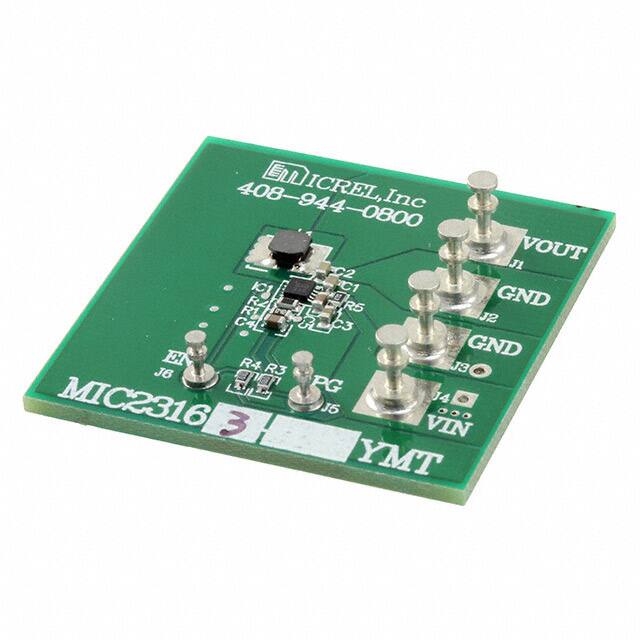

MIC23163/4 Evaluation Board

4MHz PWM 2A Buck Regulator with

HyperLight Load® and Power Good

General Description

Getting Started

The MIC23163/4 evaluation board allows the customer to

evaluate a fully-integrated 2A, 4MHz synchronous buck

®

regulator that features HyperLight Load mode, a Power

Good output indicator, and programmable soft-start. The

MIC23163/4 is highly efficient throughout the output

current range. The tiny 2mm x 2mm DFN package, in

combination with the 4MHz switching frequency, provides

a compact sub-1mm height solution that requires few

external components. The MIC23163/4 has a maximum

100% duty cycle and incorporates an active discharge

feature. It provides accurate output voltage regulation

under the most demanding conditions and responds

extremely quickly to a load transient with exceptionally

small output voltage ripple.

1. Connect an external supply to the VIN (J4) and GND

(J3) terminals.

With the output of the power supply disabled, set its

voltage to the desired input test voltage (2.7V ≤ VIN ≤

5.5V). An ammeter may be placed between the input

supply and the VIN (J4) terminal. Be sure to monitor

the supply voltage at the VIN (J4) terminal, as the

ammeter and/or power lead resistance can reduce the

voltage supplied to the device.

Requirements

The MIC23156 evaluation board requires a single 15W

bench power source adjustable from 2.7V to 5.5V. The

loads can either be active (electronic load) or passive

(resistor), and must be able to dissipate 10W. It is ideal,

but not essential, to have an oscilloscope available to view

the circuit waveforms. The simplest tests require two

voltage meters to measure input and output voltages.

Efficiency measurements require two voltage meters and

two ammeters to prevent errors caused by measurement

inaccuracies.

Precautions

There is no reverse input protection on this board. Be

careful when connecting the input source to ensure correct

polarity is observed.

Datasheets and support documentation are available on

Micrel’s web site at: www.micrel.com.

2. Connect a load to the VOUT (J1) and GND (J2)

terminals.

The load can be either passive (resistive) or active

(electronic load). An ammeter may be placed between

the load and the output terminal. Make sure the output

voltage is monitored at the VOUT (J1) terminal.

3. Enable the MIC23163/4.

The MIC23163/4 evaluation board has a pull-up

resistor to VIN. By default, the output voltage is

enabled when the input supply of >2.7V is applied. To

disable the device, apply a voltage below 0.5V to the

EN (J6) terminal.

4. Power Good.

A PG test point (J5) is provided to monitor the Power

Good feature. The Power Good output will go high

(VOUT) approximately 90µs after the output voltage

reaches 92% of its nominal voltage.

Ordering Information

Part Number

Description

MIC23163YMT EV

MIC23163 Evaluation Board

MIC23164YMT EV

MIC23164 Evaluation Board

HyperLight Load is a registered trademark of Micrel, Inc.

Micrel Inc. • 2180 Fortune Drive • San Jose, CA 95131 • USA • tel +1 (408) 944-0800 • fax + 1 (408) 474-1000 • http://www.micrel.com

August 23, 2013

Revision 1.0

�Micrel, Inc.

MIC23156 Evaluation Board

The feedforward capacitor, C4, provides essential

compensation for the MIC23163/4. A typical value range of

15pF to 68pF is recommended.

Evaluation Board

Power Good (PG)

The evaluation board has a test point provided for testing

the Power Good feature. This is an open-drain connection

with an on-board pull-up resistor of 100kΩ to the output

voltage. Power Good is asserted high approximately 90µs

after the output voltage passes 92% of the nominal set

voltage.

HyperLight Load Mode

MIC23156 uses a minimum on and off time proprietary

control loop (patented by Micrel). When the output voltage

falls below the regulation threshold, the error comparator

begins a switching cycle that turns the PMOS on and

keeps it on for the duration of the minimum-on-time. This

increases the output voltage. If the output voltage is more

than the regulation threshold, then the error comparator

turns the PMOS off for a minimum-off-time until the output

drops below the threshold. The NMOS acts as an ideal

rectifier that conducts when the PMOS is off. Using an

NMOS switch instead of a diode allows for lower voltage

drop across the switching device when the NMOS is on.

The asynchronous switching combination between the

PMOS and the NMOS allows the control loop to work in

discontinuous mode for light load operations. In

discontinuous mode, the MIC23163/4 works in pulse

frequency modulation (PFM) to regulate the output. As the

output current increases, the off-time decreases. This

provides more energy to the output. This switching

scheme improves the efficiency of MIC231563/4 during

light load currents by only switching when it is needed.

Features

Soft-Start Capacitor (C3)

The soft start (SS) pin is used to control the output voltage

ramp-up time. Setting C3 to 1nF sets the start-up time to

the minimum. The start-up time can be determined by

Equation 1:

TSS = 250 × 10 3 × ln(10 ) × C SS

Eq. 1

As the load current increases, the MIC23163/4 goes into

continuous conduction mode (CCM) and switches at a

frequency centered at 4MHz. The f to calculate the load

when the MIC23163/4 goes into continuous conduction

mode is approximated by Equation 2:

The action of the soft-start capacitor is to control the rise

time of the internal reference voltage between 0% and

100% of its nominal steady state value.

Feedback Resistors (R1, R2)

The output voltage is set nominally to 1.8V. This output

can be changed by adjusting the upper resistor, R1, in the

feedback potential divider. Therefore:

(V − VOUT ) × D

ILOAD > IN

2L × f

R1

VOUT = VREF × 1 +

R2

Eq. 2

As shown in Equation 2, the load at which MIC23163/4

transitions from HyperLight Load mode to PWM mode is a

function of the input voltage (VIN), output voltage (VOUT),

duty cycle (D), inductance (L), and frequency (f).

Where VREF = 0.7V

Table 1. Example Feedback Resistor Values

VOUT

R1

R2

1.2V

215k

301k

1.5V

301k

261k

1.8V

340k

215k

2.5V

274k

107k

3.3V

383k

102k

August 23, 2013

2

Revision 1.0

�Micrel, Inc.

MIC23156 Evaluation Board

Evaluation Board Schematic

Bill of Materials

Item

C1

C2

C3

C4

C5

L1

Part Name

C1608X5R0J475K

Manufacturer

TDK

(2)

GRM188R60J475KE19D

Murata

C1608X5R0J106K080AB

TDK

GRM188R60J106ME84D

Murata

GRM188R71H102MA01D

Murata

06035C102KAT2A

AVX

06035A150KAT2A

GRM1885C1H150JA01D

C1608X7R1A105K

GRM188R71A105KA61D

FLF3215T-R47N

LQH32PNR47NNC

R1

CRCW0603301KFKEA

R2

CRCW0603158KFKEA

R3, R4

Description

Qty.

(1)

(3)

AVX

Murata

TDK

Murata

4.7µF, 6.3V, X5R, Size 0603

1

10µF, 6.3V, X5R, Size 0603

1

1nF/50V, X7R, 0603

1

15pF, 50V, 0603

1

1µF, 10V, X7R, Size 0603

1

TDK

0.47µH, 2.8A, 21mΩ, L3.2mm x W2.5mm x H1.55mm

Murata

0.47µH, 2.9A, 24mΩ, L3.2mm x W2.5mm x H1.55mm

(4)

Vishay

1

301kΩ, 1%, 1/10W, Size 0603

1

Vishay

158kΩ, 1%, 1/10W, Size 0603

1

CRCW0603100KFKEA

Vishay

100kΩ, 1%, 1/10W, Size 0603

1

R5

CRCW060310R0FKEA

Vishay

10Ω, 1%, 1/10W, Size 0603

1

U1

MIC23163YMT

4MHz 2A Adjustable Buck Regulator with HyperLight

Load Mode

1

(5)

Micrel, Inc.

Notes:

1. TDK: www.tdk.com.

2. Murata: www.murata.com.

3. AVX: www.avx.com.

4. Vishay: www.vishay.com.

5. Micrel, Inc.: www.micrel.com.

August 23, 2013

3

Revision 1.0

�Micrel, Inc.

MIC23156 Evaluation Board

PCB Layout Recommendations

Top Layer

Bottom Layer

August 23, 2013

4

Revision 1.0

�Micrel, Inc.

MIC23156 Evaluation Board

MICREL, INC. 2180 FORTUNE DRIVE SAN JOSE, CA 95131 USA

TEL +1 (408) 944-0800 FAX +1 (408) 474-1000 WEB http://www.micrel.com

Micrel makes no representations or warranties with respect to the accuracy or completeness of the information furnished in this data sheet. This

information is not intended as a warranty and Micrel does not assume responsibility for its use. Micrel reserves the right to change circuitry,

specifications and descriptions at any time without notice. No license, whether express, implied, arising by estoppel or otherwise, to any intellectual

property rights is granted by this document. Except as provided in Micrel’s terms and conditions of sale for such products, Micrel assumes no liability

whatsoever, and Micrel disclaims any express or implied warranty relating to the sale and/or use of Micrel products including liability or warranties

relating to fitness for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual property right.

Micrel Products are not designed or authorized for use as components in life support appliances, devices or systems where malfunction of a product

can reasonably be expected to result in personal injury. Life support devices or systems are devices or systems that (a) are intended for surgical

implant into the body or (b) support or sustain life, and whose failure to perform can be reasonably expected to result in a significant injury to the user. A

Purchaser’s use or sale of Micrel Products for use in life support appliances, devices or systems is a Purchaser’s own risk and Purchaser agrees to fully

indemnify Micrel for any damages resulting from such use or sale.

© 2013 Micrel, Incorporated.

August 23, 2013

5

Revision 1.0

�