DATASHEET

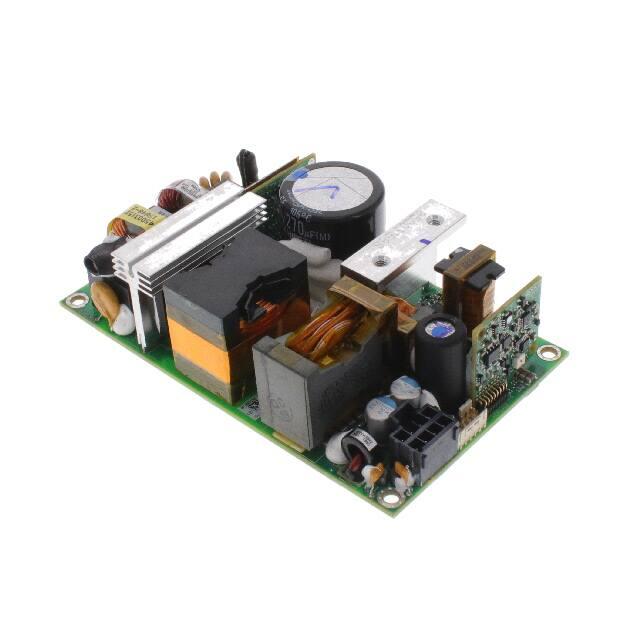

CLP0412 Open Frame Power Supply

90 - 265Vac Input; 12Vdc Output; 450W Output Power;

Trapezoidal 75-130Vac Input; 12Vdc Output

.

Description

Offering a

W/in3 power density in a 1U high,

less form

in new products from industrial equipment and

Higher temperature operation is possible at derated output The

leveraging zero

switching

in conjunction

Protection features include

overvoltage (OVP)

the

a broad range of

(OEMs).

utilizes a unique design approach at

power level,

power factor

(PFC) circuits.

Applications include:

Industrial Equipment | Telecommunications Equipment | CATV Equipment (Trapezoidal Input)

Features

•

Compact size 76.2 mm x 127 mm x 36.8 mm (3 in x 5 in x

1.45 in) with density of 20.7 W/in3

•

Output overcurrent protection (non-latching)

•

•

Universal AC Input Range (90 - 265VAC )

Overtemperature and output over-voltage protections

•

•

Trapezoid AC Input Range (75V - 130VAC)

Minimum of 11ms of holdup time at 450W out

•

•

Output voltage of 12V or 54V (adjustable ±3% )

Parallelable with output current sharing

•

•

Standby output of 5V @ 1A (standard versions)

Active power factor corrected input

•

•

Maximum output current of 37.5A @ 12Vout (450W)

Conducted EMI - meets CISPR22 (EN55022) and FCC Class

B requirements

•

High efficiency (92% at Full Load, 230VAC in )

•

Meets IEC61000-4-5, Level 4 (2kV/4kV)

•

450W capability at 42

and 1m/s airflow with derating at •

higher temperatures or lower airflows

•

Capable of 320W output in sealed enclosure applications,

with enclosure ambient at 55

•

Capable of 225W at 75Vin Trapezoidal inside sealed

enclosure with enclosure outside ambient at 55

See footnotes on page 4

Page 1

© 2020 ABB. All rights reserved.

•

UL and cUL approved to UL/CSA60950-1, TUV (EN609501), CE Mark (for LVD) and CB Report available

ISO** 9001 and ISO 14001 certified manufacturing facilities

�Technical Specifications

Absolute Maximum Ratings

Stresses over the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings

only. Functional operation of the device is not implied at these or any other conditions over those given in the operations

sections of the data sheet. Exposure to absolute maximum ratings for extended periods can adversely affect the device

reliability.

Parameter

Device

Min

Max

Unit

All

90

265

Vac

All

90

275

Vac

CLP0412-FPXXXZ05A

75

130

VRMS

All

-40

85

°C

Storage Temperature

All

-40

85

°C

Humidity (non-condensing)

All

5

95

%

Altitude

All

5000

m

Isolation Voltage—Input to output

All

3000

Vac

Input to safety ground

All

1500

Vac

Outputs to safety ground

All

50

Vac

Input Voltage - Continuous Operation

For up to 10 seconds operation

Input Voltage-continuous-CATV Powering trapezoidal waveform (Note: Output power is limited to 254W when 75V input,

275W when 90V input, 320W when 130V input

Operating Ambient Temperature

(see Thermal Considerations section)

Electrical Specifications

Parameter

Operating Input Voltage

Device

Min

Typ

Max

Unit

All

90

75

47

115/230

90

50/60

5.57

265

130

63

Vac

VRMS

Hz

ARMS

60

3.5

A Peak

mA

Vdc

CLP0412FPXXXZ05A

Input Source Frequency

Input Current (VIN = 90Vac)

Input Power Factor (230Vac, Full Load)

Inrush Transient Current (VIN = 265Vac, Tamb = 25ºC)

Leakage Current to earth ground (VIN = 265Vac)

Output Voltage Setpoint

Output Voltage Tolerance (due to set point, temperature variations, load

and line regulation)

Output Voltage Adjustment Range (adjust potentiometer see page 9)

Output Remote Sense Range

All

All

All

All

All

All

0.95

12

All

-2

2

%

Z01A

All

45

51

250

Vdc

mVdc

Output Load Regulation

All

1

%Vout

Output Line Regulation

All

0.5

%Vout

Output Ripple and Noise – measured with 0.1µF ceramic capacitor

and 470µF polymer capacitor in parallel.1 Peak-to-peak (20MHz

All

240

mV p-p

Bandwidth)

Dynamic Load Response – 50% to 100% load transient,

1°/µs slew rate

Output voltage deviation

Settling Time

Output Current

Output Current Limit Inception

Maximum Output Capacitance

Standby Output Voltage

Standby Output Current

All

5%

%

All

500

µs

Z01A

0

37.5

Adc

Z03A

0

37.5

Adc

Z05A

0

26.7

Adc

All

All

All

105

140

1000

% IO,max

µF

Vdc

1

Adc

All

-continued on next page-

See footnotes on page 4

Page 2

© 2020 ABB. All rights reserved.

5

�Technical Specifications (continued)

Electrical Specifications con’t.

Parameter

Device

Min

Efficiency: VIN = 230Vac—20% load

50% load

100% load

All

All

All

86.8

91.7

91.9

%

%

%

Efficiency: VIN = 115Vac— 20% load

All

85.8

%

50% load

100% load

Efficiency: VIN = 115Vac— 20% load

All

All

89.9

89.7

76.8

%

%

%

Z05A

88.1

90.2

11

%

%

ms

50% load

100% load

Holdup Time2 — VIN = 115 or 230Vac, 450W load

All

Typ

Max

Unit

General Specifications

Parameter

Device

Symbol

Typ

Unit

Calculated Reliability based on Telcordia SR-332 Issue 3:

Method 1 Case 3 (VIN=230Vac, Io = 30A, TA = 40ºC, airflow

200LFM, 90% confidence)

All

MTBF

2,938,636

Hours

Weight

All

382

13.5

g

oz.

Feature Specifications

Parameter

Device

Min

Typ

Max

Unit

On/Off Signal Interface – signal referenced to zero

Logic Low (Power Supply ON)

Input Low Current

All

7

mA

Input Low Voltage

Logic High (Power Supply OFF)

Input High Current

Input Voltage

Delay from ON/OFF being enabled to start of output voltage rise

All

1

V

All

All

All

600

5.5

50

µA

V

ms

Output Voltage Rise Time (from 10 to 90% of final value)

All

Delay from Input being applied to all outputs being in regulation

All

Output Overvoltage Protection

All

13.8

Z01A

85.0

Z03A

85.0

20

ms

1

S

16

Vdc

87.6

90

Vac

87.6

90

Input Undervoltage lockout3

Turn-on Threshold (100% load)

Z05A

Turn-off Threshold (100% load)

72

Vac

VRMS

Z01A

82.0

83.9

88

Vac

Z03A

82.0

83.9

88

Vac

Z05A

69

VRMS

DC OK – open collector, High when output available

Sink Current

All

4

mA

Maximum Collector Voltage

All

12

V

See footnotes on page 4

Page 3

© 2020 ABB. All rights reserved.

�Technical Specifications (continued)

Safety Specifications

Parameter

Device

Specification

Dielectric Withstand Voltage (between input and output)

All

Minimum of 4,250Vdc for 1 minute

Insulation Resistance (between input and output)

All

Minimum of 5 MΩ

All

Class 1, IEC60950, EN60950, with the following

deviations: Nemko, UL 60950 (Recognized Component), cUL (Canadian Approval by UL)

Safety Standards

Environmental Specifications

Parameter

Device

Specification

Radiated Emissions4

Conducted Emissions

ESD

Radiated Susceptibility5

All

All

All

All

CISPR22 Class B with 3dB margin

CISPR22 Class B with 6dB margin

IEC 61000-4-2, Level 4 Performance Criteria

IEC 61000-4-3, Level 3

Electrical Fast Transient Common Mode

All

IEC 61000-4-4, Level 3

Surge Immunity

Conducted RF Immunity

All

All

Input Voltage Dips

All

Input Harmonics

All

IEC 61000-4-5, Level 4

IEC 61000-4-6, Level 3

Output stays within regulation for either ½ cycle interruption or 25% dip from

nominal line for 1 second

IEC61000-3-2

Shock and Vibration

All

Per IPC-9592B, Class II

FOOTNOTES

*UL is a registered trademark of Underwriters Laboratories, Inc.

†

CSA is a registered trademark of Canadian Standards Association.

‡

VDE is a registered trademark of Verband Deutscher Elektrotechniker e..V.

** ISO is a registered trademark of the International Organization of Standard

1

Output ripple specification is met over 25 to 85ºC

2

Holdup time may be lower at cold temperatures

3

Undervoltage lockout threshold may vary with output load current level – decreasing as load goes lower

4

Meets when tested in a suitable enclosure

5

Meets when tested in a suitable enclosure

Page 4

© 2020 ABB. All rights reserved.

�Technical Specifications (continued)

Characteristic Curves (CLP0412)

EFFICIENCY, (%)

OUTPUT CURRENT, Io (A)

The following figures provide typical characteristics for the CLP0412 power supply.

AMBIENT TEMPERATURE, Ta 0C

OUTPUT LOAD, A

Figure 2: Power . Data shown for model CLP0412FPXXXZ03A,

115VAC in. At 230VAC in derating is the same or better. Standby

output is loaded at 0.25A. For derating at other input voltages and

other models, consult the GE Technical representative.

OUTPUT VOLTAGE

VO (V) (100mV/div)

IO (A) (18.8Adiv)

TIME, t (5µs/div)

OUTPUT CURRENT

OUTPUT VOLTAGE

VO (V) (50mV/div)

Figure 1: Power Supply Efficiency Versus Out Current

Figure 4. Transient Response to Dynamic Load Change from 50%

to 100% at VIN = 115Vac

Page 5

© 2020 ABB. All rights reserved.

OUTPUT VOLTAGE

Vo (V) (2v/div)

VIN (V) (200V/div)

Vo (V) (2v/div)

VIN (V) (100V/div)

TIME, t (200µs/div)

INPUT VLTAGE (Red)

OUTPUT VOLTAGE

INPUT VOLTAGE (Red)

Figure 3. Typical output ripple and noise (VIN = 115Vac, 100% load )

Figure 5. Typical Start-up (VIN = 90Vac, Full Load)

TIME, t (200µs/div)

TIME, t (200µs/div)

Figure 6. Typical Start-up (VIN = 230Vac, Full Load)

�Technical Specifications (continued)

Characteristic Curves con’t. (CLP0412)

Page 6

© 2020 ABB. All rights reserved.

OUTPUT VOLTAGE

Vo (V) (2v/div)

VIN (V) (100V/div)

Vo (V) (2v/div)

VIN (V) (100V/div)

TIME, t (10µs/div)

Figure 7. Typical Hold-up (VIN = 115V, 100% Load)

INPUT VOLTAGE (Green)

OUTPUT VOLTAGE

INPUT VOLTAGE (Green)

The following figures provide typical characteristics for the CLP0412 power supply.

TIME, t (10µs/div)

Figure 8. Typical Hold-up (VIN = 230V, 100% Load)

�Technical Specifications (continued)

Safety Considerations

overvoltage condition is removed. It is necessary to recycle

The CLP0412 embedded power supply is intended for inclusion in

is activated.

end product equipment and shall be installed in compliance with

the input to restart the power supply when this protection

the enclosure, mounting, spacing, casualty and segregation

Overtemperature Protection

requirements of the end-use application. A suitable Electrical

For additional protection in a fault condition the CLP0412 is

and Fire enclosure shall be provided and is not intended to be

operated as a stand-alone product. It is cURus, TUV approved

using the applicable requirements in the Safety of Information

Technology Equipment – Safety – Part 1: General Requirements,

ANSI/UL60950-1-2014 and CAN/CSA C22.2 No. 60950-1-07,

Second Edition + A2:2014 (MOD), dated October 14, 2014 and

EN60950-1:2006+A2:2013. A CB report to the requirement of

IEC60950-1 2nd Ed. + Am1 + Am2 with global national deviations

has been issued.

Feature Descriptions

Standby Power Supply

A standby output of 5V in the CLP0412 power supply, comes on

when AC input in the operating range is applied.

Remote On/Off

The CLP0412 power supply features a TTL-compatible On/Off

control input. The power supply turns ON when the On/Off

input goes low, and turns OFF when the input goes high. Note

that if the On/Off pin is left unconnected, the power supply

equipped with a thermal shutdown circuit which detects excessive

internal temperatures and shuts the unit down. Once the power

supply goes into overtemperature shutdown, it will cool before

attempting to restart. The overtemperature protection circuit will

typically kick in when the unit is operated at 450W output with

an ambient temperature of 53ºC and 1m/s (200LFM) airflow.

In a sealed enclosure OTP will depend on enclosure design

and cooling.

Input Undervoltage Lockout

At input voltages below the input under-voltage lockout limit,

power supply operation is disabled. The power supply will begin

to operate at an input voltage above the under-voltage lockout

turn-on threshold.

DC OK

The CLP0412 provides a DC OK signal that indicates when

the output has come up and is in regulation. This is an

open-collector type signal that goes high when the output is

available and within regulation.

main output will turn ON when AC input is present.

Power Good LED

Output Voltage Adjustment

A green LED on board the power supply illuminates when the

For all units, the output voltage can be adjusted between 11.4V

and 12.6V using a potentiometer on the power

supply.

Remote Sense

For all versions, the power supply has both positive and negative

remote sense connections that can be connected to the positive

and negative rails of the main output near the load. The power

supply operates even without the remote sense connections

main output voltage is above 10V.

Paralleling with Active Output Current Sharing

The CLP0412 is capable of being employed in a paralleling scheme,

following are some design attributes that need to be carefully

considered prior to attempting a parallel operation with multiple

CLP0412’s. With the following design criteria the CLP0412 will load

share at an accuracy of +/-5%, when the total current draw is at

levels above 20% of max overall loading.

being made.

Current share signals of each power supply to be connected.

Overcurrent Protection

An external Oring function needs to be employed at the Vout(+)

To provide protection in a fault condition (output overload), the

power supply is equipped with internal current-limiting circuitry

signal. An oring diode or a Mosfet & controller scheme can

be used.

and can endure current limiting continuously. At the point of

The 5V Standby Return SHOULD NEVER be connected with the

current-limit inception, the unit enters hiccup mode. The power

VOUT-(RETURN ). 5V stby returns will need to be connected

supply operates normally once the output current is brought back

together, the 5V stby Vout(+) leg remain separate. The 5V stby

into its specified range.

output is not designed to be paralleled, if there is a desire for

Overvoltage Protection

Overvoltage protection is a feature of the CLP0412 power

supply that protects both the load and the power supply from

an output overvoltage condition. When an overvoltage occurs,

the power supply shuts down and latches off until the

Page 7

© 2020 ABB. All rights reserved.

these to be paralleled for load sharing, then other considerations need to be included as well. Contact your local GE sales

rep for FAE involvement.

In the parallel scheme the remote sense function needs to be

unused and remote sense signals left floating.

�Technical Specifications (continued)

Thermal Considerations

The power supply can be operated in a variety of thermal

environments; however sufficient cooling should be provided to

ensure reliable operation.

Considerations include ambient temperature, airflow, power

supply dissipation and the need for increased reliability.

A reduction in the operating temperature of the power supply will

result in increased reliability. The thermal data presented here is

Vin(T)

Max. Output

Current (A)

Max. Output

Power (W)

Max. Enclosure

Outside Ambient

(‘C)

75

21.2

225

55

90

22.9

275

55

130

26.7

320

55

Table 2. Output Power Capability for Trapezoidal Input when the

CLP0412FPXXXZ05A is cooled primarily via conduction.

based on measurements taken during testing in a wind tunnel or

temperature chamber.

Heat Transfer via Convection

Increased airflow through the power supply enhances the heat

transfer via convection. Figure below shows the preferred airflow

direction. Contact your ABB technical representative for derating

information in other airflow directions.

Enclosure Wall

Fig.9. Preferred airflow direction for cooling.

Operation in a Sealed Enclosure (201A and 205A)

The CLP0412 power supply can also be operated in a sealed

enclosure or in an environment where cooling is primarily via

conduction. Figure 11 shows an arrangement where thermally

Enclosure Wall

conductive pads are used to transfer heat from the top and bottom

of the power supply into the enclosure. Under such conditions, the

power supply is capable of reduced power operation as shown

in Table 1.

Thermally Conductive Pad

Fig. 11. Example arrangement of the CLP0412 for sealed enclosure

applications.

Difference Between Z01A and Z03A Product Codes

Outside Ambient

Temperature (ºC)

Max. Output Power (W)

25

420

55

320

Table 1. Output Power Capability when the CLP0412FPXXXZ01A is

cooled primarily via conduction.

The only difference between Z01A (Enclosure Version) and the

Z03A (Airflow Version) is the over temperature protection (OTP)

setpoints. For the Z01A enclosure version, the OTP setpoints were

lowered to protect the unit from excessive temperatures in the

enclosure environment. For the Z03A airflow version the OTP

trip points were increased to a higher temperature, while still

maintaining safe component temperatures. OTP setpoints were

increased on the airflow version in order to obtain better derating

performance in airflow applications.

Page 8

© 2020 ABB. All rights reserved.

�Technical Specifications (continued)

Mechanical Outline (CLP0412)

Page 9

© 2020 ABB. All rights reserved.

�Technical Specifications (continued)

Connector Information

Connector

Connector on Power Supply

Mating Connector

AC Input Connector (HDR200)

Molex 41671-3473 or equivalent

Molex 09-50-8031 or equivalent

Molex 172298-1208 or equivalent

Molex 172258-1008 or equivalent

FCI 98414-G04-10ULF or equivalent

FCI 90311-010LF or equivalent

DC Output Connector (HDR600)

Auxiliary Connector (HDR800)

Pinout Information

AC Input Connector

Pin 1

Pin 2

Pin 3

DC Output Connector

Line

NC (removed)

Neutral

Pin 1, 2, 3, 4

Pin 5, 6, 7, 8

Auxiliary Connector

VOUT +

VOUT - (return)

Pin A1 - SV Standby

Pin A2 - SV Standby

Pin A3 - NC

Pin B1 - PARALLEL

Pin B2 - SV Standby Return

Pin B3 - SV Standby Return

Pin A4 - REMOTE SENSE +

Pin B4 - DC_OK

Pin A5 - REMOTE SENSE -

Pin B5 - ON/OFF

Ordering Information

Device

Code

Input

Voltage

Range

Output

Voltage

Output

Current

On/Off

Control

Standby

Supply

Temperature

Range

CLP0412FPXX

XZ01A

90-265Vac

12.OVdc

37.5A

Negative

Logic

5V@A

-40 to 85ºC

CLP0412FPXX

XZ03A

90-265Vac

CLP0412FPXX

XZ03A

75 –

130VRMS

Trapezoidal

Waveform

Intended

Application

Enclosed with

conduction

© 2020 ABB. All rights reserved.

CLP0412FPXXXZ01A

cooling*

12.0Vdc

37.5A

Negative

Logic

5V@A

-40 to 85ºC

12.0Vdc

26.7A

Negative

Logic

5V@A

-40 to 85ºC

Open with

external airflow

CLP0412FPXXXZ03A

Enclosed with

*Enclosure not provided with power supply. To be designed by user. Different OTP setting than open frame version.

Page 10

Comcodes

conduction

cooling*

CLP0412FPXXXZ05A

�ABB

601 Shiloh Rd.

Plano, TX USA

Go.ABB/Industrial

We reserve the right to make technical changes or modify the

We reserve all rights in this document and in the subject matter and

contents of this document without prior notice. With regard

illustrations contained therein. Any reproduction, disclosure to third

to purchase orders, the agreed particulars shall prevail.

parties or utilization of its contents – in whole or in parts – is

ABB does not accept any responsibility whatsoever

forbidden without prior written consent of ABB.

for potential errors or possible lack of information in this

document.

Copyright© 2020 ABB

All rights reserved

Page 11

© 2020 ABB. All rights reserved.

�