25AA040A/25LC040A

4-Kbit SPI Bus Serial EEPROM

Device Selection Table

Part Number

VCC Range

Page Size

Temp. Ranges

Packages

25AA040A

1.8V-5.5V

16 bytes

I

MC, MS, P, OT, SN, MN, ST

25LC040A

2.5V-5.5V

16 bytes

I, E

MC, MS, P, OT, SN, MN, ST

Features

Description

• 10 MHz Maximum Clock Speed

• Low-Power CMOS Technology:

- Maximum Write current: 5 mA at 5.5V

- Read current: 5 mA at 5.5V, 10 MHz

- Standby current: 5 µA at 5.5V

• 512 x 8-bit Organization

• 16-Byte Page

• Sequential Read

• Self-Timed Erase and Write Cycles

(5 ms maximum)

• Block Write Protection:

- Protect none, 1/4, 1/2 or all of array

• Built-In Write Protection:

- Power-on/off data protection circuitry

- Write enable latch

- Write-protect pin

• High Reliability:

- Endurance: 1M erase/write cycles

- Data retention: > 200 years

- ESD protection: > 4000V

• Temperature Ranges Supported:

- Industrial (I):

-40C to +85C

- Extended (E):

-40C to +125C

• RoHS Compliant

• Automotive AEC-Q100 Qualified

The Microchip Technology Inc. 25XX040A(1) is a 4-Kbit

Serial Electrically Erasable PROM (EEPROM). The

memory is accessed via a simple Serial Peripheral

Interface (SPI) compatible serial bus. The bus signals

required are a clock input (SCK) plus separate data in

(SI) and data out (SO) lines. Access to the device is

controlled through a Chip Select (CS) input.

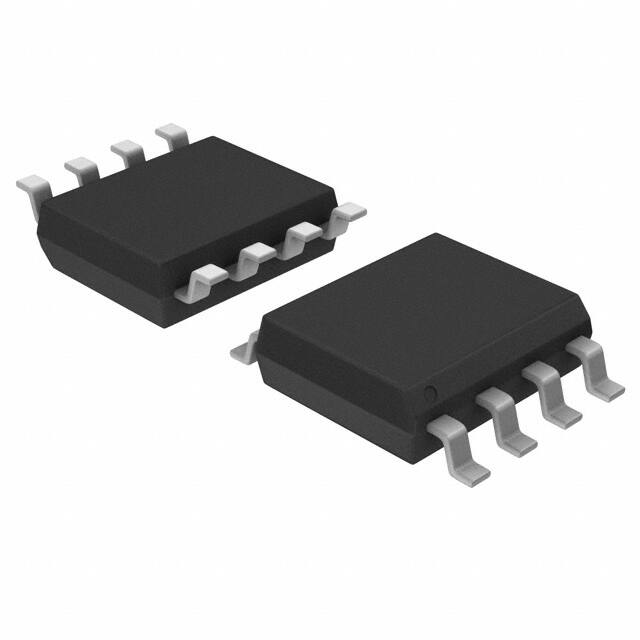

Packages

• 8-Lead DFN, 8-Lead MSOP, 8-Lead PDIP,

8-Lead SOIC, 6-Lead SOT23, 8-Lead TDFN and

8-Lead TSSOP

Pin Function Table

Name

Function

CS

Chip Select Input

SO

Serial Data Output

WP

Write-Protect Pin

VSS

Ground

SI

Serial Data Input

SCK

Serial Clock Input

HOLD

Hold Input

VCC

Supply Voltage

2003-2022 Microchip Technology Inc. and its subsidiaries

Communication to the device can be paused via the

hold pin (HOLD). While the device is paused, transitions on its inputs will be ignored, with the exception of

Chip Select, allowing the host to service higher priority

interrupts.

Note 1: 25XX040A is used in this document as a

generic part number for the 25AA040A

and 25LC040A devices.

Package Types (not to scale)

DFN/TDFN

(Top View)

CS

SO

WP

VSS

1

2

3

4

8

7

6

5

VCC

HOLD

SCK

SI

CS

SO

WP

VSS

MSOP/TSSOP

(Top View)

1

8

2

7

3

6

4

5

PDIP/SOIC

(Top View)

CS

SO

WP

VSS

1

2

3

4

8

7

6

5

VCC

HOLD

SCK

SI

VCC

HOLD

SCK

SI

SOT-23

(Top View)

SCK

1

6

VDD

VSS

SI

2

3

5

4

CS

SO

X-Rotated TSSOP

(Top View)

8 SCK

HOLD 1

VCC 2

7 SI

6 VSS

CS 3

5 WP

SO 4

DS20001827J-page 1

�25AA040A/25LC040A

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings(†)

VCC .............................................................................................................................................................................6.5V

All inputs and outputs w.r.t. VSS ......................................................................................................... -0.6V to VCC +1.0V

Storage temperature ...............................................................................................................................-65°C to +150°C

Ambient temperature under bias .............................................................................................................-40°C to +125°C

ESD protection on all pins ..........................................................................................................................................4 kV

† NOTICE: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only and functional operation of the device at those or any other conditions above those

indicated in the operational listings of this specification is not implied. Exposure to maximum rating conditions for an

extended period of time may affect device reliability.

TABLE 1-1:

DC CHARACTERISTICS

Electrical Characteristics:

Industrial (I): TA = -40°C to +85°C

Extended (E): TA = -40°C to +125°C

DC CHARACTERISTICS

Param.

Symbol

No.

Characteristic

Min.

Max.

Units

High-Level Input Voltage

0.7 VCC

VCC +1

V

-0.3

0.3 VCC

V

VCC2.7V (Note 1)

-0.3

0.2 VCC

V

VCC < 2.7V (Note 1)

D001

VIH1

D002

VIL1

D003

VIL2

D004

VOL

D005

VOL

D006

VOH

High-Level Output Voltage

D007

ILI

D008

D009

D010

Low-Level Input Voltage

D012

Note 1:

Test Conditions

—

0.4

V

IOL = 2.1 mA

—

0.2

V

IOL = 1.0 mA, VCC = 2.5V

VCC -0.5

—

V

IOH = -400 µA

Input Leakage Current

—

±1

µA

CS = VCC, VIN = VSS or VCC

ILO

Output Leakage Current

—

±1

µA

CS = VCC, VOUT = VSS or VCC

CINT

Internal Capacitance

(all inputs and outputs)

—

7

pF

TA = +25°C, CLK = 1.0 MHz,

VCC = 5.0V (Note 1)

—

5

mA

VCC = 5.5V; FCLK = 10.0 MHz;

SO = Open

—

2.5

mA

VCC = 2.5V; FCLK = 5.0 MHz;

SO = Open

—

5

mA

VCC = 5.5V

—

3

mA

VCC = 2.5V

—

5

µA

CS = VCC = 5.5V, Inputs tied to

VCC or VSS, TA = +125°C

—

1

µA

CS = VCC = 2.5V, Inputs tied to

VCC or VSS, TA = +85°C

Low-Level Output Voltage

ICC Read

Operating Current

D011

VCC = 1.8V to 5.5V

VCC = 2.5V to 5.5V

ICC Write

ICCS

Standby Current

This parameter is periodically sampled and not 100% tested.

DS20001827J-page 2

2003-2022 Microchip Technology Inc. and its subsidiaries

�25AA040A/25LC040A

TABLE 1-2:

AC CHARACTERISTICS

Electrical Characteristics:

Industrial (I): TA = -40°C to +85°C

VCC = 1.8V to 5.5V

Extended (E): TA = -40°C to +125°C VCC = 2.5V to 5.5V

AC CHARACTERISTICS

Param.

Symbol

No.

1

FCLK

2

TCSS

3

TCSH

4

TCSD

5

Tsu

Characteristic

Clock Frequency

CS Setup Time

CS Hold Time

CS Disable Time

Data Setup Time

6

THD

Data Hold Time

7

TR

CLK Rise Time

8

TF

CLK Fall Time

9

THI

Clock High Time

Min.

Max.

Units

Test Conditions

—

10

MHz

4.5V VCC 5.5V

—

5

MHz

2.5V VCC 4.5V

—

3

MHz

1.8V VCC 2.5V

50

—

ns

4.5V VCC 5.5V

100

—

ns

2.5V VCC 4.5V

150

—

ns

1.8V VCC 2.5V

100

—

ns

4.5V VCC 5.5V

200

—

ns

2.5V VCC 4.5V

250

—

ns

1.8V VCC 2.5V

50

—

ns

10

—

ns

4.5V VCC 5.5V

20

—

ns

2.5V VCC 4.5V

30

—

ns

1.8V VCC 2.5V

20

—

ns

4.5V VCC 5.5V

40

—

ns

2.5V VCC 4.5V

50

—

ns

1.8V VCC 2.5V

—

100

ns

Note 1

—

100

ns

Note 1

50

—

ns

4.5V VCC 5.5V

100

—

ns

2.5V VCC 4.5V

150

—

ns

1.8V VCC 2.5V

50

—

ns

4.5V VCC 5.5V

100

—

ns

2.5V VCC 4.5V

—

ns

1.8V VCC 2.5V

—

ns

10

TLO

Clock Low Time

150

11

TCLD

Clock Delay Time

50

12

TCLE

Clock Enable Time

50

—

ns

—

50

ns

4.5V VCC 5.5V

—

100

ns

2.5V VCC 4.5V

—

160

ns

1.8V VCC 2.5V

13

TV

14

THO

15

TDIS

Note 1:

2:

3:

Output Valid from Clock Low

Output Hold Time

Output Disable Time

0

—

ns

Note 1

—

40

ns

4.5V VCC 5.5V (Note 1)

—

80

ns

2.5V VCC 4.5V (Note 1)

—

160

ns

1.8V VCC 2.5V (Note 1)

This parameter is periodically sampled and not 100% tested.

TWC begins on the rising edge of CS after a valid write sequence and ends when the internal write cycle is

complete.

This parameter is not tested but ensured by characterization.

2003-2022 Microchip Technology Inc. and its subsidiaries

DS20001827J-page 3

�25AA040A/25LC040A

TABLE 1-2:

AC CHARACTERISTICS (CONTINUED)

Electrical Characteristics:

Industrial (I): TA = -40°C to +85°C

VCC = 1.8V to 5.5V

Extended (E): TA = -40°C to +125°C VCC = 2.5V to 5.5V

AC CHARACTERISTICS

Param.

Symbol

No.

16

THS

17

HOLD Hold Time

HOLD Low to Output High-Z

THZ

19

20

Min.

HOLD Setup Time

THH

18

Characteristic

Max.

Units

Test Conditions

20

—

ns

4.5V VCC 5.5V

40

—

ns

2.5V VCC 4.5V

80

—

ns

1.8V VCC 2.5V

20

—

ns

4.5V VCC 5.5V

40

—

ns

2.5V VCC 4.5V

80

—

ns

1.8V VCC 2.5V

—

30

ns

4.5V VCC 5.5V (Note 1)

—

60

ns

2.5V VCC 4.5V (Note 1)

—

160

ns

1.8V VCC 2.5V (Note 1)

—

30

ns

4.5V VCC 5.5V

—

60

ns

2.5V VCC 4.5V

THV

HOLD High to Output Valid

—

160

ns

1.8V VCC 2.5V

TWC

Internal Write Cycle Time

(byte or page)

—

5

ms

Note 2

Endurance

1M

—

21

Note 1:

2:

3:

E/W +25°C, VCC = 5.5V, Page Mode

Cycles (Note 3)

This parameter is periodically sampled and not 100% tested.

TWC begins on the rising edge of CS after a valid write sequence and ends when the internal write cycle is

complete.

This parameter is not tested but ensured by characterization.

TABLE 1-3:

AC TEST CONDITIONS

AC Waveform

VLO = 0.2V

—

VH I = VCC - 0.2V

Note 1

VHI = 4.0V

Note 2

CL = 100 pF

—

Timing Measurement Reference Level

Input

0.5 VCC

Output

Note 1:

2:

0.5 VCC

For VCC 4.0V

For VCC 4.0V

DS20001827J-page 4

2003-2022 Microchip Technology Inc. and its subsidiaries

�25AA040A/25LC040A

FIGURE 1-1:

HOLD TIMING

CS

17

16

17

16

SCK

18

SO

n+2

SI

n+2

n+1

n

19

High-Impedance

n

5

Don’t Care

n+1

n-1

n

n

n-1

HOLD

FIGURE 1-2:

SERIAL INPUT TIMING

4

CS

2

7

Mode 1,1

3

8

12

11

SCK Mode 0,0

5

SI

6

MSb in

LSb in

High-Impedance

SO

FIGURE 1-3:

SERIAL OUTPUT TIMING

CS

9

3

10

Mode 1,1

SCK

Mode 0,0

13

SO

SI

14

MSb out

15

LSb out

Don’t Care

2003-2022 Microchip Technology Inc. and its subsidiaries

DS20001827J-page 5

�25AA040A/25LC040A

2.0

PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 2-1.

TABLE 2-1:

PIN FUNCTION TABLE

Name

DFN(1)

MSOP

PDIP

SOIC

SOT-23

TDFN(1)

TSSOP

Rotated

TSSOP

CS

1

1

1

1

5

1

1

3

Chip Select Input

Function

SO

2

2

2

2

4

2

2

4

Serial Data Output

WP

3

3

3

3

—

3

3

5

Write-Protect Pin

Vss

4

4

4

4

2

4

4

6

Ground

SI

5

5

5

5

3

5

5

7

Serial Data Input

SCK

6

6

6

6

1

6

6

8

Serial Clock Input

HOLD

7

7

7

7

—

7

7

1

Hold Input

8

8

8

8

6

8

8

2

Supply Voltage

Vcc

Note 1:

2.1

The exposed pad on the DFN/TDFN packages can be connected to VSS or left floating.

Chip Select (CS)

A low level on this pin selects the device. A high level

deselects the device and forces it into Standby mode.

However, a programming cycle which is already

initiated or in progress will be completed, regardless of

the CS input signal. If CS is brought high during a

program cycle, the device will go into Standby mode as

soon as the programming cycle is complete. When the

device is deselected, SO goes to the high-impedance

state, allowing multiple parts to share the same SPI

bus.

A low-to-high transition on CS after a valid write

sequence initiates an internal write cycle. After

power-up, a low level on CS is required prior to any

sequence being initiated.

2.2

Serial Output (SO)

The SO pin is used to transfer data out of the

25XX040A. During a read cycle, data are shifted out on

this pin after the falling edge of the serial clock.

2.3

Write-Protect (WP)

The WP pin is a hardware write-protect input pin.

When it is low, all writes to the array or STATUS

registers are disabled, but any other operations

function normally. When WP is high, all functions,

including nonvolatile writes, operate normally. At any

time, when WP is low, the write enable latch will be

reset and programming will be inhibited. However, if a

write cycle is already in progress, WP going low will not

change or disable the write cycle. See Table 3-4 for the

Write-Protect Functionality Matrix.

DS20001827J-page 6

2.4

Serial Input (SI)

The SI pin is used to transfer data into the device. It

receives instructions, addresses and data. Data are

latched on the rising edge of the serial clock.

2.5

Serial Clock (SCK)

The SCK is used to synchronize the communication

between a host and the 25XX040A. Instructions,

addresses or data present on the SI pin are latched on

the rising edge of the clock input, while data on the SO

pin are updated after the falling edge of the clock input.

2.6

Hold (HOLD)

The HOLD pin is used to suspend transmission to the

25XX040A while in the middle of a serial sequence

without having to retransmit the entire sequence again.

It must be held high any time this function is not being

used. Once the device is selected and a serial

sequence is underway, the HOLD pin may be pulled

low to pause further serial communication without

resetting the serial sequence.

The HOLD pin must be brought low while SCK is low,

otherwise the HOLD function will not be invoked until

the next SCK high-to-low transition. The 25XX040A

must remain selected during this sequence. The SI and

SCK levels are “don’t cares” during the time the device

is paused and transitions on these pins will be ignored.

To resume serial communication, HOLD must be

brought high while the SCK pin is low, otherwise serial

communication will not be resumed until the next SCK

high-to-low transition.

The SO line will tri-state immediately upon a

high-to-low transition of the HOLD pin and will begin

outputting again immediately upon a subsequent

low-to-high transition of the HOLD pin, independent of

the state of SCK.

2003-2022 Microchip Technology Inc. and its subsidiaries

�25AA040A/25LC040A

3.0

FUNCTIONAL DESCRIPTION

3.1

Principles of Operation

BLOCK DIAGRAM

STATUS

Register

The 25XX040A is a 512-byte Serial EEPROM

designed to interface directly with the Serial Peripheral

Interface (SPI) port of many of today’s popular

microcontroller families, including Microchip’s PIC®

microcontrollers. It may also interface with

microcontrollers that do not have a built-in SPI port by

using discrete I/O lines programmed properly in

firmware to match the SPI protocol.

The 25XX040A contains an 8-bit instruction register.

The device is accessed via the SI pin, with data being

clocked in on the rising edge of SCK. The CS pin must

be low and the HOLD pin must be high for the entire

operation.

Table 3-1 contains a list of the possible instruction

bytes and format for device operation. All instructions,

addresses and data are transferred Most Significant bit

(MSb) first, Least Significant bit (LSb) last.

I/O Control

Logic

Dec

SI

SO

Y Decoder

CS

SCK

Sense Amp.

R/W Control

HOLD

WP

VCC

VSS

Instruction Format

011(1)

Description

Read data from memory array beginning at selected address

WRITE

0000 A8

0000 A8010(1)

WRDI

0000

x100(2)

WREN

0000 x110(2)

Set the write enable latch (enable write operations)

RDSR

0000 x101(2)

Read STATUS register

WRSR

x001(2)

Write STATUS register

Note 1:

2:

EEPROM

Array

X

INSTRUCTION SET

Instruction Name

READ

Memory

Control

Logic

Page Latches

Data (SI) are sampled on the first rising edge of SCK

after CS goes low. If the clock line is shared with other

peripheral devices on the SPI bus, the user can assert

the HOLD input and place the 25XX040A in ‘HOLD’

mode. After releasing the HOLD pin, operation will

resume from the point when the HOLD was asserted.

TABLE 3-1:

HV Generator

0000

Write data to memory array beginning at selected address

Reset the write enable latch (disable write operations)

A8 is the 9th address bit, which is used to address the entire 512-byte array.

x = don’t care

2003-2022 Microchip Technology Inc. and its subsidiaries

DS20001827J-page 7

�25AA040A/25LC040A

3.2

Read Sequence

The device is selected by pulling CS low. The 8-bit

READ instruction is transmitted to the 25XX040A

followed by a 9-bit address. The MSb (A8) is sent to the

client during the instruction sequence. See Figure 3-1

for more details.

After the correct READ instruction and address are sent,

the data stored in the memory at the selected address

are shifted out on the SO pin. Data stored in the memory at the next address can be read sequentially by

continuing to provide clock pulses to the client.

The internal Address Pointer is automatically

incremented to the next higher address after each byte

of data is shifted out. When the highest address is

reached (1FFh), the address counter rolls over to

address 000h, allowing the read cycle to be continued

indefinitely. The read operation is terminated by raising

the CS pin (Figure 3-1).

FIGURE 3-1:

READ SEQUENCE

CS

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

SCK

Instruction+Address MSb

SI

0

0

0

0

A8 0

1

Lower Address Byte

1 A7 A6 A5 A4 A3 A2 A1 A0

Data Out

High-Impedance

SO

DS20001827J-page 8

7

6

5

4

3

2

1

0

2003-2022 Microchip Technology Inc. and its subsidiaries

�25AA040A/25LC040A

3.3

Write Sequence

Note:

Prior to any attempt to write data to the 25XX040A, the

write enable latch must be set by issuing the WREN

instruction (Figure 3-4). This is done by setting CS low

and then clocking out the proper instruction into the

25XX040A. After all eight bits of the instruction are

transmitted, CS must be driven high to set the write

enable latch.

If the write operation is initiated immediately after the

WREN instruction without CS driven high, data will not

be written to the array since the write enable latch was

not properly set.

After setting the write enable latch, the user may

proceed by driving CS low, issuing a WRITE instruction,

followed by the remainder of the address and then the

data to be written. Keep in mind that the Most

Significant address bit (A8) is included in the instruction

byte for the 25XX040A. Up to 16 bytes of data can be

sent to the device before a write cycle is necessary.

The only restriction is that all of the bytes must reside

in the same page. Additionally, a page address begins

with XXXX 0000 and ends with XXXX 1111. If the

internal address counter reaches XXXX 1111 and

clock signals continue to be applied to the chip, the

address counter will roll back to the first address of the

page and overwrite any data that previously existed in

those locations.

FIGURE 3-2:

Page write operations are limited to

writing bytes within a single physical page,

regardless of the number of bytes

actually being written. Physical page

boundaries start at addresses that are

integer multiples of the page buffer size

(or ‘page size’) and end at addresses that

are integer multiples of page size – 1. If a

Page Write command attempts to write

across a physical page boundary, the

result is that the data wrap around to the

beginning of the current page (overwriting

data previously stored there), instead of

being written to the next page as might be

expected. It is therefore necessary for the

application software to prevent page write

operations that would attempt to cross a

page boundary.

For the data to be actually written to the array, the CS

must be brought high after the Least Significant bit (D0)

of the nth data byte has been clocked in. If CS is driven

high at any other time, the write operation will not be

completed. Refer to Figure 3-2 and Figure 3-3 for more

detailed illustrations on the byte write sequence and

the page write sequence, respectively. While the write

is in progress, the STATUS register may be read to

check the status of the WPEN, WIP, WEL, BP1 and

BP0 bits (Figure 3-6). Attempting to read a memory

array location will not be possible during a write cycle.

Polling the WIP bit in the STATUS register is recommended in order to determine if a write cycle is in progress. When the write cycle is completed, the write

enable latch is reset.

BYTE WRITE SEQUENCE

CS

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Twc(1)

SCK

Lower Address Byte

Instruction+Address MSb

SI

0

0

0

0

A8 0 1

0 A7 A6 A5 A4 A3 A2 A1 A0 7

SO

Data Byte

6

5

4

3

2

1

0

High-Impedance

Note 1: This sequence initiates a self-timed internal write cycle on the rising edge of CS after a valid sequence.

2003-2022 Microchip Technology Inc. and its subsidiaries

DS20001827J-page 9

�25AA040A/25LC040A

FIGURE 3-3:

PAGE WRITE SEQUENCE

CS

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

SCK

Lower Address Byte

Instruction+Address MSb

SI

0

0

0

0

Data Byte 1

0 A7 A6 A5 A4 A3 A2 A1 A0 7

A8 0 1

6

5

4

3

2

1

0

CS

(1)

TWC

24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

SCK

Data Byte 2

SI

7

6

5

4

3

2

Data Byte 3

1

0

7

6

5

4

3

2

Data Byte n (16 max)

1

0

7

6

5

4

3

2

1

0

Note 1: This sequence initiates a self-timed internal write cycle on the rising edge of CS after a valid sequence.

DS20001827J-page 10

2003-2022 Microchip Technology Inc. and its subsidiaries

�25AA040A/25LC040A

3.4

Write Enable (WREN) and Write

Disable (WRDI)

The following is a list of conditions under which the

write enable latch will be reset:

•

•

•

•

•

The 25XX040A contains a write enable latch. See

Table 3-4 for the Write-Protect Functionality Matrix.

This latch must be set before any write operation will be

completed internally. The WREN instruction will set the

latch and the WRDI will reset the latch.

FIGURE 3-4:

Power-up

WRDI instruction successfully executed

WRSR instruction successfully executed

WRITE instruction successfully executed

WP pin is brought low

WRITE ENABLE SEQUENCE (WREN)

CS

0

1

2

3

4

5

6

7

SCK

0

SI

0

0

0

1

1

0

High-Impedance

SO

FIGURE 3-5:

0

WRITE DISABLE SEQUENCE (WRDI)

CS

0

1

2

3

4

5

6

7

SCK

SI

0

0

0

0

0

1

10

0

High-Impedance

SO

2003-2022 Microchip Technology Inc. and its subsidiaries

DS20001827J-page 11

�25AA040A/25LC040A

3.5

Read Status Register Instruction

(RDSR)

The Write Enable Latch (WEL) bit indicates the status

of the write enable latch and is read-only. When set to

a ‘1’, the latch allows writes to the array, when set to

a ‘0’, the latch prohibits writes to the array. The state of

this bit can always be updated via the WREN or WRDI

commands regardless of the state of write protection

on the STATUS register. These commands are shown

in Figure 3-4 and Figure 3-5.

The Read Status Register instruction (RDSR) provides

access to the STATUS register. See Figure 3-6 for the

RDSR timing sequence. The STATUS register may be

read at any time, even during a write cycle. The

STATUS register is formatted as follows:

TABLE 3-2:

The Block Protection (BP0 and BP1) bits indicate

which blocks are currently write-protected. These bits

are set by the user issuing the WRSR instruction (see

Figure 3-7). These bits are nonvolatile and are

described in more detail in Table 3-3.

STATUS REGISTER

7

6

5

4

3

2

1

0

–

–

–

–

W/R

W/R

R

R

X

X

X

BP1

BP0

WEL

WIP

X

Note 1:

See Figure 3-6 for the RDSR timing sequence.

W/R = writable/readable. R = read-only.

The Write-In-Process (WIP) bit indicates whether the

25XX040A is busy with a write operation. When set to

a ‘1’, a write is in progress, when set to a ‘0’, no write

is in progress. This bit is read-only.

FIGURE 3-6:

READ STATUS REGISTER TIMING SEQUENCE (RDSR)

CS

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

0

SCK

Instruction

SI

0

0

0

0

0

High-Impedance

SO

DS20001827J-page 12

1

0

1

Data from STATUS Register

7

6

5

4

3

2

2003-2022 Microchip Technology Inc. and its subsidiaries

�25AA040A/25LC040A

3.6

Write Status Register Instruction

(WRSR)

TABLE 3-3:

The Write Status Register instruction (WRSR) allows the

user to write to the nonvolatile bits in the STATUS register as shown in Table 3-2. Four levels of protection for

the array are selectable by writing to the appropriate bits

in the STATUS register. The user has the ability to

write-protect none, one, two or all four of the segments

of the array as shown in Table 3-3. See Figure 3-7 for

the WRSR timing sequence.

TABLE 3-4:

ARRAY PROTECTION

BP1

BP0

Array Addresses

Write-Protected

0

0

none

0

1

upper 1/4

(180h-1FFh)

1

0

upper 1/2

(100h-1FFh)

1

1

all

(000h-1FFh)

WRITE-PROTECT FUNCTIONALITY MATRIX

WP

(pin 3)

WEL

(SR bit 1)

Protected Blocks

Unprotected Blocks

STATUS Register

0 (low)

x

Protected

Protected

Protected

1 (high)

0

Protected

Protected

Protected

1 (high)

1

Protected

Writable

Writable

Note 1:

x = don’t care

FIGURE 3-7:

WRITE STATUS REGISTER TIMING SEQUENCE (WRSR)

CS

(1)

TWC

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

0

SCK

Instruction

SI

0

0

0

0

Data to STATUS register

0

0

0

1

7

6

5

4

3

2

High-Impedance

SO

Note 1: This sequence initiates a self-timed internal write cycle on the rising edge of CS after a valid sequence.

2003-2022 Microchip Technology Inc. and its subsidiaries

DS20001827J-page 13

�25AA040A/25LC040A

4.0

DATA PROTECTION

The following protection has been implemented to

prevent inadvertent writes to the array:

• The write enable latch is reset on power-up

• A write enable instruction must be issued to set

the write enable latch

• After a byte write, page write or STATUS register

write, the write enable latch is reset

• CS must be set high after the proper number of

clock cycles to start an internal write cycle

• Access to the array during an internal write cycle

is ignored and programming is continued

5.0

POWER-ON STATE

The 25XX040A powers on in the following state:

• The device is in low-power Standby mode

(CS = 1)

• The write enable latch is reset

• SO is in high-impedance state

• A high-to-low-level transition on CS is required to

enter active state

DS20001827J-page 14

2003-2022 Microchip Technology Inc. and its subsidiaries

�25AA040A/25LC040A

6.0

PACKAGING INFORMATION

6.1

Package Marking Information

8-Lead 2X3 DFN

XXX

YWW

NN

8-Lead MSOP (150 mil)

XXXXXXT

YWWNNN

8-Lead PDIP (300 mil)

XXXXXXX

T/XXXNNN

YYWW

Example

421

145

13

Example

5L4AI

14513F

Example

25AA040A

I/P e3 13F

2145

8-Lead SOIC

Example

XXXXXXXT

XXXXYYWW

NNN

25AA04AI

SN e3 2145

13F

6-Lead SOT-23

Example

XXNN

3213

8-Lead 2x3 TDFN

Example

XXX

YWW

NN

C24

145

13

8-Lead TSSOP

Example

XXXX

TYWW

NNN

2003-2022 Microchip Technology Inc. and its subsidiaries

5A4A

I145

13F

DS20001827J-page 15

�25AA040A/25LC040A

1st Line Marking Codes

Part

Number

DFN

I-Temp.

E-Temp.

MSOP

SOT-23

I-Temp.

TDFN

E-Temp.

I-Temp.

TSSOP

E-Temp.

Standard

Rotated

25AA040A

421

—

5A4AT

32NN

—

C21

—

5A4A

A4AX

25LC040A

424

425

5L4AT

35NN

36NN

C24

C25

5L4A

L4AX

Legend: XX...X

T

Y

YY

WW

NNN

e3

Part number or part number code

Temperature (I, E)

Year code (last digit of calendar year)

Year code (last 2 digits of calendar year)

Week code (week of January 1 is week ‘01’)

Alphanumeric traceability code (2 characters for small packages)

RoHS-compliant JEDEC® designator for Matte Tin (Sn)

Note:

For very small packages with no room for the RoHS-compliant JEDEC®

designator e3 , the marking will only appear on the outer carton or reel label.

Note:

In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

DS20001827J-page 16

2003-2022 Microchip Technology Inc. and its subsidiaries

�25AA040A/25LC040A

��/HDG�3ODVWLF�'XDO�)ODW��1R�/HDG�3DFNDJH��0&�����[�[��PP�%RG\�>')1@

1RWH�

)RU�WKH�PRVW�FXUUHQW�SDFNDJH�GUDZLQJV��SOHDVH�VHH�WKH�0LFURFKLS�3DFNDJLQJ�6SHFLILFDWLRQ�ORFDWHG�DW

KWWS���ZZZ�PLFURFKLS�FRP�SDFNDJLQJ

'

$

%

1

�'$780�$�

�'$780�%�

(

127(��

�;

���� &

�

�;

���� &

�

723�9,(:

���� &

&

$�

$

6($7,1*

3/$1(

�;

�$��

���� &

6,'(�9,(:

'�

�

127(��

����

& $ %

�

����

& $ %

(�

.

/

1

�;�E

H

%27720�9,(:

����

����

& $ %

&

0LFURFKLS�7HFKQRORJ\�'UDZLQJ��&�������5HY�(�6KHHW���RI��

2003-2022 Microchip Technology Inc. and its subsidiaries

DS20001827J-page 17

�25AA040A/25LC040A

��/HDG�3ODVWLF�'XDO�)ODW��1R�/HDG�3DFNDJH��0&�����[�[��PP�%RG\�>')1@

1RWH�

)RU�WKH�PRVW�FXUUHQW�SDFNDJH�GUDZLQJV��SOHDVH�VHH�WKH�0LFURFKLS�3DFNDJLQJ�6SHFLILFDWLRQ�ORFDWHG�DW

KWWS���ZZZ�PLFURFKLS�FRP�SDFNDJLQJ

127(��

1RWHV�

��

��

��

��

8QLWV

'LPHQVLRQ�/LPLWV

1XPEHU�RI�7HUPLQDOV

1

H

3LWFK

2YHUDOO�+HLJKW

$

6WDQGRII

$�

7HUPLQDO�7KLFNQHVV

$�

2YHUDOO�/HQJWK

'

([SRVHG�3DG�/HQJWK

'�

2YHUDOO�:LGWK

(

([SRVHG�3DG�:LGWK

(�

7HUPLQDO�:LGWK

E

7HUPLQDO�/HQJWK

/

.

7HUPLQDO�WR�([SRVHG�3DG

0,1

����

����

����

����

����

����

����

0,//,0(7(56

120

�

�����%6&

����

����

�����5()

�����%6&

�

�����%6&

�

����

����

�

0$;

����

����

����

����

����

����

�

3LQ���YLVXDO�LQGH[�IHDWXUH�PD\�YDU\��EXW�PXVW�EH�ORFDWHG�ZLWKLQ�WKH�KDWFKHG�DUHD�

3DFNDJH�PD\�KDYH�RQH�RU�PRUH�H[SRVHG�WLH�EDUV�DW�HQGV�

3DFNDJH�LV�VDZ�VLQJXODWHG

'LPHQVLRQLQJ�DQG�WROHUDQFLQJ�SHU�$60(�')1@

1RWH�

)RU�WKH�PRVW�FXUUHQW�SDFNDJH�GUDZLQJV��SOHDVH�VHH�WKH�0LFURFKLS�3DFNDJLQJ�6SHFLILFDWLRQ�ORFDWHG�DW

KWWS���ZZZ�PLFURFKLS�FRP�SDFNDJLQJ

;�

(9

�

9

&