PARA LIGHT ELECTRONICS CO., LTD.

T

11F., No. 8, Jiankang Rd., Zhonghe Dist., New Taipei City 235, Taiwan,

Tel: 886-2-2225-3733

Fax: 886-2-2225-4800

E-mail: para@para.com.tw

www.paralighttaiwan.com

L-H339005B-HTS

PA

RA

PART NO. :

LI

GH

DATA SHEET

REV :

A/1

CUSTOMER’S APPROVAL : _______________

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

DCC : ____________

Page : 1

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

RA

LI

GH

T

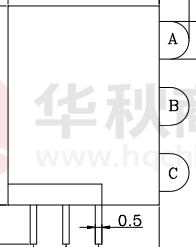

PACKAGE DIMENSIONS

Note:

PA

1.All Dimensions are in millimeters.

2.Tolerance is ±0.25mm(0.010 ")

Unless otherwise specified.

3.Protruded resin under flange

is 1.5mm(0.059 ") max.

4.Lead spacing is measured where

the leads emerge from the package.

5.Specification are subject to change

without notice

6. A=B=C= LGR3G128

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page : 2

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

FEATURES

ABSOLUTE MAXIMUM RATING : ( Ta = 25C )

PARAMETER

Green

UNIT

78

mW

5

V

30

mA

GH

SYMBOL

T

* 3.0mm DIA LED LAMP

* LOW POWER CONSUMPTION.

* I.C. COMPATIBLE.

* LONG LIFE SOLID STATE RELIABILITY.

* PB FREE PRODUCTS(Compliant with EU’s RoHS.)

CHIP MATERIALS

* Dice Material :GaP/GaP

* Light Color :Green

* Lens Color :Green Diffused

Power Dissipation

VR

Reverse Voltage

IF

Average Forward Current

IPF

Peak Forward Current Per Chip (Duty=0.1,1KHz)

120

mA

-

Derating Linear From 25C

0.3

mA/C

LI

PAD

Operating Temperature Range

-25C to 85C

Tstg

Storage Temperature Range

-40C to 85C

RA

Topr

SYMBOL

PA

ELECTRO-OPTICAL CHARACTERISTICS : ( Ta = 25C )

DESCRIPTION

TEST

MIN.

TYP.

MAX.

UNIT

1.8

2.1

2.6

V

100

μA

574

nm

Vf

Forward Voltage

IF=20mA

IR

Reverse Current

VR=5 V

D

Dominant Wavelength

IF=20mA

△

Spectral Line Half-Width

IF=20mA

30

nm

2θ1/2

Half Intensity Angle

IF=20mA

60

deg

Iv

Luminous Intensity

IF= 20mA

DRAWING NO. : DS-60-09-0055

566

15.1

DATE :2021-09-14

568

30

80.9

mcd

Page : 3

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

REV:A / 1

PA

RA

LI

GH

T

L-H339005B-HTS

HOLDER

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page : 4

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

Label Explanation

PARA NO. : Refer to p13

NO. : E

L

4

7

A B C

D

A---E: For series number

B---L: Local

F: Foreign

C---L: LAMP

D---Year

E---Month

F---SPEC.

E

0009

F

PA

RA

L

LI

LOT

GH

T

光鼎电子股份有限公司

N’W : Net Weight

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page : 5

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

SOLDERING

METHOD

SOLDERING CONDITIONS

REMARK

Solder no closer than 3mm from the

base of the package

Using soldering flux,” RESIN FLUX”

is recommended.

Attached data of temperatuare cure

for your reference

During soldering, take care not to

press the tip of iron against the

Soldering iron: 30W or smaller

lead.

SOLDERING

Temperature at tip of iron: 300℃ or lower (To prevent heat from being

IRON

transferred directly to the lead, hold

Soldering time: within 3 sec.

the lead with a pair of tweezers

while soldering

1) When soldering the lead of LED in a condition that the package is fixed with a panel (See Fig.1),

be careful not to stress the leads with iron tip.

�

Bath temperature: 260℃

Immersion time: with 5 sec, 1 time

LI

GH

T

DIP

SOLDERING

RA

s

e

i

r

w

d

a

e

L

l

e

n

a

P

(Fig.1)

s

e

i

r

w

d

a

e

L

PA

2) When soldering wire to the lead, work with a Fig (See Fig.2) to avoid stressing the package.

�

te

hc

gn

ia

lr

sa

e

al

c

e

v

a

e

L

(Fig.2)

Regarding solution in the tinning oven for product-tinning, compound sub-solution made of tin &

copper and sliver is proposed with the temperature of Celsius 260. The proportion of the

alloyed solution is tin 95.5: copper 3.5: silver 0.5 by percentage. The time of tinning is constantly 3

seconds.

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page : 6

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

3) Similarly, when a jig is used to solder the LED to PC board, take care as much as possible to avoid

steering the leads (See Fig.3).

d

r

a

o

b

C

P

�

(Fig.3

)

jig

GH

T

4) Repositioning after soldering should be avoided as much as possible. If inevitable, be sure to

preserve the soldering conditions with irons stated above: select a best-suited method that

assures the least stress to the LED.

5) Lead cutting after soldering should be performed only after the LED temperature has returned to

normal temperature.

LI

STORAGE

PA

RA

1) The LEDs should be stored at 30℃ or less and 70% RH or less after being shipped from PARA

and the storage life limits are 3 months .

2) PARA LED lead frames are comprised of a stannum plated iron alloy. The silver surface may be

affected by environments which contain corrosive gases and so on. Please avoid conditions which

may cause the LEDs to corrode, tarnish or discolor. This corrosion or discoloration may cause

difficulty during soldering operations. It is recommended that the LEDs be used as soon as

possible.

Please avoid rapid transitions in ambient temperature, especially, in high humidity environments

where condensation can occur.

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page : 7

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

LED MOUNTING METHOD

3) When mounting the LED by using a case, as shown Fig.4, ensure that the mounting holds on the

PC board match the pitch of the leads correctly-tolerance of dimensions of the respective

components including the LED should be taken into account especially when designing the case,

PC board, etc. to prevent pitch misalignment between the leads and board holes, the diameter of

the board holes should be slightly larger than the size of the lead. Alternatively, the shape of the

holes should be made oval. (See Fig.4)

case

LI

GH

T

pc board

Fig.4

PA

RA

4) Use LEDs with stand-off (Fig.5) or the tube or spacer made of resin (Fig.6) to position the LEDs.

Tube

Stand-off

Fig.5

DRAWING NO. : DS-60-09-0055

Fig.6

DATE :2021-09-14

Page : 8

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

FORMED LEAD

1) The lead should be bent at a point located at least 2mm away from the package. Bending should

be performed with base fixed means of a jig or pliers (Fig.7)

m

m

2

7

.

g

i

F

LEAD STRENGTH

RA

LI

GH

T

2) Forming lead should be carried our prior to soldering and never during or after soldering.

3) Form the lead to ensure alignment between the leads and the hole on board, so that stress against

the LED is prevented. (Fig.8)

PA

1) Bend strength

Do not bend the lead more than twice. (Fig.9)

Fig.9

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page :9

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

2) Tensile strength (@Room Temperature)

If the force is 1kg or less, there will be no problem. (Fig.10)

OK!

1Kg

Fig.10

HEAT GENERATION

CHEMICAL RESISTANCE

LI

GH

T

1) Thermal design of the end product is of paramount importance. Please consider the heat

generation of the LED when making the system design. The coefficient of temperature increase

per input electric power is affected by the thermal resistance of the circuit board and density of

LED placement on the board, as well as other components. It is necessary to avoid intense heat

generation and operate within the maximum ratings given in this specification.

The operating current should be decided after considering the ambient maximum temperature of

LEDs.

PA

RA

1) Avoid exposure to chemicals as it may attack the LED surface and cause discoloration.

2) When washing is required, refer to the following table for the proper chemical to be sued.

(Immersion time: within 3 minutes at room temperature.)

SOLVENT

ADAPTABILITY

NOTE: Influences of ultrasonic cleaning of the LED

Freon TE

⊙

Chlorothene

╳

resin body differ depending on such factors

Isopropyl Alcohol

⊙

as the oscillator output, size of the PC board

Thinner

╳

and the way in which the LED is mounted.

Acetone

╳

Therefore, ultrasonic cleaning should only be

Trichloroethylene

╳

performed after confirming there is no problem by

⊙--Usable ╳--Do not use.

conducting a test under practical.

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page :10

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

OTHERS

PA

RA

LI

GH

T

1) Care must be taken to ensure that the reverse voltage will not exceed the absolute maximum

rating when using the LEDs with matrix drive.

2) Flashing lights have been known to cause discomfort in people; you can prevent this by taking

precautions during use. Also, people should be cautious when using equipment that has had

LEDs incorporated into it.

3) The LEDs described in this brochure are intended to be used for ordinary electronic equipment

(such as office equipment, communications equipment, measurement instruments and household

appliances). Consult PARA’s sales staff in advance for information on the applications in which

exceptional quality and reliability are required , particularly when the failure or malfunction of the

LEDs may directly jeopardize life or health (such as for airplanes, aerospace, submersible

repeaters, nuclear reactor control systems, automobiles, traffic control equipment, life support

systems and safety devices).

4) User shall not reverse engineer by disassembling or analysis of the LEDs without having prior

written consent from PARA. When defective LEDs are found, the User shall inform PARA directly

before disassembling or analysis.

5) The formal specifications must be exchanged and signed by both parties before large volume

purchase begins.

6) The appearance and specifications of the product may be modified for improvement without

notice.

7) Recommended Wave Soldering Profile

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page :11

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

L

H 3

1

1

0

HOLDER

REV:A / 1

5

0

B

T

LENGTH

LI

GH

A: 2.75mm

B: 3.00mm

C: 3.20mm

D: 3.30mm

E: 3.50mm

F: 4.00mm

G: 5.00mm

H: 18.05mm

PA

RA

Series number

HOLDERS Type

1: 1PCS

2: 2PCS

3: 3PCS

4: 4PCS

5: 5PCS

3: 3mmLAMPS

4: 4mmLAMPS

5: 5mmLAMPS

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page :12

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

L-H339005B-HTS

HOLDER

REV:A / 1

Bin Code List:

Dominant Wavelength (D), Unit:nm@20mA

Bin Code

G16

Min

566

Max

568

G17

568

570

G18

570

572

G19

572

574

T

Tolerance of each bin are±1nmt

Bin Code

J

K

L

Min

Max

15.1

21.1

21.1

29.5

29.5

41.3

41.3

57.8

57.8

80.9

LI

I

GH

Luminous Intensity(IV), Unit:mcd@20mA

RA

M

PA

Tolerance of each bin are±15%

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page :13

�3.0 mm

LED

LAMP WITH

LA73B-1A/B

HOLDER

L-H339005B-HTS

LI

GH

T

REV:A / 1

PA

RA

2 9 .5 x 2 2 x 1 4 re fe r 1 .2 ...5 to b e

c o n tin u e d 4 5 x 3 0 .5 x 5 7 .

L -H 3 3 9 0 0 5 B p a c k a g e ru le N o te :

1 、 2 9 .5 x 2 2 x 1 4 p re s e n ts little p a c k a g e b o x ,1 4 little b a g s in e v e ry 2 9 .5 x 2 2 x 1 4 ,0 .2 5 K in e v e ry b a g .

2 、 4 5 x 3 0 .5 x 5 7 p re s e n ts b ig p a c k a g e b o x , fiv e little 2 9 .5 x 2 2 x 1 4 b o x e s in e v e ry 4 5 x 3 0 .5 x 5 7 ,to ta l 1 7 .5 K in e v e ry 4 5 x 3 0 .5 x 5 7 .

3 、 S p e c ific p a c k a g e c o u rs e re fe rs to th e a tta c h e d g ra p h .

DRAWING NO. : DS-60-09-0055

DATE :2021-09-14

Page :14

�