NCP6343

Configurable 3.0 A Step

Down Converter

The NCP6343 is a synchronous buck converter optimized to supply

the different sub systems of portable applications powered by one cell

Li−Ion or three cell Alkaline/NiCd/NiMH batteries. The device is able

to deliver up to 3.0 A, with programmable output voltage from 0.6 V

to 1.4 V. It can share the same output rail with another DCDC and

works as a transient load helper. Operation at a 3 MHz switching

frequency allows the use of small components. Synchronous

rectification and automatic PWM/PFM transitions improve overall

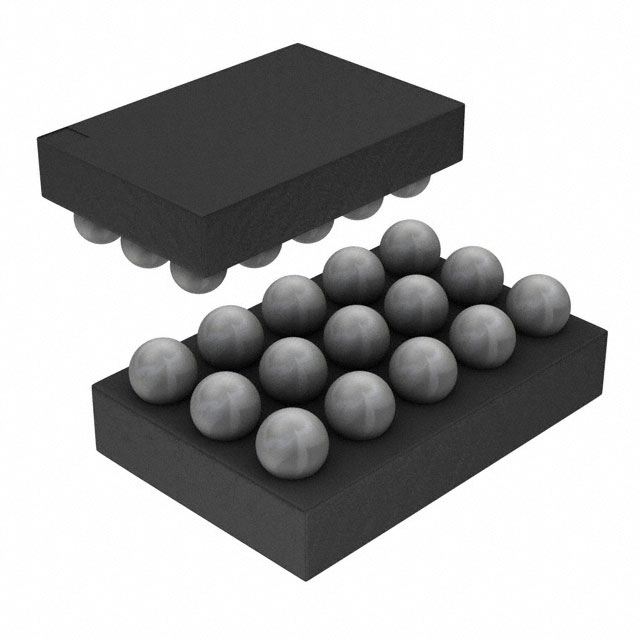

solution efficiency. The NCP6343 is in a space saving, low profile

1.99 x 1.34 mm CSP−15 package.

www.onsemi.com

MARKING

DIAGRAM

Features

x

= P: Prototype

= Blank: 1.225 V − 2.0 A

= A: 1.225 V − 3.0 A

= B: 1.225 V − 3.0 A

= D: 1.18125 V − 3.0 A

= S: 1.050 V − 3.0 A

= V: 1.225 V − 3.0 A

= M: 0.925 V − 3.0 A

A

= Assembly Location

L

= Wafer Lot

Y

= Year

WW = Work Week

G

= Pb−Free Package

• Input Voltage Range from 2.3 V to 5.5 V: Battery and 5 V Rail

•

•

•

•

•

•

•

•

•

•

•

•

6343x

ALYWW

G

WLCSP15

CASE 567GB

Powered Applications

Programmable Output Voltage: 0.6 V to 1.4 V in 6.25 mV Steps

Modular Output Stage Drive Strength for Increased Efficiency

Depending on the Output Current

3 MHz Switching Frequency with On Chip Oscillator

Uses 470 nH Inductor and 22 mF Capacitors for Optimized Footprint

and Solution Thickness

PFM/PWM Operation for Optimum Increased Efficiency

Ultra Low 0.8 mA Off Mode Current

Low 35 mA Quiescent Current

I2C Control Interface with Interrupt and Dynamic Voltage Scaling

Support

Thermal Protections and Temperature Management

Transient Load Helper: Share the Same Rail with Another DCDC

Small 1.99 x 1.34 mm / 0.4 mm Pitch CSP Package

These are Pb−Free Devices

Pb−Free indicator, G or microdot (G),

may or may not be present

PINOUT DIAGRAM

1

NCP6343

2

3

A

PVIN

SW

PGND

B

PVIN

SW

PGND

C

PVIN

PGND

PGND

D

AVIN

EN

SDA

E

AGND

SCL

FB

Typical Applications

• Smartphones

• Webtablets

NCP6343

Supply Input

AVIN

D1

AGND

E1

A1

B1

C1

Core

References

Oscillator

A2

B2

Thermal

Protection

Processor I@C

Control Interface

EN

D2

SDA

D3

SCL

E2

SW

470 nH

22 uF

A3

B3

C3

C2

Operating

Mode

Control

I@C

Supply Input

10 uF

DCDC

3.0 A

Enable Control

Input

PVIN

DCDC

3 MHz

Controller

E3

PGND

FB

Sense

22 uF

(Top View)

15−Pin 0.40 mm pitch WLCSP

Figure 1. Typical Application Circuit

This document contains information on some products that are still under development.

ON Semiconductor reserves the right to change or discontinue these products without

notice.

© Semiconductor Components Industries, LLC, 2015

November, 2017 − Rev. 8

Core

Processor

Memory

1

ORDERING INFORMATION

See detailed ordering and shipping information on page 30 of

this data sheet.

Publication Order Number:

NCP6343/D

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

SUPPLY

INPUT

AVIN

AGND

ANALOG

GROUND

PVIN

Core

3.0 A

DC−DC

Thermal

Protection

MODULAR

DRIVER

POWER

INPUT

SW

SWITCH

NODE

Output Voltage

Monitoring

ENABLE

CONTROL

INPUT

EN

Operating

Mode Control

PROCESSOR I2C

SCL

SDA

Logic Control

Interrupt

I2C

3 MHz DC−DC

Converter

Controller

Sense

CONTROL

INTERFACE

PGND

POWER

GROUND

FB

FEEDBACK

Figure 2. Simplified Block Diagram

www.onsemi.com

2

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

1

NCP6343

2

3

A

PVIN

SW

PGND

B

PVIN

SW

PGND

C

PVIN

PGND

PGND

D

AVIN

EN

SDA

E

AGND

SCL

FB

Figure 3. Pin Out (Top View)

Table 1. PIN FUNCTION DESCRIPTION

Pin

Name

Type

Description

REFERENCE

D1

AVIN

Analog

Input

Analog Supply. This pin is the device analog and digital supply. Could be connected directly to

the VIN plane or to a dedicated 1.0 mF ceramic capacitor. Must be equal to PVIN.

E1

AGND

Analog

Ground

Analog Ground. Analog and digital modules ground. Must be connected to the system ground.

CONTROL AND SERIAL INTERFACE

D2

EN

Digital Input

Enable Control. Active high will enable the part. There is an internal pull down resistor on this pin.

E2

SCL

Digital Input

I2C interface Clock line. There is an internal pull down resistor on this pin; could be left open if not

used

D3

SDA

Digital

Input/Output

I2C interface Bi−directional Data line. There is an internal pull down resistor on this pin; could be

left open if not used

Switch Supply. These pins must be decoupled to ground by a 10 mF ceramic capacitor. It should

be placed as close as possible to these pins. All pins must be used with short heavy connections.

Must be equal to AVIN.

DCDC CONVERTER

A1, B1,

C1

PVIN

Power Input

A2, B2

SW

Power

Output

Switch Node. These pins supply drive power to the inductor. Typical application uses 0.470 mH

inductor; refer to application section for more information.

All pins must be used with short heavy connections.

A3, B3,

C3, C2

PGND

Power

Ground

Switch Ground. This pin is the power ground and carries the high switching current. High quality

ground must be provided to prevent noise spikes. To avoid high−density current flow in a limited

PCB track, a local ground plane that connects all PGND pins together is recommended. Analog

and power grounds should only be connected together in one location with a trace.

E3

FB

Analog

Input

Feedback Voltage input. Must be connected to the output capacitor positive terminal with a

trace, not to a plane. This is the positive input to the error amplifier.

www.onsemi.com

3

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Table 2. MAXIMUM RATINGS

Rating

Symbol

Value

Unit

VA

−0.3 to + 6.0

V

VDG

IDG

−0.3 to VA +0.3 ≤ 6.0

10

V

mA

Human Body Model (HBM) ESD Rating (Note 1)

ESD HBM

2000

V

Machine Model (MM) ESD Rating (Note 1)

ESD MM

150

V

ESD CDM

2000

V

Analog and power pins: AVIN, PVIN, SW, FB

Digital pins: SCL, SDA, EN:

Input Voltage

Input Current

Charged Device Model (CDM) ESD Rating (Note 1)

Latch Up Current: (Note 2)

Digital Pins

All Other Pins

ILU

Storage Temperature Range

TSTG

−65 to + 150

°C

Maximum Junction Temperature

TJMAX

−40 to +150

°C

MSL

Level 1

Moisture Sensitivity (Note 3)

mA

±10

±100

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. This device series contains ESD protection and passes the following ratings:

Human Body Model (HBM) ±2.0 kV per JEDEC standard: JESD22−A114.

Machine Model (MM) ±150 V per JEDEC standard: JESD22−A115.

Charged Device Model (CDM) ±2.0 kV per JEDEC standard: JESD22−C101 Class IV.

2. Latch up Current per JEDEC standard: JESD78 class II.

3. Moisture Sensitivity Level (MSL): 1 per IPC/JEDEC standard: J−STD−020A.

Table 3. OPERATING CONDITIONS (Note 4)

Parameter

Symbol

AVIN, PVIN

Min

AVIN = PVIN

2.3

Typ

Max

Unit

5.5

V

TA

Ambient Temperature Range

−40

25

+85

°C

TJ

Junction Temperature Range (Note 5)

−40

25

+125

°C

CSP−15 on Demo−board

−

65

−

°C/W

RqJA

Thermal Resistance Junction to Ambient (Note 6)

PD

Power Dissipation Rating (Note 7)

TA ≤ 85°C

−

615

−

mW

PD

Power Dissipation Rating (Note 7)

TA = 65°C

−

923

−

mW

−

0.47

−

mH

L

4.

5.

6.

7.

Power Supply

Conditions

Inductor for DCDC converter (Note 4)

Co

Output Capacitor for DCDC Converter (Note 4)

28

−

55

mF

Cin

Input Capacitor for DCDC Converter (Note 4)

4.7

−

−

mF

Including de−ratings (Refer to the Application Information section of this document for further details)

The thermal shutdown set to 150°C (typical) avoids potential irreversible damage on the device due to power dissipation.

The RqJA is dependent of the PCB heat dissipation.

The maximum power dissipation (PD) is dependent by input voltage, maximum output current and external components selected.

R qJA +

125 * T A

PD

www.onsemi.com

4

�NCP6343

CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

Table 4. ELECTRICAL CHARACTERISTICS (Note 9)

Min and Max Limits apply for TA = −40°C to +85°C, AVIN = PVIN = 3.6 V and default configuration, unless otherwise specified.

Typical values are referenced to TA = +25°C, AVIN = PVIN = 3.6 V and default configuration, unless otherwise specified.

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

SUPPLY CURRENT: Pins AVIN – PVINx

IQ PWM

Operating quiescent current PWM

DCDC active in Forced PWM

no load

−

12

20

mA

IQ PFM

Operating quiescent current PFM

DCDC active in Auto mode

no load − minimal switching

−

35

70

mA

ISLEEP

Product sleep mode current

EN high, DCDC off or

EN low and Sleep_Mode high

VIN = 2.5 V to 5.5 V

−

7

15

mA

Product in off mode

EN and Sleep_Mode low

VIN = 2.5 V to 5.5 V

−

0.8

5

mA

2.3

−

5.5

V

Ipeak[1..0] = 00/01 (Note 10)

2.0

−

−

A

Ipeak[1..0] = 10 (Note 10)

2.5

−

−

Ipeak[1..0] = 11 (Note 10)

3.0

−

−

Forced PWM mode

No load

−1

−

1

Forced PWM mode, VIN range,

IOUT up to IOUTMAX (Note 10)

−1

−

1

Auto mode, VIN range,

IOUT up to IOUTMAX (Note 10)

−1

−

2

2.7

3

3.3

MHz

IOFF

DCDC CONVERTER

PVIN

IOUTMAX

DVOUT

Input Voltage Range

Maximum Output Current

Output Voltage DC Error

%

FSW

Switching Frequency

RONHS

P−Channel MOSFET

On Resistance

From PVIN to SW (all Modules)

VIN = 5.0 V

−

36

64

mW

RONLS

N−Channel MOSFET

On Resistance

From SW to PGND (all Modules)

VIN = 5.0 V

−

19

40

mW

IPK

Peak Inductor Current

Open loop – Ipeak[1..0] = 00/01

2.5

2.9

3.3

A

Open loop – Ipeak[1..0] = 10

3.0

3.4

3.8

Open loop – Ipeak[1..0] = 11

3.5

3.9

4.3

DCLOAD

Load Regulation

IOUT from 0 A to IOUTMAX (Note 10)

−

−0.2

−

%/A

DCLINE

Line Regulation

IOUT = 3 A

2.3 V ≤ VIN ≤ 5.5 V (Note 10)

−

0

−

%

ACLOAD

Transient Load Response

tr = ts = 100 ns

Load step 1.3 A (Note 10)

−

±50

−

mV

ACLINE

Transient Line Response

tr = ts = 10 ms

100 mA Load (Note 10)

D

Maximum Duty Cycle

±30

mV

−

100

−

%

tSTART

Turn on time

Time from EN transitions from Low to

High to 95% of Output Voltage

(DELAY[2..0] = 000b and DVSup = 0)

−

80

100

ms

tSTART

Turn on time

Time from EN transitions from Low to

High to 95% of Output Voltage

(DELAY[2..0] = 000b and DVSup = 1)

−

425

550

ms

DCDC Active Output Discharge

Vout = 1.225 V

−

25

35

W

RDISDCDC

8. Devices that use non−standard supply voltages which do not conform to the intent I2C bus system levels must relate their input levels to

the VDD voltage to which the pull−up resistors RP are connected.

9. Refer to the Application Information section of this data sheet for more details.

10. Guaranteed by design and characterized.

www.onsemi.com

5

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Table 4. ELECTRICAL CHARACTERISTICS (Note 9)

Min and Max Limits apply for TA = −40°C to +85°C, AVIN = PVIN = 3.6 V and default configuration, unless otherwise specified.

Typical values are referenced to TA = +25°C, AVIN = PVIN = 3.6 V and default configuration, unless otherwise specified.

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

EN

VIH

High input voltage

1.05

−

−

V

VIL

Low input voltage

−

−

0.4

V

0.5

−

4.5

ms

−

0.05

1.00

mA

1.7

−

5.0

V

TFTR

IPD

Digital input X Filter

EN rising and falling

DBN_Time = 01 (Note 10)

Digital input X Pull−Down

(input bias current)

I2C

VI2CINT

High level at SCL/SCA line

VI2CIL

SCL, SDA low input voltage

SCL, SDA pin (Notes 8, 10)

−

−

0.5

V

VI2CIH

SCL, SDA high input voltage

SCL, SDA pin (Notes 8, 10)

0.8 *

VI2CINT

−

−

V

VI2COL

SDA low output voltage

ISINK = 3 mA (Note 10)

−

−

0.4

V

I2C clock frequency

(Note 10)

−

−

3.4

MHz

FSCL

TOTAL DEVICE

VUVLO

Under Voltage Lockout

VIN falling

−

−

2.3

V

VUVLOH

Under Voltage Lockout

Hysteresis

VIN rising

60

−

200

mV

−

150

−

°C

−

135

−

°C

TSD

TWARNING

TPWTH

TSDH

TWARNINGH

TPWTH H

Thermal Shut Down Protection

Warning Rising Edge

−

105

−

°C

Thermal Shut Down Hysteresis

−

30

−

°C

Thermal warning Hysteresis

−

15

−

°C

−

6

−

°C

Pre − Warning Threshold

I2C

default value

Thermal pre−warning Hysteresis

8. Devices that use non−standard supply voltages which do not conform to the intent

the VDD voltage to which the pull−up resistors RP are connected.

9. Refer to the Application Information section of this data sheet for more details.

10. Guaranteed by design and characterized.

www.onsemi.com

6

I2C

bus system levels must relate their input levels to

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

TYPICAL OPERATING CHARACTERISTICS AVIN = PVIN = 3.6 V, TJ = +25°C

DCDC = 1.225 V, Ipeak = 3.9 A (Unless otherwise noted). L = 0.47 mH PIFE20161B – Cout = 2x 22 mF 0603, Cin = 4.7 mF 0603.

95

95

VIN = 5.0 V

VIN = 3.6 V

85

90

EFFICIENCY (%)

EFFICIENCY (%)

90

+25°C

VIN = 2.9 V

80

75

−40°C

+85°C

85

80

75

70

70

0

1000

2000

3000

1

10

100

1000

10,000

IOUT (mA)

IOUT (mA)

Figure 4. Efficiency vs. ILOAD and VIN

VOUT = 1.39375 V, SPM6530 Inductor

Figure 5. Efficiency vs. ILOAD and Temperature

VOUT = 1.39375 V, SPM6530 Inductor

95

95

+25°C

90

VIN = 5.0 V

EFFICIENCY (%)

EFFICIENCY (%)

90

85

VIN = 3.6 V

VIN = 2.9 V

80

75

+85°C

85

80

75

70

70

0

1000

2000

3000

1

10

100

1000

10,000

IOUT (mA)

IOUT (mA)

Figure 6. Efficiency vs. ILOAD and VIN

VOUT = 1.225 V, SPM6530 Inductor

Figure 7. Efficiency vs. ILOAD and Temperature

VOUT = 1.225 V, SPM6530 Inductor

90

90

85

+25°C

85

VIN = 5.0 V

EFFICIENCY (%)

EFFICIENCY (%)

−40°C

80

75

VIN = 3.6 V

VIN = 2.9 V

70

−40°C

80

+85°C

75

70

65

65

60

60

0

1000

2000

3000

1

10

100

1000

10,000

IOUT (mA)

IOUT (mA)

Figure 8. Efficiency vs. ILOAD and VIN

VOUT = 0.60 V, SPM6530 Inductor

Figure 9. Efficiency vs. ILOAD and Temperature

VOUT = 0.60 V, SPM6530 Inductor

www.onsemi.com

7

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

95

95

90

90

EFFICIENCY (%)

EFFICIENCY (%)

TYPICAL OPERATING CHARACTERISTICS AVIN = PVIN = 3.6 V, TJ = +25°C

DCDC = 1.225 V, Ipeak = 3.9 A (Unless otherwise noted). L = 0.47 mH PIFE20161B – Cout = 2x 22 mF 0603, Cin = 4.7 mF 0603.

VIN = 5.0 V

85

80

VIN = 3.6 V

VIN = 2.9 V

75

+25°C

−40°C

85

+85°C

80

75

70

70

0

1000

2000

3000

1

10

100

1000

10,000

IOUT (mA)

IOUT (mA)

Figure 10. Efficiency vs. ILOAD and VIN

VOUT = 1.225 V, PIFE20161B Inductor

Figure 11. Efficiency vs. ILOAD and Temperature

VOUT = 1.225 V, PIFE20161B Inductor

1.0

1.237

VOUT ACCURACY (%)

VOUT ACCURACY (V)

VIN = 3.6 V

1.231

VIN = 2.9 V

1.225

VIN = 5.0 V

1.219

0.5

+25°C

+85°C

0

−40°C

−0.5

−1.0

1.213

0

1000

2000

0

3000

1000

2000

3000

ILOAD (mA)

ILOAD (mA)

Figure 12. VOUT Accuracy vs. ILOAD and VIN

VOUT = 1.225 V

Figure 13. VOUT Accuracy vs. ILOAD and

Temperature, VOUT = 1.225 V, VIN = 3.6 V

1.410

0.610

VOUT ACCURACY (V)

VOUT ACCURACY (V)

1.405

0.605

VIN = 3.6 V

VIN = 2.9 V

0.600

VIN = 5.0 V

0.595

VIN = 3.6 V

1.400

VIN = 2.9 V

1.395

VIN = 5.0 V

1.390

1.385

1.380

0.590

0

1000

2000

3000

0

1000

2000

3000

ILOAD (mA)

ILOAD (mA)

Figure 14. VOUT Accuracy vs. ILOAD and VIN

VOUT = 0.60 V

Figure 15. VOUT Accuracy vs. ILOAD and VIN

VOUT = 1.39375 V

www.onsemi.com

8

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

TYPICAL OPERATING CHARACTERISTICS AVIN = PVIN = 3.6 V, TJ = +25°C

DCDC = 1.225 V, Ipeak = 3.9 A (Unless otherwise noted). L = 0.47 mH PIFE20161B – Cout = 2x 22 mF 0603, Cin = 4.7 mF 0603.

35

75

65

30

+85°C

25

+25°C

20

−40°C

55

RONLS (mW)

RONHS (mW)

+85°C

+25°C

45

−40°C

15

35

10

25

2.5

3.0

3.5

4.0

4.5

5.0

2.5

5.5

3.0

3.5

4.0

4.5

5.0

VIN (V)

VIN (V)

Figure 16. HSS RON vs. VIN and Temperature

Figure 17. LSS RON vs. VIN and Temperature

5.5

15

5

4

2

+85°C

IOFF (mA)

IOFF (mA)

10

3

+85°C

+25°C

−40°C

5

+25°C

1

−40°C

0

0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

2.5

3.0

3.5

4.0

4.5

5.0

VIN (V)

VIN (V)

Figure 18. IOFF vs. VIN and Temperature

Figure 19. ISLEEP vs. VIN and Temperature

100

5.5

20

IQ PWM (mA)

IQ (mA)

80

60

+25°C

+85°C

40

15

+85°C

−40°C

20

−40°C

+25°C

10

0

2.5

3.0

3.5

4.0

4.5

5.0

2.5

5.5

3.0

3.5

4.0

4.5

5.0

VIN (V)

VIN (V)

Figure 20. IQ PFM vs. VIN and Temperature

Figure 21. IQ PWM vs. VIN and Temperature

www.onsemi.com

9

5.5

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

TYPICAL OPERATING CHARACTERISTICS AVIN = PVIN = 3.6 V, TJ = +25°C

DCDC = 1.225 V, Ipeak = 3.9 A (Unless otherwise noted). L = 0.47 mH PIFE20161B – Cout = 2x 22 mF 0603, Cin = 4.7 mF 0603.

600

600

500

Enter PWM

Enter PWM

ISWOP (mA)

ISWOP (mA)

500

400

Exit PWM

400

Exit PWM

300

300

200

200

2.5

3.0

3.5

4.0

4.5

5.0

5.5

2.5

3.0

3.5

4.0

4.5

5.0

5.5

VIN (V)

VIN (V)

Figure 22. Switchover Point VOUT = 1.225 V

Figure 23. Switchover Point VOUT = 1.39375 V

17 mV

6.2 mV

3.01 MHz

Figure 24. PWM Ripple

Figure 25. PFM Ripple

85.8 ms

Normal

Power−Up

Figure 26. Normal Power Up, VOUT = 1.225 V

www.onsemi.com

10

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

TYPICAL OPERATING CHARACTERISTICS AVIN = PVIN = 3.6 V, TJ = +25°C

DCDC = 1.225 V, Ipeak = 3.9 A (Unless otherwise noted). L = 0.47 mH PIFE20161B – Cout = 2x 22 mF 0603, Cin = 4.7 mF 0603.

51 mV

50 mV

43 mV

44 mV

0.1 A / 1.4 A / 0.1 A

0.1 A / 1.4 A / 0.1 A

Figure 27. Transient Load 0.1 − 1.4 A

Transient Line 4.2 − 3.6 V Auto Mode

Figure 28. Transient Load 0.1 − 1.4 A

Transient Line 3.6 − 4.2 V Auto Mode

52 mV

51 mV

42 mV

48 mV

1 A / 1.3 A / 1 A

1 A / 1.3 A / 1 A

Figure 29. Transient Load 1.0 − 2.3 A

Transient Line 4.2 − 3.6 V Auto Mode

Figure 30. Transient Load 1.0 − 2.3 A

Transient Line 3.6 − 4.2 V Auto Mode

41 mV

48 mV

38 mV

41 mV

1 A / 1.3 A / 1 A

1 A / 1.3 A / 1 A

Figure 31. Fast Transient Load

0.1 − 1.4 A Auto Mode

Figure 32. Fast Transient Load

1.0 − 2.3 A Auto Mode

www.onsemi.com

11

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

DETAILED OPERATING DESCRIPTION

Detailed Descriptions

Forced PWM

The NCP6343 is voltage mode stand alone synchronous

DC to DC converter optimized to supply different sub

systems of portable applications powered by one cell Li−Ion

or three cells Alkaline/NiCd/NiMh. The IC can deliver up to

3 A at an I2C selectable voltage ranging from 0.60 V to

1.40 V. It can share the same output rail with another DCDC

and works as a transient load helper without sinking current

on shared rail. A 3 MHz switching frequency allows the use

of smaller output filter components. Synchronous

rectification and automatic PWM/PFM transitions improve

overall solution efficiency. Forced PWM is also

configurable. Operating modes, configuration, and output

power can be easily selected either by programming a set of

registers using an I2C compatible interface capable of

operation up to 3.4 MHz. Default I2C settings are factory

programmable.

The NCP6343 can be programmed to only use PWM and

disable the transition to PFM if so desired. (PWM bits of

COMMAND register).

Output Stage

NCP6343 is a high output current capable integrated DC

to DC converter. To supply such a high current, the internal

MOSFETs need to be large. The output stage is composed

of 8 modules that can be individually Enabled / Disabled by

setting the MODULE register.

Inductor Peak Current Limitation

NCP6343 is a 2.0 A to 3.0 A output current capable.

During normal operation, peak current limitation will

monitor and limit the current through the inductor. This

current limitation is particularly useful when size and/or

height constrain inductor power. The user can select peak

current to keep inductor within its specifications. The peak

current can be set by writing IPEAK[1..0] bits in LIMCONF

register.

DC to DC Buck Operation

The converter is a synchronous rectifier type with both

high side and low side integrated switches. Neither external

transistor nor diodes are required for NCP6343 operation.

Feedback and compensation network are also fully

integrated. The converter can operate in two different

modes: PWM and PFM. The transition between PWM/PFM

modes can occur automatically or the switcher can be placed

in forced PWM mode by I2C programming (PWM bits of

COMMAND register).

Table 5. Ipeak VALUES

IPEAK[1..0]

PWM (Pulse Width Modulation) Operating Mode

Default Inductor Peak Current (A)

00

2.9 A for 2.0 A output current

01

2.9 A for 2.0 A output current

10

3.4 A for 2.5 A output current

11

3.9 A for 3.0 A output current

Output Voltage

In medium and high load conditions, NCP6343 operates

in PWM mode from a fixed clock and adapts its duty cycle

to regulate the desired output voltage. In this mode, the

inductor current is in CCM (Continuous Current Mode) and

the voltage is regulated by PWM. The internal N−MOSFET

switch operates as synchronous rectifier and is driven

complementary to the P−MOSFET switch. In CCM, the

lower switch (N−MOSFET) in a synchronous converter

provides a lower voltage drop than the diode in an

asynchronous converter, which provides less loss and higher

efficiency.

Output voltage is set internally by integrated resistor

bridge and error amplifier that drives the PWM/PFM

controller. No extra component is needed to set output

voltage. However, writing in the Vout[6..0] bits of the PROG

register will change settings. Output voltage level can be

programmed in the 0.6 V to 1.4 V range by 6.25 mV steps.

Under Voltage Lock Out (UVLO)

NCP6343 core does not operate for voltages below the

Under Voltage lock Out (UVLO) level. Below UVLO

threshold, all internal circuitry (both analog and digital) is

held in reset.

NCP6343 operation is guaranteed down to VUVLO when

battery voltage is dropping off. To avoid erratic on / off

behavior, a maximum 200 mV hysteresis is implemented.

Restart is guaranteed at 2.5 V when VBAT voltage is

recovering or rising.

PFM (Pulse Frequency Modulation) Operating Mode

In order to save power and improve efficiency at low loads

the NCP6343 operates in PFM mode as the inductor drops

into DCM (Discontinuous Current Mode). The upper FET

on time is kept constant and the switching frequency is

variable. Output voltage is regulated by varying the

switching frequency which becomes proportional to loading

current. As it does in PWM mode, the internal N−MOSFET

operates as synchronous rectifier after each P−MOSFET

on−pulse. When load increases and current in inductor

becomes continuous again, the controller automatically

turns back to PWM mode.

Thermal Management

Thermal shutdown (TSD)

The thermal capability of IC can be exceeded due to step

down converter output stage power level. A thermal

protection circuitry is therefore implemented to prevent the

IC from damage. This protection circuitry is only activated

www.onsemi.com

12

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Active Output Discharge

when the core is in active mode (output voltage is turned on).

During thermal shut down, output voltage is turned off.

When NCP6343 returns from thermal shutdown, it can

re−start in 2 different configurations depending on REARM

bit in the LIMCONF register (see register description

section):

• If REARM = 0 then NCP6343 does not re−start after

TSD. To restart, an EN pin toggle is required.

• If REARM = 1, NCP6343 re−starts with register values

set prior to thermal shutdown.

A Thermal shut down interrupt is raised upon this event.

Thermal shut down threshold is set at 150°C (typical)

when the die temperature increases and, in order to avoid

erratic on / off behavior, a 30°C hysteresis is implemented.

After a typical 150°C thermal shut down, NCP6343 will

resume to normal operation when the die temperature cools

to 120°C.

To make sure that no residual voltage remains in the power

supply rail, an active discharge path can ground the

NCP6343 output voltage.

For maximum flexibility, this feature can be easily

disabled or enabled with DISCHG bit in PGOOD register

However the discharged path is activated during the first

100 ms after battery insertion.

Enabling

The EN pin controls NCP6343 start up: EN pin Low to

High transition starts the power up sequencer. If EN is made

low, the DC to DC converter is turned off and device enters:

• In Sleep Mode if Sleep_Mode I2C bit is high,

• In Off Mode if Sleep_Mode I2C bit is low.

When EN pin is set to a high level, the DC to DC converter

can be enabled / disabled depending of the state of the EN

bit of the PROG register: If EN I2C bit is high, DCDC is

activated, If EN I2C is low the DC to DC converter is turned

off and device enters:

• In Sleep Mode if Sleep_Mode I2C bit is high,

• In Off Mode if Sleep_Mode I2C bit is low.

A built in pull down resistor disables the device when this

pin is left unconnected or not driven.

Thermal Warnings

In addition to the TSD, the die temperature monitoring

will flag potential die over temperature. A thermal warning

and thermal pre−warning are implemented which can

inform the processor through two different interrupts

(accessible via I2C) that NCP6343 is close to its thermal

shutdown so that preventive measures to cool down die

temperature can be taken by software.

The Warning threshold is set by hardware to 135°C typical

when the die temperature increases. The Pre−Warning

threshold is set by default to 105°C, but can be changed by

user by setting the TPWTH[1..0] bits in the LIMCONF

register.

Power Up Sequence (PUS)

In order to power up the circuit, the input voltage AVIN

has to rise above the VUVLO threshold. This triggers the

internal core circuitry power up which is the “Wake Up

Time” (including “Bias Time”).

This delay is internal and cannot be bypassed. EN pin

transition within this delay corresponds to the “Initial power

up sequence” (IPUS):

AVIN

UVLO

POR

EN

VOUT

ÏÏÏÏÏ

ÏÏÏÏÏ

DELAY[2..0]

~ 50 us

32 us

Wake up

Time

Init

Time

DVS ramp

Time

Figure 33. Initial Power Up Sequence

www.onsemi.com

13

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Normal, Quick and Fast Power Up Sequence

In addition a user programmable delay will also take place

between end of Core circuitry turn on (Wake Up Time and

Bias Time) and Init time: The DELAY[2..0] bits of TIME

register will set this user programmable delay with a 2 ms

resolution. With default delay of 0 ms, the NCP6343 IPUS

takes roughly 85 ms, means DCDC output voltage will be

ready within 110 ms.

NOTE: During the Wake Up time, the I2C interface is not

active. Any I2C request to the IC during this time period will

result in a NACK reply.

The previous description applies only when the EN

transitions during the internal core circuitry power up (Wake

up and calibration time). Otherwise 3 different cases are

possible:

Enabling the part by setting EN pin from Off Mode will

result in “Normal power up sequence” (NPUS, with

DELAY;[2..0]).

Enabling the part by setting EN pin from Sleep Mode will

result in “Quick power up sequence” (QPUS, with

DELAY;[2..0]).

Enabling the part by setting EN bits of the PROG register

(whereas EN is already high results in “Fast power up

sequence” (FPUS, without DELAY[2..0]).

AVIN

UVLO

POR

EN

O

F

F

DELAY[2..0]

VOUT M

20 us

32 us

TFTR Bias

Time

Init

Time

O

D

E

DVS ramp

Time

Figure 34. Normal Power Up Sequence (EN pin)

AVIN

UVLO

POR

EN

S

L

E

E

P

VOUT

M

O

D

E

DELAY[2..0]

32 us

TFTR

Init

Time

DVS ramp

Time

Figure 35. Quick Power Up Sequence (EN pin)

AVIN

UVLO

POR

EN I@C S

L

E

E

P

VOUT

M

O

D

E

32 us

Init

Time

DVS ramp

Time

Figure 36. Fast Power Up Sequence (EN bit)

www.onsemi.com

14

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

• In Auto mode when output voltage has not to be

In addition the delay set in DELAY[2..0] bits in TIME

register will apply only for the EN pins turn ON sequence

(NPUS and QPUS).

discharged. Note that approximately 30 ms is needed to

transition from PFM mode to PWM mode.

Note that the sleep mode needs about 150 ms to be

established.

nV

DC to DC converter Shut Down

When shutting down the device, no shut down sequence

is required. Output voltage is disabled and, depending on the

DISCHG bit state of PGOOD register, output may be

discharged.

Shutdown is initiated by either grounding the EN pin

(Hardware Shutdown) or by clearing the EN I2C bit

(Software shutdown) in PROG register.

In hardware shutdown (EN = 0), the internal core is still

active and I2C accessible.

NCP6343 shuts internal core down when AVIN falls

below UVLO.

nt

V1

Figure 38. DVS in Auto Mode Diagram

Power Good

To indicate the output voltage level is established, a power

good signal is available.

The power good signal is high when the channel is off and

goes low when enabling the channel. Once the output

voltage reaches 95% of the expected output level, the power

good logic signal becomes high (ACK_PG, SEN_PG bits).

During operation when the output drops below 90% of the

programmed level the power good logic signal goes low,

indicating a power failure. When the voltage rises again to

above 95% the power good signal goes high again.

During a positive DVS sequence, when target voltage is

higher than initial voltage, the Power Good logic signal will

be set low during output voltage ramping and transition to

high once the output voltage reaches 95% of the target

voltage. When the target voltage is lower than the initial

voltage, Power Good logic signals will remain at high level

during transition.

Power Good signal during normal operation can be

disabled by clearing the PGDCDC bit in PGOOD register.

Power Good operation during DVS can be controlled by

setting / clearing the bit PGDVS in PGOOD register

Dynamic Voltage Scaling (DVS)

This converter supports dynamic voltage scaling (DVS)

allowing the output voltage to be reprogrammed via I2C

commands and provides the different voltages required by

the processor. The change between set points is managed in

a smooth fashion without disturbing the operation of the

processor.

When programming a higher voltage, output raises with

controlled dV/dt defined by DVSup bit in TIME register

(default 6.25 mV/0.166 ms). When programming a lower

voltage, output will decrease in equidistant steps defined by

DVSdown[1..0] bits in TIME register (default

6.25 mV/2.666 ms).

DVS sequence is automatically initiated by changing

output voltage settings.

The DVS transition mode can be changed with the

DVSMODE bit in COMMAND register:

• In forced PWM mode when accurate output voltage

control is needed.

DCDC_EN

DCDC

V2

Internal

Reference

Output

Voltage

V2

Internal

Reference

95%

90%

32 us

min

3.5−

14 us

Output

Voltage

nV

3.5 us

3.5−

14 us

PG

nt

Figure 39. Power Good Signal

V1

Figure 37. DVS in Forced PWM Mode Diagram

www.onsemi.com

15

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Interrupt

Individual bits generating interrupts will be set to 1 in the

INT_ACK register (I2C read only registers), indicating the

interrupt source. INT_ACK register is automatically reset

by an I2C read. The INT_SEN register (read only register)

contains real time indicators of interrupt sources.

When the host reads the INT_ACK registers the interrupt

register INT_ACK is cleared.

Figure 40 is UVLO event example:

INT_SEN/INT_MSK/INT_ACK and an I2C read access

behavior.

The interrupt controller continuously monitors internal

interrupt sources, generating an interrupt signal when a

system status change is detected (dual edge monitoring).

Table 6. INTERRUPT SOURCES

Interrupt Name

TSD

Description

Thermal Shut Down

TWARN

Thermal Warning

TPREW

Thermal Pre Warning

UVLO

Under Voltage Lock Out

IDCDC

DCDC current Over / below limit

PG

Power Good

UVLO

SEN_UVLO

ACK_UVLO

I@C access on INT_ACK

read

read

read

read

Figure 40. Interrupt Operation Example

Configurations

Default output voltages, enables, DCDC modes, current limit and other parameters can be factory programmed upon request.

The default configuration pre−defined is depicted below:

Table 7. DEFAULT CONFIGURATIONS

Configuration

NCP6343

NCP6343A

NCP6343B

I2C

0x1C

12h

xxh

00h

0x14

12h

xxh

02h

0x1C

12h

xxh

01h

VOUT

1.225 V

1.225 V

1.225 V

MODE

Auto mode

Forced PWM mode

Auto mode

DVS Up Timing

6.25mV/0.166ms

6.25mV/0.166ms

6.25mV/0.166ms

Default IPEAK

2.9 A

3.9 A

3.9 A

Default

address

PID product id.

RID revision id.

FID feature id.

Marking

OPN

6343

6343A

6343B

NCP6343FCT1G

NCP6343AFCCT1G

NCP6343BFCCT1G

Table 8. DEFAULT CONFIGURATIONS

Configuration

NCP6343D

NCP6343AV

NCP6343S

NCP6343M

Default I2C address

PID product id.

RID revision id.

FID feature id.

0x14

12h

xxh

03h

0x14

12h

xxh

02h

0x10

12h

xxh

00h

0x18

12h

xxh

00h

VOUT

1.18125 V

1.225 V

1.050 V

0.925 V

MODE

Forced PWM mode

Auto mode

Auto mode

Auto mode

DVS Up Timing

6.25mV/0.166ms

6.25mV/2.666ms

6.25mV/2.666ms

6.25mV/2.666ms

Default IPEAK

3.9 A

3.9 A

3.9 A

3.9 A

6343D

6343V

6343S

6343M

NCP6343DFCCT1G

NCP6343AVFCCT1G

NCP6343SFCCT1G

NCP6343MFCCT1G

Marking

OPN

www.onsemi.com

16

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

I2C Compatible Interface

NCP6343 can support a subset of I2C protocol Detailed below.

I2C Communication Description

FROM MCU to NCPxxxx

FROM NCPxxxx to MCU

START

IC ADDRESS

1

ACK

0

ACK

ACK

DATA 1

DATA n

/ACK

STOP

READ OUT

FROM PART

STOP

WRITE INSIDE

PART

1 à READ

/ACK

START

IC ADDRESS

ACK

DATA 1

DATA n

ACK

If PART does not Acknowledge, the /NACK will be followed by a STOP or Sr.

If PART Acknowledges, the ACK can be followed by another data or Stop or Sr

0 à WRITE

Figure 41. General Protocol Description

• In case of read operation, the NCP6343 will output the

The first byte transmitted is the Chip address (with the

LSB bit set to 1 for a read operation, or set to 0 for a Write

operation). The following data will be:

• In case of a Write operation, the register address

(@REG) pointing to the register we want to write in

followed by the data we will write in that location. The

writing process is auto−incremental, so the first data

will be written in @REG, the contents of @REG are

incremented and the next data byte is placed in the

location pointed to by @REG + 1 ..., etc.

data from the last register that has been accessed by the

last write operation. Like the writing process, the

reading process is auto−incremental.

Read Out from Part

The Master will first make a “Pseudo Write” transaction

with no data to set the internal address register. Then, a stop

then start or a Repeated Start will initiate the read transaction

from the register address the initial write transaction has

pointed to:

FROM MCU to NCPxxxx

FROM NCPxxxx to MCU

SETS INTERNAL

REGISTER POINTER

START

IC ADDRESS

0

ACK

REGISTER ADDRESS

ACK

STOP

0 à WRITE

START

IC ADDRESS

1

ACK

ACK

DATA 1

REGISTER ADDRESS

VALUE

DATA n

/ACK

STOP

REGISTER ADDRESS + (n − 1)

VALUE

n REGISTERS READ

1 à READ

Figure 42. Read Out from Part

The first WRITE sequence will set the internal pointer to the register we want access to. Then the read transaction will start

at the address the write transaction has initiated.

www.onsemi.com

17

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Transaction with Real Write then Read

With Stop Then Start

FROM MCU to NCPxxxx

FROM NCPxxxx to MCU

SETS INTERNAL

REGISTER POINTER

START

IC ADDRESS

ACK

0

WRITE VALUE IN

REGISTER REG0

ACK

REGISTER REG0 ADDRESS

WRITE VALUE IN

REGISTER REG0 + (n − 1)

ACK

REG VALUE

ACK

REG + (n − 1) VALUE

STOP

n REGISTERS WRITE

0 à WRITE

START

IC ADDRESS

1

ACK

ACK

DATA 1

/ACK

DATA k

STOP

REGISTER ADDRESS + (n − 1) +

(k − 1) VALUE

REGISTER REG + (n − 1)

VALUE

k REGISTERS READ

1 à READ

Figure 43. Write Followed by Read Transaction

Write In Part

Write operation will be achieved by only one transaction. After chip address, the MCU first data will be the internal register

we want access to, then following data will be the data we want to write in Reg, Reg + 1, Reg + 2, ...., Reg +n.

Write n Registers:

FROM MCU to NCPxxxx

FROM NCPxxxx to MCU

WRITE VALUE IN

REGISTER REG0

SETS INTERNAL

REGISTER POINTER

START

IC ADDRESS

0

ACK

ACK

REGISTER REG0 ADDRESS

WRITE VALUE IN

REGISTER REG0 + (n − 1)

ACK

REG VALUE

ACK

REG + (n − 1) VALUE

STOP

n REGISTERS WRITE

0 à WRITE

Figure 44. Write In n Registers

I2C Address

NCP6343 has four available I2C address selectable by factory settings (ADD0 to ADD3). Different address settings can be

generated upon request to ON Semiconductor. The default address is set to 38h / 39h since the NCP6343 supports 7−bit address

only and ignores A0.

Table 9. I2C ADDRESS

I2C Address

ADD0

(NCP6343S)

Hex

A7

A6

A5

A4

A3

A2

A1

A0

W 0x20

R 0x21

0

0

1

0

0

0

0

R/W

Add

ADD1

(NCP6343AV, NCP6343D)

0x10

W 0x28

R 0x29

0

0

1

Add

ADD2

(NCP6343M)

1

0

0

0x14

W 0x30

R 0x31

0

0

1

Add

ADD3 (default)

(NCP6343, NCP6343B)

0

−

1

−

0

0

0

0x18

W 0x38

R 0x39

0

0

Add

1

1

0x1C

www.onsemi.com

18

R/W

R/W

−

1

0

0

R/W

−

�NCP6343

CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

Register Map

Table 10 describes I2C registers.

Registers can be:

R

RC

RW

Reserved

Spare

Read only register

Read then Clear

Read and Write register

Address is reserved and register is not physically designed

Address is reserved and register is physically designed

Table 10. I2C REGISTERS MAP DEFAULT CONFIGURATION (NCP6343)

Add.

Register Name

Type

Def.

00h

INT_ACK

RC

00h

Interrupt register

Function

01h

INT_SEN

R

00h

Sense register (real time status)

02h

−

−

−

03h

PID

R

12h

Product Identification

04h

RID

R

Metal

Revision Identification

Reserved for future use

05h

FID

R

00h

06h to 10h

−

−

−

Feature Identification (trim)

11h

PROG

RW

E4h

Output voltage settings and (trim)

12h

PGOOD

RW

00h

Power good and active discharge settings (partial trim)

13h

TIME

RW

19h

Enabling and DVS timings (trim)

14h

COMMAND

RW

00h

Enabling and Operating mode Command register (partial trim)

15h

MODULE

RW

80h

Active module count settings

16h

LIMCONF

RW

23h

Reset and limit configuration register (partial trim)

17h to 1Fh

−

−

−

Reserved for future use

20h to FFh

−

−

−

Reserved. Test Registers

Reserved for future use

Table 11. I2C REGISTERS MAP DEFAULT CONFIGURATION (NCP6343A)

Add.

Register Name

Type

Def.

Function

00h

INT_ACK

RC

00h

Interrupt register

01h

INT_SEN

R

00h

Sense register (real time status)

02h

−

−

−

03h

PID

R

12h

Reserved for future use

Product Identification

04h

RID

R

Metal

Revision Identification

05h

FID

R

02h

06h to 10h

−

−

−

11h

PROG

RW

E4h

Output voltage settings and (trim)

12h

PGOOD

RW

00h

Power good and active discharge settings (partial trim)

13h

TIME

RW

19h

Enabling and DVS timings (trim)

14h

COMMAND

RW

80h

Enabling and Operating mode Command register (partial trim)

15h

MODULE

RW

80h

Active module count settings

16h

LIMCONF

RW

E3h

Reset and limit configuration register (partial trim)

17h to 1Fh

−

−

−

Reserved for future use

20h to FFh

−

−

−

Reserved. Test Registers

Feature Identification (trim)

Reserved for future use

www.onsemi.com

19

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Table 12. I2C REGISTERS MAP DEFAULT CONFIGURATION (NCP6343B)

Add.

Register Name

Type

Def.

Function

00h

INT_ACK

RC

00h

Interrupt register

01h

INT_SEN

R

00h

Sense register (real time status)

02h

−

−

−

03h

PID

R

12h

Product Identification

04h

RID

R

Metal

Revision Identification

05h

FID

R

01h

06h to 10h

−

−

−

11h

PROG

RW

E4h

Output voltage settings and (trim)

12h

PGOOD

RW

00h

Power good and active discharge settings (partial trim)

13h

TIME

RW

19h

Enabling and DVS timings (trim)

14h

COMMAND

RW

00h

Enabling and Operating mode Command register (partial trim)

15h

MODULE

RW

80h

Active module count settings

16h

LIMCONF

RW

E3h

Reset and limit configuration register (partial trim)

17h to 1Fh

−

−

−

Reserved for future use

20h to FFh

−

−

−

Reserved. Test Registers

Reserved for future use

Feature Identification (trim)

Reserved for future use

Table 13. I2C REGISTERS MAP DEFAULT CONFIGURATION (NCP6343D)

Add.

Register Name

Type

Def.

00h

INT_ACK

RC

00h

Interrupt register

Function

01h

INT_SEN

R

00h

Sense register (real time status)

02h

−

−

−

03h

PID

R

12h

Product Identification

04h

RID

R

Metal

Revision Identification

Reserved for future use

05h

FID

R

03h

06h to 10h

−

−

−

Feature Identification (trim)

11h

PROG

RW

DDh

Output voltage settings and (trim)

12h

PGOOD

RW

00h

Power good and active discharge settings (partial trim)

13h

TIME

RW

19h

Enabling and DVS timings (trim)

14h

COMMAND

RW

80h

Enabling and Operating mode Command register (partial trim)

15h

MODULE

RW

80h

Active module count settings

16h

LIMCONF

RW

E3h

Reset and limit configuration register (partial trim)

17h to 1Fh

−

−

−

Reserved for future use

20h to FFh

−

−

−

Reserved. Test Registers

Reserved for future use

www.onsemi.com

20

�NCP6343

CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

Table 14. I2C REGISTERS MAP DEFAULT CONFIGURATION (NCP6343AV)

Add.

Register Name

Type

Def.

Function

00h

INT_ACK

RC

00h

Interrupt register

01h

INT_SEN

R

00h

Sense register (real time status)

02h

−

−

−

03h

PID

R

12h

Product Identification

04h

RID

R

Metal

Revision Identification

05h

FID

R

02h

06h to 10h

−

−

−

11h

PROG

RW

E4h

Output voltage settings and (trim)

12h

PGOOD

RW

00h

Power good and active discharge settings (partial trim)

13h

TIME

RW

1Dh

Enabling and DVS timings (trim)

14h

COMMAND

RW

00h

Enabling and Operating mode Command register (partial trim)

15h

MODULE

RW

80h

Active module count settings

16h

LIMCONF

RW

E3h

Reset and limit configuration register (partial trim)

17h to 1Fh

−

−

−

Reserved for future use

20h to FFh

−

−

−

Reserved. Test Registers

Reserved for future use

Feature Identification (trim)

Reserved for future use

Table 15. I2C REGISTERS MAP DEFAULT CONFIGURATION (NCP6343S)

Add.

Register Name

Type

Def.

00h

INT_ACK

RC

00h

Interrupt register

Function

01h

INT_SEN

R

00h

Sense register (real time status)

02h

−

−

−

03h

PID

R

12h

Product Identification

04h

RID

R

Metal

Revision Identification

Reserved for future use

05h

FID

R

00h

06h to 10h

−

−

−

Feature Identification (trim)

11h

PROG

RW

C8h

Output voltage settings and (trim)

12h

PGOOD

RW

00h

Power good and active discharge settings (partial trim)

13h

TIME

RW

1Dh

Enabling and DVS timings (trim)

14h

COMMAND

RW

00h

Enabling and Operating mode Command register (partial trim)

15h

MODULE

RW

80h

Active module count settings

16h

LIMCONF

RW

E3h

Reset and limit configuration register (partial trim)

17h to 1Fh

−

−

−

Reserved for future use

20h to FFh

−

−

−

Reserved. Test Registers

Reserved for future use

www.onsemi.com

21

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Table 16. I2C REGISTERS MAP DEFAULT CONFIGURATION (NCP6343M)

Add.

Register Name

Type

Def.

Function

00h

INT_ACK

RC

00h

Interrupt register

01h

INT_SEN

R

00h

Sense register (real time status)

02h

−

−

−

03h

PID

R

12h

Product Identification

04h

RID

R

Metal

Revision Identification

05h

FID

R

00h

06h to 10h

−

−

−

11h

PROG

RW

B4h

Output voltage settings and (trim)

12h

PGOOD

RW

00h

Power good and active discharge settings (partial trim)

13h

TIME

RW

1Dh

Enabling and DVS timings (trim)

14h

COMMAND

RW

00h

Enabling and Operating mode Command register (partial trim)

15h

MODULE

RW

80h

Active module count settings

16h

LIMCONF

RW

E3h

Reset and limit configuration register (partial trim)

17h to 1Fh

−

−

−

Reserved for future use

20h to FFh

−

−

−

Reserved. Test Registers

Reserved for future use

Feature Identification (trim)

Reserved for future use

www.onsemi.com

22

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Registers Description

Table 17. INTERRUPT ACKNOWLEDGE REGISTER

Name: INTACK

Address: 00h

Type: RC

Default: 00000000b (00h)

Trigger: Dual Edge [D7..D0]

D7

D6

D5

D4

D3

D2

D1

D0

ACK_TSD

ACK_TWARN

ACK_TPREW

Spare = 0

Spare= 0

ACK_UVLO

ACK_IDCDC

ACK_PG

Bit

Bit Description

ACK_PG

Power Good Sense Acknowledgement

0: Cleared

1: DCDC Power Good Event detected

ACK_IDCDC

DCDC Over Current Sense Acknowledgement

0: Cleared

1: DCDC Over Current Event detected

ACK_UVLO

Under Voltage Sense Acknowledgement

0: Cleared

1: Under Voltage Event detected

ACK_TPREW

Thermal Pre Warning Sense Acknowledgement

0: Cleared

1: Thermal Pre Warning Event detected

ACK_TWARN

Thermal Warning Sense Acknowledgement

0: Cleared

1: Thermal Warning Event detected

ACK_TSD

Thermal Shutdown Sense Acknowledgement

0: Cleared

1: Thermal Shutdown Event detected

Table 18. INTERRUPT SENSE REGISTER

Name: INTSEN

Address: 01h

Type: R

Default: 00000000b (00h)

Trigger: N/A

D7

D6

D5

D4

D3

D2

D1

D0

SEN_TSD

SEN_TWARN

SEN_TPREW

Spare = 0

Spare = 0

SEN_UVLO

SEN_IDCDC

SEN_PG

Bit

SEN_PG

Bit Description

Power Good Sense

0: DCDC Output Voltage below target

1: DCDC Output Voltage within nominal range

SEN _IDCDC

DCDC over current sense

0: DCDC output current is below limit

1: DCDC output current is over limit

SEN _UVLO

Under Voltage Sense

0: Input Voltage higher than UVLO threshold

1: Input Voltage lower than UVLO threshold

SEN _TPREW

Thermal Pre Warning Sense

0: Junction temperature below thermal pre−warning limit

1: Junction temperature over thermal pre−warning limit

SEN _TWARN

Thermal Warning Sense

0: Junction temperature below thermal warning limit

1: Junction temperature over thermal warning limit

SEN _TSD

Thermal Shutdown Sense

0: Junction temperature below thermal shutdown limit

1: Junction temperature over thermal shutdown limit

www.onsemi.com

23

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Table 19. PRODUCT ID REGISTER

Name: PID

Address: 03h

Type: R

Default: 00010010b (12h)

Trigger: N/A

Reset on N/A

D7

D6

D5

D4

D3

D2

D1

D0

PID_7

PID_6

PID_5

PID_4

PID_3

PID_2

PID_1

PID_0

Table 20. REVISION ID REGISTER

Name: RID

Address: 04h

Type: R

Default: Metal

Trigger: N/A

D7

D6

D5

D4

D3

D2

D1

D0

Spare = 0

Spare = 0

Spare = 0

Spare = 0

RID_3

RID_2

RID_1

RID_0

Bit

Bit Description

RID[3..0]

Revision Identification

0000: First silicon

0100: Optimized silicon

1000: Production

Table 21. FEATURE ID REGISTER

Name: FID

Address: 05h

Type: R

Default: Metal

Trigger: N/A

D7

D6

D5

D4

D3

D2

D1

D0

Spare = 0

Spare = 0

Spare = 0

Spare = 0

FID_3

FID_2

FID_1

FID_0

Bit

FID[3..0]

Bit Description

Feature Identification

0000: Default Configuration

Table 22. DC to DC VOLTAGE PROG REGISTER

Name: PROG

Address: 11h

Type: RW

Default: See Register map

Trigger: N/A

D7

D6

D5

D4

D3

D2

EN

Vout[6..0]

Bit

Vout[6..0]

EN

Bit Description

Sets the DC to DC converter output

0000000b = 600 mV − 1111111b = 1393.75 mV (steps of 6.25 mV)

EN Pin Gating

0: Disabled

1: Enabled

www.onsemi.com

24

D1

D0

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Table 23. POWER GOOD REGISTER

Name: PGOOD

Address: 12h

Type: RW

Default: See Register map

Trigger: N/A

D7

Spare = 0

D6

D5

D4

D3

D2

D1

D0

Spare = 0

Spare = 0

DISCHG

Spare = 0

Spare = 0

PGDVS

PGDCDC

Bit

Bit Description

PGDCDC

Power Good Enabling

0 = Disabled

1 = Enabled

PGDVS

Power Good Active On DVS

0 = Disabled

1 = Enabled

DISCHG

Active discharge bit Enabling

0 = Discharge path disabled

1 = Discharge path enabled

Table 24. TIMING REGISTER

Name: TIME

Address: 13h

Type: RW

Default: See Register map

Trigger: N/A

D7

D6

D5

D4

DELAY[2..0]

D3

DVSdown[1..0]

Bit

DBN_Time[1..0]

Bit Description

EN debounce time

00 = No debounce

01 = 1−2 ms

10 = 2−3 ms

11 = 3−4 ms

DVSup

DVS Speed for up DVS

0 = 6.25 mV step / 0.166 ms

1 = 6.25 mV step / 2.666 ms

DVSdown[1..0]

DVS Speed for down DVS

00 = 6.25 mV step / 0.333 ms

01 = 6.25 mV step / 0.666 ms

10 = 6.25 mV step / 1.333 ms

11 = 6.25 mV step / 2.666 ms

DELAY[2..0]

Delay applied upon enabling (ms)

000b = 0 ms − 111b = 14 ms (Steps of 2 ms)

www.onsemi.com

25

D2

DVSup

D1

D0

DBN_Time[1..0]

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Table 25. COMMAND REGISTER

Name: COMMAND

Address: 14h

Type: RW

Default: See Register map

Trigger: N/A

D7

PWM

D6

D5

D4

D3

D2

D1

D0

Spare = 0

DVSMODE

Sleep_Mode

Spare = 0

Spare = 0

Spare = 0

Spare = 0

Bit

Bit Description

Sleep_Mode

Sleep mode

0 = Low Iq mode when EN low

1 = Force product in sleep mode

DVSMODE

DVS transition mode selection

0 = Auto

1 = Forced PWM

PWM

DCDC Operating mode

0 = Auto

1 = Forced PWM

Table 26. OUTPUT STAGE MODULE SETTINGS REGISTER

Name: MODULE

Address: 15h

Type: RW

Default: See Register map

Trigger: N/A

D7

D6

D5

D4

MODUL[3..0]

D3

D2

D1

D0

Spare =0

Spare =0

Spare =0

Spare =0

Bit

Bit Description

MODUL [3..0]

Number of modules

0000 = 1 Module − 0111 ~ 1111 = 8 Modules (Steps of 1)

Table 27. LIMITS CONFIGURATION REGISTER

Name: LIMCONF

Adress: 16h

Type: RW

Default: See Register map

Trigger: N/A

D7

D6

IPEAK[1..0]

D5

D4

TPWTH[1..0]

D3

D2

D1

D0

Spare = 0

FORCERST

RSTSTATUS

REARM

Bit

REARM

Bit Description

Rearming of device after TSD

0: No re−arming after TSD

1: Re−arming active after TSD with no reset of I2C registers: new power−up sequence is initiated with

previously programmed I2C registers values

RSTSTATUS

Reset Indicator Bit

0: Must be written to 0 after register reset

1: Default (loaded after Registers reset)

FORCERST

Force Reset Bit

0 = Default value. Self cleared to 0

1: Force reset of internal registers to default

TPWTH[1..0]

Thermal pre−Warning threshold settings

00 = 83°C

01 = 94°C

10 = 105°C

11 = 116°C

IPEAK

Inductor peak current settings

00 = 2.9 A (Iload 2.0 A)

01 = 2.9 A (Iload 2.0 A)

10 = 3.4 A (Iload 2.5 A)

11 = 3.9 A (Iload 3.0 A)

www.onsemi.com

26

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

APPLICATION INFORMATION

NCP6243

Supply

Input

AVIN

D1

AGND

E1

A1

B1

C1

Core

References

Oscillator

A2

B2

Thermal

Protection

Processor

I2C Control

Interface

EN

SDA

SCL

A3

B3

C3

C2

D2

Operating

Mode

Control

I2C

D3

E2

Supply

Input

10 mF

DCDC

3.0 A

Enable

Control

Input

PVIN

E3

DCDC

3 MHz

Controller

SW

470 nH

22 mF

PGND

FB

Core

Processor

Memory

22 mF

Sense

Figure 45. Typical Application Schematic

Output Filter Design Considerations

Components Selection

The output filter introduces a double pole in the system at

a frequency of:

Inductor Selection

f LC +

The inductance of the inductor is determined by given

peak−to−peak ripple current IL_PP of approximately 20% to

50% of the maximum output current IOUT_MAX for a

trade−off between transient response and output ripple. The

inductance corresponding to the given current ripple is:

1

2 @ p @ ǸL @ C

NCP6343 internal compensation network is optimized for

a typical output filter comprising a 470 nH inductor and

22 mF capacitor as describes in the basic application

schematic is described by Figure 16.

L+

Voltage Sensing Considerations

ǒVIN * VOUTǓ @ VOUT

V IN @ f SW @ I L_PP

The selected inductor must have high enough saturation

current rating to be higher than the maximum peak current

that is

In order to regulate power supply rail, NCP6343 should

sense its output voltage. Thanks to the FB pin, the IC can

support two sensing methods:

• Normal case: the voltage sensing is achieved close to

the output capacitor. In that case, FB is connected to the

output capacitor positive terminal (voltage to regulate).

• Remote sensing: In remote sensing, the power supply

rail sense is made close to the system powered by the

NCP6343. The voltage to system is more accurate, since

PCB line impedance voltage drop is within the regulation

loop. In that case, we recommend connecting the FB pin

to the system decoupling capacitor positive terminal.

I L_MAX + I OUT_MAX )

I L_PP

2

The inductor also needs to have high enough current

rating based on temperature rise concern. Low DCR is good

for efficiency improvement and temperature rise reduction.

Table 28 shows recommended.

Table 28. INDUCTOR SELECTION

Supplier

Part #

Value (mH)

Size (mm) (L x l x T)

DC Rated Current (A)

DCR Max at 255C (mW)

Cyntec

PIFE20161B−R47−MS−11

0.47

2.0 x 1.6 x 1.2

3.9

36

Cyntec

PIFE25201T−R47−MS−11

0.47

2.5 x 2.0 x 1.0

4.5

41

TOKO

DFE201612P−H−R47M

0.47

2.0 x 1.6 x 1.2

4.3

33

TOKO

DFE201610R−H−R47N

0.47

2.0 x 1.6 x 1.0

3.3

48

TOKO

DFE201612R−H−R47N

0.47

2.0 x 1.6 x 1.2

3.8

40

TDK

TFM252010A−R47M

0.47

2.5 x 2.0 x 1.0

4.5

30

TDK

SPM6530T−R47M170

0.47

7.1 x 6.5 x 3.0

20

4

www.onsemi.com

27

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

Output Capacitor Selection

The input capacitor also needs to be sufficient to protect

the device from over voltage spike, and normally at least

4.7 mF capacitor is required. The input capacitor should be

located as close as possible to the IC. All PGNDs are

connected together to the ground terminal of the input cap

which then connects to the ground plane. All PVIN are

connected together to the Vbat terminal of the input cap

which then connects to the Vbat plane.

The output capacitor selection is determined by output

voltage ripple and load transient response requirement. For

high transient load performance high output capacitor value

must be used. For a given peak−to−peak ripple current IL_PP

in the inductor of the output filter, the output voltage ripple

across the output capacitor is the sum of three components

as below.

V OUT_PP [ V OUT_PP(C) ) V OUT_PP(ESR) ) V OUT_PP(ESL)

Electrical Layout Considerations

Good electrical layout is a key to make sure proper

operation, high efficiency, and noise reduction. Electrical

layout guidelines are:

• Use wide and short traces for power paths (such as

PVIN, VOUT, SW, and PGND) to reduce parasitic

inductance and high−frequency loop area. It is also

good for efficiency improvement.

• The device should be well decoupled by input capacitor

and input loop area should be as small as possible to

reduce parasitic inductance, input voltage spike, and

noise emission.

• SW node should be a large copper, but compact

because it is also a noise source.

• It would be good to have separated ground planes for

PGND and AGND and connect the two planes at one

point. Try best to avoid overlap of input ground loop

and output ground loop to prevent noise impact on

output regulation.

• Arrange a “quiet” path for output voltage sense, and

make it surrounded by a ground plane.

Where VOUT_PP(C) is a ripple component by an equivalent

total capacitance of the output capacitors, VOUT_PP(ESR) is

a ripple component by an equivalent ESR of the output

capacitors, and VOUT_PP(ESL) is a ripple component by an

equivalent ESL of the output capacitors. In PWM operation

mode, the three ripple components can be obtained by

V OUT_PP(C) +

I L_PP

8 @ C @ f SW

, and V OUT_PP(ESR) +I L_PP@ESR

V OUT_PP(ESL) +

ESL @ V

IN

ESL ) L

and the peak−to−peak ripple current is

I L_PP +

ǒV IN * VOUTǓ @ VOUT

V IN @ f SW @ L

In applications with all ceramic output capacitors, the

main ripple component of the output ripple is VOUT_PP(C).

So that the minimum output capacitance can be calculated

regarding to a given output ripple requirement VOUT_PP in

PWM operation mode.

C MIN +

I L_PP

8 @ V OUT_PP @ f SW

Thermal Layout Considerations

Good PCB layout helps high power dissipation from a

small package with reduced temperature rise. Thermal

layout guidelines are:

• A four or more layers PCB board with solid ground

planes is preferred for better heat dissipation.

• More free vias are welcome to be around IC to connect

the inner ground layers to reduce thermal impedance.

• Use large area copper especially in top layer to help

thermal conduction and radiation.

• Use two layers for the high current paths (PVIN,

PGND, SW) in order to split current in two different

paths and limit PCB copper self heating.

Input Capacitor Selection

One of the input capacitor selection guides is the input

voltage ripple requirement. To minimize the input voltage

ripple and get better decoupling in the input power supply

rail, ceramic capacitor is recommended due to low ESR and

ESL. The minimum input capacitance regarding to the input

ripple voltage VIN_PP is

C IN_MIN +

I OUT_MAX @ (D * D 2)

V IN_PP @ f SW

where

D+

V OUT

V IN

In addition, the input capacitor needs to be able to absorb

the input current, which has a RMS value of

I IN_RMS + I OUT_MAX @ ǸD * D 2

www.onsemi.com

28

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

(See demo board example Figure 47)

Figure 46. Layout Recommendation

Legend:

In blue are top layer planes and wires

In white are layer1 plane and wires (just below top layer)

Big circles gray are normal vias

Small circles gray are top to layer1 vias

Figure 47. Demo Board Example

PGND directly connected to Cin input capacitor, and then

connected to the GND plane: Local mini planes used on the

top layer (blue) and layer just below top layer (white) with

laser vias.

SW connected to the Lout inductor with trace between input

capacitor terminals on top layer (blue) and local mini planes

on the layer just below top layer (white) with laser vias.

Input capacitor placed as close as possible to the IC.

PVIN directly connected to Cin input capacitor, and then

connected to the Vin plane. Local mini planes used on the top

layer (blue) and layer just below top layer (white) with laser

vias.

AVIN connected to the Vin plane just after the capacitor.

AGND directly connected to the GND plane.

www.onsemi.com

29

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

ORDERING INFORMATION

Marking

Package

Comment

Shipping†

6343

WLCSP15 without Back Coating

(Pb–Free)

I2C address 0x1C

(0011100x b)

3000 / Tape & Reel

NCP6343AFCCT1G

6343A

WLCSP15 with Back Coating

(Pb–Free)

I2C address 0x14

(0010100x b)

3000 / Tape & Reel

NCP6343BFCCT1G

6343B

WLCSP15 with Back Coating

(Pb–Free)

I2C address 0x1C

(0011100x b)

3000 / Tape & Reel

NCP6343DFCCT1G

6343D

WLCSP15 with Back Coating

(Pb–Free)

I2C address 0x14

(0010100x b)

3000 / Tape & Reel

NCP6343AVFCCT1G

6343V

WLCSP15 with Back Coating

(Pb–Free)

I2C address 0x14

(0010100x b)

3000 / Tape & Reel

NCP6343SFCCT1G

6343S

WLCSP15 with Back Coating

(Pb–Free)

I2C address 0x10

(0010000x b)

3000 / Tape & Reel

NCP6343MFCCT1G

6343M

WLCSP15 with Back Coating

(Pb–Free)

I2C address 0x18

(0011000x b)

3000 / Tape & Reel

Device

NCP6343FCT1G

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

Demo Board Available:

The NCP6343FGEVB/D evaluation board that configures the device in typical application to supply constant voltage.

www.onsemi.com

30

�CONFIDENTIAL AND PROPRIETARY

NOT FOR PUBLIC RELEASE

NCP6343

PACKAGE DIMENSIONS

ÈÈ

PIN A1

REFERENCE

WLCSP15, 1.34x1.99

CASE 567GB

ISSUE B

D

A

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. COPLANARITY APPLIES TO SPHERICAL

CROWNS OF SOLDER BALLS.

B

DIM

A

A1

A2

b

D

E

e

E

0.10 C

2X

0.10 C

2X

TOP VIEW

MILLIMETERS

MIN

MAX

0.60

−−−

0.17

0.23

0.33

0.39

0.24

0.29

1.34 BSC

1.99 BSC

0.40 BSC

A2

0.10 C

A

RECOMMENDED

SOLDERING FOOTPRINT*

0.05 C

NOTE 3

15X

A1

C

SIDE VIEW

SEATING

PLANE

A1

PACKAGE

OUTLINE

e

b

0.05 C A B

0.03 C

E

e

0.40

PITCH

D

15X

C

0.40

PITCH

B

0.25

DIMENSIONS: MILLIMETERS

A

1

2

3

BOTTOM VIEW