MIC2800

Evaluation Board

User’s Guide

2017 Microchip Technology Inc.

DS50002656A

�Note the following details of the code protection feature on Microchip devices:

•

Microchip products meet the specification contained in their particular Microchip Data Sheet.

•

Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

•

There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

•

Microchip is willing to work with the customer who is concerned about the integrity of their code.

•

Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC® MCUs and dsPIC® DSCs, KEELOQ® code hopping

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

QUALITY MANAGEMENT SYSTEM

CERTIFIED BY DNV

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, AVR Freaks, BeaconThings, BitCloud, CryptoMemory,

CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo, JukeBlox, KEELOQ,

KEELOQ logo, Kleer, LANCheck, LINK MD, maXStylus,

maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip

Designer, QTouch, RightTouch, SAM-BA, SpyNIC, SST, SST

Logo, SuperFlash, tinyAVR, UNI/O, and XMEGA are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMOS,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, chipKIT, chipKIT logo,

CodeGuard, CryptoAuthentication, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, Inter-Chip Connectivity, JitterBlocker,

KleerNet, KleerNet logo, Mindi, MiWi, motorBench, MPASM, MPF,

MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach,

Omniscient Code Generation, PICDEM, PICDEM.net, PICkit,

PICtail, PureSilicon, QMatrix, RightTouch logo, REAL ICE, Ripple

Blocker, SAM-ICE, Serial Quad I/O, SMART-I.S., SQI,

SuperSwitcher, SuperSwitcher II, Total Endurance, TSHARC,

USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and

ZENA are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip Technology

Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2017, Microchip Technology Incorporated, All Rights Reserved.

ISBN: 978-1-5224-2361-4

== ISO/TS 16949 ==

DS50002656A-page 2

2017 Microchip Technology Inc.

�MIC2800

EVALUATION BOARD

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 6

Introduction............................................................................................................ 6

Document Layout .................................................................................................. 6

Conventions Used in this Guide ............................................................................ 7

Warranty Registration............................................................................................ 7

Recommended Reading........................................................................................ 8

The Microchip Web Site ........................................................................................ 8

Product Change Notification Service..................................................................... 8

Customer Support ................................................................................................. 8

Document Revision History ................................................................................... 8

Chapter 1. Product Overview

1.1 Introduction ................................................................................................... 10

1.2 MIC2800 Device Short Overview ................................................................. 10

1.3 MIC2800 Evaluation Board Overview .......................................................... 11

1.4 MIC2800 Evaluation Board Kit Contents ...................................................... 12

Chapter 2. Installation and Operation

2.1 Introduction ................................................................................................... 14

2.2 Getting Started ............................................................................................ 14

2.3 Evaluation Board Description ....................................................................... 15

Appendix A. Schematic and Layouts

A.1 Introduction .................................................................................................. 18

A.2 Board – Schematic ....................................................................................... 19

A.3 Board – Top Silk .......................................................................................... 20

A.4 Board – Top Copper and Silk ....................................................................... 21

A.5 Board – Top Copper .................................................................................... 22

A.6 Board – Bottom Copper ............................................................................... 23

A.7 Board – Bottom Copper and Silk ................................................................. 24

A.8 Board – Bottom Silk ..................................................................................... 25

Appendix B. Bill of Materials (BOM)........................................................................... 26

Worldwide Sales and Service .................................................................................... 28

2017 Microchip Technology Inc.

DS50002656A-page 3

�MIC2800 Evaluation Board User’s Guide

NOTES:

DS50002656A-page 4

2017 Microchip Technology Inc.

�MIC2800

EVALUATION BOARD

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB® IDE online help.

Select the Help menu, and then Topics, to open a list of available online help files.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MIC2800 Evaluation Board. Items discussed in this chapter include:

•

•

•

•

•

•

•

Document Layout

Conventions Used in this Guide

Warranty Registration

Recommended Reading

The Microchip Web Site

Customer Support

Document Revision History

DOCUMENT LAYOUT

This document describes how to use the MIC2800 Evaluation Board as a development

tool to emulate and debug firmware on a target board. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information about the MIC2800

Evaluation Board.

• Chapter 2. “Installation and Operation” – Includes instructions on installing and

starting the Microchip Chip Manager application.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the MIC2800 Evaluation Board.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

MIC2800 Evaluation Board.

2017 Microchip Technology Inc.

DS50002656A-page 5

�MIC2800 Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description

Represents

Examples

Arial font:

MPLAB® IDE User’s Guide

Italic characters

Referenced books

Emphasized text

...is the only compiler...

Initial caps

A window

the Output window

A dialog

the Settings dialog

A menu selection

select Enable Programmer

Quotes

A field name in a window or

dialog

“Save project before build”

Underlined, italic text with

right angle bracket

A menu path

File>Save

Bold characters

A dialog button

Click OK

A tab

Click the Power tab

N‘Rnnnn

A number in verilog format,

4‘b0010, 2‘hF1

where N is the total number of

digits, R is the radix and n is a

digit.

Text in angle brackets < >

A key on the keyboard

Press ,

Sample source code

#define START

Filenames

autoexec.bat

File paths

c:\mcc18\h

Keywords

_asm, _endasm, static

Command-line options

-Opa+, -Opa-

Bit values

0, 1

Courier New font:

Plain Courier New

DS50002656A-page 6

Constants

0xFF, ‘A’

Italic Courier New

A variable argument

file.o, where file can be

any valid filename

Square brackets [ ]

Optional arguments

mcc18 [options] file

[options]

Curly brackets and pipe

character: { | }

Choice of mutually exclusive

arguments; an OR selection

errorlevel {0|1}

Ellipses...

Replaces repeated text

var_name [,

var_name...]

Represents code supplied by

user

void main (void)

{ ...

}

2017 Microchip Technology Inc.

�Preface

RECOMMENDED READING

This user’s guide describes how to use the MIC2800 Evaluation Board. Another

useful document is listed below. The following Microchip document is available and

recommended as a supplemental reference resource:

MIC2800 Data Sheet – “Digital Power Management IC 2 MHz, 600 mA

DC/DC with Dual 300 mA/300 mA Low VIN LDOs” (DS20005839A)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

PRODUCT CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive email notifications whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Product

Change Notification and follow the registration instructions.

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

•

•

•

•

Distributor or Representative

Local Sales Office

Field Application Engineer (FAE)

Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support

DOCUMENT REVISION HISTORY

Revision A (November 2017)

• Initial Release of this Document.

2017 Microchip Technology Inc.

DS50002656A-page 7

�MIC2800 Evaluation Board User’s Guide

NOTES:

DS50002656A-page 8

2017 Microchip Technology Inc.

�MIC2800

EVALUATION BOARD

USER’S GUIDE

Chapter 1. Product Overview

1.1

INTRODUCTION

This chapter provides an overview of the MIC2800 Evaluation Board and covers the

following topics:

• MIC2800 Device Short Overview

• MIC2800 Evaluation Board Overview

• MIC2800 Evaluation Board Kit Contents

1.2

MIC2800 DEVICE SHORT OVERVIEW

1.2.1

MIC2800 Key Features

The key features of the MIC2800 include:

• 2.7V to 5.5V input voltage range

• 2 MHz DC/DC converter and two LDOs

- LDO1 is powered from DC/DC converter for highest efficiency

- LDO2 is powered directly from VIN

• Integrated power-on reset (AND function for all outputs)

• Adjustable delay time

• LOWQ mode for DC/DC and LDOs

• 30 µA Total IQ when in LOWQ mode

• Thermal Shutdown Protection

• Current Limit Protection

• Tiny 16-pin 3 mm x 3 mm QFN package

DC to DC Converter

•

•

•

•

•

Output current to 600 mA in PWM mode

LOWQ Mode: NO NOISE Light load mode

75 µVRMS output noise in LOWQ mode

2 MHz PWM operation in normal mode

>90% efficiency

LDOs

• LDO1: input voltage directly connected to DC/DC converter output voltage for

maximum efficiency

- Ideal for 1.8V to 1.5V conversion

- 300 mA output current from 1.8V input

- Output voltage down to 0.8V

• LDO2: 300 mA output current capable

2017 Microchip Technology Inc.

DS50002656A-page 9

�MIC2800 Evaluation Board User’s Guide

1.2.2

MIC2800 Device Overview

The MIC2800 device is a high-performance power management IC, giving three output

voltages with maximum efficiency. Combining a 2 MHz DC/DC converter with an LDO

regulator (LDO1), the MIC2800 gives two high-efficiency outputs (DC/DC and LDO1),

combined with the flexibility of a third output, a 300 mA LDO (LDO2). The MIC2800 features a LOWQ mode, reducing the total current draw in this mode to less than 30 µA.

In LOWQ mode, the output noise of the DC to DC converter is 75 µVRMS, significantly

lower than other converters which use a PFM light load mode that can interfere with

sensitive RF circuitry.

The DC to DC converter uses small values of the inductor and capacitors to reduce

board space, but still retains efficiencies over 90%, at load currents up to 600 mA.

The MIC2800 is a µCap design, operating with very small ceramic output capacitors

and inductors for stability, reducing required board space and component cost and it is

available in fixed output voltages in the 16-pin 3 mm x 3 mm QFN lead-free package.

FIGURE 1-1:

1.3

MIC2800 Typical Application Circuit.

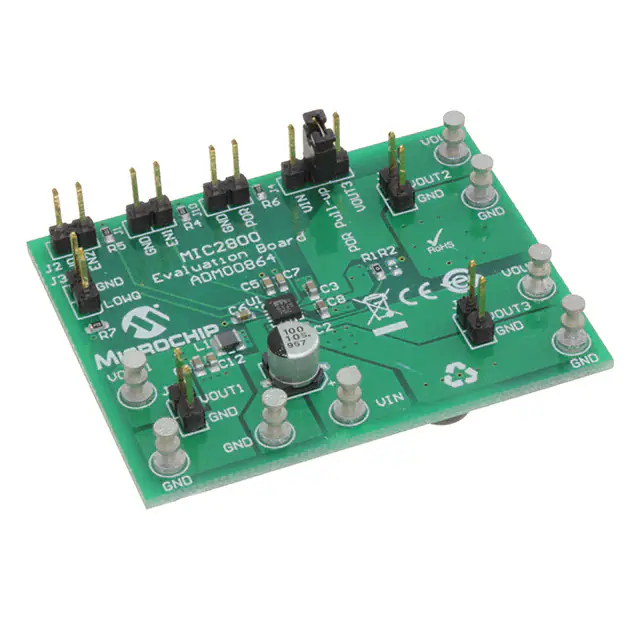

MIC2800 EVALUATION BOARD OVERVIEW

The MIC2800 Evaluation Board has been developed to evaluate the capabilities of the

MIC2800 multi-output (DC-DC and 2 x LDO) device. The board is populated with the

MIC2800-G1JS device and it is set to the following voltages:

• VOUT1 (DC-DC Buck converter): 1.8V

• VOUT2 (LDO1): 1.25V

• VOUT3 (LDO2): 3.3V

The MIC2800-G1JS allows support of the SAMA5D2 family MPUs when operating off

a 5V input rail. However, by populating the board with another MIC2800 IC voltage

option, other power supply solutions can be demonstrated.

The MIC2800 Evaluation Board features independent Enable connectors (EN1 and

EN2). To disable the regulators, a jumper must be placed on J1 (to disable the DC/DC

converter and LDO1) or to J2 (to disable LDO2). Since it is not recommended to leave

EN pins floating, the MIC2800 Evaluation Board features 100 kΩ pull-up resistors, so

the default value when the board is powered is ON.

DS50002656A-page 10

2017 Microchip Technology Inc.

�Product Overview

The MIC2800 Evaluation Board also features a LOWQ pin to switch the functionality of

the DC/DC converter. When the LOWQ is logic high (>1V), the DC/DC converter works

in PWM mode (normal operation mode with 600 mA output current capability). When

the LOWQ is logic low (2.7V is applied. To

disable the device, apply a voltage of 0V to the EN1, EN2 terminals (J1 and/or

J2).

5. Power-on Reset (POR) test point is provided to monitor the POR function (J10).

The power-on reset output will go high after all the output voltages have reached

96% of their nominal voltage and will go low as son as one of the output voltages

go below 91% of its nominal voltage. The POR flag has programmable assertion

delay set by the capacitor placed on CSET pin to ground.

6. The inductance associated with long wires between the power supply and the

board input may cause voltage spikes at load stepping, start-up into heavy loads

or hot wire plug conditions. If the spikes exceed 6V absolute maximum input voltage, the MIC2800 may fail. This behavior is prevented by C9 capacitor (100µF

Al-Electrolytic capacitor) by absorbing voltage spikes.

2017 Microchip Technology Inc.

DS50002656A-page 13

�MIC2800 Evaluation Board User’s Guide

VOUT2

LDO1

VOUT3

LDO2

VOUT1

BUCK

POWER SUPPLY

FIGURE 2-1:

2.3

MIC2800 Evaluation Board – Test Points Description.

EVALUATION BOARD DESCRIPTION

2.3.1

Power-on Reset Pull-up Resistor

The MIC2800 Evaluation Board offers the possibility of connecting the POR pin to

either VIN or VOUT3 (LDO2, 3.3V) by using J4. This provides the flexibility for direct

interfacing with 3.3V systems or directly to VIN when the 3.3V rail is disabled.

2.3.2

Power-on Reset Capacitor (C7)

The MIC2800 has a programmable POR delay set by placing a capacitor on the CSET

pin. This pin is a current source output that charges a capacitor that sets the delay time

for the POR output, from low to high. The current source of 1.25 µA charges a capacitor

up from 0V. When the capacitor reaches 1.25V, the output of the POR is allowed to go

high. The delay time in microseconds is equal to the CSET capacitor in picofarads

(Equation 2-1).

EQUATION 2-1:

PORDelay uS = CSET pF

2.3.3

LOWQ Mode

MIC2800 is 2 MHz 600 mA DC/DC converter with two integrated 300 mA LDOs. This

design combines good overall efficiency with low output noise. However, the DC/DC

converter is always switching in PWM mode. To reduce quiescent current in light-load

conditions, the MIC2800 features a LOWQ pin. In this mode, the DC/DC converter is

disabled and the output voltage is provided by a low noise linear regulator (LDO) capable of supplying 60 mA to the load. In this mode, the other linear regulators (LDO1 and

LDO2) will also be internally limited to 10 mA.

DS50002656A-page 14

2017 Microchip Technology Inc.

�Installation and Operation

2.3.4

Using Fixed and Adjustable Voltage Options

The MIC2800 Evaluation Board is designed for both fixed and adjustable options.

Resistors R1 and R2 are used for setting the output voltage of the adjustable option of

the DC/DC converter: R1 is the top voltage divider resistor and R2 is the bottom voltage

divider resistor. The feedback voltage is 0.8V (nominal) and the output voltage can be

adjusted from 1V to 2V. Note that LDO1 is powered from the DC/DC converter's output,

so in order for LDO1 to maintain good regulation, the DC/DC output voltage should be

minimum VDCDC - VDO.

2.3.5

Output Noise and Ripple Measurements

The MIC2800 Evaluation Board is populated with headers used for measuring output

noise and ripple on both the DC/DC converter and the LDOs (J5, J8 and J9). Each connector is designed to probe the output signal using the local ground as reference. This

is the proper way of measuring low-amplitude ripple signals because it eliminates any

noise caused by long oscilloscope ground leads or ground plane noise.

2.3.6

Board Layout Considerations

It is recommended that the connection between the GND pins of the MIC2800 and

GND terminals of the input capacitors is kept on the TOP of the PCB and no vias

should be placed between them. This will improve transient behavior and decrease

noise. It is also recommended that the TOP GND plane should extend under the

device for optimal noise performance.

2017 Microchip Technology Inc.

DS50002656A-page 15

�MIC2800 Evaluation Board User’s Guide

NOTES:

DS50002656A-page 16

2017 Microchip Technology Inc.

�MIC2800

EVALUATION BOARD

USER’S GUIDE

Appendix A. Schematic and Layouts

A.1

INTRODUCTION

This appendix contains the following schematics and layouts for the MIC2800

Evaluation Board:

•

•

•

•

•

•

•

Board – Schematic

Board – Top Silk

Board – Top Copper and Silk

Board – Top Copper

Board – Bottom Copper

Board – Bottom Copper and Silk

Board – Bottom Silk

2017 Microchip Technology Inc.

DS50002656A-page 17

�BOARD – SCHEMATIC

VOUT1

VIN

U1

100uF

10V

AL-C

GND

C1

10uF

35V

0603

R7

100k

0603

1%

100k

0603

1%

7

100k

0603

1%

EN1

LOWQ

EN2

VIN

SW

15

EN1

1

LOWQ

16

EN2

FB

TP2

C5

C6

0.1uF

16V

0603

GND

GND

4

0.1uF

16V

0603

GND

GND

PGND

MIC2800

L1

5

9

LDO1

LDO2

R1

0R

0603

11

GND

VOUT3

12

POR

13

CSET

3

SGND

C7

0.010uF

25V

0603

GND

GND

R2

C2

C3

10uF

35V

0603

10uF

35V

0603

GND

GND

GND

10uF

35V

0603

GND

2 1

2 1

LOWQ

GND

GND

GND

100k

0603

1%

J10

POR

GND

0.1uF

16V

0603

GND

C8

TP3

TP4 GND

GND

Shunt 2.54mm 1x2

HDR-2.54 Male 1x3

VOUT3

TP6

TP7

TP8

GND

GND

GND

2.2uF

16V

0603

J4 JP1

3

2

1

R6

2 1

2 1

J3

EN1

C12

C4

DNP

J1

EN2

VOUT2

8

VIN

J2

VOUT1

J5

2.2uH

VOUT2

GND

14

CBYP

2

BIAS

10

J8

VOUT3

J9

2 1

C9

R4

R5

LDO

2 1

TP1

VIN

2 1

6

TP5

GND

MIC2800 Evaluation Board User’s Guide

DS50002656A-page 18

A.2

2017 Microchip Technology Inc.

�Schematic and Layouts

A.3

BOARD – TOP SILK

�����

����

�����

5,31�d

�

%��)/

%�d

A