DATA SHEET

Product Name Precision Metal Film Fixed Resistors

Part Name MF Series

Uniroyal Electronics Global Co., Ltd.

88#, Longteng Road, Economic & Technical Development Zone, Kunshan, Jiangsu, China

Tel

Email

Manufacture Plant

+86 512 5763 1411 / 22 /33

marketing@uni-royal.cn

Uniroyal Electronics Industry Co., Ltd.

Aeon Technology Corporation

Royal Electronic Factory (Thailand) Co., Ltd.

Royal Technology (Thailand) Co., Ltd.

�Precision Metal Film Fixed Resistors

1. Scope

1.1 This datasheet is the characteristics of Precision Metal Film Fixed Resistors manufactured by UNI-ROYAL.

1.2 Flame Retardant type available

1.3 Low noise & voltage coefficient

1.4 Low temperature coefficient range

1.5 Multiple epoxy coating on vacuum-deposited metal flim provideds superior moiseure protection

1.6 Nichrome resistive element provides stable performance in various environments

2. Part No. System

The standard Part No. includes 14 digits with the following explanation:

2.1 Coated type, the 1st to 2rd digits are to indicate the product type .

Example: MF= Metal Film Fixed Resistors

2.2 The 3th digit is the special feature.

Example: 0= Standard product ; F= Flame Retardant ; I= Non-inductive

2.3 4th~6th digits:

2.3.1 This is to indicate the wattage or power rating. To dieting the size and the numbers,

The following codes are used; and please refer to the following chart for detail:

W=Normal Size; S=Small Size; U=Extra Small Size; “1”~“G”to denotes“1”~“16”as Hexadecimal:

1/16W~1/2W (<1W )

Wattage

Normal Size

Small Size

Extra Small Size

1/2

W2

S2

U2

1/3

W3

S3

U3

1/4

W4

S4

U4

3

3W

3S

3U

5

5W

5S

5U

1/5

W5

S5

U5

1/6

W6

S6

U6

1/8

W8

S8

U8

0.6

/

06

/

0.4

/

/

04

1W~16W (≧1W )

Wattage

Normal Size

Small Size

Extra Small Size

1

1W

1S

1U

2

2W

2S

2U

7

7W

7S

7U

8

8W

8S

8U

9

9W

9S

9U

10

AW

AS

AU

15

FW

FS

FU

2.3.2 For power rating less than 1 watt, the 4th digit will be the letters W, S or U to represent the size required & the 5th digit will be a number or

aletter code.

Example: WA=1/10W; U2=1/2W-SS.

2.3.3 For power of 1 watt to 16 watt, the 4th digit will be a number or a letter code and the 5th digit will be the letters of W, S or U.

Example: AW=10W; 3S=3W-S

2.4 The 6th digits will be used to indicated the requested Temperature Coefficient.

(1) B=15PPM (2) B=25PPM (3) F=50PPM (4) G=100PPM (5) J=200PPM

2.5 The 7th digit is to denote the Resistance Tolerance. The following letter code is to be used for indicating the standard Resistance Tolerance.

F=±1% G=±2% J=±5%

2.6 The 8th to 11th digits is to denote the Resistance Value.

2.6. 1 For the standard resistance values of E-24 series, the 8th digit is “0”,the 9th & 10th digits are to denote the significant figures of the resistance

and the 11th digit is the number of zeros following;

For the standard resistance values of E-96 series, the 8th digit to the 10th digits is to denote the significant figures of the resistance and the

11th digit is the 11th digit is the zeros following.

2.6.2 The following number s and the letter codes are to be used to indicate the number of zeros in the 11th digit:

0=100 1=101 2=102 3=103 4=104 5=105 6=106 J=10-1 K=10-2 L=10-3 M=10-4

2.7 The 12th, 13th & 14th digits.

The 12th digit is to denote the Packaging Type with the following codes:

A=Tape/Box (Ammo pack) B=Bulk/Box T=Tape/Reel P=Tape/Box of PT-26 products

2.8 The 13th digit is normally to indicate the Packing Quantity of Tape/Box & Tape/Reel packaging types. The following letter code and number

is to be used for some packing quantities:

A=500pcs B=2500pcs 1=1000pcs 2=2000pcs

2.9 For some items, the 14th digit alone can use to denote special features of additional information with the following codes:

0=NIL

P=Panasert type

1=Avisert type 1

2=Avisert type 2

3=Avisert type 3

8=PT-58mm

9=PT-64mm

7=Lead wire(H)38mm

A=PT-83mm

C=PT-73mm

D=PT-71mm

Feb.18,2019 V.3

www. uni-royal.cn

Page 2/8

�Precision Metal Film Fixed Resistors

3.

Ordering Procedure

(Example: MF 1/4W ±1% 100Ω T/B-5000 )

M

F

0

W

4

F

Product Type:

MF=Precision

metal film fixed

resistors

Special Features:

0= Standard product

F= Flame Retardant

I= Non-inductive

Wattage:

Normal size:

W8=1/8W

W4=1/4W

W2=1/2W

1W=1W

2W=2W

3W=3W

Small size:

S4=1/4W-S

S2=1/2W-S

06=0.6W-S

1S=1WS

2S=2WS

3S=3WS

Extra small size:

04=0.4WSS

Tolerance

B=±0.1%

C=±0.25%

D=±0.5%

F=±1%

G=±2%

J=±5%

F

1

0

0

0

Resistance Value:

±2%、±5%、10% series:

The 1st digit will be ”0”; the

2nd & 3rd digits are for the

significant figures of the

resistance and the 4th digit

denotes number of zeros

following

Example:20KΩ:0203

≤±1%series:

The 1st to 3rd digits are

for the significant figures of

the resistance and 4th digit

denotes number of zeros

following.

Example:20KΩ:2002

J=10-1; K=10-2; L=10-3

PPM

requirement:

B=±15PPM

C=±25PPM

F=±50PPM

G=±100PPM

J=±200PPM

A

5

0

Packing

quantity:

1=1,000pcs

2=2,000pcs

3=3,000pcs

4=4,000pcs

5=5,000pcs

A=500pcs

B=2,500pcs

Additional Information:

0=NIL

P=Panasert type

1=Avisert type 1

2=Avisert type 2

3=Avisert type 3

8=PT-58mm

9=PT-64mm

7=Lead wire(H)38mm

A=PT-83mm

C=PT-73mm

D=PT-71mm

Packing Type:

A=Tape/Box

T=Tape/Reel

B=Bulk/Box

P=Tape/Box of PT-26 product

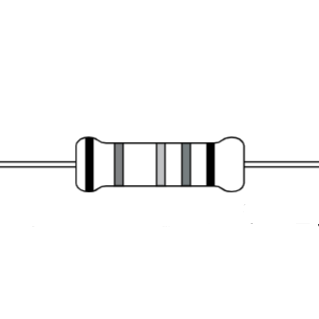

4. Marking

Resistors shall be marked with color coding

Colors shall be in accordance with JIS C 0802

For 1/8W, ,1/4WS,0.4WSS (±1%)

The other

For 1/8W,1/6W,1/4WS,0.4WSS (±2%,±5%)

The other

4.1 Label:

Label shall be marked with following items:

(1) Type and style

(2) Nominal resistance

(3) Resistance tolerance

(4) Quantity

(5) Lot number

(6) PPM

Feb.18,2019 V.3

Example:

METAL FILM FIXED RESISTORS

WATT: 1/4W

Q’TY: 5,000

LOT: 5021548

www. uni-royal.cn

VAL:100

TOL: 1%

PPM: 50

Page 3/8

�Precision Metal Film Fixed Resistors

5. Dimension

For 1/8W, 1/4WS, 0.4WSS

Other

Dimension(mm)

Type

MF 1/8W

MF 1/4WS

MF 0.4WSS

MF 1/4W

MF 1/2WS

MF 1/2W

MF 0.6WS

MF 1WS

MF 1W

MF 2WS

MF 2W

MF 3WS

MF 3W

D

1.9±0.3

1.9±0.3

1.9±0.5

2.2±0.3

2.2±0.5

3.0±0.6

2.2±0.5

3.0±0.6

4.5±0.6

4.5±0.6

5.0±0.6

5.0±0.6

6.0±0.6

L

3.3±0.3

3.3±0.3

3.3±0.3

6.5±1.0

6.5±1.0

9.5±1.0

6.5±1.0

9.5±1.0

11.5±1.0

11.5±1.0

15.5±1.0

15.5±1.0

17.5±1.0

d±0.05

0.45

0.45

0.45

0.54

0.54

0.54

0.54

0.54

0.70

0.70

0.70

0.70

0.75

H±3

28

28

28

28

28

28

28

28

25

25

28

28

28

PT

52

52

52

52

52

52

52

52

52

52

64

64

64

Max

Working

Voltage

200V

200V

200V

250V

250V

350V

250V

350V

500V

500V

500V

500V

500V

Max

Overload

Voltage

400V

400V

400V

500V

500V

700V

500V

700V

1000V

1000V

1000V

1000V

1000V

Dielectric

Withstanding

Voltage

400V

400V

400V

500V

250V

700V

500V

700V

1000V

1000V

1000V

1000V

1000V

6. Resistance Range

Standard

Type

MF 1/8W

MF 1/4WS

MF 0.4WSS

MF 1/4W

MF 1/2WS

MF 0.6WS

MF 1/2W

MF 1WS

MF 1W

MF 2WS

MF 2W

MF 3WS

MF 3W

Feb.18,2019 V.3

Special Order

Tolerance

Resistance Range

TCR

PPM/℃

Tolerance

Resistance Range

TCR

PPM/℃

±1%

10Ω~1MΩ

50

±0.25%

51.1Ω~200KΩ

15

±2%

10Ω~1MΩ

100

±0.5%

51.1Ω~511KΩ

25

±5%

1Ω~1MΩ

200

±0.5%

51.1Ω~511KΩ

50

±1%

10Ω~1MΩ

50

±0.1%

10Ω~1MΩ

15

±2%

1Ω~1MΩ

100

±0.25%

10Ω~1MΩ

25

±5%

1Ω~1MΩ

200

±0.5%

10Ω~1MΩ

50

±1%

10Ω~1MΩ

50

±0.1%

100Ω~330KΩ

15

±2%

10Ω~1MΩ

100

±0.25%

51.1Ω~511KΩ

25

±5%

1Ω~1MΩ

200

±0.5%

10Ω~1MΩ

50

±1%

51.1Ω~1MΩ

50

±0.1%

100Ω~330KΩ

15

±2%

51.1Ω~1MΩ

100

±0.25%

51.1Ω~511KΩ

25

±5%

1Ω~1MΩ

200

±0.5%

51.1Ω~ 1MΩ

50

www. uni-royal.cn

Page 4/8

�Precision Metal Film Fixed Resistors

7. Derating Curve

Power rating will change based on continuous load at ambient temperature from -55 to 155℃.

It is constant between -55 to 70℃, and derate to zero when temperature rise from 70 to 155℃.

Voltage rating:

Resistors shall have a rated direct-current (DC) continuous working voltage or an approximate sine-wave

root-mean-square (RMS) alternating-current (AC) continuous working voltage at commercial-line

frequency and waveform corresponding to the power rating, as determined from the following formula:

Remark: RCWV: Rating Continuous Working Voltage (Volt.) P: power rating (Watt)

R: nominal resistance (Ω)

In no case, the rated DC or RMS AC continuous working voltage must be greater than the applicable maximum value.

The overload voltage is 2.5 times RCWV or Max. Overload voltage whichever is lower.

8. Structure

No.

Name

Material

1

Basic Body

Rod type ceramics

2

Resistor

Metal Film

3

End Cap

Cold steel plated with copper/tin

4

Lead Wire

Tin solder coated copper wire

5

Joint

By Welding

(1). Celluloid paint

6

Coating

7

Color Code

(2) Insulated Resin Color :Blue

1/2WS:Deep Green

0.6WS:Apple Green

Epoxy resin

9. Performance Specification

Characteristic

Test Method

(GB/T5729&JIS-C-5201&IEC60115-1)

Limits

Reference 6.0

4.8 Natural resistance changes per temp. Degree centigrade

R2-R1

× 106 (PPM/℃)

R1(t2-t1)

R1: Resistance Value at room temperature (t1);

R2: Resistance at test temperature

(Upper limit temperature or Lower limit temperature)

t1: +25°C or specified room temperature

t2: Upper limit temperature or Lower limit temperature test temperature

Short-time overload

ΔR/R ≤ ±(0.5%+0.05 Ω),with no

evidence of mechanical damage

4.13 Permanent resistance change after the application of a potential of

2.5 times RCWV for 5 seconds.

Dielectric

withstanding voltage

No evidence of flashover mechanical

damage, arcing or insulation break

down.

4.7 Resistors shall be clamped in the trough of a 90metallic v-block

and shall be tested at ac potential respectively specified in the above list

for 60-70 seconds.

ΔR/R ≤ ±(1%+0.05),with no

evidence of mechanical damage

4.28 Resistance change after 10,000 cycles (1 second “ON ”, 25

seconds “OFF ”) at 4 times RCWV.

Temperature

Coefficient

Pulse overload

Feb.18,2019 V.3

www. uni-royal.cn

Page 5/8

�Precision Metal Film Fixed Resistors

Resistance to

soldering heat

Resistance to solvent

Terminal strength

Solderability

Rapid change of

temperature

ΔR/R ≤ ±(1%+0.05 Ω) with no

evidence of mechanical damage

4.18 Permanent resistance change when leads immersed to a point 2.02.5mm from the body in 260℃5℃ solder for 10±1 seconds.

No deterioration of protective coatings

& markings

4.29 Specimens shall be immersed in a bath of trichloroethylene

completely for 3 min. With ultrasonic

No evidence of mechanical damage

4.16 Direct load:

Resistance to a 2.5 kg direct load for 10 seconds in the direction of the

longitudinal axis of the terminal leads.

Twist test:

Terminal leads shall be bent through 90at a point of about 6mm from

the body of the resistor and shall be rotated through 360 about the

original axis of the bent terminal in alternating direction for a total of 3

rotations.

Coverage must be over 95%.

4.17 The area covered with a new, smooth, clean, shiny and continuous

surface free from concentrated pinholes.

Test temp. Of solder:245℃±3℃

Dwell time in solder: 2~3seconds.

ΔR/R ≤ ±(1%+0.05 Ω) with no

evidence of mechanical damage

4.19 30 min at -55 °C and 30 min at 155°C; 100 cycles.

7.9 resistance change after 1,000 hours (1.5 hours “ON”,0.5 hour

“OFF”) at RCWV in a humidity test chamber controlled at 40℃±2℃

and 90 to 95% relative humidity.

Load life in humidity

Normal type: ΔR/R ≤±1.5%;

flame retardant type: ΔR/R ≤ ±5%

Load life

Normal type: ΔR/R ≤±1.5%;

flame retardant type: ΔR/R ≤±5%

4.25.1 permanent resistance change after 1,000 hours operating at

RCWV with duty cycle of 1.5 hours “ON”, 0.5 hour “OFF” at 70℃±2

℃ ambient.

Low

Temperature

Storage

Normal type: ΔR/R ≤±1.5%;

flame retardant type: ΔR/R ≤±5%

4.23.4 Lower limit temperature,for 2H.

High

Temperature

Exposure

Normal type: ΔR/R ≤±1.5%;

flame retardant type: ΔR/R ≤±5%

4.23.4 Upper limit temperature ,for 16H.

Feb.18,2019 V.3

www. uni-royal.cn

Page 6/8

�Precision Metal Film Fixed Resistors

10. Packing

10.1 Tapes in Box Packing

Dimension of T/B (mm)

Part No.

MF 1/8W

MF 1/4WS

MF 0.4WSS

MF 1/4W

MF 1/2WS

MF 0.6WS

MF 1/2W

MF 1WS

MF 1W

MF 2WS

MF 2W

MF 3WS

MF 3W

O

P

A±5

B±5

C±5

Qty/Box

52±1

52±1

52±1

52±1

52±1

52±1

52±1

52±1

52±1

52±1

64±5

64±5

64±5

5±0.3

5±0.3

5±0.3

5±0.3

5±0.3

5±0.3

5±0.3

5±0.3

5±0.3

5±0.3

10±0.5

10±0.5

10±0.5

75

75

75

75

75

75

75

75

86

86

94

94

90

70

70

70

98

98

98

45

45

82

82

88

88

88

255

255

255

255

255

255

255

255

255

255

255

255

255

5,000pcs

5,000pcs

5,000pcs

5,000pcs

5,000pcs

5,000pcs

1,000pcs

1,000pcs

1,000pcs

1,000pcs

1000pcs

1000pcs

500pcs

10.2 Tapes in Reel Packing

Dimension of Reel (mm)

Part No.

MF 1/8W

MF 1/4WS

MF 0.4WSS

MF 1/4W

MF 1/2WS

MF 1/2W

MF 0.6WS

MF 1WS

MF 1W

MF 2WS

MF 2W

MF 3WS

MF 3W

Feb.18,2019 V.3

O

52±1

52±1

52±1

52±1

52±1

52±1

52±1

52±1

52±1

52±1

64±5

64±5

64±5

A

73±2

73±2

73±2

73±2

73±2

73±2

73±2

73±2

73±2

73±2

80±5

80±5

80±5

W±5

85

85

85

85

85

85

85

85

85

85

95

95

95

www. uni-royal.cn

H±5

295

295

295

295

295

295

295

295

295

295

295

295

295

L±5

293

293

293

293

293

293

293

293

293

293

293

293

293

Qty/Box

5,000pcs

5,000pcs

5,000pcs

5,000pcs

5,000pcs

2,500pcs

5,000pcs

2,500pcs

2,500pcs

2,500pcs

1,000pcs

1,000pcs

1,000pcs

Page 7/8

�Precision Metal Film Fixed Resistors

10.3 Bulk in Box Packing

Dimension of Box (mm)

Part No.

A±5

B±5

C±5

Qty/Box

MF 1/8W

140

80

240

1,000/20,000pcs

MF 1/4WS

140

80

240

1,000/20,000pcs

MF 0.4WSS

140

80

240

1,000/20,000pcs

MF 1/4W

140

80

240

500/10,000pcs

500/10,000pcs

MF 1/2WS

140

80

240

MF 1/2W

140

80

240

250/5,000pcs

MF 0.6WS

140

80

240

500/10,000pcs

MF 1WS

140

80

240

250/5,000pcs

MF 1W

140

80

240

100/2,500pcs

MF 2WS

140

80

240

100/2,500pcs

MF 2W

140

80

240

100/1,500pcs

MF 3WS

140

80

240

100/1,500pcs

MF 3W

140

80

240

100/1,500pcs

11. Note

11.1. UNI-ROYAL recommend products store in warehouse with temperature between 15 to 35℃ under humidity between 25 to 75%RH.

Even under storage conditions recommended above, solder ability of products will be degraded stored over 1 year old.

11.2. Cartons must be placed in correct direction which indicated on carton, otherwise the reel or wire will be deformed.

11.3. Storage conditions as below are inappropriate:

a. Stored in high electrostatic environment

b. Stored in direct sunshine, rain, snow or condensation.

c. Exposed to sea wind or corrosive gases, such as Cl2, H2S, NH3, SO2, NO2, etc.

12.

Record

Version

Description

Page

Date

Amended by

Checked by

1

First version

1~7

Mar.20, 2018

Chen Haiyan

Chen Nana

2

Modify coating color

5

May.08, 2018

Chen Haiyan

Chen Nana

3

Modify characteristic

5~6

Feb.18, 2019

Chen Haiyan

Xu Yuhua

© Uniroyal Electronics Global Co., Ltd. All rights reserved. Specification herein will be changed at any time without prior notice

Feb.18,2019 V.3

www. uni-royal.cn

Page 8/8

�