Product Overview

The DW1000 is a fully integrated single chip Ultra Wideband (UWB)

low-power low-cost transceiver IC compliant to IEEE802.15.4-2011. It

can be used in 2-way ranging or TDoA location systems to locate

assets to a precision of 10 cm. It also supports data transfer at rates

up to 6.8 Mbps

Key Features

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Applications

•

•

ANALOG RECEIVER

PLL / CLOCK GENERATOR

ANALOG TRANSMITTER

Supports precision location and

data transfer concurrently

Asset location to a precision of

10 cm

Extended communications

range up to 290 m @ 110 kbps

10% PER minimises required

infrastructure in RTLS

High multipath fading immunity

Supports high tag densities in

RTLS

Small PCB footprint allows costeffective hardware

implementations

Long battery life minimises

system lifetime cost

Precision real time location

systems (RTLS) using two-way

ranging or TDOA schemes in a

variety of markets: o Healthcare

o Consumer

o Industrial

o Other

Location aware wireless sensor

networks

POWER MANAGEMENT

HOST INTERFACE / SPI

STATE CONTROLLER

DW1000

High Level Block Diagram

TO HOST

IEEE802.15.4-2011 UWB Transceiver

•

•

•

•

•

•

DW1000

•

IEEE802.15.4-2011 UWB

compliant

Supports 6 RF bands from

3.5 GHz to 6.5 GHz

Programmable transmitter

output power

Fully coherent receiver for

maximum range and accuracy

Complies with FCC & ETSI

UWB spectral masks

Supply voltage 2.8 V to 3.6 V

Low power consumption

SLEEP current 1 µA

DEEPSLEEP current 50 nA

Data rates of 110 kbps, 850

kbps, 6.8 Mbps

Maximum packet length of

1023 bytes for high data

throughput applications

Integrated MAC support

features

Supports TWR and TDOA

SPI interface to host processor

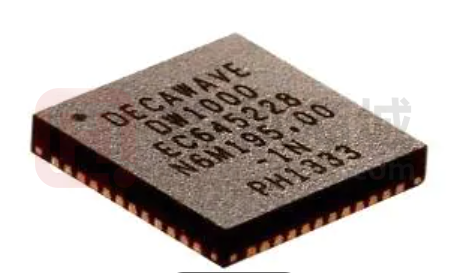

6 mm x 6 mm 48-pin QFN

package with 0.4 mm lead

pitch

Small number of external

components

DIGITAL TRANSCEIVER

•

Key Benefits

�DW1000 Datasheet

Table of Contents

1

IC DESCRIPTION ............................................. 5

2

PIN CONNECTIONS ......................................... 6

2.1

2.2

3

5.12

MAC FEATURES ....................................... 28

5.12.1

Timestamping ............................... 28

5.12.2

FCS Generation and Checking....... 28

5.12.3

Automatic Frame Filtering............ 28

5.12.4

Automatic Acknowledge............... 28

5.12.5

Double Receive Buffer .................. 28

5.13

EXTERNAL SYNCHRONIZATION ..................... 28

5.14

CALIBRATION AND SPECTRAL TUNING OF THE

DW1000 29

5.14.1

Introduction .................................. 29

5.14.2

Crystal Oscillator Trim .................. 29

5.14.3

Transmitter Calibration ................ 30

5.14.4

Antenna Delay Calibration ........... 30

PIN NUMBERING ............................................ 6

PIN DESCRIPTIONS .......................................... 6

ELECTRICAL SPECIFICATIONS ........................ 10

3.1 NOMINAL OPERATING CONDITIONS ................. 10

3.2 DC CHARACTERISTICS.................................... 10

3.3 RECEIVER AC CHARACTERISTICS ...................... 10

3.4 RECEIVER SENSITIVITY CHARACTERISTICS ........... 11

3.5 REFERENCE CLOCK AC CHARACTERISTICS .......... 12

3.5.1

Reference Frequency ........................ 12

3.6 TRANSMITTER AC CHARACTERISTICS ................ 12

3.7 TEMPERATURE AND VOLTAGE MONITOR

CHARACTERISTICS.................................................... 13

3.8 ABSOLUTE MAXIMUM RATINGS ...................... 13

4

TYPICAL PERFORMANCE .............................. 14

5

FUNCTIONAL DESCRIPTION .......................... 18

5.1 PHYSICAL LAYER MODES ................................ 18

5.1.1

Supported Channels and Bandwidths

18

5.1.2

Supported Bit Rates and Pulse

Repetition Frequencies (PRF) .......................... 18

5.1.3

Frame Format ................................... 19

5.1.4

Symbol Timings ................................ 19

5.1.5

Proprietary Long Frames .................. 19

5.1.6

Turnaround Times ............................ 19

5.1.7

Frame Filter ...................................... 20

5.1.8

Frame Check Sequence (FCS) ............ 20

5.2 REFERENCE CRYSTAL OSCILLATOR .................... 20

5.3 SYNTHESIZER ............................................... 20

5.4 RECEIVER .................................................... 20

5.4.1

Bandwidth setting ............................ 20

5.4.2

Automatic Gain Control (AGC) ......... 20

5.5 TRANSMITTER .............................................. 20

5.5.1

Transmit Output Power .................... 20

5.5.2

Transmit Bandwidth Setting............. 21

5.6 POWER-UP SEQUENCE ................................... 22

5.6.1

Typical power-up sequence .............. 22

5.6.2

Variation in the power-up sequence 22

5.6.3

External control of RSTn / use of RSTn

by external circuitry ........................................ 23

5.7 VOLTAGE/TEMPERATURE MONITORS ............... 23

5.8 HOST CONTROLLER INTERFACE........................ 23

5.8.1

Configuring the SPI Mode................. 25

5.8.2

SPI Signal Timing .............................. 26

5.9 GENERAL PURPOSE INPUT OUTPUT (GPIO) ...... 27

5.10

MEMORY ................................................ 27

5.10.1

Receive and Transmit data buffers27

5.10.2

Accumulator memory ................... 27

5.10.3

One Time Programmable (OTP)

Calibration Memory ........................................ 28

5.11

INTERRUPTS AND DEVICE STATUS ................. 28

© Decawave Ltd 2017

6 OPERATIONAL STATES AND POWER

MANAGEMENT ................................................... 31

6.1

6.2

OVERVIEW.................................................. 31

OPERATING STATES AND THEIR EFFECT ON POWER

CONSUMPTION ....................................................... 31

6.3 TRANSMIT AND RECEIVE POWER PROFILES......... 32

6.3.1

Typical transmit profile .................... 35

6.3.2

Typical receive profiles ..................... 35

7

POWER SUPPLY ............................................ 36

7.1

7.2

7.3

8

POWER SUPPLY CONNECTIONS ....................... 36

USE OF EXTERNAL DC / DC CONVERTER .......... 36

POWERING DOWN THE DW1000 ................... 37

APPLICATION INFORMATION ....................... 38

8.1 APPLICATION CIRCUIT DIAGRAM ..................... 38

8.2 RECOMMENDED COMPONENTS ...................... 39

8.3 APPLICATION CIRCUIT LAYOUT ........................ 40

8.3.1

PCB Stack ......................................... 40

8.3.2

RF Traces .......................................... 41

8.3.3

PLL Loop Filter Layout ...................... 41

8.3.4

Decoupling Layout ........................... 41

8.3.5

Layout Guidance .............................. 41

9

PACKAGING & ORDERING INFORMATION .... 42

9.1 PACKAGE DIMENSIONS.................................. 42

9.2 DEVICE PACKAGE MARKING ........................... 43

9.3 TRAY INFORMATION ..................................... 43

9.4 TAPE & REEL INFORMATION........................... 44

9.4.1

Important note................................. 44

9.4.2

Tape Orientation and Dimensions ... 44

9.4.3

Reel Information: 330 mm Reel ....... 45

9.5 REFLOW PROFILE.......................................... 45

9.6 ORDERING INFORMATION .............................. 46

10

GLOSSARY ................................................. 47

11

REFERENCES ............................................. 48

12

DOCUMENT HISTORY ................................ 48

13

MAJOR CHANGES...................................... 49

14

FURTHER INFORMATION .......................... 53

Subject to change without notice

Version 2.22

Page 2

�DW1000 Datasheet

List of Figures

FIGURE 1: IC BLOCK DIAGRAM ...................................... 5

FIGURE 2: DW1000 PIN ASSIGNMENTS ......................... 6

FIGURE 3 : RX INTERFERER IMMUNITY ON CHANNEL 2..... 14

FIGURE 4: TX OUTPUT POWER OVER TEMP & VOLTAGE ... 14

FIGURE 5: RECEIVER SENSITIVITY CHANNEL 5 110KBPS DATA

RATE 16 MHZ PRF 2048 PREAMBLE SYMBOLS ...... 14

FIGURE 6: RECEIVER SENSITIVITY CHANNEL 5 110KBPS DATA

RATE 64 MHZ PRF 2048 PREAMBLE SYMBOLS ...... 15

FIGURE 7: RECEIVER SENSITIVITY CHANNEL 5 850KBPS DATA

RATE 16 MHZ PRF 1024 PREAMBLE SYMBOLS ...... 15

FIGURE 8: RECEIVER SENSITIVITY CHANNEL 5 850KBPS DATA

RATE 64 MHZ PRF 1024 PREAMBLE SYMBOLS ...... 15

FIGURE 9: RECEIVER SENSITIVITY CHANNEL 5 6.81MBPS

DATA RATE 16 MHZ PRF 256 PREAMBLE SYMBOLS 16

FIGURE 10: RECEIVER SENSITIVITY CHANNEL 5 6.81MBPS

DATA RATE 64 MHZ PRF 1256 PREAMBLE SYMBOLS

...................................................................... 16

FIGURE 11: TYPICAL PROBABILITY DISTRIBUTION OF LINE OF

SIGHT 2-WAY RANGING PERFORMANCE.................. 16

FIGURE 12: TX SPECTRUM CHANNEL 1 ......................... 17

FIGURE 13: TX SPECTRUM CHANNEL 2 ......................... 17

FIGURE 14: TX SPECTRUM CHANNEL 3 ......................... 17

FIGURE 15: TX SPECTRUM CHANNEL 4 ......................... 17

FIGURE 16: TX SPECTRUM CHANNEL 5 ......................... 17

FIGURE 17: TX SPECTRUM CHANNEL 7 ......................... 17

FIGURE 18: IEEE802.15.4-2011 PPDU STRUCTURE ... 19

FIGURE 19: IEEE802.15.4-2011 MAC FRAME FORMAT

...................................................................... 20

FIGURE 20: DW1000 POWER-UP SEQUENCE................ 22

FIGURE 21: POWER UP EXAMPLE WHERE VDDLDOD

CANNOT BE GUARANTEED TO BE READY IN TIME FOR THE

RSTN GOING HIGH ............................................. 22

FIGURE 22: DW1000 SPIPHA=0 TRANSFER PROTOCOL 24

FIGURE 23: DW1000SPIPHA=1 TRANSFER PROTOCOL. 24

FIGURE 24: SPI BYTE FORMATTING ............................. 24

FIGURE 25: SPI CONNECTIONS .................................... 25

FIGURE 26: DW1000 SPI TIMING DIAGRAM ............... 26

FIGURE 27: DW1000 SPI DETAILED TIMING DIAGRAM .. 26

FIGURE 28: SYNC SIGNAL TIMING RELATIVE TO XTAL1 .... 29

FIGURE 29: TYPICAL DEVICE CRYSTAL TRIM PPM

ADJUSTMENT .................................................... 30

FIGURE 30: SLEEP OPTIONS BETWEEN OPERATIONS ......... 32

FIGURE 31: TYPICAL RANGE VERSUS TX AVERAGE CURRENT

(CHANNEL 2)..................................................... 34

FIGURE 32: TYPICAL TX POWER PROFILE....................... 35

FIGURE 33: TYPICAL RX POWER PROFILE ...................... 35

FIGURE 34: TYPICAL RX POWER PROFILE USING SNIFF

MODE .............................................................. 35

FIGURE 35: POWER SUPPLY CONNECTIONS.................... 36

FIGURE 36: SWITCHING REGULATOR CONNECTION.......... 36

FIGURE 37: DW1000 APPLICATION CIRCUIT ................. 38

FIGURE 38: PCB LAYER STACK FOR 4-LAYER BOARD ........ 40

FIGURE 39: DW1000 RF TRACES LAYOUT .................... 41

FIGURE 40: DEVICE PACKAGE MECHANICAL SPECIFICATIONS

...................................................................... 42

FIGURE 41: DEVICE PACKAGE MARKINGS ...................... 43

FIGURE 42: TRAY ORIENTATION .................................. 43

FIGURE 43: TAPE & REEL ORIENTATION ........................ 44

FIGURE 44: TAPE DIMENSIONS .................................... 44

FIGURE 45: 330 MM REEL DIMENSIONS ........................ 45

List of Tables

TABLE 1: DW1000 PIN FUNCTIONS............................... 6

TABLE 2: EXPLANATION OF ABBREVIATIONS ..................... 9

TABLE 3: DW1000 OPERATING CONDITIONS ................ 10

TABLE 4: DW1000 DC CHARACTERISTICS .................... 10

TABLE 5: DW1000 RECEIVER AC CHARACTERISTICS ....... 11

TABLE 6: TYPICAL RECEIVER SENSITIVITY CHARACTERISTICS11

TABLE 7: DW1000 REFERENCE CLOCK AC CHARACTERISTICS

...................................................................... 12

TABLE 8: DW1000 TRANSMITTER AC CHARACTERISTICS . 12

TABLE 9: DW1000 TEMPERATURE AND VOLTAGE MONITOR

CHARACTERISTICS .............................................. 13

TABLE 10: DW1000 ABSOLUTE MAXIMUM RATINGS ..... 13

TABLE 11: CHANNELS SUPPORTED BY THE DW1000 ....... 18

TABLE 12: UWB BIT RATES AND PRF MODES SUPPORTED BY

THE DW1000 .................................................. 18

TABLE 13: DW1000 SYMBOL DURATIONS................... 19

TABLE 14: TURN-AROUND TIMES ................................ 19

TABLE 15: DW1000 POWER-UP TIMINGS .................... 22

TABLE 16: EXTERNAL USE OF RSTN .............................. 23

© Decawave Ltd 2017

TABLE 17: DW1000 SPI MODE CONFIGURATION .......... 25

TABLE 18: DW1000 SPI TIMING PARAMETERS @ A) 125

MHZ SYSTEM CLOCK AND B) 19.2 MHZ SYSTEM CLOCK

...................................................................... 26

TABLE 19: TRANSMIT & RECEIVE BUFFER MEMORY SIZE .. 27

TABLE 20: ACCUMULATOR MEMORY SIZE ..................... 28

TABLE 21: OTP CALIBRATION MEMORY......................... 28

TABLE 22: SYNC SIGNAL TIMING RELATIVE TO XTAL ....... 29

TABLE 23: OPERATING STATES .................................... 31

TABLE 24: OPERATING STATES AND THEIR EFFECT ON POWER

CONSUMPTION .................................................. 31

TABLE 25: OPERATIONAL MODES ................................ 32

TABLE 26: TYPICAL TX CURRENT CONSUMPTION ............ 33

TABLE 27: TYPICAL RX CURRENT CONSUMPTION ............ 33

TABLE 28: LOWEST POWER AND LONGEST RANGE MODES OF

OPERATION ....................................................... 34

TABLE 29: DEVICE ORDERING INFORMATION .................. 46

TABLE 30: GLOSSARY OF TERMS .................................. 47

TABLE 31: DOCUMENT HISTORY .................................. 48

Subject to change without notice

Version 2.22

Page 3

�DW1000 Datasheet

DOCUMENT INFORMATION

Disclaimer

Decawave reserves the right to change product specifications without notice. As far as possible changes to

functionality and specifications will be issued in product specific errata sheets or in new versions of this

document. Customers are advised to check with Decawave for the most recent updates on this product.

Copyright © 2015 Decawave Ltd

LIFE SUPPORT POLICY

Decawave products are not authorized for use in safety-critical applications (such as life support) where a

failure of the Decawave product would reasonably be expected to cause severe personal injury or death.

Decawave customers using or selling Decawave products in such a manner do so entirely at their own risk

and agree to fully indemnify Decawave and its representatives against any damages arising out of the use of

Decawave products in such safety-critical applications.

Caution! ESD sensitive device. Precaution should be used when handling the device in order

to prevent permanent damage.

REGULATORY APPROVALS

The DW1000, as supplied from Decawave, has not been certified for use in any particular geographic region

by the appropriate regulatory body governing radio emissions in that region although it is capable of such

certification depending on the region and the manner in which it is used.

All products developed by the user incorporating the DW1000 must be approved by the relevant authority

governing radio emissions in any given jurisdiction prior to the marketing or sale of such products in that

jurisdiction and user bears all responsibility for obtaining such approval as needed from the appropriate

authorities.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 4

�DW1000 Datasheet

VDDLNA

1 IC DESCRIPTION

DIGITAL RX

ADC

Digital Filter

Rx Analog

Baseband

Carrier/

Timing

Recovery

Leading Edge

and Diagnostics

(LDE)

RF_P

IF Gain Control

Digital AON

I/F

Convolutional

Encoder

ReedSolomon

Encoder

DIGITAL TX

RF TX

Tx / Rx

Calibration

RF PLL / Synth

To all

circuits

Loop

Circuits

Oscillator

VDDAON

AON

CAS

Memory

Array

Power

Management

and State

Control

(PMSC)

13kHz

Osc

Temperature

/ Battery

monitor

CLKTUNE

XTAL1

XTAL2

VDDBAT

VCOTUNE

VREF

VDDDIG

VDDSYN

VDDVCO

VDDIF

VDDCLK

CLK PLL / Synth

Transmit

Control

POR

WAKEUP

Bias

SECDED

To all

circuits

DIGITAL Control

Loop

Circuits

To all

circuits

GPIO[0..6]

EXTON

Burst

Control

On-Chip

Regulators

SPIMOSI

IRQ

SYNC

Timers

RSTn

VDDPA2

VDDLDOD

Register

File

SPICSn

SPIMISO

FORCEON

VDDPA1

SPICLK

SPI

To all digital

blocks via PMSC

Pulse Generator

VDDMS

H/W

MAC

OTP

RF RX

SECDED/

ReedSolomon

Decoder

Viterbi

Decoder

Host Interface

Configuration

Retention

RF_N

VDDLDOA

Despreader

Figure 1: IC Block Diagram

DW1000 is a fully integrated low-power, single chip

CMOS RF transceiver IC compliant with the

IEEE802.15.4-2011 [1] UWB standard.

DW1000 consists of an analog front end containing

a receiver and a transmitter and a digital back end

that interfaces to an off-chip host processor. A

TX/RX switch is used to connect the receiver or

transmitter to the antenna port. Temperature and

voltage monitors are provided on-chip

The receiver consists of an RF front end which

amplifies the received signal in a low-noise amplifier

before down-converting it directly to baseband. The

receiver is optimized for wide bandwidth, linearity

and noise figure. This allows each of the supported

UWB channels to be down converted with minimum

additional noise and distortion. The baseband signal

is demodulated and the resulting received data is

made available to the host controller via SPI.

The transmit pulse train is generated by applying

digitally encoded transmit data to the analog pulse

generator. The pulse train is up-converted by a

double balanced mixer to a carrier generated by the

synthesizer and centred on one of the permitted

UWB channels. The modulated RF waveform is

amplified before transmission from the external

antenna.

The IC has an on-chip One-Time Programmable

(OTP) memory. This memory can be used to store

calibration data such as TX power level, crystal initial

© Decawave Ltd 2017

frequency error adjustment, and range accuracy

adjustment.

These adjustment values can be

automatically retrieved when needed. See section

5.14 for more details.

The Always-On (AON) memory can be used to retain

DW1000 configuration data during the lowest power

operational states when the on-chip voltage

regulators are disabled. This data is uploaded and

downloaded automatically. Use of DW1000 AON

memory is configurable.

The DW1000 clocking scheme is based around 3

main circuits; Crystal Oscillator, Clock PLL and RF

PLL. The on-chip oscillator is designed to operate at

a frequency of 38.4 MHz using an external crystal.

An external 38.4 MHz clock signal may be applied in

place of the crystal if an appropriately stable clock is

available elsewhere in the user’s system. This

38.4 MHz clock is used as the reference clock input

to the two on-chip PLLs. The clock PLL (denoted

CLKPLL) generates the clock required by the digital

back end for signal processing.

The RF PLL

generates the down-conversion local oscillator (LO)

for the receive chain and the up-conversion LO for

the transmit chain. An internal 13 kHz oscillator is

provided for use in the SLEEP state.

The host interface includes a slave-only SPI for

device communications and configuration.

A

number of MAC features are implemented including

CRC generation, CRC checking and receive frame

filtering.

Subject to change without notice

Version 2.22

Page 5

�DW1000 Datasheet

2 PIN CONNECTIONS

2.1

Pin Numbering

QFN-48 package with pin assignments as follows: -

Figure 2: DW1000 Pin Assignments

2.2

Pin Descriptions

Table 1: DW1000 Pin functions

SIGNAL

NAME

PIN

I/O

(defaul

t)

DESCRIPTION

Crystal Interface

EXTCLK /

XTAL1

3

AI

Reference crystal input or external reference overdrive pin.

XTAL2

4

AI

Reference crystal input. Leave floating if external clock is used.

SPICLK

41

DI

SPI clock

SPIMISO

40

DO

(O-L)

SPIMOSI

39

DI

SPI data input. Refer to section 5.8.

SPI chip select. This is an active low enable input. The high-to-low transition

on SPICSn signals the start of a new SPI transaction. SPICSn can also act

as a wake-up signal to bring DW1000 out of either SLEEP or DEEPSLEEP

states. Refer to section 6.

Digital Interface

SPICSn

24

DI

SYNC /

GPIO7

29

DIO

(I)

WAKEUP

23

DI

EXTON

21

© Decawave Ltd 2017

DO

(O-L)

SPI data output. Refer to section 5.8.

The SYNC input pin is used for external synchronization (see section 5.13).

When the SYNC input functionality is not being used this pin may be

reconfigured as a general purpose I/O pin, GPIO7.

When asserted into its active high state, the WAKEUP pin brings the

DW1000 out of SLEEP or DEEPSLEEP states into operational mode.

When this pin is not being used as WAKEUP it should be tied to VSSIO

External device enable. Asserted during wake-up process and held active

until device enters sleep mode. Can be used to control external DC-DC

converters or other circuits that are not required when the device is in sleep

mode so as to minimize power consumption. Refer to sections 5.5.1 & 7.

EXTON can be left floating if not used.

Subject to change without notice

Version 2.22

Page 6

�DW1000 Datasheet

SIGNAL

NAME

PIN

I/O

(defaul

t)

FORCEON

22

DI

IRQ / GPIO8

GPIO6 /

EXTRXE /

SPIPHA

GPIO5 /

EXTTXE /

SPIPOL

GPIO4 /

EXTPA

GPIO3 /

TXLED

GPIO2 /

RXLED

GPIO1 /

SFDLED

GPIO0 /

RXOKLED

45

30

33

34

35

36

37

38

© Decawave Ltd 2017

DESCRIPTION

Not used in normal operation. Must be connected to ground

DIO

(O-L)

Interrupt Request output from the DW1000 to the host processor. By default

IRQ is an active-high output but may be configured to be active low if

required. For correct operation in SLEEP and DEEPSLEEP modes it should

be configured for active high operation. This pin will float in SLEEP and

DEEPSLEEP states and may cause spurious interrupts unless pulled low.

When the IRQ functionality is not being used the pin may be reconfigured as

a general purpose I/O line, GPIO8.

This pin has an internal pulldown to VSSIO and can be left unconnected if

not being used.

DIO

(I)

General purpose I/O pin.

On power-up it acts as the SPIPHA (SPI phase selection) pin for configuring

the SPI operation mode. For details of this please refer to section 5.8.

After power-up, the pin will default to a General Purpose I/O pin.

It may be configured for use as EXTRXE (External Receiver Enable). This

pin goes high when the DW1000 is in receive mode.

This pin has an internal pulldown to VSSIO and can be left unconnected if

not being used.

DIO

(I)

General purpose I/O pin.

On power-up it acts as the SPIPOL (SPI polarity selection) pin for configuring

the SPI mode of operation. Refer to section 5.8 for further information.

After power-up, the pin will default to a General Purpose I/O pin.

It may be configured for use as EXTTXE (External Transmit Enable). This pin

goes high when the DW1000 is in transmit mode.

This pin has an internal pulldown to VSSIO and can be left unconnected if

not being used.

DIO

(I)

General purpose I/O pin.

It may be configured for use as EXTPA (External Power Amplifier). This pin

can enable an external Power Amplifier.

This pin has an internal pulldown to VSSIO and can be left unconnected if

not being used.

DIO

(I)

General purpose I/O pin.

It may be configured for use as a TXLED driving pin that can be used to light

a LED following a transmission. Refer to the DW1000 User Manual [2] for

details of LED use.

This pin has an internal pulldown to VSSIO and can be left unconnected if

not being used.

DIO

(I)

General purpose I/O pin.

It may be configured for use as a RXLED driving pin that can be used to light

a LED during receive mode. Refer to the DW1000 User Manual [2] for

details of LED use.

This pin has an internal pulldown to VSSIO and can be left unconnected if

not being used.

DIO

(I)

General purpose I/O pin.

It may be configured for use as a SFDLED driving pin that can be used to

light a LED when SFD (Start Frame Delimiter) is found by the receiver. Refer

to the DW1000 User Manual [2] for details of LED use.

This pin has an internal pulldown to VSSIO and can be left unconnected if

not being used.

DIO

(I)

General purpose I/O pin.

It may be configured for use as a RXOKLED driving pin that can be used to

light a LED on reception of a good frame. Refer to the DW1000 User Manual

[2] for details of LED use.

This pin has an internal pulldown to VSSIO and can be left unconnected if

not being used.

Subject to change without notice

Version 2.22

Page 7

�DW1000 Datasheet

PIN

I/O

(defaul

t)

RSTn

27

DIO

(O-H)

TESTMODE

46

DI

SIGNAL

NAME

DESCRIPTION

Reset pin. Active Low Output.

May be pulled low by external open drain driver to reset the DW1000. Must

not be pulled high by external source. Refer to section 5.6.

Not used in normal operation. Must be connected to ground.

Reference voltages

VREF

5

AIO

Used for on-chip reference current generation. Must be connected to an

11 kΩ (1% tolerance) resistor to ground.

Digital Power Supplies

VDDLDOD

26

P

External supply for digital circuits.

VDDIOA

28

P

External supply for digital IO ring.

VSSIO

32

43

G

Negative I/O ring supply. Must be connected to ground.

Digital Decoupling

VDDREG

20

PD

Output of on-chip regulator. Connect to VDDDIG on PCB. Requires a local

100 nF capacitor to VSSIO.

VDDDIG

44

PD

Output of on-chip regulator. Connect to VDDREG on PCB. Requires a local

100 nF capacitor to VSSIO.

VDDIO

31

42

PD

Digital IO Ring Decoupling.

RF Interface

RF_P

16

AIO

Positive pin of the 100 Ω differential RF pair. Should be AC coupled.

RF_N

17

AIO

Negative pin of the 100 Ω differential RF pair. Should be AC coupled.

PLL Interface

CLKTUNE

8

AIO

Clock PLL loop filter connection to off-chip filter components. Referenced to

VDDCLK.

VCOTUNE

12

AIO

RF PLL loop filter connection to off-chip filter components. Referenced to

VDDVCO.

Analog Power Supplies

VDDAON

25

P

External supply for the Always-On (AON) portion of the chip. See 7.3

VDDPA1

18

P

External supply to the transmitter power amplifier.

VDDPA2

19

P

External supply to the transmitter power amplifier.

VDDLNA

15

P

External supply to the receiver LNA.

VDDLDOA

48

P

External supply to analog circuits.

VDDBATT

47

P

External supply to all other on-chip circuits. If a TCXO is being used with the

DW1000 this pin should be supplied by the regulated supply used to power

the TCXO. See Figure 37.

Analog Supply Decoupling

VDDCLK

9

PD

Output of on-chip regulator to off-chip decoupling capacitor.

VDDIF

7

PD

Output of on-chip regulator to off-chip decoupling capacitor.

VDDMS

6

PD

Output of on-chip regulator to off-chip decoupling capacitor.

VDDSYN

10

PD

Output of on-chip regulator to off-chip decoupling capacitor.

VDDVCO

11

PD

Output of on-chip regulator to off-chip decoupling capacitor.

Ground Paddle

GND

49

G

Ground Paddle on underside of package. Must be soldered to the PCB

ground plane for thermal and RF performance.

Others

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 8

�DW1000 Datasheet

SIGNAL

NAME

NC

PIN

I/O

(defaul

t)

1

2

13

14

NC

DESCRIPTION

Not used in normal operation. Do not connect.

Table 2: Explanation of Abbreviations

ABBREVIATION

AI

AIO

EXPLANATION

Analog Input

Analog Input / Output

AO

Analog Output

DI

Digital Input

DIO

Digital Input / Output

DO

Digital Output

G

Ground

P

Power Supply

PD

Power Decoupling

NC

No Connect

O-L

Defaults to output, low level after reset

O-H

Defaults to output, high level after reset

I

Defaults to input.

Note: Any signal with the suffix ‘n’ indicates an active low signal.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 9

�DW1000 Datasheet

3 ELECTRICAL SPECIFICATIONS

3.1

Nominal Operating Conditions

Table 3: DW1000 Operating Conditions

Parameter

Min.

Typ.

Max.

Units

Condition/Note

Operating temperature

-40

+85

˚C

Supply voltage VDDIOA

2.8

3.3

3.6

V

Supply voltage VDDBATT, VDDAON,

VDDLNA, VDDPA

2.8

3.3

3.6

V

Supply voltage VDDLDOA, VDDLDOD

1.6

1.8

3.6

V

See section 7.2

Optional: Supply voltage VDDIO

3.7

3.8

3.9

V

Only to be used if programming

the OTP memory. See the

DW1000 User Manual [2] for

details.

3.6

V

Note that 3.6 V is the max

voltage that should be applied

to these pins

Voltage on GPIO0..8, WAKEUP, RSTn,

SPICSn, SPIMOSI, SPICLK, TESTMODE,

FORCEON

Note: Unit operation is guaranteed by design when operating within these ranges

3.2

DC Characteristics

Tamb = 25 ˚C, all supplies centered on typical values

Table 4: DW1000 DC Characteristics

Parameter

Min.

Typ.

Max.

Units

Supply current DEEPSLEEP mode

50

nA

Supply current SLEEP mode

1

µA

Supply current IDLE mode

19

mA

Supply current INIT mode

5

mA

TX : 3.3 V supplies

(VDDBAT, VDDPA1, VDDPA2, VDDLNA,

VDDAON, VDDIOA)

TX : 1.8 V supplies

(VDDLDOA, VDDLDOD)

RX : 3.3 V supplies

(VDDBAT, VDDPA1, VDDPA2, VDDLNA,

VDDAON, VDDIOA)

mA

30

mA

0.7*VDDIO

Channel 5

TX Power = MAX mean

( -9.3 dBm/500 MHz)

0.3*VDDIO

0.7*VDDIO

Digital output voltage low

0.3*VDDIO

4

8

3

mA

V

Digital input voltage low

Digital Output Drive Current

GPIOx, IRQ

SPIMISO

EXTON

90*

210*

(VDDLDOA, VDDLDOD)

Digital output voltage high

mA

Total current drawn from

all 3.3 V and 1.8 V

supplies.

Channel 5

RX : 1.8 V supplies

Digital input voltage high

70

Condition/Note

6

10

4

V

V

Assumes 500 Ω load.

V

Assumes 500 Ω load.

mA

* These currents are on the 1.8 V supplies, not referenced back to the 3.3 V supply

3.3

Receiver AC Characteristics

Tamb = 25 ˚C, all supplies centered on nominal values

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 10

�DW1000 Datasheet

Table 5: DW1000 Receiver AC Characteristics

Parameter

Min.

Frequency range

Typ.

3244

Max.

Units

6999

MHz

500

900

Channel bandwidths

MHz

Input P1Db compression point

-39

In-band blocking level*

30

Out-of-band blocking level*

55

Relative velocity between Receiver &

Transmitter

Condition/Note

Channel 1,2,3 and 5

Channel 4 and 7

dBm

Measured at balun input

dBc

Continuous wave interferer

dBc

Continuous wave interferer

0

5

m/s

0

500

m/s

4096 preamble 110kbps, 128

bytes

64 preamble 6.8 Mbps, 12

bytes

*Blocking level is power relative to reference sensitivity level plus 3 dB to cause 1% packet error rate, e.g. -60

dBm in-band blocking for -93 dBm receiver sensitivity.

A continuous wave interferer is one which has no modulation applied - just a sinusoidal signal. In-band blocking

is where the interferer is within the UWB channel bandwidth being used and out-of-band is where the interferer is

outside the channel bandwidth.

3.4

Receiver Sensitivity Characteristics

Tamb = 25 ˚C, all supplies centered on typical values. 20 byte payload

Table 6: Typical Receiver Sensitivity Characteristics

Packet

Error

Rate

Data Rate

Typical

Receiver

Sensitivity

Units

Condition/Note

1%

110 kbps

-106

dBm/500 MHz

Preamble 2048

10%

110 kbps

-107

dBm/500 MHz

Preamble 2048

110 kbps

-102

dBm/500 MHz

Preamble 2048

850 kbps

-101

dBm/500 MHz

Preamble 1024

6.8 Mbps

-93 (*-97)

dBm/500 MHz

Preamble 256

110 kbps

-106

dBm/500 MHz

Preamble 2048

850 kbps

-102

dBm/500 MHz

Preamble 1024

6.8 Mbps

-94 (*-98)

dBm/500 MHz

Preamble 256

1%

10%

Carrier frequency

offset ±1 ppm.

Requires use of the

“tight” Rx operating

parameter set –

see [2]

Carrier frequency

offset ±10 ppm

All

measureme

nts

performed

on Channel

5, PRF 16

MHz.

Channel 2

is

approximat

ely 1 dB

less

sensitive

*equivalent sensitivity with Smart TX Power enabled

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 11

�DW1000 Datasheet

3.5

Reference Clock AC Characteristics

Tamb = 25 ˚C, all supplies centered on typical values

3.5.1

Reference Frequency

Table 7: DW1000 Reference Clock AC Characteristics

Parameter

Min.

Crystal oscillator reference

frequency

Typ.

Max.

38.4

Units

Condition/Note

MHz

A 38.4 MHz signal can be provided from an

external reference in place of a crystal if

desired. See Figure 37

pF

Depends on crystal used and PCB parasitics

Crystal specifications

Load capacitance

0

Shunt capacitance

0

35

4

pF

Drive level

200

µW

Equivalent Series

Resistance (ESR)

60

Ω

Frequency tolerance

±20

ppm

DW1000 includes circuitry to trim the crystal

oscillator to reduce the initial frequency offset.

ppm

Trimming range provided by on-chip circuitry.

Depends on the crystal used and PCB design.

Vpp

Must be AC coupled. A coupling capacitor

value of 2200 pF is recommended

Crystal trimming range

±25

Depends on crystal & load capacitance used

External Reference

Amplitude

0.8

SSB phase noise power

density

-132

-145

SSB phase noise power

density

Duty Cycle

Low Power RC Oscillator

3.6

40

5

12

dBc/Hz

@1 kHz offset.

dBc/Hz

@10 kHz offset.

60

%

15

kHz

Transmitter AC Characteristics

Tamb = 25 ˚C, all supplies centered on typical values

Table 8: DW1000 Transmitter AC Characteristics

Parameter

Frequency range

Min.

Typ.

3244

Max.

Units

6999

MHz

Channel Bandwidths

500

900

Output power spectral density

(programmable)

-39

Load impedance

100

Power level range

37

dB

Coarse Power level step

3

dB

Fine Power level step

0.5

dB

Output power variation with

temperature

0.05

dB/OC

Output power variation with

voltage

2.73

3.34

dB/V

© Decawave Ltd 2017

Subject to change without notice

MHz

-35

dBm/MHz

Ω

Condition/Note

Channel 1, 2, 3 and 5

Channel 4 and 7

See Section 5.5

Differential

Channel 2

Channel 5

Version 2.22

Page 12

�DW1000 Datasheet

3.7

Temperature and Voltage Monitor Characteristics

Table 9: DW1000 Temperature and Voltage Monitor Characteristics

Parameter

Min.

Voltage Monitor Range

2.4

Voltage Monitor Precision

Max.

3.75

20

Voltage Monitor Accuracy

-40

Units

Condition/Note

V

mV

140

Temperature Monitor Range

3.8

Typ.

mV

+100

°C

Temperature Monitor Precision

0.9

°C

Temperature Monitor Accuracy

+/-5%

°C

Absolute Maximum Ratings

Table 10: DW1000 Absolute Maximum Ratings

Parameter

Voltage

VDDPA / VDDLNA / VDDLDOD / VDDLDOA / VDDBATT /

VDDIOA / VDDAON / VDDIO

Min.

Max.

Units

-0.3

4.0

V

0

dBm

Receiver Power

Temperature - Storage temperature

-65

+150

˚C

Temperature – Operating temperature

-40

+85

˚C

2000

V

ESD (Human Body Model)

Stresses beyond those listed in this table may cause permanent damage to the device. This is a stress rating

only; functional operation of the device at these or any other conditions beyond those indicated in the operating

conditions of the specification is not implied. Exposure to the absolute maximum rating conditions for extended

periods may affect device reliability.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 13

�DW1000 Datasheet

4 TYPICAL PERFORMANCE

90

Blocker Rejection (dB)

80

70

60

50

40

30

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

Blocker Frequency (GHz)

Wanted channel 2 (3.9936 GHz)

Figure 3 : RX Interferer Immunity on Channel 2

-32

-34

-36

2.5 Volts, +25⁰C

Tx Pwr (dBm/MHz)

-38

3.3 Volts, +25⁰C

-40

3.6 Volts, +25⁰C

-42

2.5 Volts, -40⁰C

3.3 Volts, -40⁰C

-44

3.6 Volts, -40⁰C

-46

2.5 Volts, +85⁰C

-48

3.3 Volts, +85⁰C

-50

3.6 Volts, +85⁰C

-52

0

1

2

3

4

5

6

7

Channel

Figure 4: TX output Power over Temp & Voltage

(note that 2.5 volt data points are shown for information only)

Figure 5: Receiver Sensitivity Channel 5 110kbps Data Rate 16 MHz PRF 2048 Preamble Symbols

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 14

�DW1000 Datasheet

Figure 6: Receiver Sensitivity Channel 5 110kbps Data Rate 64 MHz PRF 2048 Preamble Symbols

Figure 7: Receiver Sensitivity Channel 5 850kbps Data Rate 16 MHz PRF 1024 Preamble Symbols

Figure 8: Receiver Sensitivity Channel 5 850kbps Data Rate 64 MHz PRF 1024 Preamble Symbols

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 15

�DW1000 Datasheet

Figure 9: Receiver Sensitivity Channel 5 6.81Mbps Data Rate 16 MHz PRF 256 Preamble Symbols

Figure 10: Receiver Sensitivity Channel 5 6.81Mbps Data Rate 64 MHz PRF 1256 Preamble Symbols

0.12

0.1

Probability

0.08

0.06

0.04

0.02

0

-8

-6

-4

-2

0

Error (cm)

2

4

6

8

Figure 11: Typical probability distribution of Line of Sight 2-way ranging performance

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 16

�DW1000 Datasheet

Ref -40 dBm

Att

5 dB

*RBW 1 MHz

*RBW 1 MHz

*VBW 1 MHz

*SWT 4 s

Ref -40 dBm

A

-45

A

-50

-55

-55

-60

-60

-65

-65

3DB

-70

3DB

-70

-75

-75

-80

-80

-85

-85

-90

-90

Center 3.499 GHz

400 MHz/

Span 4 GHz

Center 3.9936 GHz

16:07:44

Date: 25.SEP.2013

Ref -40 dBm

Att

5 dB

*RBW 1 MHz

*VBW 1 MHz

*SWT 4 s

Ref -40 dBm

Att

*RBW 1 MHz

*VBW 1 MHz

*SWT 4 s

A

-45

1 RM *

CLRWR

-50

-50

-55

-55

-60

-60

-65

-65

3DB

-70

3DB

-70

-75

-75

-80

-80

-85

-85

-90

-90

Center 4.493 GHz

400 MHz/

Span 4 GHz

Center 3.9936 GHz

16:09:23

Date: 25.SEP.2013

Ref -40 dBm

Att

5 dB

400 MHz/

Span 4 GHz

15:49:33

Figure 14: TX Spectrum Channel 3

Figure 15: TX Spectrum Channel 4

*RBW 1 MHz

*VBW 1 MHz

*SWT 4 s

Ref -40 dBm

Att

5 dB

*RBW 1 MHz

*VBW 1 MHz

*SWT 4 s

-40

-40

A

-45

-50

-55

-55

-60

-60

-65

A

-45

1 RM *

CLRWR

-50

-65

3DB

-70

-75

-80

-80

-85

-85

-90

3DB

-70

-75

-90

Center 6.489 GHz

Date: 25.SEP.2013

5 dB

-40

A

-45

1 RM *

CLRWR

Span 4 GHz

Figure 13: TX Spectrum Channel 2

-40

Date: 25.SEP.2013

400 MHz/

15:47:44

Figure 12: TX Spectrum Channel 1

1 RM *

CLRWR

*VBW 1 MHz

*SWT 4 s

-45

1 RM *

AVG

-50

Date: 25.SEP.2013

5 dB

-40

-40

1 RM *

CLRWR

Att

400 MHz/

Span 4 GHz

16:10:30

Center 6.489 GHz

Date: 25.SEP.2013

Figure 16: TX Spectrum Channel 5

© Decawave Ltd 2017

Subject to change without notice

400 MHz/

Span 4 GHz

16:20:23

Figure 17: TX Spectrum Channel 7

Version 2.22

Page 17

�DW1000 Datasheet

5 FUNCTIONAL DESCRIPTION

5.1

Physical Layer Modes

Please refer to IEEE802.15.4-2011 [1] for the PHY specification.

5.1.1

Supported Channels and Bandwidths

The DW1000 supports the following six IEEE802.15.4-2011 [1] UWB channels: Table 11: Channels supported by the DW1000

UWB Channel

Number

Centre Frequency

(MHz)

Band

(MHz)

Bandwidth

(MHz)

1

3494.4

3244.8 – 3744

499.2

2

3993.6

3774 – 4243.2

499.2

3

4492.8

4243.2 – 4742.4

499.2

4

3993.6

3328 – 4659.2

1331.2*

5

6489.6

6240 – 6739.2

499.2

7

6489.6

5980.3 – 6998.9

1081.6*

*DW1000 maximum receiver bandwidth is approximately 900 MHz

5.1.2

Supported Bit Rates and Pulse Repetition Frequencies (PRF)

The DW1000 supports standard bit rates of 110 kbps, 850 kbps and 6.81 Mbps and nominal PRF values of 16

and 64 MHz.

Table 12: UWB bit rates and PRF modes supported by the DW1000

PRF*

(MHz)

Data Rate

(Mbps)

16

0.11

16

0.85

16

6.81

64

0.11

64

0.85

64

6.81

*Actual PRF mean values are slightly higher for SYNC as opposed to the other portions of a frame. Mean PRF values are

16.1/15.6 MHz and 62.89/62.4 MHz, nominally referred to as 16 and 64MHz in this document. Refer to [1] for full details of

peak and mean PRFs.

Generally speaking, lower data rates give increased receiver sensitivity, increased link margin and longer range

but due to longer frame lengths for a given number of data bytes they result in increased air occupancy per frame

and a reduction in the number of individual transmissions that can take place per unit time.

16 MHz PRF gives a marginal reduction in transmitter power consumption over 64 MHz PRF.

When using 16 MHz and 64 MHz PRF on the same physical while using different preamble codes some

interference may result because while the preamble codes have a low cross-correlation they are not orthogonal.

See APH010 [6] for further details on channel interference.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 18

�DW1000 Datasheet

5.1.3

Frame Format

UWB frames are structured as shown in Figure 18. Detailed descriptions of the frame format are given in the

UWB standard [1]. The frame consists of a synchronisation header (SHR) which includes the preamble symbols

and start frame delimiter (SFD), followed by the PHY header (PHR) and data. The data frame is usually specified

in number of bytes and the frame format will include 48 Reed-Solomon parity bits following each block of 330

data bits (or less).

The maximum standard frame length is 127 bytes, including the 2-byte FCS.

Figure 18: IEEE802.15.4-2011 PPDU Structure

5.1.4

Symbol Timings

Timing durations in UWB standard are expressed in an integer number of symbols. This convention is adopted in

DW1000 documentation. Symbol times vary depending on the data rate and PRF configuration of the device and

the part of the frame. See Table 13: DW1000 Symbol Durations, for all symbol timings supported by DW1000.

Table 13: DW1000 Symbol Durations

5.1.5

PRF

(MHz)

Data Rate

(Mbps)

SHR (ns)

PHR (ns)

Data (ns)

16

0.11

993.59

8205.13

8205.13

16

0.85

993.59

1025.64

1025.64

16

6.81

993.59

1025.64

128.21

64

0.11

1017.63

8205.13

8205.13

64

0.85

1017.63

1025.64

1025.64

64

6.81

1017.63

1025.64

128.21

Proprietary Long Frames

The DW1000 offers a proprietary long frame mode where frames of up to 1023 bytes may be transferred. This

requires a non-standard PHR encoding and so cannot be used in a standard system. Refer to the DW1000 User

Manual for full details [2].

5.1.6

Turnaround Times

Turn-around times given in the table below are as defined in [1].

Table 14: Turn-around Times

Parameter

Min.

Typ.

Max.

Units

Turn-around time RX to TX*.

10

μs

Turn-around time TX to RX*.

6

μs

© Decawave Ltd 2017

Subject to change without notice

Condition/Note

Achievable turnaround time depends

on device configuration and frame

parameters and on external host

controller.

Version 2.22

Page 19

�DW1000 Datasheet

5.1.7

Frame Filter

A standard frame filtering format is defined in IEEE802.15.4-2011 [1]. An overview of the MAC frame format is

given in Figure 19 . Note that the Auxiliary Security Header is not processed in DW1000 hardware.

Bytes:

2

Frame Control

Field (FCF)

0 to 14

1

0 to 20

Auxiliary

Sequence Address

Number Information Security Header

MAC Header (MHR)

variable

Frame Payload

MAC Payload

8*Frame Length + Reed-Solomon Encoding bits

2

Frame Check

Seq. (FCS)

MAC Footer

(MFR)

MAC Protocol Data Unit (MPDU)

PHY Service Data Unit (PSDU)

Figure 19: IEEE802.15.4-2011 MAC Frame Format

Frame filtering allows the receiver to automatically discard frames that do not match a defined set of criteria. The

DW1000 has a number of separately configurable frame filtering criteria to allow selection of the frame types to

accept or discard. See IEEE802.15.4-2011 standard [1] for filtering field definition and acceptance rules.

5.1.8

Frame Check Sequence (FCS)

The FCS is also known as the MAC Footer (MFR). It is a 2-byte CRC appended to frames. See standard for

information on FCS generation.

5.2

Reference Crystal Oscillator

The on-chip crystal oscillator generates the reference frequency for the integrated frequency synthesizers RFPLL

and CLKPLL. The oscillator operates at a frequency of 38.4 MHz.

DW1000 provides the facility to trim out initial frequency error in the 38.4 MHz reference crystal, see section 5.14.

The trimming range depends on the crystal chosen and the loading capacitors used. Typically a trimming range

of ±25 ppm is possible. Loading capacitors should be chosen such that minimum frequency error (from the

channel center frequency) is achieved when the trim value is approximately mid-range.

In applications that require tighter frequency tolerance (maximum range) an external oscillator such as a TCXO

can be used to drive the XTAL1 pin directly.

5.3

Synthesizer

DW1000 contains 2 frequency synthesizers, RFPLL which is used as a local oscillator (LO) for the TX and RX

and CLKPLL which is used as a system clock. Both of these synthesizers are fully integrated apart from external

passive 2nd order loop filters. The component values for these loop filters do not change regardless of the RF

channel used. The register programming values for these synthesizers is contained in the user manual [2]

5.4

5.4.1

Receiver

Bandwidth setting

The receiver can be configured to operate in one of two bandwidth modes; 500 MHz or 900 MHz. The selection

of a particular bandwidth mode is made by register settings and is described in the DW1000 User Manual [2].

5.4.2

Automatic Gain Control (AGC)

Automatic Gain Control is provided to ensure optimum receiver performance by adjusting receiver gain for

changing signal and environmental conditions. The DW1000 monitors the received signal level and makes

appropriate automatic adjustments to ensure optimum receiver performance is maintained.

5.5

5.5.1

Transmitter

Transmit Output Power

DW1000 transmit power is fully adjustable as is the transmit spectrum width ensuring that applicable regulatory

standards such as FCC [4] and ETSI [3] can be met. For maximum range the transmit power should be set such

that the EIRP at the antenna is as close as possible to the maximum allowed, -41.3 dBm/MHz in most regions.

See section 5.14.3 for more details.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 20

�DW1000 Datasheet

5.5.2

Transmit Bandwidth Setting

The transmitter can be configured to operate over a wide range of bandwidths. The selection of a particular

bandwidth mode is made by register settings and is described in the DW1000 User Manual [2]

Transmit spectral shape can also be adjusted to compensate for PCB and external components in order to give

an optimal transmit spectral mask.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 21

�DW1000 Datasheet

5.6

Power-up sequence

5.6.1

Typical power-up sequence

3.3 V Supplies

Von

(VDDAON / VDDBAT / VDDIOA /

VDDLNA / VDDPA1 / VDDPA2)

Tosc_on

XTAL1 (38.4MHz)

XTAL1

VLDO_OK

VDDLDOA & VDDLDOD

TRST_OK

EXTON

Text_on

RSTn

Tdig_on

STATE

OFF

POWER UP

INIT

Figure 20: DW1000 Power-up Sequence

When power is applied to the DW1000, RSTn is driven low by the DW1000 internal circuitry as part of its power

up sequence. See Figure 20 above. RSTn remains low until the XTAL oscillator has powered up and its output

is suitable for use by the rest of the device. Once that time is reached the DW1000 de-asserts RSTn.

Table 15: DW1000 Power-up Timings

Parameter

VON

Min

Value

Description

Nominal

Value

Units

2.0

V

Voltage threshold to enable overall IC power up.

TOSC_ON

Time taken for oscillator to start up and stabilise.

1.0

1.5

ms

TEXT_ON

EXTON goes high this long before RSTn is released.

1.5

2

ms

TDIG_ON

RSTn held low by internal reset circuit / driven low by external

reset circuit.

1.5

2

ms

VLDO_OK

Voltage threshold on the VDDLDOD supply at which the digital

core powers up.

1.6

TRST_OK

Time for which RSTn must continue to remain low once

VDDLDOD exceeds VLDO_OK min.

If TRST_OK min cannot be met due to the timing of the

VDDLDOD supply ramp then RSTn should be manually driven

low for at least TRST_OK min time to ensure correct reset

operation

10

5.6.2

V

50

ns

Variation in the power-up sequence

It is possible, that in some circuit arrangements, the start-up sequence may need to be altered. This can happen

if, for example, the VDDLDOD supply is controlled via an external controller or if a slow ramp regulator is used to

provide the VDDLDOD supply. In these situations the RSTn pin would have to be controlled by the external

circuitry to ensure the digital circuits receive proper reset on power up.

VLDO_OK

VDDLDOA & VDDLDOD

TRST_OK

EXTON

RSTn

VDDLDOD not ready

STATE

OFF

POWER UP

User asserts RSTn to

ensure reset occurs

INIT

Figure 21: Power up example where VDDLDOD cannot be guaranteed to be ready in time for the RSTn

going high

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 22

�DW1000 Datasheet

Figure 21 shows a situation where the VDDLDOD supply is not high until after the first RSTn low to high

transition (start of shaded area of RSTn). In this case the external circuitry must pull RSTn down again after the

VDDLDOD supply has exceeded VLDO_OK. This will ensure the digital circuits receive proper reset on power up.

The RSTn pin should be either held low during power up until TRST_OK is met or driven low for a minimum of

TRST_OK.

5.6.3

5.6.3.1

External control of RSTn / use of RSTn by external circuitry

External control of RSTn

An external circuit can reset the DW1000 by asserting RSTn for a minimum of TRST_OK. RSTn is an

asynchronous input. DW1000 initialization will proceed when the RSTn pin is released to high impedance.

An external source should open-drain the RSTn pin once the DW1000 has been reset. If RSTn is controlled by a

GPIO of an external micro-controller care should be taken to ensure that the GPIO is configured as highimpedance as soon as it is released from the LOW state.

When in DEEPSLEEP mode, the DW1000 drives RSTn to ground. This can result in current flowing if RSTn is

driven high externally and will result in incorrect wake-up operation.

RSTn should never be driven high by an external source.

5.6.3.2

Use of RSTn by external circuitry

Table 16: External use of RSTn

Use of RSTn

Description

As output to control

external circuitry

RSTn may be used as an output to reset external circuitry as part of an orderly bring up

of a system as power is applied.

As interrupt input to

external host

RSTn may be used as an interrupt input to the external host to indicate that the

DW1000 has entered the INIT state. When RSTn is used in this way care should be

taken to ensure that the interrupt pin of the external host does not pull-up the RSTn

signal which should be left open-drain. Refer to Table 1 and Figure 37.

5.7

Voltage/Temperature Monitors

The on-chip voltage and temperature monitors allow the host to read the voltage on the VDDAON pin and the

internal die temperature information from the DW1000. See Table 9 for characteristics.

5.8

Host Controller Interface

The DW1000 host communications interface is a slave-only SPI. Both clock polarities (SPIPOL=0/1) and phases

(SPIPHA=0/1) are supported. The data transfer protocol supports single and multiple byte read/writes accesses.

All bytes are transferred MSB first and LSB last. A transfer is initiated by asserting SPICSn low and terminated

when SPICSn is deasserted high.

The DW1000 transfer protocols for each SPIPOL and SPIPHA setting are given in Figure 22 and Figure 23.

Note: Figure 22 and Figure 23 detail the SPI protocol as defined for SPICLK polarities and phases. The

sampling and launch edges used by the SPI bus master are shown. DW1000 is a SPI slave device and

will comply with the protocol by ensuring that the SPIMISO data is valid on the required SPICLK edge

with setup and hold times as given by Table 18.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 23

�DW1000 Datasheet

Cycle

Number, #

1

2

3

4

5

6

7

8

8*Number of

bytes

9

SPIPOL=0, SPIPHA=0

SPICLK

SPIPOL=1, SPIPHA=0

SPICLK

SPICSn

SPIMISO

z

MSB

6

5

4

3

2

1

LSB

MSB

LSB

X

Z

SPIMOSI

z

MSB

6

5

4

3

2

1

LSB

MSB

LSB

X

Z

Figure 22: DW1000 SPIPHA=0 Transfer Protocol

Cycle

Number, #

1

2

3

4

5

6

7

8

8*Number of

bytes

9

SPIPOL=0, SPIPHA=1

SPICLK

SPIPOL=1, SPIPHA=1

SPICLK

SPICSn

SPIMISO

z

X

MSB

6

5

4

3

2

1

LSB

MSB

LSB

Z

SPIMOSI

z

X

MSB

6

5

4

3

2

1

LSB

MSB

LSB

Z

Figure 23: DW1000SPIPHA=1 Transfer Protocol

The MSB of the first byte is the read/write indicator, a low bit indicates a read access and a high bit indicates a

write access. The second bit, bit 6 of the first byte, indicates whether a sub address byte will be included in the

SPI access, a high bit indicates a further address byte to follow the initial byte and a low bit indicating that the

bytes to follow the first byte are data. The 6 LSBs of the first byte contain an access address.

The second byte of a transfer command, if included, gives the sub address being accessed. If the MSB of this

optional second byte is high, it indicates a second sub address byte to follow in the third transfer byte. The 7

LSBs of this second byte give the 7 LSBs of the sub address.

The third byte of a transfer command, if included give the 8 MSBs of the sub address.

The number of data bytes to follow the 1-3 command bytes is not limited by the DW1000 transfer protocol.

Figure 24: SPI Byte Formatting

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Read/Write

0 – Read

1 – Write

Sub address

0 – no sub address

1 – sub address present

Sub Address 0

(Optional)

Extended sub address

0 – 1 byte sub address

1 – 2 byte sub address

7-bits of sub address. These will be the LSBs if more bits are to follow.

Sub Address 1

(Optional)

8 bits of sub address. These will form the MSBs, bits [14:7] of the 15-bit sub address.

Command

Data

6-bit access address

8-bit read/write bytes (variable number).

The SPIMISO line may be connected to multiple slave SPI devices each of which is required to go open-drain

when their respective SPICSn lines are de-asserted.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 24

�DW1000 Datasheet

The DW1000 has internal pull up and pull down circuits to ensure safe operation

in the event of the host interface signals being disconnected. These are for

internal use only, and should not be used to pull an external signal high or low.

Internal pull-down resistance values are in the range 34 kΩ – 90 kΩ, internal pullup resistance values are in the range 40 kΩ - 90 kΩ.

GPIO5

(SPIPOL)

~60kΩ

~55kΩ

30

DW1000

~55 kΩ

24

39

~55kΩ

40

41

SPICSn

SPI PORT

GPIO6

(SPIPHA)

VDDIOA

33

SPIMOSI

SPIMISO

Host Controller

SPICLK

~55kΩ

Figure 25: SPI Connections

More details of the protocol used for data transfer, the description of the accessible registers and the description

of the bit functions of those registers are published in the DW1000 User Manual [2].

5.8.1

Configuring the SPI Mode

The SPI interface supports a number of different clock polarity and clock / data phase modes of operation. These

modes are selected using GPIO5 & 6 as follows: Table 17: DW1000 SPI Mode Configuration

GPIO 5

(SPIPOL)

GPIO 6

(SPIPHA)

SPI

Mode

0

0

0

Data is sampled on the rising (first) edge of the clock and launched on the

falling (second) edge.

0

1

1

Data is sampled on the falling (second) edge of the clock and launched on

the rising (first) edge.

1

0

2

Data is sampled on the falling (first) edge of the clock and launched on the

rising (second) edge.

1

1

3

Data is sampled on the rising (second) edge of the clock and launched on

the falling (first) edge.

Description (from the master / host point of view)

Note: The 0 on the GPIO pins can either be open circuit or a pull down to ground. The 1 on the GPIO pins is a pull up to VDDIO.

GPIO 5 / 6 are sampled / latched on the rising edge of the RSTn pin to determine the SPI mode. They are

internally pulled low to configure a default SPI mode 0 without the use of external components. If a mode other 0

is required then they should be pulled up using an external resistor of value no greater than 10 kΩ to the VDDIO

output supply.

If GPIO5 / 6 are also being used to control an external transmit / receive switch then external pull-up resistors of

no less than 1 kΩ should be used so that the DW1000 can correctly drive these outputs in normal operation after

the reset sequence / SPI configuration operation is complete.

The recommended range of resistance values to pull-up GPIO 5 / 6 is in the range of 1-10 kΩ. If it is required to

pull-down GPIO 5 / 6, such as in the case where the signal is also pulled high at the input to an external IC, the

resistor value chosen needs to take account of the DW1000 internal pull-down resistor values as well as those of

any connected external pull-up resistors.

It is possible to set the SPI mode using the DW1000’s one-time programmable configuration block to avoid the

need for external components and to leave the GPIO free for use. This is a one-time activity and cannot be

reversed so care must be taken to ensure that the desired SPI mode is set. Please refer to the DW1000 User

Manual [2] for details of OTP use and configuration.

The operating mode of the SPI is determined when the DW1000’s digital control function is initialised as a result

of a device reset or is woken up from a SLEEP or DEEPSLEEP state and is in state INIT or IDLE. At this time

GPIO lines 5 and 6 are sampled and their values act to select the SPI mode.

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 25

�DW1000 Datasheet

See section 6 OPERATIONAL STATES AND POWER MANAGEMENT

When the DW1000 is put in SLEEP or DEEPSLEEP modes, the SPI MISO is held low. It is possible to share a

SPI bus with the DW1000, in this case access to the other SPI slave would have to occur when the DW1000 is

not in SLEEP or DEEPSLEEP.

5.8.2

SPI Signal Timing

SPICSn

S PICLK

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

SPIMOSI

7

SPIMISO

6

5

4

3

2

1

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0

t7

7

6

5

4

3

2

1

Bit 7 Bit 6 Bit 5

0

7

t5

t8

6

5

t6

t9

Figure 26: DW1000 SPI Timing Diagram

SPICSn

S PICLK

Bit 7

SPIMOSI

Bit 6

7

SPIMISO

t3

t1

6

t4

Bit 5

5

t2

Figure 27: DW1000 SPI Detailed Timing Diagram

SPI transactions are initiated by the assertion of the active low chip select line, SPICSn. The high-to-low

assertion (low) of SPICSn initialises the SPI transaction handler so that the DW1000 interprets the next octet(s)

as a new transaction header. The low-to-high de-assertion of SPICSn ends the SPI transaction.

Note- The SPICSn should remain low for an entire SPI transaction. If the CSn goes high between octets, the

transaction will be terminated where the CSn goes high and the next octet will be treated as a new transaction.

See the DW1000 User Manual [2] for further details on SPI transactions.

Table 18: DW1000 SPI Timing Parameters @ A) 125 MHz system clock and B) 19.2 MHz system clock

A:

Parameter

Min

SPICLK

Period

50

t1

Typ

Max

38

Unit

Description @ 125 MHz

ns

The maximum SPI frequency is 20 MHz when the CLKPLL is locked,

otherwise the maximum SPI frequency is 3 MHz.

ns

SPICSn select asserted low to valid slave output data

t2

12

ns

SPICLK low to valid slave output data

t3

10

ns

Master data output setup and hold time i.e Master data = MOSI

t4

10

ns

Master data output setup and hold time i.e Master data = MOSI

t5

32

ns

LSB last byte to MSB next byte

t6

ns

SPICSn de-asserted high to SPIMISO tri-state

t7

16

10

ns

Start time; time from select asserted to first SPICLK

t8

40

ns

Last SPICLK to SPICSn de-asserted

t9

40

ns

Idle time between consecutive accesses

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 26

�DW1000 Datasheet

B:

Parameter

Min

SPICLK

Period

Max

300

t1

210

Unit

Description @ 19.2 MHz

ns

The SPI will be clocked directly from the crystal when the PLL is not

active or has not been switched in due to settling. The maximum SPI

frequency is 3 MHz when the system is clocked from the crystal

@19.6 MHz.

ns

SPICSn select asserted low to valid slave output data

t2

55

ns

SPICLK low to valid slave output data

t3

10

ns

Master data output setup and hold time i.e Master data = MOSI

t4

10

ns

Master data output setup and hold time i.e Master data = MOSI

t5

205

ns

LSB last byte to MSB next byte

t6

5.9

Typ

ns

SPICSn de-asserted high to SPIMISO tri-state

t7

105

55

ns

Start time; time from select asserted to first SPICLK

t8

250

ns

Last SPICLK to SPICSn de-asserted

t9

250

ns

Idle time between consecutive accesses

General Purpose Input Output (GPIO)

The DW1000 provides 8 user-configurable I/O pins.

On reset, all GPIO pins default to input. GPIO inputs, when appropriately

configured, are capable of generating interrupts to the host processor via

the IRQ signal. Some GPIO lines have multiple functions as described in

2.2 above.

GPIO0, 1, 2, & 3, as one of their optional functions, can drive LEDs to

indicate the status of various chip operations. Any GPIO line being used

to drive an LED in this way should be connected as shown. GPIO5 & 6

are used to configure the operating mode of the SPI as described in

5.8.1. GPIO4, 5 & 6 may be optionally used to implement a scheme with

an external power amplifier to provide a transmit power level in excess of

that provided by the DW1000.

FROM GPIO

470Ω

LED

The DW1000 User Manual [2] provides details of the configuration and use of the GPIO lines.

5.10 Memory

The DW1000 includes a number of user accessible memories: -

5.10.1 Receive and Transmit data buffers

Buffers used to store received data to be read from the DW1000 by the host controller and data for transmission

written into the DW1000 by the host controller. These are sized as follows: Table 19: Transmit & Receive Buffer Memory Size

Memory

Size (bits)

Description

Tx Buffer

1024 x 8

Transmit data buffer. Contains data written by the host processor

to be transmitted via the transmitter

Rx Buffer

1024 x 8 x 2

Receive data buffer. Contains data received via the receiver to

be read by the host processor via the SPI interface. Double

buffered so that the receiver can receive a second packet while

the first is being read by the host controller

5.10.2 Accumulator memory

© Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 27

�DW1000 Datasheet

The accumulator memory is used to store the channel impulse response estimate.

Table 20: Accumulator Memory Size

Memory

Size (bits)

Accumulator

1016 x 32

Description

Accumulator buffer. Used to store channel impulse response

estimate data to be optionally read by the host controller

5.10.3 One Time Programmable (OTP) Calibration Memory

The DW1000 contains a small amount of user programmable OTP memory that is used to store per chip

calibration information. When programming the OTP, the user should ensure that the VDDIO pins are supplied

with 3.7 V minimum. If the VDDIO pin is unavailable, then the VDDIOA pin should be driven instead.

Table 21: OTP calibration memory

Memory

Size (bits)

Calibration

56 x 32

Description

One time programmable area of memory used for storing

calibration data.

5.11 Interrupts and Device Status

DW1000 has a number of interrupt events that can be configured to drive the IRQ output pin. The default IRQ

pin polarity is active high. A number of status registers are provided in the system to monitor and report data of

interest. See DW1000 User Manual [2] for a full description of system interrupts and their configuration and

status registers.

5.12 MAC Features

5.12.1 Timestamping

DW1000 generates transmit timestamps and captures receive timestamps. These timestamps are 40-bit values

at a nominal 64 GHz resolution, for approximately 15 ps event timing precision. These timestamps enable

ranging calculations.

DW1000 allows antenna delay values to be programmed for automatic adjustment of timestamps. See the

DW1000 User Manual [2] for more details of DW1000 implementation and IEEE802.15.4-2011 [1] for details of

definitions and required precision of timestamps and antenna delay values.

5.12.2 FCS Generation and Checking

DW1000 will automatically append a 2-byte FCS to transmitted frames and check received frames’ FCS. The

DW1000 can be used to send frames with a host-generated FCS, if desired.

5.12.3 Automatic Frame Filtering

Automatic frame filtering can be carried out using the DW1000. Incoming frames can be rejected automatically if

they fail frame type or destination address checks. See the DW1000 User Manual [2] for details.

5.12.4 Automatic Acknowledge

The DW1000 can be configured to automatically acknowledge received frames requesting acknowledgement.

See the DW1000 User Manual [2] for details.

Note that RX-TX turnaround is optimised for Automatic Acknowledge and is typically ~6.5 µs, but depends on the

configured frame parameters. The delay applied between frames is programmable in preamble symbol durations

to allow compliance with standard SIFS and LIFS requirements.

5.12.5 Double Receive Buffer

The DW1000 has two receive buffers to allow the device to receive another frame whilst the host is accessing a

previously received frame. Achievable throughput is increased by this feature. See the DW1000 User Manual [2]

for details.

5.13 External Synchronization

The DW1000 provides a SYNC input. This allows: © Decawave Ltd 2017

Subject to change without notice

Version 2.22

Page 28

�DW1000 Datasheet

•

•

•

Synchronization of multiple DW1000 timestamps.

Transmission synchronous to an external reference.

Receive timestamping synchronous to an external counter.

As shown in Figure 28 the SYNC input must be source synchronous with the external frequency reference. The

SYNC input from the host system provides a common reference point in time to synchronise all the devices with

the accuracy necessary to achieve high resolution location estimation.

XTAL1

SYNC

tsync_su

tsync_hd

Figure 28: SYNC signal timing relative to XTAL1

Table 22: SYNC signal timing relative to XTAL

Parameter

Min

Typ

Max

Unit

Description

tSYNC_SU

10