HV9985

3-Channel Closed-Loop Switch-Mode LED Driver IC

Features

General Description

• Switch Mode Controller for Single-Switch

Converters

• Gate Drivers Optimized for Driving Logic Level

FETs

- 0.25A Sourcing

- 0.5A Sinking

• Typical ±2% Absolute and String-to-String Current

Accuracy (with ±1% Sense Resistors)

• High Pulse-Width Modulation (PWM) Dimming

Ratio up to 5000:1

• 10V to 40V Input Range

• Constant Frequency Operation up to 1 MHz

• On-Chip Clock or External Clock Option

• Programmable Slope Compensation

• Linear and PWM Dimming

• Output LED Short-Circuit Protection

• Output Overvoltage Protection

• Hiccup Mode Protection

The HV9985 is a 3-channel Peak Current mode PWM

controller for driving single-switch converters in a

constant output Current mode. It can be used for

driving either RGB LEDs or multiple channels of white

LEDs.

The HV9985 features a 40V linear regulator, which

provides a 5V supply to power the IC. The switching

frequencies of the three converters in the IC are

controlled either with an external clock signal (the

channels operate at a switching frequency of 1/12th of

the external clock frequency) or using the internal

oscillator. The three channels are positioned 120°

out-of-phase to reduce the input current ripple. Each

converter is driven by a Peak Current mode controller

with output current feedback.

The three output currents can be individually dimmed

using either linear or PWM dimming. The IC also

includes three disconnect FET drivers, which enable

high PWM dimming ratios and disconnect the LED load

in case of an output LED Short-circuit condition. The

HV9985 includes Hiccup mode protection for both open

LED and Short-circuit condition to prevent the IC from

shutting down in cases of intermittent Fault conditions.

Applications

• RGB Backlight Applications

• Boost, Buck, and SEPIC Topologies

• Multiple String White LED Driver Applications

Package Type

VDD1

1

GATE3

GND3

VDD2

GND2

FLT2

GATE2

FDBK2

CS2

GND1

GATE1

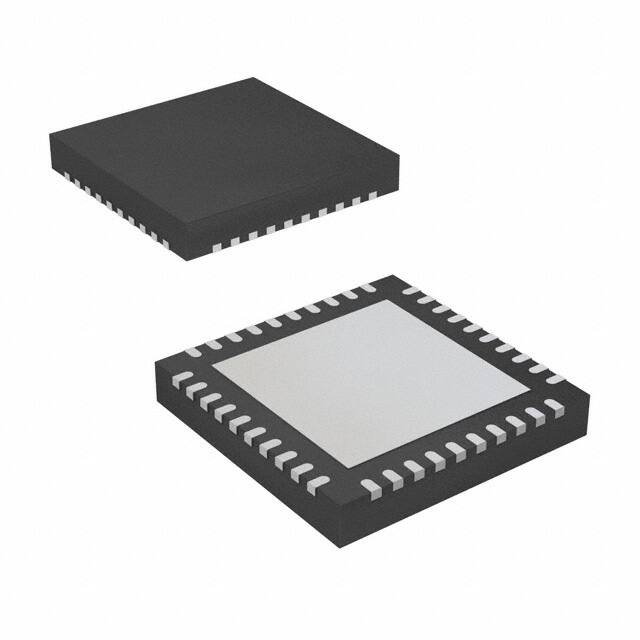

40-lead QFN

(Top view)

40

VDD3

FLT1

FLT3

CS1

CS3

COMP3

COMP1

FDBK1

FDBK3

GND

REF1

REF3

OVP1

OVP3

VIN

CLK

VDD

RT

EP

NC

PWMD3

PWMD1

PWMD2

NC

SKIP

OVP2

REF2

GND

NC

COMP2

EN

Refer to Table 2-1 for pin information.

2019 Microchip Technology Inc.

DS20005558B-page 1

�HV9985

Typical Application

D1b (Optional)

CIN

Q1a

L1

CIN1

D1a

CSC1

CVDD1

CVDD

VDD

VDD1

RCS1

GATE1

CS1

GND1 OVP1

HV9985

(One Channel Shown)

RT

RT

PWMD1

CLK

SKIP

CSKIP

DS20005558B-page 2

ROVP1b

Q1b

FLT1

GND

CO1

RSC1

VIN

EN

ROVP1a

FDBK1

COMP1

CC1

REF1

CREF1 RREF1

RS1

REF

2019 Microchip Technology Inc.

�HV9985

Functional Block Diagram

VIN

POR

FDA

FDB

FDC

S

Q

0.1V

+

Fault

EN

VDD

GND

Linear

Regulator

UVLO

POR

R

-

5μA

1.6V

+

-

SKIP

DIS

CLK A

CLK B

CLK C

Fault

θ=0

θ = 120

θ = 240

CLK

FC

RT

Common Circuitry

Circuitry for a single channel

PWMDA

CLKA

VDD1

S

R

GATE1

FC

Q

1

+

-

PWMDA

PWMD1

Q

100kΩ

CS1

BLANKING

CLKA

GND1

1

PWMDA

FC

FLT1

R

1

+

+

OVP1

REF

-

FDA

0.2V

8R

PWMDA

REF1

+

-

FDBK1

2

BLANKING

PWMDA

COMP1

DIS

1

2019 Microchip Technology Inc.

DS20005558B-page 3

�HV9985

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings †

VIN to GND ................................................................................................................................................–0.3V to +45V

VDD to GND, VDD1-3 to GND .......................................................................................................................–0.3V to +6V

All other pins to GND .....................................................................................................................–0.3V to (VDD +0.3V)

Junction Temperature, TJ ..................................................................................................................... –40°C to +150°C

Storage Ambient Temperature, TS ....................................................................................................... –65°C to +150°C

Continuous Power Dissipation (TA= +25°C) .................................................................................................... 4000 mW

† Notice: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only, and functional operation of the device at those or any other conditions above those

indicated in the operational sections of this specification is not intended. Exposure to maximum rating conditions for

extended periods may affect device reliability.

ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise noted, specifications are at TA = 25°C.

VIN = 24V, VDD1 = VDD2 = VDD3 = VDD unless otherwise indicated.

Parameter

Sym.

Min.

Typ.

Max.

Unit

INPUT

Input DC Supply Voltage

Shutdown Mode Supply Current

Supply Current

VINDC

IINSD

IIN

10

—

—

—

—

—

40

200

1.5

V

µA

mA

DC input voltage (Note 1)

VEN ≤ 0.8V (Note 1)

VEN ≥ 2V, PWMD1 = PWMD2 =

PWMD3 = GND

VDD

4.75

5

5.25

V

VIN = 10V to 40V, EN = HIGH,

PWMD1-3 = VDD;

GATE1-3 = 2 nF; CLK = 6 MHz

(Note 1)

VDD rising

INTERNAL REGULATOR

Internally Regulated Voltage

Conditions

VDD Undervoltage Lockout

UVLORISE 4.25

—

4.75

V

Threshold

UVLOHYST

—

250

—

mV VDD falling

VDD Undervoltage Lockout

Hysteresis

ENABLE INPUT

EN Input Low Voltage

VEN(LO)

—

—

0.8

V

Note 1

EN Input High Voltage

VEN(HI)

2

—

—

V

Note 1

EN Pull-Down Resistor

REN

50

100

150

kΩ VEN = 5V

PWM DIMMING (PWMD1, PWMD2, AND PWMD3)

PWMD Input Low Voltage

VPWMD(LO)

—

—

0.8

V

Note 1

PWMD Input High Voltage

VPWMD(HI)

2

—

—

V

Note 1

PWMD Pull-Down Resistor

RPWMD

50

100

150

kΩ VPWMD = 5V

GATE (GATE1, GATE2, AND GATE3)

VGATE = 0V (Note 2)

GATE Short-Circuit Current,

ISOURCE

0.25

—

—

A

Sourcing

VGATE = VDD (Note 2)

GATE Sinking Current

ISINK

0.5

—

—

A

GATE Output Rise Time

TRISE

—

—

85

ns CGATE = 2 nF (Note 1)

GATE Output Fall Time

TFALL

—

—

45

ns CGATE = 2 nF (Note 1)

Maximum Duty Cycle

DMAX

—

91.7

—

%

Note 2

Note 1: Specifications apply over the full operating ambient temperature range of –40°C < TA < +85ºC. Limits are

obtained by design and characterization.

2: For design guidance only

DS20005558B-page 4

2019 Microchip Technology Inc.

�HV9985

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, specifications are at TA = 25°C.

VIN = 24V, VDD1 = VDD2 = VDD3 = VDD unless otherwise indicated.

Parameter

Sym.

Min.

Typ.

OVERVOLTAGE PROTECTION (OVP1, OVP2, AND OVP3)

Overvoltage Rising Trip Point

VOVP,RISING 1.13 1.25

Overvoltage Hysteresis

VOVP,HYST

—

125

CURRENT SENSE (CS1, CS2, and CS3)

Leading Edge Blanking

TBLANK

100

—

Delay to Output of GATE

TDELAY

—

—

Max.

Unit

Conditions

1.37

—

V

mV

OVP rising (Note 1)

OVP falling

250

200

ns

ns

Note 1

100 mV overdrive to the current sense

comparator

GATE = Low (Note 1)

Discharge Resistance for Slope

RDIS

—

—

100

Ω

Compensation

INTERNAL TRANSCONDUCTANCE OP-AMP (OTA1, OTA2, AND OTA3)

Gain Bandwidth Product

GBW

—

1

—

MHz 75 pF capacitance at COMP pin

(Note 2)

Open-Loop DC Gain

AV

65

—

—

dB Output open

Input Common-Mode Range

VCM

–0.3

—

3

V

Note 2

Output Voltage Range

VO

—

—

VDD

— Note 2

Transconductance

gm

500

625

750 µA/V

Input Offset Voltage

VOFFSET

–5

—

5

mV

Input Bias Current

IBIAS

—

0.5

1

nA Note 2

Resistor Divider Ratio

—

0.11

—

— Note 2

RRATIO

(∆VCS/∆VCOMP)

EXTERNAL CLOCK INPUT

Oscillator Frequency

fOSC1

—

500

—

kHz FCLOCK = 6 MHz

Oscillator Divider Ratio

KSW

—

12

—

— Note 2

GATE1–GATE2 Phase Delay

—

120

—

°

Note 2

PHI1

GATE1–GATE3 Phase Delay

—

240

—

°

Note 2

Minimum CLOCK Low Time

TOFF,MIN

50

—

—

ns Note 2

Minimum CLOCK High Time

TON,MIN

50

—

—

ns Note 2

CLOCK Input High

VCLOCK,HI

2

—

—

V

Note 1

CLOCK Input Low

VCLOCK,LO

—

—

0.8

V

Note 1

OSCILLATOR

110

125

140

kHz RT = 400 kΩ

FOSC1

Switching Frequency (Common

for all Channels)

FOSC2

440

500

560

kHz RT = 100 kΩ

Switching Frequency Range

FOSC

—

—

1000 kHz Note 2

DISCONNECT DRIVER (FLT1, FLT2, AND FLT3)

Fault Output Rise Time

TRISE,FAULT

—

—

300

ns 500 pF capacitor at FLT pin (Note 1)

Fault Output Fall Time

TFALL,FAULT

—

—

200

ns 500 pF capacitor at FLT pin (Note 1)

SHORT-CIRCUIT PROTECTION (ALL THREE CHANNELS)

PWMD changes from low to high.

400

—

700

ns

Blanking Time

TBLANK,SC

(Note 1)

Gain for Short-Circuit

GSC

1.85

2

2.15

—

Comparator

Minimum Current Limit

0.15

—

0.25

V

REF = GND

VCL(MIN)

Threshold

Note 1: Specifications apply over the full operating ambient temperature range of –40°C < TA < +85ºC. Limits are

obtained by design and characterization.

2: For design guidance only

2019 Microchip Technology Inc.

DS20005558B-page 5

�HV9985

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise noted, specifications are at TA = 25°C.

VIN = 24V, VDD1 = VDD2 = VDD3 = VDD unless otherwise indicated.

Parameter

Sym.

Min.

Typ.

Max.

Unit

Conditions

Propagation Time for

TOFF

—

—

250

ns VFDBK = 2 • VREF + 0.1V (Note 1)

Short-Circuit Detection

SKIP TIMER

—

5

—

µA

Current Source at SKIP Pin

IHC,SOURCE

used for Hiccup Mode Protection

—

1.5

—

V

Note 2

Voltage Swing at SKIP Pin

ΔVSKIP

Note 1: Specifications apply over the full operating ambient temperature range of –40°C < TA < +85ºC. Limits are

obtained by design and characterization.

2: For design guidance only

TEMPERATURE SPECIFICATIONS

Parameter

Sym.

Min.

Typ.

Max.

Unit

TA

–40

—

+85

°C

Operating Junction Temperature

TJ

–40

—

+125

°C

Maximum Junction Temperature

TJ(ABSMAX)

—

—

+150

°C

TS

–65

—

+150

°C

JA

—

24

—

°C/W

Conditions

TEMPERATURE RANGES

Operating Ambient Temperature

Storage Ambient Temperature

PACKAGE THERMAL RESISTANCES

40-lead QFN

Note 1:

Note 1

JA for QFN package is based on a four-layer PCB as per JESD51-9.

DS20005558B-page 6

2019 Microchip Technology Inc.

�HV9985

2.0

PIN DESCRIPTION

The details on the pins of HV9985 40-lead QFN are

listed in Table 2-1. Refer to Package Type for the

location of pins.

TABLE 2-1:

PIN FUNCTION TABLE

Pin Number

Pin Name

Description

1

VDD1

33

VDD2

30

VDD3

These pins are the power supply pins of the three channels. They can either be connected to the VDD pin or powered by an external power supply. They must be

bypassed with a low-ESR capacitor to their respective GNDs (at least 0.1 μF). All VDD

pins (VDD, VDD1-3) must be connected together externally when the internal 5V linear

regulator is used. An external 5V supply can be connected to these pins to power the IC

if the internal regulator is not used.

2

FLT1

36

FLT2

29

FLT3

3

CS1

37

CS2

28

CS3

4

COMP1

12

COMP2

27

COMP3

5

FDBK1

38

FDBK2

26

FDBK3

6

REF1

13

REF2

These pins are used to drive external logic-level disconnect switches. The disconnect

switches are used to protect the LEDs in case of Fault conditions and serve to provide

excellent PWM dimming response by disconnecting and reconnecting the LEDs from

the output capacitor during PWM dimming.

These pins are used to sense the source current of the external power FETs. They

include a built-in 100 ns (minimum) blanking timer. Connecting an RC-network to these

pins programs the slope compensation. Refer to Section 3.5 “Slope Compensation”

for additional information.

Stable closed-loop control can be accomplished by connecting a compensation network

between each COMP pin and its respective GND.

These pins are the output current feedback inputs for each channel. They receive voltage signal from external sense resistors.

The voltage at these pins sets the output current level for each channel. The recommended voltage range for these pins is 0V to 1.25V.

25

REF3

7

OVP1

14

OVP2

24

OVP3

8

VIN

This is the input of the internal 40V maximum input linear regulator with 5V regulated

output.

9

VDD

This pin is the output of the linear regulator. It maintains a regulated 5V as long as the

voltage of the VIN pin is between 10V and 40V. It must be bypassed with a low-ESR

capacitor to GND (at least 0.1 µF). This pin can be used as a power supply for the three

channels.

10

EN

When the pin is pulled below 0.8V, the IC goes into a Standby mode and draws minimal

current.

11

GND

Ground connection for the common circuitry in the HV9985

15

SKIP

This pin programs the hiccup timer for Fault conditions. A capacitor to GND programs

the hiccup time.

16

NC

17

PWMD1

18

PWMD2

19

PWMD3

20

21

NC

These pins provide the overvoltage protection for the three channels. When the voltage

at any of these pins exceeds 1.25V, the HV9985 is turned off. The fault timer starts

when the voltage drops below 1.125V. Upon completion of the fault timer, the IC

attempts to restart.

No connect

PWM dimming of the three channels is accomplished by using the PWMD pins. The

three pins directly control the PWM dimming of the three channels, and a square wave

input should be applied to these pins.

No connect

2019 Microchip Technology Inc.

DS20005558B-page 7

�HV9985

TABLE 2-1:

PIN FUNCTION TABLE (CONTINUED)

Pin Number

Pin Name

Description

22

RT

A resistor at this pin programs the on-board oscillator. If an external clock is being used,

this pin should be either left open or connected to GND.

23

CLK

This pin is the clock input for the HV9985. The input to the CLK pin should be a

TTL-compatible square wave signal. The three channels will switch at 1/12th the frequency of the signal applied at the CLK pin. This pin is used if multiple HV9985s are

being used in a system. If the on-chip oscillator is being used, this pin should be connected to GND.

40

GATE1

35

GATE2

31

GATE3

39

GND1

34

GND2

32

GND3

EP

GND

DS20005558B-page 8

These pins are the gate drivers which drive the external logic-level N-channel boost

converter MOSFETs.

Ground return for each of the channels. It is recommended that all the GNDs of the IC

be connected together in a STAR connection at the input GND terminal to ensure best

performance.

Exposed backside pad. It must be connected to pin 11 and GND plane on PCB to

maximize the thermal performance of the package.

2019 Microchip Technology Inc.

�HV9985

3.0

FUNCTIONAL DESCRIPTION

3.1

Power Topology

The HV9985 is a 3-channel Switch-mode converter

LED driver designed to control a boost, a buck, or a

SEPIC converter in a constant frequency, Peak

Current-controlled mode. The IC includes an internal

linear regulator, which operates from input voltage 10V

to 40V and provides a 5V supply to power the IC. The

IC can also be powered directly with the VDD pins and

bypassing the internal linear regulator. The IC includes

features typically required in LED drivers like open LED

protection, output LED string short-circuit protection,

linear and PWM dimming, and accurate control of the

LED current. The IC is ideally suited for backlight

application using either RGB or multi-channel white

LED configurations.

3.2

Power Supply to the IC

(VIN, VDD, and VDD1–3)

The device can be powered directly from its VIN pin that

takes a voltage up to 40V. When a voltage is applied to

the VIN pin, the HV9985 tries to maintain a constant 5V

(typical) at the VDD pin. The regulator also has a built-in

under-voltage lockout which shuts off the IC if the

voltage at the VDD pin falls below the UVLO threshold.

By connecting this VDD pin to the individual VDD pins of

the three channels, the internal regulator can be used

to power all three channels in the IC.

If the internal regulator is not utilized, an external power

supply (5V +/– 10%) can be used to power the IC. In

this case, the power supply is directly connected to the

VDD pins and the VIN pin.

All four VDD pins must be bypassed by a low-ESR

capacitor (≥0.1 μF) to provide a low impedance path for

the high frequency current of the output gate driver.

These capacitors must be referenced to the individual

grounds for proper noise rejection (see Figure 3-5 for

more information). Also, in all cases, the four VDD pins

must be connected together externally.

The input current drawn from the external power supply

or VIN pin is the sum of the 1 mA (maximum) current

drawn by the internal circuitry for all three channels and

the current drawn by the gate drivers. In turn, the

current drawn by the gate drivers depends on the

switching frequency and the gate charge of the external

FET.

EQUATION 3-1:

I IN = 1mA + Q G1 + Q G2 + Q G3 f S

In Equation 3-1, fS is the switching frequency of the

converters, and QG1-3 are the gate charges of the

external FETs which can be obtained from the FET data

sheets.

2019 Microchip Technology Inc.

The EN pin is a TTL-compatible input used to disable

the IC. Pulling the EN pin to GND will shut down the IC

and reduce the quiescent current drawn by the IC to

less than 200 μA. If the enable function is not required,

the EN pin can be connected to VDD.

3.3

Clock Input (CLK)

The switching frequency of the converters can be set in

two ways. The first is by using the on-chip oscillator

with a resistor at the RT pin. In this case, the CLK pin

should be connected to GND. If the on-chip clock is

used, two or more HV9985s cannot be synchronized

with each other.

The second is by using a TTL compatible square wave

input at the CLK pin. The switching frequencies of the

3 converters will be 1/12th the frequency of the external

clock. By using the same clock for multiple ICs, all the

ICs can be synchronized together. In this case, the RT

pin can either be left open or connected to GND.

3.4

Current Sense (CS1–CS3)

The current sense input is used to sense the source

current of the switching FET. Each CS input of the

HV9985 includes a built-in 100 ns (minimum) blanking

time to prevent spurious turn-off due to the initial

current spike when the FET turns on.

The IC includes an internal resistor divider network,

which steps down the voltage at the COMP pins by a

factor of 9. This voltage is used as the reference for the

current sense comparators. Since the maximum

voltage of the COMP pin is approximately (VDD–1V),

this voltage determines the maximum reference current

for the current sense comparator and thus the

maximum inductor current.

The current sense resistor RCS should be chosen, so

that the input inductor current is limited to below the

saturation current level of the input inductor. For

Discontinuous

Conduction

mode,

no

slope

compensation is necessary. In this case, the current

sense resistor is chosen with Equation 3-2.

EQUATION 3-2:

V DD – 1V

R CS = -----------------------9 I IN PK

Where:

“IIN,PK” is the maximum desired peak input

current

For Continuous Conduction mode converters operating

in Constant Frequency mode, slope compensation

becomes necessary to ensure the stability of the Peak

Current mode controller if the operating duty cycle is

DS20005558B-page 9

�HV9985

greater than 50%. This factor must also be accounted

for when determining RCS. (Refer to Section 3.5

“Slope Compensation”.)

3.5

Slope Compensation

Choosing a slope compensation that is one half of the

down slope of the inductor current ensures that the

converter will be stable for all duty cycles.

VDD

CS

CSC

GATE

FIGURE 3-1:

RCS

Slope Compensation.

As illustrated in Figure 3-1, slope compensation in

HV9985 can be programmed by two external

components. A resistor for VDD sets a current, which is

almost constant since the VDD voltage is much larger

than the voltage at the CS pin. This current flows into

the capacitor and produces a ramp voltage across the

capacitor. The voltage at the CS pin is then the sum of

the voltage across the capacitor and the voltage across

the current sense resistor, with the voltage across the

capacitor providing the required slope compensation.

When the GATE turns off, an internal pull-down FET

discharges the capacitor. The 100Ω resistance of the

internal FET (RDIS) will prevent the voltage at the CS

pin from going all the way to zero. Equation 3-3 shows

how much the minimum value of the voltage will

become.

EQUATION 3-3:

V DD

V CS MIN = ----------- R DIS

R SC

The slope compensation capacitor is chosen, so that it

can be completely discharged by the internal FET at

the CS pin when FET is switched off. Assuming the

worst case switch duty cycle of 92%, CSC may be

determined with Equation 3-4.

EQUATION 3-4:

0.08

C SC = -----------------------------3 R DIS f S

DS20005558B-page 10

EQUATION 3-5:

V DD – 1

1

R CS = -------------------- ----------------------------------------------------------------9

DS 10 6 0.92

-------------------------------------- + I IN PK

2 fS

2 V DD

R SC = ---------------------------------------------------DS 10 6 C SC R CS

RSC

+

Assuming a down slope current slew rate of DS (A/μs)

for the inductor current, the current sense resistor and

the slope compensation resistor can be computed as

demonstrated in Equation 3-5.

Note that sometimes excessive stray inductance in the

current sense path may cause the slope compensation

circuit to mistrigger. Figure 3-2 shows the detailed

slope compensation circuit with a parasitic inductance

LP between the ground of the boost converter power

stage and the ground of the respective controller

channel in HV9985. The figure also includes the drain

capacitance of the boost FET Q1, which is the total

capacitance at the drain node.

GATE

Q1

VDD

CS

+

RSC

CDRAIN

CSC

+

VDRAIN

-

GATE

Q2

RCS

- VLP +

GND

LP

FIGURE 3-2:

Operation.

ILP

Slope Compensation Circuit

When the boost FET Q1 is turned off, the internal

discharge FET Q2 is turned on and capacitor CSC is

discharged. Also, CDRAIN is charged to the output

voltage VO. When the FET Q1 is turned on, the drain

node of the FET Q1 is pulled to ground. (Q2 is turned

off just before Q1 is turned on.) This causes the drain

capacitance to discharge through the FET, leading to a

current spike as illustrated in Figure 3-3. This current

spike causes a voltage to develop across the parasitic

inductance. As long as the current is increasing

through the inductance, the voltage developed across

parasitic inductance is successfully blocked by the

body diode of Q2. However, during the falling edge of

the current spike, the voltage across the parasitic

inductor causes the body diode to become forward

biased. This conduction path through the body diode of

2019 Microchip Technology Inc.

�HV9985

Q2 causes pre-charge of CSC. The pre-charge voltage

can be fairly high since the rate of fall of the current is

very large.

VDRAIN

ILP

VLP

FIGURE 3-3:

Waveforms during Turn-on.

EQUATION 3-6:

3A

V PRE – CHARGE = 10nH ------------ = 600mV

50ns

As shown in the equation, a very optimistic estimate of

the pre-charge voltage is already larger than the

Steady state peak current sense voltage. This will

cause the converter to false trip.

To prevent this behavior, a resistor REXT (typically

500Ω to 800Ω) can be added in series with the

capacitor CSC as shown in Figure 3-4. This resistor

limits the charging current from parasitic inductance

into the capacitor. However, the resistor will also slow

down the discharge of the capacitor during the FET

off-time, so a smaller CSC will be necessary. The

component values for the slope compensation design

that include REXT can be computed by substituting

REXT + RDIS in place of RDIS in Equation 3-3 to

Equation 3-5.

GATE

Q1

VDD

-

RSC

CS

REXT

CDRAIN

CSC

GATE

RCS

Q2

GND

LED Current Control

The LED currents in the HV9985 are controlled using

three independent current feedbacks. The reference

voltage inputs, which set the three LED currents,

should be provided at each REF pin (REF1-3). These

reference voltages are compared to the voltage from

the LED current sense resistors at the corresponding

FDBK

pins

(FDBK1-3)

by

the

respective

transconductance amplifiers. HV9985 includes three

1 MHz transconductance amplifiers with tri-state

output, which are used to close the feedback loops and

provide accurate current control. The compensation

networks are connected to the COMP pins (COMP1-3).

The full brightness LED current in each channel can be

set by Equation 3-7.

For example, a typical current spike usually lasts about

100 ns. Assuming a 3A peak current, which is the

FET’s typical saturation current, and equal distribution

between the rise and fall times, a 10 nH parasitic

inductance causes a pre-charge voltage. Refer to

Equation 3-6.

+

3.6

- VLP +

LP

ILP

FIGURE 3-4:

Modified Slope

Compensation Circuit.

2019 Microchip Technology Inc.

+

VDRAIN

-

EQUATION 3-7:

V REFn

I On = --------------R Sn

Where n is the channel number.

The output of each op-amp is buffered and connected

to the current sense comparators using an 8:1 divider.

The outputs of the op-amps are controlled by the signal

applied to the PWMD pins (PWMD1-3). When PWMD

is high, the op-amp output is connected to the COMP

pin. When PWMD is low, the output is left open. This

enables the integrating capacitor to hold the charge

and the voltage at the COMP pin unchanged when the

PWMD signal is low, and the gate driver output

(GATE1-3) is off. When PWMD is changed from low

back to high again, the voltage on the integrating

capacitor will force the converter into Steady state

almost instantly.

3.7

Linear Dimming

Linear dimming can be achieved by varying the

voltages at the REF pins. Since the HV9985 is a Peak

Current mode controller, it has a minimum on-time for

the GATE outputs. This minimum on-time prevents the

converters from completely turning off even when the

REF pins are pulled to GND. Thus, linear dimming

cannot accomplish true zero-LED current. To get

zero-LED current, PWM dimming has to be used for

this IC device. Different signals can be connected to

the three REF pins if desired, and these inputs need not

be connected together.

Due to the offset voltage of the short-circuit comparator

and the non-linearity of the X2 gain stage, pulling the

REF pin very close to GND would cause the internal

short-circuit comparator to trigger and shut down the

IC. To overcome this, the output of the gain stage is

limited to 125 mV (minimum), allowing the REF pin to

be pulled all the way to 0V without triggering the

short-circuit comparator.

DS20005558B-page 11

�HV9985

3.8

PWM Dimming

PWM dimming in the HV9985 can be done using TTL

compatible square wave sources at the PWMD pins

(PWMD1-3). All three channels can be individually

PWM dimmed as desired.

When the PWM signal is high, the GATE and FLT pins

are enabled and the output of the transconductance

op-amp is connected to the external compensation

network. Thus, the internal amplifier controls the output

current. When the PWMD signal goes low, the output of

the transconductance amplifier is disconnected from

the compensation network. Thus, the integrating

capacitor maintains the voltage across it. The GATE is

disabled, so the converter stops switching, and the FLT

pin goes low, turning off the disconnect switch.

The output capacitor of the converter determines its

PWM dimming response since it has to get charged

and discharged whenever the PWMD signal goes high

or low. In the case of a buck converter, since the

inductor current is continuous, a very small capacitor is

used across the LEDs. This minimizes the effect of the

capacitor on the PWM dimming response of the

converter. However, for a boost converter, the output

current is discontinuous, and a large output capacitor is

required to reduce the ripple in the LED current.

Therefore, this capacitor will have a significant impact

on the PWM dimming response. By turning off the

disconnect switch when PWMD goes low, the output

capacitor is prevented from being discharged, and the

PWM dimming response of the boost converter

improves dramatically.

Note that disconnecting the LED load during PWM

dimming causes the energy stored in the inductor to be

dumped into the output capacitor. The chosen filter

capacitor should be large enough, so that it can absorb

the inductor energy without causing any significant

change in voltage across it.

3.9

Fault Conditions

hiccup time is long enough, it will ensure that the

compensation networks are all completely discharged

and that the converters start at a minimum duty cycle.

The hiccup timing capacitor can be programmed as

demonstrated in Equation 3-8:

EQUATION 3-8:

5A t HICCUP

C SKIP = ------------------------------------1.5V

3.10

Output LED Short-Circuit

Protection

When an output LED string Short-circuit condition is

detected (i.e. output current becomes higher than twice

the Steady state current), the GATE and FLT outputs

are pulled low. As soon as the disconnect FET is turned

off, the output current goes to zero and the Short-circuit

condition disappears. At this time, the hiccup timer is

started. Once the timing is complete, the converter

attempts to restart. If the Fault condition still persists,

the converter shuts down and goes through the cycle

again. If the Fault condition is cleared (a momentary

output short), the converter will start regulating the

output current. This allows the LED driver to recover

from accidental shorts without the need to reset the IC.

During Short-circuit conditions, there are two factors

that determine the hiccup time. First is the time

required to discharge the compensation capacitors.

Assuming a pole-zero R-C network at the COMP pin

(series combination of RZ and CZ in parallel with CC),

tCOMP,n is calculated as shown in Equation 3-9:

EQUATION 3-9:

t COMP n = 3 R Zn C Zn

Where:

n refers to the channel number

HV9985 is a robust controller which can protect the

LEDs and the LED driver in Fault conditions. The

outputs of the HV9985 LED driver are protected from

both Open and Short LED conditions. In both cases,

the HV9985 shuts down and attempts to restart. The

hiccup time can be programmed by a single external

capacitor at the SKIP pin.

When the compensation networks are only of Type 1

(single capacitor), the computation in Equation 3-10 is

used.

During start-up or when a Fault condition is detected,

both GATE and FLT outputs are disabled, the COMP

and SKIP pins are pulled to GND. Once the voltage at

the SKIP pin falls below 0.1V, and the Fault condition(s)

have disappeared, the capacitor at the SKIP pin is

released, and it begins charging slowly from a 5 μA

current source. Once the capacitor is charged to 1.6V,

the COMP pins are released, and the gate driver

outputs (GATE and FLT) are allowed to turn on. If the

Therefore, the maximum COMP discharge time

required can be calculated as specified in

Equation 3-11:

DS20005558B-page 12

EQUATION 3-10:

t COMP n = 3 300 C Zn

EQUATION 3-11:

t COMP MAX = max t COMP1 t COMP2 t COMP3

2019 Microchip Technology Inc.

�HV9985

The second factor is the time required for the inductors

to discharge completely after the Short-circuit condition

has been cleared. The time can be computed as

illustrated in Equation 3-12:

3.12

EQUATION 3-12:

When the load is disconnected in a boost converter, the

output voltage rises as the output capacitor starts

charging. When the output voltage reaches the OVP

rising threshold, HV9985 detects an Overvoltage

condition and turns off the converter. The converter is

turned back on only when the output voltage falls below

the falling OVP threshold, which is 10% lower than the

rising threshold. This time is mostly dictated by the R-C

time constant of the output capacitor CO and the

resistor network used to sense overvoltage (ROVP1+

ROVP2). In case of a persistent Open Circuit condition,

this cycle maintains the output voltage within a 10%

band.

t IND n = ---- L n C On

4

Where:

L and CO are input inductor and output

capacitor of each power stage. n refers to the

channel number.

The hiccup time is then chosen as shown in

Equation 3-13:

EQUATION 3-13:

t HICCUP max t COMP MAX t IND MAX

3.11

False Triggering of the

Short-Circuit Comparator During

PWM Dimming

During PWM dimming, the parasitic capacitance of the

LED string causes a spike in the output current when

the disconnect FET is turned on. If this spike is

detected by the short-circuit comparator, it will cause

the IC to falsely detect an Overcurrent condition and

shut down.

In HV9985, to prevent these false triggerings, a built-in

500 ns blanking network for the short-circuit

comparator is included. This blanking network is

activated when the PWMD input goes high. Thus, the

short-circuit comparator will not see the spike in the

LED current during the turn-on transition of the PWM

Dimming. Once the blanking time is over, the

short-circuit comparator will start monitoring the output

current. Thus, the total delay time for detecting a

short-circuit will depend on the condition of the PWMD

input.

If the output short-circuit exists before the PWM

dimming signal goes high, the total detection time is

computed as shown in Equation 3-14:

EQUATION 3-14:

t DETECT1 = t BLANK + t DELAY 900ns max

If the short-circuit occurs when the PWM dimming

signal is already high, the time to detect will be

calculated as illustrated in Equation 3-15:

EQUATION 3-15:

t DETECT1 = t DELAY 200ns max

2019 Microchip Technology Inc.

Overvoltage Protection

HV9985 provides hysteretic overvoltage protection,

allowing the IC to recover in case the LED load is

disconnected momentarily.

In most designs, the falling OVP threshold is more than

the LED string voltage. Therefore, when the LED load

is reconnected to the output of the converter, the

voltage differential between the actual output voltage

and the LED string voltage results in a spike in output

current. This leads to the detection of a short circuit,

and the short-circuit protection in the HV9985 is

triggered. This behavior continues until the output

voltage becomes lower than the LED string voltage.

When this occurs, no Fault condition will be detected,

and the normal operation of the circuit will commence.

Note:

3.13

The overvoltage thresholds for the three

channels in the HV9985 are derived using

resistor dividers from the respective VDDs.

The resistor dividers are adjusted to give

a 1.25V OVP rising trip point and a 1.125V

OVP falling trip point at VDD = 5V. The

OVP trip points mentioned in the electrical

characteristics table of the data sheet

assume a VDD voltage generated by the

linear regulator of the HV9985. Using an

external voltage source at VDD will change

the OVP trip points proportionally.

Layout Considerations

For multi-channel Peak Current mode controller IC to

work properly with minimum interference between the

channels, it is important to have a good PCB layout

which minimizes noise. (Refer to Figure 3-5.) Following

the layout rules stated below will help ensure proper

performance of all three channels.

3.13.1

GND CONNECTION

The IC has four separate ground connections—one for

each of the three channels and one analog ground for

the common circuitry. It is recommended that four

DS20005558B-page 13

�HV9985

separate ground planes be used in the PCB, and all the

GND planes be connected together at the return

terminal of the input power lines.

3.13.2

VDD CONNECTION

Each VDD pin should be bypassed with a low-ESR

capacitor to its OWN ground (i.e. VDD1 is bypassed to

GND1 and so on). The common VDD pin can be

bypassed to the common GND.

3.13.3

3.13.5

OVP PROTECTION

Typically, the OVP resistor dividers are located away

from the IC. To prevent false trigerrings of the IC due to

noise at the OVP pin, placing a small bypass capacitor

(1 nF) right at the OVP pin is recommended.

REF CONNECTION

In case all the references are going to be driven from a

single voltage source, it is recommended to have a

small R-C low pass filter (1k, 1 nF) at each REF pin with

the filter being referenced to the appropriate channel’s

ground (as in the case of the VDD pins). If the REF pins

are driven with three individual voltage sources, then a

small capacitor (1 nF) at each pin would be suitable.

3.13.4

GATE AND CS CONNECTION

The connection from GATE output to the gate of the

external FET and the connection from the CS pin to the

external sense resistor are designed to be short to

avoid false trigerrings.

VDD

Connection

Input

Return

Terminal

GND2 VDD2

GND1

VDD1

GND3

VDD3

Star

Connection

of GND

HV9985

REF1

REF3

Reference

VDD

GND

REF2

REF

Connection

GND Exposed Pad

Connection

FIGURE 3-5:

DS20005558B-page 14

Layout Guidelines.

2019 Microchip Technology Inc.

�HV9985

4.0

PACKAGING INFORMATION

4.1

Package Marking Information

40-lead QFN

XXXXXX

XX e3

YYWWNNN

Legend: XX...X

Y

YY

WW

NNN

e3

*

Note:

Example

HV9985

K6 e3

1925456

Product Code or Customer-specific information

Year code (last digit of calendar year)

Year code (last 2 digits of calendar year)

Week code (week of January 1 is week ‘01’)

Alphanumeric traceability code

Pb-free JEDEC® designator for Matte Tin (Sn)

This package is Pb-free. The Pb-free JEDEC designator ( e3 )

can be found on the outer packaging for this package.

In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for product code or customer-specific information. Package may or

not include the corporate logo.

2019 Microchip Technology Inc.

DS20005558B-page 15

�HV9985

Note: For the most current package drawings, see the Microchip Packaging Specification at www.microchip.com/packaging.

DS20005558B-page 16

2019 Microchip Technology Inc.

�HV9985

APPENDIX A:

REVISION HISTORY

Revision A (August 2019)

• Converted Supertex Doc #s DSFP-HV9985 to

Microchip DS20005558B

• Removed the 44-lead QSOP Package and the K6

M935 media type

• Made minor text changes throughout the document

Revision B (September 2019)

• Changed "PWMD changes from low to high (Note

1)" to "Note 2" in Switching Frequency Range

conditions under the Electrical Characteristics

Table

• Changed “Note 1” to “PWMD changes from low to

high (Note 1)” in Blanking Time conditions under

the Electrical Characteristics Table

2019 Microchip Technology Inc.

DS20005558B-page 17

�HV9985

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, contact your local Microchip representative or sales office.

XX

PART NO.

Device

-

Package

Options

X

-

Environmental

X

Media Type

Device:

HV9985

=

3-Channel Closed-Loop Switch-Mode LED

Driver IC

Package:

K6

=

40-lead QFN (6x6)

Environmental:

G

=

Lead (Pb)-free/RoHS-compliant Package

Media Type:

(blank)

=

490/Tray for K6 Package

DS20005558B-page 18

Example:

a)

HV9985K6-G:

3-Channel Closed-Loop

Switch-Mode LED Driver IC,

40-lead QFN (6x6), 490/Tray

2019 Microchip Technology Inc.

�Note the following details of the code protection feature on Microchip devices:

•

Microchip products meet the specification contained in their particular Microchip Data Sheet.

•

Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

•

There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

•

Microchip is willing to work with the customer who is concerned about the integrity of their code.

•

Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Trademarks

The Microchip name and logo, the Microchip logo, Adaptec,

AnyRate, AVR, AVR logo, AVR Freaks, BesTime, BitCloud, chipKIT,

chipKIT logo, CryptoMemory, CryptoRF, dsPIC, FlashFlex,

flexPWR, HELDO, IGLOO, JukeBlox, KeeLoq, Kleer, LANCheck,

LinkMD, maXStylus, maXTouch, MediaLB, megaAVR, Microsemi,

Microsemi logo, MOST, MOST logo, MPLAB, OptoLyzer,

PackeTime, PIC, picoPower, PICSTART, PIC32 logo, PolarFire,

Prochip Designer, QTouch, SAM-BA, SenGenuity, SpyNIC, SST,

SST Logo, SuperFlash, Symmetricom, SyncServer, Tachyon,

TempTrackr, TimeSource, tinyAVR, UNI/O, Vectron, and XMEGA

are registered trademarks of Microchip Technology Incorporated in

the U.S.A. and other countries.

APT, ClockWorks, The Embedded Control Solutions Company,

EtherSynch, FlashTec, Hyper Speed Control, HyperLight Load,

IntelliMOS, Libero, motorBench, mTouch, Powermite 3, Precision

Edge, ProASIC, ProASIC Plus, ProASIC Plus logo, Quiet-Wire,

SmartFusion, SyncWorld, Temux, TimeCesium, TimeHub,

TimePictra, TimeProvider, Vite, WinPath, and ZL are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BlueSky, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity, JitterBlocker,

KleerNet, KleerNet logo, memBrain, Mindi, MiWi, MPASM, MPF,

MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach,

Omniscient Code Generation, PICDEM, PICDEM.net, PICkit,

PICtail, PowerSmart, PureSilicon, QMatrix, REAL ICE, Ripple

Blocker, SAM-ICE, Serial Quad I/O, SMART-I.S., SQI,

SuperSwitcher, SuperSwitcher II, Total Endurance, TSHARC,

USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and

ZENA are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

The Adaptec logo, Frequency on Demand, Silicon Storage

Technology, and Symmcom are registered trademarks of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology Germany

II GmbH & Co. KG, a subsidiary of Microchip Technology Inc., in

other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2019, Microchip Technology Incorporated, All Rights Reserved.

For information regarding Microchip’s Quality Management Systems,

please visit www.microchip.com/quality.

2019 Microchip Technology Inc.

ISBN: 978-1-5224-5006-1

DS20005558B-page 19

�Worldwide Sales and Service

AMERICAS

ASIA/PACIFIC

ASIA/PACIFIC

EUROPE

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Australia - Sydney

Tel: 61-2-9868-6733

India - Bangalore

Tel: 91-80-3090-4444

China - Beijing

Tel: 86-10-8569-7000

India - New Delhi

Tel: 91-11-4160-8631

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

China - Chengdu

Tel: 86-28-8665-5511

India - Pune

Tel: 91-20-4121-0141

China - Chongqing

Tel: 86-23-8980-9588

Japan - Osaka

Tel: 81-6-6152-7160

China - Dongguan

Tel: 86-769-8702-9880

Japan - Tokyo

Tel: 81-3-6880- 3770

China - Guangzhou

Tel: 86-20-8755-8029

Korea - Daegu

Tel: 82-53-744-4301

China - Hangzhou

Tel: 86-571-8792-8115

Korea - Seoul

Tel: 82-2-554-7200

China - Hong Kong SAR

Tel: 852-2943-5100

Malaysia - Kuala Lumpur

Tel: 60-3-7651-7906

China - Nanjing

Tel: 86-25-8473-2460

Malaysia - Penang

Tel: 60-4-227-8870

China - Qingdao

Tel: 86-532-8502-7355

Philippines - Manila

Tel: 63-2-634-9065

China - Shanghai

Tel: 86-21-3326-8000

Singapore

Tel: 65-6334-8870

China - Shenyang

Tel: 86-24-2334-2829

Taiwan - Hsin Chu

Tel: 886-3-577-8366

China - Shenzhen

Tel: 86-755-8864-2200

Taiwan - Kaohsiung

Tel: 886-7-213-7830

China - Suzhou

Tel: 86-186-6233-1526

Taiwan - Taipei

Tel: 886-2-2508-8600

China - Wuhan

Tel: 86-27-5980-5300

Thailand - Bangkok

Tel: 66-2-694-1351

China - Xian

Tel: 86-29-8833-7252

Vietnam - Ho Chi Minh

Tel: 84-28-5448-2100

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

DS20005558B-page 20

China - Xiamen

Tel: 86-592-2388138

China - Zhuhai

Tel: 86-756-3210040

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

Finland - Espoo

Tel: 358-9-4520-820

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-72400

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Israel - Ra’anana

Tel: 972-9-744-7705

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-7288-4388

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

2019 Microchip Technology Inc.

05/14/19

�