INTEGRATED CIRCUITS

EtherCAT Slave Controller for

TMC8462 Datasheet

Document Revision V1.5 • 2019-June-21

The TMC8462 is a complete EtherCAT® Slave Controller optimized for real time. It comprises all

blocks required for an EtherCAT slave including two 100-Mbit PHYs, a dual switch regulator power

supply and 24V capable high voltage I/Os for industrial environments. Timer, watchdog, PWM

and SPI/IIC master units allow for enhanced capabilities either in device emulation mode or in

combination with an external CPU.

Features

• Standard compliant EtherCAT® Slave

• Dual Integrated 100-Mbit Ethernet

PHY

• SPI Process Data Interface (PDI)

• IO Block with 24 Multi-Function I/Os

• Internal 3.3V plus free 5V-24V switch

regulator

• 8 High Voltage I/Os (up to 35V, 100mA)

• Multifunction block comprises Watchdog, 4 PWM outputs and Step/Dir

generator

• Direct EtherCAT access to external

ADCs, stepper motor controllers, etc.

• EtherCAT-P compatible voltage range

Applications

• Factory Automation

• Process Automation

• Communication Modules

• Industrial IoT

• Industry 4.0

• Sensors & Encoders

Simplified Block Diagram

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at: www.trinamic.com

Read entire documentation.

• Robotics

• Industrial Motion Control

• Building Automation

�2 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Contents

1

Product Features

5

2

Order Codes

6

3

Principles of Operation / Key Concepts

3.1 General Device Architecture . . . . .

3.2 EtherCAT Slave Controller . . . . . . .

3.3 Multi-Function and Control IO Block .

3.4 Analog and High Voltage Block . . . .

3.5 Interfaces . . . . . . . . . . . . . . . .

3.6 Software- and Tool-Support . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7

. 7

. 8

. 8

. 9

. 10

. 10

4

Device Pin Definitions

15

4.1 Pinout and Pin Coordinates of TMC8462-BA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5

Device Usage and Handling

5.1 Process Data Interface . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 SPI protocol description . . . . . . . . . . . . . . . . . . .

5.1.2 Timing example . . . . . . . . . . . . . . . . . . . . . . . .

5.2 MFC IO Control Interface . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 SPI Protocol description . . . . . . . . . . . . . . . . . . .

5.2.2 Timing example . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Sharing Bus Lines with the PDI SPI . . . . . . . . . . . . .

5.3 Ethernet Physical Layer Connection . . . . . . . . . . . . . . . . .

5.4 External Circuitry and Applications Examples . . . . . . . . . . .

5.4.1 Device Reset . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Supply Filtering for PLL Supply . . . . . . . . . . . . . . .

5.4.3 PHY Power Regulator Filtering . . . . . . . . . . . . . . . .

5.4.4 External Circuit for Fixed Switching Regulator 0 . . . . . .

5.4.5 External Circuit for Adjustable Switching Regulator 1 . .

5.4.6 Minimum External Supply Circuit for Single 3.3V Supply .

5.4.7 Minimum External Supply Circuit for Single 5V Supply . .

5.4.8 Minimum External Supply Circuit for Single Supply >5V .

5.4.9 Typical Power Supply Chain Using Both Buck Converters

5.4.10 Status LED Circuit . . . . . . . . . . . . . . . . . . . . . . .

5.4.11 SII EEPROM Circuit . . . . . . . . . . . . . . . . . . . . . . .

5.4.12 Considerations on PHY to PHY Connection . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

23

23

24

26

27

27

28

28

30

31

31

31

32

33

34

35

36

37

38

38

38

39

EtherCAT Slave Controller Description

6.1 General EtherCAT Information . . . .

6.2 Overview of Available Chip Features

6.3 EtherCAT Register Overview . . . . .

6.4 EtherCAT Register Set . . . . . . . . .

6.4.1 ESC Information . . . . . . . .

6.4.2 Station Address . . . . . . . .

6.4.3 Write Protection . . . . . . . .

6.4.4 Data Link Layer . . . . . . . .

6.4.5 Application Layer . . . . . . .

6.4.6 PDI . . . . . . . . . . . . . . . .

6.4.7 Interrupts . . . . . . . . . . . .

6.4.8 Error Counters . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

40

40

41

43

49

49

53

54

56

61

64

68

71

6

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

�3 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

6.4.9

6.4.10

6.4.11

6.4.12

6.4.13

6.4.14

6.4.15

6.4.16

6.4.17

6.4.18

6.4.19

6.4.20

6.4.21

6.4.22

7

Watchdogs . . . . . . . . . . . . . . . . . . . . .

SII EEPROM Interface . . . . . . . . . . . . . . .

ESC Parameter RAM . . . . . . . . . . . . . . . .

MII Management Interface . . . . . . . . . . . .

FMMUs . . . . . . . . . . . . . . . . . . . . . . .

SyncManagers . . . . . . . . . . . . . . . . . . .

Distributed Clocks Receive Times . . . . . . . .

Distributed Clocks Time Loop Control Unit . .

Distributed Clocks Cyclic Unit Control . . . . .

Distributed Clocks SYNC Out Unit . . . . . . . .

Distributed Clocks LATCH In Unit . . . . . . . .

Distributed Clocks SyncManager Event Times .

ESC Specific . . . . . . . . . . . . . . . . . . . . .

Process Data RAM . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

74

77

81

82

86

89

93

94

98

99

103

107

108

109

MFC IO Block Description

7.1 General Information . . . . . . . . . . . . . . . . . . . . . .

7.2 MFC IO Register Overview . . . . . . . . . . . . . . . . . .

7.3 MFC IO Register Set . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Incremental Encoder Interface . . . . . . . . . . .

7.3.2 SPI Master Interface . . . . . . . . . . . . . . . . . .

7.3.3 I2C Master Interface . . . . . . . . . . . . . . . . . .

7.3.4 Step and Direction Signal Generator . . . . . . . .

7.3.5 PWM Unit . . . . . . . . . . . . . . . . . . . . . . . .

7.3.6 General Purpose I/Os . . . . . . . . . . . . . . . . .

7.3.7 DAC Unit . . . . . . . . . . . . . . . . . . . . . . . .

7.3.8 IRQ Control Block . . . . . . . . . . . . . . . . . . .

7.3.9 Watchdog . . . . . . . . . . . . . . . . . . . . . . . .

7.3.10 High Voltage Status and General Control . . . . .

7.3.11 Application Layer Control . . . . . . . . . . . . . .

7.4 SII EEPROM MFC IO Block Parameter Map . . . . . . . . .

7.5 SII EEPROM MFC IO Crossbar Mapping . . . . . . . . . . .

7.6 SII EEPROM MFC IO High Voltage IO (HVIO) Configuration

7.7 SII EEPROM MFC IO Switching Regulator Configuration .

7.8 SII EEPROM MFC IO Memory Block Mapping . . . . . . . .

7.9 SII EEPROM MFC IO Register Configuration . . . . . . . .

7.10 MFC IO ESI/XML Configuration Block . . . . . . . . . . . .

7.11 MFC IO Incremental Encoder Block . . . . . . . . . . . . .

7.12 MFC IO SPI Master Block . . . . . . . . . . . . . . . . . . .

7.12.1 SPI Examples . . . . . . . . . . . . . . . . . . . . . .

7.13 MFC IO I2C Master Block . . . . . . . . . . . . . . . . . . .

7.13.1 I2C Example . . . . . . . . . . . . . . . . . . . . . .

7.14 MFC IO Step and Direction Block . . . . . . . . . . . . . . .

7.15 MFC IO PWM Block . . . . . . . . . . . . . . . . . . . . . . .

7.16 MFC IO DAC Block . . . . . . . . . . . . . . . . . . . . . . .

7.17 MFC IO General Purpose IO Block . . . . . . . . . . . . . .

7.18 MFC IO IRQ Block . . . . . . . . . . . . . . . . . . . . . . . .

7.19 MFC IO Watchdog Block . . . . . . . . . . . . . . . . . . . .

7.20 MFC IO Emergency Switch Input . . . . . . . . . . . . . . .

7.21 MFC IO Analog and High Voltage Block . . . . . . . . . . .

7.21.1 Multi Voltage High Current I/O Lines . . . . . . . .

7.21.2 Switching Regulators . . . . . . . . . . . . . . . . .

7.21.3 Analog Block Status Register . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

110

110

112

115

115

118

120

122

128

132

133

134

136

139

143

144

148

152

153

155

156

157

158

160

161

165

167

169

172

178

179

180

181

185

186

186

187

188

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

.

.

.

.

.

.

.

.

.

.

.

.

.

.

�4 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

8

9

Electrical Ratings

8.1 Absolute Maximum Ratings . . . . . . . . . .

8.2 Operational Ratings . . . . . . . . . . . . . . .

8.3 DC Characteristics and Timing Characteristics

8.3.1 High Voltage I/O Block . . . . . . . . .

8.3.2 Switching Regulators . . . . . . . . . .

8.3.3 Digital IOs . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

190

190

191

191

191

192

193

Manufacturing Data

194

9.1 Package Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

9.2 Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

9.3 Board and Layout Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

10 Abbreviations

197

11 TMC8462-BA Errata

199

11.1 Case 1 – Lost Link Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

12 Figures Index

200

13 Tables Index

201

14 Revision History

204

14.1 IC Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

14.2 Document Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

1

5 / 204

Product Features

TMC8462 is an advanced EtherCAT Slave Controller device used for EtherCAT communication. It provides

the interface for data exchange between EtherCAT master and the slave’s local application controller. In

addition, TMC8462 provides complex IO functions paired with high voltage features and integrated 100Bit

Ethernet PHYs.

Advantages:

• Fully standard compliant and proven EtherCAT engine

• Highly integrated with highest feature count vs. package size

• License-free & royalty-free

• High Voltage & robust

• Saves board space & reduces BOM

• Long-term availability

Major Features:

• EtherCAT Slave Controller with 2 ports for bus interfacing, 8 FMMU & 8 Sync Managers, Distributed

clocks with 64 bit, 16KByte of Process Data Memory, external I2C EEPROM, SPI Process Data Interface

(PDI), optional device emulation

• TRINAMIC Multi-Function Control and IO block with 24 configurable IO ports for complex real-time IO

functions (GPIOs, PWM, Step/Direction, I2C, SPI, DAC, incremental encoder) including 8 high voltage

IOs

• TRINAMIC high voltage block with 8 short circuit protected push-/pull or open drain high voltage IOs

for up to 24V and 100mA drive current

• Two integrated 500mA step down switching voltage regulators with one being fixed at 3.3V and one

being programmable between 5V and 24V

• Internal 1.8V linear regulator for core voltage generation

• Two integrated 100-Mbit Ethernet PHYs to directly connect to twisted pair copper or back-to-back

directly to another PHY

• Simple configuration of EtherCAT Slave Controller and Multi-Function Control and IO block via

EEPROM

• 3.3V Digital IO Voltage

• Working with a single supply voltage depending on application: 3.3V only or 5V to 35V (5V, 12V, or

24V typical)

• Industrial Temperature Range -40°C to +85°C

• Integrated temperature measurement and over-temperature shutdown

• Package: 9mm x 9mm BGA packge with 121 pins and 0.75mm pitch

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�6 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

2

Order Codes

Order Code

Description

Size

TMC8462-BA

TMC8462 Advanced EtherCAT® Slave Controller in 121 pin BGA

package with 0.75mm pitch

9mm x 9mm

TMC8462-EVAL

Evaluation Board for TMC8462-BA, compatible with the modular Landungsbruecke system, RJ45 twisted pair copper interface

79mm x 85mm

Landungsbruecke

MCU Board

85mm x 55mm

TMC8462-BOB-ETH

Breakout Board (BOB) for TMC8462-BA, with 0.1" header rows,

reference clock source, SII-EEPROM, and RJ45 twisted pair copper transceiver interface

2.0" x 1.5"

Table 1: TMC8462 order codes

Trademark and Patents

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

3

7 / 204

Principles of Operation / Key Concepts

TMC8462 is a highly integrated ASIC providing the interface between the Ethernet-based EtherCAT real-time

field bus and the local application. Its extended digital and high voltage feature set provides additional

functions to the EtherCAT slave.

3.1

General Device Architecture

Figure 1 shows the general device architecture and major connections of TMC8462. The four function

blocks EtherCAT Slave Controller, Multi-Function Control and IO, Analog and High Voltage, and Ethernet

PHYs are introduced in the following sub-sections.

For operation, a stable 100MHz clock source, an IIC EEPROM, and power supply for IO and high voltage

operation are required (if the high voltage features are used). An application controller, which also runs

the EtherCAT slave stack, connects to the SPI interfaces. The application and onboard peripherals can be

controlled by the application controller or the Multi-Function Control and IO block.

Figure 1: General device architecture

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

3.2

8 / 204

EtherCAT Slave Controller

TMC8462 contains a standard-conform EtherCAT Slave Controller (ESC) providing real-time EtherCAT MAC

layer functionality to EtherCAT slaves. It connects via MII interface to standard Ethernet PHYs and provides

a digital control interface to a local application controller while also providing the option for standalone

operation.

The ESC part of TMC8462 provides the following EtherCAT-related features. More information is available

in Section 6.

• Two internal 100Mbit Ethernet PHYs

• Eight Fieldbus Memory Management Units (FMMU)

• Eight Sync Managers (SM)

• 16 KByte of Process Data RAM (PDRAM)

• 64B bit Distributed Clocks support

• I2C interface for external EEPROM for ESC configuration

• SPI Process Data Interface (PDI) with 30Mbit/s

• Proven EtherCAT State Machine (ESM)

• Device Emulation Mode

3.3

Multi-Function and Control IO Block

In addition to the EtherCAT functionality, the TMC8462 comes with a dedicated function block providing a

configurable set of complex real-time IO functionality for smart (embedded) EtherCAT slave systems. This

IO functionality is called Multi-Function Control and IO block (MFC IO). Its special focus is on motor and

motion control while it is not limited to this application area.

The MFC IO block combines various functional sub blocks that are helpful in an embedded design to

reduce complexity, to simplify bill of materials (BOM), and to provide hardware acceleration to compute

intensive or time critical tasks. More information is available in Section 7.

Configurable IO Ports The whole MFC IO block provides in total 24 IO ports that can be configured and

assigned to any of the available functional units inside the MFC IO block. If not used, each IO port can be

tristated.

General Purpose IOs Up to sixteen (16) general purpose IOs are available. Each IO can be configured

either as input or as output. For the outputs, a safe state can be configured which is used in case of

emergency event.

Incremental Encoder Interface Configurable incremental encoder interface with 32 bit position registers, single-ended or differential inputs, configurable counting constant for different resolutions, configurable polarity and N-signal behavior.

Step/Direction Generator Block The step and direction unit provides upt to 3 independent channels.

Various configuration options and modes allow for example for continuous or one-shot mode, reading of

the internal total step counters, pre-loading the next step frequency to be used at a certain counter value.

The step and direction outputs signals can be single-ended or differential.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

9 / 204

PWM Block The integrated PWM block provides up to 4 PWM channels. PWM frequency and duty cycle

as well as polarities and dead times are configurable. The outputs can be configured for a safe state in

case of emergency.

Generic SPI Master Interface The TMC8462 provides a generic SPI master interface to connect to onor off-board SPI slave peripherals like ADCs, sensors, or motor drivers. The SPI master interface is fully

configurable and offers 4 slave select lines.

Generic I2C Master Interface A generic I2C master interface is also available in TMC8462 to connect to

I2C slaves. The I2C bus speed is configurable.

Digital DAC A simple digital 16 bit DAC channel is available which requires an external RC circuit for

operation.

Safety Functions

The following safety functions are available with the TMC8462

• Configurable watchdog functionality for the MFC IO block to monitor internal and external signals as

well as EtherCAT activity. This block is fully configurable.

• A general emergency switch input can be activated. For critical outputs, a safe state can be configured

which is used when the emergency switch triggers.

• A common IRQ signal is available at the MFC IO block which can be mapped to various events of the

MFC IO block. The IRQ events can be processed by a local application controller.

3.4

Analog and High Voltage Block

TMC8462 has an integrated powerful high voltage sub block that provides analog functions and high

voltage support to your EtherCAT slave. The integrated high voltage capabilities allow for BOM reduction

and save board space. More information is available in Section 7.21.

High Voltage Ports 8 of the 24 configurable IO ports of the MFC IO block are high voltage IO ports. For

pure digital systems operating at 3.3V or 5V these ports can simply be used as standard IO ports. When

using a higher supply voltage at the VIOx inputs the high voltage ports can be used at up to 35V (5V, 12V,

24V typical). The 8 high voltage ports are grouped into 3 groups with 2, 3, and 3 ports. Each group can be

used a different supply voltage level using VIO1, VIO2, and VIO3 inputs.

Each high voltage port has a short circuit protected push-/pull or open drain output stage with 100mA

drive current (ca. 200mA short time) and can be combined with any signal of the MFC IO block functions.

The outputs’ slope can be controlled. An optional input filter is selectable as well as pull downs or pull ups

with 100µA.

The high voltage ports have an over-temperature shutdown.

WARNING

When driving inductive loads a freewheeling diode must be provided to the high

voltage I/O pins to prevent from latch-up.

Switching Regulators Two switching regulators (buck regulators) are integrated into TMC8462 – SW0

and SW1. Both are capable of driving up to 500mA.

SW0 generates a fixed 3.3V rail for internal and external logic supply. SW1 is programmable between 3.3V

and VS (up to 24V) and can be used for peripheral supply, e.g, to generate a 5V encoder supply.

Each switching regulator comes with a separate over-temperature shutdown.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

10 / 204

Single Supply Operation TMC8462 is designed to work with a single external power supply rail. All

required supply voltages are generated internally. The required external supply rail depends on the

application scenario (between 3.3V and 24V).

3.5 Interfaces

Field Bus Interface TMC8462 contains 2 integrated 100-Mbit Ethernet PHYs and directly connects to the

field bus using an external transformer circuit. In addition, the PHY interfaces of two TMC8462 devices can

also be connected directly to allow back-to-back connection with only low part count and a small circuit.

This is useful when extending the EtherCAT bus on the board or to a another slave close by.

ESC Process Data Interface The ESC part can be accessed via the so-called Process Data Interface (PDI).

TMC8462 comes with an SPI PDI. Besides the standard SPI bus lines additional control signals belong to

the SPI PDI, which are further described in Section 5.1..

MFC IO Control Interface The MFC IO block of TMC8462 can be accessed from EtherCAT master side

or from the local application controller. For connection to the local application controller, a second SPI

interface – the MFC IO SPI – is provided. The protocol used nearly identical to the SPI PDI interface.

Additional information on the MFC IO SPI is given in Section 5.2.

EEPROM Interface The EEPROM interface is intended to be a point-to-point interface between TMC8462

and EEPROM with TMC8462 being the master. If other I2C masters are required to access the I2C bus,

TMC8462 must be held in reset state, for example for in-circuit-programming of the EEPROM. During

operation, the application controller must tristate its I2C interface. Depending on the EEPROM size the

addressing mode must be properly set using the PROM_SIZE configuration pin.

Configuration Inputs Hard-wired configuration pins are available at the TMC8462, which are used to

configure various options related to the hardware configuration and application scenario and which will

not change. These pins are PROM_SIZE, PDI_SHARED_SPI_BUS, and DEVICE_EMULATION.

More information on these configuration pins and signals is given in Section 4.2 and Section 5.

3.6

Software- and Tool-Support

TRINAMIC’s EtherCAT Slave Controller family comes with extensive hardware and software tool support to

get started quickly.

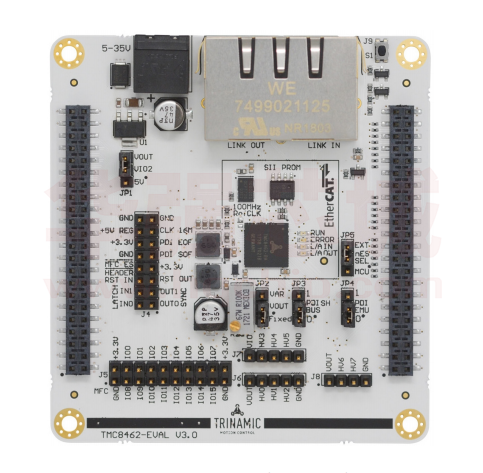

Evaluation Board An evaluation board is available for the TMC8462 with standard RJ45 connectors and

transformers for interfacing twisted pair copper (TPC) media.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

11 / 204

Figure 2: TMC8462 Evaluation Board

The complete board design files are available for download and can be used as reference. All information

is available for download on the specific product page on TRINAMIC’s website at

http://www.trinamic.com/products/integrated-circuits/evalboards.

Breakout Board (BOB) Besides the Evaluation board another smaller breakout board is available. It

allows for easy integration into own systems or connection to a prototyping platform. The breakout

board provides the bus interface along with the ESC and requires an appropriate supply and controller

connection. The BOB comes with standard RJ45 connectors to connect to TPC using the TMC8462 ESC

with integrated Ethernet PHYs. TMC8462 is functionally equal to the TMC8461. The difference is in using

external PHYs vs. integrated PHYs. The complete board design files are available for download and can

be used as reference. All information is available for download from the evaluation board section on

TRINAMIC’s website at

https://www.trinamic.com/support/eval-kits/.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

12 / 204

Figure 3: TMC8462 breakout board for RJ45 and TPC

TRINAMIC Technology Access Package In addition, a comprehensive source code and software package

– TRINAMIC Technology Access Package (TTAP) – is available for download to get started quickly with own

code.

The TTAP is available at https://www.trinamic.com/support/software/access-package/.

TMCL-IDE The TMCL-IDE is TRINAMIC’s primary tool (for Windows PCs) to control TRINAMIC modules and

evaluation boards. Besides, it provides feature like remote firmware updates, module monitoring options,

and specific Wizard support. The TMCL-IDE can be used along with TRINAMICs modular evaluation board

system.

Figure 4: TMCL-IDE

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

13 / 204

The latest version and additional information is available for download from TRINAMIC’s website at

http://www.trinamic.com/software-tools/tmcl-ide.

EtherCAT Slave Configuration Configuration of the EtherCAT Slave Controller is done during boot time

with configuration information read from the SII EEPROM after reset or power cycling. This information

must be (pre)programmed into the SII EEPROM. This can be done via the EtherCAT master using a so-called

EtherCAT Slave Information (ESI) file in standardized XML format. The SII EEPROM can also be (re)written

using the local application controller.

ESI Configuration Wizard The TMCL-IDE contains a wizard to assist users with the configuration of the

TMC8462 various MFC IO functions. The wizard shows available and allowed options and provides XML

code snippets for the ESI file for the SII EEPROM as well as generic C-Code blocks. These can be used as

starting point for own firmware development for the application controller.

Figure 5: Configuration wizard example – MFC IO block configuration

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Figure 6: Configuration wizard example – SII EEPROM content and C-code output

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

14 / 204

�15 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

4

4.1

Device Pin Definitions

Pinout and Pin Coordinates of TMC8462-BA

1

3

2

4

5

6

7

8

9

10

11

A

B

C

D

E

F

G

H

J

K

L

Figure 7: TMC8462-BA Pinout top view

4.2

Signal Descriptions

Name

Pin

Type (I,O,PU,PD)

Function

NRESET

K4

I/O

Low active system reset. NRESET is an I/O pin.

Connected to VCCIO via a 10K resistor and to

GND via a 10nF capacitor if no other reset source

for proper power-on reset is used. For more

information see Section 5.4.1.

REF_CLK100_IN

L3

I

100MHz Reference clock input, connect to a clock

source 16kBit is used (an additional address byte is required then). 0 = up to

16kBit EEPROM, 1 = 32 kBit-4Mbit EEPROM

EEPROM IOs

DC Synchronization IOs

SYNC_OUT0

D7

O

Distributed Clocks synchronization output 0, typically connect to MCU

SYNC_OUT1

D6

O

Distributed Clocks synchronization output 1, typically connect to MCU

LATCH_IN0

C7

I

Latch input 0 for Distributed Clocks, connect to

GND if not used.

LATCH_IN1

C6

I

Latch input 1 for Distributed Clocks, connect to

GND if not used.

LED_RUN

B3

O

Run Status LED, connect to green LED (Anode) 0

= LED off, 1 = LED on

LED_ERR

C3

O

Error Status LED, connect to red LED (Anode) 0 =

LED off, 1 = LED on

LINK_ACT0

D3

O

Link In Port Status and Activity, connect to green

LED (Anode) 0 = LED off, 1 = LED on

LINK_ACT1

E3

O

Link Out Port Status and Activity, connect to

green LED (Anode) 0 = LED off, 1 = LED on

LEDs

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�18 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Name

Pin

Type (I,O,PU,PD)

Function

Process Data Interface IOs to/from MCU

PDI_SOF

H3

O

Ethernet Start-of-Frame if 1

PDI_EOF

G3

O

Ethernet End-of-Frame if 1

PDI_SPI_CSN

L4

I

Chip select signal of the process data interface

PDI_SPI_SCK

K3

I

Serial clock signal of the process data interface

PDI_SPI_MOSI

L5

I

Serial data out signal of the process data interface

PDI_SPI_MISO

K5

O

Serial data in signal of the process data interface

PDI_SPI_IRQ

J3

O

Interrupt signal for primary process data interface, connect to MCU

PDI_WDSTATE

G4

O

EtherCAT Watchdog state, 0: Expired, 1: Not expired

PDI_WDTRIGGER

F4

O

EtherCAT Watchdog trigger if 1

PDI_EMULATION

J7

I

Selects between PDI interface (SPI) or standalone

operation with state machine emulation inside

ESC. Has weak internal pull down. 0 = default,

PDI interface active, 1 = standalone operation,

state machine emulation in Slave Controller

MFC IO Control Interface IOs

MFC_CTRL_SPI_CSN

D4

I

Chip select signal of the MFC IO control interface

MFC_CTRL_SPI_SCK

E4

I

Serial clock signal of the MFC IO control interface

MFC_CTRL_SPI_MOSI

C4

I

Serial data out signal of the MFC IO control interface

MFC_CTRL_SPI_MISO

E7

O

Serial data in signal of the MFC IO control interface

MFC_IRQ

E6

O

MFCIO block IRQ for configurable events, connect

to MCU, high active

MFC_NES

C5

I

low active (not) Emergency Stop/Switch/Halt (to

bring PWM or other outputs into a safe state),

the event must be cleared actively, has weak internal pull down, must be driven high for normal

operation

PDI_SHARED_BUS

F9

I

Selects between separate SPI buses (MISO, MOSI,

SCK) or one SPI bus with two CS lines for the PDI

and MFC CTRL SPI interface: 0 = two separate SPI

buses, 1 = one shared SPI bus using the PDI_SPI_x

bus lines

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�19 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Name

Pin

Type (I,O,PU,PD)

Function

MFCIO00

J8

I/O

MFCIO block low voltage I/O

MFCIO01

J9

I/O

MFCIO block low voltage I/O

MFCIO02

J10

I/O

MFCIO block low voltage I/O

MFCIO03

J11

I/O

MFCIO block low voltage I/O

MFCIO04

H8

I/O

MFCIO block low voltage I/O

MFCIO05

H9

I/O

MFCIO block low voltage I/O

MFCIO06

H10

I/O

MFCIO block low voltage I/O

MFCIO07

H11

I/O

MFCIO block low voltage I/O

MFCIO08

D8

I/O

MFCIO block low voltage I/O

MFCIO09

D9

I/O

MFCIO block low voltage I/O

MFCIO10

D10

I/O

MFCIO block low voltage I/O

MFCIO11

D11

I/O

MFCIO block low voltage I/O

MFCIO12

C8

I/O

MFCIO block low voltage I/O

MFCIO13

C9

I/O

MFCIO block low voltage I/O

MFCIO14

C10

I/O

MFCIO block low voltage I/O

MFCIO15

C11

I/O

MFCIO block low voltage I/O

MFC_HV0 (MFCIO16)

A4

I/O

MFCIO block high voltage I/O

MFC_HV1 (MFCIO17)

A5

I/O

MFCIO block high voltage I/O

MFC_HV2 (MFCIO18)

A6

I/O

MFCIO block high voltage I/O

MFC_HV3 (MFCIO19)

A7

I/O

MFCIO block high voltage I/O

MFC_HV4 (MFCIO20)

A8

I/O

MFCIO block high voltage I/O

MFC_HV5 (MFCIO21)

A9

I/O

MFCIO block high voltage I/O

MFC_HV6 (MFCIO22)

A10

I/O

MFCIO block high voltage I/O

MFC_HV7 (MFCIO23)

A11

I/O

MFCIO block high voltage I/O

MFC IOs

MFC High Voltage IOs

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�20 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Name

Pin

Type (I,O,PU,PD)

Function

MFC High Voltage IO Supplies

VIO1

B5

I

MFCHVIO block 1 supply voltage

VIO2

B7

I

MFCHVIO block 2 supply voltage

VIO3

B9

I

MFCHVIO block 3 supply voltage

GNDIO1

B6

I

MFCHVIO block 1 ground, connect to GND

GNDIO2

B8

I

MFCHVIO block 2 ground, connect to GND

GNDIO3

B10

I

MFCHVIO block 3 ground, connect to GND

Device Supply and Ground

VS

B11

I

Supply voltage, use a 100nF filter capacitor

VCCIO

E10, F10,

I

I/O supply voltage, use a 100nF filter capacitor

per pin

I

Core supply voltage, connect to VDD1V8_OUT,

use a 100nF filter capacitor per pin

G10, F11

VCC_CORE

F6, G6,

F7, G7

PLLCLK_VCCIO

K6

I

PLL supply voltage, connect to VCCIO through

a filter (R/L/C)

TSTCLK_SELECT

H6

I

Test input, always connect to VCCIO for normal operation

GND

C1, F1,

I

Supply Ground

J6

I

PLL supply ground, connect to GND

VDD1V8_OUT

G11

O

Output of internal 1.8V regulator, use a 100nF

filter capacitor

VDD5_OUT

E11

O

Output of internal 5V regulator, use a 100nF filter capacitor if VS≥5V

J1, A3,

B4, F5,

G5, E8,

F8, G8

PLLCLK_GND

Voltage Regulator IOs

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�21 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Name

Pin

Type (I,O,PU,PD)

Function

Switching Regulator 0 IOs

VS0

L7

I

Switching regulator 0 supply voltage, Switching

regulator 0 provides a fixed 3.3V output.

GND0

L9

I

Switching regulator 0 ground, connect to GND

SW0

L8

O

Switching regulator 0 output, fixed 3.3V

SW_DIODE

K7

I

Switching regulator 0 internal diode, connect to

SW0 only if VS0 is at or below 5V

GND_DIODE

K8

I

Switching regulator 0 internal diode ground, connect to GND

Switching Regulator 1 IOs

VS1

L11

I

Switching regulator 1 supply voltage, Switching

regulator 1 provides an adjustable output voltage.

GND1

K9

I

Switching regulator 1 ground, connect to GND

SW1

L10

O

Switching regulator 1 output, adjustable

VOUT

K10

I

Switching regulator 1 inductor ringing suppression feedback

VOUT_FB

K11

I

Switching regulator 1 feedback voltage, 1.2V typically

Bus Interface 0 IOs (EtherCAT IN Port)

TN0

D1

O

Negative pin of differential transmit output pair

TP0

E1

O

Positive pin of differential transmit output pair

RN0

A1

I

Negative pin of differential receive output pair

RP0

B1

I

Positive pin of differential receive output pair

REGOUT0

A2

O

Regulator power output, use a 10uF and 0.1uF

for filtering power noise

MCLK

F2

O

PHY management clock, leave open if not needed

MDIO

F3

I/O, PU

PHY management data, use 4K7 pull up resistor

to VCCIO (3.3V)

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�22 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Name

Pin

Type (I,O,PU,PD)

Function

Bus Interface 1 IOs (EtherCAT OUT Port)

TN1

K1

IO

Negative pin of differential transmit output pair

TP1

L1

IO

Positive pin of differential transmit output pair

RN1

G1

IO

Negative pin of differential receive output pair

RP1

H1

IO

Positive pin of differential receive output pair

REGOUT1

L2

O

Regulator power output, use a 10uF and 0.1uF

for filtering power noise

TST_MODE

E5

I

Test mode enable, connect to GND

TST_ANA

D5

O

Analog test output, leave open

RXCLK0

D2

IO

Clock test pin, leave open

RXCLK1

G2

IO

Clock test pin, leave open

TXCLK0

E2

IO

Clock test pin, leave open

TXCLK1

H2

IO

Clock test pin, leave open

RXDV0

B2

I, PD

Test pin, leave open for normal operation

RXDV1

K2

I, PD

Test pin, leave open for normal operation

TXER0

C2

I, PD

Test pin, leave open for normal operation

TXER1

J2

I, PD

Test pin, leave open for normal operation

CLKO_100

L6

O

100MHz clock output

Test Pins only

Table 2: Pin and Signal description for TMC8462-BA

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�23 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

5

5.1

Device Usage and Handling

Process Data Interface

The Process Data Interface (PDI) is an SPI interface with a clock frequency of up to 30 MHz. The ESC

registers and the process data RAM can be accessed from an external microcontroller using this interface.

The interface can be configured via the EEPROM, however it is recommended to use the default configuration (SPI mode 3 with low active chip select). For further details, see the ESC SPI slave configuration

registers in Section 6.

Additionally, some signals are available that can be evaluated by the application controller.

Figure 8: PDI control signals

TMC8462 pin

Description

Typical pin on a MCU

PDI_SPI_CSN

SPI chip select for the TMC8462 PDI

SSx

PDI_SPI_SCK

SPI master clock

SCK

PDI_SPI_MOSI

Master out slave in data

MOSI

PDI_SPI_MISO

Master in slave out data

MISO

PDI_SPI_IRQ

Configurable IRQ from PDI

General purpose Input

PDI_EMULATION

0: default mode for complex slaves, state

machine changes processed in microcontroller

firmware (SSC); 1: device emulation mode for,

e.g., simple slaves, state machine changes

directly handled in the ESC

General purpose Output

or connected to either

ground or 3.3V.

PDI_SOF

Indicates start of an Ethernet/EtherCAT frame

(MII_RXDV = ’1’)

General purpose Input

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�24 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

TMC8462 pin

Description

Typical pin on a MCU

PDI_EOF

Indicates end of an Ethernet/EtherCAT frame

General purpose Input

PDI_WDSTATE

0: Watchdog expired; 1: Watchdog not expired

General purpose Input

PDI_WDTRIGGER

Watchdog triggered if ’1’

General purpose Input

Table 3: PDI signal description

5.1.1

SPI protocol description

Each SPI datagram contains a 2- or 3-byte address/command part and a data part. For addresses below

0x2000, the 2-byte addressing mode can be used, the 3 byte addressing mode can be used for all addresses.

C2

C1

C0

Command

0

0

0

NOP (no operation, no following data bytes)

0

0

1

Reserved

0

1

0

Read

0

1

1

Read with wait state byte

1

0

0

Write

1

0

1

Reserved

1

1

0

Address extension, signaling 3 byte mode

1

1

1

Reserved

Table 4: PDI SPI commands

Address

A12 A11 A10 A9

A8

A7

A6

A5

A12 A11 A10 A9

A8

A7

A6

A5

Command

A4

A3

A2

A1

A0

A4

A3

A2

A1

Byte 0

Byte 1

Figure 9: PDI SPI 2 byte addressing

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

A0

C2

C1

C0

C2

C1

C0

�25 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Address

A15 A14 A13 A12 A11 A10 A9

A12 A11 A10 A9

A8

A7

A6

A5

A4

Byte 0

Command

A8

A7

A6

A5

A4

A3

A2

A3

A2

A1

A0

1

1

0

Byte 1

A1

Address

extension

command

A0

C2

C1

C0

A15 A14 A13

C2

C1

Byte 2

C0

0

0

Reserved

Figure 10: PDI SPI 3 byte addressing

Unless highest performance is required, using only the 3-byte addressing mode and the read with wait

state command is recommended since it reduces the need for special cases in the software. During the

address/command bytes, the ESC replies with the contents of the event request registers (0x0220, 0x0221

and in 3 byte addressing mode 0x0222).

Command 0 - NOP

This command can be used for checking the event request registers and resetting the PDI watchdog

without a read or write access.

Example datagram:

Example reply (AL Control event bit is set):

0x00 0x00

0x01 0x00

Command 2 - READ

With the read command, an arbitrary amount of data can be read from the device. The first byte read is

the data from the address given by the address/command bytes. With every read byte, the address is

incremented. During the data transfer, the SPI master sends 0x00 except for the last byte where a 0xFF is

sent.

When using this command, a pause of 240ns or more must be included between the address/command

bytes and the data bytes for the ESC to fetch the requested data.

Example datagram (Read from address 0x0120 and 0x0121): 0x09 0x02 0x00 0xFF

Example reply (Operational State requested):

0x01 0x00 0x08 0x00

Command 3 - READ WITH WAIT STATE BYTE

This command is similar to the Read command with an added dummy byte between the address/command

part and the data part of the datagram. This allows enough time to fetch the data in any case.

Example datagram (Read starting at address 0x3400): 0xA0 0x06 0x2C 0xFF 0x00 0x00 0x00 0xFF

Example reply (0xXX is undefined data):

0x00 0x00 0x00 0xXX 0x44 0x41 0x54 0x41

Command 4 - WRITE

The write command allows writing of an arbitrary number of bytes to writable ESC registers or the process

data RAM. It requires no wait state byte or delay after the address/command bytes. After every transmitted

byte, the address is incremented.

Example datagram (Write starting at address 0x4200): 0x10 0x06 0x50 0x4C 0x48

Example reply (0xXX is undefined data):

0x00 0x00 0x00 0xXX 0xXX

Address 0x4200 now contains 0x4C, Address 0x4201 contains 0x48

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�26 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

Command 6 - ADDRESS EXTENSION

The address extension command is mainly used for the 3-byte addressing mode as shown in Figure 10.

For SPI masters that can only process datagrams with an even number of bytes, it might be necessary to

pad the datagram to an even number of bytes. This can be achieved by duplicating the third byte of the

3-byte address/command part and using the address extension command in all but the last duplicate.

For example, a SPI master that is only capable of transmitting a multiple of 4 bytes cannot use the example

datagram for a write access above since it contains 5 bytes. With three added padding bytes, the master

has to transmit two 4-byte groups.

Example datagram (Write starting at address 0x4200):

Example reply (0xXX is undefined data):

5.1.2

0x10 0x06 0x58 0x58 0x58 0x50 0x4C 0x48

0x00 0x00 0x00 0xXX 0xXX 0xXX 0xXX 0xXX

Timing example

This example shows a generic read access with wait state and 2 byte addressing. All configurable options

are shown. The delays between the transferred bytes are just to show the byte boundaries and are not

required.

CSN active low

CSN acti ve high

SCK mode 0

SCK mode 1

SCK mode 2

SCK mode 3

A

12

MOSI

MISO mode 0/2

normal sample

I

7

MISO mode 0/2

late sample

MISO mode 1/3

normal sample

MISO mode 1/3

late sample

I

7

S

A

10

A

9

A

8

A

7

A

6

A

5

A

4

A

3

A

2

A

1

A

0

C

2

C

1

C

0

I

6

I

5

I

4

I

3

I

2

I

1

I

0

I

15

I

14

I

13

I

12

I

11

I

10

I

9

I

8

I

7

S

S

A

11

I

6

I

6

I

7

I

5

I

4

I

5

I

6

I

4

I

5

I

3

I

3

I

4

I

2

I

1

I

2

I

3

I

1

I

2

I

0

I

0

I

1

I

15

I

15

I

0

I

14

I

14

I

15

I

13

I

13

I

14

I

12

I

12

I

13

I

11

I

11

I

12

I

10

I

10

I

11

I

9

I

9

I

10

D

7

I

8

I

8

I

9

D

6

D

7

D

7

I

8

D

5

D

6

D

6

D

7

D

5

D

5

D

6

Figure 11: SPI timing example

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

D

4

D

3

D

4

D

4

D

5

D

2

D

3

D

3

D

4

D

1

D

2

D

2

D

3

D

0

D

1

D

1

D

2

D

15

D

0

D

0

D

1

D

14

D

15

D

15

D

0

D

13

D

14

D

14

D

15

D

12

D

13

D

13

D

14

D

11

D

12

D

12

D

13

D

10

D

11

D

11

D

12

D

9

D

10

D

10

D

11

D

8

D

9

D

9

D

10

D

8

D

8

D

9

D

8

�27 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

5.2

MFC IO Control Interface

The MFC IO block of the TMC8462 comes with a dedicated SPI slave interface to allow direct access from

a local application controller. It is called MFC CTRL SPI interface. This interface to the MFC IO block’s

functions is always available, even if the EtherCAT state machine is currently not in operational state (OP).

Protocol structure and timing are identical to the PDI SPI.

The MFC Control SPI is a SPI mode 3 slave with low active chip select. The SPI clock frequency can be up to

30MHz. The following diagram shows all signals related to the MFC CTRL SPI interface.

Figure 12: MFC control signals

TMC8462 pin

Description

Typical pin on a MCU

MFC_CTRL_SPI_CSN

SPI chip select for the TMC8462 PDI

SSx

MFC_CTRL_SPI_SCK

SPI master clock

SCK

MFC_CTRL_SPI_MOSI

Master out slave in data

MOSI

MFC_CTRL_SPI_MISO

Master in slave out data

MISO

MFC_IRQ

Configurable IRQ from MFC IO block

General purpose Input

PDI_SHARED_BUS

0: separate SPI buses for PDI and MFC CTRL; 1:

shared/common SPI bus for PDI and MFC CTRL

with 2 CSN signals using the PDI SPI bus. The SPI

bus signals MFC_CTRL_SPI_SCK,

MFC_CTRL_SPI_MISO, MFC_CTRL_SPI_MOSI can

be left open in this case

General purpose Output

or connected to either

ground or 3.3V.

Table 5: MFC CTRL SPI signal description

5.2.1

SPI Protocol description

The protocol of the MFC CTRL SPI is the same as the PDI SPI interface (see section 5.1.1) The addresses for

register access are calculated using the register number and the byte number in each register. To calculate

the address, the register number is shifted left by 4 bits and the byte number is added as the 4 lowest bits.

Access using the 3 byte addressing mode is possible, and can be used when 2 byte mode is not implemented for the PDI SPI but since the highest bits of the address are always 0, accessing the MFC Control

SPI via 2 byte mode is sufficient.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

28 / 204

6

6

Figure 13: MFC CTRL SPI 2 byte addressing

6

6

Figure 14: MFC CTRL SPI 3 byte addressing

5.2.2

Timing example

This example shows a generic MFC register read access with wait state. The delays between the transferred

bytes are just to show the byte boundaries and are not required.

Figure 15: MFC SPI timing example

5.2.3

Sharing Bus Lines with the PDI SPI

To reduce the number of signals on the PCB or if the local application controller has only one SPI interface,

the MFC CTRL SPI bus can share the SPI bus signals of the PDI SPI, requiring only separate chip select

signals. In this case, both interfaces are internally switched to the PDI SPI interface pins. The original MFC

CTRL SPI signals (MOSI, MISO, and SCK) remain unconnected in this case. Only the MFC_CTRL_SPI_CSN

pin/signal must be used if the MFCIO block is accessed.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

29 / 204

To share the SPI bus lines, configuration pin PDI_SHARED_BUS must be pulled high as shown in the figure

below.

Figure 16: SPI bus sharing

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

5.3

30 / 204

Ethernet Physical Layer Connection

TMC8462 comes with two integrated 100-Mbit Ethernet PHYs eliminating the need for external PHY

components. The physical media interface can connect to (shielded) twisted pair copper buses ((S)TPC).

Port signals with index 0 represent the EtherCAT IN port. Port signals with index 1 represent the EtherCAT

OUT port.

Figure 17: Physical bus interface pins

TMC8462 pin

Description

TNx

Negative pin of differential transmit output pair

TPx

Positive pin of differential transmit output pair

RNx

Negative pin of differential receive output pair

RPx

Positive pin of differential receive output pair

REGOUTx

This is a regulator power output. A 10uF and 0.1uF should be connected to

this pin for filtering power noise.

MCLK

PHY configuration clock output

MDIO

PHY configuration data in-/output

Table 6: Physical bus interface pin description

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�31 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

5.4

5.4.1

External Circuitry and Applications Examples

Device Reset

The NRESET signal should at least be connected to VCCIO via a 10K resistor and to GND via a 10nF capacitor

if no other controlled reset source for proper power-on behavior and reset is used.

VCCIO (3.3V)

TMC8462

10kΩ

NRESET

10nF

Figure 18: Minimum external circuit for power-on reset

5.4.2

Supply Filtering for PLL Supply

The internal PLL is supplied with the same 3.3V as used for VCCIO. An R/L/C filter structure as shown in the

circuit diagram is used. PLLCLK_GND is connected to common ground.

VCCIO (3.3V)

VCCIO (3.3V)

TMC8462

TSTCLK_SELECT

1Ω

600 Ω @100MHz

PLLCLK_VCCIO

100nF

PLLCLK_GND

Figure 19: PLL supply filter

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�32 / 204

TMC8462 Datasheet • Document Revision V1.5 • 2019-June-21

5.4.3

PHY Power Regulator Filtering

The internal PHY circuits require external filter capacitors.

TMC8462

REGOUT0

10µF

100nF

REGOUT1

10µF

100nF

Figure 20: PHY power regulator filtering