71T75902

1M x 18

2.5V Synchronous ZBT™ SRAM

2.5V I/O, Burst Counter

Flow-Through Outputs

Features

◆

◆

◆

◆

◆

◆

◆

◆

◆

1M x 18 memory configuration

Supports high performance system speed - 100 MHz

(7.5 ns Clock-to-Data Access)

ZBTTM Feature - No dead cycles between write and read cycles

Internally synchronized output buffer enable eliminates the

need to control OE

Single R/W (READ/WRITE) control pin

4-word burst capability (Interleaved or linear)

Individual byte write (BW1 - BW2 control (May tie active)

◆

◆

◆

◆

◆

◆

Three chip enables for simple depth expansion

2.5V power supply (±5%)

2.5V (±5%) I/O Supply (VDDQ)

Power down controlled by ZZ input

Boundary Scan JTAG Interface (IEEE 1149.1 Compliant)

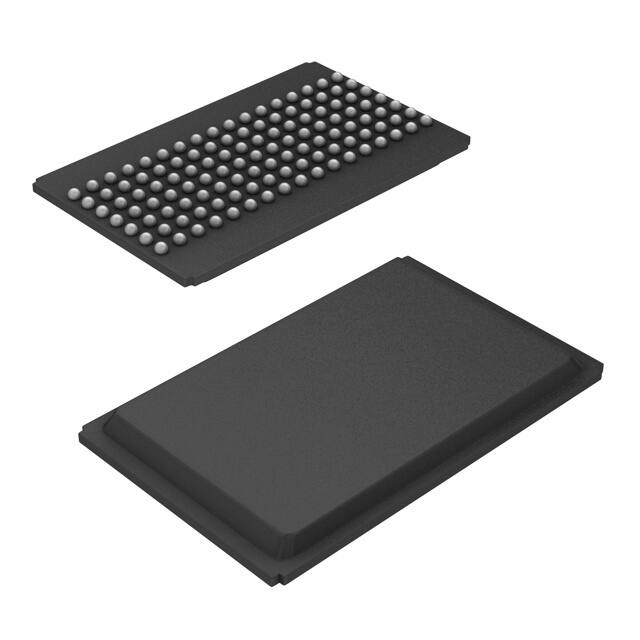

Packaged in a JEDEC standard 100-pin plastic thin quad

flatpack (TQFP), 119 ball grid array (BGA)

Industrial temperature range (–40°C to +85°C) is available

for selected speeds

Green parts available, see Ordering Information

Functional Block Diagram — 1M x 18

LBO

Address A [0:19]

1M x 18 BIT

MEMORY ARRAY

D

Q

Address

D

Q

Control

CE1, CE2, CE2

R/W

Input Register

CEN

ADV/LD

BWx

D

DI

DO

Control Logic

Q

Clk

Mux

Clock

Gate

OE

TMS

TDI

TCK

TRST

Data I/O [0:15], I/O P[1:2]

JTAG

TDO

(optional)

1

Apr.07.20

Sel

5319 drw 01a

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Description

Commercial and Industrial Temperature Ranges

The IDT71T75902 is a 2.5V high-speed 18,874,368-bit (18 Megabit)

synchronous SRAM organized as 1M x 18. It is designed to eliminate

dead bus cycles when turning the bus around between reads and writes,

or writes and reads. Thus it has been given the name ZBTTM, or Zero Bus

Turnaround.

Address and control signals are applied to the SRAM during one

clock cycle, and on the next clock cycle the associated data cycle occurs,

be it read or write.

The IDT71T75902 contain address, data-in and control signal registers. The outputs are flow-through (no output data register). Output enable

is the only asynchronous signal and can be used to disable the outputs

at any given time.

A Clock Enable (CEN) pin allows operation of the IDT71T75902 to be

suspended as long as necessary. All synchronous inputs are

ignored when CEN is high and the internal device registers will hold their

previous values.

There are three chip enable pins (CE1, CE2, CE2) that allow the user

to deselect the device when desired. If any one of these three is not

asserted when ADV/LD is low, no new memory operation can be initiated.

However, any pending data transfers (reads or writes) will be completed.

The data bus will tri-state one cycle after the chip is deselected or a write

is initiated.

The IDT71T75902 has an on-chip burst counter. In the burst mode,

the IDT71T75902 can provide four cycles of data for a single address

presented to the SRAM. The order of the burst sequence is defined by the

LBO input pin. The LBO pin selects between linear and interleaved burst

sequence. The ADV/LD signal is used to load a new external address

(ADV/LD = LOW) or increment the internal burst counter (ADV/LD =

HIGH).

The IDT71T75902 SRAM utilizes a high-performance CMOS process, and are packaged in a JEDEC Standard 14mm x 20mm 100-pin

plastic thin quad flatpack (TQFP) as well as a 119 ball grid array (BGA).

Pin Description Summary

A0-A19

Address Inputs

Input

Synchronous

CE1, CE2, CE2

Chip Enables

Input

Synchronous

OE

Output Enable

Input

Asynchronous

R/W

Read/Write Signal

Input

Synchronous

CEN

Clock Enable

Input

Synchronous

BW1, BW2

Individual Byte Write Selects

Input

Synchronous

CLK

Clock

Input

N/A

ADV/LD

Advance Burst Address/Load New Address

Input

Synchronous

LBO

Linear/Interleaved Burst Order

Input

Static

TMS

Test Mode Select

Input

N/A

TDI

Test Data Input

Input

N/A

TCK

Test Clock

Input

N/A

TDO

Test Data Output

Output

N/A

TRST

JTAG Reset (Optional)

Input

Asynchronous

ZZ

Sleep Mode

Input

Synchronous

I/O0-I/O31, I/OP1-I/OP2

Data Input/Output

I/O

Synchronous

V DD, V DDQ

Core Power, I/O Power

Supply

Static

V SS

Ground

Supply

Static

5319 tbl 01a

6.42

2

Apr.07.20

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Pin Definitions(1)

Symbol

Pin Function

I/O

Active

Description

A0-A19

Address Inputs

I

N/A

Synchronous Address inputs. The address register is triggered by a combination of the rising edge of CLK,

ADV/LD low, CEN low, and true chip enables.

ADV/LD

Advance / Load

I

N/A

ADV/LD is a synchronous input that is used to load the internal registers with new address and control

when it is sampled low at the rising edge of clock with the chip selected. When ADV/LD is low with the

chip deselected, any burst in progress is terminated. When ADV/LD is sampled high then the internal burst

counter is advanced for any burst that was in progress. The external addresses are ignored when ADV/LD

is sampled high.

R/W

Read / Write

I

N/A

R/W signal is a synchronous input that identifies whether the current load cycle initiated is a Read or Write

access to the memory array. The data bus activity for the current cycle takes place one clock cycle later.

CEN

Clock Enable

I

LOW Synchronous Clock Enable Input. When CEN is sampled high, all other synchronous inputs, including

clock are ignored and outputs remain unchanged. The effect of CEN sampled high on the device outputs

is as if the low to high clock transition did not occur. For normal operation, CEN must be sampled low at

rising edge of clock.

BW1-BW2

Individual Byte

Write Enables

I

LOW Synchronous byte write enables. Each 9-bit byte has its own active low byte write enable. On load write

cycles (When R/W and ADV/LD are sampled low) the appropriate byte write signal (BW1-BW2) must be

valid. The byte write signal must also be valid on each cycle of a burst write. Byte Write signals are

ignored when R/W is sampled high. The appropriate byte(s) of data are written into the device one cycle

later. BW1-B2 can all be tied low if always doing write to the entire 18-bit word.

CE1, CE2

Chip Enables

I

LOW Synchronous active low chip enable. CE1 and CE2 are used with CE2 to enable the IDT71T75902 (CE1 or

CE2 sampled high or CE2 sampled low) and ADV/LD low at the rising edge of clock, initiates a deselect

cycle. The ZBTTM has a one cycle deselect, i.e., the data bus will tri-state one clock cycle after deselect is

initiated.

CE2

Chip Enable

I

HIGH Synchronous active high chip enable. CE2 is used with CE1 and CE2 to enable the chip. CE2 has inverted

polarity but otherwise identical to CE1 and CE2.

CLK

Clock

I

N/A

This is the clock input to the IDT71T75902. Except for OE, all timing references for the device are made

with respect to the rising edge of CLK.

I/O

N/A

Data input/output (I/O) pins. The data input path is registered, triggered by the rising edge of CLK. The

data output path is flow-through (no output register).

I/O0-I/O31 Data Input/Output

I/OP1-I/OP2

LBO

Linear Burst Order

I

LOW Burst order selection input. When LBO is high the Interleaved burst sequence is selected. When LBO is

low the Linear burst sequence is selected. LBO is a static input, and it must not change during device

operation.

OE

Output Enable

I

LOW

Asynchronous output enable. OE must be low to read data from the IDT71T75902. When OE is HIGH the

I/O pins are in a high-impedance state. OE does not need to be actively controlled for read and write

cycles. In normal operation, OE can be tied low.

TMS

Test Mode Select

I

N/A

Gives input command for TAP controller; sampled on rising edge of TCK. This pin has an internal pullup.

TDI

Test Data Input

I

N/A

Serial input of registers placed between TDI and TDO. Sampled on rising edge of TCK. This pin has an

internal pullup.

TCK

Test Clock

I

N/A

Clock input of TAP controller. Each TAP event is clocked. Test inputs are captured on rising edge of TCK,

while test outputs are driven from falling edge of TCK. This pin has an internal pullup.

TDO

Test Data Output

O

N/A

Serial output of registers placed between TDI and TDO. This output is active depending on the state of the

TAP controller.

TRST

JTAG Reset

(Optional)

I

Optional asynchronous JTAG reset. Can be used to reset the TAP controller, but not required. JTAG

LOW reset occurs automatically at power up and also resets using TMS and TCK per IEEE 1149.1. If not used

TRST can be left floating. This pin has an internal pullup. Only available in BGA package.

ZZ

Sleep Mode

I

Synchronous sleep mode input. ZZ HIGH will gate the CLK internally and power down the IDT71T75902 to

HIGH its lowest power consumption level. Data retention is guaranteed in Sleep Mode. This pin has an internal

pulldown.

V DD

Power Supply

N/A

N/A

2.5V core power supply.

V DDQ

Power Supply

N/A

N/A

2.5V I/O Supply.

V SS

Ground

N/A

N/A

Ground.

NOTE:

5319 tbl 02a

1. All synchronous inputs must meet specified setup and hold times with respect to CLK.

6.42

3

Apr.07.20

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Absolute Maximum Ratings(1)

Symbol

Commercial

Industrial

Terminal Voltage with

Respect to GND

-0.5 to +3.6

-0.5 to +3.6

(3,6)

VTERM

Terminal Voltage with

Respect to GND

-0.5 to VDD

-0.5 to VDD

VTERM(4,6)

Terminal Voltage with

Respect to GND

-0.5 to VDD +0.5

-0.5 to VDD +0.5

VTERM(5,6)

Terminal Voltage with

Respect to GND

VTERM(2)

Rating

-0.5 to VDDQ +0.5

Operating Ambient

Temperature

TA(7)

-0.5 to VDDQ +0.5

0 to +70

-40 to +85

Unit

V

Symbol

V

VDD

V

V

o

C

TBIAS

Temperature Under Bias

-55 to +125

-55 to +125

o

C

o

C

TSTG

Storage Temperature

-55 to +125

-55 to +125

PT

Power Dissipation

2.0

2.0

IOUT

DC Output Current

50

50

Recommended DC Operating

Conditions

Min.

Typ.

Max.

Unit

Core Supply Voltage

2.375

2.5

2.625

V

VDDQ

I/O Supply Voltage

2.375

2.5

2.625

V

VSS

Ground

0

0

0

V

VIH

Input High Voltage — Inputs

1.7

____

VDD +0.3

VIH

Input High Voltage — I/O

1.7

____

VIL

Parameter

Input Low Voltage

(1)

-0.3

VDDQ +0.3

____

V

0.7

V

NOTE:

1. VIL (min.) = –0.8V for pulse width less than tCYC/2, once per cycle.

W

V

(2)

5319 tbl 03

mA

5319 tbl 06

NOTES:

1. Stresses greater than those listed under ABSOLUTE MAXIMUM RATINGS may

cause permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated

in the operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect reliability.

2. VDD terminals only.

3. VDDQ terminals only.

4. Input terminals only.

5. I/O terminals only.

6. This is a steady-state DC parameter that applies after the power supply has

reached its nominal operating value. Power sequencing is not necessary;

however, the voltage on any input or I/O pin cannot exceed VDDQ during power

supply ramp up.

7. During production testing, the case temperature equals TA.

Recommended Operating

Temperature and Supply Voltage

(TA = +25°°C, f = 1.0MHz)

Parameter(1)

CIN

Input Capacitance

CI/O

I/O Capacitance

Conditions

Max.

Unit

VIN = 3dV

5

pF

VOUT = 3dV

7

pF

5319 tbl 07

BGA Capacitance

(TA = +25°°C, f = 1.0MHz)

Symbol

Parameter(1)

Conditions

Max.

Unit

CIN

Input Capacitance

VIN = 3dV

7

pF

CI/O

I/O Capacitance

VOUT = 3dV

7

pF

5319 tbl 07a

NOTE:

1. This parameter is guaranteed by device characterization, but not production tested.

6.42

4

Apr.07.20

Ambient

Temperature(1)

VSS

VDD

VDDQ

Commerical

0 °C to +70 °C

OV

2.5V ± 5%

2.5V ± 5%

Industrial

-40 °C to +85 °C

OV

2.5V ± 5%

2.5V ± 5%

5319 tbl 05

NOTE:

1. During production testing, the case temperature equals the ambient temperature.

TQFP Capacitance

Symbol

Grade

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

A6

A7

CE1

CE2

NC

NC

BW2

BW1

CE2

VDD

VSS

CLK

R/W

CEN

OE

ADV/L

D

A19

A18

A8

A9

Pin Configuration — 1M x 18, PKG100(1,2,3,4)

100 99 98 97 96 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81

NC

NC

NC

1

80

2

79

3

78

VDDQ

VSS

NC

NC

I/O8

I/O9

VSS

VDDQ

I/O10

I/O11

VSS(1)

VDD

VDD(2)

VSS

I/O12

I/O13

VDDQ

VSS

I/O14

I/O15

I/OP2

NC

VSS

VDDQ

NC

NC

NC

4

77

5

6

76

75

7

74

8

73

9

72

71

10

11

70

12

69

71T75902

PKG100(4)

13

14

15

68

67

66

16

65

17

64

18

19

63

62

20

61

21

60

22

59

23

24

58

57

25

56

26

55

27

28

54

53

29

52

30

51

A10

NC

NC

VDDQ

VSS

NC

I/OP1

I/O7

I/O6

VSS

VDDQ

I/O5

I/O4

VSS

VSS(1)

VDD

ZZ

I/O3

I/O2

VDDQ

VSS

I/O1

I/O0

NC

NC

VSS

VDDQ

NC

NC

NC

NC/TMS(3)

NC/TDI(3)

VSS

VDD

NC/TDO(3)

NC/TCK(3,4)

A11

A12

A13

A14

A15

A16

A17

LBO

A5

A4

A3

A2

A1

A0

31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

5319 drw 02a

Top View

100 TQFP

NOTES:

1. Pins 14 and 66 do not have to be connected directly to VSS as long as the input voltage is < VIL.

2. Pin 16 does not have to be connected directly to VDD as long as the input voltage is > VIH.

3. Pins 38, 39 and 43 will be pulled internally to VDD if not actively driven. To disable the TAP controller without interfering with normal operation, several settings are possible. Pins 38, 39

and 43 could be tied to VDD or VSS and pin 42 should be left unconnected. Or all JTAG inputs (TMS, TDI and TCK) pins38, 39 and 43 could be left unconnected “NC” and the JTAG

circuit will remain disabled from power up.

4. This text does not indicate orientation of the actual part-marking.

6.42

5

Apr.07.20

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Pin Configuration — 1M x 18, BG119, BGG119(1,2,3,4,5)

1

2

3

4

5

6

7

A

V DDQ

A6

A4

A19

A8

A16

V DDQ

B

NC

CE2

A3

ADV/LD

A9

CE2

NC

C

NC

A7

A2

V DD

A13

A17

NC

D

I/O8

NC

V SS

NC

V SS

I/OP1

NC

E

NC

I/O9

V SS

CE1

V SS

NC

I/O7

F

V DDQ

NC

V SS

OE

V SS

I/O6

V DDQ

G

NC

I/O10

BW2

A18

V SS

NC

I/O5

H

I/O11

NC

V SS

R/W

V SS

I/O4

NC

J

V DDQ

V DD

V DD(2)

V DD

V SS(1)

V DD

V DDQ

K

NC

I/O12

V SS

CLK

V SS

NC

I/O3

L

I/O13

NC

V SS

NC

BW1

I/O2

NC

M

V DDQ

I/O14

V SS

CEN

V SS

NC

V DDQ

N

I/O15

NC

V SS

A1

V SS

I/O1

NC

P

NC

I/OP2

V SS

A0

V SS

NC

I/O0

R

NC

A5

LBO

V DD

V SS(1)

A12

NC

T

NC

A10

A15

NC(3)

A14

A11

ZZ

U

V DDQ

NC/TMS(3)

NC/TDI(3)

NC/TCK(3)

NC/TDO(3)

NC/TRST(3)

V DDQ

5319 tbl 25a

Top View

119 BGA

NOTES:

1. Pins R5 and J5 do not have to be connected directly to VSS as long as the input voltage is < VIL

2. Pin J3 does not have to be connected directly to VDD as long as the input voltage is > VIH.

3. U2, U3, U4 and U6 will be pulled internally to VDD if not actively driven. To disable the TAP controller without interfering with normal operation, several settings are possible. U2, U3, U4

and U6 could be tied to VDD or VSS and U5 should be left unconnected. Or all JTAG inputs(TMS, TDI, and TCK and TRST) U2, U3, U4 and U6 could be left unconnected “NC” and

the JTAG circuit will remain disabled from power up.

4. TRST is offered as an optional JTAG reset if required in the application. If not needed, can be left floating and will internally be pulled to VDD.

5. This text does not indicate orientation of the actual part-marking.

6.42

6

Apr.07.20

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

(1)

Synchronous Truth Table

CEN

R/W

CE1, CE2(5)

ADV/LD

BWx

ADDRESS

USED

PREVIOUS CYCLE

CURRENT CYCLE

I/O

(One cycle later)

L

L

L

L

Valid

External

X

LOAD WRITE

D(7)

L

H

L

L

X

External

X

LOAD READ

Q(7)

L

X

X

H

Valid

Internal

LOAD WRITE /

BURST WRITE

BURST WRITE

(Advance burst counter)(2)

D(7)

L

X

X

H

X

Internal

LOAD READ /

BURST READ

BURST READ

(Advance burst counter)(2)

Q(7)

L

X

H

L

X

X

X

DESELECT or STOP(3)

HIZ

L

X

X

H

X

X

DESELECT / NOOP

NOOP

HIZ

H

X

X

X

X

X

X

SUSPEND(4)

Previous Value

5319 tbl 08

NOTES:

1. L = VIL, H = VIH, X = Don’t Care.

2. When ADV/LD signal is sampled high, the internal burst counter is incremented. The R/W signal is ignored when the counter is advanced. Therefore the nature of

the burst cycle (Read or Write) is determined by the status of the R/W signal when the first address is loaded at the beginning of the burst cycle.

3. Deselect cycle is initiated when either (CE1, or CE2 is sampled high or CE2 is sampled low) and ADV/LD is sampled low at rising edge of clock. The data bus will

tri-state one cycle after deselect is initiated.

4. When CEN is sampled high at the rising edge of clock, that clock edge is blocked from propagating through the part. The state of all the internal registers and the

I/Os remains unchanged.

5. To select the chip requires CE1 = L, CE2 = L and CE2 = H on these chip enable pins. The chip is deselected if any one of the chip enables is false.

6. Device Outputs are ensured to be in High-Z during device power-up.

7. Q - data read from the device, D - data written to the device.

Partial Truth Table for Writes(1)

R/W

BW1

BW2

H

X

X

L

L

L

L

L

H

WRITE BYTE 2 (I/O[8:15], I/OP2)

L

H

L

NO WRITE

L

H

H

OPERATION

READ

WRITE ALL BYTES

(2)

WRITE BYTE 1 (I/O[0:7], I/OP1)

(2)

5319 tbl 09a

NOTES:

1. L = VIL, H = VIH, X = Don’t Care.

2. Multiple bytes may be selected during the same cycle.

Interleaved Burst Sequence Table (LBO=VDD)

Sequence 1

Sequence 2

Sequence 3

Sequence 4

A1

A0

A1

A0

A1

A0

A1

A0

First Address

0

0

0

1

1

0

1

1

Second Address

0

1

0

0

1

1

1

0

Third Address

1

0

1

1

0

0

0

1

Fourth Address (1)

1

1

1

0

0

1

0

0

NOTE:

1. Upon completion of the Burst sequence the counter wraps around to its initial state and continues counting.

6.42

7

Apr.07.20

5319 tbl 10

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Linear Burst Sequence Table (LBO=VSS)

Sequence 1

Sequence 2

Sequence 3

Sequence 4

A1

A0

A1

A0

A1

A0

A1

A0

First Address

0

0

0

1

1

0

1

1

Second Address

0

1

1

0

1

1

0

0

Third Address

1

0

1

1

0

0

0

1

Fourth Address (1)

1

1

0

0

0

1

1

0

5319 tbl 11

NOTE:

1. Upon completion of the Burst sequence the counter wraps around to its initial state and continues counting.

Functional Timing Diagram(1)

CYCLE

n+29

n+30

n+31

n+32

n+33

n+34

n+35

n+36

n+37

A29

A30

A31

A32

A33

A34

A35

A36

A37

C29

C30

C31

C32

C33

C34

C35

C36

C37

D/Q28

D/Q29

D/Q30

D/Q31

D/Q32

D/Q33

D/Q34

D/Q35

D/Q36

CLOCK

ADDRESS

(2)

(A0 - A18)

(2)

CONTROL

(R/W, ADV/LD, BWx)

DATA

(2)

I/O [0:31], I/O P[1:2]

5319 drw 03a

,

NOTES:

1. This assumes CEN, CE1, CE2 and CE2 are all true.

2. All Address, Control and Data_In are only required to meet set-up and hold time with respect to the rising edge of clock. Data_Out is valid after a clock-to-data

delay from the rising edge of clock.

6.42

8

Apr.07.20

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Device Operation - Showing Mixed Load, Burst,

Deselect and NOOP Cycles(2)

Cycle

Address

R/W

ADV/LD

CE1(1)

CEN

BWx

OE

I/O

Comments

n

A0

H

L

L

L

X

X

D1

Load read

n+1

X

X

H

X

L

X

L

Q0

Burst read

n+2

A1

H

L

L

L

X

L

Q0+1

Load read

n+3

X

X

L

H

L

X

L

Q1

Deselect or STOP

n+4

X

X

H

X

L

X

X

Z

NOOP

n+5

A2

H

L

L

L

X

X

Z

Load read

n+6

X

X

H

X

L

X

L

Q2

Burst read

n+7

X

X

L

H

L

X

L

Q2+1

n+8

A3

L

L

L

L

L

X

Z

Load write

n+9

X

X

H

X

L

L

X

D3

Burst write

n+10

A4

L

L

L

L

L

X

D3+1

Load write

n+11

X

X

L

H

L

X

X

D4

Deselect or STOP

n+12

X

X

H

X

L

X

X

Z

NOOP

n+13

A5

L

L

L

L

L

X

Z

Load write

n+14

A6

H

L

L

L

X

X

D5

Load read

n+15

A7

L

L

L

L

L

L

Q6

Load write

n+16

X

X

H

X

L

L

X

D7

Burst write

n+17

A8

H

L

L

L

X

X

D7+1

Load read

n+18

X

X

H

X

L

X

L

Q8

Burst read

n+19

A9

L

L

L

L

L

L

Q8+1

Load write

Deselect or STOP

NOTES:

1. CE2 timing transition is identical to CE1 signal. CE2 timing transition is identical but inverted to the CE1 and CE2 signals.

2. H = High; L = Low; X = Don't Care; Z = High Impedance.

6.42

9

Apr.07.20

5319 tbl 12

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Read Operation(1)

Cycle

Address

R/W

ADV/LD

CE1(2)

CEN

BWx

OE

I/O

Comments

n

A0

H

L

L

L

X

X

X

Address and Control meet setup

n+1

X

X

X

X

X

X

L

Q0

Contents of Address A0 Read Out

NOTES:

1. H = High; L = Low; X = Don’t Care; Z = High Impedance.

2. CE2 timing transition is identical to CE1 signal. CE2 timing transition is identical but inverted to the CE1 and CE2 signals.

5319 tbl 13

Burst Read Operation(1)

Cycle

Address

R/W

ADV/LD

CE1(2)

CEN

BWx

OE

I/O

Comments

n

A0

H

L

L

L

X

X

X

Address and Control meet setup

n+1

X

X

H

X

L

X

L

Q0

Address A0 Read Out, Inc. Count

n+2

X

X

H

X

L

X

L

Q0+1

Address A0+1 Read Out, Inc. Count

n+3

X

X

H

X

L

X

L

Q0+2

Address A0+2 Read Out, Inc. Count

n+4

X

X

H

X

L

X

L

Q0+3

Address A0+3 Read Out, Load A1

n+5

A1

H

L

L

L

X

L

Q0

Address A0 Read Out, Inc. Count

n+6

X

X

H

X

L

X

L

Q1

Address A1 Read Out, Inc. Count

n+7

A2

H

L

L

L

X

L

Q1+1

Address A1+1 Read Out, Load A2

NOTES:

1. H = High; L = Low; X = Don’t Care; Z = High Impedance.

2. CE2 timing transition is identical to CE1 signal. CE2 timing transition is identical but inverted to the CE1 and CE2 signals.

5319 tbl 14

Write Operation(1)

Cycle

Address

R/W

ADV/LD

CE1(2)

CEN

BWx

OE

I/O

Comments

n

A0

L

L

L

L

L

X

X

Address and Control meet setup

n+1

X

X

X

X

L

X

X

D0

Write to Address A0

NOTES:

1. H = High; L = Low; X = Don’t Care; Z = High Impedance.

2. CE2 timing transition is identical to CE1 signal. CE2 timing transition is identical but inverted to the CE1 and CE2 signals.

5319 tbl 15

Burst Write Operation(1)

Cycle

Address

R/W

ADV/LD

CE1(2)

CEN

BWx

OE

I/O

Comments

n

A0

L

L

L

L

L

X

X

Address and Control meet setup

n+1

X

X

H

X

L

L

X

D0

Address A0 Write, Inc. Count

n+2

X

X

H

X

L

L

X

D0+1

Address A0+1 Write, Inc. Count

n+3

X

X

H

X

L

L

X

D0+2

Address A0+2 Write, Inc. Count

n+4

X

X

H

X

L

L

X

D0+3

Address A0+3 Write, Load A1

n+5

A1

L

L

L

L

L

X

D0

Address A0 Write, Inc. Count

n+6

X

X

H

X

L

L

X

D1

Address A1 Write, Inc. Count

n+7

A2

L

L

L

L

L

X

D1+1

Address A1+1 Write, Load A2

NOTES:

1. H = High; L = Low; X = Don’t Care; Z = High Impedance.

2. CE2 timing transition is identical to CE1 signal. CE2 timing transition is identical but inverted to the CE1 and CE2 signals.

6.42

10

Apr.07.20

5319 tbl 16

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Read Operation with Clock Enable Used(1)

Cycle

Address

R/W

ADV/LD

CE1(2)

CEN

BWx

OE

I/O

Comments

n

A0

H

L

L

L

X

X

X

Address A0 and Control meet setup

n+1

X

X

X

X

H

X

X

X

Clock n+1 Ignored

n+2

A1

H

L

L

L

X

L

Q0

Address A0 Read out, Load A1

n+3

X

X

X

X

H

X

L

Q0

Clock Ignored. Data Q0 is on the bus.

n+4

X

X

X

X

H

X

L

Q0

Clock Ignored. Data Q0 is on the bus.

n+5

A2

H

L

L

L

X

L

Q1

Address A1 Read out, Load A 2

n+6

A3

H

L

L

L

X

L

Q2

Address A2 Read out, Load A 3

n+7

A4

H

L

L

L

X

L

Q3

Address A3 Read out, Load A 4

NOTES:

1. H = High; L = Low; X = Don’t Care; Z = High Impedance.

2. CE2 timing transition is identical to CE1 signal. CE2 timing transition is identical but inverted to the CE1 and CE2 signals.

5319 tbl 17

Write Operation with Clock Enable Used(1)

Cycle

Address

R/W

ADV/LD

CE1(2)

CEN

BWx

OE

I/O

Comments

n

A0

L

L

L

L

L

X

X

Address A0 and Control meet setup.

n+1

X

X

X

X

H

X

X

X

Clock n+1 Ignored.

n+2

A1

L

L

L

L

L

X

D0

Write data D0, Load A1.

n+3

X

X

X

X

H

X

X

X

Clock Ignored.

n+4

X

X

X

X

H

X

X

X

Clock Ignored.

n+5

A2

L

L

L

L

L

X

D1

Write Data D1, Load A2

n+6

A3

L

L

L

L

L

X

D2

Write Data D2, Load A3

n+7

A4

L

L

L

L

L

X

D3

Write Data D3, Load A4

NOTES:

1. H = High; L = Low; X = Don’t Care; Z = High Impedance.

2. CE2 timing transition is identical to CE1 signal. CE2 timing transition is identical but inverted to the CE1 and CE2 signals.

6.42

11

Apr.07.20

5319 tbl 18

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Read Operation with Chip Enable Used(1)

Cycle

Address

R/W

ADV/LD

CE1(2)

CEN

BWx

OE

I/O(3)

Comments

n

X

X

L

H

L

X

X

?

Deselected.

n+1

X

X

L

H

L

X

X

Z

Deselected.

n+2

A0

H

L

L

L

X

X

Z

Address A0 and Control meet setup.

n+3

X

X

L

H

L

X

L

Q0

Address A0 read out, Deselected.

n+4

A1

H

L

L

L

X

X

Z

Address A1 and Control meet setup.

n+5

X

X

L

H

L

X

L

Q1

Address A1 read out, Deselected.

n+6

X

X

L

H

L

X

X

Z

Deselected.

n+7

A2

H

L

L

L

X

X

Z

Address A2 and Control meet setup.

n+8

X

X

L

H

L

X

L

Q2

Address A2 read out, Deselected.

n+9

X

X

L

H

L

X

X

Z

Deselected.

NOTES:

1. H = High; L = Low; X = Don’t Care; ? = Don’t Know; Z = High Impedance.

2. CE2 timing transition is identical to CE1 signal. CE2 timing transition is identical but inverted to the CE1 and CE2 signals.

3. Device outputs are ensured to be in High-Z during device power-up.

5319 tbl 19

Write Operation with Chip Enable Used(1)

Cycle

Address

R/W

ADV/LD

CE(2)

CEN

BWx

OE

I/O

Comments

n

X

X

L

H

L

X

X

?

Deselected.

n+1

X

X

L

H

L

X

X

Z

Deselected.

n+2

A0

L

L

L

L

L

X

Z

Address A0 and Control meet setup

n+3

X

X

L

H

L

X

X

D0

Data D0 Write In, Deselected.

n+4

A1

L

L

L

L

L

X

Z

Address A1 and Control meet setup

n+5

X

X

L

H

L

X

X

D1

Data D1 Write In, Deselected.

n+6

X

X

L

H

L

X

X

Z

Deselected.

n+7

A2

L

L

L

L

L

X

Z

Address A2 and Control meet setup

n+8

X

X

L

H

L

X

X

D2

Data D2 Write In, Deselected.

n+9

X

X

L

H

L

X

X

Z

Deselected.

NOTES:

1. H = High; L = Low; X = Don’t Care; ? = Don’t Know; Z = High Impedance.

2. CE = L is defined as CE1 = L, CE2 = L and CE2 = H. CE = H is defined as CE1 = H, CE2 = H or CE2 = L.

6.42

12

Apr.07.20

5319 tbl 20

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

DC Electrical Characteristics Over the Operating

Temperature and Supply Voltage Range (VDD = 2.5V±5%)

Symbol

Parameter

Test Conditions

Min.

Max.

Unit

5

µA

|ILI|

Input Leakage Current

VDD = Max., VIN = 0V to V DD

___

|ILI|

LBO, JTAG and ZZ Input Leakage Current(1)

VDD = Max., VIN = 0V to V DD

___

30

µA

|ILO|

Output Leakage Current

VOUT = 0V to V CC

___

5

µA

VOL

Output Low Voltage

IOL = +6mA, VDD = Min.

___

0.4

V

VOH

Output High Voltage

IOH = -6mA, VDD = Min.

2.0

___

V

NOTE:

1. The LBO, TMS, TDI, TCK and TRST pins will be internally pulled to VDD and the ZZ pin will be internally pulled to VSS if they are not actively driven in the application.

5319 tbl 21

DC Electrical Characteristics Over the Operating

Temperature and Supply Voltage Range(1) (VDD = 2.5V±5%)

Symbol

Parameter

Test Conditions

7.5ns

8.5ns

Com'l

Ind

Com'l

Ind

Unit

IDD

Operating Power

Supply Current

Device Selected, Outputs Open,

ADV/LD = X, V DD = Max.,

VIN > V IH or < V IL, f = fMAX(2)

275

295

225

245

mA

ISB1

CMOS Standby Power

Supply Current

Device Deselected, Outputs Open,

VDD = Max., V IN > V HD or < V LD,

f = 0(2,3)

40

60

40

60

mA

ISB2

Clock Running Power

Supply Current

Device Deselected, Outputs Open,

VDD = Max., V IN > V HD or < V LD,

f = fMAX(2,3)

105

125

95

115

mA

ISB3

Idle Power

Supply Current

Device Selected, Outputs Open,

CEN > VIH, V DD = Max.,

VIN > V HD or < V LD, f = fMAX(2,3)

60

80

60

80

mA

Full Sleep Mode

Supply Current

Device Selected, Outputs Open,

CEN < VIH, V DD = Max., ZZ > V HD

VIN > V HD or < V LD, f = fMAX(2,3)

40

60

40

60

mA

IZZ

5319 tbl 22a

NOTES:

1. All values are maximum guaranteed values.

2. At f = fMAX, inputs are cycling at the maximum frequency of read cycles of 1/tCYC; f=0 means no input lines are changing.

3. For I/Os VHD = VDDQ – 0.2V, VLD = 0.2V. For other inputs VHD = VDD – 0.2V, VLD = 0.2V.

AC Test Load

AC Test Conditions

VDDQ/2

Input Pulse Levels

50Ω

I/O

Input Rise/Fall Times

Z0 = 50Ω

5319 drw 04

,

Figure 1. AC Test Load

6

•

4

ΔtCD 3

(Typical, ns)

2

• •

20 30 50

•

•

80 100

Capacitance (pF)

200

5319 drw 05

Figure 2. Lumped Capacitive Load, Typical Derating

6.42

13

Apr.07.20

2ns

Input Timing Reference Levels

(VDDQ/2)

Output Reference Levels

(VDDQ/2)

Output Load

Figure 1

5319 tbl 23

5

1

0 to 2.5V

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

AC Electrical Characteristics

(VDD = 2.5V±5%, Commercial and Industrial Temperature Ranges)

7.5ns

Symbol

Parameter

8.5ns

Min.

Max.

Min.

Max.

Unit

tCYC

Clock Cycle Time

10

____

11

____

ns

tCH(1)

Clock High Pulse Width

2.5

____

3.0

____

ns

tCL(1)

Clock Low Pulse Width

2.5

____

3.0

____

ns

____

7.5

____

8.5

ns

Output Parameters

tCD

Clock High to Valid Data

tCDC

Clock High to Data Change

2

____

2

____

ns

tCLZ(2,3,4)

Clock High to Output Active

3

____

3

____

ns

tCHZ(2,3,4)

Clock High to Data High-Z

____

5

____

5

ns

tOE

Output Enable Access Time

____

5

____

5

ns

0

____

0

____

ns

____

5

____

5

ns

(2,3)

tOLZ

Output Enable Low to Data Active

tOHZ(2,3)

Output Enable High to Data High-Z

Set Up Times

tSE

Clock Enable Setup Time

2.0

____

2.0

____

ns

tSA

Address Setup Time

2.0

____

2.0

____

ns

tSD

Data In Setup Time

2.0

____

2.0

____

ns

tSW

Read/Write (R/W) Setup Time

2.0

____

2.0

____

ns

tSADV

Advance/Load (ADV/LD) Setup Time

2.0

____

2.0

____

ns

tSC

Chip Enable/Select Setup Time

2.0

____

2.0

____

ns

tSB

Byte Write Enable (BWx) Setup Time

2.0

____

2.0

____

ns

tHE

Clock Enable Hold Time

0.5

____

0.5

____

ns

tHA

Address Hold Time

0.5

____

0.5

____

ns

tHD

Data In Hold Time

0.5

____

0.5

____

ns

tHW

Read/Write (R/W) Hold Time

0.5

____

0.5

____

ns

tHADV

Advance/Load (ADV/LD) Hold Time

0.5

____

0.5

____

ns

tHC

Chip Enable/Select Hold Time

0.5

____

0.5

____

ns

tHB

Byte Write Enable (BWx) Hold Time

0.5

____

0.5

____

ns

Hold Times

5319 tbl 24a

NOTES:

1. Measured as HIGH above 0.6VDDQ and LOW below 0.4VDDQ.

2. Transition is measured ±200mV from steady-state.

3. These parameters are guaranteed with the AC load (Figure 1) by device characterization. They are not production tested.

4. To avoid bus contention, the output buffers are designed such that tCHZ (device turn-off) is about 1ns faster than tCLZ (device turn-on) at a given temperature and voltage.

The specs as shown do not imply bus contention because tCLZ is a Min. parameter that is worse case at totally different test conditions (0 deg. C, 2.625V) than tCHZ,

which is a Max. parameter (worse case at 70 deg. C, 2.375V).

6.42

14

Apr.07.20

�Apr.07.20

6.42

15

tCLZ

A1

tHA

tHW

tHE

tSC

tCD

tHC

A2

tSA

tSW

Q(A1)

Read

tSADV

tSE

Read

Q(A2)

tCDC

tHADV

tCH

Q(A2+1)

tCD

tCL

Burst Read

Q(A2+2)

Q(A2+3)

(CEN high, eliminates

current L-H clock edge)

tCDC

Q(A2+3)

Q(A2)

(Burst Wraps around

to initial state)

tCHZ

NOTES:

1. Q (A1) represents the first output from the external address A1. Q (A2) represents the first output from the external address A2; Q (A2+1) represents the next output data in the burst sequence

of the base address A2, etc. where address bits A0 and A1 are advancing for the four word burst in the sequence defined by the state of the LBO input.

2. CE2 timing transitions are identical but inverted to the CE1 and CE2 signals. For example, when CE1 and CE2 are LOW on this waveform, CE2 is HIGH.

3. Burst ends when new address and control are loaded into the SRAM by sampling ADV/LD LOW.

4. R/W is don't care when the SRAM is bursting (ADV/LD sampled HIGH). The nature of the burst access (Read or Write) is fixed by the state of the R/W signal when new address and control

are loaded into the SRAM.

DATAOUT

OE

BW1 - BW2

CE1, CE2(2)

ADDRESS

R/W

ADV/LD

CEN

CLK

tCYC

5319 drw 06a

71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Timing Waveform of Read Cycle(1,2,3,4)

.

�Apr.07.20

6.42

16

B(A1)

A1

Write

tSADV

tHW

tHE

tHC

tHD

D(A1)

tSD

tHB

B(A2)

tSB

tSC

tHA

A2

tSA

tSW

tSE

Write

D(A2)

B(A2+1)

tHADV

tCH

tHD

D(A2+1)

tSD

B(A2+2)

tCL

(CEN high, eliminates

current L-H clock edge)

Burst Write

D(A2+2)

B(A2+3)

D(A2+3)

(Burst Wraps around

to initial state)

B(A2)

D(A2)

5319 drw 07a

,

NOTES:

1. D (A1) represents the first input to the external address A1. D (A2) represents the first input to the external address A2; D (A2+1) represents the next input data in the burst sequence

of the base address A2, etc. where address bits A0 and A1 are advancing for the four word burst in the sequence defined by the state of the LBO input.

2. CE2 timing transitions are identical but inverted to the CE1 and CE2 signals. For example, when CE1 and CE2 are LOW on this waveform, CE2 is HIGH.

3. Burst ends when new address and control are loaded into the SRAM by sampling ADV/LD LOW.

4. R/W is don't care when the SRAM is bursting (ADV/LD sampled HIGH). The nature of the burst access (Read or Write) is fixed by the state of the R/W signal when new address and control are

loaded into the SRAM.

5. Individual Byte Write signals (BWx) must be valid on all write and burst-write cycles. A write cycle is initiated when R/W signal is sampled LOW. The byte write information comes in one

cycle before the actual data is presented to the SRAM.

DATAin

OE

BW1 - BW2

CE1, CE2(2)

ADDRESS

R/W

ADV/LD

CEN

CLK

tCYC

71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Timing Waveform of Write Cycles(1,2,3,4,5)

�Apr.07.20

6.42

17

A1

tCD

tHW

tHE

tHC

tCHZ

tHB

B(A2)

tSB

tSC

tHA

A2

tSA

tSW

Q(A1)

Read

tSADV

tSE

Write

A3

tCLZ

D(A2)

tSD tHD

tHADV

tCH

Read

Q(A3)

tCDC

B(A4)

A4

tCL

Write

D(A4)

B(A5)

A5

Write

D(A5)

A6

Read

Q(A6)

A7

Read

Q(A7)

B(A8)

A8

D(A8)

A9

5319 drw 08a

Write

NOTES:

1. Q (A1) represents the first output from the external address A1. D (A2) represents the input data to the SRAM corresponding to address A2.

2. CE2 timing transitions are identical but inverted to the CE1 and CE2 signals. For example, when CE1 and CE2 are LOW on this waveform, CE2 is HIGH.

3. Individual Byte Write signals (BWx) must be valid on all write and burst-write cycles. A write cycle is initiated when R/W signal is sampled LOW. The byte write information comes in one

cycle before the actual data is presented to the SRAM.

DATAOUT

DATAIN

OE

BW1 - BW2

CE1, CE2(2)

ADDRESS

R/W

ADV/LD

CEN

CLK

tCYC

71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Timing Waveform of Combined Read and Write Cycles(1,2,3)

�Apr.07.20

6.42

18

tCD

tCLZ

A1

Q(A1)

tSE

tSADV

tHE

tHW

tHC

Q(A1)

tCDC

tCHZ

tHB

B(A2)

tSB

tSC

tHA

A2

tSA

tSW

tCH

tHADV

tCL

tCD

D(A2)

tSD tHD

A3

Q(A3)

tCDC

A4

NOTES:

1. Q (A1) represents the first output from the external address A1. D (A2) represents the input data to the SRAM corresponding to address A2.

2. CE2 timing transitions are identical but inverted to the CE1 and CE2 signals. For example, when CE1 and CE2 are LOW on this waveform, CE2 is HIGH.

3. CEN when sampled high on the rising edge of clock will block that L-H transition of the clock from propagating into the SRAM. The part will behave as if the L-H clock transition did not occur. All internal registers

in the SRAM will retain their previous state.

4. Individual Byte Write signals (BWx) must be valid on all write and burst-write cycles. A write cycle is initiated when R/W signal is sampled LOW. The byte write information comes in one

cycle before the actual data is presented to the SRAM.

DATAOut

DATAIn

OE

BW1 - BW2

CE1, CE2(2)

ADDRESS

R/W

ADV/LD

CEN

CLK

tCYC

5319 drw 09a

Q(A4)

A5

71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Timing Waveform of CEN Operation(1,2,3,4)

�Apr.07.20

6.42

19

tCD

tCLZ

A1

tSADV

tSC

Q(A1)

tHW

tHE

tHC

tHA

A2

tSA

tSW

tSE

tCHZ

tCDC

Q(A2)

tHADV

tCH

tHB

B(A3)

tSB

A3

tCL

D(A3)

tSD tHD

A4

Q(A4)

A5

5319 drw 10a

Q(A5)

NOTES:

1. Q (A1) represents the first output from the external address A1. D (A3) represents the input data to the SRAM corresponding to address A3 etc.

2. CE2 timing transitions are identical but inverted to the CE1 and CE2 signals. For example, when CE1 and CE2 are LOW on this waveform, CE2 is HIGH.

3. When either one of the Chip enables (CE1, CE2, CE2) is sampled inactive at the rising clock edge, a deselect cycle is initiated. The data-bus tri-states one cycle after the initiation of the

deselect cycle. This allows for any pending data transfers (reads or writes) to be completed.

4. Individual Byte Write signals (BWx) must be valid on all write and burst-write cycles. A write cycle is initiated when R/W signal is sampled LOW. The byte write information comes in one

cycle before the actual data is presented to the SRAM.

DATAOut

DATAIn

OE

BW1 - BW2

CE1, CE2(2)

ADDRESS

R/W

ADV/LD

CEN

CLK

tCYC

71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Timing Waveform of CS Operation(1,2,3,4)

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

JTAG Interface Specification

tJF

tJCL

tJCYC

tJR

tJCH

TCK

Device Inputs(1)/

TDI/TMS

tJS

Device Outputs(2)/

TDO

tJDC

tJH

tJRSR

tJCD

TRST(3)

x

M5319 drw 01

tJRST

NOTES:

1. Device inputs = All device inputs except TDI, TMS and TRST.

2. Device outputs = All device outputs except TDO.

3. During power up, TRST could be driven low or not be used since the JTAG circuit resets automatically. TRST is an optional JTAG reset.

JTAG AC Electrical

Characteristics(1,2,3,4)

Symbol

Parameter

Min.

Max.

Units

tJCYC

JTAG Clock Input Period

100

____

ns

tJCH

JTAG Clock HIGH

40

____

ns

tJCL

JTAG Clock Low

40

____

ns

tJR

JTAG Clock Rise Time

____

5(1)

ns

tJF

JTAG Clock Fall Time

____

5(1)

ns

tJRST

JTAG Reset

50

____

ns

tJRSR

JTAG Reset Recovery

50

____

ns

tJCD

JTAG Data Output

____

20

ns

tJDC

JTAG Data Output Hold

0

____

ns

tJS

JTAG Setup

25

____

ns

tJH

JTAG Hold

25

____

ns

Scan Register Sizes

Register Name

Instruction (IR)

4

Bypass (BYR)

1

JTAG Identification (JIDR)

Boundary Scan (BSR)

32

Note (1)

I5319 tbl 03

NOTE:

1. The Boundary Scan Descriptive Language (BSDL) file for this device is available

by contacting your local IDT sales representative.

I5319 tbl 01

NOTES:

1. Guaranteed by design.

2. AC Test Load (Fig. 1) on external output signals.

3. Refer to AC Test Conditions stated earlier in this document.

4. JTAG operations occur at one speed (10MHz). The base device may run at any speed

specified in this datasheet.

6.42

20

Apr.07.20

Bit Size

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

JTAG Identification Register Definitions

Instruction Field

Value

Description

Revision Number (31:28)

0x2

Reserved for version number.

IDT Device ID (27:12)

0x223

Defines IDT part number 71T75902

IDT JEDEC ID (11:1)

0x33

Allows unique identification of device vendor as IDT.

ID Register Indicator Bit (Bit 0)

1

Indicates the presence of an ID register.

I5319 tbl 02a

Available JTAG Instructions

Instruction

Description

OPCODE

EXTEST

Forces contents of the bound ary scan cells onto the device outputs (1).

Places the boundary scan registe r (BSR) between TDI and TDO.

0000

SAMPLE/PRELOAD

Places the boundary scan registe r (BSR) between TDI and TDO.

SAMPLE allows data from device inputs (2) and outputs(1) to be captured

in the boundary scan cells and shifted serially through TDO. PRELOAD

allows data to be input serially into the bo undary scan cells via the TDI.

0001

DEVICE_ID

Loads the JTAG ID register (JIDR) with the vendor ID code and places

the register between TDI and TDO.

0010

HIGHZ

Places the bypass register (BYR) be tween TDI and TDO. Forces all

device o utput drivers to a High-Z state.

0011

RESERVED

RESERVED

RESERVED

0100

Several combinations are reserved. Do not use codes other than those

identified for EXTEST, SAMPLE/PRELOAD, DEVICE_ID, HIGHZ, CLAMP,

VALIDATE and BYPASS instructions.

RESERVED

CLAMP

RESERVED

0110

0111

Uses BYR. Forces contents of the bound ary scan cells onto the device

outputs. Places the byp ass registe r (BYR) between TDI and TDO.

RESERVED

RESERVED

0101

1000

1001

1010

Same as above.

1011

RESERVED

1100

VALIDATE

Automatically loaded into the instruction register whenever the TAP

controller passes through the CAPTURE-IR state. The lower two bits '01'

are mand ated by the IEEE std. 1149.1 specification.

1101

RESERVED

Same as above.

1110

BYPASS

The BYPASS instruction is used to truncate the boundary scan register

as a single bit in length.

1111

I5319tbl 04

NOTES:

1. Device outputs = All device outputs except TDO.

2. Device inputs = All device inputs except TDI, TMS, and TRST.

6.42

21

Apr.07.20

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Timing Waveform of OE Operation

Commercial and Industrial Temperature Ranges

(1)

OE

tOE

tOHZ

DATAOUT

tOLZ

Q

Q

,

5319 drw 11

NOTE:

1. A read operation is assumed to be in progress.

Ordering Information

X

XXXX

S

XX

XX

Device

Type

Power

Speed

Package

X

X

Blank

8

Tray

Tape & Reel

Blank

I(1)

Commercial (0°C to +70°C)

Industrial (-40°C to +85°C)

G(2)

Green

PF

BG

100-pin Plastic Thin Quad Flatpack (PKG100)

119 Ball Grid Array (BG119, BGG119)

75

85

Access time (tCD) in tenths of nanoseconds

IDT71T75902

1Mx18 Flow-Through ZBT SRAM

NOTES:

1. Contact your local sales office for industrial temp range for other speeds, packages and powers.

2. Green parts available. For specific speeds, packages and powers contact your local sales office.

Orderable Part Information

Speed

Orderable Part ID

(ns)

75

85

Pkg.

Code

Pkg.

Type

Temp.

Grade

71T75902S75BG

BG119

PBGA

C

71T75902S75BG8

BG119

PBGA

C

71T75902S75BGG

BGG119

PBGA

C

71T75902S75BGG8

BGG119

PBGA

C

71T75902S75PFG

PKG100

TQFP

C

71T75902S75PFG8

PKG100

TQFP

C

71T75902S75PFGI

PKG100

TQFP

I

71T75902S75PFGI8

PKG100

TQFP

I

BG119

PBGA

C

71T75902S85BG8

BG119

PBGA

C

71T75902S85BGG

BGG119

PBGA

C

71T75902S85BGG8

BGG119

PBGA

71T75902S85BG

C

5319t27.tbl

6.42

22

Apr.07.20

5319 drw 12

�71T75902 1M x 18, 2.5V Synchronous ZBT™ SRAM with

2.5V I/O, Burst Counter and Flow-Through Outputs

Commercial and Industrial Temperature Ranges

Datasheet Document History

Rev

0

1

Date

05/25/00

08/24/01

2

3

4

5

10/16/01

12/21/01

05/29/02

06/07/02

6

7

11/19/02

05/23/03

8

04/01/04

9

10

02/20/09

09/08/17

04/07/20

Pages

Description

Created Advance Information Datasheet

p. 1, 25

Removed reference of BQ165 package

p. 8

Removed page of the 165 BGA pin configuration

p. 24

Removed page of the 165 BGA package diagram outline

p. 7

Corrected 3.3V to 2.5V in Note 3

p. 5-7

Added clarification to JTAG pins, allow for NC. Added 36M address pin locations

p. 21

Corrected 100-pin TQFP package drawing

p. 1-4,7,14,21,22 Added complete JTAG functionality.

p. 2,14

Added notes for ZZ pin internal pulldown and ZZ leakage current.

p. 14

Updated ISB3 power supply current from 40 to 60mA for all speeds.

p.1-26

Changed datasheet from Advanced information to final release.

p.5,6,14,15,25

Added I-temp to the datasheet.

p.6

Updated 165 BGA table.

p.1

Updated logo with new design.

p.5,6

Clarified ambient and case operating temperatures.

p.7

Updated I/O pin number order for the 119 BGA.

p.24

Updated 119BGA Package Diagram Drawing.

p.25

Removed “IDT” from orderable parts number

p.1-23

Removed IDT71T75702 & 512K x 36 throughout the datasheet

p. 1

In Features: Added text: "Green parts available, see Ordering Information"

Moved the FBD from page 3 to page 1 & the Pin Description Summary from page 1 to page 2

& the Pin Definitions from page 2 to page 3 in accordance with our standard datasheet format

p.2

Description text corrected grammatical errors

p.2-3

Removed BW4 & replaced with BW2, removed I/OP4 and replaced with I/OP2 in the Pin Description

Summary & Pin Definitions tables

Updated “36-bit word” to “18-bit word” for BW1-BW2 in Pin Definitions table

p.3

Removed Functional Block Diagram for 512K x 36

p.4

Removed fBGA capacitance table as this package is no longer offered for this device

p.5

Added IDT logo, device & in accordance with the packaging code added PKG100

p.5

Removed Pin Configuration 512K x 36, PKG100

p.5

Removed footnote 4. for Pin Configuration 1M x 18, 119BGA

p.7

Removed Pin Configuration 512K X 36, 119BGA

p.7

Removed Description columns for BW3 and BW4 and removed Write Byte 3 and Write Byte 4 rows

from Partial Truth Table for Writes and removed footnote 3

p.8

Replaced P[1:4] with P[1:2] in Functional Timing Diagram

p.13

Removed 8.0ns column from DC Electrical Chars Table

p.14

Removed 8.0ns column from AC Electrical Chars Table

p.15-19

Removed BW1 - BW4 from all of the Timing Waveforms and replaced with BW1 - BW2

p.21

Changes made to the JTAG Identification Register Definitions Table for Instruction

Field IDT Device ID (27:12), where Value 0x221 was removed and 71T75702 was removed

from the Description column

p.22

Ordering Information added Tray, T&R and Green indicators

Updated package codes in Ordering Information for TQFP from PK100 to PKG100

& for BGA from BGA119 to BGG119

Ordering Information removed 80 speed grade

Added Orderable Part Information from idt.com

p.23-24

Removed Package Diagram Outlines for TQFP (PSC-4045) and BGA (PSC-4063)

p. 1-24

Rebranded as Renesas datasheet

p, 1 & 23

Updated green and industrial temp range product offerings

p.5 & 6

Updated package codes

6.42

23

Apr.07.20

�IMPORTANT NOTICE AND DISCLAIMER

RENESAS ELECTRONICS CORPORATION AND ITS SUBSIDIARIES (“RENESAS”) PROVIDES TECHNICAL

SPECIFICATIONS AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING

REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND

OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for developers skilled in the art designing with Renesas products. You are solely responsible

for (1) selecting the appropriate products for your application, (2) designing, validating, and testing your application, and (3)

ensuring your application meets applicable standards, and any other safety, security, or other requirements. These

resources are subject to change without notice. Renesas grants you permission to use these resources only for

development of an application that uses Renesas products. Other reproduction or use of these resources is strictly

prohibited. No license is granted to any other Renesas intellectual property or to any third party intellectual property.

Renesas disclaims responsibility for, and you will fully indemnify Renesas and its representatives against, any claims,

damages, costs, losses, or liabilities arising out of your use of these resources. Renesas' products are provided only subject

to Renesas' Terms and Conditions of Sale or other applicable terms agreed to in writing. No use of any Renesas resources

expands or otherwise alters any applicable warranties or warranty disclaimers for these products.

(Rev.1.0 Mar 2020)

Corporate Headquarters

Contact Information

TOYOSU FORESIA, 3-2-24 Toyosu,

Koto-ku, Tokyo 135-0061, Japan

www.renesas.com

For further information on a product, technology, the most

up-to-date version of a document, or your nearest sales

office, please visit:

www.renesas.com/contact/

Trademarks

Renesas and the Renesas logo are trademarks of Renesas

Electronics Corporation. All trademarks and registered

trademarks are the property of their respective owners.

© 2020 Renesas Electronics Corporation. All rights reserved.

�