FAN53713

1.5 A Synchronous Buck

Regulator

Description

The FAN53713 is a Super Low Iq, step−down switching voltage

regulator, that delivers a fixed output from an input voltage supply of

2.3 V to 5.5 V. Using a proprietary architecture with synchronous

rectification, the FAN53713 is capable of delivering a peak efficiency

of 93%, while maintaining efficiency over 90% at load currents as low

as 1 mA.

The regulator operates with 0402 and 0603 input and output

capacitors, respectively, which reduces the total solution size to

5.5 mm2. At moderate and light load, Pulse Frequency Modulation

(PFM) is used to operate the device with a low quiescent current. Even

with such a low quiescent current, the part exhibits excellent transient

response during load swings. In Shutdown Mode, the supply current

drops to 100 nA, reducing power consumption. The Mode pin allows

the part to be in a Super Low IQ (SLIQ) mode with a typical quiescent

current of 2 mA.

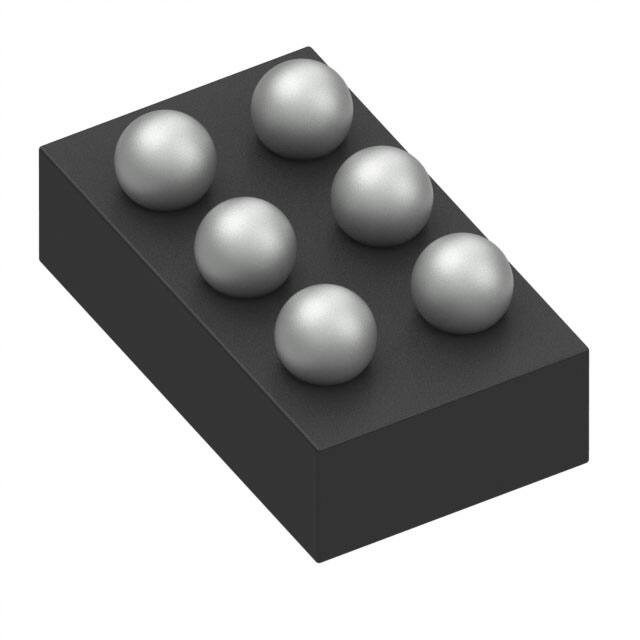

The FAN53713 is available in 6−bump, 0.4 mm pitch, Wafer−Level

Chip−Scale Package (WLCSP).

Features

•

•

•

•

•

•

•

•

•

•

•

•

2 mA Typical Quiescent Current

5.5 mm2 Total Solution Size

1.5 A Output Current Capability

0.6 V to 1.8 V Fixed Output Voltage

2.3 V to 5.5 V Input Voltage Range

Best−in−Class Load Transient Response

Best−in−Class Efficiency with Sub 1 mA Output Currents

Internal Soft−Start Limits Battery Current Below 150 mA to avoid

Brown−out Scenarios

Protection Faults (UVLO, OCP and OTP)

Thermal Shutdown and Overload Protection

6−Bump WLCSP, 0.4 mm Pitch

These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

www.onsemi.com

WLCSP6 1.38 � 0.94 � 0.625

CASE 567UH

MARKING DIAGRAM

12KK

XYZ

12

KK

X

Y

Z

= Alphanumeric Device Marking

= Lot Run Code

= Alphabetical Year Code

= 2 Weeks Date Code

= Assembly Plant Code

ORDERING INFORMATION

See detailed ordering and shipping information on page 2 of

this data sheet.

2.2 mF

SW

VIN

CIN

1.0 mH

FAN53713

MODE

EN

L1

VOUT

COUT

22 mF

FB

GND

Applications

•

•

•

•

•

•

•

Figure 1. Typical Application

Wearables

Smart Watch

Health Monitoring

Sensor Drive

Energy Harvesting

Utility and Safety Modules

RF Modules

© Semiconductor Components Industries, LLC, 2017

June, 2018 − Rev. 1

1

Publication Order Number:

FAN53713/D

�FAN53713

Table 1. ORDERING INFORMATION

Part Number

Output Voltage

(Note 1)

Max. Output

Current (Note 1)

Temperature

Range

Package

Packing

Method

Device

Marking

FAN53713UC02X

0.7 V

1.5 A

−40 to 85°C

WLCSP

Tape & Reel

GJ

1. Other voltage and output current options are available. Contact an On Semiconductor representative.

Table 2. RECOMMENDED EXTERNAL COMPONENTS

Component

Description

Vendor

Parameter

Typ.

Unit

L

1.0 mH, 20%, 2.3 A, 107 mW, 1608

DFE160810S−1R0M (Murata)

L

1.0

mH

CIN

2.2 mF, 20%, 6.3 V, X5R, 0402

C1005X5R0J225M050BC (TDK)

C

2.2

COUT (Note 1)

22 mF, 20%, 6.3 V, X5R, 0603

C1608X5R0J226M080AC (TDK)

C

22

mF

1. A 10 mF, 0402 capacitor can be used to reduce total solution size at the expense of load transient performance.

Pin Configuration

EN

A1

A2

VIN

VIN

A2

A1

EN

MODE

B1

B2

SW

SW

B2

B1

MODE

FB

C1

C2

GND

GND

C2

C1

FB

Figure 2. Top View

Figure 3. Bottom View

Table 3. PIN DEFINITIONS

Pin #

Name

A1

EN

Enable. The device is in Shutdown Mode when voltage to this pin is 1.2 V. Do not leave this pin floating. Recommended for GPIO 1.8 V to drive this pin

A2

VIN

Input Voltage. Connect to input power source across CIN

B1

MODE

Description

MODE. Logic “LOW” allows the IC to be in a Super Low IQ (SLIQ) state. A Logic HIGH

allows the part to be in normal Iq state Auto Mode

B2

SW

Switching Node. Connect to SW pad of inductor

C1

FB

Feedback. Connect to positive side of output capacitor

C2

GND

Ground. Power and IC ground. All signals are referenced to this pin

Table 4. ABSOLUTE MAXIMUM RATINGS

Symbol

Parameter

Min.

Max.

Unit

VIN

Input Voltage

−0.3

6.5

V

VSW

Voltage on SW Pin

−0.3

VIN + 0.3 (Note 1)

V

EN, FB and Mode Pin Voltage

−0.3

VIN + 0.3 (Note 1)

V

VCTRL

ESD

Human Body Model per JESD22−A114

2.0

Charged Device Model per JESD22−C101

1.0

kV

TJ

Junction Temperature

−40

+150

°C

TSTG

Storage Temperature

−40

+150

°C

+260

°C

TL

Lead Soldering Temperature, 10 Seconds

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Lesser of 6 V or VIN + 0.3 V.

www.onsemi.com

2

�FAN53713

Table 5. RECOMMENDED OPERATING CONDITIONS

Symbol

Parameter

Max.

Unit

2.3

5.5

V

Continuous Output Current

0

1.5

A

Pulsed Output Current, 100 ms

0

1.6

VIN

Supply Voltage Range

IOUT

CIN

COUT (Note 1)

Min.

Typ.

Input Capacitor

A

mF

2.2

100

mF

1.3

mH

−40

+85

°C

−40

+125

°C

Output Capacitor

3

L

Inductor

0.47

TA

Operating Ambient Temperature

TJ

Operating Junction Temperature

1.0

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

1. Effective capacitance after DC bias.

Table 6. THERMAL PROPERTIES

Symbol

θJA

Parameter

Min.

Junction−to−Ambient Thermal Resistance (Note 1)

Typ.

Max.

Unit

°C/W

125

1. Junction−to−ambient thermal resistance is a function of application and board layout. This data is simulated with four−layer 2s2p boards with

vias in accordance to JESD51− JEDEC standard. Special attention must be paid not to exceed the junction temperature.

Table 7. ELECTRICAL CHARACTERISTICS Minimum and Maximum Values are at VIN = VEN = 3.6 V, TA = −40°C to

+85°C, unless otherwise noted. Typical values are at TA = 25°C, VIN = VEN = 3.6 V, VOUT = 1.8 V

Symbol

Parameter

Condition

Min.

Typ.

Max.

Unit

IQ,SLIQ

Quiescent Current

SLIQ Mode, no load, non−switching

2

mA

IQ,PFM

PFM Quiescent Current

PFM Mode, no load, non−switching

5

mA

Shutdown Supply Current

EN=GND, VIN=3.6 V, no load

Under−Voltage Lockout Threshold

VIN Rising

2.10

2.15

2.21

V

VIN Falling

2.00

2.05

2.10

V

ISD

VUVLO_RISE

VUVLO_FALL

100

nA

VIH

HIGH−Level Input Voltage

VIL

LOW−Level Input Voltage

ILIM

Peak Current Limit

VIN = 4.35 V

Output Voltage Accuracy

VOUT = 0.6 V to 1.8 V, IOUT(DC) = 0,

PWM Mode

−25

+25

mV

VOUT = 0.6 V to 1.8 V, IOUT(DC )= 0,

PFM Mode

−40

+40

mV

VOACC

RDS(on)

1.2

V

0.4

2215

V

mA

PMOS On Resistance

VIN = VGS = 3.6 V

135

mW

NMOS On Resistance

VIN = VGS = 3.6 V

95

mW

TTSD

Thermal Shutdown

150

°C

THYS

Thermal Shutdown Hysteresis

15

°C

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

www.onsemi.com

3

�FAN53713

Table 8. SYSTEM CHARACTERISTICS The following system characteristics are guaranteed by design and are not performed in

production testing. Recommended operating conditions, unless otherwise noted, VIN = 2.3 V to 5.5 V, TA = −40°C to +85°C, VOUT = 1.8

V. Typical values are given at TA = 25°C, VIN = 3.6 V. System characteristics are based on circuit per Figure 1.

L = 1.0 mH, 2.3 A, 107 mW DCR, DFE160810S−1R0M (Murata), CIN = 1 × 2.2 mF, 6.3 V, 0402 (1005 metric), C1005X5R0J225M050BC

(TDK) and COUT = 1 × 22 mF, 6.3 V, 0603 (1608 metric), C1608X5R0J226M080AC (TDK).

Symbol

Parameter

LOADREG

Load Regulation

LINEREG

Line Regulation

VOUT_RIPPLE

Ripple Voltage

Eff

Eff

ΔVOUT_LOAD

ΔVOUT_LINE

Efficiency

Efficiency

Load Transient

Line Transient

Condition

Min.

Typ.

Max.

Unit

IOUT = 10 mA to 1 mA, SLIQ Mode

−9.0

mV/mA

IOUT = 200 mA to 300 mA, PWM

−2.0

mV/A

3.0 V ≤ VIN ≤ 4.35 V,

IOUT = 1 A, PWM

−0.5

mV/V

IOUT = 250 mA, SLIQ Mode

40

mV

IOUT = 20 mA, PFM Mode

25

IOUT = 200 mA, PWM Mode

5

IOUT = 100 mA, SLIQ Mode

88

IOUT = 500 mA, SLIQ Mode

91

IOUT = 1 mA, PFM Mode

90

IOUT = 100 mA, PFM Mode

91

IOUT = 300 mA, PWM Mode

91

IOUT = 500 mA, PWM Mode

90

IOUT = 700 mA, PWM Mode

88

IOUT = 10 mA ⇔ 150 mA,

TR = TF = 1 ms, Auto Mode

±40

mV

IOUT = 100 mA ⇔ 500 mA,

TR = TF = 1 ms, SLIQ Mode

±15

mV

VIN = 3.0 V ⇔ 3.6 V, TR = TF = 10 ms,

IOUT = 300 mA, PWM Mode

±20

mV

www.onsemi.com

4

%

%

�FAN53713

Typical Characteristics

94%

94%

90%

90%

86%

86%

Efficiency

Efficiency

Unless otherwise specified, VIN = 3.6 V, VOUT = 1.8 V, Auto Mode, TA = 25°C; circuit and components according to Figure 1 and Table 2.

82%

VIN = 2.5 V

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

VIN = 5.0 V

78%

74%

70%

1

10

100

Load Current (mA)

78%

70%

1

1,000

90%

85%

85%

80%

80%

Efficiency

Efficiency

95%

90%

75%

VIN = 2.5 V

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

VIN = 5.0 V

65%

60%

55%

50%

0.01

0.10

Load Current (mA)

10

100

Load Current (mA)

1,000

Figure 5. Efficiency vs. Load Current and

Temperature, VIN = 3.6 V , VOUT = 1.8 V, Auto Mode

95%

70%

−40°C

+25°C

+85°C

74%

Figure 4. Efficiency vs. Load Current and Input

Voltage, VOUT = 1.8 V, Auto Mode

75%

70%

65%

−40°C

+25°C

+85°C

60%

55%

50%

0.01

1.00

Figure 6. Efficiency vs. Load Current and Input Voltage,

VOUT = 1.8 V, SLIQ Mode

0.10

Load Current (mA)

1.00

Figure 7. Efficiency vs. Load Current and

Temperature, VIN = 3.6 V , VOUT = 1.8 V, SLIQ Mode

3,000

60

Output Ripple (mVpp)

Switching Frequency (KHz)

82%

2,500

2,000

1,500

1,000

VIN = 2.5 V

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

500

0

0

250

500

750

VIN = 2.5 V

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

50

40

30

20

10

1000

1250

0

1500

0

Load Current (mA)

250

500

750

1000

1250

1500

Load Current (mA)

Figure 8. Frequency vs. Load Current and Input Voltage,

Auto Mode, VOUT = 1.8 V, Auto Mode

www.onsemi.com

5

Figure 9. Output Ripple vs. Load Current and

Input Voltage, VOUT = 1.8 V, Auto Mode

�FAN53713

Typical Characteristics (continued)

Unless otherwise specified, VIN = 3.6 V, VOUT = 1.8 V, Auto Mode, TA = 25°C; circuit and components according to Figure 1 and Table 2.

2.0

VIN = 2.5 V

VIN = 3.0 V

VIN = 3.6 V

VIN = 4.2 V

VIN = 5.0 V

1.5

1.0

Output Regulation (%)

Output Regulation (%)

2.0

0.5

0.0

−0.5

1.5

1.0

0.5

0.0

−0.5

−1.0

−40°C

+25°C

+85°C

−1.5

−2.0

−1.0

0

250

500

750

1000

1250

0

1500

250

500

750

1000

1250

1500

Load Current (mA)

Load Current (mA)

Figure 10. Output Regulation vs. Load Current and

Input Voltage, VOUT = 1.8 V, Auto Mode

Figure 11. Output Regulation vs. Load Current and

Temperature, VIN = 3.6 V, VOUT = 1.8 V, Auto Mode

4

8

Input Current (mA)

Input Current (mA)

7

6

5

4

−40°C

+25°C

+85°C

3

2

2.3

2.8

3.3

3.8

4.3

Input Voltage (V)

4.8

3

2

1

−40°C

−405C

+25°C

+255C

+85°C

+855C

0

5.3

2.3

2.8

3.3

3.8

4.3

Input Voltage (V)

4.8

5.3

Figure 13. Quiescent Current vs. Input Voltage and

Temperature, VOUT = 1.8 V, SLIQ Mode

Figure 12. Quiescent Current vs. Input Voltage and

Temperature, VOUT = 1.8 V, Auto Mode

Input Current (mA)

0.5

−40°C

+25°C

+85°C

0.4

0.3

0.2

0.1

0.0

2.3

2.8

3.3

3.8

4.3

Input Voltage (V)

4.8

5.3

Figure 14. Shutdown Current vs. Input Voltage

and Temperature

Figure 15. Load Transient, VIN = 3.6 V, VOUT = 1.8 V,

10 mA �150 mA, 1 ms Edge, Auto Mode

www.onsemi.com

6

�FAN53713

Typical Characteristics (continued)

Unless otherwise specified, VIN = 3.6 V, VOUT = 1.8 V, Auto Mode, TA = 25°C; circuit and components according to Figure 1 and Table 2.

Figure 16. Load Transient, VIN = 3.6 V, VOUT = 1.8 V,

5 mA �300 mA, 1 ms Edge, Auto Mode

Figure 17. Load Transient, VIN = 3.6 V, VOUT = 1.8 V,

100 mA �300 mA, 1 ms Edge, Auto Mode

Figure 19. Line Transient, VIN = 3.0 V � 3.6 V,

VOUT = 1.8 V, 10 ms Edge, 300 mA Load, Auto Mode

Figure 18. Load Transient, VIN = 3.6 V, VOUT = 1.8 V,

10 mA �1500 mA, 1 ms Edge, Auto Mode

Figure 20. Start−up, VIN= 3.6 V, VOUT= 1.8 V,

50 mA Resistive Load, Auto Mode

Figure 21. Start−up, VIN= 3.6 V, VOUT= 1.8 V,

300 mA Resistive Load, Auto Mode

www.onsemi.com

7

�FAN53713

Operation Description

The FAN53713 is a Super Low Iq (SLIQ), step−down

switching voltage regulator, typically operating at 2.5 MHz

in Continuous Conduction Mode(CCM). Using a

proprietary architecture with synchronous rectification, the

FAN53713 is capable of delivering a peak efficiency of

93%, while maintaining efficiency over 90% at load currents

sub 1mA.

In SLIQ mode the device is very efficient with load

currents in the uA range. In SLIQ mode the device draws less

than 2 mA typical from the battery with no load. The load

transients in SLIQ mode are best in class.

The FAN53713 provides a fixed output voltage of 0.6 V

to 1.8 V and load capability of 1.5 A, which can support

wearable or mobile phone applications which use Li−Ion

batteries. Specialized soft−start limits the battery current to

150 mA to limit any brown out occurrences.

this point, the high−side switch turns off, preventing high

currents from causing damage. The regulator continues to

limit the current cycle−by−cycle. After 500 ms of current

limit, the regulator triggers an over−current fault, causing

the regulator to shut down for about 20 ms before attempting

a restart.

Under−Voltage Lockout (UVLO)

When EN is HIGH, the under−voltage lockout keeps the

part from operating until the input supply voltage rises high

enough to properly operate. This ensures no misbehavior of

the regulator during startup or shutdown.

Over−Temperature Protection (OTP)

When the die temperature increases, due to a high load

condition and/or a high ambient temperature, the output

switching is disabled until the die temperature falls

sufficiently. The junction temperature at which the thermal

shutdown activates is nominally 150°C with a 15°C

hysteresis. Once the junction temperature falls below the

hysteresis threshold, the regulator performs a soft−start.

Control Scheme

Enable and Disable

When EN pin is Low, all circuits are off and the IC draws

100 nA current. When EN is High and VIN is above its

UVLO threshold, the regulator begins a soft−start cycle. The

FAN53713 has internal soft−start which limits the battery

current draw to 150 mA. Once the part reaches 95% of VOUT

target, the part will transition to the correct mode of

operation depending on load current. The part starts up

within 400 ms typical with the recommended external

components listed in Table 2.

Modes of Operations

SLIQ (Super Low IQ)

Protection Features

In SLIQ Mode the device acts in a modified PFM mode

with a super low Iq state. The part draws 2 mA with no load.

The part enters SLIQ Mode when the Mode pin is set to

logic “LOW”. Before pulling the Mode Pin Low, the load

current should drop below 1 mA to maintain output voltage

regulation in SLIQ mode. The maximum load current in

SLIQ Mode that the device can support is 1 mA. If load

current exceeds 1 mA, it is recommended to place part in

Auto Mode by pulling Mode pin High so that the device can

support more current.

The part can support more than 1 mA in SLIQ Mode if the

output capacitor is increased.

VOUT Fault

PFM

If the VOUT fails to reach 95% of VOUT target within 1.8

ms during startup, a VOUT fault is declared. During the fault

condition the part restarts every 20 ms to achieve the 95%

target voltage. Once the output voltage reaches the 95%

VOUT target voltage within 1.8 ms during startup, the VOUT

fault clears.

At light load operation in Auto Mode, the device enters

PFM mode when load current is below 100 mA typically.

PFM mode reduces switching frequency as well as battery

current draw, which yields high efficiency.

When Mode pin goes High, the part will transition from

SLIQ Mode into normal PFM mode within 10 ms, typically.

Over−Current Protection (OCP)

PWM

A heavy load or short circuit on the output causes the

current in the inductor to increase until a maximum current

threshold is reached in the high−side switch. Upon reaching

When load is high, the part transitions smoothly from

PFM mode to PWM mode. The part enters PWM mode

when load current exceeds 132 mA, typically.

MODE Pin

Setting Mode Pin Low sets the device in SLIQ mode;

setting Mode Pin High sets the device in normal Iq Auto

Mode.

www.onsemi.com

8

�FAN53713

Applications Information

physical inductor size, increased inductance usually results

in an inductor with lower saturation current and higher DCR.

Table 3 shows the effects of inductance higher or lower

than the recommended 1.0 mH on regulator performance.

Selecting the Inductor

The output inductor must meet both the required

inductance and the energy-handling capability of the

application. The inductor value affects average current limit,

output voltage ripple, and efficiency.

The ripple current (ΔI) of the regulator is:

DI ≈

V OUT

V IN

ǒ

V IN * V OUT

L f SW

Ǔ

Output Capacitor

Increasing COUT has no effect on loop stability and can

therefore be increased to reduce output voltage ripple or to

improve transient response. Vice versa, lower COUT can be

used but with a compromise of load transient response.

Output voltage ripple, ΔVOUT, is:

(eq. 1)

The maximum average load current, IMAX(LOAD), is

related to the peak current limit, ILIM(PK), by the ripple

current, given by:

I MAX(LOAD) + I LIM(PK) *

DI

2

DV OUT + DI L

DI

2

ǸI

(eq. 3)

2

OUT(DC)

)

DI 2

12

1

F SW

ƫ

C OUT (eq. 5)

PCB Layout Guidelines

1. The input capacitor (CIN) should be connected as

close as possible to the VIN and GND pins

Connect to VIN and GND using only top metal.

Do not route through vias (see Figure 22)

2. Place the inductor (L) as close as possible to the

IC. Use short wide traces for the main current

paths

3. An output capacitor (COUT) should be placed as

close as possible to the IC. Connection to GND

should only be on top metal. Feedback signal

connection to VOUT should be routed away from

noisy components and traces (e.g. SW line)

(eq. 4)

The increased RMS current produces higher

through the RDS(ON) of the IC MOSFETs, as well

inductor DCR.

Increasing the inductor value produces lower

currents, but degrades transient response. For a

C OUT

ESR 2

)

D

(1 * D)

8

The 2.2 mF ceramic input capacitor should be placed as

close as possible between the VIN pin and GND to minimize

the parasitic inductance. If a long wire is used to bring power

to the IC, additional “bulk” capacitance (electrolytic or

tantalum) should be placed between CIN and the power

source lead to reduce the ringing that can occur between the

inductance of the power source leads and CIN.

The effective capacitance value decreases as VIN

increases due to DC bias effects.

The FAN53713 is optimized for operation with L =

1.0 mH, but is stable with inductances up to 1.3 H (nominal).

The inductor should be rated to maintain at least 80% of its

value at ILIM(PK).

Efficiency is affected by the inductor DCR and inductance

value. Decreasing the inductor value for a given physical

size typically decreases the DCR; but because DI increases,

the RMS current increases, as do the core and skin effect

losses.

I RMS +

f SW

2

Input Capacitor

(eq. 2)

The transition between PFM and PWM operation is

determined by the point at which the inductor valley current

crosses zero. The regulator DC current when the inductor

current crosses zero, IDCM, is:

I DCM +

ƪ

losses

as the

RMS

given

Table 9. EFFECTS OF CHANGES in Inductor Value (from 1.0 mH Recommended Value) on Regulator Performance

Inductor Value

IMAX(LOAD)

DVOUT

Transient Response

Increase

Increase

Decrease

Degraded

Decrease

Decrease

Increase

Improved

www.onsemi.com

9

�FAN53713

Connect VIN pin and CIN using only top metal.

Connect COUT and GND pin only on top layer

Put as many as possible vias connected to

ground plane (Layer 2), to help dissipate heat.

Connect GND vias to system ground

VOUT trace should be as wide and as short

as possible, for low impedance, also should

be routed away from noisy components and

traces (e.g. SW line)

The ground area should be made as large as

possible to help dissipate heat

Figure 22. Top Layer

Layer 2 should be a solid ground layer, to

shield VOUT from capacitive coupling of the

fast edges of SW node.

Logic signals can be routed on this layer.

Figure 23. Layer 1

SW trace should be as wide and as short as

possible, and be isolated with GND area from

any other sensitive traces.

Figure 24. Layer 3

www.onsemi.com

10

�FAN53713

PACKAGE DIMENSIONS

WLCSP6 1.38 � 0.94 � 0.625

CASE 567UH

ISSUE O

Table 10. PRODUCT−SPECIFIC DIMENSIONS

D

E

X

Y

1.380 ±0.030

0.940 ±0.030

0.270

0.290

www.onsemi.com

11

�FAN53713

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

◊

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

www.onsemi.com

12

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

FAN53713/D

�