MCP1662

High-Voltage Step-Up LED Driver with UVLO and Open Load Protection

Features

General Description

•

•

•

•

The MCP1662 device is a compact, space-efficient,

fixed-frequency, non-synchronous step-up converter

optimized to drive LED strings with constant current

from a two- or three-cell alkaline or lithium Energizer®,

or NiMH/NiCd, or one-cell Lithium-Ion or Li-Polymer

batteries.

•

•

•

•

•

•

•

•

•

•

36V, 800 m Integrated Switch

Up to 92% Efficiency

Drive LED Strings in Constant Current

1.3A Peak Input Current Limit:

- ILED up to 200 mA @ 5.0V VIN, 4 White LEDs

- ILED up to 125 mA @ 3.3V VIN, 4 White LEDs

- ILED up to 100 mA @ 4.2V VIN, 8 White LEDs

Input Voltage Range: 2.4V to 5.5V

Feedback Voltage Reference: VFB = 300 mV

Undervoltage Lockout (UVLO):

- UVLO @ VIN Rising: 2.3V, typical

- UVLO @ VIN Falling: 1.85V, typical

Sleep Mode with 20 nA Typical Quiescent Current

PWM Operation: 500 kHz Switching Frequency

Cycle-by-Cycle Current Limiting

Internal Compensation

Open Load Protection (OLP) in the Event of:

- Feedback pin shorted to GND (prevent

excessive current into LEDs)

- Disconnected LED string (prevent overvoltage

to the converter’s Output and SW pin)

Overtemperature Protection

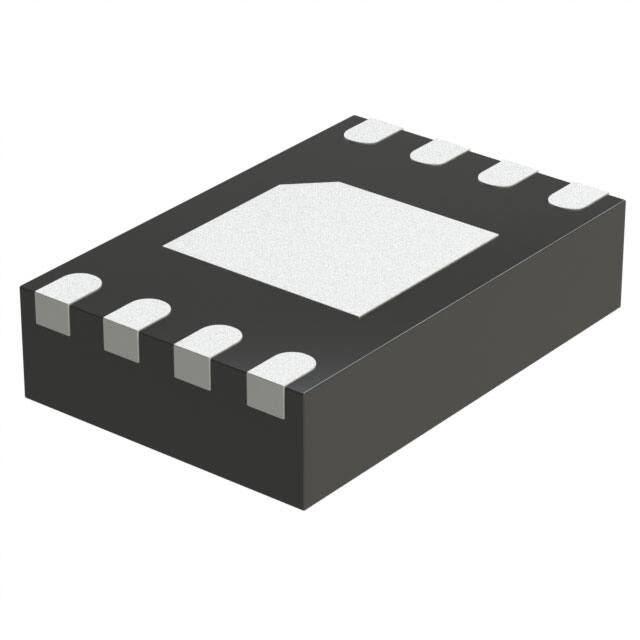

Available Packages:

- 5-Lead SOT-23

- 8-Lead 2x3 TDFN

The device integrates a 36V, 800 m low-side switch,

which is protected by the 1.3A cycle-by-cycle inductor

peak current limit operation. All compensation and protection circuitry is integrated to minimize the number of

external components.

The internal feedback (VFB) voltage is set to 300 mV for

low power dissipation when sensing and regulating the

LED current. A single resistor sets the LED current.

The device features an Undervoltage Lockout (UVLO)

that avoids start-up with low inputs or discharged batteries for two-cell-powered applications.

There is an open load protection (OLP) which turns off

the operation in situations when the LED string is accidentally disconnected or the feedback pin is short-circuited to GND.

For standby applications (EN = GND), the device stops

switching, enters into Sleep mode and consumes

20 nA typical of input current.

Package Types

MCP1662

SOT-23

Applications

• Two and Three-Cell Alkaline or NiMH/NiCd White

LED Driver for Backlighting Products

• Li-Ion Battery LED Lighting Application

• Camera Flash

• LED Flashlights and Backlight Current Source

• Medical Equipment

• Portable Devices:

- Handheld Gaming Devices

- GPS Navigation Systems

- LCD Monitors

- Portable DVD Players

SW 1

5 VIN

GND 2

VFB 3

4 EN

MCP1662

2x3 TDFN*

VFB 1

SGND 2

SW 3

NC 4

8 EN

EP

9

7 PGND

6 NC

5 V

IN

* Includes Exposed Thermal Pad (EP); see

Table 3-1.

2014-2015 Microchip Technology Inc.

DS20005316E-page 1

�MCP1662

Typical Application

D

MBR0540

L

4.7 – 10 µH

VOUT

LED1

CIN

4.7 – 30 µF

VIN

2.4V – 3.0V

SW

LED2

VIN

+

ALKALINE

ILED =

LED6

EN

VFB

ON

ALAKLINE

COUT

10 µF

MCP1662

-

+

0.3V

RSET

OFF

GND

VFB = 0.3V

RSET

12

ILED = 25 mA

-

L

= 4.7 µH for maximum 4 white LEDs

L

= 10 µH for 5 to 10 white LEDs

CIN = 4.7-10 µF for VIN > 2.5V

CIN = 20-30 µF for VIN < 2.5V

Maximum LED Current in Regulation vs. Input Voltage, TA = + 25°C

250

4 wLEDs, L = 4.7 µH

IOUT

LED (mA)

200

150

8 wLEDs, L = 10 µH

100

50

0

2

DS20005316E-page 2

2.5

3

3.5

4

VIN (V)

4.5

5

5.5

2014-2015 Microchip Technology Inc.

�MCP1662

1.0

ELECTRICAL

CHARACTERISTICS

† Notice: Stresses above those listed under “Maximum

Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of

the device at those or any other conditions above those

indicated in the operational sections of this specification is not intended. Exposure to maximum rating conditions for extended periods may affect device

reliability.

Absolute Maximum Ratings †

VSW – GND .....................................................................+36V

EN, VIN – GND...............................................................+6.0V

VFB ...............................................................................+0.35V

Power Dissipation ....................................... Internally Limited

Storage Temperature .................................... -65°C to +150°C

Ambient Temperature with Power Applied .... -40°C to +125°C

Operating Junction Temperature................... -40°C to +150°C

ESD Protection on All Pins:

HBM ................................................................. 4 kV

MM ..................................................................300V

DC AND AC CHARACTERISTICS

Electrical Specifications: Unless otherwise specified, all limits apply for typical values at ambient temperature

TA = +25°C, VIN = 3.3V, VOUT = 9V or 3 white LEDs (VF = 2.75V @ IF = 20 mA or VF = 3.1V @ IF = 100 mA),

ILED = 20 mA, CIN = COUT = 10 µF, X7R ceramic, L = 4.7 µH.

Boldface specifications apply over the controlled TA range of -40°C to +125°C.

Parameters

Sym.

Min.

Typ.

Max.

Units

VIN

2.4

—

5.5

V

UVLOSTART

—

2.3

—

V

VIN rising, ILED = 20 mA

UVLOSTOP

—

1.85

—

V

VIN falling, ILED = 20 mA

Maximum Output Voltage

VOUTmax

—

—

32

V

Maximum Output Current

IOUT

—

100

—

mA

4.2V VIN, 8 LEDs

125

—

mA

3.3V VIN, 4 LEDs

200

—

mA

5.0V VIN, 4 LEDs

Input Voltage Range

Undervoltage Lockout (UVLO)

Feedback Voltage Reference

Conditions

Note 1

VFB

275

300

325

mV

VFB_OLP

—

50

—

mV

Feedback Input Bias Current

IVFB

—

0.005

—

µA

Shutdown Quiescent Current

IQSHDN

—

0.02

—

µA

EN = GND

IN(MAX)

—

1.3

—

A

Note 2

INLK

—

0.4

—

µA

VIN = VSW = 5V;

VOUT = 5.5V

VEN = VFB = GND

RDS(ON)

—

0.8

—

VIN = 5V,

ILED = 100 mA,

4 series white LEDs

(Note 2)

|(VFB/VFB)/VIN|

—

0.25

—

%/V

Feedback Open Load

Protection (OLP) Threshold

NMOS Peak Switch Current

Limit

NMOS Switch Leakage

NMOS Switch ON Resistance

Feedback Voltage

Line Regulation

VFB falling (Note 2)

VIN = 3.0V to 5V

Maximum Duty Cycle

DCMAX

—

90

—

%

Note 2

Switching Frequency

fSW

425

500

575

kHz

±15%

EN Input Logic High

VIH

85

—

—

% of VIN

Note 1:

2:

Minimum input voltage in the range of VIN (VIN < 5.5V < VOUT) depends on the maximum duty cycle

(DCMAX) and on the output voltage (VOUT), according to the boost converter equation:

VINmin = VOUT x (1 – DCMAX). Output voltage is equal to the LED voltage plus the voltage on the sense

resistor (VOUT = VLED + V_RSET).

Determined by characterization, not production tested.

2014-2015 Microchip Technology Inc.

DS20005316E-page 3

�MCP1662

DC AND AC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise specified, all limits apply for typical values at ambient temperature

TA = +25°C, VIN = 3.3V, VOUT = 9V or 3 white LEDs (VF = 2.75V @ IF = 20 mA or VF = 3.1V @ IF = 100 mA),

ILED = 20 mA, CIN = COUT = 10 µF, X7R ceramic, L = 4.7 µH.

Boldface specifications apply over the controlled TA range of -40°C to +125°C.

Parameters

Sym.

Min.

Typ.

Max.

Units

VIL

—

—

7.5

% of VIN

IENLK

—

0.025

—

µA

VEN = 5V

Start-up Time

tSS

—

100

—

µs

EN Low-to-High,

90% of ILED

(Note 2, Figure 2-10)

Thermal Shutdown

Die Temperature

TSD

—

150

—

°C

TSDHYS

—

15

—

°C

EN Input Logic Low

EN Input Leakage Current

Die Temperature Hysteresis

Note 1:

2:

Conditions

Minimum input voltage in the range of VIN (VIN < 5.5V < VOUT) depends on the maximum duty cycle

(DCMAX) and on the output voltage (VOUT), according to the boost converter equation:

VINmin = VOUT x (1 – DCMAX). Output voltage is equal to the LED voltage plus the voltage on the sense

resistor (VOUT = VLED + V_RSET).

Determined by characterization, not production tested.

TEMPERATURE SPECIFICATIONS

Electrical Specifications: Unless otherwise specified, all limits apply for typical values at ambient temperature

TA = +25°C, VIN = 3.0V, IOUT = 20 mA, VOUT = 12V, CIN = COUT = 10 µF, X7R ceramic, L = 4.7 µH.

Boldface specifications apply over the air-forced TA range of -40°C to +125°C.

Parameters

Sym.

Min.

Typ.

Max.

Units

Operating Junction Temperature

Range

TJ

-40

—

+125

°C

Storage Temperature Range

TA

-65

—

+150

°C

Maximum Junction Temperature

TJ

—

—

+150

°C

Thermal Resistance, 5L-SOT-23

JA

—

201.0

—

°C/W

Thermal Resistance, 8L 2x3 TDFN

JA

—

52.5

—

°C/W

Conditions

Temperature Ranges

Steady State

Transient

Package Thermal Resistances

DS20005316E-page 4

2014-2015 Microchip Technology Inc.

�MCP1662

2.0

TYPICAL PERFORMANCE CURVES

Note:

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated: VIN = 3.3V, ILED = 20 mA, VOUT = 12V or 4 white LEDs (VF = 2.75V @ IF = 20 mA or

VF = 3.1V @ IF = 100 mA), CIN = COUT = 10 µF, X7R ceramic, L = 4.7 µH.

150

100

4 x wLED, L = 4.7 µH

RSET = 2.2ȍ

80

Efficiency (%)

LED Current (mA)

VIN = 5.5V

90

125

RSET = 3.2ȍ

100

75

RSET = 6.2ȍ

50

VIN = 4.0V

70

60

VIN = 3.0V

50

40

30

25

L = 4.7 µH,

4 wLEDs

20

RSET = 15ȍ

10

0

0

2.3

2.7

FIGURE 2-1:

3.1

3.5 3.9 4.3

Input Voltage (V)

4.7

5.1

5.5

4 White LEDs, ILED vs. VIN.

0

50

75 100 125 150 175 200 225 250

ILED (mA)

FIGURE 2-4:

ILED.

4 White LEDs, Efficiency vs.

100

120

4 x wLED, L = 4.7 µH, VIN = 3.3V

90

RSET = 3.2ȍ

80

60

RSET = 6.2ȍ

40

80

Efficiency (%)

100

LED Current (mA)

25

VIN = 5.5V

70

VIN = 3.0V

VIN = 4.0V

60

50

40

30

RSET = 15ȍ

20

L = 10 µH,

8 wLEDs

20

10

0

0

-40 -25 -10

FIGURE 2-2:

4 White LEDs, ILED vs.

Ambient Temperature.

40

60

80 100

ILED (mA)

120

140

160

8 White LEDs, Efficiency vs.

300

8 x wLED, L = 10 µH, VIN = 4.2V

250

RSET = 3.2ȍ

100

LED Current (mA)

20

FIGURE 2-5:

ILED.

80

60

RSET = 6.2ȍ

40

RSET = 15ȍ

20

LED Current (mA)

120

0

5 20 35 50 65 80 95 110 125

Ambient Temperature (oC)

200

2 wLEDs, L = 4.7 µH

150

5 wLEDs, L = 10 µH

4 wLEDs, L = 4.7 µH

100

8 wLEDs, L = 10 µH

50

0

0

-40 -25 -10

5 20 35 50 65 80 95 110 125

Ambient Temperature (oC)

FIGURE 2-3:

8 White LEDs, ILED vs.

Ambient Temperature.

2014-2015 Microchip Technology Inc.

2.3

2.7

FIGURE 2-6:

3.1

3.5 3.9 4.3

Input Voltage (V)

4.7

5.1

5.5

Maximum ILED vs. VIN.

DS20005316E-page 5

�MCP1662

Note: Unless otherwise indicated: VIN = 3.3V, ILED = 20 mA, VOUT = 12V or 4 white LEDs (VF = 2.75V @ IF = 20 mA or

VF = 3.1V @ IF = 100 mA), CIN = COUT = 10 µF, X7R ceramic, L = 4.7 µH.

2.5

250

UVLO Start

2.3

Blue Bars - ILED = 20 mA

Red Bars - ILED = 40 mA

200

2.2

2.1

2

UVLO Stop

1.9

1.8

1.7

Start-up Time (µs)

UVLO Thresholds (V)

2.4

150

100

50

1.6

0

1.5

-40 -25 -10

5

3

20 35 50 65 80 95 110 125

Ambient Temperature

4

5

6

Number of LEDs

7

8

(oC)

FIGURE 2-7:

Undervoltage Lockout

(UVLO) vs. Ambient Temperature.

FIGURE 2-10:

of LEDs.

Soft Start Time vs. Number

50

3 LEDs, ILED = 20 mA

Shutdown Iq (nA)

40

ILED

10 mA/div

30

20

VEN

2V/div

10

VIN

2V/div

0

2.2 2.5 2.8 3.1 3.4 3.7 4.0 4.3 4.6 4.9 5.2 5.5

Input Voltage (V)

FIGURE 2-8:

Shutdown Quiescent

Current, IQSHDN, vs. VIN (EN = GND).

40 µs/div

FIGURE 2-11:

VIN = VENABLE.

Start-Up When

Switching Frequency (kHz)

550

3 LED, ILED = 20 mA

525

ILED

10 mA/div

500

VEN

2V/div

475

VIN

2V/div

450

-40 -25 -10

5 20 35 50 65 80 95 110 125

Ambient Temperature (°C)

FIGURE 2-9:

Switching Frequency, fSW

vs. Ambient Temperature.

DS20005316E-page 6

40 µs/div

FIGURE 2-12:

Start-Up After Enable.

2014-2015 Microchip Technology Inc.

�MCP1662

Note: Unless otherwise indicated: VIN = 3.3V, ILED = 20 mA, VOUT = 12V or 4 white LEDs (VF = 2.75V @ IF = 20 mA or

VF = 3.1V @ IF = 100 mA), CIN = COUT = 10 µF, X7R ceramic, L = 4.7 µH.

3 LEDs

3 LEDs

VOUT

3V/div

ILED

10 mA/div

VSW

4V/div

VSW

4V/div

ILED

20 mA/div

VEN

3V/div

1 µs/div

2 ms/div

FIGURE 2-13:

Duty Cycle.

100 Hz PWM Dimming, 15%

FIGURE 2-16:

3.3V Input, 20 mA 3 White

LEDs PWM Discontinuous Mode Waveforms.

3 LEDs

3 LEDs

ILED

100 mA/div

VOUT

3V/div

VSW

4V/div

ILED

50 mA/div

VSW

4V/div

VEN

3V/div

1 µs/div

2 ms/div

FIGURE 2-14:

Duty Cycle.

100 Hz PWM Dimming, 85%

FIGURE 2-17:

3.3V Input, 100 mA 3 White

LEDs PWM Continuous Mode Waveforms.

3 LEDs

VFB

300 mV/div

ILED

10 mA/div

VSW

4V/div

50 ms/div

FIGURE 2-15:

Open Load (LED Fail or FB

to GND) Response.

2014-2015 Microchip Technology Inc.

DS20005316E-page 7

�MCP1662

3.0

PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1:

3.1

PIN FUNCTION TABLE

MCP1662

SOT-23

MCP1662

2x3 TDFN

3

1

VFB

—

2

SGND

Symbol

Description

Feedback Voltage Pin

Signal Ground Pin

1

3

SW

Switch Node, Boost Inductor Input Pin

—

4, 6

NC

Not Connected

Input Voltage Pin

5

5

VIN

—

7

PGND

Power Ground Pin

4

8

EN

Enable Control Input Pin

—

9

EP

Exposed Thermal Pad (EP); must be connected to Ground

2

—

GND

Ground Pin

Feedback Voltage Pin (VFB)

The VFB pin is used to regulate the voltage across the

RSET sense resistor to 300 mV to keep the output LED

current in regulation. Connect the cathode of the LED

to the VFB pin.

3.2

Signal Ground Pin (SGND)

The signal ground pin is used as a return for the integrated reference voltage and error amplifier. The signal

ground and power ground must be connected externally in one point.

3.3

Switch Node Pin (SW)

Connect the inductor from the input voltage to the SW

pin. The SW pin carries inductor current and has a typical value of 1.3A peak. The integrated N-Channel

switch drain is internally connected to the SW node.

3.4

Not Connected (NC)

3.7

Enable Pin (EN)

The EN pin is a logic-level input used to enable or disable device switching and lower quiescent current

while disabled. A logic high (>85% of VIN) will enable

the regulator output. A logic low (

4

�!�����/�

�

���;

:

���=

4

�!�