Dual-Axis, High-g,

iMEMS® Accelerometers

ADXL278

FEATURES

GENERAL DESCRIPTION

Complete dual-axis acceleration measurement system on a

single monolithic IC

Available in ±35 g/±35 g, ±50 g/±50 g, or ±70 g/±35 g output

full-scale ranges

Full differential sensor and circuitry for high resistance to

EMI/RFI

Environmentally robust packaging

Complete mechanical and electrical self-test on digital

command

Output ratiometric to supply

Sensitive axes in the plane of the chip

High linearity (0.2% of full scale)

Frequency response down to dc

Low noise

Low power consumption

Tight sensitivity tolerance and 0 g offset capability

Largest available prefilter clipping headroom

400 Hz, 2-pole Bessel filter

Single-supply operation

Compatible with Sn/Pb and Pb-free solder processes

Qualified for automotive applications

The ADXL278 is a low power, complete, dual-axis

accelerometer with signal conditioned voltage outputs that are

on a single monolithic IC. This product measures acceleration

with a full-scale range of (X-axis/Y-axis) ±35 g/±35 g, ±50 g/

±50 g, or ±70 g/±35 g (minimum). The ADXL278 can also

measure both dynamic acceleration (vibration) and static

acceleration (gravity).

The ADXL278 is the fourth-generation surface micromachined

iMEMS® accelerometer from ADI with enhanced performance

and lower cost. Designed for use in front and side impact airbag

applications, this product also provides a complete costeffective solution useful for a wide variety of other applications.

The ADXL278 is temperature stable and accurate over the

automotive temperature range, with a self-test feature that fully

exercises all the mechanical and electrical elements of the sensor

with a digital signal applied to a single pin.

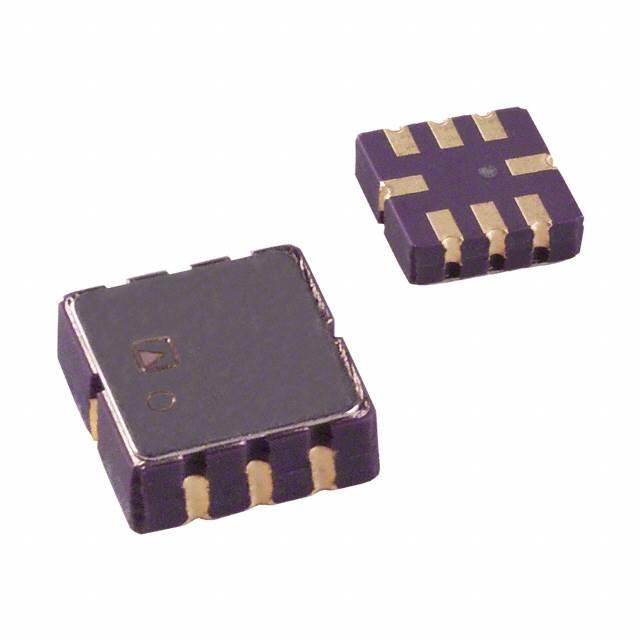

The ADXL278 is available in a 5 mm × 5 mm × 2 mm,

8-terminal ceramic LCC package.

APPLICATIONS

Vibration monitoring and control

Vehicle collision sensing

Shock detection

FUNCTIONAL BLOCK DIAGRAM

ADXL278

EXC

DIFFERENTIAL

SENSOR

DEMOD

AMP

400Hz

BESSEL

FILTER

XOUT

DEMOD

AMP

400Hz

BESSEL

FILTER

YOUT

VS

VDD

VDD2

EXC

DIFFERENTIAL

SENSOR

SELF-TEST

05365-001

TIMING

GENERATOR

VDD3

Figure 1.

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

www.analog.com

Tel: 781.329.4700

Fax: 781.461.3113

©2010 Analog Devices, Inc. All rights reserved.

�ADXL278* Product Page Quick Links

Last Content Update: 11/01/2016

Comparable Parts

Design Resources

View a parametric search of comparable parts

•

•

•

•

Documentation

Application Notes

• AN-652: Considerations for Soldering Accelerometers in

LCC-8 Packages onto Printed Circuit Boards

• AN-688: Phase and Frequency Response of iMEMS®

Accelerometers and Gyros

Data Sheet

• ADXL278: Dual-Axis, High-g, iMEMS® Accelerometers

Data Sheet

ADXL278 Material Declaration

PCN-PDN Information

Quality And Reliability

Symbols and Footprints

Discussions

View all ADXL278 EngineerZone Discussions

Sample and Buy

Visit the product page to see pricing options

Technical Support

Submit a technical question or find your regional support

number

* This page was dynamically generated by Analog Devices, Inc. and inserted into this data sheet. Note: Dynamic changes to

the content on this page does not constitute a change to the revision number of the product data sheet. This content may be

frequently modified.

�ADXL278

TABLE OF CONTENTS

Features .............................................................................................. 1

Theory of Operation .........................................................................7

Applications ....................................................................................... 1

Applications........................................................................................8

General Description ......................................................................... 1

Power Supply Decoupling ............................................................8

Functional Block Diagram .............................................................. 1

Self-Test ..........................................................................................8

Revision History ............................................................................... 2

Clock Frequency Supply Response .............................................8

Specifications..................................................................................... 3

Signal Distortion ...........................................................................8

Absolute Maximum Ratings ............................................................ 4

Outline Dimensions ..........................................................................9

ESD Caution .................................................................................. 4

ADXL278 Ordering Guide ...........................................................9

Pin Configuration and Function Descriptions ............................. 5

Automotive Products ....................................................................9

REVISION HISTORY

8/10—Rev. A to Rev. B

Updated Format .................................................................. Universal

Change to Features Section ............................................................. 1

Updated Outline Dimensions ......................................................... 9

Changes to Ordering Guide ............................................................ 9

Added Automotive Products Section............................................. 9

7/02—Rev. D to Rev. E

Edits to Features ................................................................................ 1

5/05—Rev. 0 to Rev. A

Rev. B | Page 2 of 12

�ADXL278

SPECIFICATIONS1

At TA = −40°C to +105°C, 5.0 V dc ± 5%, acceleration = 0 g, unless otherwise noted.

Table 1.

Parameter

SENSOR

Output Full-Scale Range

Nonlinearity

Package Alignment Error

Sensor-to-Sensor

Alignment Error

Cross-Axis Sensitivity

Resonant Frequency

Sensitivity, Ratiometric

(Over Temperature)

OFFSET

Zero-g Output Voltage

(Over Temperature)2

NOISE

Noise Density

Clock Noise

FREQUENCY RESPONSE

−3 dB Frequency

−3 dB Frequency Drift

SELF-TEST

Output Change

(Cube vs. VDD)3

Logic Input High

Logic Input Low

Input Resistance

OUTPUT AMPLIFIER

Output Voltage Swing

Conditions

Model No. AD22284

Min

Typ Max

Model No. AD22285

Min

Typ Max

Model No. AD22286

Axis Min

Typ Max

IOUT ≤ ±100 µA

37

55

X

Y

0.2

1

0.1

−5

VDD = 5 V,

100 Hz

VOUT − VDD/2,

VDD = 5 V

52.25

10 Hz − 400 Hz,

5V

+150

0.2

1

0.1

−5

36.1

3

2

0.2

1

0.1

+5

24

38

−150

39.9

+150

1.4

5

3

−5

2

+5

g

g

%

Degree

Degree

28.35

%

kHz

mV/g

57.75

mV/g

X

25.65

24

27

Y

52.25

55

X

−100

+100

mV

Y

−150

+150

mV

X

1.8

3.5

mg/√Hz

Y

1.1

5

3

mg/√Hz

mV p-p

360

400

2

440

Hz

Hz

X

216

270

324

mV

Y

440

3.5

550

660

30

50

mV

V

V

kΩ

5

2-pole Bessel

360

400

2

440

360

400

2

440

VDD = 5 V

440

550

660

304

380

456

VDD = 5 V

VDD = 5 V

Pull-down

resistor to GND

3.5

25°C to

TMIN or TMAX

IOUT = ±400 µA

3.5

1

30

50

4.75

3.5

1

30

0.25

POWER SUPPLY (VDD)

Functional Range

Quiescent Supply Current

TEMPERATURE RANGE

3

57.75

1.1

1000

2

+5

24

55

−150

Capacitive Load Drive

PREFILTER HEADROOM

CFSR @ 400 kHz

1

2

70

37

Unit

VDD −

0.25

0.25

2.2

−40

VDD −

0.25

1000

280

6

VDD = 5 V

50

1

0.25

1000

400

4.5

5.25

6

2.9

+105

4.75

3.5

2.2

−40

All minimum and maximum specifications are guaranteed. Typical specifications are not guaranteed.

Zero g output is ratiometric.

Self-test output at VDD = (Self-Test Output at 5 V) × (VDD/5 V)3.

Rev. B | Page 3 of 12

VDD −

0.25

560

3

6

5.25

6

2.9

+105

4.75

3.5

2.2

−40

5.25

6

2.9

+105

V

pF

g

V/V

V/V

V

V

mA

°C

�ADXL278

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter

Acceleration (Any Axis, Unpowered)

Acceleration (Any Axis, Powered)

VS

All Other Pins

Output Short-Circuit Duration

(Any Pin to Common)

Operating Temperature Range

Storage Temperature

Rating

4,000 g

4,000 g

−0.3 V to +7.0 V

(COM − 0.3 V) to

(VS + 0.3 V)

Indefinite

−65°C to +150°C

−65°C to +150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. B | Page 4 of 12

�ADXL278

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

VDD2

8

VDD3 1

YOUT 2

COM 3

7

VDD

ADXL278

6 XOUT

TOP VIEW

(Not to Scale)

5 NC

05365-002

4

ST

NC = NO CONNECT

Figure 2. Pin Configuration

Table 3. Pin Function Descriptions

Pin No.

1

2

3

4

5

6

7

8

Mnemonic

VDD3

YOUT

COM

ST

NC

XOUT

VDD

VDD2

Description

3.5 V to 6 V

Y Channel Output

Common

Self-Test

Do Not Connect

X Channel Output

3.5 V to 6 V

3.5 V to 6 V

Rev. B | Page 5 of 12

�ADXL278

CRITICAL ZONE

TL TO TP

tP

TP

TEMPERATURE

RAMP-UP

TL

tL

TSMAX

TSMIN

tS

RAMP-DOWN

05365-003

PREHEAT

t25°C TO PEAK

TIME

Figure 3. Recommended Soldering Profile

Table 4. Recommended Soldering Profile

Profile Feature

AVERAGE RAMP RATE (TL TO TP)

PREHEAT

Minimum Temperature (TSMIN)

Maximum Temperature (TSMAX)

TIME (TSMIN TO TSMAX), tS

TSMAX TO TL

Ramp-Up Rate

TIME MAINTAINED ABOVE LIQUIDOUS (TL)

Liquidous Temperature (TL)

Time (tL)

PEAK TEMPERATURE (TP)

TIME WITHIN 5°C OF ACTUAL PEAK TEMPERATURE (tP)

RAMP-DOWN RATE

TIME 25°C TO PEAK TEMPERATURE

Sn63/Pb37

3°C/s max

Pb-Free

3°C/s max

100°C

150°C

60 s − 120 s

150°C

200°C

60 s − 150 s

3°C/s

3°C/s

183°C

60 s − 150 s

240°C + 0°C/−5°C

10 s − 30 s

6°C/s max

6 min max

217°C

60 s − 150 s

260°C + 0°C/−5°C

20 s − 40 s

6°C/s max

8 min max

PIN 8

XXXXX

XXXX

22285

XXXXX

XXXX

22285

XOUT = 2.500V

YOUT = 2.462V

22285

XXXXX

XXXX

XOUT = 2.538V

YOUT = 2.500V

XOUT = 2.500V

YOUT = 2.500V

EARTH'S SURFACE

Figure 4. Output Response vs. Orientation

Rev. B | Page 6 of 12

05365-004

XOUT = 2.500V

YOUT = 2.538V

XXXXX

XXXX

22285

XOUT = 2.462V

YOUT = 2.500V

�ADXL278

THEORY OF OPERATION

Complementary 200 kHz square waves drive the fixed plates.

Electrical feedback adjusts the amplitudes of the square waves

such that the ac signal on the moving plates is 0. The feedback

signal is linearly proportional to the applied acceleration. This

unique feedback technique ensures that there is no net

electrostatic force applied to the sensor. The differential

feedback control signal is also applied to the input of the filter,

where it is filtered and converted to a single-ended signal.

Rev. B | Page 7 of 12

MOVABLE

FRAME

PLATE

CAPACITORS

UNIT

SENSING

CELL

FIXED

PLATES

UNIT

FORCING

CELL

MOVING

PLATE

ANCHOR

Figure 5. Simplified View of Sensor Under Acceleration

05365-005

Figure 5 is a simplified view of one of the differential sensor

elements. Each sensor includes several differential capacitor

unit cells. Each cell is composed of fixed plates attached

to the substrate and movable plates attached to the frame.

Displacement of the frame changes the differential capacitance,

which is measured by the on-chip circuitry.

ANCHOR

ACCELERATION

The ADXL278 provides a fully differential sensor structure and

circuit path, resulting in the industry’s highest resistance to

EMI/RFI effects. This latest generation uses electrical feedback

with zero-force feedback for improved accuracy and stability.

The sensor resonant frequency is significantly higher than the

signal bandwidth set by the on-chip filter, avoiding the signal

analysis problems caused by resonant peaks near the signal

bandwidth.

�ADXL278

APPLICATIONS

POWER SUPPLY DECOUPLING

For most applications, a single 0.1 µF capacitor, CDC, adequately

decouples the accelerometer from noise on the power supply.

However, in some cases, particularly where noise is present at

the 200 kHz internal clock frequency (or any harmonic

thereof), noise on the supply can cause interference on the

ADXL278’s output. If additional decoupling is needed, a 50 Ω

(or smaller) resistor or ferrite bead cany be inserted in the

supply line. Additionally, a larger bulk bypass capacitor (in the

1 µF to 4.7 µF range) can be added in parallel to CDC.

SELF-TEST

The fixed fingers in the forcing cells are normally kept at the

same potential as that of the movable frame. When the self-test

digital input is activated, the voltage on the fixed fingers on one

side of the moving plate in the forcing cells is changed. This

creates an attractive electrostatic force, which causes the frame

to move towards those fixed fingers. The entire signal channel is

active; therefore, the sensor displacement causes a change in

VOUT. The ADXL278’s self-test function is a comprehensive

method of verifying the operation of the accelerometer.

Because electrostatic force is independent of the polarity of the

voltage across capacitor plates, a positive voltage is applied in

half of the forcing cells, and its complement in the other half of

the forcing cells. Activating self-test causes a step function force

to be applied to the sensor, while the capacitive coupling term is

canceled. The ADXL278 has improved self-test functionality,

including excellent transient response and high speed switching

capabilities. Arbitrary force waveforms can be applied to the

sensor by modulating the self-test input, such as test signals to

measure the system frequency response or even crash signals to

verify algorithms within the limits of the self-test swing.

The ST pin should never be exposed to voltages greater than

VS + 0.3 V. If this cannot be guaranteed due to the system

design (for instance, if there are multiple supply voltages), then

a low VF clamping diode between ST and VS is recommended.

CLOCK FREQUENCY SUPPLY RESPONSE

In any clocked system, power supply noise near the clock

frequency may have consequences at other frequencies. An

internal clock typically controls the sensor excitation and the

signal demodulator for micromachined accelerometers.

If the power supply contains high frequency spikes, they may be

demodulated and interpreted as an acceleration signal. A signal

appears as the difference between the noise frequency and the

demodulator frequency. If the power supply spikes are 100 Hz

away from the demodulator clock, there is an output term at

100 Hz. If the power supply clock is at exactly the same frequency

as the accelerometer clock, the term appears as an offset.

If the difference frequency is outside of the signal bandwidth,

the filter attenuates it. However, both the power supply clock

and the accelerometer clock may vary with time or temperature,

which can cause the interference signal to appear in the output

filter bandwidth.

The ADXL278 addresses this issue in two ways. First, the high

clock frequency eases the task of choosing a power supply clock

frequency such that the difference between it and the accelerometer clock remains well outside of the filter bandwidth.

Second, the ADXL278 is the only micromachined accelerometer

to have a fully differential signal path, including differential

sensors. The differential sensors eliminate most of the power

supply noise before it reaches the demodulator. Good high

frequency supply bypassing, such as a ceramic capacitor close to

the supply pins, also minimizes the amount of interference.

The clock frequency supply response (CFSR) is the ratio of the

response at VOUT to the noise on the power supply near the

accelerometer clock frequency. A CFSR of 3 means that the

signal at VOUT is 3× the amplitude of an excitation signal at VDD

near the accelerometer internal clock frequency. This is

analogous to the power supply response, except that the

stimulus and the response are at different frequencies. The

ADXL278’s CFSR is 10× better than a typical single-ended

accelerometer system.

SIGNAL DISTORTION

Signals from crashes and other events may contain high

amplitude, high frequency components. These components

contain very little useful information and are reduced by the

2-pole Bessel filter at the output of the accelerometer. However,

if the signal saturates at any point, the accelerometer output

does not look like a filtered version of the acceleration signal.

The signal may saturate anywhere before the filter. For example,

if the resonant frequency of the sensor is low, the displacement

per unit acceleration is high. The sensor may reach the

mechanical limit of travel if the applied acceleration is high

enough. This can be remedied by locating the accelerometer

where it does not see high values of acceleration and by using a

higher resonant frequency sensor, such as the ADXL278.

Also, the electronics may saturate in an overload condition

between the sensor output and the filter input. Ensuring that

internal circuit nodes operate linearly to at least several times

the full-scale acceleration value can minimize electrical

saturation. The ADXL278 circuit is linear to approximately 8×

full scale.

Rev. B | Page 8 of 12

�ADXL278

OUTLINE DIMENSIONS

0.087

0.078

0.069

0.020

0.015

0.010

(R 4 PLCS)

7

0.180

0.177 SQ

0.174

0.028

0.020 DIA

0.012

1

0.106

0.100

0.094

0.075 REF

R 0.008

(8 PLCS)

0.008

0.006

0.004

TOP VIEW

R 0.008

(4 PLCS)

0.054

0.050

0.046

(PLATING OPTION 1,

SEE DETAIL A

FOR OPTION 2)

5

3

BOTTOM VIEW

0.077

0.070

0.063

0.019 SQ

DETAIL A

(OPTION 2)

05-21-2010-D

0.203

0.197 SQ

0.193

0.030

0.025

0.020

Figure 6. 8-Lead Ceramic Leadless Chip Carrier [LCC]

(E-8-1)

Dimensions shown in inches

ADXL278 ORDERING GUIDE

Model1, 2, 3

AD22284-A-R2

AD22284-A

ADW22284ZC

ADW22284ZC-RL7

AD22285-R2

AD22285

ADW22285ZC

ADW22285ZC-RL7

AD22286-R2

AD22286

ADW22286ZC

ADW22286ZC-RL7

1

2

3

Parts

per Reel

250

3,000

3,000

250

250

3,000

3,000

250

250

3,000

3,000

250

Measurement

Range

±35 g/±35 g

±35 g/±35 g

±35 g/±35 g

±35 g/±35 g

±50 g/±50 g

±50 g/±50 g

±50 g/±50 g

±50 g/±50 g

±70 g/±35 g

±70 g/±35 g

±70 g/±35 g

±70 g/±35 g

Specified

Voltage (V)

5

5

5

5

5

5

5

5

5

5

5

5

Temperature

Range

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

−40°C to +105°C

Package Description

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

8-Lead Ceramic Leadless Chip Carrier

Package

Option

E-8-1

E-8-1

E-8-1

E-8-1

E-8-1

E-8-1

E-8-1

E-8-1

E-8-1

E-8-1

E-8-1

E-8-1

All models are on tape and reel and are RoHS compliant parts.

Z = RoHS Compliant Part.

W = Qualified for Automotive Applications.

AUTOMOTIVE PRODUCTS

The ADW22284, ADW22285, and ADW22286 models are available with controlled manufacturing to support the quality and reliability

requirements of automotive applications. Note that these automotive models may have specifications that differ from the commercial

models; therefore, designers should review the Specifications section of this data sheet carefully. Only the automotive grade products

shown are available for use in automotive applications. Contact your local Analog Devices account representative for specific product

ordering information and to obtain the specific Automotive Reliability reports for these models.

Rev. B | Page 9 of 12

�ADXL278

NOTES

Rev. B | Page 10 of 12

�ADXL278

NOTES

Rev. B | Page 11 of 12

�ADXL278

NOTES

©2010 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D05365-0-8/10(B)

Rev. B | Page 12 of 12

�