Digital Power

Development Board

User’s Guide

2018 Microchip Technology Inc.

DS50002814A

�Note the following details of the code protection feature on Microchip devices:

•

Microchip products meet the specification contained in their particular Microchip Data Sheet.

•

Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

•

There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

•

Microchip is willing to work with the customer who is concerned about the integrity of their code.

•

Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC® MCUs and dsPIC® DSCs, KEELOQ® code hopping

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

QUALITY MANAGEMENT SYSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

DS50002814A-page 2

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, AVR Freaks, BitCloud, chipKIT, chipKIT logo,

CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo,

JukeBlox, KeeLoq, Kleer, LANCheck, LINK MD, maXStylus,

maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip

Designer, QTouch, SAM-BA, SpyNIC, SST, SST Logo,

SuperFlash, tinyAVR, UNI/O, and XMEGA are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMOS,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity,

JitterBlocker, KleerNet, KleerNet logo, memBrain, Mindi, MiWi,

motorBench, MPASM, MPF, MPLAB Certified logo, MPLIB,

MPLINK, MultiTRAK, NetDetach, Omniscient Code Generation,

PICDEM, PICDEM.net, PICkit, PICtail, PowerSmart, PureSilicon,

QMatrix, REAL ICE, Ripple Blocker, SAM-ICE, Serial Quad I/O,

SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2018, Microchip Technology Incorporated, All Rights

Reserved.

ISBN: 978-1-5224-3762-8

2018 Microchip Technology Inc.

�DIGITAL POWER DEVELOPMENT

BOARD USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 5

Chapter 1. Overview....................................................................................................... 9

1.1 Introduction ..................................................................................................... 9

1.2 Features ......................................................................................................... 9

1.2.1 Socket for DP PIM Boards ........................................................................ 10

1.2.2 Test Points ................................................................................................ 10

1.2.3 Grounding System ..................................................................................... 11

1.2.4 External Analog Signal Input ..................................................................... 11

1.2.5 DC Level Insertion ..................................................................................... 11

1.2.6 Analog Input Connection Jumpers ............................................................ 11

1.2.7 Push Buttons ............................................................................................. 11

1.2.8 MikroBUS™ Socket ................................................................................... 11

1.2.9 ICSP™ Programming Port ........................................................................ 12

1.2.10 General Purpose Soldering Pad Area ..................................................... 12

1.2.11 Solder Pad for Ground Connection ......................................................... 12

1.2.12 USB Connector ....................................................................................... 12

1.2.13 On-Board LDO ........................................................................................ 12

1.2.14 Power Indicator LED ............................................................................... 12

1.2.15 User LEDs ............................................................................................... 12

1.3 Electrical Characteristics .............................................................................. 12

Appendix A. Board Layout and Schematics.............................................................. 13

A.1 Pinout ........................................................................................................... 13

A.2 Board Schematic .......................................................................................... 14

A.3 PCB Layout .................................................................................................. 15

Appendix B. Bill of Materials (BOM)........................................................................... 19

B.1 Bill of Materials ............................................................................................. 19

Worldwide Sales and Service .................................................................................... 22

2018 Microchip Technology Inc.

DS50002814A-page 3

�Digital Power Development Board User’s Guide

NOTES:

DS50002814A-page 4

2018 Microchip Technology Inc.

�DIGITAL POWER DEVELOPMENT

BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB® IDE online help.

Select the Help menu, and then Topics to open a list of available online help files.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

Digital Power Development Board. Items discussed in this chapter include:

•

•

•

•

•

•

•

Document Layout

Conventions Used in this Guide

Recommended Reading

The Microchip Website

Product Change Notification Service

Customer Support

Document Revision History

DOCUMENT LAYOUT

This document describes how to use the Digital Power Development Board User’s

Guide as a demonstration tool to provide a measurement platform for the Microchip

dsPIC33 devices’ Digital Power Plug-In Modules. The document is organized as

follows:

• Chapter 1. “Overview” — This chapter introduces the Digital Power Development

Board and provides a brief overview of its various features.

• Appendix A. “Board Layout and Schematics” — This appendix presents the schematics and the board layouts for the Digital Power Development Board.

• Appendix B. “Bill of Materials (BOM)” — This appendix presents the Bill of Materials for the Digital Power Development Board.

2018 Microchip Technology Inc.

DS50002814A-page 5

�Digital Power Development Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description

Arial font:

Italic characters

Initial caps

Quotes

Underlined, italic text with

right angle bracket

Bold characters

N‘Rnnnn

Text in angle brackets < >

Courier New font:

Plain Courier New

Represents

Referenced books

Emphasized text

A window

A dialog

A menu selection

A field name in a window or

dialog

A menu path

MPLAB® IDE User’s Guide

...is the only compiler...

the Output window

the Settings dialog

select Enable Programmer

“Save project before build”

A dialog button

A tab

A number in verilog format,

where N is the total number of

digits, R is the radix and n is a

digit.

A key on the keyboard

Click OK

Click the Power tab

4‘b0010, 2‘hF1

Italic Courier New

Sample source code

Filenames

File paths

Keywords

Command-line options

Bit values

Constants

A variable argument

Square brackets [ ]

Optional arguments

Curly brackets and pipe

character: { | }

Ellipses...

Choice of mutually exclusive

arguments; an OR selection

Replaces repeated text

Represents code supplied by

user

DS50002814A-page 6

Examples

File>Save

Press ,

#define START

autoexec.bat

c:\mcc18\h

_asm, _endasm, static

-Opa+, -Opa0, 1

0xFF, ‘A’

file.o, where file can be

any valid filename

mcc18 [options] file

[options]

errorlevel {0|1}

var_name [,

var_name...]

void main (void)

{ ...

}

2018 Microchip Technology Inc.

�Preface

RECOMMENDED READING

This user’s guide describes how to use the Digital Power Development Board. Other

useful document(s) are listed below. The following Microchip document(s) are

recommended as supplemental reference resources.

• dsPIC33 Family Digital Power PIM User’s Guides are available for download

from the Microchip website (www.microchip.com)

THE MICROCHIP WEBSITE

Microchip provides online support via our website at www.microchip.com. This website

is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the website contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events; and listings of Microchip sales

offices, distributors and factory representatives

PRODUCT CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip website at www.microchip.com, click on Product

Change Notification and follow the registration instructions.

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

•

•

•

•

Distributor or Representative

Local Sales Office

Corporate Application Engineer (CAE)

Embedded Solutions Engineer (ESE)

Customers should contact their distributor, representative or Embedded Solutions

Engineer (ESE) for support. Local sales offices are also available to help customers.

A listing of sales offices and locations is included in the back of this document.

Technical support is available through the website at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (October 2018)

This is the initial version of this document.

2018 Microchip Technology Inc.

DS50002814A-page 7

�Digital Power Development Board User’s Guide

NOTES:

DS50002814A-page 8

2018 Microchip Technology Inc.

�DIGITAL POWER DEVELOPMENT

BOARD USER’S GUIDE

Chapter 1. Overview

1.1

INTRODUCTION

The Digital Power Development Board is a demonstration board that provides the user

with a flexible measurement platform for all compatible Microchip dsPIC33 Digital

Power Plug-In Modules (DP PIMs). DP PIMs can be inserted into the mating socket J1

in the middle of the Digital Power Development Board. All pins of the DP PIM are

accessible via test loops or pin headers. The on-board micro USB connector provides

a DC power input to all circuitry. In addition, a mikroBUS™ socket is provided to extend

functionality.

This chapter provides an overview of the features of the Digital Power Development

Board. The topics covered include:

• Features

• Electrical Characteristics

1.2

FEATURES

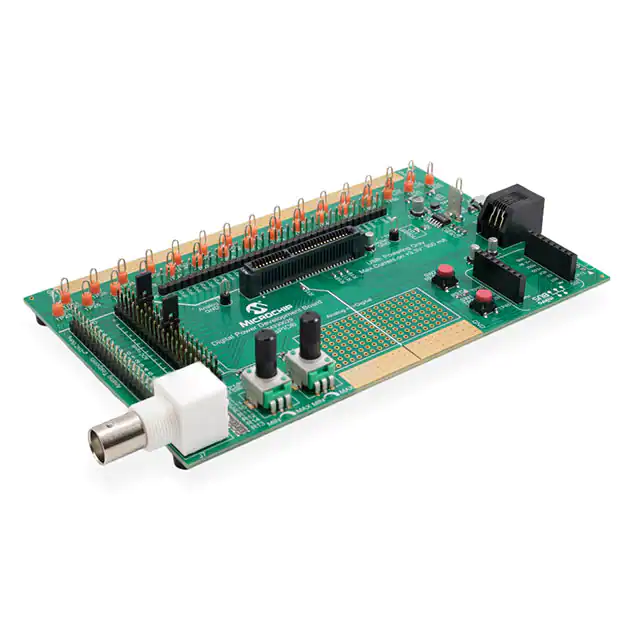

The Digital Power Development Board has the following features, as shown in Figure 1-1.

FIGURE 1-1:

DIGITAL POWER DEVELOPMENT BOARD

14

2

18

16

1

15

17

7

3

12

9

13

5

10

6

11

8

4

14

1.

2.

3.

4.

5.

Socket for DP PIM boards.

Digital GPIO test points. Pin header with connection to the digital test points.

ADC and DAC test points.

External analog signal input.

Potentiometer for DC level insertion from GND to +3.3V; it can be connected to

the lower half of the ADC inputs.

2018 Microchip Technology Inc.

DS50002814A-page 9

�Digital Power Development Board User’s Guide

6. Potentiometer for DC level insertion from GND to +3.3V; it can be connected to

the upper half of the ADC inputs.

7. Analog input connection jumpers.

8. User push button.

9. Reset push button.

10. mikroBUS socket.

11. ICSP™ header to program the on-board MCU (6-pin, 2.54 mm header).

12. ICSP header to program the on-board MCU (RJ25 connector).

13. General purpose soldering pad area.

14. Solder pads for ground connection.

15. USB connector.

16. On-board LDO with Power Good (PG) function.

17. Power indicator LED (Green).

18. User LEDs (Red and Green).

Board dimensions are: 160 mm (length) x 100 mm (height).

1.2.1

Socket for DP PIM Boards

Insert the DP PIM board under test into the socket located in the middle of the Digital

Power Development Board. Socket J1 has a slot that defines the DP PIM board

direction. Be careful not to break the slot when inserting the DP PIM board into

the socket.

1.2.2

Test Points

The Digital Power Development Board ensures good signal integrity and provides

access to all pins of a DP PIM board. Each signal line is named after the DP PIM edge

connector pin number, with a “TP” (Test Point) prefix on the schematic diagram, which

is similarly marked on the silkscreen. These signals are divided into two main sections:

Analog and Digital (see Figure 1-1). For a detailed pinout, refer to the User’s Guide of

the DP PIM under test.

1. Analog Section

The analog section is located at the left connector side (smaller sector of the

socket). It consists of 18 signal lines, all referenced to analog ground. These lines

are split into two subsections:

• ADC inputs

• DAC output

2. Digital Section

The digital section is located at the right connector side (larger sector of the

socket). It consists of 31 lines, all referenced to digital ground. These lines

support all the digital lines of the DP PIMs. Some of them have dedicated

functions, such as:

• High-speed PWM outputs

• Medium speed GPIO

• Communication lines (SPI, I2C, UART)

• User push button and LEDs

DS50002814A-page 10

2018 Microchip Technology Inc.

�Overview

1.2.3

Grounding System

The entire board ground potential is connected together and forms one galvanically

common domain. The labels, “Analog” and “Digital”, indicate the geometrical domain.

The copper pour connected to the ground potential is split into two geometrical

domains, but the two geometrical domains are jointed together under the PIM socket,

thus improving the signal integrity and keeping noise confined to near their sources.

1.2.4

External Analog Signal Input

It is possible to insert an analog signal to any ADC input from a signal generator via a

standard BNC connector. The input impedance is 50. Input signals between the

ground and +3.3V are accepted. An overvoltage protection is implemented on this input

with a series resistor, and a pair of parallel diodes between the ground and the positive

supply rail.

1.2.5

DC Level Insertion

Two on-board potentiometers are connected between the ground and the +3.3V supply

rail to provide two stable DC levels. The two DC levels can be set independently with

potentiometers: P1 and P2. These DC signals can be used as an input signal to any

ADC input. The DC level set by P1 can be connected to the upper half, while P2 can

be connected to the lower half of the ADC inputs, at the analog input connection

jumpers.

1.2.6

Analog Input Connection Jumpers

The ADC inputs of the DP PIM board can be accessed directly from the pin header (J3)

located at the left side of the board. These inputs can also be connected to either the

external analog signal input (J7) or to the DC level insertion, respectively. The

three-row pin header matrix, J4, J5, J6 (No. 7 in Figure 1-1), forms a three-pin selection

jumper for each ADC input. When placing a jumper over the left, or over the right and

the middle pins, the corresponding ADC input can be connected to the extra input as

indicated on the silkscreen. The left side pins connect the external analog signal input,

while the right side pins connect the DC level insertion to the given ADC input. Two

positions on the DAC outputs are not connected. The pins on those positions are just

placeholders to keep the pin order. Three pins are connected to GND at both ends of

the jumper row. Jumpers can be stored on those pins if not needed. Two jumpers are

provided in the kit.

1.2.7

Push Buttons

There are two push buttons on the board: SW1 and SW2. Push button SW2, which is

directly connected to the RESET pin of the DP PIM board, is for the system Reset. For

dual core devices, this RESET is connected to the Master core Reset line. Push button

SW1 is a general purpose user interface connected to the TP27 test point and the

corresponding pin on the DP PIM.

1.2.8

MikroBUS™ Socket

A standard extension socket (J10) is provided on the board for mikroBUS

click boards™. The functionality of the board can be easily extended by using this

feature. The DP PIM board communicates with the mikroBUS socket via dedicated SPI

lines and the I2C bus. Both +5V and +3.3V supply rails are connected to the

corresponding pins of the mikroBUS socket. The Reset button is connected to the

mikroBUS socket RESET pin.

2018 Microchip Technology Inc.

DS50002814A-page 11

�Digital Power Development Board User’s Guide

1.2.9

ICSP™ Programming Port

Dedicated lines for programming the MCU device on the inserted DP PIM board are

accessible via an RJ-25 modular connector or on a 6-pin header.

1.2.10

General Purpose Soldering Pad Area

The soldering point matrix on the bottom of the board with Plated-Through-Hole (PTH)

pads can be used to assemble any small extension circuitry needed for testing or

prototyping.

1.2.11

Solder Pad for Ground Connection

A bare gold-plated copper area is located on the upper and the bottom edges of the

board. These areas can either be used for soldering a solid ground connection or for

attaching alligator clips to connect instrument ground.

1.2.12

USB Connector

The Digital Power Development Board can be powered via the micro USB connector,

J2, at the right side of the board. The DP PIM board supply input and the +5V power

rail for the mikroBUS click board are directly connected to the positive supply line of the

USB. This connector is only for powering. The input voltage must be in the range of

3.6V to 6.3V. The mikroBUS click board can tighten this constraint; please refer to the

specifications before powering. Communication is not possible via this USB connector.

1.2.13

On-Board LDO

The +3.3V power rail for the mikroBUS click board is supplied by the on-board LDO

(Microchip’s MCP1755), connected to the +5V supply rail coming from the USB. The

total load for the mikroBUS click board supply current and the additional load caused

by its active GPIO lines should not exceed 300 mA. The DC level insertion

potentiometer and the pull-up resistor of the user push button are also connected to this

line. The Power Good output drives the Reset line of the board, ensuring stable

performance.

1.2.14

Power Indicator LED

The green LED (LD1) is on when the supply voltage is applied on the +5V supply rail.

1.2.15

User LEDs

The Digital Power Development Board has two user-programmable on-board LEDs.

The red LED is connected to TP52, while the green LED is connected to TP54. Logic

level high drives the LEDs.

1.3

ELECTRICAL CHARACTERISTICS

Table 1-1 shows the electrical characteristics of the Digital Power Development Board.

TABLE 1-1:

ELECTRICAL CHARACTERISTICS

Parameter

Input Voltage Range

DS50002814A-page 12

Value

3.6 VDC to 6.3 VDC

Current Consumption