dsPIC33EP128GS808

Development Board

User’s Guide

2017 Microchip Technology Inc.

DS50002632A

�Note the following details of the code protection feature on Microchip devices:

•

Microchip products meet the specification contained in their particular Microchip Data Sheet.

•

Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

•

There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

•

Microchip is willing to work with the customer who is concerned about the integrity of their code.

•

Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC® MCUs and dsPIC® DSCs, KEELOQ® code hopping

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

QUALITY MANAGEMENT SYSTEM

CERTIFIED BY DNV

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, AVR Freaks, BeaconThings, BitCloud, CryptoMemory,

CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo, JukeBlox, KEELOQ,

KEELOQ logo, Kleer, LANCheck, LINK MD, maXStylus,

maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip

Designer, QTouch, RightTouch, SAM-BA, SpyNIC, SST, SST

Logo, SuperFlash, tinyAVR, UNI/O, and XMEGA are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMOS,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, chipKIT, chipKIT logo,

CodeGuard, CryptoAuthentication, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, Inter-Chip Connectivity, JitterBlocker,

KleerNet, KleerNet logo, Mindi, MiWi, motorBench, MPASM, MPF,

MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach,

Omniscient Code Generation, PICDEM, PICDEM.net, PICkit,

PICtail, PureSilicon, QMatrix, RightTouch logo, REAL ICE, Ripple

Blocker, SAM-ICE, Serial Quad I/O, SMART-I.S., SQI,

SuperSwitcher, SuperSwitcher II, Total Endurance, TSHARC,

USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and

ZENA are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip Technology

Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2017, Microchip Technology Incorporated, All Rights Reserved.

ISBN: 978-1-5224-1406-3

== ISO/TS 16949 ==

DS50002632A-page 2

2017 Microchip Technology Inc.

�Object of Declaration: dsPIC33EP128GS808 Development Board

EU Declaration of Conformity

This declaration of conformity is issued by the manufacturer.

The development/evaluation tool is designed to be used for research and development in a laboratory environment. This

development/evaluation tool is not a Finished Appliance, nor is it intended for incorporation into Finished Appliances that are made

commercially available as single functional units to end users under EU EMC Directive 2004/108/EC and as supported by the European

Commission's Guide for the EMC Directive 2004/108/EC (8th February 2010).

This development/evaluation tool complies with EU RoHS2 Directive 2011/65/EU.

This development/evaluation tool, when incorporating wireless and radio-telecom functionality, is in compliance with the essential

requirement and other relevant provisions of the R&TTE Directive 1999/5/EC and the FCC rules as stated in the declaration of conformity

provided in the module datasheet and the module product page available at www.microchip.com.

For information regarding the exclusive, limited warranties applicable to Microchip products, please see Microchip’s standard terms and

conditions of sale, which are printed on our sales documentation and available at www.microchip.com.

Signed for and on behalf of Microchip Technology Inc. at Chandler, Arizona, USA.

2017 Microchip Technology Inc.

DS50002632A-page 3

�dsPIC33EP128GS808 Development Board User’s Guide

NOTES:

DS50002632A-page 4

2017 Microchip Technology Inc.

�dsPIC33EP128GS808 DEVELOPMENT

BOARD USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 7

Introduction............................................................................................................ 7

Document Layout .................................................................................................. 7

Conventions Used in this Guide ............................................................................ 8

Recommended Reading........................................................................................ 9

The Microchip Web Site ........................................................................................ 9

Product Change Notification Service..................................................................... 9

Customer Support ................................................................................................. 9

Document Revision History ................................................................................... 9

Chapter 1. Product Overview

1.1 Introduction ................................................................................................... 11

1.2 Overview ...................................................................................................... 11

1.3 Development Board Functionality and Features .......................................... 12

1.4 Electrical Specifications ................................................................................ 12

Chapter 2. Hardware

2.1 Top Assembly ............................................................................................... 13

2.2 Signal Configuration ..................................................................................... 15

2.3 Application Components .............................................................................. 17

2.4 Board Connectors ........................................................................................ 17

2.5 Indicators and Human Interfaces ................................................................. 18

2.6 Test Points ................................................................................................... 19

2.7 Programmer/Debugger ................................................................................. 20

Chapter 3. Demonstration Program Operation

3.1 Hardware Description ................................................................................... 21

3.2 Program Demonstration ............................................................................... 25

3.3 Code Demonstration .................................................................................... 28

3.4 Other Code Examples .................................................................................. 30

Appendix A. Board Layout and Schematics.............................................................. 31

Worldwide Sales and Service .................................................................................... 36

2017 Microchip Technology Inc.

DS50002632A-page 5

�dsPIC33EP128GS808 Development Board User’s Guide

NOTES:

DS50002632A-page 6

2017 Microchip Technology Inc.

�dsPIC33EP128GS808 DEVELOPMENT

BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB® IDE online help.

Select the Help menu, and then Topics, to open a list of available online help files.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

dsPIC33EP128GS808 Development Board. Items discussed in this chapter include:

•

•

•

•

•

•

Document Layout

Conventions Used in this Guide

Recommended Reading

The Microchip Web Site

Customer Support

Document Revision History

DOCUMENT LAYOUT

This document describes how to use the dsPIC33EP128GS808 Development Board

as a development tool to emulate and debug firmware on a target board. The manual

layout is as follows:

• Product Overview – This chapter introduces the dsPIC33EP128GS808

Development Board and provides an overview of its features.

• Hardware – This chapter describes the hardware components of the

dsPIC33EP128GS808 Development Board.

• Demonstration Program Operation – This chapter includes a program

demonstration, code demonstration and code examples for the

dsPIC33EP128GS808 Development Board.

• Appendix A – Shows the schematics and board layouts for the

dsPIC33EP128GS808 Development Board.

2017 Microchip Technology Inc.

DS50002632A-page 7

�dsPIC33EP128GS808 Development Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description

Represents

Examples

Arial font:

MPLAB® IDE User’s Guide

Italic characters

Referenced books

Emphasized text

...is the only compiler...

Initial caps

A window

the Output window

A dialog

the Settings dialog

A menu selection

select Enable Programmer

Quotes

A field name in a window or

dialog

“Save project before build”

Underlined, italic text with

right angle bracket

A menu path

File>Save

Bold characters

A dialog button

Click OK

A tab

Click the Power tab

N‘Rnnnn

A number in verilog format,

4‘b0010, 2‘hF1

where N is the total number of

digits, R is the radix and n is a

digit.

Text in angle brackets < >

A key on the keyboard

Press ,

Sample source code

#define START

Filenames

autoexec.bat

File paths

c:\mcc18\h

Keywords

_asm, _endasm, static

Command-line options

-Opa+, -Opa-

Bit values

0, 1

Constants

0xFF, ‘A’

Italic Courier New

A variable argument

file.o, where file can be

any valid filename

Square brackets [ ]

Optional arguments

mcc18 [options] file

[options]

Curly brackets and pipe

character: { | }

Choice of mutually exclusive

arguments; an OR selection

errorlevel {0|1}

Ellipses...

Replaces repeated text

var_name [,

var_name...]

Represents code supplied by

user

void main (void)

{ ...

}

Courier New font:

Plain Courier New

DS50002632A-page 8

2017 Microchip Technology Inc.

�Preface

RECOMMENDED READING

This quick start guide describes how to use the dsPIC33EP128GS808 Development

Board. Other useful documents are listed below. The following Microchip document is

available and recommended as a supplemental reference resource:

• “dsPIC33EPXXXGS70X/80X Family Data Sheet” (DS70005258)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This

web site is used as a means to make files and information easily available to

customers. Accessible by using your favorite Internet browser, the web site contains

the following information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

PRODUCT CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notifications whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Product

Change Notification and follow the registration instructions.

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

•

•

•

•

Distributor or Representative

Local Sales Office

Embedded Solutions Engineer (ESE)

Technical Support

Customers should contact their distributor, representative or Embedded Solutions

Engineer (ESE) for support. Local sales offices are also available to help customers.

A listing of sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (June 2017)

• Initial Release of this Document.

2017 Microchip Technology Inc.

DS50002632A-page 9

�dsPIC33EP128GS808 Development Board User’s Guide

NOTES:

DS50002632A-page 10

2017 Microchip Technology Inc.

�dsPIC33EP128GS808 DEVELOPMENT

BOARD USER’S GUIDE

Chapter 1. Product Overview

1.1

INTRODUCTION

This chapter introduces the dsPIC33EP128GS808 Development Board and provides

an overview of its features. The topics covered include:

• Overview

• Development Board Functionality and Features

• Electrical Specifications

1.2

OVERVIEW

The dsPIC33EP128GS808 Development Board (referred to as development board) is

designed to aid in the evaluation and development of firmware for the dsPIC33EP ‘GS’

family of Digital Signal Controllers (DSCs). There are 3 primary objectives for

development of this board:

• Evaluation of peripherals and core features of the GS family

• Support for dual CAN solutions with the “CAN/LIN/J2602 PICtail™ (Plus)

Daughter Board User’s Guide” (DS70319)

• Demonstration of emulated power supply transient response

The development board can be used as a stand-alone platform for evaluating DSC core

features, such as throughput and device peripherals, which include ADC, PWM, PGA,

CMP, SPI, I2C, etc. Table 2-3 provides a comprehensive list of I/O signals available for

evaluation. Note that the remappable I/Os provide additional flexibility to access

additional signals on the I/O pins. Refer to the “dsPIC33EPXXXGS70X/80X Family

Data Sheet” (DS70005258) for further details.

The development board provides support for development of dual CAN applications,

along with the CAN/LIN/J2602 PICtail (Plus) Daughter Board. The CAN/LIN/J2602

PICtail (Plus) Daughter Board consists of 2 sets of CAN drivers and 2 sets of LIN

drivers. The development board plugs into the PICtail board and allows

development of CAN or LIN communication.

The development board contains multiple first-order RC filters to emulate power supply

functionality. The board can be operated in Open or Closed-Loop mode. Furthermore,

there is additional hardware on the board to simulate power supply transient behavior.

The board can be powered with a standard 9V adapter or through the mini-USB. The

board can be programmed with standard Microchip programming tools via an RJ25

connector and contains LEDs, switch, selectable jumpers for maximizing peripheral

interconnectivity, potentiometers and analog feedback networks, all of which help to

facilitate development of firmware on the dsPIC33EP ‘GS’ devices.

2017 Microchip Technology Inc.

DS50002632A-page 11

�dsPIC33EP128GS808 Development Board User’s Guide

1.3

DEVELOPMENT BOARD FUNCTIONALITY AND FEATURES

The dsPIC33EP128GS808 Development Board allows users to evaluate the features

of dsPIC33EP ‘GS’ series devices. The dsPIC33EP ‘GS’ devices offer new peripherals

and features that can be explored using the development board. Configurable connectors make it easy to connect different peripherals together to test features that would

otherwise require additional hardware. The development board can also be used to

develop dual CAN communication systems when used along with the CAN/LIN/J2602

PICtail (Plus) Daughter Board.

The development board provides the following features:

• Dual CAN/LIN Interface:

- Used as an add-on board to the CAN/LIN/J2602 PICtail (Plus)

Daughter Board

- Interfaces with CAN and LIN drivers on the CAN/LIN/J2602 PICtail (Plus)

Daughter Board

- Provides power to CAN and LIN drivers on the CAN/LIN/J2602 PICtail (Plus)

Daughter Board

• Power Supply Simulation Using First-Order Filters:

- Separate voltage and current loop emulation

- Provision to simulate dynamic response

- Multiple first-order filters on board, selectable by jumpers

- Ramp generator circuit

- Constant-current test circuit

• General Features:

- External voltage input provision

- Debug switch and LEDs

- On-board power supply – operates from 9V input

- Optional USB power

- RJ25 connector programming interface

- PICkit™ 3 serial analyzer

1.4

ELECTRICAL SPECIFICATIONS

TABLE 1-1:

DC INPUT RATING (J1)

Parameter Minimum Typical Maximum

DS50002632A-page 12

11

Units

V

Remarks

Voltage

7.0

9

9V Adapter

Current

0.2

—

—

A

Stand-Alone Mode

—

—

0.7

A

With CAN/LIN Operating on the

PICtail™ Board

2017 Microchip Technology Inc.

�dsPIC33EP128GS808 DEVELOPMENT

BOARD USER’S GUIDE

Chapter 2. Hardware

This chapter describes the hardware components of the dsPIC33EP128GS808

Development Board. The topics covered include:

•

•

•

•

•

•

•

2.1

Top Assembly

Signal Configuration

Application Components

Board Connectors

Indicators and Human Interfaces

Test Points

Programmer/Debugger

TOP ASSEMBLY

The top and bottom assemblies of the board are shown in Figure 2-1 and Figure 2-2.

Table 2-1 and Table 2-2 provide a description of the components.

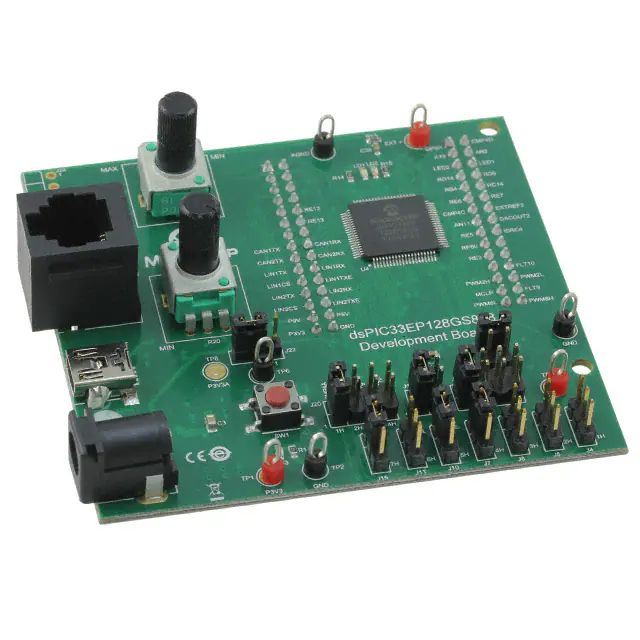

FIGURE 2-1:

2017 Microchip Technology Inc.

DEVELOPMENT BOARD COMPONENTS (TOP)

DS50002632A-page 13

�dsPIC33EP128GS808 Development Board User’s Guide

TABLE 2-1:

DEVELOPMENT BOARD COMPONENTS (TOP)

Number

Description

1

dsPIC33EP128GS808

2

Configurable Jumpers

3

Switch (SW1)

4

Diagnostic LEDs

5

Potentiometers

6

Power LED

7

9V Power Connector (J1)

8

USB Connector (J2)

9

Programming Connector

10

PICkit™ 3 Serial Analyzer (J24)

FIGURE 2-2:

TABLE 2-2:

DEVELOPMENT BOARD COMPONENTS (BOTTOM)

DEVELOPMENT BOARD COMPONENTS (BOTTOM)

Number

DS50002632A-page 14

Description

1

Voltage Regulators

2

Connector J17

3

Connector J18

4

Op Amp U3

5

Op Amp U5

6

MOSFET Q2

7

MOSFET Q1

2017 Microchip Technology Inc.

�Hardware

2.2

SIGNAL CONFIGURATION

Table 2-3 provides a full list of the dsPIC33EP ‘GS’ DSC connections and a brief

functional description of the pins used on the development board.

TABLE 2-3:

dsPIC33 PIN CONFIGURATION DETAILS

Development

Board Signal

Label

Device

Pin #

Device Pin

Function

PWM4L

1

PWM4L

PWM Output

PWM1H

2

PWM1H

PWM Output

PWM1L

3

PWM1L

PWM Output

Description

PWM8L

4

PWM8L

PWM Output

PWM8H

5

PWM8H

PWM Output

RP48

6

CAN1TX

CAN1 Transmit

RP61

7

CAN1RX

CAN1 Receive

FLT10

8

FLT10

Fault Signal, I/O

MCLR

9

MCLR

Reset Signal

FLT9

10

FLT9

Fault Signal, I/O

VSS

11

VSS

3.3V Return

VDD

12

VDD

3.3V

RE2

13

RE2

I/O

RE3

14

RE3

I/O

AVDD

15

AVDD

Filtered 3.3V

RP60

16

RP60

Reconfigurable Pin

AN0

17

AN0

Analog ADC Input

AN1

18

AN1

Analog ADC Input

AN2

19

AN2

Analog ADC Input

AN3

20

AN3

Analog ADC Input

ISRC4

21

ISRC4

RE4

22

SW1

Current Source Input

Switch Input

RE5

23

RE5

I/O

AVDD

24

AVDD

Filtered 3.3V

AVDD

25

AVDD

Filtered 3.3V

AVSS

26

AVSS

Filtered 3.3V Return

AN15

27

AN15

DACOUT2

28

DACOUT2

AN11

29

AN11

EXTREF2

30

EXTREF2

Analog ADC Input

DAC Output

Analog ADC Input

External ADC Reference Voltage

VSS

31

VSS

3.3V Return

VDD

32

VDD

3.3V

CMP4C

33

CMP4C

Comparator Input

CMP4A

34

CMP4A

Comparator Input

CMP4B

35

CMP4B

Comparator Input

AN16

36

AN16

Analog ADC Input

RE6

37

RE6

I/O

RE7

38

RE7

I/O

RP63

39

LIN1RX

2017 Microchip Technology Inc.

LIN1 Receive

DS50002632A-page 15

�dsPIC33EP128GS808 Development Board User’s Guide

TABLE 2-3:

DS50002632A-page 16

dsPIC33 PIN CONFIGURATION DETAILS (CONTINUED)

Development

Board Signal

Label

Device

Pin #

Device Pin

Function

DACOUT1

40

DACOUT1

RB4

41

RB4

I/O

RC14

42

RC14

I/O

RE8

43

GPIO1

I/O

Description

DAC Output

RE9

44

GPIO2

I/O

CMP4D

45

CMP4D

Comparator Input

RP55

46

CAN2TX

CAN2 Transmit

RP56

47

CAN2RX

CAN2 Receive

VDD

48

VDD

RD14

49

RD14

I/O

RD9

50

RD9

I/O

VSS

51

VSS

3.3V Return

RE10

52

LED2

LED Control Signal

RE11

53

LED1

LED Control Signal

RP72

54

LIN1TX

LIN1 Transmit

PGED3/SD2

55

PGED3

Programmer Interface for J3

PGEC3/SCL2

56

PGEC3

RP75

57

LIN1TXE

AN19

58

AN19

RP64

59

LIN1CS

3.3V

Programmer Interface for J3

LIN1 Transmit Enable

Analog ADC Input

LIN1 Control Signal

PGED1/SCL1

60

SCL1

PICkit™ Serial Analyzer

PGEC1/SDA1

61

SDA1

PICkit Serial Analyzer

RP52

62

LIN2CS

RE12

63

RE12

I/O

RE13

64

RE13

I/O

RP53

65

LIN2TX

LIN2 Transmit

RP54

66

LIN2RX

LIN2 Receive

RP69

67

LIN2TXE

LIN2 Transmit Enable

PWM5H

68

PWM5H

PWM Output

PWM5L

69

PWM5L

PWM Output

VCAP

70

VCAP

Core Voltage

VDD

71

VDD

3.3V

PWM6H

72

PWM6H

PWM Output

PWM6L

73

PWM6L

PWM Output

LIN2 Control Signal

PWM7L

74

PWM7L

PWM Output

PWM7H

75

PWM7H

PWM Output

PWM3H

76

PWM3H

PWM Output

PWM3L

77

PWM3L

PWM Output

PWM2H

78

PWM2H

PWM Output

PWM2L

79

PWM2L

PWM Output

PWM4H

80

PWM4H

PWM Output

2017 Microchip Technology Inc.

�Hardware

2.3

APPLICATION COMPONENTS

Table 2-4 describes the application components that are available on the

dsPIC33EP128GS808 Development Board (see Figure 2-1 and Figure 2-2 for

component locations).

TABLE 2-4:

COMPONENT DETAILS

Component

Label

Description

Top Assembly Components (see Figure 2-1)

Microcontroller (DSC)

U4

Main Controller

Configurable Jumpers

Jx

Jumpers for Selecting Various Inputs

Switch

SW1

Diagnostic LEDs

LD1, LD2

Potentiometers

R12, R20

Power LED

LD3

Switch Input

LEDs for Diagnostics

Variable Input Voltage to Controller

Power Indicator

Input Power Connector

J1

9V DC Input

USB Connector

J2

USB Power Connection

Programming Connector

J3

Connection to Programmer/Debugger

PICkit™ Serial Analyzer

J24

Communication Interface (not mounted)

Bottom Assembly Components (see Figure 2-2)

2.4

Voltage Regulator

U1

Converts 9V DC Input to 5V

Voltage Regulator

U2

Converts 5V DC Input to 3.3V

Op Amp

U3

Used as a Buffer or Summing Node

Op Amp

U5

Used as a Buffer

MOSFET

Q1

Switch for Generating a Ramp Signal

MOSFET

Q2

Switch for Generating Transient Loading

Interface Connector

J17

CAN/LIN Interface with PICtail™ Plus

Interface Connector

J18

CAN/LIN Interface with PICtail Plus

BOARD CONNECTORS

Table 2-5 describes the hardware connections available on the development board

(see Figure 2-1 and Figure 2-2 for component locations).

TABLE 2-5:

CONNECTOR DETAILS

Label

2017 Microchip Technology Inc.

Description

J1

9V DC Input

J2

USB Connection for Powering the Board (provides 5V DC input)

J3

J25 Connector to Provide External Programmer/Debugger Interface

J24

PICkit™ 3 Serial Analyzer Communication Interface (not mounted)

DS50002632A-page 17

�dsPIC33EP128GS808 Development Board User’s Guide

2.5

INDICATORS AND HUMAN INTERFACES

Table 2-6 describes the user interfaces available on the development board kit.

TABLE 2-6:

HUMAN INTERFACE DETAILS

Label

SW1

DS50002632A-page 18

Description

Switch Input.

LD1

Diagnostic Green LED.

LD2

Diagnostic Red LED.

LD3

Green LED Power Indicator.

R12

Potentiometer to Provide Variable Voltage (0-3.3V) to Controller I/O Pins.

R20

Potentiometer to Provide Variable Voltage (0-3.3V) to Controller I/O Pins.

J4

Selects PWM1H or PWM1L as an Input to the RC Filter.

J5

Selects PWM2H or PWM2L as an Input to the RC Filter.

J6

Selects PWM3H or PWM3L as an Input to the RC Filter.

J7

Selects PWM4H or PWM4L as an Input to the RC Filter.

J8

Selects PWM1-4 Passed through an RC Filter as Input to the Op Amp Buffer.

The Circuit Emulates Output of a Switched Mode Power Supply (SMPS).

Multiple PWMs can be Selected if Necessary.

J10

Selects PWM5H or PWM5L as an Input to the RC Filter.

J11

Selects PWM6H or PWM6L as an Input to the RC Filter.

J12

Selects PWM5-6 Passed through an RC Filter as Input to the Op Amp Buffer.

The Circuit Emulates Output of a Switched Mode Power Supply (SMPS). Both

PWMs can be Selected if Necessary.

J15

Selects PWM7H or PWM7L as an Input to the Ramp Generator Circuit.

J20

Allows Connection of PWM Signals to Comparator or Fault Inputs.

J22

Connects a Variable Voltage Generated by Potentiometer R20 or DACOUT2.

J23

Connects Current Source to a Resistive or Capacitive Load.

2017 Microchip Technology Inc.

�Hardware

2.6

TEST POINTS

Table 2-7 describes the test points that are available on the development board. See

Figure 2-3 for test point locations.

TABLE 2-7:

TEST POINTS

Label

TP1

3.3V (P3V3)

TP2

3.3V Return (GND)

TP3

External 3.3V Input to ADC

TP4

External 3.3V Return (AGND)

TP5

Buffer Output from RC Filters

TP6

Filtered 3.3V Return (AGND)

TP7

3.3V Return (GND)

TP8

Filtered 3.3V (P3V3A) (not mounted on board)

FIGURE 2-3:

2017 Microchip Technology Inc.

Description

TEST POINT LOCATIONS

DS50002632A-page 19

�dsPIC33EP128GS808 Development Board User’s Guide

2.7

PROGRAMMER/DEBUGGER

The development board needs an external programmer/debugger, such as the

MPLAB® ICD 3 or REAL ICE™ emulator to program the controller on the board.

TABLE 2-8:

PROGRAMMER/DEBUGGER COMPONENTS

Component

Programmer/Debugger

Connector

DS50002632A-page 20

Label

J3

RJ25 Connection for Interface to MPLAB® ICD 3

(DV164035)/REAL ICE™ Emulator (DV244005)

2017 Microchip Technology Inc.

�dsPIC33EP128GS808 DEVELOPMENT

BOARD USER’S GUIDE

Chapter 3. Demonstration Program Operation

The dsPIC33EP128GS808 Development Board is preprogrammed with application

software that emulates the closed-loop operation of a power supply. The program illustrates 2-Pole, 2-Zero (2P2Z) compensator control of the output voltage for the power

supply emulation circuit. This code can be downloaded from Microchip web site

(www.microchip.com).

This section covers the following topics:

•

•

•

•

3.1

Hardware Description

Software Demonstration

Code Demonstration

Other Code Examples

HARDWARE DESCRIPTION

The hardware on the development board emulates the behavior of a power supply.

Most of the power supply topologies consist of 2nd order Inductor-Capacitor (LC)

filters, which smooth out the high-frequency switching content from the output voltage,

resulting in a DC output voltage. The controller monitors the output voltage, compares

it with a reference voltage and generates the required PWM duty cycle to maintain the

output voltage equal to the reference voltage. The switching frequency is fixed and the

output voltage regulation is maintained by controlling the on time of the switch. The

ratio of the on time to the total switch duration is known as the duty cycle. The DSC

implements a digital compensator, with the voltage error as input and the duty cycle as

output. The development board does not use any inductor, but relies on the

single-order RC filter and PWM to emulate the power stage of the supply. Figure 3-1

shows the hardware used for emulating the power supply.

2017 Microchip Technology Inc.

DS50002632A-page 21

�dsPIC33EP128GS808 Development Board User’s Guide

FIGURE 3-1:

EMULATED POWER SUPPLY HARDWARE

J4

PWM1L

R4

1 2 3

PWM1H

P3V3A

1k

0603

1%

C15

TP7

PWM2L

1 2 3

J5

PWM2H

1000 pF

50V

0603

R5

PWM3L

1 2 3

J6

C19

GND

1k

0603

1%

R6

1k

0603

1%

OUTA

A

GND

C17

7

5

3

1

3

8

6

4

2

1 2 3

PWM4L

JP7

GND

R7

1k

0603

1%

J7 – 1 & 2

Default Jumper Positions

Shunt 2.54 mm 1x2

VSS

+A

A

4

1

MCP6L92T-E/SN

R35

R8

0R

0603

AN0

100R

0603

1%

AGND

J8

JP8

R30

J8 – 1 & 2

Default Jumper Positions

Shunt 2.54 mm 1x2

R32

PWM8L

PWM4H

AGND

VDD

C16

0.1 µF

16V

0603

J7

8

-A

AN15

0.1 µF

16V

0603

U3A

2

10000 pF

16V

0603

PWM3H

TP5

G1

100R

0603

1%

R31

470R

0603

1%

D1

6

Q2A

1

DMG6601LVT

5

S1

470R

0603

1%

D2

4

R33

PWM8H

G2

100R

0603

1%

Q2B

3

DMG6601LVT

2

S2

P3V3

GND

C18

1 µF

16V

0603

GND

The power section on the board consists of one of the PWM outputs, depending on the

jumper installed. The default jumper position uses the JP7 jumper between Pins 1 and

2, and JP8 between Pins 1 and 2. JP7 selects PWM4L as the input to the RC circuit,

while JP8 connects the output of the RC filter to the input of the U3-A buffer. The PWM

signal, together with the RC filter, forms a power stage. Note the difference in the RC

filter values connected to jumper J8. The capacitor value changes by a factor of 10 and

can be used to emulate power supplies with a wide range of switching frequencies. The

output voltage can be monitored at test point, TP5. The range of the output voltage

varies from 0-3.3V, depending upon the reference voltage and PWM duty cycle. The

output voltage is connected to the ADC input, AN0. The DSC computes the duty cycle

based on the output voltage sample by using a digitized version of a 2P2Z filter. The

duty cycle controls the on time, during which, the output of the PWM pin is at 3.3V and

at 0V for the rest of the duration. The PWM output generates a near DC value when

passed through an RC filter.

DS50002632A-page 22

2017 Microchip Technology Inc.

�Demonstration Program Operation

The load current in a power supply is dependent on the external load impedance and

could be constant or varying. The real test for a power supply is when the load

transitions from 0% to 100% or from 100% to 0% of rated current values. In a

non-regulated power supply, a load transition leads to a drastic fall/rise in the output

voltage. However, in a well regulated closed-loop system, a load transient will lead to

a smaller output voltage drop (rise) when transitioning from 0 to 100% (100 to 0%),

depending on the control design. The development board has additional hardware

provided by the Q2 MOSFET to emulate the power supply loading condition. The Q2A

and Q2B MOSFETS are controlled by signals PWM8L and PWM8H respectively. Q2A

is connected between the buffer input and GND, while Q2B is connected between the

buffer input and 3.3V. When Q2A is turned on, the buffer input gets pulled down to GND

through the R30 resistor. Depending on the duration of the PWM8L pulse, the output

voltage is pulled down from its steady-state value, thereby emulating a 0 to100%

loading condition. Figures 3-2 and 3-3 indicate the transient loading condition. The

green waveform corresponds to the PWM4L signal and the blue waveform to the buffer

output (TP5) in the following figures.

FIGURE 3-2:

2017 Microchip Technology Inc.

0 TO 100% LOADING CONDITION

DS50002632A-page 23

�dsPIC33EP128GS808 Development Board User’s Guide

FIGURE 3-3:

0 TO 100% LOADING CONDITION

A load throw effect is seen when the load is suddenly switched off. During this

condition, the output voltage rises. When PWM8H is turned on for a small duration, the

input buffer gets connected to 3.3V through the R31 resistor. The output voltage

subsequently rises, as seen from Figure 3-4 and Figure 3-5. The control loop tries to

correct the situation by changing the duty cycle.

FIGURE 3-4:

DS50002632A-page 24

100 TO 0% LOADING CONDITION

2017 Microchip Technology Inc.

�Demonstration Program Operation

FIGURE 3-5:

100 TO 0% LOADING CONDITION (ZOOMED)

There are additional features on the board, such as a second power loop (PWM5-6 and

U3-B) and a ramp generator (Q1), which can be used for demonstrating the Current

mode control of the power supply.

3.2

SOFTWARE DEMONSTRATION

The demonstration software provides closed-loop control of the output voltage. The

2P2Z control loop controls the converter output voltage based on the reference voltage

set by potentiometer R12. The switching frequency is fixed and set to 100 kHz.

The 2P2Z control scheme consists of the following parameters:

•

•

•

•

•

Reference – Desired set point for the output voltage

Error – Calculation of (Reference – Feedback)

System Plant – This is the converter being controlled

Output – Output voltage or current

Feedback – The measured output signal level

The demonstration program requires no manual preparation except to connect 9V to

the J1 connector or connecting a USB cable to connector J2 with the other end

connected to a laptop.

2017 Microchip Technology Inc.

DS50002632A-page 25

�dsPIC33EP128GS808 Development Board User’s Guide

FIGURE 3-6:

VOLTAGE MODE CONTROL BLOCK DIAGRAM

System Plant

RC Filter

Voltage

Reference

Error

+

VOUT

2P2Z

Compensator

PWM

–

Voltage Feedback

1001011011

VOUT

Sense

K1

ADC

S&H

FIGURE 3-7:

PROGRAM FLOWCHART

Start

Initialize Peripherals

• System Clock

• I/O

• PWM

• ADC

• CMP

• Timer

Mode = Closed

Loop

Yes

Closed-Loop State Machine

No

Read

Potentiometer

R12

Calculate and

Write Duty Cycle

Switch

Press = 1

No

Yes

Enable Transient

Load Control

Switch

Press = 2

No

Yes

Disable

Transient Load

Control

DS50002632A-page 26

2017 Microchip Technology Inc.

�Demonstration Program Operation

FIGURE 3-8:

CLOSED-LOOP STATE MACHINE

Idle

Restart Enabled

Fault Clear

Delay Complete

• Initialize Compensator

• Optional Delay

• Enable PWM

Soft Start

• Disable PWM

• Turn Red LED On

• Check for Fault Clear

• Increment Reference

Voltage

• Read Potentiometer R12

• Calculate Fault Threshold

• Read Potentiometer R20

• Detect Switch

• Transient Load Control

VO = Reference Voltage

Fault

VO > VHIGH

or

Vo < VLOW

Normal

2017 Microchip Technology Inc.

DS50002632A-page 27

�dsPIC33EP128GS808 Development Board User’s Guide

3.3

CODE DEMONSTRATION

The software code is based on a state machine, implemented as a foreground process,

and interrupt routines are executed in the background. After the initialization phase, the

code checks for the operating mode. If it is Open-Loop mode, the output voltage is set

to the value decided by potentiometer R12. If it is Closed Loop mode, the state machine

routine is executed. There are four states in the state machine, namely Idle, Soft Start,

Normal and Fault. The details of each mode are given in the following sections.

3.3.1

System Initialization

When power is applied to the board, the program starts by executing the following

system initialization routines:

• Peripherals – The required peripherals (PWM, ADC, Comparators, Timers and

GPIO) are configured and enabled.

• Interrupts – Include ADC(s), Timer(s) and comparator(s) interrupts.

3.3.2

Modes

There are two modes of operation: Open-Loop mode and Closed-Loop mode. The

Closed-Loop mode is set as the default. In the Open-Loop mode, the output of the

PWM is set based on the value set by potentiometer R12. The Open-Loop mode does

not execute any Soft Start or Fault state, but executes a load control routine. The transient response of the supply can be monitored by pressing the SW1 switch once. This

enables the load control routine, where the transient pulses appear periodically.

In the Closed-Loop mode, the output voltage is set by the control loop based on the

reference voltage set. The Closed-Loop mode executes Idle, Soft Start, Normal and

Fault states, as shown in Figure 3-8. Load control is part of the Normal state. During

load control, if SW1 is pressed once, a transient pulse of duration LDTRANSTIME is

applied to MOSFET Q2 with a repeat duration of LDPERIOD. The default settings are

set to 1000 µs (LDTRANSTIME) and 1000 ms (LDPERIOD). Depending on the

LOADSW setting to PULLUP or PULLDOWN in the user.h file, MOSFET Q2A or Q2B is

controlled. A second press of SW1 will turn off the load control feature.

The mode can be changed by setting the variable, MODE, to either OPENLOOPDEMO or

CLOSELOOPDEMO in the user.h file.

3.3.2.1

IDLE STATE

During the Idle state, the 2P2Z compensator is initialized. The ADC reads the value of

potentiometer R12 and sets the reference voltage of the output. The PWM module and

the interrupts are enabled in this state. Once all the tasks are completed, the next state

is set to Soft Start.

3.3.2.2

SOFT START STATE

In this state, the Soft Start routine ramps up the output voltage in a closed-loop fashion

until it is at the programmed output voltage value. This routine ensures that the output

does not overshoot the desired voltage caused by a sudden inrush of current.

DS50002632A-page 28

2017 Microchip Technology Inc.

�Demonstration Program Operation

3.3.2.3

NORMAL STATE

The program reaches the Normal state of operation after Soft Start is complete and

stays in this state as long as the operating parameters are within the Fault threshold.

The routine checks for a switch press to enable/disable transient pulses. The Fault

thresholds are set based on the value of the output voltage. Alternately, the Fault

thresholds can be set by potentiometer R20. This helps in changing the thresholds to

verify the Fault condition. The ADC interrupt routine runs in the background and occurs

at regular intervals of the PWM cycle (decided by the TRIG value). The ADC routine

samples the output voltage and runs the 2P2Z controller.

The 2-Pole, 2-Zero (2P2Z) controller, implemented in software, is the digital implementation of the Analog Type II controller. This filter maintains regulation of the output

voltage and ensures stability during different line/load conditions. This controller

requires three feedback errors multiplied by their associated coefficients, plus the two

latest controller output values multiplied by their associated coefficients, along the

delay line to provide proper compensation of the power converter. The control design

is carried out using the DCDT tool which can be installed as an MPLAB® X plug-in. The

DCDT supports different types of filters, such as 2P2Z, 3P3Z, PID, etc. The bode plots

of the system plant, compensator and overall system can be viewed with the DCDT

tool. The tool automatically converts the design into digital form and generates the

coefficients. The coefficient file, filterx_dcdt.h, is added as a header file to the

project. The filter routine is written in assembly language for faster execution. The

routine, smps_2p2z_dspic_v2.s, refers to the coefficient file and creates a duty

cycle based on the output voltage error.

During operation in Normal mode, the output voltage is checked against Fault thresholds. The Fault checking occurs at a fixed interval, set by Timer2, in the timer interrupt

routine. The Fault is enabled or disabled based on the value set for VLTFLTENABLED

in the user.h file. If the output voltage is beyond the thresholds, the state machine

changes state to Fault mode.

3.3.2.4

FAULT STATE

The program enters the Fault mode when the output voltage is beyond the Fault

thresholds. The PWM module is disabled immediately after entering the Fault state

routine. The red LED is lit continuously for visual indication of a Fault. Based on the

value set for RESTARTENABLED in the user.h file, the program enters Latch mode or

Restart mode. In Latch mode, the program enters an endless while loop and needs a

power recycle to start again. In the Restart mode, the routine checks for Faults to

clear and enters Idle mode to start all over again.

2017 Microchip Technology Inc.

DS50002632A-page 29

�dsPIC33EP128GS808 Development Board User’s Guide

3.4

OTHER CODE EXAMPLES

There are several code examples available on the Microchip web site. One such code

example developed exclusively for this board is mentioned below. Refer to the Readme

files located in each code example folder for details on what each code example

demonstrates. Check the Microchip web site (www.microchip.com/SMPS) for the latest

updates to the code examples and for additional code examples.

3.4.1

Dual CAN Communication

The dual CAN communication code is provided to demonstrate basic control of LEDs

on the development board. The development board is connected to the

CAN/LIN/J2602 PICtail™ (Plus) Daughter Board, which is connected to the CAN host

(CAN analyzer). The CAN host communicates with both the CAN (CAN1/CAN2)

modules on the development board. Each CAN module has a specific address. The

controller on the development board reads the potentiometers R12 and R20, and

sends the value to the CAN host periodically, along with the CAN module address. The

CAN host sends specific timer values for the CAN1 and CAN2 modules, which are used

to blink the LEDs. Thus, changing the potentiometer on the development board will

change the LED blink rate based on successful CAN communication.

3.4.2

Other Code Ideas

The development board is versatile and can be programmed to test a number of

features. Most of the I/O pins are accessible on one of the several connectors on the

board. The connector pins can be used to monitor outputs, connect input signals or

provide cross connection between different controller pins. Some of the code ideas are:

•

•

•

•

•

•

•

•

•

•

•

DS50002632A-page 30

Peak Current Mode Control

Ramp Generation

ADC Reference Voltage Control

Constant Current Source

Peripheral Pin Select (PPS)

I2C Communication

PGA

PTG/CLC

PWM Signal as a Fault/Comparator Input

Fault/Current Limit

External Period Reset

2017 Microchip Technology Inc.

�dsPIC33EP128GS808 DEVELOPMENT

BOARD USER’S GUIDE

Appendix A. Board Layout and Schematics

This appendix contains the schematics and board layouts for the

dsPIC33EP128GS808 Development Board.

FIGURE A-1:

2017 Microchip Technology Inc.

DEVELOPMENT BOARD LAYOUT (TOP)

DS50002632A-page 31

�dsPIC33EP128GS808 Development Board User’s Guide

FIGURE A-2:

DS50002632A-page 32

DEVELOPMENT BOARD LAYOUT (BOTTOM)

2017 Microchip Technology Inc.

�DEVELOPMENT BOARD SCHEMATIC (PAGE 1 OF 2)

P3V3

P9V

1

3

2

POWER 2.1 mm

R16

J3

10k

0603

1%

R17

MCLR

1

C24 1%

TP2

0.1 µF

16V

0603

RJ 25

VIN

C1

10 µF

16V

0805

470R

0603

PGED3/SDA2

PGEC3/SCL2

P5V

MIC39100-5.0WS

U1

J1

6 5 4 3 2 1

GND

VOUT

GND

1

VIN

C2

2

VOUT

GND

GND

TP1

3

C3

2

10 µF

16V

0805

GND

P3V3

MCP1703/3.3V

U2

3

GND

TP LOOP Red

LD3

GREEN

10 µF

16V

0805

R1

330R

0603

1%

GND

TP LOOP Black

GND

GND

GND

1

2

3

4

5

P5V

D3

CDBA120-G

C23

MCLR

VCAP

0.1 µF

16V

0603

0

J2

VBUS

DD+

ID

GND

GND

P3V3

C11

10 µF

25V

0805

GND

GND

P3V3A

GND

AGND

R25

4

2

3

R24

SW1

470R

0603

1%

GND

LED1

LED2

LD1

LD2

GREEN

R14

RED

R15

1k

0603

1%

1k

0603

1%

GND

GND

P3V3

20

34

35

40

41

58

60

61

55

21

AN3

CMP4A

CMP4B

DACOUT1

RB4

AN19

PGED1/SCL1

PGEC1/SDA1

PGED3/SDA2

ISRC4

76

77

78

79

56

PWM3H

PWM3L

PWM2H

PWM2L

PGEC3/SCL2

GPIO1

AN19

LED2

RD14

RB4

RE6

CMP4C

AN11

RE5

RP60

RE3

11

VSS

31

VSS

51

VSS

15

AVDD

24

AVDD

25

AVDD

LIN1CS

PWM4H

AN16

PWM4L

PWM6H

LIN2TXE

PWM5H

AN15

LIN1TX

RD9

FLT10

LIN1TXE

FLT9

DACOUT2

RD14

PWM6L

59

80

36

1

72

67

68

27

54

50

8

57

10

28

49

73

PWM8L

PWM8H

RE2

RE3

SW1

RE5

RE6

RE7

GPIO1

GPIO2

LED2

LED1

RE12

RE13

PWM7L

PWM7H

4

5

13

14

22

23

37

38

43

44

52

53

63

64

74

75

AN3/CMP1D/CMP2B/PGA2P3/RP32/RB0

OSCI/CLKI/AN6/CMP3C/CMP4A/ISRC2/RP33/RB1

OSC2/CLKO/AN0ALT/AN7/CMP3D/CMP4B/PGA1N2/RP34/RB2

PGED2/DACOUT1/AN18/ASCL2/INT0/RP35/RB3

PGEC2/ADTRG31/RP36/RB4

TD0/AN19/PGA2N2/RP37/RB5

PGED1/TDI/AN20/SCL1/RP38/RB6

PGEC1/AN21/SDA1/RP39/RB7

PGED3/SDA2/FLT31/RP40/RB8

AN4/CMP2C/CMP3A/ISRC4/RP41/RB9

AVSS

T4CK/RP64/RD0

PWM4H/RP65/RD1

AN16/RP66/RD2

PWM4L/RP67/RD3

PWM6H/RP68/RD4

AN12/RP69/RD5

PWM5H/RP70/RD6

AN15/RP71/RD7

AN5/CMP2D/CMP3B/ISRC3/RP72/RD8

SCK3/RP73/RD9

FLT10/RP74/RD10

INT4/RP75/RD11

T5CK/FLT9/RP76/RD12

DACOUT2/AN13/RD13

RD14

PWM6L/RD15

TMS/PWM3H/RP43/RB11

TCK/PWM3L/RP44/RB12

PWM2H/RP45/RB13

PWM2L/RP46/RB14

PGEC3/SCL2/RP47/RB15

6

33

45

69

62

65

66

46

47

29

30

CAN1TX

CMP4C

CMP4D

PWM5L

LIN2CS

LIN2TX

LIN2RX

CAN2TX

CAN2RX

AN11

EXTREF2

16

AN14/PGA2N3/RP60/RC12

7

FLT11/RP61/RC13

42

RP62/RC14

39

RP63/ASDA2/RC15

RP60

CAN1RX

RC14

LIN1RX

FLT12/RP48/RC0

AN8/CMP4C/PGA2P4/RP49/RC1

EXTREF1/AN9/CMP4D/RP50/RC2

PWM5L/RP51/RC3

AN1ALT/RP52/RC4

AN0ALT/RP53/RC5

AN17/RP54/RC6

RP55/ASDA1/RC7

RP56/ASCL1/RC8

AN11/PGA1N3/RP57/RC9

EXTREF2/AN10/PGA1P4/RP58/RC10

PWM8L/RE0

PWM8H/RE1

FLT17/RE2

FLT18/RE3

RE4

RE5

FLT19/RE6

FLT20/RE7

RE8

RE9

FLT21/RE10

FLT22/RE11

RE12

RE13

PWM7L/RE14

PWM7H/RE15

DS50002632A-page 33

C26

R23

0R

0603

P3V3

TP8

P3V3

C27

C12

0.1 µF

16V

0603

10 µF

25V

0805

AGND

GND

P3V3

P3V3

P3V3A

P3V3A

PWM2H

MCLR

PWM8L

CMP4D

AN2

LED1

RD9

RC14

RE7

EXTREF2

DACOUT2

ISRC4

RE2

FLT10

PWM2L

FLT9

PWM8H

J17

P3V3

P9V

CAN1TX

CAN2TX

LIN1TX

LIN1CS

LIN2TX

LIN2CS

RE12

RE13

CAN1RX

CAN2RX

LIN1RX

LIN1TXE

LIN2RX

LIN2TXE

J18

U4 PIN 48

U4 PIN 71

C4

C5

C6

C7

C8

C9

C10

0.1 µF

16V

0603

0.1 µF

16V

0603

0.1 µF

16V

0603

0.1 µF

16V

0603

0.1 µF

16V

0603

0.1 µF

16V

0603

0.1 µF

16V

0603

Pin 11

GND

Pin 31

GND

Pin 51

GND

U4 PIN 15

U4 PIN 24

U4 PIN 26

GND

AGND

U4 PIN 26

AGND

U4 PIN 25

U4 PIN 26

AGND

P5V

GND

P3V3A

U4 PIN 32

TP6

TP LOOP Black

P3V3

U4 PIN 12

DNP

TP LOOP Red

26R

GND

AN0

AN1

AN2

PWM1L

PWM1H

P3V3A

FB1

0.1 µF

16V

0603

17

18

19

3

2

Designed with

Altium.com

Board Layout and Schematics

10k

0603

1%

AN0/CMP1A/PGA1P1/RP16/RA0

AN1/CMP1B/PGA1P2/PGA2P1/RP17/RA1

AN2/CMP1C/CMP2A/PGA1P3/PGA2P2/RP18/RA2

PWM1L/RP19/RA3

PWM1H/RP20/RA4

12

VDD

32

VDD

48

VDD

71

VDD

26

P3V3

1SW1

U4 dsPIC33EP128GS808

9

MCLR

70

VCAP

29 27 25 23 21 19 17 15 13 11 9 7 5 3 1

30 28 26 24 22 20 18 16 14 12 10 8 6 4 2

USB2.0 Mini-B FEMALE

29 27 25 23 21 19 17 15 13 11 9 7 5 3 1

30 28 26 24 22 20 18 16 14 12 10 8 6 4 2

2017 Microchip Technology Inc.

FIGURE A-3:

�DEVELOPMENT BOARD SCHEMATIC (PAGE 2 OF 2)

R4

P3V3A

R6

1k

0603

1%

7

5

3

1

GND

3

8

6

4

2

R32

PWM8L

PWM4H

PWM4L

1 2 3

J7

JP7

G1

GND

R7

1k

0603

1%

J7 – 1 & 2

Default Jumper Positions

Shunt 2.54 mm 1x2

100R

0603

1%

MCP6L92T-E/SN

J11

PWM6H

PWM6L

Q2A

1

PWM8H

G2

1 µF

16V

0603

C21

0.1 µF

16V

0603

P3V3

P3V3

P3V3

R2

GND

2.2k

0603

1%

-A

8

PGED1/SCL1

C13 Yes

130 pF

50V

0603

3

2

1

10k

P090S

20%

3

VSS

+A

A

0R

0603

130 pF

50V

0603

FDV301N

2

GND

GND

GND

GND

PWM1H

PWM2H

PWM3H

PWM4H

1

3

5

7

2

4

6

8

CMP4A

CMP4B

FLT9

FLT10

Default Jumper Positions

J20 – 1 & 2

Shunt 2.54 mm 1x2

DACOUT1

3

10k

P090S

20%

AGND

R21

DACOUT2

10k

0603

1%

R22

10k

0603

1%

AGND

JP22

J22

AN16

0R

0603

R26

AN3

0R

0603

Default Jumper Positions

J22 – 2 & 3

Shunt 2.54 mm 1x2

AN11

R28

J23

ISRC4

1

3

2

4

100k

0603

1%

C29

JP23

1000 pF

0603

Default Jumper Positions 50V

J23 – 1 & 2

Shunt 2.54 mm 1x2

Designed with

AGND

1

2

3

4

5

6

DNP

GND

JP20

1k

0603

1%

EXTREF2

R20

2

0R

0603

0.1 µF

16V

0603

AN19

AGND

C25

BAT54SLT1

P3V3

0R

0603

MCP6L92T-E/SN

+B

AGND

1

2017 Microchip Technology Inc.

1

GPIO2

D2 DNP

C14

R27

AGND

CMP4D

Q1

R39

7

R13

TP4

R38

3

5

AN2

4

U5B

-B

OUTB

TP3

R36

1

MCP6L92T-E/SN

P3V3A

10k

0603

1%

GPIO1

J20

6

AGND

OUTA

A

R12

J24

P3V3

2.2k

0603

1%

PGEC1/SDA1

P3V3

0.1 µF

16V

0603

U5A

2

D1 DNP GND

BAT54SLT1

R3

C28

R19

1 2 3

JP12

GND

P3V3

Default Jumper Positions

J15 – 1 & 2

Shunt 2.54 mm 1x2

AN1

100R

0603

1%

Default Jumper Positions

J12 – 1 & 2

Shunt 2.54 mm 1x2

P3V3A

AGND

JP15

+B

C18

0.1 µF

16V

0603

R18

2

4

DMG6601LVT

2

S2

C22

100R

0603

1%

1

3

R11

7

MCP6L92T-E/SN

Q2B

3

100R

0603

1%

VDD

PWM7L

OUTB

5

GND

P3V3A

PWM7H

1k

0603

1%

U3B

-B

J12

R10 GND

470R

0603

1%

D2

4

R33

DMG6601LVT

5

S1

GND

J15

C20

R31

470R

0603

1%

D1

6

100R

0603

1%

6

AN0

R30

J8 – 1 & 2

Default Jumper Positions

Shunt 2.54 mm 1x2

0.1 µF

16V

0603

4

R9

1k

0603

1%

10000 pF

16V

0603

AGND

J8

JP8

C17

VSS

+A

A

R8

1

OUTA

A

C16

PWM5L

2

1 2 3

J6

PWM3L

AGND

VDD

10000 pF

16V

0603

PWM3H

8

-A

R35

0R

0603

1

2

1k

0603

1%

PWM5H

3

U3A

J10

AN15

0.1 µF

16V

0603

3

C19

GND

2

R5

Shunt 2.54 mm 1x2

1 2 3

1000 pF

50V

0603

1 2 3

PWM2L

1 2 3

PWM2H

JP10

C15

TP7

J5

Default Jumper Positions

J10 – 1 & 2

TP5

1

1k

0603

1%

1 2 3

PWM1L

1 2 3

J4

PWM1H

Altium.com

dsPIC33EP128GS808 Development Board User’s Guide

DS50002632A-page 34

FIGURE A-4:

�Board Layout and Schematics

NOTES:

2017 Microchip Technology Inc.

DS50002632A-page 35

�Worldwide Sales and Service

AMERICAS

ASIA/PACIFIC

ASIA/PACIFIC

EUROPE

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

Finland - Espoo

Tel: 358-9-4520-820

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Hong Kong

Tel: 852-2943-5100

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

Austin, TX

Tel: 512-257-3370

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

DS50002632A-page 36

China - Dongguan

Tel: 86-769-8702-9880

China - Guangzhou

Tel: 86-20-8755-8029

China - Hangzhou

Tel: 86-571-8792-8115

Fax: 86-571-8792-8116

China - Hong Kong SAR

Tel: 852-2943-5100

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-3326-8000

Fax: 86-21-3326-8021

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8864-2200

Fax: 86-755-8203-1760

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-3019-1500

Japan - Osaka

Tel: 81-6-6152-7160

Fax: 81-6-6152-9310

Japan - Tokyo

Tel: 81-3-6880- 3770

Fax: 81-3-6880-3771

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-213-7830

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

Taiwan - Taipei

Tel: 886-2-2508-8600

Fax: 886-2-2508-0102

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

France - Saint Cloud

Tel: 33-1-30-60-70-00

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-67-3636

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Israel - Ra’anana

Tel: 972-9-744-7705

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-7289-7561

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

2017 Microchip Technology Inc.

11/07/16

�