HV9150

High-Voltage Output Hysteretic-Mode Step-Up DC/DC Controller

Features

General Description

• 6V to 500V Wide Output Voltage Range

• 2.7V Low Input Voltage

• 5W Maximum Output Power with External

MOSFET Driver

• Built-in Charge Pump Converter for the Gate

Driver

• Programmable Switching Frequency from 40 kHz

to 400 kHz

• Four Programmable Duty Cycles from 50% to

87.5%

• FB Return Ground Switch for Power-Saving

Applications

• Built-In Delay Timer for Internal Protection

• Non-Isolated DC/DC Converter

The HV9150 is a high output voltage Hysteretic mode

step-up DC/DC controller that has a built-in charge

pump converter and a linear regulator for a wide range

of input voltage. The Charge Pump Converter mode is

ideal for battery-powered applications. The internal

converter can provide a minimum of 5V gate driver

output voltage (at VIN = 2.7V) to the external N-channel

MOSFET. The range of 2.7V to 4.5V input supply

voltage is ideal for battery-powered applications, such

as portable electronic equipment. The internal linear

regulator is selected when a higher supply voltage rail

is available in the system.

Applications

In addition, a built-in timer is available to protect the

internal circuit and help dissipate the energy from the

external high-voltage storage capacitor. This device is

designed for systems requiring high-voltage and

low-current applications such as MEMS devices.

A feedback return ground path switch is also integrated

into the device to minimize the quiescent current during

the controller shutdown. This feature provides power

savings for energy-critical applications.

• Portable Electronic Equipment

• MEMS

• Printers

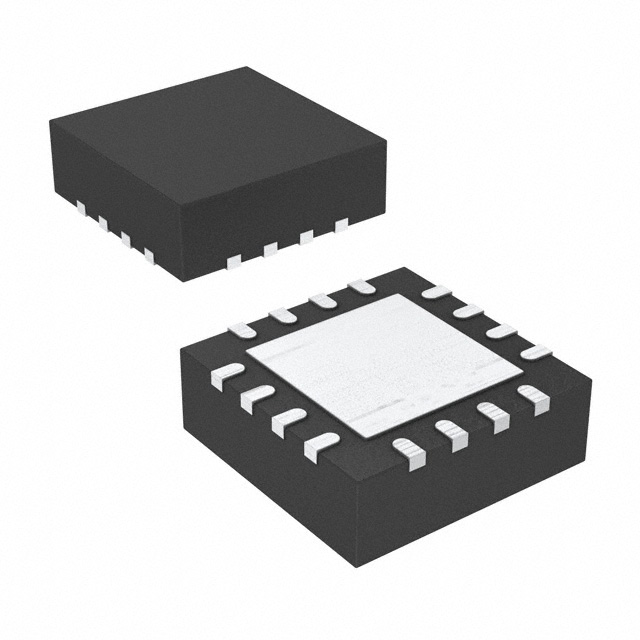

Package Type

CCP2+

CCP2-

CCP1+

CCP1-

16-lead QFN

(Top View)

16

VLL

1

VDD

GND

GATE

EN

FB_RTN

CT

EXT_REF

FREQ_ADJ

FB

VCONTROL

CP_EN

Pads are at the bottom of the package. Center heat slug is at ground potential. See Table 3-1 for pin information.

2017-2019 Microchip Technology Inc.

DS20005689B-page 1

�HV9150

Functional Block Diagram

VDD

CCP1+/-

CCP2+/-

VLL

CP

Mode

3x Charge Pump

Converter

LDO

Mode

VLL

VDD

LDO

VLL

CP_EN

VDD

VCONTROL

(Duty Cycle Adj)

GATE

OSC

VLL

FREQ_ADJ

VLL

VREF

-

+

Hysteretic Mode

Controller

EXT_REF

FB

FP_RTN

EN

Delay

CT

DS20005689B-page 2

GND

2017-2019 Microchip Technology Inc.

�HV9150

Typical Application Circuits

VDD

0.22μF

CCP1± CCP2±

0.22μF 0.22μF

VIN

2.7 - 4.5V

1.0μF

VLL

CP

Mode

L

LDO

Mode

VDD

3x Charge Pump

Converter

LDO

CP_EN

VLL

VOUT

6.0 - 500V

VDD

VCONTROL

GATE

OSC

VLL

VLL

FREQ_ADJ

VREF

- +

RFREQ

EXT_REF

FB

R2

FB_RTN

0V/3.3V

R1

EN

Delay

CT

GND

Charge Pump (CP) Mode

VDD

CCP1± CCP2±

CP

Mode

3x Charge Pump

Converter

VIN

5.0 - 12V

1.0μF

VLL

L

LDO

Mode

VDD

LDO

CP_EN

VLL

VOUT

15 - 500V

VDD

GATE

VCONTROL

OSC

VLL

VLL

FREQ_ADJ

VREF

- +

RFREQ

EXT_REF

FB

R2

FB_RTN

0V/3.3V

EN

R1

Delay

CT

GND

Linear Regulator (LDO) Mode

2017-2019 Microchip Technology Inc.

DS20005689B-page 3

�HV9150

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

Input Voltage Supply, VLL ........................................................................................................................... –0.5V to +5V

Charge Pump Output Voltage, VDD ....................................................................................................... –0.5V to +13.6V

Logic Input Levels ............................................................................................................................. –0.5V to VLL +0.5V

Operating Ambient Temperature, TA ................................................................................................... –25°C to +125°C

Storage Temperature, TS...................................................................................................................... –65°C to +150°C

Continuous Power Dissipation (On a 3 x 4-inch FR4 PCB at TA= 25°C):

16-lead QFN .......................................................................................................................................... 3000 mW

† Notice: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only, and functional operation of the device at those or any other conditions above those

indicated in the operational sections of this specification is not intended. Exposure to maximum rating conditions for

extended periods may affect device reliability.

RECOMMENDED OPERATING CONDITIONS

Parameter

Sym.

Min.

Typ.

Max.

Unit

Input Voltage (CP Mode)

VLL

2.7

—

4.5

V

High-level Input Voltage

VIH

0.8 VLL

—

VLL

V

Low-level Input Voltage

VIL

0

—

0.2 VLL

V

Conditions

DC ELECTRICAL CHARACTERISTICS

Electrical Specifications: Over recommended operating supply voltages and temperatures; unless otherwise noted,

TJ = 25°C.

Parameter

Sym.

Min.

Typ.

Max.

Unit

ILLQ(off)

—

—

2

μA

—

—

1.5

—

—

4

—

—

1

—

—

2.5

Conditions

POWER SUPPLY

Quiescent VLL Supply Current

(EN = ‘0’)

VLL Supply Current

(EN = ‘1’)

GATE = NC

GATE = 300 pF

ILL(on)

mA

fOSC = 100 kHz, VLL = 4.5V

mA

fOSC = 100 kHz, VDD = 12.6V

VDD Supply Current GATE = NC

(EN = ‘1’)

GATE = 300 pF

IDD(on)

Quiescent VDD Supply Current

(EN = ‘0’)

IDDQ(off)

—

—

2

μA

High-level Logic Input Current

IIH

—

—

1

μA

VIH = VLL

Low-level Logic Input Current

IIL

—

—

–1

μA

VIL = 0V

10.2

—

12.3

Gate Driver Output

Voltage

VLL = 4.5V

GATE = NC

VLL = 2.7V

GATE = NC

Linear Regulator Output Voltage

DS20005689B-page 4

GATE

VLL(LDO)

V

5

—

6.9

3

—

3.6

V

2017-2019 Microchip Technology Inc.

�HV9150

AC ELECTRICAL CHARACTERISTICS

Electrical Specifications: Over recommended operating supply voltages and temperatures; unless otherwise noted

TJ = 25°C.

Parameter

Sym.

Min.

Typ.

Max.

Unit

1.22

1.25

1.28

1.2

1.25

1.3

—

—

1

μA

0

—

VLL–1.4

V

0

—

0.12

V

0.5

—

VLL–1.4

V

—

—

500

Ω

—

—

13.5

V

Conditions

FEEDBACK (FB)

Internal Feedback Reference

Voltage

Accuracy

VREF

Range

Input Bias Current

IBIAS

Range

External

Reference

Voltage

Trigger INT

Reference

EXT_REF

Trigger EXT

Reference

On-resistance, RDS

Breakdown Voltage, BV

FB_RTN

V

TA = –25 to 85°C

EXT_REF is selected.

During EN positive triggering

IO= 2 mA

GATE DRIVER OUTPUT (GATE)

Rise Time

tr

—

—

36

ns

Fall Time

tf

—

—

12

ns

—

—

45

—

—

30

—

—

15

—

—

12

—

½ fOSC

—

Pull-up

Resistance

VDD = 5V

Pull-down

Resistance

VDD = 5V

RUP

VDD = 12V

RDOWN

VDD = 12V

Oscillator Frequency

fGATE

Ω

Ω

CL = 300 pF, VDD = 12V

IO = 20 mA

IO = 50 mA

IO = 20 mA

IO = 50 mA

kHz

CHARGE PUMP CONVERTER

Charge Pump Output Voltage

Oscillator

Frequency

VDD

Accuracy

fOSC

Range

Oscillator Frequency Tolerance

∆f

Accuracy

Duty Cycle

12.6

170

195

220

40

—

400

V

kHz

RFREQ = 270 kΩ, VLL= 3.3V

Over RFREQ range

—

15

—

%

50 kHz ≤ fOSC ≤ 250 kHz

86

87.5

90

%

RFREQ = 270 kΩ

—

0

—

%

0 < VCNTL ≤ 0.18 VLL

50

—

%

0.22 VLL < VCNTL ≤ 0.38 VLL

—

62.5

—

%

0.42 VLL < VCNTL ≤ 0.58 VLL

—

75

—

%

0.62 VLL < VCNTL ≤ 0.78 VLL

—

87.5

—

%

0.82 VLL < VCNTL ≤ VLL

VCONTROL

0

—

VLL

V

See Table 4-2.

RFREQ

120k

—

1.2M

Ω

—

—

20

—

—

20

Frequency Adjustment Resistor

Maximum Charge

Pump Output

Resistance

3 VLL–1.8

—

DC

Range

Duty Cycle Adjustment

5

2.7V ≤ VLL ≤ 4.5V

CCP1 = 220 nF

CCP2 = 220 nF

CCP3 = 220 nF

Pull-up

Pull-down

2017-2019 Microchip Technology Inc.

RCP

Ω

VLL = 2.7V, IO = 10 mA

DS20005689B-page 5

�HV9150

AC ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Over recommended operating supply voltages and temperatures; unless otherwise noted

TJ = 25°C.

Parameter

Sym.

Output Ripple at VDD

Min.

Typ.

Max.

Unit

Conditions

VRIPPLE

—

—

100

mV

2.7V ≤ VLL ≤ 4.5V

fOSC = 200 kHz

CCP1 = 220 nF

CCP2 = 220 nF

CCP3 = 220 nF

CGATE = 300 pF

BW = 20 MHz

tDELAY

—

240

—

ms

CT = 1 μF

DELAY TIMER

Shutdown Delay Timer

TEMPERATURE SPECIFICATIONS

Parameter

Sym.

Min.

Typ.

Max.

Unit

Operating Ambient Temperature

TA

–25

—

+125

°C

Storage Temperature

TS

–65

—

+150

°C

—

33

—

°C/W

Conditions

TEMPERATURE RANGE

PACKAGE THERMAL RESISTANCE

JA

16-lead QFN

100

87.5% Duty Cycle

87.5% Duty Cycle

90

82%

80

78%

Percentage of VLL

60

62%

58%

62.5% Duty Cycle

62.5% Duty Cycle

50

40

75% Duty Cycle

75% Duty Cycle

70

42%

38%

50% Duty Cycle

50% Duty Cycle

30

22%

20

10

0

FIGURE 1-1:

DS20005689B-page 6

18%

0% Duty Cycle

0% Duty Cycle

VCONTROL from Max to Min

VCONTROL from Min to Max

Duty Cycle Selection Hysteresis at VCONTROL Pin at 25°C.

2017-2019 Microchip Technology Inc.

�HV9150

Timing Waveforms

XQWV"*GZVaTGH+

XQWV"*KPVaTGH+

XQWV

2X

XKJ

GP

XKN

Initial power up

FIGURE 1-2:

Enabling to use the External Voltage Reference.

XQWV

2X

tDELAY

HDaTVP

2X

XKJ

GP

FIGURE 1-3:

XKN

Delay Time at FB_RTN.

VIN = 4.5V

VIN = 2.7V

FIGURE 1-4:

VCP Noise.

2017-2019 Microchip Technology Inc.

DS20005689B-page 7

�HV9150

2.0

TYPICAL PERFORMANCE CURVES

Note:

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g. outside specified power supply range) and therefore outside the warranted range.

35

12.0

Charge Pump Output Voltage VDD (V)

30

Rise time tr, VDD = 5V

(LDO mode)

25

11.0

CL = 100 pF

CL = 220 pF

CL = 330 pF

10.0

Rise time tr, VDD = 11V

(CP mode)

Time (ns)

20

15

Fall time tf, VDD = 5V

(LDO mode)

10

Fall time tf, VDD = 11V

(CP mode)

5

0

9.0

8.0

7.0

6.0

0

50

100

150

200

250

300

350

2.5

3.0

3.5

Load Capacitance (pF)

4.5

5.0

FIGURE 2-4:

Charge Pump Output

Voltage vs. Input Voltage at 25°C.

FIGURE 2-1:

Gate Driver Rise Time (tr)

and Fall Time (tf) vs. Load Capacitance at

25°C.

(VIN = 3.3V at 25OC)

1000

4.0

Input Voltage VLL (V)

(fGATE = 100 kHz, CCP1 = CCP2 = 0.22 µF, CVDD = 1.0 µF)

12

VLL = 4.5V

Output Voltage VDD (V)

Frequency (kHz)

11

100

10

9

VLL = 3.6V

8

VLL = 3.3V

7

6

10

10

100

1000

5

RFREQ (kΩ)

0

50

100

150

200

250

300

350

Load Capacitance (pF)

fGATE vs. RFREQ.

FIGURE 2-2:

VLL = 2.7V

FIGURE 2-5:

Charge Pump Output

Voltage vs. Load Capacitance at 25°C.

(Gate output load capacitance = 330 pF, RFREQ = 255 kΩ @ 25OC)

100

101

CP mode

Frequency (kHz)

Capacitance (µF)

100

10

1

99

LDO mode

98

97

96

0.1

10

100

1000

Delay (ms)

FIGURE 2-3:

CT Capacitor Value vs.

Delay Time at 25°C.

DS20005689B-page 8

10000

2

3

4

5

6

7

8

9

10

11

12

13

14

VLL Input Voltage (V)

FIGURE 2-6:

Gate Driver Switching

Frequency vs. VLL Input Voltage.

2017-2019 Microchip Technology Inc.

�HV9150

3.0

PIN DESCRIPTION

The details of the pins of HV9150 16-lead QFN are

listed in Table 3-1. Refer to Package Type for the pin

locations.

TABLE 3-1:

PIN FUNCTION TABLE

Pin Number

Pin Name

1

VLL

Input supply voltage

2

GND

Ground connection

3

EN

4

CP_EN

5

VCONTROL

Duty cycle adjustment voltage control input

6

FREQ_ADJ

Frequency adjustment

7

EXT_REF

8

CT

Timing capacitor

9

FB

Feedback input voltage

10

FB_RTN

11

GATE

Gate control output

12

VDD

Charge pump output voltage

13

CCP2+

Charge pump storage capacitor #2 plus terminal

14

CCP2–

Charge pump storage capacitor #2 minus terminal

15

CCP1+

Charge pump storage capacitor #1 plus terminal

16

CCP1–

Charge pump storage capacitor #1 minus terminal

Center Pad

Description

Enable

Charge pump/LDO enable input

External reference voltage input

Feedback return

Substrate connection (at ground potential)

2017-2019 Microchip Technology Inc.

DS20005689B-page 9

�HV9150

4.0

FUNCTIONAL DESCRIPTION

Follow the steps in Table 4-1 to power up and power

down the HV9150.

TABLE 4-1:

POWER-UP AND POWER-DOWN SEQUENCE

Power-up

Step

1

2

3

Power-down

Description

Step

Connect ground.

Apply VIN.

Set all inputs to a known state.

4.1

1

2

3

Hysteretic Mode Controller

4.2

A Hysteretic mode controller consists of an oscillator, a

voltage reference, a comparator and a driver. Both the

internal oscillator and the duty cycle of the gate driver

are running at a fixed rate.

As this device is designed for a step-up conversion, a

pulse train is used to control the switch of a classical

switching boost converter. The pulse train is gated by

the output of the comparator, which compares the

feedback of the output voltage with the voltage

reference.

If the output voltage reaches the target voltage, the

comparator will turn off the pulse train. When the output

voltage drops below the target voltage, the comparator

will pass the pulse train to the switch and start the

inductor charging cycle. The advantage of this

Hysteretic mode controller is its stability and simple

operation. The diagram in Figure 4-1 shows a

Hysteretic Mode controller and a classical boost

converter.

XKP

XQWV

J{uvgtgvke"Oqfg

Eqpvtqnngt

FIGURE 4-1:

A Hysteretic Mode

Controller and a Classical Boost Converter.

DS20005689B-page 10

Description

Remove all inputs.

Remove VIN.

Disconnect ground.

Internal Oscillator

This device has an internal oscillator which generates

the reference clock for the Hysteretic mode controller.

The controller is running at half of the frequency of the

internal oscillator. This oscillator is powered by the VLL

power supply pin. The frequency of the oscillator is set

by the external resistor RFREQ, and this frequency is

inversely proportional to the value of RFREQ. Its

characteristic is shown in Figure 2-2, fGATE vs. RFREQ

diagram, where fGATE = 1/2 fOSC. See Equation 4-1.

EQUATION 4-1:

1

f OSC = ----------------------------------4 R FREQ C

Where: C = 4.75 pF

4.3

Voltage Reference (VREF)

The voltage reference is used by the comparator to

compare it with the feedback voltage and the boost

converter output. This device provides the options of

using either its internal voltage reference or an external

voltage reference.

The internal voltage reference provides a stable 1.25V

with a tolerance of ±2.5%. With the use of ±1%

tolerance feedback resistors, the output can be

achieved with a tolerance of ±4.5%. In order to use the

internal voltage reference, the EXT_REF pin must be

connected to ground.

If the output voltage of the boost converter is required

to have high precision and tight tolerance, the external

voltage reference can be used to achieve that purpose.

The external reference voltage must be between 0.5V

and VLL–1.4V and connected to the EXT_REF pin. A

single low-to-high transition must be presented at the

EN pin to trigger the device to select an external

voltage reference. If no enable control signal is

available in the application, this signal can be easily

mimicked by a simple RC circuit. See Figure 4-2.

2017-2019 Microchip Technology Inc.

�HV9150

4.6

VIN

EXT_REF

GND

EXT_REF

Internal

FIGURE 4-2:

Reference.

4.4

Voltage

Reference

GND

External

Voltage Connection

Gate Driver (Gate)

The MOSFET gate driver of this controller is especially

designed to drive the gate of the external MOSFET up

to 12V. A high pulse voltage will help minimize the

on-resistance of the external MOSFET transistor. A

lower on-resistance improves the overall efficiency and

heat dissipation.

This gate driver is powered by the supply voltage VDD

which can be generated by either the internal charge

pump converter (CP mode) or the external power

supply (LDO mode), depending on the available

voltage supply rail of the application. See Typical

Application Circuits.

4.5

Charge Pump Converter

(CP Mode)

A 3X charge pump converter is integrated into this

device to provide a 5V to 12V rail for the gate driver.

(See Figure 4-3.) It can be activated by setting CP_EN

to ground. A 3.3V supply is more common and easily

available for digital logic systems. However, this

voltage level is less desirable for driving a high-voltage

MOSFET to obtain a lower on-resistance, which

improves efficiency.

To reduce the number of supply rails used in the

system, an internal two-stage charge pump converter

is added, which can boost the 3.3V supply voltage to

8V. Compared to a 3.3V gate driver, an 8V gate driver

output will substantially improve the on-resistance of

the external MOSFET.

The charge pump input can operate with an input

voltage from 2.7V to 4.5V. Its input and output are

connected to the VLL and VDD pins, respectively.

XNN

XFF

Linear Regulator (LDO Mode)

In some applications, efficiency may be a key factor,

and higher voltage rails such as 5V, 6V, 9V or 12V may

be available in the system. The internal charge pump

converter cannot operate with these voltage levels

because of the maximum output voltage limit of the

charge pump converter. At the same time, these

voltage levels are high enough to provide adequate

supply for the gate driver.

Under this circumstance, an internal linear regulator is

used to replace the charge pump converter. This linear

regulator input can accept voltage from 5V to 12V and

generate a 3.3V output to supply the internal circuit.

This linear regulator can be activated by setting CP_EN

to VLL.

In a scenario when the device is operating in LDO

mode and in Shutdown state (EN = ‘0’), the voltage at

VLL is undefined. To wake up the controller device, a

voltage above 2.7V has to be presented at the enable

pin (EN).

4.7

FB Ground Return Switch

(FB_RTN)

Any DC/DC controller requires feedback from the

output to monitor its operation so that it can regulate its

output accordingly. A simple resistor network is used in

conjunction with a feedback ground switch as a

feedback path. The purpose of this feedback ground

switch is to save power consumed by the feedback

resistor network when the controller is disabled. This

function is quite useful for power saving, especially for

battery-operated applications.

4.8

Shutdown Timer and Timing

Capacitor (CT)

A shutdown timer is also integrated into the controller

for safety purposes. When the controller shuts down

from its normal operation, the converter’s initial output

is still at its high level. If the feedback ground return

switch is disabled at the same time, a current path is

created from the output via the feedback resistor and

the internal protection clamping diode at the FB pin.

(See Figure 4-4.) Depending upon the value of the FB

resistor, this momentarily conducting current can be

high enough to damage this clamping diode. To avoid

this potential problem, a timer is added to the disable

function to keep the feedback ground switch to on

position for a short period of time. This on-time duration

is controlled by an external capacitor CT. The larger the

capacitor value is, the longer the on-time is. Its

characteristic is shown in Figure 2-3.

QUE

FIGURE 4-3:

Converter.

A 3X Charge Pump

2017-2019 Microchip Technology Inc.

DS20005689B-page 11

�HV9150

4.10

VOUT

R2

FB

Internal

Protection

Diode

R1

FB_RTN

0V/3.3V

EN

Delay

CT

Duty Cycle Control (VCONTROL)

The input voltage at the VCONTROL pin manages the

duty cycle of the internal oscillator output to the gate

driver. All internal comparators are powered by the VLL

supply and all their input threshold voltages are

referenced to VLL voltage. A voltage divider formed by

the two external resistors shown in Figure 4-6 can be

adjusted accordingly to select the desired duty cycle of

the pulse signal to the gate driver. See Table 4-2.

GND

TABLE 4-2:

FIGURE 4-4:

FB Pin.

4.9

VCONTROL

Internal Protection Diode at

The controller enable pin (EN), serves two main

purposes. The most obvious function is to turn on and

off the controller, and the other function is to act as a

trigger to activate the device to accept external voltage

reference.

For any applications requiring a highly precise voltage

reference, an external voltage reference should be

used. To activate the device to accept the external

voltage reference, a low-to-high transition has to

appear at the EN pin while the voltage at the EXT_REF

pin is above 0.5V.

0.22 VLL to 0.38 VLL

50%

62.5%

0.62 VLL to 0.78 VLL

87.5%

VLL

VLL

VCONTROL

EN

+

-

Duty Cycle 87.5%

+

-

Duty Cycle 75.0%

+

-

Duty Cycle 62.5%

+

-

Duty Cycle 50.0%

GND

Simple RC Circuit for EN

FIGURE 4-6:

DS20005689B-page 12

75%

0.82 VLL to 1 VLL

R

C

0%

0.42 VLL to 0.58 VLL

If the system lacks enable function control, an RC

circuit can be used to mimic this function to allow the

external voltage reference. Refer to Figure 4-5.

FIGURE 4-5:

Pin.

Duty Cycle

0 VLL to 0.18 VLL

Hysteretic Controller Enable

3.3V (min)

DUTY CYCLE SELECTION

Duty Cycle Control Circuit.

2017-2019 Microchip Technology Inc.

�HV9150

4.11

Design Procedure

There are several parameters that a user needs to

consider for the DC/DC converter design. The input

voltage, output voltage and output power requirement

are usually defined at the beginning. The other

parameters that may be included are: operating

frequency, inductor value, duty cycle and the

on-resistance of the MOSFET. There is some degree of

flexibility in deciding the values of these parameters.

The following provides the user a general design

approach:

4.11.1

STEP 1

Since this DC/DC controller device is operating in a

Discontinuous Conduction mode, determine the

inductance and the switching frequency with

Equation 4-2.

EQUATION 4-2:

Given:

D = Duty cycle

R = Load resistance of the high voltage output

Vi = Minimum input voltage

Vo = Output voltage

Unknown:

L = Inductance

fGATE = Driver switching frequency

Where:

2

Vi

4D

V o = ----- 1 + 1 + ----------

2

K

2 L f GATE

K = -------------------------------R

The maximum duty cycle can be computed with

Equation 4-3.

EQUATION 4-3:

V

D MAX = 1 – ------i

Vo

4.11.2

STEP 2

The standard inductor is usually sold in an incremental

inductance value, for example, 10 µH, 22 µH, 33 µH or

47 µH. The user can choose the inductance based on

the size of the inductor, the peak current, the maximum

operating frequency and the DC resistance. After the

value of L is decided, the gate driver switching

frequency can be computed. The required RFREQ

resistance can be found in the fGATE vs. RFREQ

diagram. (See Figure 2-2.) Next, the user may check

the peak current of the inductor with Equation 4-4. The

saturation current of the inductor must be larger than

IPEAK.

EQUATION 4-4:

Vi D

I PEAK = ----------------------L f GATE

4.11.3

STEP 3

The most important factors in determining the

MOSFET are the breakdown voltage, the current

capability, the on-resistance, the minimum VGS

threshold voltage and the input capacitance.

The HV9150 gate driver is designed to drive a

maximum of 300 pF capacitive load. Therefore, the

maximum input capacitance of the external MOSFET

should be less than 300 pF. The minimum breakdown

voltage must be larger than the required DC/DC

converter output voltage. If the breakdown voltage is

too low, the output will never reach the required voltage

output. A MOSFET with high on-resistance will limit the

peak current charging the inductor. The user can use a

simple RL charging circuit equation to determine its

final charging current. See Equation 4-5.

EQUATION 4-5:

R ON

Vi

D

I L = ---------- 1 – exp – -------------- ----------

R ON

L

f GATE

It is recommended that the calculated value of IL is

within 95% of the IPEAK calculated in Equation 4-4. An

on-resistance of less than 1Ω is usually a good starting

point.

If the final circuit is short on the output current

capability, the user can do any or all of the following to

boost the output:

Then, the user can select any duty cycle less than

DMAX. Choosing the largest possible setting is highly

recommended.

1. Increase the duty cycle.

2. Decrease the fGATE.

3. Use a MOSFET with lower on-resistance.

To compensate for the limited efficiency, the user can

add the efficiency factor into the load resistance R. With

the above equation, the product of L and fGATE is

determined. The product will also limit the design.

2017-2019 Microchip Technology Inc.

DS20005689B-page 13

�HV9150

NOTES:

DS20005689B-page 14

2017-2019 Microchip Technology Inc.

�HV9150

5.0

PACKAGE MARKING INFORMATION

5.1

Packaging Information

16-lead QFN

XXXXX

XYWW

NNN

Legend: XX...X

Y

YY

WW

NNN

e3

*

Note:

Example

H15

0724

485

Product Code or Customer-specific information

Year code (last digit of calendar year)

Year code (last 2 digits of calendar year)

Week code (week of January 1 is week ‘01’)

Alphanumeric traceability code

Pb-free JEDEC® designator for Matte Tin (Sn)

This package is Pb-free. The Pb-free JEDEC designator ( e3 )

can be found on the outer packaging for this package.

In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for product code or customer-specific information. Package may or

not include the corporate logo.

2017-2019 Microchip Technology Inc.

DS20005689B-page 15

�HV9150

Note: For the most current package drawings, see the Microchip Packaging Specification at www.microchip.com/packaging.

DS20005689B-page 16

2017-2019 Microchip Technology Inc.

�HV9150

APPENDIX A:

REVISION HISTORY

Revision B (March 2019)

• Updated AC Electrical Characteristics table.

Revision A (February 2017)

• Converted Supertex Doc# DSFP-HV9150 to

Microchip DS20005689B

• Changed the quantity of the 16-lead QFN K6

package from 3000/Reel to 3300/Reel

• Made minor text changes throughout the document

2017-2019 Microchip Technology Inc.

DS20005689B-page 17

�HV9150

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, contact your local Microchip representative or sales office.

PART NO.

Device

XX

-

Package

Options

X

-

Environmental

X

Media Type

Device:

HV9150

=

High-Voltage Output Hysteretic-Mode

Step-Up DC/DC Controller

Package:

K6

=

16-lead VQFN

Environmental:

G

=

Lead (Pb)-free/RoHS-compliant Package

Media Type:

(blank)

=

3300/Reel for a K6 Package

DS20005689B-page 18

Example:

a) HV9150K6-G:

High-Voltage Output HystereticMode Step-Up DC/DC Controller,

16-lead VQFN Package,

3300/Reel

2017-2019 Microchip Technology Inc.

�Note the following details of the code protection feature on Microchip devices:

•

Microchip products meet the specification contained in their particular Microchip Data Sheet.

•

Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

•

There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

•

Microchip is willing to work with the customer who is concerned about the integrity of their code.

•

Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC® MCUs and dsPIC® DSCs, KEELOQ® code hopping

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

QUALITY MANAGEMENT SYSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

2017-2019 Microchip Technology Inc.

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, AVR Freaks, BitCloud, chipKIT, chipKIT logo,

CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo,

JukeBlox, KeeLoq, Kleer, LANCheck, LINK MD, maXStylus,

maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip

Designer, QTouch, SAM-BA, SpyNIC, SST, SST Logo,

SuperFlash, tinyAVR, UNI/O, and XMEGA are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMOS,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity,

JitterBlocker, KleerNet, KleerNet logo, memBrain, Mindi, MiWi,

motorBench, MPASM, MPF, MPLAB Certified logo, MPLIB,

MPLINK, MultiTRAK, NetDetach, Omniscient Code Generation,

PICDEM, PICDEM.net, PICkit, PICtail, PowerSmart, PureSilicon,

QMatrix, REAL ICE, Ripple Blocker, SAM-ICE, Serial Quad I/O,

SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2019, Microchip Technology Incorporated, All Rights

Reserved.

ISBN: 978-1-5224-4311-7

DS20005689B-page 19

�Worldwide Sales and Service

AMERICAS

ASIA/PACIFIC

ASIA/PACIFIC

EUROPE

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Australia - Sydney

Tel: 61-2-9868-6733

India - Bangalore

Tel: 91-80-3090-4444

China - Beijing

Tel: 86-10-8569-7000

India - New Delhi

Tel: 91-11-4160-8631

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

China - Chengdu

Tel: 86-28-8665-5511

India - Pune

Tel: 91-20-4121-0141

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

China - Chongqing

Tel: 86-23-8980-9588

Japan - Osaka

Tel: 81-6-6152-7160

Finland - Espoo

Tel: 358-9-4520-820

China - Dongguan

Tel: 86-769-8702-9880

Japan - Tokyo

Tel: 81-3-6880- 3770

China - Guangzhou

Tel: 86-20-8755-8029

Korea - Daegu

Tel: 82-53-744-4301

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

China - Hangzhou

Tel: 86-571-8792-8115

Korea - Seoul

Tel: 82-2-554-7200

China - Hong Kong SAR

Tel: 852-2943-5100

Malaysia - Kuala Lumpur

Tel: 60-3-7651-7906

China - Nanjing

Tel: 86-25-8473-2460

Malaysia - Penang

Tel: 60-4-227-8870

China - Qingdao

Tel: 86-532-8502-7355

Philippines - Manila

Tel: 63-2-634-9065

China - Shanghai

Tel: 86-21-3326-8000

Singapore

Tel: 65-6334-8870

China - Shenyang

Tel: 86-24-2334-2829

Taiwan - Hsin Chu

Tel: 886-3-577-8366

China - Shenzhen

Tel: 86-755-8864-2200

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Israel - Ra’anana

Tel: 972-9-744-7705

China - Suzhou

Tel: 86-186-6233-1526

Taiwan - Taipei

Tel: 886-2-2508-8600

China - Wuhan

Tel: 86-27-5980-5300

Thailand - Bangkok

Tel: 66-2-694-1351

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

China - Xian

Tel: 86-29-8833-7252

Vietnam - Ho Chi Minh

Tel: 84-28-5448-2100

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

DS20005689B-page 20

China - Xiamen

Tel: 86-592-2388138

China - Zhuhai

Tel: 86-756-3210040

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-67-3636

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-7288-4388

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

2019 Microchip Technology Inc.

08/15/18

�