MIC2127A

75V, Synchronous Buck Controller Featuring Adaptive

On-Time Control

Features

General Description

• Hyper Speed Control® Architecture Enables:

- High input to output voltage conversion ratio

capability

- Any Capacitor™ stable

- Ultra-fast load transient response

• Wide 4.5V-75V Input Voltage Range

• Adjustable Output Voltage from 0.6V to 30V

• 270 kHz-800 kHz Programmable Switching

Frequency

• Built-In 5V Regulator for Single-Supply Operation

• Auxiliary Bootstrap LDO for Improving System

Efficiency

• Internal Bootstrap Diode

• Selectable Light Load Operating Mode

• Enable Input and Power Good Output

• Programmable Current Limit

• Hiccup Mode Short-Circuit Protection

• Soft Start, Internal Compensation and Thermal

Shutdown

• Supports Safe Start-Up into a Prebiased Output

• AEC-Q100 Qualified (VAO suffix)

The MIC2127A device is a constant-frequency

synchronous buck controller featuring a unique

adaptive on-time control architecture. The MIC2127A

device operates over an input voltage range from

4.5V-75V. The output voltage is adjustable down to

0.6V with an accuracy of ±1%. The device operates

with programmable switching frequency from 270 kHz

to 800 kHz.

The MIC2127A device features a MODE pin that allows

the user to select either Continuous Conduction mode

or HyperLight Load® (HLL) mode under light loads. An

auxiliary bootstrap LDO improves the system efficiency

by supplying the MIC2127A internal circuit bias power

and gate drivers from the output of the converter. A

logic level enable (EN) signal can be used to enable or

disable the controller. MIC2127A can start-up

monotonically into a prebiased output. The MIC2127A

device features an open drain power good signal (PG)

that signals when the output is in regulation and can be

used for simple power supply sequencing.

MIC2127A offers a full suite of protection features to

ensure protection of the IC during Fault conditions.

These include undervoltage lockout to ensure proper

operation under power-sag conditions, “hiccup” mode

short-circuit protection, internal soft start of 5 ms to

reduce inrush current during start-up and thermal shutdown.

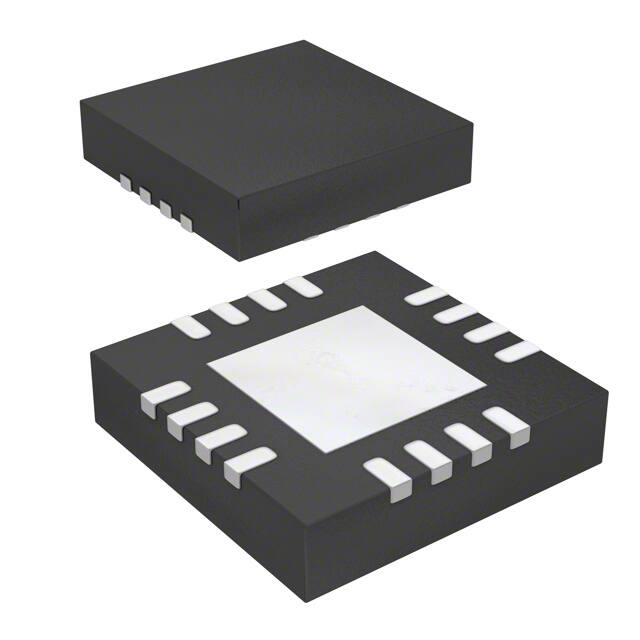

The MIC2127A device is available in a 16-pin

3 mm × 3 mm VQFN package, with an operating

junction temperature range from –40°C to +125°C.

Applications

•

•

•

•

•

Networking/Telecom Equipment

Base Station, Servers

Distributed Power Systems

Industrial Power Supplies

Automotive Power Supplies

Typical Application Circuit

VIN

PVDD

4.7 μF

VIN

*

4.5V to 75V

0.1 μF

Q1

2.2 μFX3

DH

10

BST

VDD

L1

10 μH

0.1 μF

4.7 μF

VOUT

5V@5A

SW

MIC2127A

ILIM

+ C1

330 μF

1.3 k

47 μF

0.1 μF

PG

Q2

DL

VIN

7.5 k

EN

4.7 nF

36 k

VDD

MODE

FB

1 k

100 k

EXTVDD

FREQ

VIN

60 k

AGND

2016-2020 Microchip Technology Inc.

PGND

VOUT

1 μF

Q1,Q3: SiR878ADP

L1: SRP1265A-100M, Bourns

C1: 10SVP330M

*Output voltage follows input voltage when the input is below the target output voltage

DS20005676F-page 1

�MIC2127A

Package Type

FB

AGND

VDD

VIN

MIC2127A

3 x 3 VQFN*

(Top View)

16 15 14 13

PG 1

12 MODE

ILIM 2

11 FREQ

EP

SW 3

10 EN

BST 4

PGND

7

8

PVDD

6

DL

5

DH

9 EXTVDD

* Includes Exposed Thermal Pad (EP); see Table 3-1.

Functional Block Diagram

VDD

EXTVDD

PVDD

EN

VIN

15

9

8

10

16

LINEAR

REGULATOR

UVLO

LINEAR

REGULATOR

THERMAL

SHUTDOWN

MODE

12

FREQ

11

Control

Logic

TON

ESTIMATION

Zero Crossing

Detection (ZCD) and

Negative Current Limit

4

BST

5

DH

3

SW

7

DL

2

ILIM

6

PGND

COMPENSATION

PVDD

FB

13

gm

Soft

Start

PG

CURRENT

LIMIT

DETECTION

VREF

0.6V

100 μA

1

0.9

VREF

FB

14

AGND

2016-2020 Microchip Technology Inc.

DS20005676F-page 2

�MIC2127A

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings †

VIN, FREQ, ILIM, SW to PGND .................................................................................................................... –0.3V to +76V

VSW to PGND (Transient < 50 ns) ............................................................................................................................... –5V

VDD, PVDD, FB, PG, MODE to AGND ........................................................................................................... –0.3V to +6V

EXTVDD to AGND ...................................................................................................................................... –0.3V to +16V

BST to SW .................................................................................................................................................. –0.3V to +6V

BST to AGND ............................................................................................................................................. –0.3V to +82V

EN to AGND ...................................................................................................................................... –0.3V to (VIN +0.3V)

DH, DL to AGND .............................................................................................................................. –0.3V to (VDD +0.3V)

PGND to AGND ........................................................................................................................................... –0.3V to +0.3V

Junction Temperature........................................................................................................................................... +150°C

Storage Temperature (TS)..................................................................................................................... –65°C to +150°C

Lead Temperature (soldering, 10s) ........................................................................................................................ 260°C

ESD Rating(1) ......................................................................................................................................................... 1000V

† Notice: Stresses above those listed under “Maximum Ratings” may cause permanent damage to the device. This is

a stress rating only and functional operation of the device at those or any other conditions above those indicated in the

operational sections of this specification is not intended. Exposure to maximum rating conditions for extended periods

may affect device reliability.

Note 1: Devices are ESD sensitive. Handling precautions recommended. Human body model, 1.5 k in series with

100 pF.

Operating Ratings(1)

Supply Voltage (VIN) ..................................................................................................................................... 4.5V to 75V

SW, FREQ, ILIM, EN........................................................................................................................................... 0V to VIN

EXTVDD ....................................................................................................................................................... 0V to 13.2V

Junction Temperature (TJ)..................................................................................................................... –40°C to +125°C

Package Thermal Resistance (3 mm × 3 mm VQFN 16LD)

Junction-to-Ambient (JA) ................................................................................................................................. 50.8°C/W

Junction-to-Case (JC) ...................................................................................................................................... 25.3°C/W

Note 1: The device is not ensured to function outside the operating range.

2016-2020 Microchip Technology Inc.

DS20005676F-page 3

�MIC2127A

ELECTRICAL CHARACTERISTICS

(Note

1)

Electrical Specifications: unless otherwise specified, VIN = 12V, VOUT = 1.2V; VBST – VSW = 5V, TA = +25°C.

Boldface values indicate –40°C TJ +125°C (Note 4)

Parameter

Symbol

Min.

Typ.

Max.

Units

Test Conditions

VVIN

4.5

—

5.5

V

PVDD and VDD shorted to VIN

(VPVDD = VVIN = VVDD)

Power Supply Input

Input Voltage Range (Note 2)

Quiescent Supply Current

Shutdown Supply Current

IQ

IVIN(SHDN)

5.5

—

75

—

1.4

1.8

mA

VFB = 1.5V, MODE = VDD,

no switching

—

—

300

600

µA

VFB = 1.5V, MODE = AGND,

no switching

—

0.1

5

µA

EN = Low

—

30

60

µA

EN = Low, VIN = VDD = 5.5V

5.1

5.4

V

VVIN = 7V to 75V,

IPVDD = 10 mA

PVDD,VDD and EXTVDD

PVDD Output Voltage

VPVDD

4.8

VDD UVLO Threshold

VVDD_UVLO_Rise

3.7

4.2

4.5

V

VDD UVLO Hysteresis

VVDD_UVLO_Hys

—

600

—

mV

EXTVDD Bypass Threshold

VEXTVDD_Rise

4.4

4.6

4.85

V

EXTVDD Bypass Hysteresis

VEXTVDD_Hys

—

200

—

mV

—

—

—

250

—

mV

VEXTVDD = 5V, IPVDD = 25 mA

VREF

0.597

0.6

0.603

V

0.594

0.6

0.606

V

–40°C TJ 125°C

IFB

—

50

500

nA

VFB = 0.6V

VEN_H

1.6

—

—

V

—

—

EXTVDD Dropout Voltage

VDD rising

VDD falling (Note 5)

EXTVDD rising

Reference

Feedback Reference Voltage

FB Bias Current (Note 3)

TJ = 25°C

Enable Control

EN Logic Level High

EN Logic Level Low

EN Hysteresis

EN Bias Current

VEN_L

—

—

0.6

V

VEN_Hys

—

100

—

mV

Note 5

IEN

—

6

30

µA

VEN = 12V

kHz

VFREQ = VVIN, VVIN = 12V

ON Timer

Switching Frequency

fSW

—

800

—

230

270

300

VFREQ = 33% of VVIN,

VVIN = 12V

Maximum Duty Cycle

DMAX

—

85

—

%

VFREQ = VVIN = 12V

Minimum Duty Cycle

DMIN

—

0

—

%

VFB > 0.6V (Note 5)

Minimum ON Time

tON(MIN)

—

80

—

ns

—

Minimum OFF Time

tOFF(MIN)

150

230

350

ns

—

Note 1:

2:

3:

4:

5:

Specification for packaged product only.

The application is fully functional at low VDD (supply of the control section) if the external MOSFETs have

low voltage VTH.

Design specification.

Temperature limits apply for automotive AEC-Q100 qualified part.

Not production tested.

2016-2020 Microchip Technology Inc.

DS20005676F-page 4

�MIC2127A

ELECTRICAL CHARACTERISTICS

Electrical Specifications: unless otherwise specified, VIN = 12V, VOUT = 1.2V; VBST – VSW = 5V, TA = +25°C.

Boldface values indicate –40°C TJ +125°C (Note 4)

Parameter

Symbol

Min.

Typ.

Max.

Units

Test Conditions

VMODE_H

1.6

—

—

V

—

—

MODE

MODE Logic High Level

MODE Logic Low Level

VMODE_L

—

—

0.6

V

VMODE_Hys

—

70

—

mV

Note 5

VOFFSET

–15

0

15

mV

VFB = 0.59V

ICL

85

100

115

µA

VFB = 0.59V

TCICL

—

0.3

—

µA/°C

VNCLTH

—

48

—

mV

—

VZCDTH

–15

–8

10

mV

—

DH On-Resistance, High

State

RDH(PULL-UP)

—

2

3

—

DH On-Resistance, Low

State

RDH(PULL_DOWN)

—

2

4

—

DL On-Resistance, High

State

RDL(PULL-UP)

—

2

4

—

—

0.36

0.8

—

MODE Hysteresis

Current Limit

Current Limit Comparator

Offset

ILIM Source Current

ILIM Source Current Tempco

Negative Current Limit

Comparator Threshold

Note 5

Zero Crossing Detection Comparator

Zero Crossing Detection

Comparator Threshold

FET Drivers

DL On-Resistance, Low State RDL(PULL_DOWN)

SW, VIN, and BST Leakage

BST Leakage

ILK(BST)

—

—

30

µA

—

VIN Leakage

ILK(VIN)

—

—

50

µA

—

SW Leakage

ILK(SW)

—

—

50

µA

—

PG Threshold Voltage

VPG_Rise

85

—

95

%VOUT VFB rising

PG Hysteresis

VPG_Hys

—

6

—

%VOUT VFB falling

PG Delay Time

PG_R_DLY

—

150

—

µs

VFB rising

PG Low Voltage

VOL_PG

—

140

200

mV

VFB < 90% × VNOM,

IPG = 1 mA

Overtemperature Shutdown

TSHDN

—

150

—

°C

Junction temperature rising

Overtemperature Shutdown

Hysteresis

TSHDN_Hys

—

15

—

°C

—

Power Good (PG)

Thermal Protection

Note 1:

2:

3:

4:

5:

Specification for packaged product only.

The application is fully functional at low VDD (supply of the control section) if the external MOSFETs have

low voltage VTH.

Design specification.

Temperature limits apply for automotive AEC-Q100 qualified part.

Not production tested.

2016-2020 Microchip Technology Inc.

DS20005676F-page 5

�MIC2127A

TEMPERATURE SPECIFICATIONS

Parameters

Sym.

Min.

Typ.

Max.

Units

Conditions

Operating Junction Temperature

TJ

–40

—

+125

°C

Note 1

Maximum Junction Temperature

TJ(MAX)

—

—

+150

°C

—

Temperature Ranges

TS

–65

—

+150

°C

—

TLEAD

—

—

+260

°C

Soldering, 10s

Junction-to-Ambient

JA

—

50.8

—

°C/W

—

Junction-to-Case

JC

—

25.3

—

°C/W

—

Storage Temperature

Lead Temperature

Package Thermal Resistances

Thermal Resistance,

16 Lead,

3 x 3 mm VQFN

Note 1:

The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable

junction temperature and the thermal resistance from junction-to-air (i.e., TA, TJ, JA). Exceeding the

maximum allowable power dissipation will cause the device operating junction temperature to exceed the

maximum +125°C rating. Sustained junction temperatures above +125°C can impact the device reliability.

2016-2020 Microchip Technology Inc.

DS20005676F-page 6

�MIC2127A

2.0

TYPICAL CHARACTERISTIC CURVES

Note:

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

1.8

VOUT = 5V

IOUT = 0A

FSW = 300 kHz

VEN = VVIN

20

Input Supply Current (mA)

Input Supply Current (mA)

25

15

10

5

6

1.2

1

VEXTVDD = VOUT

0.8

0.6

VVIN = 48V

IOUT = 0A

FSW = 300 kHz

VEN = VIN

HLL Mode

0.4

0.2

-50

12 18 24 30 36 42 48 54 60 66 72 78

Input Voltage (V)

FIGURE 2-1:

Input Voltage.

Input Supply Current vs.

30

600

25

500

EXTVDD = GND

20

15

VEXTVDD = VOUT

10

VVIN = 48V

IOUT = 0A

FSW = 300 kHz

5

-25

0

25

50

Temperature (°C)

75

100

FIGURE 2-4:

Input Supply Current vs.

Temperature (HLL Mode).

Input Current (μA)

Input Supply Current (mA)

EXTVDD = GND

1.4

0

0

VVIN = 48V, with resistor divider

between VIN and AGND at FREQ pin

(100 k and 60 k)

EN = GND

400

300

200

100

0

0

-50

-25

FIGURE 2-2:

Temperature.

0

25

50

Temperature (°C)

75

6

100

Input Supply Current vs.

0.4

0.3

VOUT =5V

IOUT =0A

FSW =300 kHz

VEN =VVIN

HLL Mode

0.2

0.1

0

6

12 18 24 30 36 42 48 54 60 66 72 78

Input Voltage (V)

FIGURE 2-3:

Input Supply Current vs.

Input Voltage (HLL Mode).

2016-2020 Microchip Technology Inc.

Input Current (μA)

0.6

0.5

18

FIGURE 2-5:

Input Voltage.

0.7

Input Supply Current (mA)

1.6

350

340

330

320

310

300

290

280

270

260

250

30

42

Input Voltage (V)

54

66

78

Input Shutdown Current vs.

VVIN = 48V, with resistor divider between VIN

and AGND at FREQ pin

(100 k and 60 k)

EN = GND

-50

FIGURE 2-6:

Temperature.

-25

0

25

Temperature (°C)

50

75

100

Input Shutdown Current vs.

DS20005676F-page 7

�MIC2127A

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

4.5

5.4

IPVDD = 10 mA

VEN = VVIN

EXTVDD = GND

VDD Voltage (V)

5.2

5.1

5

3.9

3.7

VDD falling

3.5

3.3

4.8

3.1

12 18 24 30 36 42 48 54 60 66 72 78

Input Voltage (V)

FIGURE 2-7:

VVDD rising

4.1

4.9

6

IVDD = 0 mA

EXTVDD = GND

-50

-25

0

25

50

Temperature (°C)

FIGURE 2-10:

Temperature.

PVDD Line Regulation.

75

100

125

VDD UVLO Threshold vs.

4.8

5.4

PVDD Voltage (V)

4.3

VVIN = 48V

IPVDD = 10 mA

VEN = VVIN

5.3

EXTVDD Voltage (V)

PVDD Voltage (V)

5.3

5.2

VEXTVDD = 12V

5.1

5

EXTVDD = GND

4.9

4.7

VEXTVDD rising

4.6

4.5

4.4

VEXTVDD falling

4.3

VEXTVDD = 5V

4.8

4.2

-50

-25

FIGURE 2-8:

Temperature.

0

25

Temperature (°C)

50

75

100

PVDD Voltage vs.

-50

0

25

50

Temperature (°C)

FIGURE 2-11:

Temperature.

5.2

75

100

125

EXTVDD Threshold vs.

1.6

5

VEXTVDD = 12V

EXTVDD = GND

4.8

Enable Voltage (V)

PVDD Voltage (V)

-25

4.6

VEXTVDD = 5V

4.4

4.2

VVIN = 48V

VEN = VVIN

4

0

10

20

30

40

50

IPVDD (mA)

FIGURE 2-9:

PVDD Load Regulation.

2016-2020 Microchip Technology Inc.

60

1.4

1.2

VEN rising

1.0

VEN falling

0.8

0.6

-50

-25

FIGURE 2-12:

Temperature.

0

25

50

Temperature (°C)

75

100

125

Enable Threshold vs.

DS20005676F-page 8

�MIC2127A

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

140

5.6

EN Current (µA)

ILIM Source Current (µA)

VVIN = 12V

VEN = 5V

5.4

5.2

5.0

4.8

4.6

4.4

4.2

4.0

-50

-25

0

25

50

Temperature (°C)

320

310

300

290

280

270

260

250

240

230

220

100

110

100

90

80

70

125

-50

-25

FIGURE 2-16:

Temperature.

Enable Bias Current vs.

0

25

50

Temperature (°C)

75

100

125

ILIM Source Current vs.

1.4

IOUT = 5A

IOUT = 0A

VOUT = 5V

FSW_SETPONIT = 300 kHz

VEXTVDD = VOUT

VEN = VVIN

6

1.2

1.0

0.8

0.6

0.4

0.2

0.0

-50

12 18 24 30 36 42 48 54 60 66 72 78

Input Voltage (V)

FIGURE 2-14:

Input Voltage.

Switching Frequency vs.

-25

0

25

50

Temperature (°C)

75

100

125

FIGURE 2-17:

Current Limit Comparator

Offset vs Temperature.

606.0

310

TA = 25°C

305

Feedback Voltage (mV)

Switching Frequency (kHz)

120

Current Limit Comparator

Offset Voltgae (mV)

Switching frequency (kHz)

FIGURE 2-13:

Temperature.

75

130

TA = -40°C

300

TA = 85°C

295

290

285

280

VVIN = 48V

VOUT = 5V

FSW_SETPONIT = 300 kHz

VEXTVDD = VOUT

VEN = VVIN

275

270

265

604.0

602.0

600.0

598.0

596.0

594.0

0

0.5

FIGURE 2-15:

Load Current.

1

1.5

2

2.5

3

Load Current (A)

3.5

4

4.5

Switching Frequency vs.

2016-2020 Microchip Technology Inc.

5

-50

-25

FIGURE 2-18:

Temperature.

0

25

50

Temperature (°C)

75

100

125

Feedback Voltage vs.

DS20005676F-page 9

�MIC2127A

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

Efficiency

Efficiency

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

VOUT=1.0V

V

OUT = 1.0V

VOUT=1.2V

V

OUT = 1.2V

VOUT=1.5V

V

OUT = 1.5V

VOUT=1.8V

V

OUT = 1.8V

VOUT=2.5V

V

OUT = 2.5V

V

VOUT=3.3V

OUT = 3.3V

VOUT=5V

V

OUT = 5V

0

0.5

1

1.5 2 2.5 3

Output Current (A)

3.5

4

4.5

0.5

1

1.5

2

2.5

3

3.5

4

4.5

Efficiency

Efficiency

VOUT=1.5V

VOUT = 1.5V

VOUT=1.8V

VOUT = 1.8V

VOUT=2.5V

VOUT = 2.5V

VOUT=3.3V

VOUT = 3.3V

VOUT=5V

VOUT = 5V

0.5

1

5

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

0

Efficiency

Efficiency

VOUT=1.0V

V

OUT = 1.0V

V

VOUT=1.2V

OUT = 1.2V

VOUT=1.5V

V

OUT = 1.5V

V

VOUT=1.8V

OUT = 1.8V

VOUT=2.5V

VOUT = 2.5V

VOUT=3.3V

V

OUT = 3.3V

V

VOUT=5V

OUT = 5V

0.5

1

1.5 2 2.5 3

Output Current (A)

3.5

4

4.5

FIGURE 2-21:

Efficiency vs. Output

Current (Input Voltage = 36V, CCM Mode).

2016-2020 Microchip Technology Inc.

4

4.5

5

VOUT=1.0V

VOUT = 1.0V

VOUT=1.5V

VOUT = 1.5V

V

VOUT=1.2V

OUT = 1.2V

VOUT=2.5V

VOUT = 2.5V

VOUT = 3.3V

VOUT=3.3V

VOUT = 1.8V

VOUT=1.8V

0.5

1

1.5 2 2.5 3

Output Current (A)

3.5

4

4.5

5

FIGURE 2-23:

Efficiency vs. Output

Current (Input Voltage = 60V, CCM Mode).

FIGURE 2-20:

Efficiency vs. Output

Current (Input Voltage = 24V, CCM Mode).

0

3.5

VOUT=5V

VOUT = 5V

Output Current (A)

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

1.5 2 2.5 3

Output Current (A)

FIGURE 2-22:

Efficiency vs. Output

Current (Input Voltage = 48V, CCM Mode).

VOUT=1.0V

VOUT = 1.0V

VOUT=1.2V

VOUT = 1.2V

VOUT = 1.5V

VOUT=1.5V

VOUT=1.8V

VOUT = 1.8V

VOUT=2.5V

VOUT = 2.5V

VOUT = 3.3V

VOUT=3.3V

VOUT=5V

VOUT = 5V

0

VOUT=1.0V

VOUT = 1.0V

VOUT=1.2V

VOUT = 1.2V

0

5

FIGURE 2-19:

Efficiency vs. Output

Current (Input Voltage = 12V, CCM Mode).

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

5

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

VOUT=1.0V

VOUT = 1.0V

VOUT = 1.5V

VOUT=1.5V

VOUT = 1.2V

VOUT=1.2V

VOUT=2.5V

VOUT = 2.5V

VOUT = 3.3V

VOUT=3.3V

VOUT = 1.8V

VOUT=1.8V

VOUT = 5V

VOUT=5V

0

0.5

1

1.5 2 2.5 3

Output Current (A)

3.5

4

4.5

5

FIGURE 2-24:

Efficiency vs. Output

Current (Input Voltage = 75V, CCM Mode).

DS20005676F-page 10

�MIC2127A

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

100%

90%

80%

70%

VOUT=5.0V

VOUT = 5V

Efficiency

Efficiency

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

VOUT=3.3V

VOUT = 3.3V

VOUT = 2.5V

VOUT=2.5V

VOUT = 1.8V

VOUT=1.8V

0

0.5

1

1.5 2 2.5 3

Load Current (A)

3.5

40%

30%

V

VOUT=1.2V

OUT = 1.2V

20%

VOUT=1.0V

VOUT = 1.0V

10%

4

4.5

80%

70%

70%

Efficiency

90%

80%

VOUT=5.0V

VOUT = 5V

VOUT=3.3V

VOUT = 3.3V

VOUT=2.5V

VOUT = 2.5V

VOUT=1.8V

VOUT = 1.8V

VOUT = 1.5V

VOUT=1.5V

VOUT = 1.2V

VOUT=1.2V

30%

20%

10%

0.5

1

1.5 2 2.5 3

Load Current (A)

3.5

0.5

1

1.5 2 2.5 3

Load Current (A)

3.5

4

4.5

5

VOUT=3.3V

VOUT = 3.3V

40%

VOUT=2.5V

VOUT = 2.5V

30%

VOUT = 1.8V

VOUT=1.8V

20%

VOUT = 1.5V

VOUT=1.5V

5

VOUT=1.2V

VOUT = 1.2V

VOUT=1.0V

VOUT = 1.0V

0

0.5

1

1.5 2 2.5 3

Load Current (A)

3.5

4

4.5

5

FIGURE 2-29:

Efficiency vs. Output

Current (Input Voltage = 60V, HLL Mode).

FIGURE 2-26:

Efficiency vs. Output

Current (Input Voltage = 24V, HLL Mode).

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

4.5

VOUT = 5V

VOUT=5.0V

50%

0%

0

4

60%

10%

VOUT = 1.0V

VOUT=1.0V

0%

VOUT=1.0V

V

OUT = 1.0V

FIGURE 2-28:

Efficiency vs. Output

Current (Input Voltage = 48V, HLL Mode).

100%

40%

V

VOUT=1.2V_D4

OUT = 1.2V

0

90%

50%

V

VOUT=1.8V

OUT = 1.8V

V

VOUT=1.5V_D4

OUT = 1.5V

0%

5

100%

60%

VOUT=5V_D4

V

OUT = 5V

VOUT=3.3V_D4

V

OUT = 3.3V

V

VOUT=2.5V_D4

OUT = 2.5V

50%

VOUT = 1.5V

VOUT=1.5V

FIGURE 2-25:

Efficiency vs. Output

Current (Input Voltage = 12V, HLL Mode).

Efficiency

60%

100%

90%

80%

Efficiency

Efficiency

70%

VOUT=5.0V

VOUT = 5V

VOUT=3.3V

VOUT = 3.3V

VOUT=2.5V

VOUT = 2.5V

VOUT = 1.8V

VOUT=1.8V

VOUT = 1.5V

VOUT=1.5V

VOUT = 1.2V

VOUT=1.2V

0.5

1

1.5 2 2.5 3

Load Current (A)

3.5

4

4.5

FIGURE 2-27:

Efficiency vs. Output

Current (Input Voltage = 36V, HLL Mode).

2016-2020 Microchip Technology Inc.

50%

40%

30%

VOUT=5.0V

VOUT = 5V

VOUT = 3.3V

VOUT=3.3V

20%

VOUT=2.5V

VOUT = 2.5V

VOUT=1.8V

VOUT = 1.8V

VOUT = 1.5V

VOUT=1.5V

VOUT = 1.2V

VOUT=1.2V

10%

VOUT = 1.0V

VOUT=1.0V

0

60%

5

VOUT = 1.0V

VOUT=1.0V

0%

0

0.5

1

1.5 2 2.5 3

Load Current (A)

3.5

4

4.5

5

FIGURE 2-30:

Efficiency vs. Output

Current (Input Voltage = 75V, HLL Mode).

DS20005676F-page 11

�MIC2127A

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

VVIN

20V/div

VVIN

20V/div

VSW

20V/div

VVIN = 0V to 48V

VOUT = 5V

IOUT = 5A

VOUT

2V/div

IL

5A/div

FIGURE 2-31:

IL

2A/div

10 ms/div

Power-Up.

10 ms/div

FIGURE 2-34:

Power-Up at Light Load in

HLL Mode (IOUT = 0.1A).

VVIN = 48V to 0V

VOUT = 5V

IOUT = 5A

VVIN = 48V

VOUT = 5V

IOUT = 5A

VEN

2V/div

VSW

20V/div

VOUT

2V/div

VOUT

2V/div

IL

5A/div

IL

5A/div

VPG

5V/div

10 ms/div

Power-Down.

FIGURE 2-35:

VVIN

20V/div

4 ms/div

Enable Turn-On/Turn-Off.

VEN

2V/div

VSW

20V/div

VVIN = 0V to 48V

VOUT = 5V

IOUT = 0.1A

VOUT

2V/div

IL

2A/div

VVIN = 0V to 48V

VOUT = 5V

IOUT = 0.1A

VOUT

2V/div

VVIN

20V/div

FIGURE 2-32:

VSW

20V/div

VVIN = 48V

VOUT = 5V

IOUT = 5A

VOUT

2V/div

IL

5A/div

10 ms/div

FIGURE 2-33:

Power-Up at Light Load in

CCM Mode (IOUT = 0.1A).

2016-2020 Microchip Technology Inc.

VPG

5V/div

FIGURE 2-36:

2 ms/div

Enable Turn-On Delay.

DS20005676F-page 12

�MIC2127A

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

VVIN = 48V

VOUT = 5V

IOUT = 5A

VEN

2V/div

VEN

2V/div

VOUT

2V/div

VOUT

2V/div

IL

5A/div

VSW

50V/div

VPG

5V/div

IL

2A/div

2 ms/div

FIGURE 2-37:

Enable Turn-Off Delay.

VVIN = 48V

VOUT = 5V

IOUT = 0.2A

VEN

2V/div

4 ms/div

FIGURE 2-40:

Enable Turn-On with

Prebiased Output (CCM Mode).

VEN

2V/div

VOUT

2V/div

VOUT

2V/div

VVIN = 48V

VOUT = 5V

IOUT = 0A

VOUT_PREBIAS = 2.5V

VSW

50V/div

IL

2A/div

VPG

5V/div

VVIN = 48V

VOUT = 5V

IOUT = 0A

VOUT_PREBIAS = 2.5V

IL

2A/div

10 ms/div

FIGURE 2-38:

Enable Turn-On/Turn-Off at

Light Load in CCM Mode.

4 ms/div

FIGURE 2-41:

Enable Turn-On with

Prebiased Output (HLL Mode).

VVIN = 48V

VOUT = 5V

IOUT = 0.2A

VEN

2V/div

VVIN = 48V

VOUT = 5V

IOUT = 0A

VEN

1V/div

VOUT

2V/div

VOUT

2V/div

IL

2A/div

VPG

5V/div

VSW

50V/div

4 ms/div

10 ms/div

FIGURE 2-39:

Enable Turn-On/Turn-Off at

Light Load in HLL Mode.

2016-2020 Microchip Technology Inc.

FIGURE 2-42:

Enable Thresholds.

DS20005676F-page 13

�MIC2127A

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

VVIN = Rising

VOUT = 5V

IOUT = 0A

VVDD

1V/div

VVIN = 0V to 48V

VOUT = 5V

Load = Short

RCL = 1.3 k

VVIN

20V/div

VOUT

500 mV/div

VOUT

2V/div

VSW

5V/div

FIGURE 2-43:

Rising.

IL

5A/div

10 ms/div

4 ms/div

VDD UVLO Threshold-

VVDD

1V/div

VVIN = Falling

VOUT = 5V

IOUT = 0A

FIGURE 2-46:

Power-Up into Output Short.

VVIN = 48V

VOUT = 5V

RCL = 1.3 k

VOUT

2V/div

VOUT

2V/div

VSW

5V/div

IOUT

5A/div

2 ms/div

100 ms/div

FIGURE 2-44:

Falling.

VDD UVLO Threshold-

VEN

2V/div

VVIN = 48V

VOUT = 5V

Load = Short

RCL = 1.3 k

FIGURE 2-47:

Threshold.

Output Current Limit

VVIN = 48V

VOUT = 5V

Load = Short

RCL = 1.3 k

VOUT

2V/div

VOUT

500 mV/div

IL

5A/div

IL

5A/div

4 ms/div

FIGURE 2-45:

Enable into Output Short.

2016-2020 Microchip Technology Inc.

2 ms/div

FIGURE 2-48:

Output Short Circuit.

DS20005676F-page 14

�MIC2127A

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

VOUT

2V/div

VVIN = 48V

VOUT = 5V

Load = Short

RCL = 1.3 k

VOUT

100 mV/div

AC coupled

VVIN = 48V

VOUT = 5V

IOUT = 0A to 2.5A

IL

5A/div

IOUT

2A/div

4 ms/div

FIGURE 2-49:

Circuit.

100 µs/div

Recovery from Output Short

VOUT

200 mV/div

AC coupled

VVIN = 48V

VOUT = 5V

IOUT = 0A to 5A

IOUT

2A/div

FIGURE 2-52:

(CCM Mode).

VOUT

100 mV/div

AC coupled

2 ms/div

Load Transient Response

VOUT

200 mV/div

AC coupled

VVIN = 48V

VOUT = 5V

IOUT = 0A to 5A

IOUT

2A/div

FIGURE 2-53:

(HLL Mode).

IOUT

2A/div

Load Transient Response

2016-2020 Microchip Technology Inc.

Load Transient Response

VOUT

100 mV/div

AC coupled

2 ms/div

FIGURE 2-51:

(HLL Mode).

VVIN = 48V

VOUT = 5V

IOUT = 0A to 2.5A

IOUT

2A/div

100 µs/div

FIGURE 2-50:

(CCM Mode).

Load Transient Response

FIGURE 2-54:

(HLL Mode).

VVIN = 48V

VOUT = 5V

IOUT = 2.5A to 5A

100 µs/div

Load Transient Response

DS20005676F-page 15

�MIC2127A

Note: Unless otherwise indicated, VVIN = 12V, fSW = 300 kHz, RCL = 1.3 k, L = 10 µH, VEXTVDD = VOUT, TA = +25°C

(refer to the Typical Application Circuit circuit).

VVIN = 48V

VOUT = 5V

IOUT = 0A

VOUT

50 mV/div

AC coupled

VVIN = 48V

VOUT = 5V

IOUT = 5A

VOUT

50 mV/div

AC coupled

VSW

50V/div

IL

2A/div

IL

5A/div

VSW

50 V/div

2 µs/div

2 µs/div

FIGURE 2-55:

Switching Waveform at No

Load (CCM Mode).

FIGURE 2-57:

Load.

Switching Waveform at Full

VVIN = 48V

VOUT = 5V

IOUT = 0A

VOUT

50 mV/div

AC coupled

IL

2A/div

VSW

50V/div

10 µs/div

FIGURE 2-56:

Switching Waveform at No

Load (HLL Mode).

2016-2020 Microchip Technology Inc.

DS20005676F-page 16

�MIC2127A

3.0

PIN DESCRIPTION

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1:

PIN FUNCTION TABLE

Pin Number

Pin Name

1

PG

3.1

Pin Function

Open-drain Power Good Output Pin

2

ILIM

Current Limit Setting Resistor Connection Pin

3

SW

Switch Pin and Current Sense Input for negative current limit

4

BST

Bootstrap Capacitor Connection Pin

5

DH

High-side N-MOSFET Gate Driver Output

6

PGND

7

DL

8

PVDD

9

EXTVDD

Power Ground

Low-side N-MOSFET Gate Driver Output

Internal Low Dropout Regulators Output of the MIC2127A

Supply Input for the internal low voltage LDO

10

EN

11

FREQ

Switching Frequency Programming Input

Enable Input

12

MODE

Light Load Mode Selection Input

13

FB

Feedback Input

Analog Ground

14

AGND

15

VDD

Supply Input for the MIC2127A internal analog circuits

16

VIN

Supply Input for the internal high-voltage LDO

17

EP

Exposed Pad

Power Good Output Pin (PG)

3.5

High-Side N-MOSFET Gate Driver

Output Pin (DH)

Connect PG to VDD through a pull-up resistor. PG is low

when the FB voltage is 10% below the 0.6V reference

voltage.

High-side N-MOSFET gate driver Output. Connect DH

to the gate of external high-side N-MOSFET.

3.2

3.6

Current Limit Pin (ILIM)

Connect a resistor from ILIM to SW to set the current

limit. Refer to Section 4.3 “Current Limit (ILIM)” for

more details.

3.3

Switch Pin (SW)

The SW pin provides the return path for the high-side

N-MOSFET gate driver when High-Side MOSFET

Gate Drive (DH) is low and is also used to sense

low-side MOSFET current by monitoring the SW node

voltage for negative current limit function.

Connect SW to the pin where the high-side MOSFET

source and the low-side MOSFET drain terminal are

connected together.

3.4

Bootstrap Capacitor Pin (BST)

BST capacitor acts as supply for the high-side

N-MOSFET driver. Connect a minimum of 0.1 µF low

ESR ceramic capacitor between BST and SW. Refer to

Section 4.5 “High-Side MOSFET Gate Drive (DH)”

for more details.

2016-2020 Microchip Technology Inc.

Power Ground Pin (PGND)

PGND provides the return path for the internal low-side

N-MOSFET gate driver output and also acts as

reference for the current limit comparator. Connect

PGND to the external low-side N-MOSFET source

terminal and to the return terminal of PVDD bypass

capacitor.

3.7

Low-Side N-MOSFET Gate Driver

Output Pin (DL)

Low-side N-MOSFET gate driver output. Connect to

the gate terminal of the external low-side N-MOSFET.

3.8

Internal Low Dropout Regulators

Output Pin (PVDD)

Combined output of the two internal LDOs (one LDO

powered by VIN and the other LDO powered by

EXTVDD). PVDD is the supply for the low-side

MOSFET driver and for the floating high-side MOSFET

driver. Connect a minimum of 4.7 µF low ESR ceramic

capacitor from PVDD to PGND.

DS20005676F-page 17

�MIC2127A

3.9

EXTVDD

3.13

Feedback Input Pin (FB)

Supply to the internal low voltage LDO. Connect

EXTVDD to the output of the buck converter if it is

between 4.7V to 14V to improve system efficiency.

Bypass EXTVDD with a minimum of 1 µF low ESR

ceramic capacitor. Refer to Section 4.7 “Auxiliary

Bootstrap LDO (EXTVDD)” for more details.

FB is input to the transconductance amplifier of the

control loop. The control loop regulates the FB voltage

to 0.6V. Connect the FB node to the mid-point of the

resistor divider between output and AGND.

3.10

AGND is the reference to the analog control circuits

inside the MIC2127A. Connect AGND to PGND at one

point on the PCB.

Enable Input Pin (EN)

EN is a logic input. Connect to logic high to enable the

converter, and connect to logic low to disable the

converter.

3.11

Switching Frequency

Programming Input Pin (FREQ)

Switching Frequency Programming Input. Connect to

mid-point of the resistor divider formed between VIN

and AGND to set the switching frequency of the

converter. Tie FREQ to VIN to set the switching

frequency to 800 kHz. Refer to Section 5.1 “Setting

the Switching Frequency” for more details.

3.12

Light Load Mode Selection Input

Pin (MODE)

Light Load Mode Selection Input. Connect MODE pin

to VDD to select Continuous Conduction mode under

light loads, or connect to AGND to select HyperLight

Load (HLL) mode of operation under light loads. Refer

to Section 4.2 “Light Load Operating Mode

(MODE)” for further details.

2016-2020 Microchip Technology Inc.

3.14

3.15

Analog Ground Pin (AGND)

Bias Voltage Pin (VDD)

Supply for the MIC2127A internal analog circuits.

Connect VDD to PVDD of the MIC2127A through a

low-pass filter. Connect a minimum of 4.7 µF low ESR

ceramic capacitor from VDD to AGND for decoupling.

3.16

Input Voltage Pin (VIN)

Supply Input to the internal high-voltage LDO. Connect

to the main power source and bypass to PGND with a

minimum of 0.1 µF low ESR ceramic capacitor.

3.17

Exposed Pad (EP)

Connect to the AGND copper plane to improve thermal

performance of the MIC2127A device.

DS20005676F-page 18

�MIC2127A

4.0

FUNCTIONAL DESCRIPTION

The MIC2127A device is an adaptive on-time

synchronous buck controller, designed to cover a wide

range of input voltage applications ranging from

4.5V-5V. An adaptive on-time control scheme is

employed to get a fast transient response and to obtain

high-voltage conversion ratios at constant switching

frequency. Overcurrent protection is implemented by

sensing low-side MOSFET's RDS(ON), which eliminates

lossy current sense resistor. The device features

internal soft-start, enable input, UVLO, power good

output (PG), secondary bootstrap LDO and thermal

shutdown.

4.1

Theory of Operation

The MIC2127A is an adaptive on-time synchronous

buck controller that operates based on ripple at the

feedback node. The output voltage is sensed by the

MIC2127A feedback pin (FB) and is compared to a

0.6V reference voltage (VREF) at the low-gain

transconductance error amplifier (gM), as shown in the

Functional Block Diagram. Figure 4-1 shows the

MIC2127A control loop timing during steady-state

operation.

The error amplifier behaves as the short circuit for the

ripple voltage frequency on the FB pin, which causes

the error amplifier output voltage ripple to follow the

feedback voltage ripple. When the transconductance

error amplifier output (VgM) is below the reference

voltage of the comparator, which is same as the error

amplifier reference (VREF), the comparator triggers and

generates an on-time event. The on-time period is

predetermined by the fixed tON estimator circuitry,

which is given by Equation 4-1:

EQUATION 4-1:

The maximum duty cycle can be calculated using

Equation 4-2:

EQUATION 4-2:

t SW – tOFF MIN

230 ns

DMAX = --------------------------------------- = 1 – ---------------t SW

tSW

Where:

tSW

= Switching period, equal to 1/fSW

It is not recommended to use the MIC2127A device

with an OFF time close to tOFF(MIN) during steady-state

operation.

The adaptive on-time control scheme results in a

constant switching frequency over the wide range of

input voltage and load current. The actual ON time and

resulting switching frequency varies with the different

rising and falling times of the external MOSFETs. The

minimum controllable ON time (tON(MIN)) results in a

lower switching frequency than the target switching

frequency in high VIN to VOUT ratio applications.

Equation 4-3 shows the output-to-input voltage ratio,

below which the MIC2127A device lowers the switching

frequency in order to regulate the output to set value.

EQUATION 4-3:

VOUT

------------- tON(MIN) f SW

V IN

Where:

VOUT

= Output voltage

VIN

= Input voltage

fSW

= Switching frequency

tON(MIN)

= Minimum controllable ON time (80 ns typ.)

VOUT

t ON ESTIMATED = -------------------------V VIN f SW

Where:

VOUT

= Output voltage

VVIN

= Power stage input voltage

fSW

= Switching frequency

At the end of the ON time, the internal high-side driver

turns off the high-side MOSFET and the low-side driver

turns on the low-side MOSFET. The OFF time of the

high-side MOSFET depends on the feedback voltage.

When the feedback voltage decreases, the output of

the gM amplifier (VgM) also decreases. When the output

of the gM amplifier (VgM) is below the reference voltage

of the comparator (which is same as the error amplifier

reference (VREF)), the OFF time ends and ON time is

triggered. If the OFF time determined by the feedback

voltage is less than the minimum OFF time (tOFF(MIN))

of the MIC2127A, which is about 230 ns (typical), the

MIC2127A control logic applies the tOFF(MIN), instead.

2016-2020 Microchip Technology Inc.

DS20005676F-page 19

�MIC2127A

Full Load

ǻIL

IL

IL

No Load

ǻVOUT

VOUT

ǻVOUT = ESR*ǻIL

VOUT

ǻVFB

VREF

VFB

ǻVFB = ǻVOUT *(VREF/VOUT)

ǻVFB

VREF

VgM

VREF

VFB

MIC2127A Triggers ON-Time event if

the error amplifier output (VgM) is below VREF

VDH

VREF

VgM

Estimated ON-Time

FIGURE 4-1:

Timing.

MIC2127A Control Loop

Figure 4-2 shows operation of the MIC2127A during

load transient. The output voltage drops due to a

sudden increase in load, which results in the error

amplifier output (VgM) falling below VREF. This causes

the comparator to trigger an on-time event. At the end

of the ON time, a minimum OFF time tOFF(MIN) is

generated to charge the bootstrap capacitor. The next

ON time is triggered immediately after the tOFF(MIN) if

the error amplifier output voltage (VgM) is still below

VREF due to the low feedback voltage. This operation

results in higher switching frequency during load

transients. The switching frequency returns to the

nominal set frequency once the output stabilizes at new

load current level. The output recovery time is fast and

the output voltage deviation is small in the MIC2127A

converter due to the varying duty cycle and switching

frequency.

2016-2020 Microchip Technology Inc.

VDH

toff(MIN)

FIGURE 4-2:

Response.

MIC2127A Load Transient

Unlike true current-mode control, the MIC2127A uses

the output voltage ripple to trigger an on-time event. In

order to meet the stability requirements, the MIC2127A

feedback voltage ripple should be in phase with the

inductor current ripple and large enough to be sensed

by the internal error amplifier. The recommended

feedback voltage ripple is approximately 20 mV100 mV over the full input voltage range. If a low-ESR

output capacitor is selected, then the feedback voltage

ripple may be too small to be sensed by the internal

error amplifier. Also, the output voltage ripple and the

feedback voltage ripple are not necessarily in phase

with the inductor current ripple if the ESR of the output

capacitor is very low. For these applications, ripple

injection is required to ensure proper operation. Refer

to Section 5.7 “Ripple Injection” for details about the

ripple injection technique.

DS20005676F-page 20

�MIC2127A

4.2

Light Load Operating Mode

(MODE)

4.3

MIC2127A features a MODE pin that allows the user to

select either Continuous Conduction mode or

HyperLight Load (HLL) mode under light loads. HLL

mode increases the system efficiency at light loads by

reducing the switching frequency. Continuous

Conduction mode keeps the switching frequency

almost constant over the load current range.

Figure 4-3 shows the control loop timing in HLL mode.

The MIC2127A device has a zero crossing comparator

(ZC Detection) that monitors the inductor current by

sensing the voltage drop across the low-side MOSFET

during its ON time. The zero crossing comparator

triggers whenever the low-side MOSFET current goes

negative and turns off the low-side MOSFET. The

switching instant of the high-side MOSFET depends on

the error amplifier output, which is same as the

comparator inverting input (see the Functional Block

Diagram). If the error amplifier output is higher than the

comparator reference, then the MIC2127A enters into

Sleep mode. During Sleep mode, both the high-side

and low-side MOSFETs are kept off and the efficiency

is optimized by shutting down all the nonessential

circuits inside the MIC2127A. The load current is

supplied by the output capacitor during Sleep mode.

The control circuitry wakes up when the error amplifier

output falls below the comparator reference and a tON

pulse is triggered.

Low side MOSFET current crosses 0A and the comparator inverting input, VgM, is higher than its reference.

This condition triggers the HLL mode

The comparator inverting input, VgM, is lower than its reference. The

MIC2127A comes out of HLL mode

IL

Current Limit (ILIM)

The MIC2127A device uses the low-side MOSFET

RDS(ON) to sense inductor current. In each switching

cycle of the MIC2127A converter, the inductor current

is sensed by monitoring the voltage across the low-side

MOSFET during the OFF period of the switching cycle,

during which low-side MOSFET is ON. An internal

current source of 100 µA generates a voltage across

the external current limit setting resistor RCL as shown

in Figure 4-4.

VIN

DH

MIC2127A

L1

SW

Control

Logic

DL

RCL

PGND

CURRENT

LIMIT

DETECTION

ICL

ILIM

FIGURE 4-4:

Circuit.

MIC2127A Current Limiting

The ILIM pin voltage (VILIM) is the difference of the

voltage across the low-side MOSFET and the voltage

across the resistor (VRCL). The sensed voltage VILIM is

compared with the power ground (PGND) after a

blanking time of 150 ns.

0A

VREF

VFB

VREF

VgM

ZCD

VDH

If the absolute value of the voltage drop across the

low-side MOSFET is greater than the absolute value of

the voltage across the current setting resistor (VRCL),

the MIC2127A triggers the current limit event.

Consecutive eight-current limit events trigger the

Hiccup mode. Once the controller enters into Hiccup

mode, it initiates a soft start sequence after a hiccup

timeout of 4 ms (typical). Both the high-side and

low-side MOSFETs are turned off during hiccup

timeout. The hiccup sequence, including the soft start,

reduces the stress on the switching FETs and protects

the load and supply from severe short conditions.

The current limit can be programmed by using the

following Equation 4-4.

VDL

FIGURE 4-3:

MIC2127A Control Loop

Timing (HLL Mode).

The typical no-load supply current during HLL mode is

only about 300 µA, allowing the MIC2127A device to

achieve high efficiency at light load operation.

2016-2020 Microchip Technology Inc.

DS20005676F-page 21

�MIC2127A

EQUATION 4-4:

RCL

IL PP

I

+ ---------------- R DS ON + V OFFSET

CLIM

2

= -------------------------------------------------------------------------------------------------I CL

Where:

ICLIM

= Load current limit

RDS (ON) = On-resistance of low-side power MOSFET

ILPP

= Inductor peak-to-peak ripple current

VOFFSET = Current-limit comparator offset (15 mV max.)

ICL

= Current-limit source current (100 µA typ)

Since MOSFET RDS(ON) varies from 30%-40% with

temperature, it is recommended to consider the

RDS(ON) variation while calculating RCL in the above

equation, to avoid false current limiting due to

increased MOSFET junction temperature rise. Also

connect the SW pin directly to the drain of the low-side

MOSFET to accurately sense the MOSFETs RDS(ON).

To improve the current limit variation, the MIC2127A

adjusts the internal source current of the current limit

(ICL) at a rate of 0.3 µA/°C when the MIC2127A

junction temperature changes to compensate the

RDS(ON) variation of external low-side MOSFET. The

effectiveness of this method depends on the thermal

gradient between the MIC2127A and the external

low-side MOSFET. The lower the thermal gradient, the

better the current limit variation.

A small capacitor (CCL) can be connected from the ILIM

pin to PGND to filter the switch node ringing during the

OFF time, allowing a better current sensing. The time

constant of RCL and CCL should be less than the

minimum OFF time.

4.4

Negative Current Limit

The MIC2127A device implements negative current

limit by sensing the SW voltage when the low-side FET

is ON. If the SW node voltage exceeds 48 mV typical,

the device turns off the low-side FET for 500 ns.

Negative current limit value is shown in Equation 4-5.

EQUATION 4-5:

48mV

I NLIM = -------------------R DS ON

Where:

INLIM

= Negative current limit

bootstrap diode between the PVDD and BST pins. This

circuit supplies energy to the high-side drive circuit. A

low ESR ceramic capacitor should be connected

between BST and SW pins (refer to the Typical

Application Circuit circuit).The capacitor between BST

and SW pins, CBST, is charged while the low-side

MOSFET is on. When the high-side MOSFET driver is

turned on, energy from CBST is used to turn the

MOSFET on. A minimum of 0.1 µF low ESR ceramic

capacitor is recommended between BST and SW pins.

The required value of CBST can be calculated using the

following Equation 4-6:

EQUATION 4-6:

Q G_HS

C BST = ------------------ V CBST

Where:

QG_HS

= High-side MOSFET total gate charge

VCBST

= Voltage drop across the CBST,

generally 50 mV to 100 mV

A small resistor in series with CBST can be used to slow

down the turn-on time of the high-side N-channel

MOSFET.

4.6

Low-Side MOSFET Gate Drive (DL)

MIC2127A's low-side drive circuit is designed to switch

an N-Channel external MOSFET. The internal low-side

MOSFET driver is powered by PVDD. Connect a

minimum of 4.7 µF low-ESR ceramic capacitor to

supply the transient gate current of the external

MOSFET.

4.7

Auxiliary Bootstrap LDO

(EXTVDD)

MIC2127A features an auxiliary bootstrap LDO that

improves the system efficiency by supplying the

MIC2127A internal circuit bias power and gate drivers

from the converter output voltage. This LDO is enabled

when the voltage on the EXTVDD pin is above 4.6V

(typical) and, at the same time, the main LDO that

operates from VIN is disabled to reduce power

consumption. Connect EXTVDD to the output of the

buck converter if it is between 4.7V and 14V. When the

EXTVDD is tied to VOUT, a voltage spike will occur at

the PVDD and VDD during a fast hard short at VOUT.

Larger decoupling ceramic capacitors of 10 µF at PVDD

and VDD are recommended for such a situation.

RDS (ON) = On-resistance of low-side power MOSFET

4.5

High-Side MOSFET Gate Drive

(DH)

The MIC2127A’s high-side drive circuit is designed to

switch an N-Channel external MOSFET. The

MIC2127A Functional Block Diagram shows a

2016-2020 Microchip Technology Inc.

DS20005676F-page 22

�MIC2127A

5.0

APPLICATIONS INFORMATION

5.2

5.1

Setting the Switching Frequency

The output voltage can be adjusted using a resistor

divider from output to AGND whose mid-point is

connected to the FB pin, as shown the Figure 5-3.

The MIC2127A device is an adjustable-frequency, synchronous buck controller, featuring a unique adaptive

on-time control architecture. The switching frequency

can be adjusted between 270 kHz-800 kHz by changing the resistor divider network between VIN and AGND

pins consisting of R1 and R2, as shown in Figure 5-1.

Output Voltage Setting

MIC2127A

MIC2127A

VOUT

R1

VIN

16

COMPENSATION

VIN

4.5V to 75V

FB

13

gm

R1

11 FREQ

SOFTSTART

Comparator

R2

VREF

R2

0.6V

14

AGND

FIGURE 5-3:

FIGURE 5-1:

Adjustment.

Switching Frequency

Equation 5-1 shows the estimated switching frequency.

The output voltage

Equation 5-2.

VREF

800

Switching Frequency (kHz)

calculated

using

Where:

fO is the switching frequency when R1 is 100 k and R2

being open; fO is typically 800 kHz. For more precise

setting, it is recommended to use Figure 5-2.

VOUT = 5V

R1 = 100 k

IOUT = 5A

600

VIN = 48V

VIN = 75V

400

be

R1

V OUT = V REF 1 + ------

R 2

R2

f SW_ADJ = fO ------------------R1 + R2

500

can

EQUATION 5-2:

EQUATION 5-1:

700

Output Voltage Adjustment.

VIN = 24V

300

= 0.6V

The maximum output voltage that can be programmed

using the MIC2127A is limited to 30V, if not limited by

the maximum duty cycle (see Equation 4-2).

A typical value of R1 is less than 30 k. If R1 is too

large, it may allow noise to be introduced into the

voltage feedback loop. It also increases the offset

between the set output voltage and actual output

voltage because of the error amplifier bias current. If R1

is too small in value, it will decrease the efficiency of the

power supply, especially at light loads. Once R1 is

selected, R2 can be calculated using Equation 5-3.

EQUATION 5-3:

200

50

FIGURE 5-2:

500

R2 (k)

5000

Switching Frequency vs. R2.

2016-2020 Microchip Technology Inc.

R1

R 2 = ----------------------V OUT

------------- – 1

V REF

DS20005676F-page 23

�MIC2127A

5.3

MOSFET Selection

EQUATION 5-5:

Important parameters for MOSFET selection are:

• Voltage rating

• On-resistance

• Total gate charge

The voltage rating for the high-side and low-side

MOSFETs is essentially equal to the power stage input

voltage VIN. A safety factor of 30% should be added to

the VIN(MAX) while selecting the voltage rating of the

MOSFETs to account for voltage spikes due to circuit

parasitic elements.

5.3.1

HIGH-SIDE MOSFET POWER

LOSSES

I RMS HS = I LOAD D

ILOAD is the load current and D is the operating duty

cycle, given by Equation 5-6.

EQUATION 5-6:

VOUT

D = ------------V IN

EQUATION 5-7:

The total power loss in the high-side MOSFET

(PHSFET) is the sum of the power losses because of

conduction (PCONDUCTION), switching (PSW), reverse

recovery charge of low-side MOSFET body diode

(PQrr) and MOSFET's output capacitance discharge, as

calculated in the Equation 5-4.

Q SW HS R DH PULL_UP + R HS GATE

t R = -----------------------------------------------------------------------------------------------------V DD – VTH

EQUATION 5-8:

Q SW HS RDH PULL_DOWN + RHS GATE

t F = ------------------------------------------------------------------------------------------------------------V TH

EQUATION 5-4:

PHSFET = PCONDUCTION HS + PSW HS + P Qrr + P COSS

Where:

RDH(PULL-UP)

2

P CONDUCTION HS = I RMS HS R DS ON_HS

P SW HS = 0.5 VIN I LOAD tR + t F f SW

P Qrr = VIN Q rr f SW

1

2

P COSS = --- C OSS HS + C OSS HS VIN f SW

2

RDH(PULL-DOWN) = High-side gate driver pull-down

resistance

RHS(GATE)

= High-side MOSFET gate resistance

VTH

= Gate to Source threshold voltage of

the high-side MOSFET

QSW(HS)

= Switching gate charge of the

high-side MOSFET which can be

approximated by Equation 5-9.

Where:

RDS(ON_HS)

=

On-resistance of the high-side MOSFET

VIN

=

Operating input voltage

ILOAD

=

Load current

fSW

=

Operating switching frequency

Qrr

=

Reverse recovery charge of low-side

MOSFET body diode or of external

diode across low-side MOSFET

EQUATION 5-9:

COSS(HS)

=

Effective high-side MOSFET output

capacitance

COSS(LS)

=

Effective low-side

capacitance

IRMS(HS)

=

RMS current of the high-side MOSFET

which can be calculated using

Equation 5-5.

tR, tF

=

The high-side MOSFET turn-on and

turn-off transition times which can be

approximated by Equation 5-7 and

Equation 5-8

2016-2020 Microchip Technology Inc.

MOSFET

= High-side gate driver pull-up

resistance

output

Q GS HS

Q SW HS = -------------------- + Q GD HS

2

Where:

QGS(HS)

= High-side MOSFET gate to source

charge

QGD(HS)

= High-side MOSFET gate to drain charge

DS20005676F-page 24

�MIC2127A

5.3.2

LOW-SIDE MOSFET POWER

LOSSES

The total power loss in the low-side MOSFET (PLSFET)

is the sum of the power losses because of conduction

(PCONDUCTION(LS)) and body diode conduction during

the dead time (PDT), as calculated in Equation 5-10.

EQUATION 5-10:

PLSFET = PCONDUCTION LS + P DT

2

P CONDUCTION LS = I RMS LS RDS ON_LS

P DT = 2 V F I LOAD t DT f SW

Where:

EQUATION 5-12:

VOUT VIN – VOUT

L = -----------------------------------------------------V IN f SW 0.3 IFL

Where:

= Input voltage

VIN

fSW

= Switching frequency

IFL

= Full load current

VOUT

= Output voltage

For a selected Inductor, the peak-to-peak inductor

current ripple can be calculated using Equation 5-13.

EQUATION 5-13:

V

RDS(ON_LS) = On-resistance of the low-side MOSFET

VF

= Low-side MOSFET body diode forward

voltage drop

tDT

= Dead time which is approximately 20 ns

fSW

= Switching Frequency

IRMS(LS)

= RMS current of the low-side MOSFET

which can be calculated using

Equation 5-11

Where:

ILOAD = load current

D

= operating duty cycle

The peak inductor current is equal to the load current

plus one half of the peak-to-peak inductor current ripple

which is shown in Equation 5-14.

EQUATION 5-14:

I L_PP

IL_PK = I LOAD + ---------------2

EQUATION 5-11:

I RMS LS = I LOAD 1 – D

V – V

V IN f SW L

OUT

IN

OUT

I L_PP = -----------------------------------------------------

The RMS and saturation current ratings of the selected

inductor should be at least equal to the RMS current

and saturation current calculated in Equation 5-15 and

Equation 5-16.

EQUATION 5-15:

5.4

Inductor Selection

Inductance value, saturation and RMS currents are

required to select the output inductor. The input and

output voltages and the inductance value determine

the peak-to-peak inductor ripple current.

The lower the inductance value, the higher the

peak-to-peak ripple current through the inductor, which

increases the core losses in the inductor. Higher

inductor ripple current also requires more output

capacitance to smooth out the ripple current. The

greater the inductance value, the lower the

peak-to-peak ripple current, which results in a larger

and more expensive inductor.

A good compromise between size, loss and cost is to

set the inductor ripple current to be equal to 30% of the

maximum output current.

2

I L_RMS =

2 I L_PP

I LOAD(MAX) + -----------------------12

Where:

ILOAD(MAX)

= Maximum load current

EQUATION 5-16:

R CL I CL + 15mV

I L_SAT = -------------------------------------------------RDS(ON)

Where:

RCL

= Current limit resistor

ICL

= Current-Limit Source Current

(100 µA typical)

RDS (ON)

= On-resistance of low-side power MOSFET

The inductance value is calculated by Equation 5-12.

2016-2020 Microchip Technology Inc.

DS20005676F-page 25

�MIC2127A

Maximizing efficiency requires the proper selection of

core material and minimizing the winding resistance.

Use of ferrite materials is recommended in the higher

switching frequency applications. Lower-cost iron

powder cores may be used, but the increase in core

loss reduces the efficiency of the power supply. This is

especially noticeable at low output power. The winding

resistance decreases efficiency at the higher output

current levels. The winding resistance must be

minimized, although this usually comes at the expense

of a larger inductor. The power dissipated in the

inductor is equal to the sum of the core and copper

losses. At higher output loads, the core losses are

usually insignificant and can be ignored. At lower

output currents, the core losses can be a significant

contributor. Core loss information is usually available

from the magnetic’s vendor.

The amount of copper loss in the inductor is calculated

by Equation 5-17.

EQUATION 5-17:

2

P INDUCTOR CU = I L_RMS R DCR

5.5

Output Capacitor Selection

The main parameters for selecting the output capacitor

are capacitance value, voltage rating and RMS current

rating. The type of the output capacitor is usually

determined by its equivalent series resistance (ESR).

Recommended capacitor types are ceramic, tantalum,

low-ESR aluminum electrolytic, OS-CON and

POSCAP. The output capacitor ESR also affects the

control loop from a stability point of view. The maximum

value of ESR can be calculated using Equation 5-18.

EQUATION 5-18:

VOUT_PP

ESR ------------------------- I L_PP

EQUATION 5-19:

I L_PP

C OUT = -------------------------------------------------8 f SW V OUT_PP

Where:

COUT

= Output capacitance value

fSW

= Switching frequency

VOUT_PP

= Steady state output voltage ripple

As described in Section 4.1 “Theory of Operation”,

the MIC2127A device requires at least 20 mV

peak-to-peak ripple at the FB pin to ensure that the gM

amplifier and the comparator behave properly. Also,

the output voltage ripple should be in phase with the

inductor current. Therefore, the output voltage ripple

caused by the output capacitor’s value should be much

smaller than the ripple caused by the output capacitor

ESR. If low-ESR capacitors, such as ceramic

capacitors, are selected as the output capacitors, a

ripple injection circuit should be used to provide

enough feedback-voltage ripple. Refer to the

Section 5.7 “Ripple Injection” for details.

The voltage rating of the capacitor should be twice the

output voltage for tantalum and 20% greater for aluminum electrolytic, ceramic or OS-CON. The output

capacitor RMS current is calculated in Equation 5-20.

EQUATION 5-20:

I L_PP

I C_OUT(RMS) = ---------------12

The power dissipated in the output capacitor is shown

in Equation 5-21.

EQUATION 5-21:

2

P DIS(C_OUT) = IC_OUT(RMS) ESRC_OUT

Where:

VOUT_PP

= Peak-to-peak output voltage ripple

IL_PP

= Peak-to-peak inductor current ripple

The required output capacitance to meet steady state

output voltage ripple can be calculated using

Equation 5-19.

2016-2020 Microchip Technology Inc.

DS20005676F-page 26

�MIC2127A

5.6

Input Capacitor Selection

The input capacitor reduces peak current drawn from

the power supply and reduces noise and voltage ripple

on the input. The input voltage ripple depends on the

input capacitance and ESR. The input capacitance and

ESR values can be calculated using Equation 5-22.

EQUATION 5-22:

The applications are divided into three situations

according to the amount of the feedback voltage ripple:

1.

Enough ripple at the feedback due to the large

ESR of the output capacitor (Figure 5-4). The

converter is stable without any additional ripple

injection at the FB node. The feedback voltage

ripple is given by Equation 5-25.

EQUATION 5-25:

I LOAD D 1 – D

C IN = ------------------------------------------------ fSW V IN_C

V IN_ESR

ESRC_IN = ----------------------I L_PK

R

R2 + R1

2

VFB PP = ----------------- ESR I L_PP

IL_PP is the peak-to-peak value of the inductor current

ripple.

Where:

ILOAD

= Load Current

IL_PK

= Peak Inductor Current

VINC

= Input ripple due to capacitance

VINESR

= Input ripple due to input capacitor ESR

η

= Power conversion efficiency

The input capacitor should be rated for ripple current

rating and voltage rating. The RMS value of input

capacitor current is determined at the maximum output

current. The RMS current rating of the input capacitor

should be greater than or equal to the input capacitor

RMS current calculated using Equation 5-23.

EQUATION 5-23:

I C_IN(RMS) = I LOAD(MAX) D 1 – D

The power dissipated in the input capacitor is

calculated using Equation 5-24.

R1

COUT

MIC2127A

FB

ESR

R2

FIGURE 5-4:

2.

Enough Ripple at FB.

Inadequate ripple at the feedback voltage due to

the small ESR of the output capacitor.

The output voltage ripple can be fed into the FB pin

through a feed forward capacitor, CFF in this case, as

shown in Figure 5-5. The typical CFF value is between

1 nF-100 nF. With the feed forward capacitor, the feedback voltage ripple is very close to the output voltage

ripple, which is shown in Equation 5-26.

EQUATION 5-26:

EQUATION 5-24:

2

PDISS(C_IN) = I C_IN(RMS) ESR C_IN

5.7

L

SW

V FB PP = ESR I L_PP

Ripple Injection

The minimum recommended ripple at the FB pin for

proper operation of the MIC2127A error amplifier and

comparator is 20 mV. However, the output voltage

ripple is generally designed as 1%-2% of the output

voltage. For low output voltages, such as a 1V, the

output voltage ripple is only 10 mV-20 mV, and the

feedback voltage ripple is less than 20 mV. If the

feedback voltage ripple is so small that the gM amplifier

and comparator cannot sense it, then the MIC2127A

loses control and the output voltage is not regulated. In

order to have sufficient VFB ripple, the ripple injection

method should be applied for low output voltage ripple

applications.

2016-2020 Microchip Technology Inc.

L

SW

R1

MIC2127A

FB

CFF

COUT

ESR

R2

FIGURE 5-5:

Inadequate Ripple at FB.

DS20005676F-page 27

�MIC2127A

3.

Virtually no ripple at the FB pin voltage due to

the very-low ESR of the output capacitors.

In this case, additional ripple can be injected into the

FB pin from the switching node SW, via a resistor RINJ

and a capacitor CINJ, as shown in Figure 5-6.

Once all the ripple injection component values are calculated, ensure that the criterion shown in

Equation 5-28 is met.

For high duty cycle applications with D > 40%, the procedures to design the ripple injection circuit components are as below:

1.

L

SW

RINJ

R1

CFF

CINJ

MIC2127A

FB

COUT

ESR

R2

FIGURE 5-6:

For given feedback divider resistor values,

select CFF such that the time constant formed by

CFF and feedback divider is 50% of the switching period as given in Equation 5-30:

EQUATION 5-30:

C FF R FBEQ = 0.5 T SW

R1 R 2

RFBEQ = R1 R 2 = -----------------R 1 + R2

Invisible Ripple at FB.

The injected ripple at the FB pin in this case is given by

the Equation 5-27.

2.

Calculate RINJ using the Equation 5-29 Make

sure that the injected ripple voltage into FB pin

is in the range of 20 mV to 100 mV.

EQUATION 5-27:

3.

Choose CINJ = 100 nF or at least 10 times the

CFF value.

VFB PP

V OUT 1 – D

= -----------------------------------------CFF RINJ f SW

In Equation 5-27, it is assumed that the time constant

associated with the CFF meets the criterion shown in

Equation 5-28.

EQUATION 5-28:

T SW

= C FF R 1 R 2 RINJ

The process of sizing the ripple injection resistor and

capacitors is:

Select CINJ in the range of 47 nF-100 nF, which

can be considered as short for a wide range of

the frequencies.

Select CFF in the range of 0.47 nF-10 nF, if R1

and R2 are in k range.

Select RINJ according to Equation 5-29.

1.

2.

3.

EQUATION 5-29:

R INJ

Where:

V OUT 1 – D

= ------------------------------------------------------CFF fSW V FB PP

VOUT

= Output voltage

D

= Duty cycle

fSW

= Switching frequency

VFB(PP)