MIC2874

1.2A High-Brightness Flash LED Driver with

Single-Wire Serial Interface

Features

General Description

• Up to 1.2A Flash LED Driving Current

• Highly Efficient Synchronous Boost Driver

• Control through Single-Wire Serial Interface or

External Control Pin

• Input Voltage Range: 2.7V to 5.5V

• True Load Disconnect

• Configurable Safety Time-Out Protection

• Output Overvoltage Protection (OVP)

• LED Short Detection and Protection

• 1 µA Shutdown Current

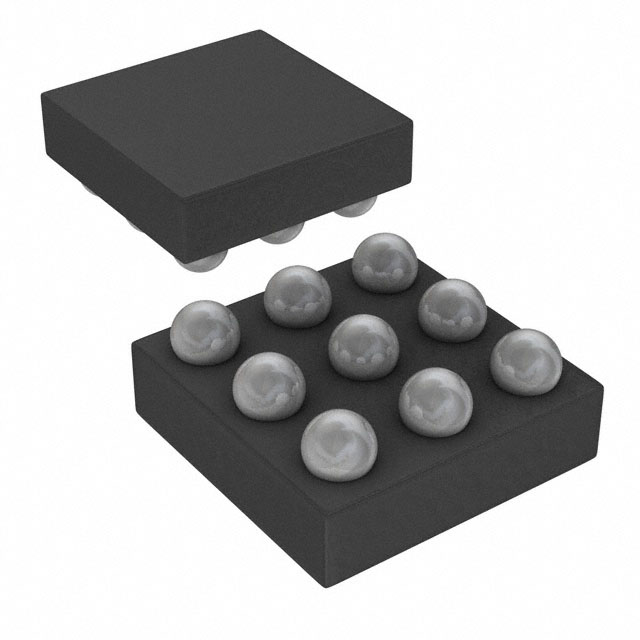

• Available in 9-Bump 1.30 mm x 1.30 mm WLCSP

Package

The MIC2874 is a high-current, high-efficiency Flash

LED driver. The LED driver current is generated by an

integrated inductive boost converter with a 4 MHz switching frequency, which allows for the use of a very small

inductor and output capacitor. These features make the

MIC2874 an ideal solution for high-resolution camera

phone LED Flash light driver applications.

MIC2874 operates in either Flash or Torch mode that can

be controlled through the single-wire serial interface

and/or external control pin. A robust single-wire serial

interface allows the host processor to control the LED

current and brightness. The MIC2874 is available in a

9-bump 1.30 mm x 1.30 mm WLCSP package.

Applications

• Camera Phones/Mobile Handsets

• Cell Phones/Smartphones

• LED Light for Image Capture/Auto-Focus/

White Balance

• Handset Video Light (Torch Light)

• Digital Cameras

• Portable Applications

2018 Microchip Technology Inc.

DS20006081A-page 1

�MIC2874

Package Type

MIC2874

9-Bump 1.30 mm x 1.30 mm WLCSP (CS)

(Top View)

1

2

3

A

LED

DC

OUT

B

LGND

FEN

SW

C

AGND

VIN

PGND

Note: WLCSP Bump A1 identifier = “•”.

Typical Application Schematic

VBAT

VIN

AGND

SW

OUT

PGND

LGND

SINGLE-WIRE SERIAL I/F

FLASH ENABLE

DS20006081A-page 2

LED

DC

FEN

2018 Microchip Technology Inc.

�MIC2874

Functional Block Diagram

SW

DIE TEMP

LBVD

VIN

2.53V/

2.35V

OTP

155°C/

140°C

UVLO

SAFETY

TIMER VIN

BODY

SWITCH

OUT

SYSTEM

CONTROL

LOGIC +

ANTI-CROSS

CONDUCTION

FEN

PGND

PGND

SINGLEWIRE

SERIAL

INTERFACE

DC

LED 1.7V

4 MHz

OSCILLATOR

AGND

LED SCP

4-BIT

OUT

Z

Z

OUT

SAFETY

TIMER

SAFETY

TIMER

DECODER

AGND

2018 Microchip Technology Inc.

LED

V/I

LGND

DS20006081A-page 3

�MIC2874

1.0

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

Input Voltage (VIN)...................................................................................................................................... -0.3V to +6.0V

General I/O Voltage (VFEN) ............................................................................................................................ -0.3V to VIN

VOUT and VLED Voltage.............................................................................................................................. -0.3V to +6.0V

Single-Wire I/O Voltage (VDC) ........................................................................................................................ -0.3V to VIN

VSW Voltage ............................................................................................................................................... -0.3V to +6.0V

ESD Rating(1)

HBM .......................................................................................................................................................................2 kV

MM ........................................................................................................................................................................200V

†

Notice: Stresses above those listed under “Maximum Ratings” may cause permanent damage to the device. This

is a stress rating only and functional operation of the device at those or any other conditions above those indicated in the operational sections of this specification is not intended. Exposure to maximum rating conditions for

extended periods may affect device reliability.

Note 1:

Devices are ESD-sensitive. Handling precautions are recommended. Human body model, 1.5 k in series

with 100 pF.

Operating Ratings(1)

Input Voltage (VIN)..................................................................................................................................... +2.7V to +5.5V

Enable Input Voltage (VFEN)............................................................................................................................... 0V to VIN

Single-Wire I/O Voltage (VDC) ............................................................................................................................ 0V to VIN

Power Dissipation (PD)....................................................................................................................... Internally Limited(2)

Note 1:

2:

The device is not ensured to function outside the operating range.

The maximum allowable power dissipation at any TA (ambient temperature) is PD(max) = (TJ(max) – TA)/JA.

Exceeding the maximum allowable power dissipation will result in excessive die temperature and the regulator

will go into thermal shutdown.

DS20006081A-page 4

2018 Microchip Technology Inc.

�MIC2874

TABLE 1-1:

ELECTRICAL CHARACTERISTICS(Note 1)

Electrical Specifications: unless otherwise specified, VIN = 3.6V; L = 0.47 µH; COUT = 4.7 µF; IOUT = 100 mA;

TA = TJ = +25°C. Boldface values indicate -40°C TJ +125°C.

Parameter

Symbol

Min.

Typ.

Max.

Units

VIN

2.7

—

5.5

V

Test Conditions

Power Supply

Supply Voltage Range

UVLO Threshold (rising)

UVLO Hysteresis

VUVLO_R

2.41

2.53

2.68

V

—

VUVLO_HYS

—

180

—

mV

—

ISTB

150

185

220

µA

VDC = 3.6V, VFEN = 0V, boost

regulator and LED current

driver are both off

Standby Current

Shutdown Current

—

ISD

—

1

2

µA

VDC = 0V

Maximum Duty Cycle

DMAX

82

86

90

%

—

Minimum Duty Cycle

DMIN

—

6.4

—

%

—

Switch Current Limit

ISW

—

4.1

—

A

VIN = VOUT = 2.7V

RDS(ON)_P

—

RDS(ON)_N

—

Switch-On Resistance

Switch Leakage Current

125

—

—

m

ISW = 100 mA

ISW = 100 mA

ISW_LK

—

0.01

1

µA

Oscillator Frequency

FSW

3.6

4

4.4

MHz

Overtemperature Shutdown

Threshold

TSD

—

155

—

°C

Overtemperature Shutdown

Hysteresis

TSD_HYS

—

15

—

°C

Safety Time-out Shutdown

TTO

—

1.25

—

s

Safety Timer Current

Threshold

ITO

—

250

—

mA

Default current threshold setting

Low-Battery Voltage

Detection Threshold

VLBVD

—

3.0

—

V

Default LBVD threshold setting

Low-Battery Voltage

Detection Threshold

Accuracy

—

—

50

—

mV

LED Short-Circuit Detection

Voltage Threshold

VSHORT

1.55

1.7

1.85

V

LED Short-Circuit Detection

Test Current

ITEST

1.6

2

2.7

mA

-6

—

6

-8

—

8

VLED

—

250

—

FEN High-Level Voltage

VFEN_H

1.3

—

—

FEN Low-Level Voltage

VFEN_L

—

—

0.6

FEN Pull-Down Current

IFEN_PD

—

1.3

5

VDC = 0V, VSW = 5.5V

—

—

—

Default timer setting

All low-battery voltage detection threshold settings

VOUT – VLED

—

Current Sink Channel

Channel Current Accuracy

Current Sink Voltage

Dropout

—

%

mV

VOUT = 4.2V, ILED = 0.20A

VOUT = 4.2V, ILED = 1.0A

Boost mode

FEN Control Pin

Note 1:

V

µA

Flash is on

Flash is off

VFEN = 5.5V

Specification for packaged product only.

2018 Microchip Technology Inc.

DS20006081A-page 5

�MIC2874

TABLE 1-2:

ELECTRICAL CHARACTERISTICS – SINGLE-WIRE INTERFACE

(ENSURED BY DESIGN)

Electrical Specifications: unless otherwise specified, VIN = 3.6V; L = 0.47 µH; COUT = 4.7 µF; IOUT = 100 mA;

TA = TJ = +25°C. Boldface values indicate -40°C TJ +125°C.

Parameter

Low-Level Input Voltage

High-Level Input Voltage

Symbol

Min.

Typ.

Max.

VL

—

—

0.4

VH

—

Units

V

Test Conditions

—

1.3

—

IDC_PD

—

2.8

5

µA

VDC = 5.5V

On Time

TON

0.1

—

72

µs

—

Off Time

TOFF

0.1

—

72

µs

—

Latch Time

TLAT

97

—

324

µs

—

End Time

TEND

405

—

—

µs

—

DC Pull-Down Current

DS20006081A-page 6

—

2018 Microchip Technology Inc.

�MIC2874

TEMPERATURE SPECIFICATIONS (Note 1)

Parameters

Symbol

Min.

Typ.

Max.

Units

Conditions

TJ

–40

—

150

°C

Operating Junction Temperature Range

TJ

–40

—

125

°C

—

Operating Ambient Temperature

TA

–40

—

85

°C

—

Storage Temperature

TS

–40

—

150

°C

—

Lead Temperature

—

—

—

260

°C

Soldering, 10s

JA

—

84

—

°C/W

Temperature Ranges

Maximum Junction Temperature Range

—

Package Thermal Resistance

Thermal Resistance 1.3x1.3 WLCSP-9BL

Note 1:

—

The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable

junction temperature and the thermal resistance from junction to air (i.e., TA, TJ, JA). Exceeding the

maximum allowable power dissipation will cause the device operating junction temperature to exceed the

maximum +150°C rating. Sustained junction temperatures above +150°C can impact the device reliability.

2018 Microchip Technology Inc.

DS20006081A-page 7

�MIC2874

2.0

Note:

TYPICAL CHARACTERISTIC CURVES

The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

FIGURE 2-1:

Temperature.

Shutdown Current vs.

FIGURE 2-4:

Temperature.

Switching Frequency vs.

FIGURE 2-2:

Temperature.

Standby Current vs.

FIGURE 2-5:

Temperature.

Maximum Duty Cycle vs.

FIGURE 2-3:

Temperature.

UVLO Thresholds vs.

FIGURE 2-6:

LED Short Threshold

Voltage vs. Temperature.

DS20006081A-page 8

2018 Microchip Technology Inc.

�MIC2874

FIGURE 2-7:

Temperature.

LED Short Test Current vs.

FIGURE 2-10:

WLED Power Efficiency vs.

Input Voltage (VF = 3.8V).

FIGURE 2-8:

vs. Input Voltage.

Boost Switching Frequency

FIGURE 2-11:

vs. Input Voltage.

Full Torch ILED Accuracy

FIGURE 2-9:

WLED Power Efficiency vs.

Input Voltage (VF = 3.4V).

FIGURE 2-12:

vs. Input Voltage.

Full Flash ILED Accuracy

2018 Microchip Technology Inc.

DS20006081A-page 9

�MIC2874

Torch Mode Turn On Sequence

(Linear Mode)

(Boost Mode)

VFEN

(5V/div)

VDC

(5V/div)

VOUT

(2V/div)

VLED

(2V/div)

VOUT-VLED

(2V/div)

ILED

(500mA/div)

ILED = 300mA

VIN = 4.0V

L = 0.47μH

VOUT

(2V/div)

VLED

(2V/div)

ILED = 1.2A

VIN = 3.0V

L = 0.47μH

Time (100μs/div)

FIGURE 2-13:

Flash Mode Turn-On

Sequence (Boost Mode).

VOUT-VLED

(2V/div)

ILED

(200mA/div)

Time (200μs/div)

FIGURE 2-16:

Torch Mode Turn-On

Sequence (Linear Mode).

q

(Linear Mode)

VDC

(5V/div)

VFEN

(5V/div)

VOUT

(2V/div)

VLED

(2V/div)

VOUT

(2V/div)

VLED

(2V/div)

VOUT-VLED

(2V/div)

ILED

(500mA/div)

ILED = 1.2A

VIN = 4.5V

L = 0.47μH

Time (100μs/div)

FIGURE 2-14:

Flash Mode Turn-On

Sequence (Linear Mode).

ILED = 1.2A

VIN = 4.2V

L = 0.47μH

ILED

(500mA/div)

FIGURE 2-17:

1250 ms.

Time (200ms/div)

Flash Safety Timer at

(Boost Mode)

VDC

(5V/div)

VDC

(5V/div)

VOUT

(2V/div)

VLED

(2V/div)

ILED = 300mA

VIN = 3.0V

L = 0.47μH

VOUT

(2V/div)

VLED

(2V/div)

VOUT-VLED

(2V/div)

ILED

(200mA/div)

ILED = 1.2A

VIN = 4.2V

L = 0.47μH

Time (200μs/div)

FIGURE 2-15:

Torch Mode Turn-On

Sequence (Boost Mode).

DS20006081A-page 10

ILED

(500mA/div)

FIGURE 2-18:

156 ms.

Time (200ms/div)

Flash Safety Timer at

2018 Microchip Technology Inc.

�MIC2874

LED Short Circuit Protection

(LED is Shorted by 0)

(VIN = 5.0V)

VDC

(5V/div)

VFEN

(5V/div)

VOUT

(2V/div)

VLED

(2V/div)

VIN = 3.6V

L = 0.47μH

LED IS SHORTED

BY 0ȍ

VOUT-VLED

(2V/div)

IL

(100mA/div)

ILED = 1.2A

VIN = 5.0V

L = 0.47μH

VFEN = 3.6V

VOUT

(2V/div)

VLED

(2V/div)

ILED

(500mA/div)

Time (40μs/div)

FIGURE 2-19:

LED Short-Circuit Protection

(LED is Shorted by 0).

Time (200ms/div)

FIGURE 2-22:

Load Disconnect at

Shutdown (VIN = 5.0V).

(Over-voltage during Start-up)

(LED is Shorted by 620)

VFEN

(5V/div)

VOUT

(2V/div)

VLED

(2V/div)

VIN = 3.6V

L = 0.47μH

LED IS SHORTED

BY 620ȍ

VOUT-VLED

(2V/div)

IL

(100mA/div)

VOUT

(2V/div)

VSW

(2V/div)

VLED

(2V/div)

IL

(1A/div)

Time (40μs/div)

FIGURE 2-20:

LED Short-Circuit Protection

(LED is Shorted by 620).

Time (40μs/div)

FIGURE 2-23:

VOUT Overvoltage

Protection (Overvoltage during Start-up).

(VIN = 2.7V)

VDC

(5V/div)

VIN = 3.6V

L = 0.47μH

(Over-voltage after Start-up)

ILED = 1.2A

VIN = 2.7V

L = 0.47μH

VFEN = 0V

VOUT

(2V/div)

VLED

(2V/div)

VOUT

(2V/div)

VSW

(2V/div)

ILED

(500mA/div)

VLED

(2V/div)

IL

(1A/div)

Time (200ms/div)

FIGURE 2-21:

Load Disconnect at

Shutdown (VIN = 2.7V).

2018 Microchip Technology Inc.

ILED = 1.2A

VIN = 3.6V

L = 0.47μH

Time (2μs/div)

FIGURE 2-24:

VOUT Overvoltage

Protection (Overvoltage after Start-up).

DS20006081A-page 11

�MIC2874

(VIN Changes from 5.5V to 2.7V)

(Torch 63mA to Flash 1.2A)

VOUT

(2V/div)

VLED

(2V/div)

VLED

VIN

(1V/div)

VOUT-VLED

(2V/div)

ILED

(500mA/div)

VIN = 3.6V

L = 0.47μH

Time (100μs/div)

FIGURE 2-25:

Load Transient

(Torch 63 mA to Flash 1.2A).

VVOUT

IN

(1V/div)

VV

OUT

LED

(1V/div)

ILED

(500mA/div)

VIN = 5.5V to 2.7V

ILED = 1.2A

L = 0.47μH

Time (100μs/div)

FIGURE 2-28:

Line Transient (VIN Changes

from 5.5V to 2.7V).

(Flash 1.2A to Torch 63mA)

VIN

(2V/div)

VOUT

(2V/div)

VLED

(2V/div)

VIN = 3.6V

L = 0.47μH

VOUT-VLED

(2V/div)

ILED

(500mA/div)

Time (40μs/div)

FIGURE 2-26:

to Torch 63 mA).

Load Transient (Flash 1.2A

VOUT

(2V/div)

VSW

(2V/div)

IL

(1A/div)

VIN = 3.6V

VOUT = 5.2V

L = 0.47μH

FIGURE 2-29:

Time (400ns/div)

Switch Current Limit.

(VIN Changes from 2.7V to 5.5V)

VLED

VIN

(1V/div)

VVOUT

IN

(1V/div)

VV

OUT

LED

(1V/div)

ILED

(500mA/div)

VIN = 2.7V to 5.5V

ILED = 1.2A

L = 0.47μH

Time (10μs/div)

FIGURE 2-27:

Line Transient (VIN Changes

from 2.7V to 5.5V).

DS20006081A-page 12

2018 Microchip Technology Inc.

�MIC2874

3.0

PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1:

PIN FUNCTION TABLE

MIC2874

Pin Number

Pin Name

A1

LED

LED Current Sink Pin: Connect the LED anode to OUT and the cathode to this pin.

A2

DC

Single-Wire Interface: Serial control input.

A3

OUT

B1

LGND

B2

FEN

Flash Mode Enable Pin: Asserting this pin high enables the MIC2874 to enter Flash

mode. If this pin is left floating, it is pulled down internally by a built-in 1 µA current

source when the device is enabled.

Inductor Connection Pin: It is connected to the internal power MOSFETs.

B3

SW

C1

AGND

C2

VIN

C3

PGND

2018 Microchip Technology Inc.

Pin Function

Boost Converter Output Pin: To be connected to the anode of the LED. Connect a

low-ESR ceramic capacitor of at least 4.7 µF at this pin to PGND.

Linear Ground: LED current return path.

Analog Ground.

Supply Input Pin: Connect a low-ESR ceramic capacitor of at least 4.7 µF at this pin to

AGND.

Power Ground: Inductor current return path.

DS20006081A-page 13

�MIC2874

4.0

FUNCTIONAL DESCRIPTION

4.7

4.1

VIN

This is the current sink pin for the LED. The LED anode

is connected to the OUT pin and the LED cathode is

connected to this pin.

The input supply provides power to the internal

MOSFETs’ gate drive and controls circuitry for the

Switch mode regulator. The operating input voltage

range is from 2.7V to 5.5V. A 4.7 µF low-ESR ceramic

input capacitor should be connected from VIN to AGND,

as close to MIC2874 as possible, to ensure a clean

supply voltage for the device. The minimum voltage

rating of 10V is recommended for the input capacitor.

4.2

SW

The MIC2874 has internal low-side and synchronous

MOSFET switches. The switch node (SW) between the

internal MOSFET switches connects directly to one end

of the inductor and provides the current paths during

switching cycles.

The other end of the inductor is connected to the input

supply voltage. Due to the high-speed switching on this

pin, the switch node should be routed away from

sensitive nodes wherever possible.

4.3

LGND

This is the ground path of the LED current sink. It should

be connected to the AGND on the PCB. The current loop

of the Analog Ground should be separated from that of

the Power Ground (PGND). LGND and AGND should be

connected to PGND at a single point.

4.4

AGND

This is the ground path for the internal biasing and control circuitry. AGND should be connected to the LGND

directly. The current loop of the Analog Ground should

be separated from that of the Power Ground (PGND).

The AGND and LGND should be connected to PGND at

a single point.

4.5

PGND

The Power Ground pin is the ground path for the high

current in the boost switch. The current loop for the

Power Ground should be as small as possible and

separate from the Analog Ground (AGND) loop as

applicable.

4.6

4.8

LED

DC

The DC is a single multiplexed device enable and serial

data control pin used for functional control, and communication in GPIO limited applications. When the DC

pin is used as a hardware device enable pin, a logic

high signal on the DC pin enables the device and a

logic low signal on the DC pin disables the device.

When the DC pin is used as the single-wire serial

interface Digital Control pin, a combination of bit edges

and the period between edges is used to communicate

a variable length data word across the single wire.

Each word is transmitted as a series of pulses, with

each pulse incrementing an internal data counter. A stop

sequence, consisting of an inactive period, is used to

latch the data word internally. Two data words in series

received are then used to set a specific register with a

specific value for controlling a specific function. The

MIC2874 supports five writable registers for controlling

Flash mode, Torch mode, safety timer duration, safety

timer threshold current and low-battery threshold.

An address/data frame is used to improve protection

against erroneous writes where communications are in

error. When the DC is in a low state, and no data is

detected for longer than 405 µs, the MIC2874 will

automatically go into a low-power Shutdown state,

simultaneously resetting all internal registers to their

default states.

4.9

FEN

FEN is the hardware enable pin for Flash mode. A logic

low-to-high transition on the FEN pin can initiate the

MIC2874 in Flash mode. If FEN is left floating, it is pulled

down internally by a built-in 1 µA current source when

the device is enabled. Flash mode is terminated when

FEN is pulled low or left floating and the Flash register is

cleared.

OUT

This is the boost converter output pin, which is connected to the anode of the LED. A low-ESR ceramic

capacitor of 4.7 µF or larger should be connected from

OUT to PGND, as close as possible to the MIC2874.

The minimum voltage rating of 10V is recommended for

the output capacitor.

DS20006081A-page 14

2018 Microchip Technology Inc.

�MIC2874

5.0

APPLICATION INFORMATION

The MIC2874 can drive a high-current Flash WLED in

either Flash mode or Torch mode.

5.1

Boost Converter

The internal boost converter is turned on/off automatically

when the LED driver is activated/deactivated without any

exception.

The boost converter is an internally compensated Current

mode PWM boost converter running at 4 MHz. It is for

stepping up the supply voltage to a high enough value at

the OUT pin to drive the LED current. If the supply voltage

is high enough, the synchronous switch of the converter

is then fully turned on. In this case, all the excessive

voltage is dropped over the linear LED driver.

5.2

Flash Mode

The maximum and default current levels in the Flash

mode are 1.2A and 1A, respectively. The Flash mode current can be initiated by asserting the FEN pin high or by

setting the Flash Control register (Address 1) for the

desired Flash duration, subjected to the safety time-out

setting. The Flash mode current is terminated when the

FEN pin is brought low and the Flash register is cleared or

when the configurable safety timer expires.

Flash mode current can be adjusted to a fraction of the

maximum Flash mode current level by selecting the

desired value in the Flash Control register through the

single-wire serial interface.

5.3

Torch Mode

By default, the maximum Torch mode level is 300 mA.

The Torch mode operation is activated by setting the

Torch Control register (Address 2) for the desired duration. The Torch mode current is terminated when the

Torch register is cleared or when the configurable safety

timer expires.

Like the Flash mode current, the Torch mode current can

be set to a fraction of the maximum Torch mode current

level by selecting the desired torch current in the Torch

Control register (Address 2) via the single-wire serial

interface.

5.4

Configurable Safety Timer

The Flash safety time-out feature automatically shuts

down the LED current, after the safety timer duration is

expired, if the programmed LED current exceeds a certain

current threshold. Both the current threshold and the timer

duration are programmable via the Safety Timer registers

(Addresses 3 and 5).

2018 Microchip Technology Inc.

5.5

Low-Battery Voltage Detection

(LBVD)

When the VIN voltage drops below the LBVD threshold

(default = 3.0V) in Flash or Torch mode, the LED current

driver is disabled. The LED driver can be resumed by raising the VIN above the LBVD threshold and toggling the

corresponding Flash or torch command. The LBVD

threshold is adjustable through the LBVD Control register

(Address 4).

5.6

Overvoltage Protection

When the output voltage rises above an internal overvoltage protection (OVP) threshold, MIC2874 is latched off

automatically to avoid permanent damage to the IC. To

clear the latched off condition, either power cycle the

MIC2874 or assert the DC pin low.

5.7

Short-Circuit Detection

Each time, before enabling the LED driver, the

MIC2874 performs the short-circuit test by driving the

Flash LED with a small (2 mA typical) current for

200 µs. If (VOUT – VLED) is less than 1.7V at the end of

the short-circuit test, then the LED is considered to be

shorted and MIC2874 will ignore the Flash and/or Torch

mode command. Note that the short-circuit test is

carried out every time, prior to Flash and Torch mode,

but the result is not latched.

5.8

Thermal Shutdown

When the internal die temperature of MIC2874 reaches

155°C, the LED driver is disabled until the die temperature falls below 140°C and either the FEN pin, FEN

register, TEN register or VIN is toggled.

5.9

Single-Wire Interface

The single-wire interface allows the use of a single

multiplexed enable and data pin (DC) for control and

communication in GPIO limited applications. The interface is implemented using a simple mechanism, allowing

any open-drain or directly driven GPIO to control the

MIC2874.

The MIC2874 uses the single-wire interface for simple

command and control functions. The interface provides

fast access to write-only registers with protection features

to avoid potentially erroneous data writes and improve

robustness. When the DC is in a low state and no data is

detected for longer than 405 µs, the MIC2874 will

automatically go into a low-power Shutdown state, simultaneously resetting the internal registers to their default

states.

DS20006081A-page 15

�MIC2874

5.10

Overview

The single-wire interface relies on a combination of bit

edges and the period between edges in order to communicate across a single wire. Each word is transmitted as a

series of pulses, with each pulse incrementing an internal

data counter. A stop sequence, consisting of an inactive

period of the DC pin remaining high, is used to latch the

data word internally. An address and data framing format

is used to improve protection against erroneous writes by

enforcing address and data field lengths, as well as the

timing duration between them.

Timing is designed such that when communicating with a

device using a low-cost on-chip oscillator, the worst-case

minimum and maximum conditions can be easily met

within the wide operating range of the oscillator. Using this

method ensures that the device can always detect the

delay introduced by the communication master.

IDLE

< TEND – TLAT

VH

VL

TLAT

TEND

VH

VL

TLAT

TEND

SHUTDOWN

IDLE

VH

VL

TLAT

TEND

5.11

Idle States and Error Conditions

In Shutdown mode, the MIC2874 is in a Reset condition,

with all functions off, while consuming minimal power.

Register settings are reset to a default state when coming

out of a Shutdown state. In Idle mode, all register settings

persist and all MIC2874 functions continue in their current

state. Table 5-1 summarizes the difference between the

two Idle modes:

TABLE 5-1:

DIFFERENCES BETWEEN

IDLE MODES

Mode

VDC

ISUPPLY (all functions off)

Shutdown

Idle

Low

High

1 µA

230 µA

Register State

Default

Persist

Start-up Time

1 µs

100 ns

Idle mode is entered automatically at the end of a communication frame by holding DC high for TEND, by enabling

the device by bringing DC high when in Shutdown mode

or when an error is detected by the single-wire interface

logic.

Shutdown mode can be entered at any time by pulling

down DC for TEND, discarding any current communication and resetting the internal registers. If a

communication is received before the shutdown period,

but after the TLAT period, the communication is

discarded. This state is also used to create an internal

error state to avoid erroneously latching data when the

communication process cannot be serviced in time.

Additionally, each register has a maximum value associated with it. If the number of bits clocked in exceeds

the maximum value for the register, the data is

assumed to be in error and the data is discarded.

DS20006081A-page 16

IDLE

FIGURE 5-1:

Abort, Shutdown and Idle

Timing Waveforms.

5.12

Communication Details

The serial interface requires delimiters to indicate the

Start-of-Frame (SOF), data as a series of pulses and

End-of-Frame (EOF), indicated by a lack of activity for

longer than TLAT. The Start-of-Frame is the first

high-to-low transition of DC when in Idle mode. The first

rising edge resets the internal data counter to 0.

END-OFFRAME

1 COUNT

VH

VL

TOFF

START

TON

TON + TOFF < TLAT

FIGURE 5-2:

TLAT

AUTOMATIC LATCH

AFTER TLAT EXPIRES

Data Word Pulse Timing.

A pulse is delimited by the signal first going below VL, and

then above VH, within the Latch Time-out, TLAT. During

this transition, the minimum on (TON) and off (TOFF)

periods are observed to improve tolerance to glitches.

Each rising edge increments the internal Data register.

Data is automatically latched into the internal shadow

address or Data registers after an inactivity period of the

DC remaining high for longer than TLAT.

To send register write commands, the address and data

are entered in series as two data words, using the above

pattern, with the second word starting after the first latch

period has expired. After the second word is entered, the

IDLE command should be issued by leaving the DC pin

high for TEND to indicate the stop sequence of the

address/data words frame.

2018 Microchip Technology Inc.

�MIC2874

After receiving the stop sequence, the internal registers’

decode and update cycle is started, with the Shadow

register values being transferred to the decoder.

Figure 5-3 shows an example of entering a write of Data 5

to Address 3.

TABLE 5-3:

FEN/FCUR Value

ADDRESS/DATA FRAME

START

LATCH

START

LATCH

TLAT

0

1

2

T LAT

< T END

3

END

REGISTER

WRITE

0

1

2

3

4

5

> T END

FIGURE 5-3:

Communication Timing

Example of Entering Write for Data 5 to Address 3.

Only a correctly formatted address/data combination will

be treated as a valid frame and processed by the

MIC2874. Any other input, such as a single data word

followed by TEND or three successive data words, will be

discarded by the target hardware as an erroneous entry.

Additionally, any register write to either an invalid register

or with invalid register data will also be discarded.

5.13

MIC2874 Registers

The MIC2874 supports five writable registers for

controlling the Torch and the Flash modes of operation, as

shown in Table 5-2. Note that register addressing starts

at 1. Writing any value above the maximum value shown

for each register will cause an invalid data error and the

frame will be discarded.

TABLE 5-2:

FIVE WRITABLE REGISTERS

OF MIC2874

FLASH CURRENT REGISTER

MAPPING INTO INTERNAL

FEN/FCUR REGISTERS AND

RELATIONSHIP BETWEEN

FLASH CURRENT AND FCUR

REGISTER SETTING

Dec. Binary FEN FCUR

IFLASH (A)

0

00000

0

0000

1.200

1

00001

0

0001

1.150

2

00010

0

0010

1.100

3

00011

0

0011

1.050

4

00100

0

0100

1.000

5

00101

0

0101

0.950

6

00110

0

0110

0.900

7

00111

0

0111

0.850

8

01000

0

1000

0.800

9

01001

0

1001

0.750

10

01010

0

1010

0.700

11

01011

0

1011

0.650

12

01100

0

1100

0.600

13

01101

0

1101

0.550

14

01110

0

1110

0.400

15

01111

0

1111

0.250

16

10000

1

0000

1.200

17

10001

1

0001

1.150

18

10010

1

0010

1.100

19

10011

1

0011

1.050

20

10100

1

0100

1.000

Address

Name

Max.

Value

21

10101

1

0101

0.950

1

FEN/FCUR

31

Flash Enable/Current

22

10110

1

0110

0.900

2

TEN/TCUR

31

Torch Enable/Current

23

10111

1

0111

0.850

3

STDUR

7

Safety Timer Duration

24

11000

1

1000

0.800

4

LB_TH

9

Low-Battery Voltage

Detection Threshold

25

11001

1

1001

0.750

5

ST_TH

5

Safety Timer Threshold

26

11010

1

1010

0.700

27

11011

1

1011

0.650

28

11100

1

1100

0.600

29

11101

1

1101

0.550

30

11110

1

1110

0.400

31

11111

1

1111

0.250

5.13.1

Description

FLASH CURRENT REGISTER

(FEN/FCUR: DEFAULT 4)

The Flash Current register enables and sets the Flash

mode current level. Valid values are 0 to 31. Values 0-15

will set the Flash current without enabling the Flash (such

that it can be triggered externally). Values 16-31 will set

the Flash current and enable the Flash. The Flash current

register maps into the internal FEN and FCUR registers,

as shown in the following table below. Table 5-3 describes

the relationship between the Flash current and the FCUR

register setting.

2018 Microchip Technology Inc.

DS20006081A-page 17

�MIC2874

5.13.2

TORCH CURRENT REGISTER

(TEN/TCUR: DEFAULT 4)

The Torch Current register enables and sets the Torch

mode current level. Valid values are 0 to 31. Values 0-15

will set the torch current without enabling the torch (such

that it can be triggered by setting the internal TEN register

value to 1). Values 16-31 will set the torch current and

enable the torch. A value of 0 at the internal TEN register

will disable the torch. The Torch Current register maps

into the internal TEN and TCUR registers, as shown in

Table 5-4. The table also describes the relationship

between the torch current and the TCUR register setting.

TABLE 5-4:

TORCH CURRENT REGISTER

MAPPING INTO INTERNAL

TEN/TCUR REGISTERS AND

RELATIONSHIP BETWEEN

TORCH CURRENT AND TCUR

REGISTER SETTING

TEN/TCUR Value

Dec. Binary TEN TCUR

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

00000

00001

00010

00011

00100

00101

00110

00111

01000

01001

01010

01011

01100

01101

01110

01111

10000

10001

10010

10011

10100

10101

10110

10111

11000

11001

11010

11011

11100

11101

11110

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

DS20006081A-page 18

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

ITORCH (mA)

300.0

287.5

275.0

262.5

250.0

237.5

225.0

212.5

200.0

187.5

175.0

162.5

150.0

137.5

100.0

62.5

300.0

287.5

275.0

262.5

250.0

237.5

225.0

212.5

200.0

187.5

175.0

162.5

150.0

137.5

100.0

TEN/TCUR Value

Dec. Binary TEN TCUR

31

11111

5.13.3

1

ITORCH (mA)

62.5

1111

SAFETY TIMER DURATION

REGISTER (STDUR: DEFAULT 7)

The Safety Timer Duration register sets the duration of the

Flash and Torch mode when the LED current exceeds the

programmed threshold current. Valid values are 0 for the

minimum timer duration to 7 for the maximum duration.

TABLE 5-5:

Value

Dec. Binary

SAFETY TIMER DURATION

REGISTER SETTING AND

SAFETY TIMER DURATION

STDUR

(Binary)

Time-out (ms)

156.25

0

000

000

1

001

001

312.5

2

010

010

468.75

3

011

011

625

4

100

100

781.25

5

101

101

937.5

6

110

110

1093.75

7

111

111

1250

5.13.4

LOW-BATTERY THRESHOLD

REGISTER (LB_TH: DEFAULT 1)

The LB_TH register sets the supply threshold voltage,

below which the internal low-battery flag is asserted and

the LED current driver is disabled. Table 5-6 shows the

threshold values that correspond to the register settings.

Setting 0 is reserved for disabling the function, and

settings between 1 and 9 inclusively enable and set the

LB_TH value, between 3.0V and 3.8V, with 100 mV

resolution.

TABLE 5-6:

Value

Dec. Binary

LOW-BATTERY THRESHOLD

REGISTER SETTING AND

SUPPLY THRESHOLD

VOLTAGE

LB_TH

VBAT Threshold (V)

0

0000

0000

Disabled

1

0001

0001

3.0

2

0010

0010

3.1

3

0011

0011

3.2

4

0100

0100

3.3

5

0101

0101

3.4

6

0110

0110

3.5

2018 Microchip Technology Inc.

�MIC2874

TABLE 5-7:

Value

Dec. Binary

LB_TH

VBAT Threshold (V)

7

0111

0111

3.6

8

1000

1000

3.7

9

1001

1001

3.8

5.13.5

SAFETY TIMER THRESHOLD

CURRENT REGISTER

(ST_TH: DEFAULT 4)

The Safety Timer Threshold Current register determines

the amount of LED current flowing through the external

LED before the internal LED safety timer is activated. Setting ST_TH to 0 disables the safety timer function, and

setting the register to Values 1-5 sets the safety timer

threshold current to 100 mA to 300 mA in 50 mA steps.

2018 Microchip Technology Inc.

SAFETY TIMER THRESHOLD

CURRENT REGISTER

SETTING AND SAFETY TIMER

THRESHOLD CURRENT

Value

Dec. Binary

ST_TH

Safety Timer

Threshold Current

(mA)

0

000

000

Disabled

1

001

001

100

2

010

010

150

3

011

011

200

4

100

100

250

5

101

101

300

DS20006081A-page 19

�MIC2874

6.0

COMPONENT SELECTION

6.1

Inductor

Inductor selection should strike a balance between

efficiency, stability, cost, size, and rated current. Because

the boost converter is compensated internally, the recommended inductance of L is limited from 0.47 µH to 1 µH to

ensure system stability, and a 0.47 µH inductor is typically

recommended. It is usually a good balance between

these considerations.

A large inductance value reduces the peak-to-peak

inductor ripple current, hence the output ripple voltage

and the LED ripple current. This also reduces both the

DC loss and the transition loss at the same inductor’s

DC Resistance (DCR). However, the DCR of an inductor

usually increases with the inductance in the same package size. This is due to the longer windings required for

an increase in inductance. Because the majority of the

input current passes through the inductor, the higher the

DCR, the lower the efficiency is, and more significantly,

at higher load currents. On the other hand, an inductor

with a smaller DCR, but the same inductance, usually

has a larger size. The saturation current rating of the

selected inductor must be higher than the maximum

peak inductor current to be encountered and should be

at least 20% to 30% higher than the average inductor

current at maximum output current.

6.2

Input Capacitor

A ceramic capacitor of 4.7 µF or larger with low-ESR is

recommended to reduce the input voltage ripple to

ensure a clean supply voltage for the device. The input

capacitor should be placed as close as possible to the

MIC2874 VIN pin with a short trace for good noise

performance. X5R or X7R type ceramic capacitors are

recommended for better tolerance over temperature.

The Y5V and Z5U type temperature rating ceramic

capacitors are not recommended due to their large

reduction in capacitance over temperature and

increased resistance at high frequencies. These reduce

their ability to filter out high-frequency noise. The rated

voltage of the input capacitor should be at least 20%

higher than the maximum operating input voltage over

the operating temperature range.

6.3

Output Capacitor

Output capacitor selection is also a trade-off between

performance, size and cost. Increasing output

capacitance will lead to an improved transient

response; however, the size and cost also increase.

The output capacitor’s preferable range of 2.2 µF to

10 µF with ESR from 10 m to 50 m, and a 4.7 µF

ceramic capacitor is typically recommended. X5R or

X7R type ceramic capacitors are recommended for

better tolerance over temperature. The Y5V and Z5U

type ceramic capacitors are not recommended due to

their wide variation in capacitance over temperature

and increased resistance at high frequencies. The

rated voltage of the output capacitor should be at least

20% higher than the maximum operating output

voltage over the operating temperature range.

7.0

POWER DISSIPATION

CONSIDERATION

As with all power devices, the ultimate current rating of the

output is limited by the thermal properties of the device

package and the PCB on which the device is mounted.

There is a simple Ohm’s law type relationship between

thermal resistance, power dissipation and temperature,

which are analogous to an electrical circuit:

RXY

VX

VY

RYZ

VZ

+

VZ

ISOURCE

FIGURE 7-1:

Circuit.

Series Electrical Resistance

From this simple circuit, we can calculate VX if we know

ISOURCE, VZ and the resistor values, RXY and RYZ, using

Equation 7-1:

EQUATION 7-1:

CALCULATING VX

VX = ISOURCE (RXY + RYZ) = VZ

DS20006081A-page 20

2018 Microchip Technology Inc.

�MIC2874

Thermal circuits can be considered using this same

rule and can be drawn similarly by replacing current

sources with power dissipation (in watts), resistance

with thermal resistance (in °C/W) and voltage sources

with temperature (in °C).

ĬJC

TJ

TC

ĬCA

TA

+

TA

PDISS

FIGURE 7-2:

Circuit.

EQUATION 7-4:

CALCULATING PDISS

Linear Mode:

PDISS = [POUT – 1 ] – IOUT2 DCR

Boost Mode:

I

PDISS = [POUT – 1 ] – OUT 2 DCR

1 – D

Duty Cycle in Boost Mode:

VOUT – VIN

D=

VOUT

Where:

= Efficiency taken from efficiency curves

DCR = Inductor DCR

Series Thermal Resistance

Now replacing the variables in the equation for VX, we

can find the Junction Temperature (TJ) from the power

dissipation, ambient temperature and the known thermal

resistance of the PCB (CA) and the package (JC).

EQUATION 7-2:

Where the real board area differs from 1 inch square,

CA (the PCB thermal resistance) values for various

PCB copper areas can be taken from Figure 7-3.

Figure 7-3 is taken from “Designing with Low Dropout

Voltage Regulators” available from the Microchip

web site (“LDO Application Hints”).

CALCULATING JUNCTION

TEMPERATURE

TJ = PDISS (JC + CA) + TA

As seen in Figure 7-2, the total thermal resistance is:

JA = JC + CA. Hence, this can also be written as in

Equation 7-3:

EQUATION 7-3:

CALCULATING THERMAL

RESISTANCE

TJ = PDISS (JA) + TA

Where:

θJA = Thermal resistance between junction and ambient,

which is typically 84°C/W for 1.3 mm x 1.3 mm

WLCSP package

Since effectively all of the power losses (minus the

inductor losses) in the converter are dissipated within

the MIC2874 package, PDISS can be calculated thus:

FIGURE 7-3:

Graph to Determine PC

Board Area for a Given PCB Thermal Resistance.

Figure 7-3 shows the total area of a round or square

pad, centered on the device. The solid trace represents

the area of a square, single-sided, horizontal orientation, solder masked, copper PC board trace heat sink,

measured in square millimeters. No airflow is assumed.

The dashed line shows the PC board’s trace heat sink

covered in black oil-based paint and with 1.3m/sec

(250 feet per minute) airflow. This approaches a

“best case” pad heat sink. Conservative design

dictates using the solid trace data, which indicates that

a maximum pad size of 5000 mm2 is needed. This is a

pad that is 71 mm by 71 mm (2.8 inches per side).

2018 Microchip Technology Inc.

DS20006081A-page 21

�MIC2874

8.0

PCB LAYOUT GUIDELINES

PCB layout is critical to achieve reliable, stable and

efficient performance. A ground plane is required to

control EMI and minimize the inductance in power and

signal return paths. The following guidelines should be

followed to ensure proper operation of the device.

8.1

IC (Integrated Circuit)

• Place the IC close to the point-of-load (in this

case, the flash LED).

• Use fat traces to route the input and output power

lines.

• Analog grounds (LGND and AGND) and power

ground (PGND) should be kept separate and connected at a single location.

• 6 to 12 thermal vias must be placed on the PCB

top layer PGND copper from the PGND pin and

connected it to the ground plane to ensure a good

PCB thermal resistance can be achieved.

• Since all the top copper areas connected directly

to the CSP package bumps are used as the

immediate PCB heat sink, these top copper areas

should be spread out from the bumps in funnel-shape to maximize the top copper PCB heat

sink areas.

8.2

8.4

Output Capacitor

• The output capacitor must be placed close to the

OUT pin and PGND pin of the IC and preferably

connected directly and closely to the OUT pin and

PGND pin without going through any via to minimize the switching current loop during the main

switch off-cycle, and the switching noise.

• Use wide and short traces to connect the output

capacitor to the OUT and PGND pins.

• Place several vias to the ground plane close to

the output capacitor ground terminal.

• Use either X5R or X7R temperature rating

ceramic capacitors. Do not use Y5V or Z5U type

ceramic capacitors.

8.5

Flash LED

• Use wide and short trace to connect the LED

anode to the OUT pin.

• Use wide and short trace to connect the LED

cathode to the LED pin.

• Make sure that the LED’s PCB land pattern can

provide sufficient PCB pad heat sink to the flash

LED, such as sufficient copper areas and thermal

vias.

VIN Decoupling Capacitor

• The VIN decoupling capacitor must be placed

close to the VIN pin of the IC and preferably connected directly to the pin and not through any via.

The capacitor must be located right at the IC.

• The VIN decoupling capacitor should be connected to analog ground (AGND).

• The VIN terminal is noise sensitive and the placement of capacitor is very critical.

8.3

Inductor

• Keep both the inductor connections to the switch

node (SW) and input power line short and wide

enough to handle the switching current. Keep the

areas of the switching current loops small to minimize the EMI problem.

• Do not route any digital lines underneath or close

to the inductor.

• Keep the switch node (SW) away from the noise

sensitive pins.

• To minimize noise, place a ground plane underneath the inductor.

DS20006081A-page 22

2018 Microchip Technology Inc.

�MIC2874

9.0

PACKAGING INFORMATION

9.1

Package Marking Information

9-Bump WLCSP*

XXX

NNN

Legend: XX...X

Y

YY

WW

NNN

e3

*

Example

74A

007

Product code or customer-specific information

Year code (last digit of calendar year)

Year code (last 2 digits of calendar year)

Week code (week of January 1 is week ‘01’)

Alphanumeric traceability code

Pb-free JEDEC® designator for Matte Tin (Sn)

This package is Pb-free. The Pb-free JEDEC designator ( e3 )

can be found on the outer packaging for this package.

●, ▲, ▼ Pin one index is identified by a dot, delta up or delta down (triangle

mark).

Note:

In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information. Package may or may not include

the corporate logo.

Underbar (_) and/or Overbar (‾) symbol may not be to scale.

2018 Microchip Technology Inc.

DS20006081A-page 23

�MIC2874

9.2

Package Details

The following sections give the technical details of the packages.

Note:

For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging.

DS20006081A-page 24

2018 Microchip Technology Inc.

�MIC2874

APPENDIX A:

REVISION HISTORY

Revision A (October 2018)

• Converted Micrel document MIC2874 to

Microchip data sheet DS20006081A.

• Minor text changes throughout document.

2018 Microchip Technology Inc.

DS20006081A-page 25

�MIC2874

NOTES:

DS20006081A-page 26

2018 Microchip Technology Inc.

�MIC2874

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, contact your local Microchip representative or sales office.

PART NO.

Device

XX

X

–

Temperature Package

XX

Examples:

a)

MIC2874YCS-T5:

MIC2874,

-40°C to +125°C Temp. Range,

9-Bump WLCSP, 500/Reel

b)

MIC2874YCS-TR:

MIC2874,

-40°C to +125°C Temp. Range,

9-Bump WLCSP, 5,000/Reel

Media

Type

Device:

MIC2874:

1.2A High-Brightness Flash LED Driver

with Single-Wire Serial Interface

Temperature:

Y

=

-40°C to +125°C

Package:

CS

=

9-bump 1.30 mm x 1.30 mm WLCSP

Media Type:

T5

TR

=

=

500/Reel

5,000/Reel

2018 Microchip Technology Inc.

Note 1:

Tape and Reel identifier only appears in the

catalog part number description. This identifier is

used for ordering purposes and is not printed on

the device package. Check with your Microchip

Sales Office for package availability with the

Tape and Reel option.

DS20006081A-page 27

�MIC2874

NOTES:

DS20006081A-page 28

2018 Microchip Technology Inc.

�Note the following details of the code protection feature on Microchip devices:

•

Microchip products meet the specification contained in their particular Microchip Data Sheet.

•

Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

•

There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

•

Microchip is willing to work with the customer who is concerned about the integrity of their code.

•

Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Trademarks

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC® MCUs and dsPIC® DSCs, KEELOQ® code hopping

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

QUALITY MANAGEMENT SYSTEM

CERTIFIED BY DNV

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, AVR Freaks, BitCloud, chipKIT, chipKIT logo,

CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo,

JukeBlox, KeeLoq, Kleer, LANCheck, LINK MD, maXStylus,

maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip

Designer, QTouch, SAM-BA, SpyNIC, SST, SST Logo,

SuperFlash, tinyAVR, UNI/O, and XMEGA are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMOS,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity,

JitterBlocker, KleerNet, KleerNet logo, memBrain, Mindi, MiWi,

motorBench, MPASM, MPF, MPLAB Certified logo, MPLIB,

MPLINK, MultiTRAK, NetDetach, Omniscient Code Generation,

PICDEM, PICDEM.net, PICkit, PICtail, PowerSmart, PureSilicon,

QMatrix, REAL ICE, Ripple Blocker, SAM-ICE, Serial Quad I/O,

SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

Silicon Storage Technology is a registered trademark of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2018, Microchip Technology Incorporated, All Rights Reserved.

ISBN: 978-1-5224-3693-5

== ISO/TS 16949 ==

2018 Microchip Technology Inc.

DS20006081A-page 29

�Worldwide Sales and Service

AMERICAS

ASIA/PACIFIC

ASIA/PACIFIC

EUROPE

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Australia - Sydney

Tel: 61-2-9868-6733

India - Bangalore

Tel: 91-80-3090-4444

China - Beijing

Tel: 86-10-8569-7000

India - New Delhi

Tel: 91-11-4160-8631

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

China - Chengdu

Tel: 86-28-8665-5511

India - Pune

Tel: 91-20-4121-0141

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

China - Chongqing

Tel: 86-23-8980-9588

Japan - Osaka

Tel: 81-6-6152-7160

Finland - Espoo

Tel: 358-9-4520-820

China - Dongguan

Tel: 86-769-8702-9880

Japan - Tokyo

Tel: 81-3-6880- 3770

China - Guangzhou

Tel: 86-20-8755-8029

Korea - Daegu

Tel: 82-53-744-4301

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

China - Hangzhou

Tel: 86-571-8792-8115

Korea - Seoul

Tel: 82-2-554-7200

China - Hong Kong SAR

Tel: 852-2943-5100

Malaysia - Kuala Lumpur

Tel: 60-3-7651-7906

China - Nanjing

Tel: 86-25-8473-2460

Malaysia - Penang

Tel: 60-4-227-8870

China - Qingdao

Tel: 86-532-8502-7355

Philippines - Manila

Tel: 63-2-634-9065

China - Shanghai

Tel: 86-21-3326-8000

Singapore

Tel: 65-6334-8870

China - Shenyang

Tel: 86-24-2334-2829

Taiwan - Hsin Chu

Tel: 886-3-577-8366

China - Shenzhen

Tel: 86-755-8864-2200

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Israel - Ra’anana

Tel: 972-9-744-7705

China - Suzhou

Tel: 86-186-6233-1526

Taiwan - Taipei

Tel: 886-2-2508-8600

China - Wuhan

Tel: 86-27-5980-5300

Thailand - Bangkok

Tel: 66-2-694-1351

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

China - Xian

Tel: 86-29-8833-7252

Vietnam - Ho Chi Minh

Tel: 84-28-5448-2100

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

DS20006081A-page 30

China - Xiamen

Tel: 86-592-2388138

China - Zhuhai

Tel: 86-756-3210040

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-67-3636

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-7288-4388

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

2018 Microchip Technology Inc.

08/15/18

�