5

V

Hiccup Latch Discharge Current

PWM Comparators

GATE(H) and GATE(L)

High Voltage (AC)

(Note 3). Measure VCCLX −

GATE(L)

or VCCHX − GATE(H)

−

0

1.0

V

Low Voltage (AC)

(Note 3). Measure GATE(L)

or GATE(H)

−

0

0.5

V

Rise Time GATE(H)x

1.0 V < GATE < 8.0 V; VCCHX = 10 V

−

35

80

ns

Rise Time GATE(L)x

1.0 V < GATE < 8.0 V; VCCLX = 10 V

−

35

80

ns

Fall Time GATE(H)x

8.0 V > GATE > 1.0 V; VCCHX = 10 V

−

35

80

ns

Fall Time GATE(L)x

8.0 V > GATE > 1.0 V; VCCLX = 10 V

−

35

80

ns

GATE(H) to GATE(L) Delay

GATE(H) < 2.0 V, GATE(L) > 2.0 V

30

65

110

ns

GATE(L) to GATE(H) Delay

GATE(L) < 2.0 V, GATE(H) > 2.0 V

30

65

110

ns

GATE Pull−down

Force 100 mA into GATE Driver

with VCCHX = VCCLX = 2.0 V

−

1.2

1.6

V

2. The VFB Bias Current changes with the value of RROSC per Figure 4.

3. Guaranteed by design. Not tested in production.

http://onsemi.com

6

�CS5301

ELECTRICAL CHARACTERISTICS (0°C < TA < 70°C; 0°C < TJ < 125°C; 4.7 V < VCCL < 14 V; 8.0 V < VCCH < 20 V;

CGATE(H) = 3.3 nF, CGATE(L) = 3.3 nF, RROSC = 53.6 k, CCOMP = 0.1 mF, CREF = 0.1 mF, DAC Code 10000, CVCC = 1.0 mF, ILIM ≥ 1.0 V;

unless otherwise specified.)

Characteristic

Test Conditions

Min

Typ

Max

Unit

Switching Frequency

Measure any phase (RROSC = 32.4 k)

(Note 4)

300

400

500

kHz

Switching Frequency

Measure any phase (RROSC = 53.6 k)

220

250

280

kHz

Switching Frequency

Measure any phase (RROSC = 16.2 k)

(Note 4)

600

800

1000

kHz

ROSC Voltage

−

−

1.00

−

V

Phase Delay

−

105

120

135

deg

Oscillator

Adaptive Voltage Positioning

VDRP Output Voltage to DACOUT Offset

CS1 = CS2 = CS3 = CSREF,

VFB = COMP,

Measure VDRP− COMP

−15

−

15

mV

Maximum VDRP Voltage

|(CS1 = CS2 = CS3) = CSREF| =

50 mV, VFB = COMP,

|Measure VDRP− COMP|

360

465

570

mV

−

2.7

3.1

3.5

V/V

−

−

0.6

2.0

mA

−

0.2

2.0

mA

3.7

4.2

4.7

V/V

−5.0

−

5.0

mV

0

−

VCCL − 2.0

V

Current Sense Amp to VDRP Gain

Current Sensing and Sharing

CSREF Input Bias Current

CS1−CS3 Input Bias Current

V(CSx) = V(CSREF) = 0 V

Current Sense Amplifiers Gain

−

Current Sense Amp Mismatch

0 V ≤ (CSx−CSREF) ≤ 50 mV

Current Sense Amplifiers Input

Common Mode Range Limit

(Note 4)

Current Sense Input to ILIM Gain

0.25 V < ILIM < 1.20 V

5.0

6.5

8.0

V/V

Current Limit Filter Slew Rate

(Note 4)

4.0

10

26

mV/ms

ILIM Bias Current

0 V < ILIM < 1.0 V

−

0.1

1.0

mA

−

75

90

115

mV

(Note 4)

1.0

−

−

MHz

0 mA < I(VREF) < 1.0 mA

3.15

3.25

3.35

V

Single Phase Pulse by Pulse Current

Limit: V(CSx) − V(CSREF)

Current Sense Amplifier Bandwidth

Reference Output

VREF Output Voltage

4. Guaranteed by design. Not tested in production.

http://onsemi.com

7

�CS5301

ELECTRICAL CHARACTERISTICS (0°C < TA < 70°C; 0°C < TJ < 125°C; 4.7 V < VCCL < 14 V; 8.0 V < VCCH < 20 V;

CGATE(H) = 3.3 nF, CGATE(L) = 3.3 nF, RROSC = 53.6 k, CCOMP = 0.1 mF, CREF = 0.1 mF, DAC Code 10000, CVCC = 1.0 mF, ILIM ≥ 1.0 V;

unless otherwise specified.)

Characteristic

Test Conditions

Min

Typ

Max

Unit

General Electrical Specifications

VCCL Operating Current

VFB = COMP(no switching)

−

22

26

mA

VCCL1 Operating Current

VFB = COMP(no switching)

−

4.0

5.5

mA

VCCL23 Operating Current

VFB = COMP(no switching)

−

8.0

11

mA

VCCH12 Operating Current

VFB = COMP(no switching)

−

5.5

7.0

mA

VCCH3 Operating Current

VFB = COMP(no switching)

−

2.5

3.5

mA

VCCL Start Threshold

GATEs switching, COMP charging

4.05

4.50

4.70

V

VCCL Stop Threshold

GATEs stop switching, COMP

discharging

3.75

4.30

4.60

V

VCCL Hysteresis

GATEs not switching, COMP not

charging

100

200

300

mV

VCCH12 Start Threshold

−

3.2

3.5

3.8

V

VCCH12 Stop Threshold

−

2.9

3.2

3.5

V

VCCH12 Start Hysteresis

−

200

300

400

mV

http://onsemi.com

8

�CS5301

PACKAGE PIN DESCRIPTION

PACKAGE PIN #

PIN SYMBOL

FUNCTION

1

COMP

2

VFB

Voltage Feedback Pin. To use Adaptive Voltage Positioning (AVP) select an

offset voltage at light load and connect a resistor between VFB and VOUT. The

input bias current of the VFB pin and the resistor value determine output voltage

offset for zero output current. Short VFB to VOUT for no AVP.

3

VDRP

Current sense output for AVP. The offset of this pin above the DAC voltage is

proportional to the output current. Connect a resistor from this pin to VFB to set

amount AVP or leave this pin open for no AVP.

4−6

CS1−CS3

7

CSREF

8

PWRGD

Power Good Output. Open collector output goes low when CSREF is out of

regulation.

9−13

VID4−VID0

Voltage ID DAC inputs. These pins are internally pulled up to 3.3 V if left open.

14

PWRGDS

Power Good Sense. Connect to Output.

15

ILIM

Sets threshold for current limit. Connect to reference through a resistive divider.

16

REF

Reference output. Decouple with 0.1 mF to LGND.

17

LGND

Return for internal control circuits and IC substrate connection.

18

VCCH3

Power for GATE(H)3.

19

Gate(H)3

20

GND3

21

Gate(L)3

22

VCCL23

23

Gate(L)2

Low side driver #2.

24

GND2

Return for #2 driver.

25

Gate(H)2

High side driver #2.

26

VCCH12

27

Gate(H)1

28

GND1

Return #1 drivers.

29

Gate(L)1

Low side driver #1.

30

VCCL1

Power for GATE(L)1.

31

VCCL

Power for internal control circuits and UVLO Sense for Logic.

32

ROSC

A resistor from this pin to ground sets operating frequency and VFB bias current.

Output of the error amplifier and input for the PWM comparators.

Current sense inputs. Connect current sense network for the corresponding

phase to each input.

Reference for current sense amplifiers. To balance input offset voltages between

the inverting and noninverting inputs of the Current Sense Amplifiers, connect a

resistor between CSREF and the output voltage. The value should be 1/3 of the

value of the resistors connected to the CSx pins.

High side driver #3.

Return for #3 drivers.

Low side driver #3.

Power for GATE(L)2 and GATE(L)3.

Power for GATE(H)1 and GATE(H)2. UVLO Sense for High Side Driver supply

connects to this pin.

High side driver #1.

http://onsemi.com

9

�CSREF

CS3

CS2

CS1

PWRGDS

PWRGD

VID4

VID3

VID2

VID1

VID0

+

×4

CSA3

−

+

CSA2

−

+

CSA1

−

S

CO3

CO2

CO1

R

RESC

LGND

DAC X

97.5 %

−

2.0 V +

−

OVIC

× 1.5

3.5 V

3.2 V

+

+

+

START

STOP

START

STOP

4.5 V

4.3 V

−

−

125 mV

−

+

DACOUT

−

+

DLY

FAULT

DAC

3.3 V

REF

Set

Dominant

VCCH12

−

5.0 mA

2

FAULT

−

× 0.75

AVPA

+

1

DACOUT

VITotal

0.25 V

+

VDRP

−

+

−

−

+

−

MAXC2

+

0.4 V

−

EA

PH3

PH2

PH1

S

R

S

R

R

OSC

Current

Source

Gen

PH 3

PH 2

PH 1

Gate

Nonoverlap

Gate

Nonoverlap

VCCH3

Gate

Nonoverlap

S

VCCH12

VFB ROSC

FAULT

FAULT

FAULT

VCCL23

DACOUT

MAXC3

+

0.4 V

CO3

−

+

CO2

−

−

MAXC1

+

0.4 V

CO1

+

2

FAULT

1

+

PWMC3

−

+

PWMC2

COMP

0.4 V

CO3

CO2

CO1

+

PWMC1

−

VCCL1

Reset

Dominant

Reset

Dominant

REF

+

−

+

−

VCCL

+

10

Reset

Dominant

−

VCCL

+

http://onsemi.com

+

−

Figure 2. Block Diagram

−

VCCL

BIAS

VCCL23

VCCH3

VCCL23

VCCH12

VCCL1

VCCH12

GND3

Gate(L)3

Gate(H)3

GND2

Gate(L)2

Gate(H)2

GND1

Gate(L)1

Gate(H)1

ILIM

CS5301

�CS5301

TYPICAL PERFORMANCE CHARACTERISTICS

900

25

VFB Bias Current, mA

800

Frequency, kHz

700

600

500

400

300

20

15

10

5

200

100

10

20

30

40

50

60

0

10

70

20

30

RROSC Value, kW

60

70

80

Figure 4. VFB Bias Current vs. RROSC Value

120

120

100

100

80

80

Time, ns

Time, ns

50

RROSC Value, kW

Figure 3. Oscillator Frequency

60

60

40

40

20

20

0

0

0

2

4

6

8

10

12

14

0

16

2

4

6

8

10

12

14

16

Load Capacitance, nF

Load Capacitance, nF

Figure 5. Gate(H) Rise−time vs. Load Capacitance

measured from 1.0 V to 4.0 V with VCC at 5.0 V.

Figure 6. Gate(H) Fall−time vs. Load Capacitance

measured from 4.0 V to 1.0 V with VCC at 5.0 V.

120

120

100

100

80

80

Time, ns

Time, ns

40

60

60

40

40

20

20

0

0

0

2

4

6

8

10

12

14

16

0

2

4

6

8

10

12

14

16

Load Capacitance, nF

Load Capacitance, nF

Figure 7. Gate(L) Rise−time vs. Load Capacitance

measured from 4.0 V to 1.0 V with VCC at 5.0 V.

Figure 8. Gate(L) Fall−time vs. Load Capacitance

measured from 4.0 V to 1.0 V with VCC at 5.0 V.

http://onsemi.com

11

�CS5301

APPLICATIONS INFORMATION

FIXED FREQUENCY MULTI−PHASE CONTROL

current increases the voltage on the positive pin of the PWM

comparator rises and terminates the PWM cycle. If the

inductor starts the cycle with a higher current, the PWM

cycle will terminate earlier providing negative feedback.

The CS5301 provides a CSx input for each phase, but the

CSREF, VFB and COMP inputs are common to all phases.

Current sharing is accomplished by referencing all phases to

the same VFB and COMP pins, so that a phase with a larger

current signal will turn off earlier than phases with a smaller

current signal.

Including both current and voltage information in the

feedback signal allows the open loop output impedance of

the power stage to be controlled. If the COMP pin is held

steady and the inductor current changes, there must also be

a change in the output voltage. Or, in a closed loop

configuration when the output current changes, the COMP

pin must move to keep the same output voltage. The required

change in the output voltage or COMP pin depends on the

scaling of the current feedback signal and is calculated as

In a multi−phase converter, multiple converters are

connected in parallel and are switched on at different times.

This reduces output current from the individual converters

and increases the apparent ripple frequency. Because several

converters are connected in parallel, output current can ramp

up or down faster than a single converter (with the same

value output inductor) and heat is spread among multiple

components.

The CS5301 uses a three−phase, fixed frequency,

Enhanced V2 architecture. Each phase is delayed 120° from

the previous phase. Normally GATE(H) transitions high at

the beginning of each oscillator cycle. Inductor current

ramps up until the combination of the current sense signal

and the output ripple trip the PWM comparator and bring

GATE(H) low. Once GATE(H) goes low, it will remain low

until the beginning of the next oscillator cycle. While

GATE(H) is high, the enhanced V2 loop will respond to line

and load transients. Once GATE(H) is low, the loop will not

respond again until the beginning of the next cycle.

Therefore, constant frequency Enhanced V2 will typically

respond within 1/3 of the off−time for a three−phase

converter.

The Enhanced V2 architecture measures and adjusts

current in each phase. An additional input (CSx) for inductor

current information has been added to the V2 loop for each

phase as shown in Figure 9.

SWNODE

L

RL

CSX

+

CSA

RS

OFFSET

CSREF

+

CSA Gain.

V

* VFB * VOFFSET

Ipkout (per phase) + COMP

RS CSA Gain

+

PWM

COMP

Figure 10 shows the step response of a single phase with the

COMP pin at a fixed level. Before T1 the converter is in

normal steady state operation. The inductor current provides

the PWM ramp through the Current Share Amplifier. The

PWM cycle ends when the sum of the current signal, voltage

signal and OFFSET exceed the level of the COMP pin. At T1

the output current increases and the output voltage sags. The

next PWM cycle begins and the cycle continues longer than

previously while the current signal increases enough to make

up for the lower voltage at the VFB pin and the cycle ends at

T2. After T2 the output voltage remains lower than at light

load and the current signal level is raised so that the sum of

the current and voltage signal is the same as with the original

load. In a closed loop system the COMP pin would move

higher to restore the output voltage to the original level.

VFB

DACOUT

DI

The multi−phase power stage output impedance is the

single−phase output impedance divided by the number of

phases. The output impedance of the power stage determines

how the converter will respond during the first few ms of a

transient before the feedback loop has repositioned the

COMP pin.

The peak output current of each phase can also be

calculated from;

+

+

CSA Gain

Single Stage Impedance + DVńDI + RS

+

+

VOUT

DV + RS

The single−phase power stage output impedance is:

E.A.

+

COMP

Figure 9. Enhanced V2 Feedback and Current

Sense Scheme

The inductor current is measured across RS, amplified by

CSA and summed with the OFFSET and Output Voltage at

the non−inverting input of the PWM comparator. The

inductor current provides the PWM ramp and as inductor

http://onsemi.com

12

�CS5301

considered when setting the ILIM threshold. If a more

accurate current sense is required than inductive sensing can

provide, current can be sensed through a resistor as shown

in Figure 9.

SWNODE

Current Sharing Accuracy

VFB (VOUT)

PCB traces that carry inductor current can be used as part

of the current sense resistance depending on where the

current sense signal is picked off. For accurate current

sharing, the current sense inputs should sense the current at

the same point for each phase and the connection to the

CSREF should be made so that no phase is favored. (In some

cases, especially with inductive sensing, resistance of the

pcb can be useful for increasing the current sense

resistance.) The total current sense resistance used for

calculations must include any pcb trace between the CSx

inputs and the CSREF input that carries inductor current.

Current Sense Amplifier Input Mismatch and the value of

the current sense element will determine the accuracy of

current sharing between phases. The worst case Current

Sense Amplifier Input Mismatch is 5.0 mV and will

typically be within 3.0 mV. The difference in peak currents

between phases will be the CSA Input Mismatch divided by

the current sense resistance. If all current sense elements are

of equal resistance a 3.0 mV mismatch with a 2.0 mW sense

resistance will produce a 1.5 A difference in current between

phases.

CSA Out

COMP − Offset

CSA Out + VFB

T1

T2

Figure 10. Open Loop Operation

Inductive Current Sensing

For lossless sensing, current can be sensed across the

inductor as shown in Figure 11. In the diagram L is the output

inductance and RL is the inherent inductor resistance. To

compensate the current sense signal the values of R1 and C1

are chosen so that L/RL = R1 × C1. If this criteria is met the

current sense signal will be the same shape as the inductor

current, the voltage signal at CSx will represent the

instantaneous value of inductor current and the circuit can be

analyzed as if a sense resistor of value RL was used as a sense

resistor (RS).

Operation at > 50% Duty Cycle

For operation at duty cycles above 50% Enhanced V2 will

exhibit subharmonic oscillation unless a compensation

ramp is added to each phase. A circuit like the one on the left

side of Figure 12 can be added to each current sense network

to implement slope compensation. The value of R1 can be

varied to adjust the ramp size.

R1

SWNODE

CSX

L

C1

RL

VOUT

+

CSA

OFFSET

CSREF

+

+

+

+

PWM

COMP

DACOUT

Switch Node

Gate(L)X

VFB

E.A.

+

COMP

R1

3.0 k

Figure 11. Lossless Inductive Current Sensing with

Enhanced V2

25 k

CSX

1.0 nF

When choosing or designing inductors for use with

inductive sensing tolerances and temperature effects should

be considered. Cores with a low permeability material or a

large gap will usually have minimal inductance change with

temperature and load. Copper magnet wire has a

temperature coefficient of 0.39% per °C. The increase in

winding resistance at higher temperatures should be

0.1 mF

.01 mF

CSREF

MMBT2222LT1

Slope Comp

Circuit

Existing Current

Sense Circuit

Figure 12. External Slope Compensation Circuit

http://onsemi.com

13

�CS5301

Ramp Size and Current Sensing

Because the current ramp is used for both the PWM ramp

and to sense current, the inductor and sense resistor values

will be constrained. A small ramp will provide a quick

transient response by minimizing the difference over which

the COMP pin must travel between light and heavy loads,

but a steady state ramp of 25 mVp−p or greater is typically

required to prevent pulse skipping and minimize pulse width

jitter. For resistive current sensing, the combination of the

inductor and sense resistor values must be chosen to provide

a large enough steady state ramp. For large inductor values

the sense resistor value must also be increased.

For inductive current sensing, the RC network must meet

the requirement of L/RL = R × C to accurately sense the AC

and DC components of the current the signal. Again the

values for L and RL will be constrained in order to provide

a large enough steady state ramp with a compensated current

sense signal. A smaller L, or a larger RL than optimum might

be required. But unlike resistive sensing, with inductive

sensing, small adjustments can be made easily with the

values of R and C to increase the ramp size if needed.

If RC is chosen to be smaller (faster) than L/RL, the AC

portion of the current sensing signal will be scaled larger

than the DC portion. This will provide a larger steady state

ramp, but circuit performance will be affected and must be

evaluated carefully. The current signal will overshoot during

transients and settle at the rate determined by R × C. It will

eventually settle to the correct DC level, but the error will

decay with the time constant of R × C. If this error is

excessive it will effect transient response, adaptive

positioning and current limit. During transients the COMP

pin will be required to overshoot along with the current

signal in order to maintain the output voltage. The VDRP pin

will also overshoot during transients and possibly slow the

response. Single phase overcurrent will trip earlier than it

would if compensated correctly and hiccup mode current

limit will have a lower threshold for fast rise step loads than

for slowly rising output currents.

The waveforms in Figure 13 show a simulation of the

current sense signal and the actual inductor current during a

positive step in load current with values of L = 500 nH,

RL = 1.6 mW, R1 = 20 k and C1 = .01 mF. For ideal current

signal compensation the value of R1 should be 31 kW. Due to

the faster than ideal RC time constant there is an overshoot of

50% and the overshoot decays with a 200 ms time constant.

With this compensation the ILIM pin threshold must be set

more than 50% above the full load current to avoid triggering

hiccup mode during a large output load step.

Figure 13. Inductive Sensing waveform during a Step

with Fast RC Time Constant (50 ms/div)

Current Limit

Two levels of overcurrent protection are provided. Any

time the voltage on a Current Sense pin exceeds CSREF by

more than the Single Phase Pulse by Pulse Current Limit, the

PWM comparator for that phase is turned off. This provides

fast peak current protection for individual phases. The

outputs of all the currents are also summed and filtered to

compare an averaged current signal to the voltage on the

ILIM pin. If this voltage is exceeded, the fault latch trips and

the Soft Start capacitor is discharged by a 5.0 mA source

until the COMP pin reaches 0.2 V. Then Soft Start begins.

The converter will continue to operate in this mode until the

fault condition is corrected.

Overvoltage Protection

Overvoltage protection (OVP) is provided as a result of

the normal operation of the Enhanced V2 control topology

with synchronous rectifiers. The control loop responds to an

overvoltage condition within 400 ns, causing the top

MOSFET’s to shut off and the synchronous MOSFET’s to

turn on. This results in a “crowbar” action to clamp the

output voltage and prevent damage to the load. The regulator

will remain in this state until the overvoltage condition

ceases or the input voltage is pulled low.

http://onsemi.com

14

�CS5301

UVLO

voltage is not repositioned quickly enough after current is

stepped up and the upper limit is exceeded.

The CS5301 has undervoltage lockout functions connected

to two pins. One intended for the logic and low−side drivers

with a 4.5 V turn−on threshold is connected to the VCCL pin.

A second for the high side drivers has a 3.5 V threshold and

is connected to the VCCH12 pin.

The UVLO threshold for the high side drivers was chosen

at a low value to allow for flexibility in the part. In many

applications this function will be disabled or will only check

that the applicable supply is on − not that is at a high enough

voltage to run the converter.

For the 12 VIN converter (see Figure 1) the UVLO pin for

the high side driver is pulled up by the 5.0 V supply (through

two diode drops) and the function is not used. The diode

between the COMP pin and the 12 V supply holds the COMP

pin near GND and prevents start−up while the 12 V supply

is off. In an application where a higher UVLO threshold is

necessary a circuit like the one in Figure 15 will lock out the

converter until the 12 V supply exceeds 8.0 V.

Normal

Fast Adaptive Positioning

Slow Adaptive Positioning

Limits

Figure 14. Adaptive Positioning

The CS5301 uses two methods to provide fast and

accurate adaptive positioning. For low frequency

positioning the VFB and VDRP pins are used to adjust the

output voltage with varying load currents. For high

frequency positioning, the current sense input pins can be

used to control the power stage output impedance. The

transition between fast and slow positioning is adjusted by

the error amp compensation.

The CS5301 can be configured to adjust the output

voltage based on the output current of the converter, as

shown in Figure 1.

To set the no−load positioning, a resistor (R9) is placed

between the output voltage and VFB pin. The VFB bias

current will develop a voltage across the resistor to decrease

the output voltage. The VFB bias current is dependent on the

value of RROSC, as shown in Figure 4.

During no load conditions the VDRP pin is at the same

voltage as the VFB pin, so none of the VFB bias current flows

through the VDRP resistor (R8). When output current

increases the VDRP pin increases proportionally and the

VDRP pin current offsets the VFB bias current and causes the

output voltage to further decrease.

The VFB and VDRP pins take care of the slower and DC

voltage positioning. The first few ms are controlled primarily

by the ESR and ESL of the output filter. The transition

between fast and slow positioning is controlled by the ramp

size and the error amp compensation. If the ramp size is too

large or the error amp too slow there will be a long transition

to the final voltage after a transient. This will be most

apparent with lower capacitance output filters.

Note: Large levels of adaptive positioning can cause pulse

width jitter.

VID Codes and Power Good

The internal VID and DACOUT levels are set up so that the

reference for the control loop is nominally 125 mV below

the VID code (see the block diagram). The nominal lower

Power Good threshold is 2.5% below the DACOUT level.

The nominal upper Power Good threshold is fixed at 2.0 V

for all VID codes. This scheme is intended to select the VID

level as the maximum output voltage and the DACOUT level

as the minimum output voltage.

TRANSIENT RESPONSE AND ADAPTIVE

POSITIONING

For applications with fast transient currents the output

filter is frequently sized larger than ripple currents require in

order to reduce voltage excursions during transients.

Adaptive voltage positioning can reduce peak−peak output

voltage deviations during load transients and allow for a

smaller output filter. The output voltage can be set higher at

light loads to reduce output voltage sag when the load

current is stepped up and set lower during heavy loads to

reduce overshoot when the load current is stepped up. For

low current applications a droop resistor can provide fast

accurate adaptive positioning. However, at high currents the

loss in a droop resistor becomes excessive. For example; in

a 50 A converter a 1.0 mW resistor to provide a 50 mV

change in output voltage between no load and full load

would dissipate 2.5 Watts.

Lossless adaptive positioning is an alternative to using a

droop resistor, but must respond quickly to changes in load

current. Figure 14 shows how adaptive positioning works.

The waveform labeled normal shows a converter without

adaptive positioning. On the left, the output voltage sags

when the output current is stepped up and later overshoots

when current is stepped back down. With fast (ideal)

adaptive positioning the peak to peak excursions are cut in

half. In the slow adaptive positioning waveform the output

Error Amp Compensation

The transconductance error amplifier can be configured to

provide both a slow soft−start and a fast transient response.

C4 in Figure 1 controls soft−start. A 0.1 mF capacitor with

the 30 mA error amplifier output capability will allow the

output to ramp up at 0.3 V/ms or 1.5 V in 5.0 ms.

R10 is connected in series with C4 to allow the error

amplifier to slew quickly over a narrow range during load

transients. Here the 30 mA error amplifier output capability

http://onsemi.com

15

�CS5301

Voltage feedback should be taken from a point of the

output or the output filter that doesn’t favor any one phase.

If the feedback connection is closer to one inductor than the

others the ripple associated with that phase may appear

larger than the ripple associated with the other phases and

poor current sharing can result.

The current sense signal is typically tens of milli−volts.

Noise pick−up should be avoided wherever possible.

Current feedback traces should be routed away from noisy

areas such as switch nodes and gate drive signals. The paths

should be matched as well as possible. It is especially

important that all current sense signals be picked off at

similar points for accurate current sharing. If the current

signal is taken from a place other than directly at the inductor

any additional resistance between the pick−off point and the

inductor appears as part of the inherent inductor resistance

and should be considered in design calculations. Capacitors

for the current feedback networks should be placed as close

to the current sense pins as practical.

works against 10 kW (R10) to limit the window of fast

slewing to 300 mV − enough to allow for fast transients, but

not enough to interfere with soft−start. This window will be

noticeable as a step in the COMP pin voltage at startup. The

size of this step must be kept smaller than the Channel

Startup Offset (nominally 0.4 V) for proper soft−start

operation. If adaptive positioning is used the R9 and R8 form

a divider with the VDRP end held at the DAC voltage during

startup, which effectively makes the Channel Startup Offset

larger.

C12 is included for error amp stability. A capacitive load

is required on the error amp output. Use of values less than

1.0 nF may result in error amp oscillation of several MHz.

C11 and the parallel resistance of the VFB resistor (R9)

and the VDRP resistor (R8) are used to roll off the error amp

gain. The gain is rolled off at high enough frequency to give

a quick transient response, but low enough to cross zero dB

well below the switching frequency to minimize ripple and

noise on the COMP pin.

+12 V

DESIGN PROCEDURE

+5.0 V

Current Sensing, Power Stage and Output Filter

Components

50 k

1. Choose the output filter components to meet peak

transient requirements. The formula below can be

used to provide an approximate starting point for

capacitor choice, but will be inadequate to calculate

actual values.

COMP

100 k

100 k

DVPEAK + (DIńDT)

ESL ) DI

ESR

Ideally the output filter should be simulated with

models including ESR, ESL, circuit board parasitics

and delays due to switching frequency and converter

response. Typically both bulk capacitance

(electrolytic, Oscon, etc.,) and low impedance

capacitance (ceramic chip) will be required. The bulk

capacitance provides “hold up” during the converter

response. The low impedance capacitance reduces

steady state ripple and bypasses the bulk capacitance

during slewing of output current.

2. For inductive current sensing (only) choose the

current sense network RC to provide a 25 mV

minimum ramp during steady state operation.

Figure 15. External UVLO Circuit

Layout Guidelines

With the fast rise, high output currents of microprocessor

applications, parasitic inductance and resistance should be

considered when laying out the power, filter and feedback

signal sections of the board. Typically, a multi−layer board

with at least one ground plane is recommended. If the layout

is such that high currents can exist in the ground plane

underneath the controller or control circuitry, the ground

plane can be slotted to reroute the currents away from the

controller. The slots should typically not be placed between

the controller and the output voltage or in the return path of

the gate drive. Additional power and ground planes or

islands can be added as required for a particular layout.

Output filter components should be placed on wide planes

connected directly to the load to minimize resistive drops

during heavy loads and inductive drops and ringing during

transients. If required, the planes for the output voltage and

return can be interleaved to minimize inductance between

the filter and load.

R + (VIN * VOUT)

f

VOUTńVIN

C 25 mV

Then choose the inductor value and inherent

resistance to satisfy L/RL = R × C.

For ideal current sense compensation the ratio of L and

RL is fixed, so the values of L and RL will be a

compromise typically with the maximum value RL

limited by conduction losses or inductor temperature

rise and the minimum value of L limited by ripple

current.

http://onsemi.com

16

�CS5301

Adaptive Positioning

3. For resistive current sensing choose L and RS to

provide a steady state ramp greater than 25 mV.

LńRS + (VIN * VOUT)

7. To set the amount of voltage positioning above the

DAC setting at no load connect a resistor (RVFB)

between the output voltage and the VFB pin. Choose

RVFB as;

VOUTńVIN

f 25 mV

Again the ratio of L and RL is fixed and the values of

L and RS will be a compromise.

4. Calculate the high frequency output impedance

(ConverterZ) of the converter during transients. This

is the impedance of the Output filter ESR in parallel

with the power stage output impedance (PwrstgZ)

and will indicate how far from the original level

(DVR) the output voltage will typically recover to

within one switching cycle. For a good transient

response DVR should be less than the peak output

voltage overshoot or undershoot.

DVR + ConverterZ

RVFB + NL PositionńVFB Bias Current

See Figure 4 for VFB Bias Current.

8. To set the difference in output voltage between no

load and full load, connect a resistor (RVDRP)

between the VDRP and VFB pins. RVDRP can be

calculated in two steps. First calculate the difference

between the VDRP and VFB pin at full load. (The VFB

voltage should be the same as the DAC voltage during

closed loop operation.) Then choose the RVDRP to

source enough current across RVFB for the desired

change in output voltage.

IOUT

DVVDRP + R

PwrstgZ ESR

ConverterZ +

PwrstgZ ) ESR

RVDRP + DVVDRP

CSA Gainń3

Multiply the converterZ by the output current step

size to calculate where the output voltage should

recover to within the first switching cycle after a

transient. If the ConverterZ is higher than the value

required to recover to where the adaptive positioning

is set the remainder of the recovery will be controlled

by the error amp compensation and will typically

recover in 10−20 ms.

DVR + DIOUT

CS to VDRP Gain

where:

R = RL or RS for one phase;

IOUT is the full load output current.

where:

PwrstgZ + RS

IOUT

RV(FB)ńDVOUT

DESIGN EXAMPLE

Choose the component values for lossless current sensing,

adaptive positioning and current limit for a 250 kHz, 1.55 V,

60 A converter. The VID code is set to 1.6 V. Adaptive

positioning is set for 100 mV above DACOUT (or 25 mV

below VID) at no load and 75 mV below the no load position

with a 60 A load. The peak output voltage transient should

be less than 100 mV during a 60 A step current. The

overcurrent limit is nominally 75 A.

ConverterZ

Current Sensing, Power Stage and

Output Filter Components

Make sure that DVR is less than the expected peak

transient for a good transient response.

5. Adjust L and RL or RS as required to meet the best

combination of transient response, steady state output

voltage ripple and pulse width jitter.

1. Assume 1.5 mW of output filter ESR.

2. Choose C + 0.01 mF

VOUTńVIN

C 25 mV

1.55ń12

+ (12 * 1.55)

250 k 0.01 mF 25 mV

+ 21.5 kW å Choose 20 kW

R + (VIN * VOUT)

Current Limit

When the sum of the Current Sense amplifiers (VITOTAL)

exceeds the voltage on the ILIM pin the part will enter hiccup

mode. For inductive sensing the ILIM pin voltage should be

set based on the inductor resistance (or current sense

resistor) at max temperature and max current. To set the level

of the ILIM pin:

f

LńRL + R C + 20 kW 0.01 mF + 200 ms

Choose RL + 2.0 mW

L + RL R C + 2.0 mW 200 ms + 400 nH

3. n/a

4. PwrstgZ + RL

6. VILIM +

where:

R is RL or RS;

IOUT(LIM) is the current limit threshold.

For the overcurrent to work properly the inductor

time constant (L/R) should be ≤ the Current sense RC.

If the RC is too fast, during step loads the current

waveform will appear larger than it is (typically for a

few hundred ms) and may trip the current limit at a

level lower than the DC limit.

CSA Gainń3

+ 2.0 mW 4.2ń3.0 + 2.8 mW

ConverterZ +

PwrstgZ

ESR

PwrstgZ ) ESR

+ 2.8 mW 1.5 mW ^ 1.0 mW

2.8 mW ) 1.5 mW

DVR + ConverterZ IOUT

+ 1.0 mW 60 A + 60 mV

5. n/a

http://onsemi.com

17

�CS5301

8. DVDRP + RL

Current Limit

IOUT

Current Sense to VDRP Gain

+ 2.0 mW 60 A 3.1

+ 372 mV

6. VILIM + RL

IOUT(LIM)

CS to ILIM Gain

+ 2.0 mW 75 A 6.5

+ 975 mV

RVDRP + DVDRP

+ 372 mV

+ 82 kW

Adaptive Positioning

RVFBńDVOUT

16.7 kWń75 mV

7. RVFB + NL PositionńVFB Bias Current

+ 100 mVń6.0 mA + 16.7 kW

+12 V

+5.0 V

+12 V

D1

BAT54S

D3

BAT54S

L4

300 nH

D2

BAS16LT1

C12

1.0 nF

C1

1.0 mF

R10

10 K

C3

1.0 mF

C2

1.0 mF

+5.0 V

C4

C11

1.0 nF

R3

0.1 mF

CS1

L1

R4

1.0 W

C14

1.0 mF

U1

R8

191 k

COMP

VFB

VDRP

CS1

CS2

CS3

CSREF

PWRGD

VID0

VID1

VID2

VID3

VID4

PWRGDS

ILIM

REF

CS5301

R11

10 k

+5.0 V

PWRGD

Q1

1.0 mF

56.2 K

C10

1.0 nF

R9

36.5 k

+ C15,16

2 × 16SP180M

R12

20 K

VID0

VID1

VID2

ROSC

VCCL

VCCL1

Gate(L)1

GND1

Gate(H)1

VCCH12

Gate(H)2

GND2

Gate(L)2

VCCL23

Gate(L)3

GND3

Gate(H)3

VCCH3

LGND

Q2

C17−24

8 × 4SP560M

Q3

CS2

L2

1.0 mF

Q4

C25−32

8 × 10 mF

R1

VID3

3.09 k

VID4

R2

Q5

C5

0.1 mF

L3

R7

R6

30 k

C6

.01 mF

CS1

VCORE

1.0 mF

2.00 k

R5

30 k

CS3

Q6

30 k

C7

.01 mF

CS3

C8

.01 mF

CS2

C9

.01 mF

Q1−Q6, NTB85N03 or NTB85N03T4 by ON Semiconductor

Figure 16. Additional Application Diagram,

12 V to 1.75 V, 45 A for AMD AthlonE Processor

http://onsemi.com

18

�CS5301

PACKAGE DIMENSIONS

SO−32WB

DW SUFFIX

CASE 751P−01

ISSUE O

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 TOTAL IN EXCESS

OF B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

−X−

D

32

17

H

E

0.25

−Y−

M

Y

M

16

1

PIN 1 IDENT

A

0.10

A1

B

0.25

G

M

T X

S

Y

−T−

L

SEATING

PLANE

DIM

A

A1

B

C

D

E

G

H

L

M

MILLIMETERS

MIN

MAX

2.29

2.54

0.10

0.25

0.36

0.51

0.15

0.32

20.57

20.88

7.42

7.60

1.27 BSC

10.29

10.64

0.53

1.04

0°

8°

C

M

S

V2 is a trademark of Switch Power, Inc.

Pentium is a registered trademark of Intel Corporation.

AMD Athlon is a trademark of Advanced Micro Devices, Inc.

ON Semiconductor and

are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

N. American Technical Support: 800−282−9855 Toll Free

Literature Distribution Center for ON Semiconductor

USA/Canada

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Phone: 81−3−5773−3850

Email: orderlit@onsemi.com

http://onsemi.com

19

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

CS5301/D

�