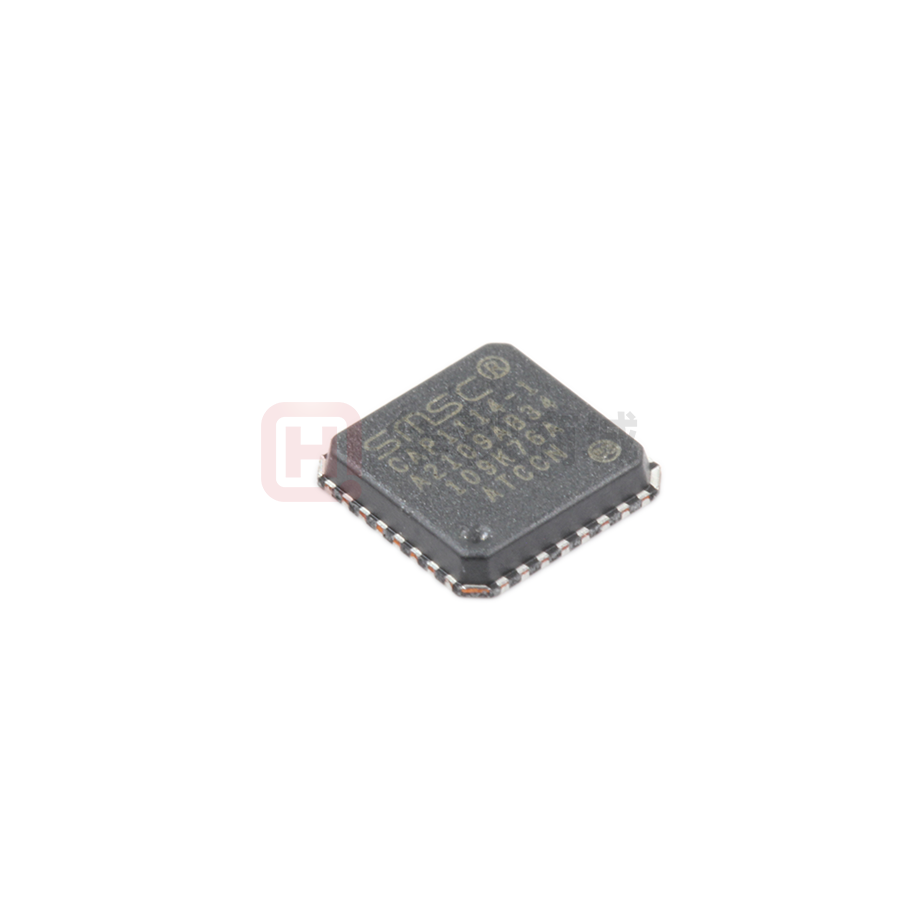

CAP1114

Multiple Channel Capacitive Touch Sensor and LED Driver

General Description

Features

The CAP1114, which incorporates Microchip’s RightTouchTM technology, is a multiple channel Capacitive

Touch sensor and LED Driver.

• Fourteen (14) capacitive touch sensor inputs

- Compensates for variable sensor capacitance

- Programmable sensitivity

- High SNR allows for easy tuning

- Automatic recalibration

- Slider acceleration detection

- Slider positional detection

- Proximity detection

• Lid closure detection

• Low power operation

- 4.5uA quiescent current in Deep Sleep

- 200uA quiescent current in Sleep while monitoring 1 button

• Alert to signal touch to host processor

• User controlled reset

• Low external component count

• SMBus 2.0 compliant interface to change operating parameters to work in a wide variety of systems

- Block Read and Write function for quick tasking

• Eleven (11) LED driver outputs

- Programmable blink, breathe, and dimness

controls

- 8 configurable as GPIOs

- Buttons can be linked to LED responses

• Development boards and software available

The CAP1114 contains up to fourteen (14) individual

Capacitive Touch sensor inputs with programmable

sensitivity for use in touch button and slider switch

applications. Each sensor also contains automatic

recalibration with programmable time delays.

The CAP1114 also includes internal circuitry to compensate for design and parasitic variance in untouched capacitance on sensors.

The CAP1114 also contains eleven (11) low side LED

drivers that offer full-on / off, variable rate blinking, dimness controls, and breathing. Capacitive buttons can

be linked to LED outputs.

Applications

• Consumer Electronics

• Desktop and Notebook PCs

• LCD Monitors

Block Diagram

LED2

LED1

LED4

LED3

LED6

LED5

LED8

LED7

LED10

LED9

LED11

RESET

LED Blink, Breathe, and Dimness control

Capacitive Sensing Algorithm

CS1

CS3

CS2

CS5

CS4

CS7

CS6

2009-2017 Microchip Technology Inc.

CS9

CS8

VDD GND

SMBus

Slave

Protocol

SMCLK

SMDATA

ALERT

CS13

CS11

CS14

CS10

CS12

DS00002444A-page 1

�CAP1114

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com. We welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000000A is version A of document DS30000000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the

revision of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include -literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

DS00002444A-page 2

2009-2017 Microchip Technology Inc.

�CAP1114

Table of Contents

1.0 Delta from CAP1014 to CAP1114 ................................................................................................................................................... 4

2.0 Pin Description ................................................................................................................................................................................ 6

3.0 Electrical Specifications .................................................................................................................................................................. 9

4.0 Communications ........................................................................................................................................................................... 12

5.0 Product Description ....................................................................................................................................................................... 15

6.0 Register Description ...................................................................................................................................................................... 26

7.0 Package Information ..................................................................................................................................................................... 74

Appendix A: Data Sheet Revision History ........................................................................................................................................... 77

The Microchip Web Site ...................................................................................................................................................................... 79

Customer Change Notification Service ............................................................................................................................................... 79

Customer Support ............................................................................................................................................................................... 79

Product Identification System ............................................................................................................................................................. 80

2009-2017 Microchip Technology Inc.

DS00002444A-page 3

�CAP1114

1.0

DELTA FROM CAP1014 TO CAP1114

1.1

Summary

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

1.2

Updated circuitry to reduce sensitivity to power supply stepping.

Updated LED Pulse 1 behavior. This function may be triggered on button press or on release. See Section 6.50.

Updated Product ID to 3Ah.

Updated LED behavior for host control during direct mode when not linked. The LED Output register will now be

able to be written to emulate a touch or release. Enables all behaviors while in host mode. See Section 6.44 and

Section 6.48.

Updated recalibration controls to add negative delta count. See Section 6.28.

Removed ACAL_RT bits.

Added digital controls to disable the slider functionality but still detect basic touches essentially bypassing the

slider algorithms entirely. See Section 6.34.

Added controls to enable individual buttons in the slider. See Section 6.35.

Updated button interrupt schemes to allow interrupt on press only, not on release. Retained previous behavior

as default. See Figure 5-2, Figure 5-3, and Section 5.7.1. Retained previous behavior as default. See

Section 6.28.

Updated Noise Threshold default settings to ~25%. See Section 6.30.

Added control bit and status registers to enable interrupt when LEDs finish their directed behavior in the same

fashion. See Section 6.53 and Section 6.40.

Updated LED driver duty cycle decode values to have more distribution at lower values - closer to a logarithmic

curve. See Section 6.54.

Renamed D_DSP[3:0] and C_DSP[3:0] to DELTA_SENSE[2:0] and BASE_SHIFT[3:0]. D_DSP[3] did nothing so

removed references. See Section 6.13.

Added filtering on RESET pin to prevent errant resets. The RESET pin must be high or low for longer than 10ms

before it will be detected by the device. See Section 8.6.

Added proximity to CS1 channel.

Updated Deep Sleep to wake on communications. See Section 5-1.

Updated controls so that the RESET pin assertion places the device into the lowest power state available. See

Section 5.2 and Section 5.1.

Added LED transition controls that affect the LED behavior when a Capacitive Touch Sensor is linked to an LED

channel to remove bouncing. See Section 6.46.

Added controls to “mirror” the LED duty cycle outputs so that when polarity changed, the LED brightness levels

look right. See Section 6.47.

Added register to force digital recalibration of all sensors. See Section 6.33.

Added register to enable oversampling on specific sensors. See Section 6.36 and Section 6.38.

Changed PWM frequency for LED drivers. The PWM frequency was derived from the programmed breathe

period and duty cycle settings and it ranged from ~4Hz to ~8000 Hz. The PWM frequency has been updated to

be a fixed value of ~2000Hz.

Register Delta

TABLE 1-1:

REGISTER DELTA

Address

Register Delta

Delta

Default

05h

Changed - Build

Revision

Reset build revision to 10h

10h

20h

Changed - Configuration

Changed functionality of RPT_EN_B bit.

Changed default

29h

2Fh

Changed - Recalibration Removed ACAL_RT[1:0] bits and replaced

Configuration

with NEG_CNT[1:0] bits. These bits control

recalibration when negative counts are

received.

93h

DS00002444A-page 4

2009-2017 Microchip Technology Inc.

�CAP1114

TABLE 1-1:

REGISTER DELTA (CONTINUED)

Address

Register Delta

Delta

Default

38h

Changed - Button Noise

Threshold 1

Changed default

AAh

39h

Changed - Button Noise

Threshold 2

Changed default

AAh

3Fh

New - Digital

Recalibration

New register to force digital recalibration

on all sensors

00h

40h

New - Configuration 2

New register to control LED touch linking

behavior, LED output behavior, and noise

detection, and interrupt on release

00h

7Fh

41h

New - Grouped Channel

Sensor Enable

New register to enable individual sensors

within the grouped sensors

42h

New - Proximity Control

New register to enable / configure

proximity settings on CS1

02h

46h

New - Group Button

Calibration Activate

New register to force calibration on

individual grouped sensors

00h

4Eh

New - Sampling Channel New register to select which channels can

Select

be controlled via the Sampling

Configuration register

00h

60h

New - LED Status 1

New register to store status for LEDs that

have finished their programmed behavior

61h

New - LED Status 2

New register to store status for LEDs that

have finished their programmed behavior

00h

77h

New - Linked LED

Transition Control 1

New register to control transition effect

when LED linked to CS sensor

00h

78h

New - Linked LED

Transition Control 2

New register to control transition effect

when LED linked to CS sensor

00h

79h

New - LED Mirror

Control 1

New register to control LED output

mirroring for brightness control when

polarity changed

00h

New - LED Mirror

Control 2

New register to control LED output

mirroring for brightness control when

polarity changed

00h

90h

Changed - LED Pulse 1

Duty Cycle

Changed bit decode to be more

logarithmic

F0h

91h

Changed - LED Pulse 2

Duty Cycle

Changed bit decode to be more

logarithmic

F0h

92h

Changed - LED Breathe

Duty Cycle

Changed bit decode to be more

logarithmic

F0h

93h

Changed - LED Direct

Duty Cycle

Changed bit decode to be more

logarithmic

F0h

FDh

Changed - Product ID

Changed bit decode for CAP1114

3Ah

7Ah

FEh

Added - Manufacturer ID Added - this register mirrors the Vendor ID

2009-2017 Microchip Technology Inc.

00h

5Dh

DS00002444A-page 5

�CAP1114

PIN DESCRIPTION

TABLE 2-1:

CS7

CS6

CS5

CS4

CS3

CS2

CS1

N/C

32

31

30

29

28

27

26

25

CAP1114 PIN DIAGRAM (32-PIN QFN)

CS8

1

24

N/C

CS9

2

23

RESET

CS10

3

22

SMCLK

CS11

4

21

SMDATA

CS12

5

20

ALERT

CS13

6

19

LED11

CS14

7

18

LED10

VDD

8

17

LED9

14

LED6 / GPIO6

16

13

LED5 / GPIO5

LED8 / GPIO8

12

LED4 / GPIO4

15

11

LED3 / GPIO3

LED7 / GPIO7

10

LED2 / GPIO2

GND

9

FIGURE 2-1:

LED1 / GPIO1

2.0

PIN DESCRIPTION FOR CAP1114

Pin Number

Pin Name

Pin Function

Pin Type

1

CS8

Capacitive Touch Sensor 8

AIO

2

CS9

Capacitive Touch Sensor 9

AIO

3

CS10

Capacitive Touch Sensor 10

AIO

4

CS11

Capacitive Touch Sensor 11

AIO

5

CS12

Capacitive Touch Sensor 12

AIO

6

CS13

Capacitive Touch Sensor 13

AIO

7

CS14

Capacitive Touch Sensor 14

AIO

8

VDD

Positive Power supply

Power

9

LED1 / GPIO1

LED1 - Open drain LED driver (default)

OD (5V)

GPI1 - GPIO 1 Input

DI (5V)

GPO1 - GPIO 1 push-pull output

DO

DS00002444A-page 6

2009-2017 Microchip Technology Inc.

�CAP1114

TABLE 2-1:

PIN DESCRIPTION FOR CAP1114 (CONTINUED)

Pin Number

Pin Name

Pin Function

Pin Type

10

LED2 / GPIO 2

LED2 - Open drain LED driver (default)

OD (5V)

11

12

13

14

15

16

LED3 / GPIO3

LED4 / GPIO4

LED5 / GPIO5

LED6 / GPIO6

LED7 / GPIO7

LED8 / GPIO8

GPI2 - GPIO 2 Input

DI (5V)

GPO2 - GPIO 2 push-pull output

DO

LED3 - Open drain LED driver (default)

OD (5V)

GPI3 - GPIO 3 Input

DI (5V)

GPO3 - GPIO 3 push-pull output

DO

LED4 - Open drain LED driver (default)

OD (5V)

GPI4 - GPIO 4 Input

DI (5V)

GPO4 - GPIO 4 push-pull output

DO

LED5 - Open drain LED driver (default)

OD (5V)

GPI5 - GPIO 5 Input

DI (5V)

GPO5 - GPIO 5 push-pull output

DO

LED6 - Open drain LED driver (default)

OD (5V)

GPI6 - GPIO 6 Input

DI (5V)

GPO6 - GPIO 6 push-pull output

DO

LED7 - Open drain LED driver (default)

OD (5V)

GPI7 - GPIO 7 Input

DI (5V)

GPO7 - GPIO 7 push-pull output

DO

LED8 - Open drain LED driver (default)

OD (5V)

GPI8 - GPIO 8 Input

DI (5V)

GPO8 - GPIO 8 push-pull output

DO

17

LED9

LED9 - Open drain LED driver

OD (5V)

18

LED10

LED10 - Open drain LED driver

OD (5V)

19

LED11

LED11 - Open drain LED driver

OD (5V)

20

ALERT

Active High Interrupt / Wake Up Input

DIO

21

SMDATA

Bi-directional SMBus data - requires a pull-up

resistor

DIOD (5V)

22

SMCLK

SMBus clock input - requires a pull-up resistor

DI (5V)

23

RESET

Soft reset for system - resets all registers to default

values

DI (5V)

24

N/C

Not Connected - connect to gnd

N/A

25

N/C

Not Connected - connect to gnd

N/A

26

CS1

Capacitive Touch Sensor 1

AIO

27

CS2

Capacitive Touch Sensor 2

AIO

28

CS3

Capacitive Touch Sensor 3

AIO

29

CS4

Capacitive Touch Sensor 4

AIO

30

CS5

Capacitive Touch Sensor 5

AIO

31

CS6

Capacitive Touch Sensor 6

AIO

32

CS7

Capacitive Touch Sensor 7

AIO

Bottom Plate

GND

Power Ground

Power

The pin types are described in Table 2-2, "Pin Types". All pins labeled with (5V) are 5V tolerant.

Note:

For all 5V tolerant pins that require a pull-up resistor, the voltage difference between VDD and the pull-up

voltage must never exceed 3.6V.

2009-2017 Microchip Technology Inc.

DS00002444A-page 7

�CAP1114

TABLE 2-2:

PIN TYPES

Pin Type

Power

DI

DIO

AIO

Description

This pin is used to supply power or ground to the device.

Digital Input - this pin is used as a digital input. This pin is 5V tolerant.

Digital Input Output - this pin is used as a digital input / output.

Analog Input / Output - this pin is used as an I/O for analog signals.

DIOD

Digital Input / Open Drain Output - this pin is used as an digital I/O. When it is used as an

output, It is open drain and requires a pull-up resistor. This pin is 5V tolerant.

OD

Open Drain Digital Output - this pin is used as a digital output. It is open drain and requires

a pull-up resistor. This pin is 5V tolerant.

DO

Push-pull Digital Output - this pin is used as a digital output and can sink and source current.

DS00002444A-page 8

2009-2017 Microchip Technology Inc.

�CAP1114

3.0

ELECTRICAL SPECIFICATIONS

TABLE 3-1:

ABSOLUTE MAXIMUM RATINGS

Voltage on VDD pin

-0.3 to 4

V

Voltage on 5V tolerant pins (V5VT_PIN)

Voltage on 5V tolerant pins (|V5VT_PIN - VDD|) (see Note 3-1)

-0.3 to 5.5

V

0 to 3.6

V

Voltage on any other pin to GND

-0.3 to VDD + 0.3

V

Package Power Dissipation up to TA = 85°C (see Note 3-2)

1

W

Junction to Ambient (JA) (see Note 3-3)

48

°C/W

Operating Ambient Temperature Range

-40 to 125

°C

Storage Temperature Range

-55 to 150

°C

ESD Rating, All Pins, HBM

8000

V

Note:

Stresses above those listed could cause permanent damage to the device. This is a stress rating only and

functional operation of the device at any other condition above those indicated in the operation sections of

this specification is not implied.

Note 3-1

For the 5V tolerant pins that have a pull-up resistor, the pull-up voltage must not exceed 3.6V when

the device is unpowered.

Note 3-2

The Package Power Dissipation specification assumes a thermal via design with the thermal landing

be soldered to the PCB ground plane with 0.3mm (12mil) diameter vias in a 4x4 matrix at 0.9mm

(35.4mil) pitch.

Note 3-3

Junction to Ambient (JA) is dependent on the design of the thermal vias. Without thermal vias and

a thermal landing, the JA is approximately 60°C/W including localized PCB temperature increase.

TABLE 3-2:

ELECTRICAL SPECIFICATIONS

VDD = 3V to 3.6V, TA = -40°C to 125°C, all Typical values at TA = 27°C unless otherwise noted.

Characteristic

Symbol

MIN

TYP

MAX

Unit

Conditions

DC Power

Supply Voltage

VDD

3.3

3.6

V

IDD

0.55

1

mA

Average current

Capacitive Sensing Active,

LEDs enabled

ISLEEP

200

250

uA

Sleep state active, 1 sensor

monitored; LED11 inactive

TA < 85°C

IDSLEEP

4.5

10

uA

Deep Sleep, LED 11 inactive

TA < 40°C

Time to

Communications

tCOMM

15

20

ms

Time from power applied to

communications active

Time to First

Conversion

tCONV

400

500

ms

Time from power applied to first

sensor sampled

Supply Current

3.0

Capacitive Touch Sensor

Base Capacitance

CBASE

5

15

50

pF

Pad untouched

Detectable Capacitive

Shift

CTOUCH

0.1

0.4

2

pF

Pad touched

Sample Time

tTOUCH

2.5

ms

Update Time

tTOUCH

35

ms

Recalibration Interval

tCAL

8

s

2009-2017 Microchip Technology Inc.

Automatic Recalibration active, no

touch active, default settings

DS00002444A-page 9

�CAP1114

TABLE 3-2:

ELECTRICAL SPECIFICATIONS (CONTINUED)

VDD = 3V to 3.6V, TA = -40°C to 125°C, all Typical values at TA = 27°C unless otherwise noted.

Characteristic

Symbol

Duty Cycle

DUTYLED

MIN

TYP

MAX

Unit

Conditions

LED / GPIO Drivers (LED / GPIO 1 - 8)

Drive Frequency

fLED

Sinking Current

ISINK

0

100

2

Sourcing Current

ISOURCE

Input High Voltage

VIH

Input Low Voltage

VIL

%

Programmable

kHz

24

mA

24

mA

VOH = VDD - 0.4

V

LED / GPIO configured as input

V

LED / GPIO configured as input

%

Programmable

2.0

0.8

VOL = 0.4

LED Drivers (LED 9 - LED 10)

Duty Cycle

DUTYLED

Drive Frequency

fLED

0

100

2

kHz

Sinking Current

ISINK

24

mA

Output Low Voltage

VOL

0.4

V

ISINK = 24mA

Duty Cycle

DUTYLED

%

Programmable

LED11 Driver

Drive Frequency

fLED

Sinking Current

ISINK

Output Low Voltage

VOL

0

100

2

kHz

48

mA

0.4

V

ISINK = 48mA

I/O Pins - SMDATA, SMCLK, and ALERT Pins

Output Low Voltage

VOL

0.4

V

ISINK_IO = 8mA

V

ALERT pin active high and

asserted

ISOURCE_IO = 8mA

Output High Voltage

VOH

VDD - 0.4

Input High Voltage

VIH

2.0

Input Low Voltage

VIL

0.8

V

Leakage Current

ILEAK

±5

uA

V

powered or unpowered

TA < 85°C

pull-up voltage < 3.6V

RESET Pin

Input High Voltage

VIH

Input Low Voltage

VIL

RESET Filter Time

tRST_FILT

RESET Pin release to

fully active operation

tRST_ON

2.0

V

0.8

10

V

ms

400

500

ms

SMBus Timing

Input Capacitance

CIN

Clock Frequency

fSMB

5

10

pF

400

kHz

50

ns

Spike Suppression

tSP

Bus free time Start to

Stop

tBUF

1.3

us

tSU:STA

0.6

us

Setup Time: Stop

tSU:STP

0.6

Data Hold Time

tHD:DAT

0.6

6

us

Data Setup Time

tSU:DAT

0.6

72

us

Clock Low Period

tLOW

1.3

us

Clock High Period

tHIGH

0.6

us

Setup Time: Start

DS00002444A-page 10

us

2009-2017 Microchip Technology Inc.

�CAP1114

TABLE 3-2:

ELECTRICAL SPECIFICATIONS (CONTINUED)

VDD = 3V to 3.6V, TA = -40°C to 125°C, all Typical values at TA = 27°C unless otherwise noted.

Characteristic

Symbol

MIN

TYP

MAX

Unit

Conditions

Clock/Data Fall time

tFALL

300

ns

Min = 20+0.1CLOAD ns

Clock/Data Rise time

tRISE

300

ns

Capacitive Load

CLOAD

400

pF

Min = 20+0.1CLOAD ns

per bus line

2009-2017 Microchip Technology Inc.

DS00002444A-page 11

�CAP1114

4.0

COMMUNICATIONS

The CAP1114 communicates via the SMBus or I2C communications protocols.

APPLICATION NOTE: Upon power up, the CAP1114 will not respond to any SMBus communications for 10ms. After

this time, full functionality is available.

4.1

System Management Bus Protocol

The CAP1114 communicates with a host controller, such as a Microchip SIO, through the SMBus. The SMBus is a twowire serial communication protocol between a computer host and its peripheral devices. A detailed timing diagram is

shown in Figure 4-1. Stretching of the SMCLK signal is supported; however, the CAP1114 will not stretch the clock signal.

FIGURE 4-1:

SMBUS TIMING DIAGRAM

T HIGH

T LOW

T HD:STA

T SU:STO

T FALL

SMCLK

T RISE

T HD:STA

T SU:DAT

T HD:DAT

T SU:STA

SMDATA

TBUF

P

4.1.1

S

S - Start Condition

S

P - Stop Condition

P

SMBUS START BIT

The SMBus Start bit is defined as a transition of the SMBus Data line from a logic ‘1’ state to a logic ‘0’ state while the

SMBus Clock line is in a logic ‘1’ state.

4.1.2

SMBUS ADDRESS AND RD / WR BIT

The SMBus Address Byte consists of the 7-bit client address followed by the RD / WR indicator bit. If this RD / WR bit

is a logic ‘0’, the SMBus Host is writing data to the client device. If this RD / WR bit is a logic ‘1’, the SMBus Host is

reading data from the client device.

The slave addresses of CAP1114 are factory-set. For CAP1114-1, it responds to the slave address 0101_000xb. For

CAP1114-2, it responds to the salve address 0101_101xb.

4.1.3

SMBUS DATA BYTES

All SMBus Data bytes are sent most significant bit first and composed of 8-bits of information.

4.1.4

SMBUS ACK AND NACK BITS

The SMBus client will acknowledge all data bytes that it receives. This is done by the client device pulling the SMBus

Data line low after the 8th bit of each byte that is transmitted. This applies to both the Write Byte and Block Write protocols.

The Host will NACK (not acknowledge) the last data byte to be received from the client by holding the SMBus data line

high after the 8th data bit has been sent. For the Block Read protocol, the Host will ACK each data byte that it receives

except the last data byte.

DS00002444A-page 12

2009-2017 Microchip Technology Inc.

�CAP1114

4.1.5

SMBUS STOP BIT

The SMBus Stop bit is defined as a transition of the SMBus Data line from a logic ‘0’ state to a logic ‘1’ state while the

SMBus clock line is in a logic ‘1’ state. When the CAP1114 detects an SMBus Stop bit, and it has been communicating

with the SMBus protocol, it will reset its client interface and prepare to receive further communications.

4.1.6

SMBUS TIME-OUT

The CAP1114 includes an SMBus time-out feature. Following a 30ms period of inactivity on the SMBus where the

SMCLK pin is held low, the device will time-out and reset the SMBus interface.

The time-out function defaults to disabled. It can be enabled by setting the TIMEOUT bit in the Configuration register

(see Section 6.14).

SMBUS AND I2C COMPLIANCE

4.1.7

The major difference between SMBus and I2C devices is highlighted here. For complete compliance information, refer

to the SMBus 2.0 specification.

1.

2.

3.

Minimum frequency for SMBus communications is 10kHz.

The client protocol will reset if the clock is held low longer than 30ms.

Except when operating in Deep Sleep, the client protocol will reset if both the clock and the data line are high for

longer than 150us (idle condition).

I2C devices do not support the Alert Response Address functionality (which is optional for SMBus).

4.

4.2

SMBus Protocols

The CAP1114 is SMBus 2.0 compatible and supports Send Byte, Read Byte, Block Read, Receive Byte as valid protocols as shown below. The CAP1114 also supports the I2C block read and block write protocols.

All of the below protocols use the convention in Table 4-1.

TABLE 4-1:

PROTOCOL FORMAT

Data Sent to

Device

Data sent

4.2.1

Data Sent to the

Host

Data sent

SMBUS WRITE BYTE

The Write Byte is used to write one byte of data to a specific register as shown in Table 4-2.

TABLE 4-2:

WRITE BYTE PROTOCOL

Start

Client

Address

WR

ACK

Register

Address

ACK

Register Data

ACK

Stop

1 ->0

0101_000

0

0

XXh

0

XXh

0

0 -> 1

4.2.2

BLOCK WRITE

The Block Write is used to write multiple data bytes to a group of contiguous registers as shown in Table 4-3. It is an

extension of the Write Byte Protocol.

APPLICATION NOTE: When using the Block Write protocol, the internal address pointer will be automatically

incremented after every data byte is received. It will wrap from FFh to 00h.

2009-2017 Microchip Technology Inc.

DS00002444A-page 13

�CAP1114

TABLE 4-3:

BLOCK WRITE PROTOCOL

Start

Client

Address

WR

ACK

Register

Address

ACK

Register Data

ACK

1 ->0

0101_000

0

0

XXh

0

XXh

0

Register

Data

ACK

Register

Data

ACK

...

Register

Data

ACK

Stop

XXh

0

XXh

0

...

XXh

0

0 -> 1

4.2.3

SMBUS READ BYTE

The Read Byte protocol is used to read one byte of data from the registers as shown in Table 4-4.

TABLE 4-4:

Client

Address

Start

1->0

READ BYTE PROTOCOL

0101_000

4.2.4

WR

0

ACK

0

Register

Address

XXh

ACK

0

Start

1 ->0

Client

Address

0101_000

RD

ACK

1

0

Register

Data

XXh

NACK

1

Stop

0 -> 1

BLOCK READ

The Block Read is used to read multiple data bytes from a group of contiguous registers as shown in Table 4-5. It is an

extension of the Read Byte Protocol.

APPLICATION NOTE: When using the Block Read protocol, the internal address pointer will be automatically

incremented after every data byte is received. It will wrap from FFh to 00h.

TABLE 4-5:

Start

BLOCK READ PROTOCOL

Client

Address

WR

Register

Address

ACK

ACK

Start

Client

Address

RD

ACK

Register

Data

1->0

0101_000

0

0

XXh

0

1 ->0

0101_000

1

0

XXh

ACK

REGISTER

DATA

ACK

REGISTER

DATA

ACK

REGISTER

DATA

ACK

...

REGISTER

DATA

NACK

STOP

0

XXh

0

XXh

0

XXh

0

...

XXh

1

0 -> 1

4.2.5

SMBUS SEND BYTE

The Send Byte protocol is used to set the internal address register pointer to the correct address location. No data is

transferred during the Send Byte protocol as shown in Table 4-6.

TABLE 4-6:

SEND BYTE PROTOCOL

Start

Client Address

WR

ACK

Register Address

ACK

Stop

1 -> 0

0101_000

0

0

XXh

0

0 -> 1

4.2.6

SMBUS RECEIVE BYTE

The Receive Byte protocol is used to read data from a register when the internal register address pointer is known to

be at the right location (e.g. set via Send Byte). This is used for consecutive reads of the same register as shown in

Table 4-7.

TABLE 4-7:

RECEIVE BYTE PROTOCOL

Start

Client Address

RD

ACK

Register Data

NACK

Stop

1 -> 0

0101_000

1

0

XXh

1

0 -> 1

DS00002444A-page 14

2009-2017 Microchip Technology Inc.

�CAP1114

5.0

PRODUCT DESCRIPTION

The CAP1114 is a multiple channel Capacitive Touch sensor and LED Driver.

The CAP1114 contains up to 14 individual Capacitive Touch sensor inputs with programmable sensitivity for use in touch

button and slider switch applications. Each sensor also contains automatic recalibration.

The CAP1114 also contains eleven (11) open drain LED drivers that offer full-on / off, variable rate breathing, and dimness controls. Eight (8) of these LEDs can double as GPIOs and support open-drain or push-pull operation. Capacitive

buttons can be linked to LED outputs. Additionally, LEDs 1-7 may be optionally linked to Buttons 1-7 so that when a

touch is detected, the LED is actuated.

The device communicates with a host controller using SMBus. The host controller may poll the device for updated information at any time or it may configure the device to flag an interrupt whenever a press is detected on any sensor.

Each sensor is polled by the device approximately every 35 ms. The host may also initiate a recalibration routine for

one or more sensors or set up times and conditions so that the device automatically invokes the re-calibration routine.

The CAP1114 contains multiple power states including several low power operating states. In addition, it contains a user

driven RESET pin to force the device to reset.

A typical system diagram is shown in Figure 5-1.

2009-2017 Microchip Technology Inc.

DS00002444A-page 15

�CAP1114

SYSTEM DIAGRAM FOR CAP1114

Touch

Button

RESET

SMCLK

3.3V

ALERT

Embedded Controller

VDD

SMDATA

FIGURE 5-1:

3.3V

3.3V

3.3V

Dual

Color

LED

LED11

CS1

LED8

LED1

CS2

CS7

LED2

LED7

Touch

Button

Touch

Button

CAP1114

CS3

CS6

LED3

LED6

Touch

Button

LED10

CS14

LED5

CS13

LED4

CS12

CS5

CS11

CS4

CS10

3.3V

Touch

Button

CS9

3.3V

Touch

Button

CS8

3.3V

Touch

Button

LED9

3.3V

3.3V

3.3V

3.3V

3.3V

Slider

5.1

Power States

The CAP1114 has four operating states depending on the status of the SLEEP, DEACT, and DSLEEP bits (see

Section 6.1). They are described below and summarized in Table 5-1. When the device transitions between power

states, previously detected touches (for deactivated channels) are cleared and the status bits reset.

1.

2.

Fully Active - The device is fully active. It is monitoring all active Capacitive Sensor channels and driving all LED

channels as defined.

Sleep - The device is in the Sleep state. It is monitoring a limited number of Capacitive Sensor channels (default

DS00002444A-page 16

2009-2017 Microchip Technology Inc.

�CAP1114

2). Interrupts will still be generated based on the active channels. The device will still respond to SMBus commands normally and can be returned to the Fully Active state by clearing the SLEEP bit. The LED11 channel is

controlled via the PWR_LED control (see Section 6.1). All other LEDs will not be affected.

Deep Sleep - The device is in Deep Sleep state. It is not monitoring any Capacitive Sensor channels or the

SMBus. The LED11 channel is controlled via the PWR_LED control (see Section 6.1). All other LEDs will be

driven to their programmed non-actuated state and no PWM operations will be done.

3.

When the device enters the Deep Sleep state, it will release control to the ALERT pin and will change the direction of

the ALERT pin (i.e. the device will monitor the ALERT pin instead of driving it).

The device has two methods to exit the Deep Sleep state. They are:

a)

b)

The ALERT pin is driven to its active state.

Any SMBus communications are directed at the device.

When the device leaves the Deep Sleep state, it automatically returns to its previously defined state and clears the

DSLEEP bit.

Note:

4.

When the device enters the Deep Sleep state, the Slider Position / Volumetric Data Register (06h) is

cleared.

Inactive - The device is inactive. It is not monitoring any Capacitive Sensor channels. The device will still respond

to SMBus commands normally and can be returned to Fully Active state by clearing the DEACT bit. All LEDs will

have PWM controls suspended so they should be disabled prior to entering this state. If these LEDs are not disabled, the system will show excess current draw from these LEDs.

TABLE 5-1:

POWER STATES

Power State

DEACT

SLEEP

DSLEEP

Fully Active

0

0

0

Deep Sleep waking to Fully Active

0

0

1

Sleep

0

1

0

Deep Sleep waking to Sleep

0

1

1

Inactive

1

0

0

Deep Sleep waking to Inactive

1

0

1

Inactive

1

1

0

Deep Sleep waking to Inactive

1

1

1

The priority of power control signals is:

1.

2.

3.

5.2

DSLEEP - when set, will override DEACT, disable all LEDs except LED11 then disable SMBus communications.

DEACT - when set, will override the SLEEP controls. It will disable sensor measurement and all LEDs.

SLEEP - when set, will enable Sleep state.

RESET Pin

The RESET pin is an active high reset that is driven from an external source. The pin contains an internal delay timer

(tRST_FILT) that will block errant glitches on the RESET pin. The RESET pin must be driven high or low longer than this

time before the CAP1114 will react to the pin state.

While the RESET pin is held high, all the internal blocks will be held in reset including the SMBus. All configuration settings will be reset to default states and all readings will be cleared. Furthermore, the device will be held in Deep Sleep

that can only be removed by driving the RESET pin low.

Once the RESET pin is pulled low, the CAP1114 will begin operation as if a power-on-reset had occurred. When this

happens, the RESET bit will be set and an interrupt will be generated.

2009-2017 Microchip Technology Inc.

DS00002444A-page 17

�CAP1114

5.3

LED Drivers

The CAP1114 contains eleven (11) LED Drivers. Each LED Driver is controlled independently of the others and may be

linked to the corresponding Capacitive Touch Sensor input. All LED drivers will operate in one of the following modes.

LED drivers 1 - 8 can be configured to operate with either push-pull or open-drain drive and may also be configured to

operate as GPIOs. LED drivers 9 - 11 will only operate as open-drain drivers.

1.

2.

3.

4.

Direct - The LED is configured to be on or off when the corresponding input stimulus is on or off (or inverted). The

brightness of the LED can be programmed from full off to full on (default). Additionally, the LED contains controls

to individually configure ramping on, off, and turn-off delay.

Pulse 1 - The LED is configured to “Pulse” (transition ON-OFF-ON) a programmable number of times with programmable rate and min / max brightness. Further, the LED can be configured to be actuated upon a touch detection or release detection (or based on user written control registers).

Pulse 2 - The LED is configured to “Pulse” while actuated and then “Pulse” a programmable number of times with

programmable rate and min / max brightness when the sensor is released.

Breathe - The LED is configured to transition continuously ON-OFF-ON (i.e. to “Breathe”) with a programmable

rate and min / max brightness.

In addition to these four behaviors, all LED drivers support user initiated ramps and have an option to assert the ALERT

pin when the ramp has reached its maximum or minimum settings.

LED11 operates differently than the other LED outputs in three ways. First, it is configured to drive up to two external

LED channels simultaneously. Second, it is not disabled during the Sleep or Deep Sleep states of operation (see

Section 6.1). The third and final difference is it allows for different behaviors when the device is in Fully Active state versus when the device is in Sleep or Deep Sleep state.

5.3.1

LINKING LEDS TO CAPACITIVE TOUCH SENSORS

LEDs 1 - 7 can be optionally linked to Capacitive Touch Sensors 1-7 so that when the sensor detects a button press,

the corresponding LED will be actuated at one of the programmed responses.

LEDs 9 and 10 may be optionally linked to the Grouped Sensors to indicate a slide / tap / press and hold in the “Up” or

“Down” directions.

5.4

Capacitive Touch Sensing

The CAP1114 contains 14 independent Capacitive Touch Sensor inputs. Each sensor has dynamic range to detect a

change of capacitance due to a touch. Additionally, each sensor can be configured to be automatically and routinely recalibrated.

5.4.1

MULTIPLE BUTTON PRESSES

If multiple sensor buttons (with a programmable threshold - see Section 6.24) are simultaneously detected, only the first

N buttons that are detected are flagged. All other buttons are ignored. Furthermore, the device remembers which buttons were legitimate so new touches are not detected so long as N buttons are pressed.

Likewise, if too many (based on the programmed threshold - see Section 6.24) grouped sensor presses are detected,

the device will block all press detections on the grouped buttons and cancel any current presses as if the sensor had

been released.

5.4.2

LID CLOSURE

To detect lid closure or other similar events, lid closure sensor thresholds can be set. A Lid Closure Event can be flagged

based on either a minimum number of sensors or on specific sensors simultaneously exceeding the lid closure threshold. An interrupt can also be generated. During a Lid Closure Event, all touches are blocked.

5.4.3

GROUPED SENSORS (CS8 - CS14)

Capacitive Touch Sensors 8 through 14 inclusive may be grouped as a single entity (which is the default state). Each

sensor is sampled independently; however, for purposes of activation, recalibration, and repeat rates, all of them are

treated as one group. The Group also has different controls and allows for different behavior such as sliding, tapping,

or press and hold.

The grouped sensors may be ungrouped as described in Section 5.6.

DS00002444A-page 18

2009-2017 Microchip Technology Inc.

�CAP1114

5.4.4

SENSING CYCLE

Each Capacitive Touch Sensor has controls to be activated and included in the sensing cycle. When the device is active,

it automatically initiates a sensing cycle and repeats the cycle every time it finishes. The cycle polls through each active

Sensor starting with CS1 and extending through CS14. As each Capacitive Touch Sensor is polled, its measurement is

compared against a baseline “not touched” measurement. If the delta measurement is large enough, a touch is detected

and an interrupt generated.

5.4.5

PROXIMITY DETECTION

Sensor CS1 can be configured to detect changes in capacitance due to proximity of a touch. This circuitry detects the

change of capacitance that is generated as an object approaches, but does not physically touch, the CS1 sensor. When

proximity detection is enabled, the signal is boosted by 8x to detect very small capacitance changes. Separate controls

determine averaging and sensitivity for proximity (see Section 6.36, "Proximity Control Register").

5.4.6

RECALIBRATING SENSORS

Each sensor is regularly recalibrated at an adjustable rate. By default, the recalibration routine stores the average 256

previous measurements and periodically updates the base “Not Touched” setting for the Capacitive Touch Sensor input.

This routine is disabled automatically if a touch is detected so the touch does not factor into the base “Not Touched”

setting.

5.4.7

LOW FREQUENCY NOISE DETECTION

Each sensor has a noise detector that will sense if low frequency noise is injected onto the input with sufficient power

to corrupt the readings. This noise detector has a fixed threshold above and below the rail that will trigger when noise

is present. If low frequency noise is detected on a CS line, that sample is removed and not compared against the threshold.

5.4.8

RF NOISE DETECTION

Each sensor also contains an integrated RF noise detector. This block will detect injected RF noise on the CS pin. The

detector threshold is dependent upon the noise frequency. If RF noise is detected on a CS line, that sample is removed

and not compared against the threshold.

5.5

Grouped Sensor Behavior

The CAP1114 Grouped sensors (CS8 - CS14) can be configured to function as a single entity that operates differently

than the individual button sensors (for ungrouped behavior see Section 5.6). When configured as a group these sensors

function as a slider and offer three different interface functions associated with it. These functions are Tap, Press and

Hold, or a Slide.

For purposes of a Tap or Press and Hold event, the “DOWN” side of the Grouped sensors are defined as CS8, CS9 and

CS10. The “UP” side of the Grouped Sensors are defined as CS12, CS13, and CS14. CS11 is neither “UP” nor “DOWN”

and a tap or press and hold event on CS11 will not cause either UP or DOWN status bits to be set.

For purposes of a slide, the “DOWN” direction is decreasing in CS channel number. Conversely, the “UP” direction is

increasing in CS number.

APPLICATION NOTE: The Grouped Sensors will cause either the UP or DOWN status bits to be set but not both

at the same time. In the case that a sensor on both the “UP” side of the slider and the

“DOWN” side of the slider are touched simultaneously, neither the UP nor DOWN status bits

will be set.

5.5.1

TAP

If a touch on any Grouped sensor is detected and held for less than or equal to the M_PRESS bit settings (default

245ms), a group press is detected, the TAP bit is set, and an interrupt is generated. Furthermore, the relative position

on the slider is determined and the appropriate UP or DOWN status bits are set and the appropriate LED is actuated.

No further action is taken. If a slide is subsequently detected, the TAP status bit is cleared.

2009-2017 Microchip Technology Inc.

DS00002444A-page 19

�CAP1114

5.5.2

PRESS AND HOLD

If a touch on any Grouped sensor is held for longer than the M_PRESS bit settings (default 245ms), a Group Touch is

detected and an interrupt is generated. Furthermore, the relative position on the slider is determined and the appropriate

UP or DOWN status bits are set, the PH bit is set, and the appropriate LED is actuated.

So long as the Grouped sensor is held, it will flag an interrupt at the programmed repeat rate (as determined by the

RPT_RATE_PH bit settings) indefinitely. Once the touch has been removed, the Group is returned to its normal operating condition.

The M_PRESS setting is important to distinguish between Tap, Press & Hold and Sliding. If M_PRESS is set too low, a

Press & Hold may be detected during a slow slide. This will cause user confusion as the Slide direction and LED may

change. Longer M_PRESS settings will ensure that the 3 Group behaviors are reliably distinct and will add more delay

prior to the Press & Hold repeat interrupt generation.

5.5.3

SLIDER

The Grouped sensors have the capability to detect a slide in either the “UP” or “DOWN” direction as referenced by the

sensor numbers that are used. For example, an “Up” direction slide would be detected if CS8 detected a touch, followed

by CS9, then by CS10, etc. Likewise, a “Down” direction slide would be detected if CS10 detected a touch, followed by

CS9, then by CS8, etc.

Slides in either direction are configured to flag an interrupt and to cause an LED to be actuated (separate for each direction). The Slide is detected independently of a Press and Hold or a Tap condition and only one condition may be present

at any one time.

So long as a slide is maintained in either direction, it will flag an interrupt at the programmed repeat rate (as determined

by the RPT_RATE_SL bit settings). If the slide is removed or changes direction, it will reset and return to normal operation.

5.5.4

RELATIVE POSITION

The CAP1114 has the option to indicate the relative position of a touch on the Grouped sensors. This value is stored

either as a scaled number from 2 to 98 indicating where a tap, press and hold, or the end of a slide was detected or as

a 8-bit number that represents volumetric data. When configured to store volumetric data, the user may write a base

setting at any time that is modified based on Grouped sensor behavior (see Section 6.4).

5.5.5

SLIDER VELOCITY

The repeat rate can be dynamically increased based on the speed of a slide. This permits slow sliding motions to have

precise, step-by-step volume control and faster motions to generate increasingly fast volume changes.

Two techniques are employed to increase the number of interrupts generated based on speed. First, the slide speed is

measured and the repeat rate is increased to provide more interrupts for the same distance traveled relative to a slower

slide. Second, additional interrupts are generated immediately after the slide ends to further increase the change in volume. The number of additional interrupts is based on slide speed; both of these dynamic slider behaviors are controlled

by the Slider Velocity Register.

5.6

Ungrouped Sensor Behavior

The CAP1114 Grouped sensors have the option to be used as individual buttons. When the group is broken (via the

VOL_UP_DOWN bit - see Section 6.34), buttons CS8 and CS14 will adopt one type of behavior while buttons CS9 CS13 will adopt another. In all cases, a slide will not be detected.

5.6.1

CS9 - CS13 UNGROUPED BEHAVIOR

These buttons will cause the corresponding status bit in the Button Status 2 register (see Section 6.2) to be asserted

when a touch is detected. This touch detection uses the button queue and button repeat rate settings. They will use the

slider maximum duration and multiple touch settings.

5.6.2

CS8 AND CS14 UNGROUPED BEHAVIOR

CS8 and CS14 will generate interrupts based on the duration of the touch detected, similar to a Tap and Press and Hold

events. Furthermore, these sensors will generate interrupts at the Grouped Sensors repeat rate based on whether a

Tap or Press and Hold event has been detected.

If a touch is detected on CS8, the DOWN status bit will be set in addition to either TAP or PH.

DS00002444A-page 20

2009-2017 Microchip Technology Inc.

�CAP1114

If a touch is detected on CS14, the UP status bit will be set in addition to either TAP or PH.

Based on the multiple button touch settings (see Section 6.24), both CS8 and CS14 may detect a touch simultaneously

and both UP and DOWN status bits may be set.

5.7

ALERT Pin

The ALERT pin is an active high output that is driven high when an interrupt event is detected. It is also used to wake

the device from Deep Sleep state.

Whenever an interrupt is generated, the INT bit (see Section 6.1) is set. The ALERT pin is cleared when INT bit is

cleared by the user. Additionally, when the INT bit is cleared by the user, status bits are cleared only if no press is

detected.

5.7.1

BUTTON INTERRUPT BEHAVIOR

For non-grouped buttons, an interrupt is generated when a touch is detected. If the repeat rate is enabled (see

Section 6.14), then, so long as the touch is held, another interrupt will be generated based on the programmed repeat

rate (see Figure 5-2) and upon release.

5.7.2

GROUPED SENSOR INTERRUPT BEHAVIOR

For grouped sensors, an interrupt is generated upon initial detection of a tap, slide, or press and hold event. Then, subsequent interrupts are generated as follows:

1.

2.

3.

For a slide event, an interrupt is generated based on the programmed repeat rate as well as the velocity of the

slide operation. See Figure 5-6 and Figure 5-7. Additional interrupts are generated after the slide has finished.

These extra interrupts are generated every round robin cycle (~35ms) and the number is determined by the

speed of the slide.

For a tap event there are no further interrupts. See Figure 5-4.

For a press and hold event, interrupts are generated based on the programmed repeat rate. If the repeat rate is

disabled, no further interrupts are generated. See Figure 5-5.

5.7.3

WAKE FROM DEEP SLEEP

When the ALERT pin is driven high from an external source, it is also used to wake the device from the Deep Sleep

power state. When the device enters the Deep Sleep power state, the ALERT pin output is put into a high-Z mode. It

requires a pull-down resistor to pull it to the inactive state. Furthermore, the CAP1114 will wait 5ms before it samples

the ALERT pin for wake activity.

FIGURE 5-2:

Interrupt on

Touch

Touch Detected

BUTTON INTERRUPT BEHAVIOR - REPEAT RATE ENABLED (DEFAULT)

Polling Cycle

(35ms)

Button Repeat Rate

(175ms)

ALERT Pin /

INT bit

Button Repeat Rate

(175ms)

Button Repeat Rate

(175ms)

Optional

Interrupt on

Release

Button Status

SMBus Write to

INT bit

2009-2017 Microchip Technology Inc.

DS00002444A-page 21

�CAP1114

.

FIGURE 5-3:

BUTTON INTERRUPT BEHAVIOR - NO REPEAT RATE ENABLED

Interrupt on

Touch

Polling Cycle

(35ms)

Optional

Interrupt on

Release

Touch Detected

ALERT Pin /

INT bit

Button Status

SMBus Write to

INT bit

FIGURE 5-4:

TAP INTERRUPT BEHAVIOR

Polling Cycle

(35ms)

Released before

M_PRESS

Touch Detected

ALERT Pin /

INT bit

M_PRESS

Setting (280ms)

Tap & UP / DOWN

Status

SMBus Write to

INT bit

DS00002444A-page 22

2009-2017 Microchip Technology Inc.

�CAP1114

FIGURE 5-5:

PRESS AND HOLD INTERRUPT BEHAVIOR

Polling Cycle

(35ms)

Touch Detected

ALERT Pin /

INT bit

Held longer than

M_PRESS Setting

Repeat Rate

Repeat Rate

(RPT_RATE_PH - 175ms) (RPT_RATE_PH - 175ms)

M_PRESS

Setting (280ms)

PH Status

UP / DOWN Status

SMBus Write to

INT bit

2009-2017 Microchip Technology Inc.

DS00002444A-page 23

�CAP1114

FIGURE 5-6:

SLIDE INTERRUPT BEHAVIOR - NO ACCELERATION

Polling Cycle

(35ms)

Touch Detected –

CS14

Touch Detected –

CS13

Touch Detected CS12

UP

DOWN

Touch Detected CS11

Touch Detected –

CS10

Touch Detected –

CS9

Touch Detected –

CS8

Repeat Rate

(175ms)

Repeat Rate

(175ms)

ALERT Pin /

INT bit

DOWN Status

UP Status

SMBus Write to

INT bit

DS00002444A-page 24

2009-2017 Microchip Technology Inc.

�CAP1114

FIGURE 5-7:

SLIDE INTERRUPT BEHAVIOR - ACCELERATION EXAMPLE

Polling Cycle

(35ms)

Maximum Slide (768ms)

Touch Detected –

CS14

Touch Detected –

CS13

Touch Detected CS12

Normal Slide – no change

in repeat rate

Touch Detected CS11

Minor Acceleration Repeat Rate reduced

70ms

Touch Detected –

CS10

Touch Detected –

CS9

Slide Ended (525ms) = 0.68 x

Max – Generate 2 extra

interrupts at 35ms apart

Major Acceleration Repeat Rate reduced

35ms

Touch Detected –

CS8

Repeat Rate (base

= 140ms)

140ms

70ms

35ms

ALERT Pin /

INT bit

SMBus Write to

INT bit

2009-2017 Microchip Technology Inc.

DS00002444A-page 25

�CAP1114

6.0

REGISTER DESCRIPTION

The registers shown in Table 6-1 are accessible through the SMBus. An entry of ‘-’ indicates that the bit is not used and

will always read ‘0’.

TABLE 6-1:

REGISTER SET IN HEXADECIMAL ORDER

Register

Address

R/W

Register Name

Function

Default

Value

Page

00h

R/W

Main Status Control

Controls general power states

00h

Page 31

00h

Page 32

03h

R

Button Status 1

Returns the state of the Cap

Sensor group and buttons 1 - 6

and slider controls

04h

R

Button Status 2

Returns the state of buttons 7 - 14

00h

Page 32

10h

Page 33

05h

R

Build Revision

Stores the functional revision of

the device build

06h

R-C / R/W

Slider Position /

Volumetric Data

Returns the relative position of a

press on the slider or volumetric

data

00h

Page 33

08h

R

Vendor ID

Stores a fixed value that identifies

Microchip

5Dh

Page 34

09h

R/W

Volumetric Step

Controls the step used for

volumetric data increases for a

slide

01h

Page 35

0Ah

R

Noise Status 1

Stores the noise flags for sensors

1-7

00h

Page 35

0Bh

R

Noise Status 2

Stores the noise flags for sensors

8 - 14

00h

Page 35

0Ch

R

Lid Closure Status 1

Stores lid closure status bits for

sensors 1 - 7

00h

Page 35

0Dh

R

Lid Closure Status 2

Stores lid closure status bits for

sensors 8 - 14

00h

Page 35

0Eh

R-C

GPIO Status

Stores the status of LED1 / GPIO1

through LED8 / GPIO8 pins

00h

Page 36

0Fh

R-C

Group Status

Returns the state of the Grouped

sensors

00h

Page 36

10h

R

Sensor 1 Delta Count

Stores the delta count for CS1

00h

Page 37

11h

R

Sensor 2 Delta Count

Stores the delta count for CS2

00h

Page 37

12h

R

Sensor 3 Delta Count

Stores the delta count for CS3

00h

Page 37

13h

R

Sensor 4 Delta Count

Stores the delta count for CS4

00h

Page 37

14h

R

Sensor 5 Delta Count

Stores the delta count for CS5

00h

Page 37

15h

R

Sensor 6 Delta Count

Stores the delta count for CS6

00h

Page 37

16h

R

Sensor 7 Delta Count

Stores the delta count for CS7

00h

Page 37

17h

R

Sensor 8 Delta Count

Stores the delta count for CS8

00h

Page 37

18h

R

Sensor 9 Delta Count

Stores the delta count for CS9

00h

Page 37

19h

R

Sensor 10 Delta

Count

Stores the delta count for CS10

00h

Page 37

1Ah

R

Sensor 11 Delta

Count

Stores the delta count for CS11

00h

Page 37

1Bh

R

Sensor 12 Delta

Count

Stores the delta count for CS12

00h

Page 37

1Ch

R

Sensor 13 Delta

Count

Stores the delta count for CS13

00h

Page 37

DS00002444A-page 26

2009-2017 Microchip Technology Inc.

�CAP1114

TABLE 6-1:

REGISTER SET IN HEXADECIMAL ORDER (CONTINUED)

Register

Address

R/W

Register Name

Function

Default

Value

Page

1Dh

R

Sensor 14 Delta

Count

Stores the delta count for CS14

00h

Page 37

1Eh

R/W

Queue Control

Controls how many samples must

exceed touch threshold for button

press detections

03h

Page 37

1Fh

R/W

Data Sensitivity

Controls the sensitivity of the

threshold and delta counts and

data scaling of the base counts

2Fh

Page 38

20h

R/W

Configuration

Controls some recalibration and

LED controls

29h

Page 39

21h

R/W

Sensor Enable

Controls whether the Capacitive

Touch Sensor group and button

inputs 1 - 7 are sampled

FFh

Page 40

22h

R/W

Button Configuration

Controls reset delay and autorepeat delay for buttons

A4h

Page 41

23h

R/W

Controls the detection dwell time

Group Configuration 1 before a press is detected within

the group

47h

Page 42

24h

R/W

Group Configuration 2

Controls reset delay and autorepeat delay for grouped sensors

D4h

Page 43

25h

R/W

Calibration Enable

Controls automatic calibration for

grouped sensors and sensors 1 7

FFh

Page 43

26h

R/W

Calibration Activate

Activates manual re-calibration for

grouped sensors and sensors 1 7

00h

Page 44

27h

R/W

Interrupt Enable 1

Enables Interrupts associated with

the grouped sensors and sensors

1-7

FFh

Page 45

28h

R/W

Interrupt Enable 2

Enables Interrupts associated with

GPIOs 1 - 8

00h

Page 45

29h

R/W

Sleep Channel

Control

Determines the number and which

channels are measured during

Sleep

00h

Page 46

2Ah

R/W

Multiple Press

Configuration

Determines the number of

simultaneous presses to flag a

multiple press condition

82h

Page 46

2Bh

R/W

Lid Closure

Configuration

Controls Lid Closure detection

and operation

00h

Page 47

2Ch

R/W

Lid Closure Queue

Control

Controls how many samples must

exceed the lid closure threshold

for Button and Slider operation

02h

Page 48

2Dh

R/W

Lid Closure Pattern 1

Stores pattern bits for lid closure

detection for channels 1 - 7

7Fh

Page 48

2Eh

R/W

Lid Closure Pattern 2

Stores pattern bits for lid closure

detection for channels 8 - 14

7Fh

Page 48

2Fh

R/W

Recalibration

Configuration

Determines re-calibration timing

and sampling window

93h

Page 48

30h

R/W

Sensor 1 Threshold

Stores the delta count threshold to

determine a touch for Capacitive

Touch Sensor 1

40h

Page 49

2009-2017 Microchip Technology Inc.

DS00002444A-page 27

�CAP1114

TABLE 6-1:

REGISTER SET IN HEXADECIMAL ORDER (CONTINUED)

Register

Address

R/W

Register Name

Function

Default

Value

Page

31h

R/W

Sensor 2 Threshold

Stores the delta count threshold to

determine a touch for Capacitive

Touch Sensor 2

40h

Page 49

32h

R/W

Sensor 3 Threshold

Stores the delta count threshold to

determine a touch for Capacitive

Touch Sensor 3

40h

Page 49

33h

R/W

Sensor 4 Threshold

Stores the delta count threshold to

determine a touch for Capacitive

Touch Sensor 4

40h

Page 49

34h

R/W

Sensor 5 Threshold

Stores the delta count threshold to

determine a touch for Capacitive

Touch Sensor 5

40h

Page 49

35h

R/W

Sensor 6 Threshold

Stores the delta count threshold to

determine a touch for Capacitive

Touch Sensor 6

40h

Page 49

36h

R/W

Sensor 7 Threshold

Stores the delta count threshold to

determine a touch for Capacitive

Touch Sensor 7

40h

Page 49

37h

R/W

Group Threshold

Stores the delta count threshold to

determine a touch on any of the

Grouped Sensors

40h

Page 49

38h

R/W

Button Noise

Threshold 1

Stores controls for selecting the

noise threshold for buttons 1 - 4

AAh

Page 50

39h

R/W

Button Noise

Threshold 2

Stores controls for selecting the

noise threshold for buttons 5 - 7

and the Grouped sensors

AAh

Page 50

3Ah

R/W

Lid Closure Threshold Stores controls for selecting the lid

1

closure threshold for buttons 1 - 4

AAh

Page 51

3Bh

R/W

Lid Closure Threshold Stores controls for selecting the lid

2

closure threshold for buttons 5 - 8

AAh

Page 51

3Ch

R/W

Lid Closure Threshold

3

Stores controls for selecting the lid

closure threshold for buttons 9 12

AAh

Page 51

3Dh

R/W

Lid Closure Threshold

4

Stores controls for selecting the lid

closure threshold for buttons 13 14

0Ah

Page 51

3Eh

R/W

Slider Velocity

Configuration

Determines speed parameters for

the slider

C5h

Page 52

3Fh

R/W

Digital Recalibration

Forces digital recalibration for all

sensors

00h

Page 53

40h

R/W

Configuration 2

Stores additional controls for

general operation

00h

Page 54

41h

R/W

Grouped Channel

Sensor Enable

Stores controls to enable some or

all sensors in the group

7Fh

Page 55

42h

R/W

Proximity Control

Controls the sensitivity settings for

CS1

02h

Page 55

46h

R/W

Grouped Sensor

Calibration Activate

Stores controls to force a

calibration on the individual

sensors in the Group

00h

Page 44

4Eh

R/W

Sampling Channel

Select

Controls which channels are

affected by the Sampling

Configuration Register settings

00h

Page 56

DS00002444A-page 28

2009-2017 Microchip Technology Inc.

�CAP1114

TABLE 6-1:

REGISTER SET IN HEXADECIMAL ORDER (CONTINUED)

Register

Address

R/W

Register Name

Function

Default

Value

Page

4Fh

R/W

Sampling

Configuration

Changes the sampling time for

one or more input channels

00h

Page 56

50h

R

Sensor 1 Base Count

Stores the reference count value

for sensor 1

00h

Page 57

51h

R

Sensor 2 Base Count

Stores the reference count value

for sensor 2

00h

Page 57

52h

R

Sensor 3 Base Count

Stores the reference count value

for sensor 3

00h

Page 57

53h

R

Sensor 4 Base Count

Stores the reference count value

for sensor 4

00h

Page 57

54h

R

Sensor 5 Base Count

Stores the reference count value

for sensor 5

00h

Page 57

55h

R

Sensor 6 Base Count

Stores the reference count value

for sensor 6

00h

Page 57

56h

R

Sensor 7 Base Count

Stores the reference count value

for sensor 7

00h

Page 57

57h

R

Sensor 8 Base Count

Stores the reference count value

for sensor 8

00h

Page 57

58h

R

Sensor 9 Base Count

Stores the reference count value

for sensor 9

00h

Page 57

59h

R

Sensor 10 Base

Count

Stores the reference count value

for sensor 10

00h

Page 57

5Ah

R

Sensor 11 Base

Count

Stores the reference count value

for sensor 11

00h

Page 57

5Bh

R

Sensor 12 Base

Count

Stores the reference count value

for sensor 12

00h

Page 57

5Ch

R

Sensor 13 Base

Count

Stores the reference count value

for sensor 13

00h

Page 57

5Dh

R

Sensor 14 Base

Count

Stores the reference count value

for sensor 14

00h

Page 57

60h

R

LED Status 1

Stores status bits for LEDs 1 - 8

00h

Page 58

61h

R

LED Status 2

Stores status bits for LEDs 9 - 11

00h

Page 58

00h

Page 58

70h

R/W

LED / GPIO Direction

Controls the direction for LED1/

GPIO1 through LED8 / GPIO8

71h

R/W

LED / GPIO Output

Type

Controls the output type for LED1

/ GPIO1 through LED8 / GPIO8

00h

Page 59

72h

R

GPIO Input

Stores the pin state of LED1 /

GPIO1 through LED8 / GPIO8

00h

Page 59

73h

R/W

LED Output Control 1

Controls the output state of the

LED drivers 1 - 8

00h

Page 60

74h

R/W

LED Output Control 2

Controls the output state of the

LED drivers 9 - 11

00h

Page 60

75h

R/W

LED Polarity 1

Controls the output polarity of

LEDs 1 - 8

00h

Page 60

76h

R/W

LED Polarity 2

Controls the output polarity of

LEDs 9 - 11

00h

Page 60

77h

R/W

Linked LED

Transition Control 1

Controls transition effects of

LEDS 1 - 7 when linked

00h

Page 62

78h

R/W

Linked LED Transition

Control 2

Controls transition effects of

LEDS 9 - 10 when linked

00h

Page 62

2009-2017 Microchip Technology Inc.

DS00002444A-page 29

�CAP1114

TABLE 6-1:

REGISTER SET IN HEXADECIMAL ORDER (CONTINUED)

Register

Address

R/W

Register Name

Function

Default

Value

Page

79h

R/W

LED Mirror Control 1

Controls the duty cycle mirroring

of LEDs 1 - 8

00h

Page 63

7Ah

R/W

LED Mirror Control 2

Controls the duty cycle mirroring

of LEDs 9 - 11

00h

Page 63

80h

R/W

Sensor LED Linking

Controls linking of CS1 - CS7 to

LED channels

00h

Page 64

81h

R/W

LED Behavior 1

Controls the behavior and

response of LEDs 1 - 4

00h

Page 64

82h

R/W

LED Behavior 2

Controls the behavior and

response of LEDs 5 - 8

00h

Page 64

83h

R/W

LED Behavior 3

Controls the behavior and

response of LEDs 9 - 11

00h

Page 64

84h

R/W

LED Pulse 1 Period

Controls the period of each

breathe during a pulse

20h

Page 66

85h

R/W

LED Pulse 2 Period

Controls the period of breath and

pulse release operation

14h

Page 68

86h

R/W

LED Breathe Period

Controls the period of an LED

breathe operation

5Dh

Page 69

88h

R/W

LED Configuration

Controls the number of pulses for

the Pulse 1 and Pulse 2 LED

behaviors

24h

Page 69

90h

R/W

LED Pulse 1 Duty

Cycle

Determines the min and max duty

cycle for the pulse operation

F0h

Page 69

91h

R/W

LED Pulse 2 Duty

Cycle

Determines the min and max duty

cycle for the breathe and pulse

release operation

F0h

Page 69

92h

R/W

LED Breathe Duty

Cycle

Determines the min and max duty

cycle for the breathe operation

F0h

Page 69

93h

R/W

LED Direct Duty

Cycle

Determines the min and max duty

cycle for Direct mode LED

operation

F0h

Page 69

94h

R/W

LED Direct Ramp

Rates

Determines the rising and falling

edge ramp rates of the LED

00h

Page 70

95h

R/W

LED Off Delay

Determines the off delay for all

LED behaviors

00h

Page 71

B1h

R

Sensor 1 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 1

00h

Page 72

B2h

R

Sensor 2 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 2

00h

Page 72

B3h

R

Sensor 3 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 3

00h

Page 72

B4h

R

Sensor 4 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 4

00h

Page 72

B5h

R

Sensor 5 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 5

00h

Page 72

DS00002444A-page 30

2009-2017 Microchip Technology Inc.

�CAP1114

TABLE 6-1:

REGISTER SET IN HEXADECIMAL ORDER (CONTINUED)

Register

Address

R/W

Register Name

Function

Default

Value

Page

B6h

R

Sensor 6 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 6

00h

Page 72

B7h

R

Sensor 7 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 7

00h

Page 72

B8h

R

Sensor 8 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 8

00h

Page 72

B9h

R

Sensor 9 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 9

00h

Page 72

BAh

R

Sensor 10 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 10

00h

Page 72

BBh

R

Sensor 11 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 11

00h

Page 72

BCh

R

Sensor 12 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 12

00h

Page 72

BDh

R

Sensor 13 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 13

00h

Page 72

BEh

R

Sensor 14 Calibration

Stores the high byte of the 10-bit

value used to drive the analog

portion of sensor 14

00h

Page 72

FDh

R

Product ID

Stores a fixed value that identifies

each product

3Ah

Page 73

FEh

R

Manufacturer ID

Stores a fixed value that identifies

Microchip

5Dh

Page 34