Poly Phase Multifunction Energy Metering

IC with Per Phase Information

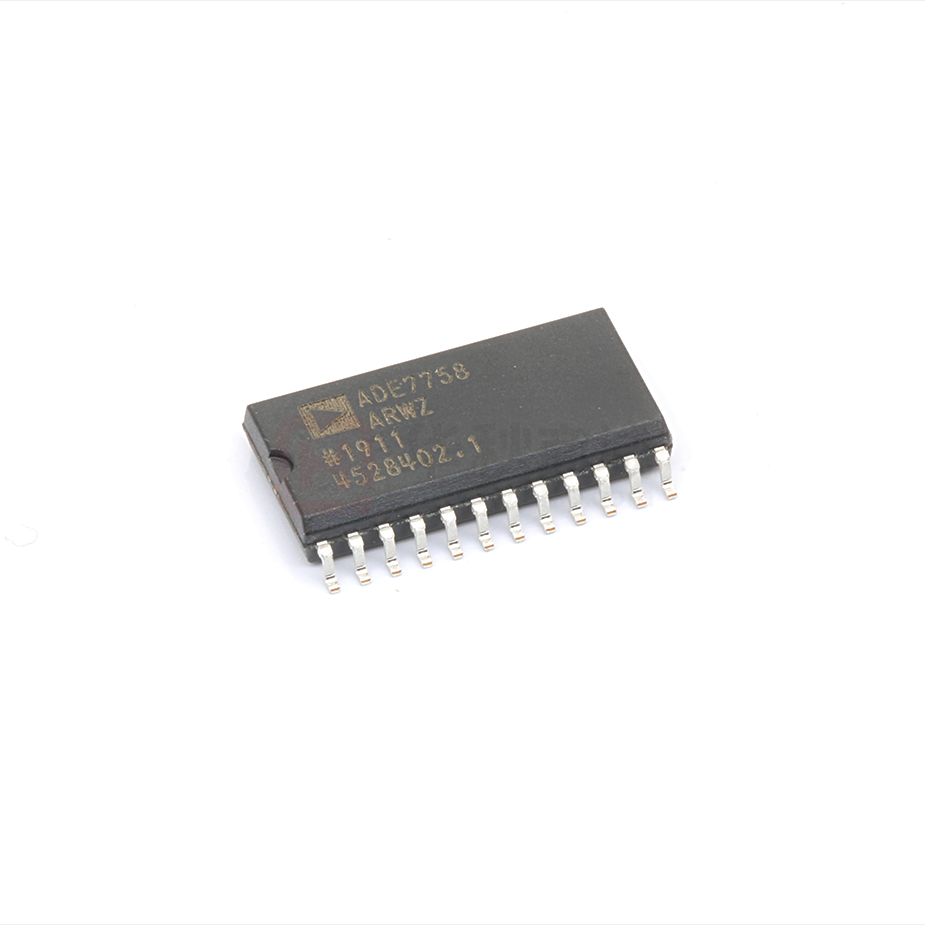

ADE7758

Data Sheet

FEATURES

Proprietary ADCs and DSP provide high accuracy over large

variations in environmental conditions and time

Reference 2.4 V (drift 30 ppm/°C typical) with external

overdrive capability

Single 5 V supply, low power (70 mW typical)

Highly accurate; supports IEC 60687, IEC 61036, IEC 61268,

IEC 62053-21, IEC 62053-22, and IEC 62053-23

Compatible with 3-phase/3-wire, 3-phase/4-wire, and other

3-phase services

Less than 0.1% active energy error over a dynamic range of

1000 to 1 at 25°C

Supplies active/reactive/apparent energy, voltage rms,

current rms, and sampled waveform data

Two pulse outputs, one for active power and the other

selectable between reactive and apparent power with

programmable frequency

Digital power, phase, and rms offset calibration

On-chip, user-programmable thresholds for line voltage SAG

and overvoltage detections

An on-chip, digital integrator enables direct interface-tocurrent sensors with di/dt output

A PGA in the current channel allows direct interface to

current transformers

An SPI®-compatible serial interface with IRQ

GENERAL DESCRIPTION

The ADE7758 is a high accuracy, 3-phase electrical energy

measurement IC with a serial interface and two pulse outputs.

The ADE7758 incorporates second-order Σ-Δ ADCs, a digital

integrator, reference circuitry, a temperature sensor, and all the

signal processing required to perform active, reactive, and

apparent energy measurement and rms calculations.

The ADE7758 is suitable to measure active, reactive, and

apparent energy in various 3-phase configurations, such as

WYE or DELTA services, with both three and four wires. The

ADE7758 provides system calibration features for each phase,

that is, rms offset correction, phase calibration, and power

calibration. The APCF logic output gives active power

information, and the VARCF logic output provides instantaneous

reactive or apparent power information.

FUNCTIONAL BLOCK DIAGRAM

4

12

PGA1

+

IAN

6

–

VAP

AVRMSGAIN[11:0]

7

PGA1

+

IBN

8

–

VBP

15

ICP

ICN

VCP

VN

9

10

14

13

dt

HPF

ADC

REACTIVE OR

APPARENT POWER

INTEGRATOR

DFC

ADC

ADC

PGA2

+

–

ADC

÷

17

VARCF

1

APCF

3

DVDD

2

DGND

19

CLKIN

20

CLKOUT

LPF2

VARCFDEN[ 11:0]

AVARG[11:0]

Φ

PHASE B

AND

PHASE C

DATA

AWATTOS[11:0]

ACTIVE/REACTIVE/AP PARENT ENERGIES

AND VOLTAGE/CURRENT RMS CALCUL ATION

FOR PHASE B

(SEE PHASE A FOR DETAILED SIGNAL PATH)

AWG[11:0]

ACTIVE POWER

APCFNUM[11:0]

%

VADIV[7:0]

%

VARDIV[7:0]

DFC

%

WDIV[7:0]

–

VARCFNUM[ 11:0]

AIRMSOS[11:0]

LPF2

ADC

–

90° PHASE

SHIFTING FILTER

π

2

AVAROS[11:0]

APHCAL[6:0]

PGA2

+

PGA1

+

AVRMSOS[11:0]

X2

ADC

–

IBP

AVAG[11:0]

LPF

PGA2

+

16

ADE7758

4kΩ

2.4V

REF

5

11

| X|

POWER

SUPPLY

MONITOR

IAP

AGND

ACTIVE/REACTIVE/AP PARENT ENERGIES

AND VOLTAGE/CURRENT RMS CALCUL ATION

FOR PHASE C

(SEE PHASE A FOR DETAILED SIGNAL PATH)

÷

APCFDEN[ 11:0]

ADE7758 REGISTERS AND

SERIAL INTERFACE

22

24

23

21

18

DIN

DOUT

SCLK

CS

IRQ

04443-001

REFIN/OUT

AVDD

Figure 1.

Rev. E

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Fax: 781.461.3113 ©2004–2011 Analog Devices, Inc. All rights reserved.

�ADE7758

Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Temperature Measurement ....................................................... 27

General Description ......................................................................... 1

Root Mean Square Measurement............................................. 28

Functional Block Diagram .............................................................. 1

Active Power Calculation .......................................................... 30

General Description ......................................................................... 4

Reactive Power Calculation ...................................................... 35

Specifications..................................................................................... 5

Apparent Power Calculation..................................................... 39

Timing Characteristics ................................................................ 6

Energy Registers Scaling ........................................................... 41

Timing Diagrams.............................................................................. 7

Waveform Sampling Mode ....................................................... 41

Absolute Maximum Ratings............................................................ 8

Calibration................................................................................... 42

ESD Caution.................................................................................. 8

Checksum Register..................................................................... 55

Pin Configuration and Function Descriptions............................. 9

Interrupts..................................................................................... 55

Terminology .................................................................................... 11

Using the Interrupts with an MCU.......................................... 56

Typical Performance Characteristics ........................................... 12

Interrupt Timing ........................................................................ 56

Test Circuits..................................................................................... 17

Serial Interface ............................................................................ 56

Theory of Operation ...................................................................... 18

Serial Write Operation............................................................... 57

Antialiasing Filter ....................................................................... 18

Serial Read Operation................................................................ 59

Analog Inputs.............................................................................. 18

Accessing the On-Chip Registers............................................. 59

Current Channel ADC............................................................... 19

Registers........................................................................................... 60

di/dt Current Sensor and Digital Integrator............................... 20

Communications Register......................................................... 60

Peak Current Detection ............................................................. 21

Operational Mode Register (0x13) .......................................... 64

Overcurrent Detection Interrupt ............................................. 21

Measurement Mode Register (0x14) ....................................... 64

Voltage Channel ADC ............................................................... 22

Waveform Mode Register (0x15) ............................................. 65

Zero-Crossing Detection........................................................... 23

Computational Mode Register (0x16)..................................... 66

Phase Compensation.................................................................. 23

Line Cycle Accumulation Mode Register (0x17) ................... 67

Period Measurement .................................................................. 25

Interrupt Mask Register (0x18) ................................................ 68

Line Voltage SAG Detection ..................................................... 25

Interrupt Status Register (0x19)/Reset Interrupt Status

Register (0x1A)........................................................................... 69

SAG Level Set.............................................................................. 26

Peak Voltage Detection.............................................................. 26

Phase Sequence Detection......................................................... 26

Outline Dimensions ....................................................................... 70

Ordering Guide .......................................................................... 70

Power-Supply Monitor............................................................... 27

Reference Circuit ........................................................................ 27

Revision History

10/11—Rev. D to Rev. E

Changes to Figure 1.......................................................................... 1

Changes to Figure 41...................................................................... 19

Changes to Figure 60...................................................................... 27

Added Figure 61; Renumbered Sequentially .............................. 27

Changes to Phase Sequence Detection Section .......................... 27

Changes to Power-Supply Monitor Section ................................ 27

Changes to Figure 62...................................................................... 28

Changes to Figure 67...................................................................... 32

Changes to Figure 68...................................................................... 32

Changes to Equation 25................................................................. 34

Changes to Figure 69...................................................................... 34

Changes to Table 17 ....................................................................... 62

Change to Table 18 ......................................................................... 64

Changes to Table 24 ....................................................................... 69

Changes to Ordering Guide .......................................................... 70

10/08—Rev. C to Rev. D

Changes to Figure 1...........................................................................1

Changes to Phase Sequence Detection Section and Figure 60. 27

Rev. E | Page 2 of 72

�Data Sheet

ADE7758

Changes to Current RMS Calculation Section............................28

Changes to Voltage Channel RMS Calculation Section and

Figure 63 ...........................................................................................29

Changes to Table 17 ........................................................................60

Changes to Ordering Guide...........................................................70

7/06—Rev. B to Rev. C

Updated Format.................................................................. Universal

Changes to Figure 1...........................................................................1

Changes to Table 2 ............................................................................6

Changes to Table 4 ............................................................................9

Changes to Figure 34 and Figure 35 .............................................17

Changes to Current Waveform Gain Registers Section and

Current Channel Sampling Section ..............................................19

Changes to Voltage Channel Sampling Section ..........................22

Changes to Zero-Crossing Timeout Section ...............................23

Changes to Figure 60 ......................................................................27

Changes to Current RMS Calculation Section............................28

Changes to Current RMS Offset Compensation Section and

Voltage Channel RMS Calculation Section .................................29

Added Table 7 and Table 9; Renumbered Sequentially..............29

Changes to Figure 65 ......................................................................30

Changes to Active Power Offset Calibration Section.................31

Changes to Reactive Power Frequency Output Section.............38

Changes to Apparent Power Frequency Output Section and

Waveform Sampling Mode Section ..............................................41

Changes to Gain Calibration Using Line

Accumulation Section ....................................................................49

Changes to Example: Power Offset Calibration Using Line

Accumulation Section ....................................................................53

Changes to Calibration of IRMS and VRMS Offset Section.....54

Changes to Table 18 ........................................................................64

Changes to Table 20 ........................................................................65

11/05—Rev. A to Rev. B

Changes to Table 1 ............................................................................5

Changes to Figure 23 Caption .......................................................14

Changes to Current Waveform Gain Registers Section .............19

Changes to di/dt Current Sensor and Digital

Integrator Section............................................................................20

Changes to Phase Compensation Section....................................23

Changes to Figure 57 ......................................................................25

Changes to Figure 60 ......................................................................27

Changes to Temperature Measurement Section

and Root Mean Square Measurement Section ............................28

Inserted Table 6................................................................................28

Changes to Current RMS Offset Compensation Section ..........29

Inserted Table 7................................................................................29

Added Equation 17 .........................................................................31

Changes to Energy Accumulation Mode Section.......................33

Changes to the Reactive Power Calculation Section..................35

Added Equation 32...........................................................................36

Changes to Energy Accumulation Mode Section.......................38

Changes to the Reactive Power Frequency Output Section ......38

Changes to the Apparent Energy Calculation Section...............40

Changes to the Calibration Section ..............................................42

Changes to Figure 76 through Figure 84............................... 43–54

Changes to Table 15 ........................................................................59

Changes to Table 16 ........................................................................63

Changes to Ordering Guide...........................................................69

9/04—Rev. 0 to Rev. A

Changed Hexadecimal Notation...................................... Universal

Changes to Features List...................................................................1

Changes to Specifications Table ......................................................5

Change to Figure 25........................................................................16

Additions to the Analog Inputs Section.......................................19

Added Figures 36 and 37; Renumbered Subsequent Figures....19

Changes to Period Measurement Section ....................................26

Change to Peak Voltage Detection Section .................................26

Added Figure 60 ..............................................................................27

Change to the Current RMS Offset Compensation Section .....29

Edits to Active Power Frequency Output Section ......................33

Added Figure 68; Renumbered Subsequent Figures ..................33

Changes to Reactive Power Frequency Output Section.............37

Added Figure 73; Renumbered Subsequent Figures ..................38

Change to Gain Calibration Using Pulse Output Example .......44

Changes to Equation 37 .................................................................45

Changes to Example—Phase Calibration of Phase A

Using Pulse Output.........................................................................45

Changes to Equations 56 and 57 ...................................................53

Addition to the ADE7758 Interrupts Section .............................54

Changes to Example-Calibration of RMS Offsets ......................54

Addition to Table 20 .......................................................................66

1/04—Revision 0: Initial Version

Rev. E | Page 3 of 72

�ADE7758

Data Sheet

GENERAL DESCRIPTION

The ADE7758 has a waveform sample register that allows access

to the ADC outputs. The part also incorporates a detection

circuit for short duration low or high voltage variations. The

voltage threshold levels and the duration (number of half-line

cycles) of the variation are user programmable. A zero-crossing

detection is synchronized with the zero-crossing point of the

line voltage of any of the three phases. This information can be

used to measure the period of any one of the three voltage

inputs. The zero-crossing detection is used inside the chip for

the line cycle energy accumulation mode. This mode permits

faster and more accurate calibration by synchronizing the

energy accumulation with an integer number of line cycles.

Data is read from the ADE7758 via the SPI serial interface. The

interrupt request output (IRQ) is an open-drain, active low logic

output. The IRQ output goes active low when one or more

interrupt events have occurred in the ADE7758. A status register

indicates the nature of the interrupt. The ADE7758 is available

in a 24-lead SOIC package.

Rev. E | Page 4 of 72

�Data Sheet

ADE7758

SPECIFICATIONS

AVDD = DVDD = 5 V ± 5%, AGND = DGND = 0 V, on-chip reference, CLKIN = 10 MHz XTAL, TMIN to TMAX = −40°C to +85°C.

Table 1.

Parameter 1, 2

ACCURACY

Active Energy Measurement Error

(per Phase)

Phase Error Between Channels

PF = 0.8 Capacitive

PF = 0.5 Inductive

AC Power Supply Rejection

Output Frequency Variation

DC Power Supply Rejection

Output Frequency Variation

Active Energy Measurement Bandwidth

IRMS Measurement Error

IRMS Measurement Bandwidth

VRMS Measurement Error

VRMS Measurement Bandwidth

ANALOG INPUTS

Maximum Signal Levels

Input Impedance (DC)

ADC Offset Error 3

Gain Error3

WAVEFORM SAMPLING

Current Channels

Signal-to-Noise Plus Distortion

Bandwidth (−3 dB)

Voltage Channels

Signal-to-Noise Plus Distortion

Bandwidth (−3 dB)

REFERENCE INPUT

REFIN/OUT Input Voltage Range

Input Capacitance

ON-CHIP REFERENCE

Reference Error

Current Source

Output Impedance

Temperature Coefficient

CLKIN

Input Clock Frequency

LOGIC INPUTS

DIN, SCLK, CLKIN, and CS

Input High Voltage, VINH

Input Low Voltage, VINL

Input Current, IIN

Input Capacitance, CIN

Specification

Unit

Test Conditions/Comments

0.1

% typ

Over a dynamic range of 1000 to 1

±0.05

±0.05

°max

°max

0.01

% typ

0.01

14

0.5

14

0.5

260

% typ

kHz

% typ

kHz

% typ

Hz

±500

380

±30

±6

mV max

kΩ min

mV max

% typ

62

14

dB typ

kHz

62

260

dB typ

Hz

2.6

2.2

10

V max

V min

pF max

Line frequency = 45 Hz to 65 Hz, HPF on

Phase lead 37°

Phase lag 60°

AVDD = DVDD = 5 V + 175 mV rms/120 Hz

V1P = V2P = V3P = 100 mV rms

AVDD = DVDD = 5 V ± 250 mV dc

V1P = V2P = V3P = 100 mV rms

Over a dynamic range of 500:1

Over a dynamic range of 20:1

See the Analog Inputs section

Differential input

Uncalibrated error, see the Terminology section

External 2.5 V reference

Sampling CLKIN/128, 10 MHz/128 = 78.1 kSPS

See the Current Channel ADC section

See the Voltage Channel ADC section

2.4 V + 8%

2.4 V − 8%

Nominal 2.4 V at REFIN/OUT pin

±200

6

4

30

mV max

μA max

kΩ min

ppm/°C typ

15

5

MHz max

MHz min

2.4

0.8

±3

10

V min

V max

μA max

pF max

All specifications CLKIN of 10 MHz

Rev. E | Page 5 of 72

DVDD = 5 V ± 5%

DVDD = 5 V ± 5%

Typical 10 nA, VIN = 0 V to DVDD

�ADE7758

Data Sheet

Parameter 1, 2

LOGIC OUTPUTS

IRQ, DOUT, and CLKOUT

Output High Voltage, VOH

Output Low Voltage, VOL

APCF and VARCF

Output High Voltage, VOH

Output Low Voltage, VOL

POWER SUPPLY

AVDD

DVDD

AIDD

DIDD

Specification

Unit

4

0.4

V min

V max

4

1

V min

V max

4.75

5.25

4.75

5.25

8

13

V min

V max

V min

V max

mA max

mA max

Test Conditions/Comments

DVDD = 5 V ± 5%

IRQ is open-drain, 10 kΩ pull-up resistor

ISOURCE = 5 mA

ISINK = 1 mA

ISOURCE = 8 mA

ISINK = 5 mA

For specified performance

5 V − 5%

5 V + 5%

5 V − 5%

5 V + 5%

Typically 5 mA

Typically 9 mA

1

See the Typical Performance Characteristics.

See the Terminology section for a definition of the parameters.

3

See the Analog Inputs section.

2

TIMING CHARACTERISTICS

AVDD = DVDD = 5 V ± 5%, AGND = DGND = 0 V, on-chip reference, CLKIN = 10 MHz XTAL, TMIN to TMAX = −40°C to +85°C.

Table 2.

Parameter 1, 2

WRITE TIMING

t1

t2

t3

t4

t5

t6

t7

t8

READ TIMING

t9 3

t10

t11 4

t12 5

t135

Specification

Unit

Test Conditions/Comments

50

50

50

10

5

1200

400

100

ns (min)

ns (min)

ns (min)

ns (min)

ns (min)

ns (min)

ns (min)

ns (min)

CS falling edge to first SCLK falling edge

SCLK logic high pulse width

SCLK logic low pulse width

Valid data setup time before falling edge of SCLK

Data hold time after SCLK falling edge

Minimum time between the end of data byte transfers

Minimum time between byte transfers during a serial write

CS hold time after SCLK falling edge

4

μs (min)

50

30

100

10

100

10

ns (min)

ns (min)

ns (max)

ns (min)

ns (max)

ns (min)

Minimum time between read command (that is, a write to communication register) and

data read

Minimum time between data byte transfers during a multibyte read

Data access time after SCLK rising edge following a write to the communications register

Bus relinquish time after falling edge of SCLK

Bus relinquish time after rising edge of CS

1

Sample tested during initial release and after any redesign or process change that may affect this parameter. All input signals are specified with tr = tf = 5 ns (10% to

90%) and timed from a voltage level of 1.6 V.

See the timing diagrams in Figure 3 and Figure 4 and the Serial Interface section.

3

Minimum time between read command and data read for all registers except waveform register, which is t9 = 500 ns min.

4

Measured with the load circuit in Figure 2 and defined as the time required for the output to cross 0.8 V or 2.4 V.

5

Derived from the measured time taken by the data outputs to change 0.5 V when loaded with the circuit in Figure 2. The measured number is then extrapolated back

to remove the effects of charging or discharging the 50 pF capacitor. This means that the time quoted here is the true bus relinquish time of the part and is

independent of the bus loading.

2

Rev. E | Page 6 of 72

�Data Sheet

ADE7758

TIMING DIAGRAMS

200µA

2.1V

CL

50pF

1.6mA

IOH

04443-002

TO OUTPUT

PIN

IOL

Figure 2. Load Circuit for Timing Specifications

t8

CS

t6

t3

SCLK

t4

t2

A6

1

DIN

A5

t7

t7

A4

t5

A3

A2

A1

DB7

A0

MOST SIGNIFICANT BYTE

COMMAND BYTE

DB0

DB7

DB0

LEAST SIGNIFICANT BYTE

04443-003

t1

Figure 3. Serial Write Timing

CS

t1

t13

t9

SCLK

0

A6

A5

A4

A3

A2

A1

A0

t12

t11

DOUT

DB7

COMMAND BYTE

DB0

MOST SIGNIFICANT BYTE

Figure 4. Serial Read Timing

Rev. E | Page 7 of 72

DB7

DB0

LEAST SIGNIFICANT BYTE

04443-004

DIN

t10

�ADE7758

Data Sheet

ABSOLUTE MAXIMUM RATINGS

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

TA = 25°C, unless otherwise noted.

Table 3.

Parameter

AVDD to AGND

DVDD to DGND

DVDD to AVDD

Analog Input Voltage to AGND,

IAP, IAN, IBP, IBN, ICP, ICN, VAP,

VBP, VCP, VN

Reference Input Voltage to AGND

Digital Input Voltage to DGND

Digital Output Voltage to DGND

Operating Temperature

Industrial Range

Storage Temperature Range

Junction Temperature

24-Lead SOIC, Power Dissipation

θJA Thermal Impedance

Lead Temperature, Soldering

Vapor Phase (60 sec)

Infrared (15 sec)

Rating

–0.3 V to +7 V

–0.3 V to +7 V

–0.3 V to +0.3 V

–6 V to +6 V

ESD CAUTION

–0.3 V to AVDD + 0.3 V

–0.3 V to DVDD + 0.3 V

–0.3 V to DVDD + 0.3 V

–40°C to +85°C

–65°C to +150°C

150°C

88 mW

53°C/W

215°C

220°C

Rev. E | Page 8 of 72

�Data Sheet

ADE7758

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

APCF 1

24

DOUT

DGND 2

23

SCLK

DVDD 3

22

DIN

AVDD 4

21

CS

IAP 5

ADE7758

CLKOUT

TOP VIEW

19 CLKIN

(Not to Scale)

IBP 7

18 IRQ

20

IBN 8

17

VARCF

ICP 9

16

VAP

ICN 10

15

VBP

AGND 11

14

VCP

REFIN/OUT 12

13

VN

04443-005

IAN 6

Figure 5. Pin Configuration

Table 4. Pin Function Descriptions

Pin

No.

1

Mnemonic

APCF

2

DGND

3

DVDD

4

AVDD

5, 6,

7, 8,

9, 10

IAP, IAN,

IBP, IBN,

ICP, ICN

11

AGND

12

REFIN/OUT

13, 14,

15, 16

VN, VCP,

VBP, VAP

Description

Active Power Calibration Frequency (APCF) Logic Output. It provides active power information. This output

is used for operational and calibration purposes. The full-scale output frequency can be scaled by writing to

the APCFNUM and APCFDEN registers (see the Active Power Frequency Output section).

This provides the ground reference for the digital circuitry in the ADE7758, that is, the multiplier, filters, and

digital-to-frequency converter. Because the digital return currents in the ADE7758 are small, it is acceptable to

connect this pin to the analog ground plane of the whole system. However, high bus capacitance on the DOUT

pin can result in noisy digital current that could affect performance.

Digital Power Supply. This pin provides the supply voltage for the digital circuitry in the ADE7758. The supply

voltage should be maintained at 5 V ± 5% for specified operation. This pin should be decoupled to DGND with

a 10 μF capacitor in parallel with a ceramic 100 nF capacitor.

Analog Power Supply. This pin provides the supply voltage for the analog circuitry in the ADE7758. The supply

should be maintained at 5 V ± 5% for specified operation. Every effort should be made to minimize power

supply ripple and noise at this pin by the use of proper decoupling. The Typical Performance Characteristics

show the power supply rejection performance. This pin should be decoupled to AGND with a 10 μF capacitor

in parallel with a ceramic 100 nF capacitor.

Analog Inputs for Current Channel. This channel is used with the current transducer and is referenced in this

document as the current channel. These inputs are fully differential voltage inputs with maximum differential

input signal levels of ±0.5 V, ±0.25 V, and ±0.125 V, depending on the gain selections of the internal PGA (see

the Analog Inputs section). All inputs have internal ESD protection circuitry. In addition, an overvoltage

of ±6 V can be sustained on these inputs without risk of permanent damage.

This pin provides the ground reference for the analog circuitry in the ADE7758, that is, ADCs, temperature sensor,

and reference. This pin should be tied to the analog ground plane or the quietest ground reference in the system.

This quiet ground reference should be used for all analog circuitry, for example, antialiasing filters, current, and

voltage transducers. To keep ground noise around the ADE7758 to a minimum, the quiet ground plane should be

connected to the digital ground plane at only one point. It is acceptable to place the entire device on the analog

ground plane.

This pin provides access to the on-chip voltage reference. The on-chip reference has a nominal value of

2.4 V ± 8% and a typical temperature coefficient of 30 ppm/°C. An external reference source can also be

connected at this pin. In either case, this pin should be decoupled to AGND with a 1 μF ceramic capacitor.

Analog Inputs for the Voltage Channel. This channel is used with the voltage transducer and is referenced as

the voltage channels in this document. These inputs are single-ended voltage inputs with the maximum signal

level of ±0.5 V with respect to VN for specified operation. These inputs are voltage inputs with maximum input

signal levels of ±0.5 V, ±0.25 V, and ±0.125 V, depending on the gain selections of the internal PGA (see the

Analog Inputs section). All inputs have internal ESD protection circuitry, and in addition, an overvoltage of

±6 V can be sustained on these inputs without risk of permanent damage.

Rev. E | Page 9 of 72

�ADE7758

Pin

No.

17

Mnemonic

VARCF

18

IRQ

19

CLKIN

20

CLKOUT

21

CS

22

DIN

23

SCLK

24

DOUT

Data Sheet

Description

Reactive Power Calibration Frequency Logic Output. It gives reactive power or apparent power information

depending on the setting of the VACF bit of the WAVMODE register. This output is used for operational and

calibration purposes. The full-scale output frequency can be scaled by writing to the VARCFNUM and VARCFDEN

registers (see the Reactive Power Frequency Output section).

Interrupt Request Output. This is an active low open-drain logic output. Maskable interrupts include: an active

energy register at half level, an apparent energy register at half level, and waveform sampling up to 26 kSPS (see

the Interrupts section).

Master Clock for ADCs and Digital Signal Processing. An external clock can be provided at this logic input.

Alternatively, a parallel resonant AT crystal can be connected across CLKIN and CLKOUT to provide a clock

source for the ADE7758. The clock frequency for specified operation is 10 MHz. Ceramic load capacitors of

a few tens of picofarad should be used with the gate oscillator circuit. Refer to the crystal manufacturer’s

data sheet for the load capacitance requirements

A crystal can be connected across this pin and CLKIN as previously described to provide a clock source for

the ADE7758. The CLKOUT pin can drive one CMOS load when either an external clock is supplied at CLKIN or

a crystal is being used.

Chip Select. Part of the 4-wire serial interface. This active low logic input allows the ADE7758 to share the serial

bus with several other devices (see the Serial Interface section).

Data Input for the Serial Interface. Data is shifted in at this pin on the falling edge of SCLK (see the Serial Interface

section).

Serial Clock Input for the Synchronous Serial Interface. All serial data transfers are synchronized to this clock

(see the Serial Interface section). The SCLK has a Schmidt-trigger input for use with a clock source that has a slow

edge transition time, for example, opto-isolator outputs.

Data Output for the Serial Interface. Data is shifted out at this pin on the rising edge of SCLK. This logic output

is normally in a high impedance state, unless it is driving data onto the serial data bus (see the Serial Interface

section).

Rev. E | Page 10 of 72

�Data Sheet

ADE7758

TERMINOLOGY

Measurement Error

The error associated with the energy measurement made by the

ADE7758 is defined by

Measuremen t Error =

Energy Registered by ADE7758 – True Energy

True Energy

× 100%

(1)

Phase Error Between Channels

The high-pass filter (HPF) and digital integrator introduce a

slight phase mismatch between the current and the voltage

channel. The all-digital design ensures that the phase matching

between the current channels and voltage channels in all three

phases is within ±0.1° over a range of 45 Hz to 65 Hz and ±0.2°

over a range of 40 Hz to 1 kHz. This internal phase mismatch

can be combined with the external phase error (from current

sensor or component tolerance) and calibrated with the phase

calibration registers.

Power Supply Rejection (PSR)

This quantifies the ADE7758 measurement error as a

percentage of reading when the power supplies are varied. For

the ac PSR measurement, a reading at nominal supplies (5 V) is

taken. A second reading is obtained with the same input signal

levels when an ac signal (175 mV rms/100 Hz) is introduced

onto the supplies. Any error introduced by this ac signal is

expressed as a percentage of reading—see the Measurement

Error definition.

For the dc PSR measurement, a reading at nominal supplies

(5 V) is taken. A second reading is obtained with the same input

signal levels when the power supplies are varied ±5%. Any error

introduced is again expressed as a percentage of the reading.

ADC Offset Error

This refers to the dc offset associated with the analog inputs to

the ADCs. It means that with the analog inputs connected to

AGND that the ADCs still see a dc analog input signal. The

magnitude of the offset depends on the gain and input range

selection (see the Typical Performance Characteristics section).

However, when HPFs are switched on, the offset is removed

from the current channels and the power calculation is not

affected by this offset.

Gain Error

The gain error in the ADCs of the ADE7758 is defined as the

difference between the measured ADC output code (minus the

offset) and the ideal output code (see the Current Channel ADC

section and the Voltage Channel ADC section). The difference

is expressed as a percentage of the ideal code.

Gain Error Match

The gain error match is defined as the gain error (minus the

offset) obtained when switching between a gain of 1, 2, or 4. It is

expressed as a percentage of the output ADC code obtained

under a gain of 1.

Rev. E | Page 11 of 72

�ADE7758

Data Sheet

TYPICAL PERFORMANCE CHARACTERISTICS

0.5

0.20

PF = 1

0.4

0.15

0.3

PERCENT ERROR (%)

PERCENT ERROR (%)

0.10

0.2

0.1

+25°C

0

–40°C

–0.1

–0.2

PF = +0.5, –40°C

0.05

PF = –0.5, +25°C

0

–0.05

PF = +0.5, +85°C

PF = +0.5, +25°C

–0.10

–0.4

–0.5

0.01

–0.15

04443-006

+85°C

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

04443-009

–0.3

–0.20

0.01

100

Figure 6. Active Energy Error as a Percentage of Reading (Gain = +1) over

Temperature with Internal Reference and Integrator Off

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

100

Figure 9. Active Energy Error as a Percentage of Reading (Gain = +1) over

Temperature with External Reference and Integrator Off

0.3

0.6

0.5

PF = +0.5, +25°C

PF = +1, +25°C

0

–0.1

PF = –0.5, +25°C

PF = +0.5, +85°C

–0.2

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

0.2

0.1

0

PF = 0.5

–0.1

–0.2

PF = +0.5, –40°C

–0.3

0.01

PF = 1

0.3

04443-010

0.1

PERCENT ERROR (%)

WITH RESPECT TO 55Hz

0.4

04443-007

PERCENT ERROR (%)

0.2

–0.3

–0.4

45

100

Figure 7. Active Energy Error as a Percentage of Reading (Gain = +1) over

Power Factor with Internal Reference and Integrator Off

47

49

51

53

55

57

59

LINE FREQUENCY (Hz)

61

63

65

Figure 10. Active Energy Error as a Percentage of Reading (Gain = +1) over

Frequency with Internal Reference and Integrator Off

0.3

0.10

PF = 1

PF = 1

0.08

0.2

PERCENT ERROR (%)

WITH RESPECT TO 5V; 3A

GAIN = +4

0

–0.1

GAIN = +1

GAIN = +2

VDD = 5.25V

0.02

0

–0.02

VDD = 5V

–0.04

VDD = 4.75V

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

–0.08

–0.10

0.01

100

Figure 8. Active Energy Error as a Percentage of Reading over

Gain with Internal Reference and Integrator Off

04443-011

–0.3

0.01

0.04

–0.06

–0.2

04443-008

PERCENT ERROR (%)

0.06

0.1

0.1

1

10

100

PERCENT FULL-SCALE CURRENT (%)

Figure 11. Active Energy Error as a Percentage of Reading (Gain = +1) over

Power Supply with Internal Reference and Integrator Off

Rev. E | Page 12 of 72

�Data Sheet

ADE7758

0.3

0.25

PF = 1

0.20

0.2

0.15

PERCENT ERROR (%)

ALL PHASES

0.05

0

–0.05

PHASE B

–0.10

PHASE C

–0.15

PF = 0, +85°C

0

–0.1

PF = 0, +25°C

PF = 0, –40°C

04443-012

–0.2

–0.20

–0.25

0.01

0.1

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

04443-015

PERCENT ERROR (%)

PHASE A

0.10

–0.3

0.01

100

Figure 12. APCF Error as a Percentage of Reading (Gain = +1)

with Internal Reference and Integrator Off

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

Figure 15. Reactive Energy Error as a Percentage of Reading (Gain = +1) over

Temperature with External Reference and Integrator Off

0.4

0.3

PF = +0.866, –40°C

0.3

0.2

PF = –0.866, +25°C

PERCENT ERROR (%)

0.1

PF = 0, +25°C

0

PF = 0, –40°C

–0.1

–0.2

0

PF = +0.866, +85°C

PF = +0.866, +25°C

–0.2

04443-013

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

–0.3

0.01

100

Figure 13. Reactive Energy Error as a Percentage of Reading (Gain = +1) over

Temperature with Internal Reference and Integrator Off

0.8

0.6

0.6

PERCENT ERROR (%)

WITH RESPECT TO 55Hz

0.4

PF = 0, +25°C

PF = –0.866, +25°C

0

–0.2

PF = +0.866, –40°C

PF = +0.866, +25°C

–0.4

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

100

Figure 16. Reactive Energy Error as a Percentage of Reading (Gain = +1) over

Power Factor with External Reference and Integrator Off

0.8

0.2

PF = 0, +25°C

–0.1

PF = 0, +85°C

–0.3

PERCENT ERROR (%)

0.1

04443-016

PERCENT ERROR (%)

0.2

–0.4

0.01

100

0.4

PF = 0

0.2

0

–0.2

PF = 0.866

–0.4

PF = +0.866, +85°C

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

–0.8

45

100

Figure 14. Reactive Energy Error as a Percentage of Reading (Gain = +1) over

Power Factor with Internal Reference and Integrator Off

04443-017

–0.8

0.01

–0.6

04443-014

–0.6

47

49

51

53

55

57

59

LINE FREQUENCY (Hz)

61

63

65

Figure 17. Reactive Energy Error as a Percentage of Reading (Gain = +1) over

Frequency with Internal Reference and Integrator Off

Rev. E | Page 13 of 72

�ADE7758

Data Sheet

0.10

0.3

0.08

0.2

5.25V

0.04

PERCENT ERROR (%)

5V

0.02

0

–0.02

–0.04

0

+25°C

–0.1

4.75V

–0.06

+85°C

–0.10

0.01

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

–0.3

0.01

100

Figure 18. Reactive Energy Error as a Percentage of Reading (Gain = +1) over

Supply with Internal Reference and Integrator Off

04443-021

04443-018

–0.2

–0.08

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

100

Figure 21. Active Energy Error as a Percentage of Reading (Gain = +4) over

Temperature with Internal Reference and Integrator On

0.3

0.5

PF = 0

0.2

0.4

0.3

GAIN = +2

GAIN = +4

PERCENT ERROR (%)

PERCENT ERROR (%)

–40°C

0.1

0.1

0

GAIN = +1

–0.1

0.2

0.1

0

–0.1

04443-019

–0.3

0.01

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

PF = +1, +25°C

–0.2

–0.3

–0.2

PF = +0.5, –40°C

PF = +0.5, +25°C

PF = –0.5, +25°C

PF = +0.5, +85°C

04443-022

PERCENT ERROR (%)

WITH RESPECT TO 5V; 3A

0.06

–0.4

–0.5

0.01

100

Figure 19. Reactive Energy Error as a Percentage of Reading over Gain with

Internal Reference and Integrator Off

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

100

Figure 22. Active Energy Error as a Percentage of Reading (Gain = +4) over

Power Factor with Internal Reference and Integrator On

0.8

0.4

PF = 1

0.6

0.3

PF = –0.866, –40°C

PERCENT ERROR (%)

PHASE C

0

–0.1

–0.2

PHASE B

PHASE A

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

PF = 0, +25°C

0

–0.2

PF = +0.866, +25°C

PF = –0.866, +25°C

–0.4

–0.3

–0.4

0.01

0.2

–0.6

–0.8

0.01

100

Figure 20. VARCF Error as a Percentage of Reading (Gain = +1)

with Internal Reference and Integrator Off

PF = –0.866, +85°C

04443-023

0.1

0.4

ALL PHASES

04443-020

PERCENT ERROR (%)

0.2

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

100

Figure 23. Reactive Energy Error as a Percentage of Reading (Gain = +4) over

Power Factor with Internal Reference and Integrator On

Rev. E | Page 14 of 72

�Data Sheet

ADE7758

0.4

0.8

PF = 0

0.6

0.3

0.4

0.1

0

+25°C

–0.1

–0.2

–0.3

0

–0.2

04443-024

+85°C

–0.5

0.01

–0.6

PF = 1

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

–1.0

–1.2

0.01

100

Figure 24. Reactive Energy Error as a Percentage of Reading (Gain = +4) over

Temperature with Internal Reference and Integrator On

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

100

Figure 27. IRMS Error as a Percentage of Reading (Gain = +1)

with Internal Reference and Integrator Off

0.5

0.8

0.4

0.6

0.3

0.4

PERCENT ERROR (%)

0.2

0.1

PF = 0.5

–0.1

–0.2

PF = 1

51

53

55

57

59

LINE FREQUENCY (Hz)

61

63

PF = +1

–0.2

–0.4

–0.8

04443-025

–0.4

49

PF = –0.5

0

–0.6

–0.3

47

0.2

–1.0

0.1

65

Figure 25. Active Energy Error as a Percentage of Reading (Gain = +4) over

Frequency with Internal Reference and Integrator On

04443-028

0

–0.5

45

PF = 0.5

–0.4

–0.8

–0.4

PERCENT ERROR (%)

0.2

04443-027

–40°C

PERCENT ERROR (%)

PERCENT ERROR (%)

0.2

1

10

PERCENT FULL-SCALE CURRENT (%)

100

Figure 28. IRMS Error as a Percentage of Reading (Gain = +4)

with Internal Reference and Integrator On

1.2

0.4

1.0

0.3

0.8

0.4

PERCENT ERROR (%)

PERCENT ERROR (%)

0.2

0.6

PF = 0

0.2

0

PF = 0.866

–0.2

0.1

0

–0.1

–0.2

–0.4

47

49

51

53

55

57

59

LINE FREQUENCY (Hz)

61

63

–0.4

65

Figure 26. Reactive Energy Error as a Percentage of Reading (Gain = +4) over

Frequency with Internal Reference and Integrator On

Rev. E | Page 15 of 72

04443-029

–0.8

45

–0.3

04443-026

–0.6

1

10

VOLTAGE (V)

100

Figure 29. VRMS Error as a Percentage of Reading (Gain = +1)

with Internal Reference

�ADE7758

Data Sheet

1.5

21

MEAN: 6.5149

SD: 2.816

18

1.0

15

0.5

+25°C

HITS

0

12

9

–0.5

6

+85°C

–1.0

04443-030

3

–1.5

0.01

0.1

1

10

PERCENT FULL-SCALE CURRENT (%)

0

100

Figure 30. Apparent Energy Error as a Percentage of Reading

(Gain = +1) over Temperature with Internal Reference and Integrator Off

04443-032

PERCENT ERROR (%)

–40°C

–2

0

2

4

6

8

CH 1 PhB OFFSET (mV)

10

12

Figure 32. Phase B Channel 1 Offset Distribution

12

MEAN: 5.55393

SD: 3.2985

MEAN: 6.69333

SD: 2.70443

18

10

15

8

HITS

6

9

4

6

0

–4

–2

0

2

4

6

8

CH 1 PhA OFFSET (mV)

10

0

12

04443-033

2

3

04443-031

HITS

12

2

4

6

8

10

CH 1 PhC OFFSET (mV)

12

14

Figure 33. Phase C Channel 1 Offset Distribution

Figure 31. Phase A Channel 1 Offset Distribution

Rev. E | Page 16 of 72

�Data Sheet

ADE7758

TEST CIRCUITS

VDD

CURRENT

10µF

TRANSFORMER

I

100nF

4

RB

3

17

AVDD DVDD VARCF APCF 1

5 IAP

1kΩ

825Ω

PS2501-1

1

4

2

3

33nF

1kΩ

6

TO FREQ.

COUNTER

ADE7758

IAN

22pF

33nF

CLKOUT 20

7 IBP

SAME AS

IAP, IAN

10MHz

8

IBN

CLKIN 19

9

ICP

DOUT 24

10

ICN

SCLK 23

16

VAP

SAME AS VAP

15

VBP

SAME AS VAP

14

VCP

22pF

SAME AS

IAP, IAN

1MΩ

220V

1kΩ

CT TURN RATIO 1800:1

CHANNEL 2 GAIN = +1

IRQ 18

REFIN/OUT 12

VN

13

1kΩ

100nF

AGND DGND

11

10µF

2

33nF

RB

10Ω

5Ω

2.5Ω

1.25Ω

04443-034

CHANNEL 1 GAIN

1

2

4

8

TO SPI BUS

CS 21

DIN 22

33nF

Figure 34. Test Circuit for Integrator Off

VDD

di/dt SENSOR

I

100nF

10µF

4

1kΩ

1kΩ

33nF

33nF

1kΩ

1kΩ

33nF

33nF

3

17

AVDD DVDD VARCF APCF 1

5 IAP

6

825Ω

PS2501-1

4

2

3

TO FREQ.

COUNTER

ADE7758

IAN

1

22pF

CLKOUT 20

7 IBP

SAME AS

IAP, IAN

10MHz

8

IBN

CLKIN 19

9

ICP

DOUT 24

10

ICN

SCLK 23

16

VAP

SAME AS VAP

15

VBP

SAME AS VAP

14

VCP

22pF

1MΩ

220V

1kΩ

CS 21

CHANNEL 1 GAIN = +8

CHANNEL 2 GAIN = +1

1kΩ

TO SPI BUS

DIN 22

33nF

IRQ 18

REFIN/OUT 12

VN

13

AGND DGND

11

100nF

10µF

2

33nF

Figure 35. Test Circuit for Integrator On

Rev. E | Page 17 of 72

04443-035

SAME AS

IAP, IAN

�ADE7758

Data Sheet

THEORY OF OPERATION

V2

This filter prevents aliasing, which is an artifact of all sampled

systems. Input signals with frequency components higher than

half the ADC sampling rate distort the sampled signal at a frequency below half the sampling rate. This happens with all ADCs,

regardless of the architecture. The combination of the high

sampling rate ∑-Δ ADC used in the ADE7758 with the relatively

low bandwidth of the energy meter allows a very simple lowpass filter (LPF) to be used as an antialiasing filter. A simple RC

filter (single pole) with a corner frequency of 10 kHz produces

an attenuation of approximately 40 dB at 833 kHz. This is usually

sufficient to eliminate the effects of aliasing.

ANALOG INPUTS

The ADE7758 has six analog inputs divided into two channels:

current and voltage. The current channel consists of three pairs

of fully differential voltage inputs: IAP and IAN, IBP and IBN,

and ICP and ICN. These fully differential voltage input pairs

have a maximum differential signal of ±0.5 V. The current

channel has a programmable gain amplifier (PGA) with possible

gain selection of 1, 2, or 4. In addition to the PGA, the current

channels also have a full-scale input range selection for the ADC.

The ADC analog input range selection is also made using the

gain register (see Figure 38). As mentioned previously, the

maximum differential input voltage is ±0.5 V. However, by

using Bit 3 and Bit 4 in the gain register, the maximum ADC

input voltage can be set to ±0.5 V, ±0.25 V, or ±0.125 V on the

current channels. This is achieved by adjusting the ADC reference

(see the Reference Circuit section).

+500mV

VAP, VBP,

OR VCP

SINGLE-ENDED INPUT

±500mV MAX PEAK

VCM

COMMON-MODE

±25mV MAX

Figure 37. Maximum Signal Levels, Voltage Channels, Gain = 1

The gain selections are made by writing to the gain register.

Bit 0 to Bit 1 select the gain for the PGA in the fully differential

current channel. The gain selection for the PGA in the singleended voltage channel is made via Bit 5 to Bit 6. Figure 38

shows how a gain selection for the current channel is made

using the gain register.

GAIN (K)

SELECTION

IAP, IBP, ICP

VIN

Figure 39 shows how the gain settings in PGA 1 (current

channel) and PGA 2 (voltage channel) are selected by various

bits in the gain register.

GAIN REGISTER1

CURRENT AND VOLTAGE CHANNEL PGA CONTROL

V1

IAN, IBN,

OR ICN

–500mV

INTEGRATOR ENABLE

0 = DISABLE

1 = ENABLE

PGA 2 GAIN SELECT

00 = ×1

01 = ×2

10 = ×4

Figure 36. Maximum Signal Levels, Current Channels, Gain = 1

The voltage channel has three single-ended voltage inputs: VAP,

VBP, and VCP. These single-ended voltage inputs have a

maximum input voltage of ±0.5 V with respect to VN. Both the

current and voltage channel have a PGA with possible gain

selections of 1, 2, or 4. The same gain is applied to all the inputs

of each channel.

Figure 37 shows the maximum signal levels on the voltage

channel inputs. The maximum common-mode signal is

±25 mV, as shown in Figure 36.

1REGISTER

7

6

5

4

3

2

1

0

0

0

0

0

0

0

0

0

RESERVED

ADDRESS: 0x23

PGA 1 GAIN SELECT

00 = ×1

01 = ×2

10 = ×4

CURRENT INPUT FULL-SCALE SELECT

00 = 0.5V

01 = 0.25V

10 = 0.125V

CONTENTS SHOW POWER-ON DEFAULTS

Figure 39. Analog Gain Register

Bit 7 of the gain register is used to enable the digital integrator

in the current signal path. Setting this bit activates the digital

integrator (see the DI/DT Current Sensor and Digital Integrator

section).

Rev. E | Page 18 of 72

04443-039

IAP, IBP,

OR ICP

V2

04443-038

Figure 38. PGA in Current Channel

04443-036

VCM

K × VIN

IAN, IBN, ICN

V1 + V2

COMMON-MODE

±25mV MAX

VCM

AGND

–500mV

+500mV

DIFFERENTIAL INPUT

V1 + V2 = 500mV MAX PEAK

VN

GAIN[7:0]

Figure 36 shows the maximum signal levels on the current

channel inputs. The maximum common-mode signal is

±25 mV, as shown in Figure 37.

VCM

V2

04443-037

ANTIALIASING FILTER

�Data Sheet

ADE7758

When in waveform sample mode, one of four output sample

rates can be chosen by using Bit 5 and Bit 6 of the WAVMODE

register (DTRT[1:0]). The output sample rate can be 26.04 kSPS,

13.02 kSPS, 6.51 kSPS, or 3.25 kSPS. By setting the WFSM bit in

the interrupt mask register to Logic 1, the interrupt request

output IRQ goes active low when a sample is available. The

timing is shown in Figure 40. The 24-bit waveform samples are

transferred from the ADE7758 one byte (8-bits) at a time, with

the most significant byte shifted out first.

CURRENT CHANNEL ADC

Figure 41 shows the ADC and signal processing path for the

input IA of the current channels (same for IB and IC). In

waveform sampling mode, the ADC outputs are signed twos

complement 24-bit data-words at a maximum of 26.0 kSPS

(thousand samples per second). With the specified full-scale

analog input signal of ±0.5 V, the ADC produces its maximum

output code value (see Figure 41). This diagram shows a fullscale voltage signal being applied to the differential inputs IAP

and IAN. The ADC output swings between 0xD7AE14

(−2,642,412) and 0x2851EC (+2,642,412).

IRQ

SCLK

DIN

The waveform samples of the current channel can be routed to

the WFORM register at fixed sampling rates by setting the

WAVSEL[2:0] bit in the WAVMODE register to 000 (binary)

(see Table 20). The phase in which the samples are routed is set

by setting the PHSEL[1:0] bits in the WAVMODE register.

Energy calculation remains uninterrupted during waveform

sampling.

DOUT

Figure 40. Current Channel Waveform Sampling

The interrupt request output IRQ stays low until the interrupt

routine reads the reset status register (see the Interrupts section).

REFERENCE

PGA1

VIN

GAIN[7]

GAIN[1:0]

×1, ×2, ×4

DIGITAL

INTEGRATOR 1

ADC

SGN

CURRENT CHANNE L DATA–24 BITS

GAIN[4:3]

2.42V, 1.21V, 0.6V

IAP

READ FROM WAVEFORM

0x12

0

04443-040

Current Channel Sampling

HPF

CURRENT RMS (IRMS)

CALCULATION

WAVEFORM SAMPLE

REGISTER

ACTIVE AND REACTIVE

POWER CALCULATION

IAN

50Hz

CHANNEL 1 (CURRENT WAVEFORM)

DATA RANGE AFTER INTEGRATOR

(50Hz AND AIGAIN[11:0] = 0x000)

0x34D1B8

CHANNEL 1

(CURRENT WAVEFORM)

DATA RANGE

0x2851EC

0V

0x000000

ANALOG

INPUT

RANGE

0x000000

0xCB2E48

60Hz

CHANNEL 1 (CURRENT WAVEFORM)

DATA RANGE AFTER INTEGRATOR

(60Hz AND AIGAIN[11:0] = 0x000)

0x2BE893

0xD7AE14

ADC OUTPUT

WORD RANGE

1WHEN

DIGITAL INTEGRATOR IS ENABLED, FULL-SCALE OUTPUT DATA IS

ATTENUATED DEPENDING ON THE SIGNAL FREQUENCY BECAUSE THE

INTEGRATOR HAS A –20dB/DECADE FREQUENCY RESPONSE. WHEN DISABLED,

THE OUTPUT WILL NOT BE FURTHER ATTENUATED.

Figure 41. Current Channel Signal Path

Rev. E | Page 19 of 72

0x000000

0xD4176D

04443-041

VIN

0.5V/GAIN

0.25V/GAIN

0.125V/GAIN

�ADE7758

Data Sheet

80

DI/DT CURRENT SENSOR AND DIGITAL

INTEGRATOR

81

82

The di/dt sensor detects changes in the magnetic field caused by

the ac current. Figure 42 shows the principle of a di/dt current

sensor.

PHASE (Degrees)

83

MAGNETIC FIELD CREATED BY CURRENT

(DIRECTLY PROPORTIONAL TO CURRENT)

84

85

86

87

88

04443-044

89

90

91

10

04443-042

+ EMF (ELECTROMOTIVE FORCE)

– INDUCED BY CHANGES IN

MAGNETIC FLUX DENSITY (di/dt)

100

1k

FREQUENCY (Hz)

10k

Figure 44. Combined Phase Response of the

Digital Integrator and Phase Compensator

Figure 42. Principle of a di/dt Current Sensor

The flux density of a magnetic field induced by a current is

directly proportional to the magnitude of the current. The

changes in the magnetic flux density passing through a conductor

loop generate an electromotive force (EMF) between the two

ends of the loop. The EMF is a voltage signal that is proportional to the di/dt of the current. The voltage output from the

di/dt current sensor is determined by the mutual inductance

between the current carrying conductor and the di/dt sensor.

5

MAGNITUDE (dB)

4

The current signal needs to be recovered from the di/dt signal

before it can be used. An integrator is therefore necessary to

restore the signal to its original form. The ADE7758 has a builtin digital integrator to recover the current signal from the di/dt

sensor. The digital integrator on Channel 1 is disabled by default

when the ADE7758 is powered up. Setting the MSB of the

GAIN[7:0] register turns on the integrator. Figure 43 to Figure 46

show the magnitude and phase response of the digital

integrator.

3

2

1

–1

40

04443-045

0

45

50

55

60

FREQUENCY (Hz)

65

70

Figure 45. Combined Gain Response of the

Digital Integrator and Phase Compensator (40 Hz to 70 Hz)

20

89.80

10

89.85

PHASE (Degrees)

–10

–20

–30

89.90

89.95

90.00

–40

100

1k

FREQUENCY (Hz)

90.10

40

10k

Figure 43. Combined Gain Response of the

Digital Integrator and Phase Compensator

04443-046

–50

10

90.05

04443-043

GAIN (dB)

0

45

50

55

60

FREQUENCY (Hz)

65

Figure 46. Combined Phase Response of the

Digital Integrator and Phase Compensator (40 Hz to 70 Hz)

Rev. E | Page 20 of 72

70

�Data Sheet

ADE7758

Note that the integrator has a −20 dB/dec attenuation and

approximately −90° phase shift. When combined with a di/dt

sensor, the resulting magnitude and phase response should be a

flat gain over the frequency band of interest. However, the di/dt

sensor has a 20 dB/dec gain associated with it and generates

significant high frequency noise. A more effective antialiasing

filter is needed to avoid noise due to aliasing (see the Theory of

Operation section).

When the digital integrator is switched off, the ADE7758 can be

used directly with a conventional current sensor, such as a

current transformer (CT) or a low resistance current shunt.

Note that the number of half-line cycles is based on counting

the zero crossing of the voltage channel. The ZXSEL[2:0] bits in

the LCYCMODE register determine which voltage channels are

used for the zero-crossing detection. The same signal is also

used for line cycle energy accumulation mode if activated (see

the Line Cycle Accumulation Mode Register (0X17) section).

OVERCURRENT DETECTION INTERRUPT

Figure 48 illustrates the behavior of the overcurrent detection.

CURRENT PEAK WAVEFORM BEING MONITORED

(SELECTED BY PKIRQSEL[2:0] IN MMODE REGISTER)

PEAK CURRENT DETECTION

IPINTLVL[7:0]

The ADE7758 can be programmed to record the peak of the

current waveform and produce an interrupt if the current

exceeds a preset limit.

Peak Current Detection Using the PEAK Register

The peak absolute value of the current waveform within a fixed

number of half-line cycles is stored in the IPEAK register.

Figure 47 illustrates the timing behavior of the peak current

detection.

PKI INTERRUPT FLAG

(BIT 15 OF STATUS

REGISTER)

L2

READ RSTATUS

REGISTER

04443-048

PKI RESET LOW

WHEN RSTATUS

REGISTER IS READ

L1

Figure 48. ADE7758 Overcurrent Detection

CURRENT WAVEFORM

(PHASE SELECTED BY

PEAKSEL[2:0] IN

MMODE REGISTER)

CONTENT OF

IPEAK[7:0]

00

L1

L2

04443-047

NO. OF HALF

LINE CYCLES

SPECIFIED BY

LINECYC[15:0]

REGISTER

L1

Figure 47. Peak Current Detection Using the IPEAK Register

Note that the content of the IPEAK register is equivalent to

Bit 14 to Bit 21 of the current waveform sample. At full-scale

analog input, the current waveform sample is 0x2851EC. The

IPEAK at full-scale input is therefore expected to be 0xA1.

Note that the content of the IPINTLVL[7:0] register is

equivalent to Bit 14 to Bit 21 of the current waveform sample.

Therefore, setting this register to 0xA1 represents putting peak

detection at full-scale analog input. Figure 48 shows a current

exceeding a threshold. The overcurrent event is recorded by

setting the PKI flag (Bit 15) in the interrupt status register. If the

PKI enable bit is set to Logic 1 in the interrupt mask register, the

IRQ logic output goes active low (see the Interrupts section).

Similar to peak level detection, multiple phases can be activated

for peak detection. If any of the active phases produce

waveform samples above the threshold, the PKI flag in the

interrupt status register is set. The phase of which overcurrent is

monitored is set by the PKIRQSEL[2:0] bits in the MMODE

register (see Table 19).

In addition, multiple phases can be activated for the peak

detection simultaneously by setting more than one of the

PEAKSEL[2:4] bits in the MMODE register to logic high. These

bits select the phase for both voltage and current peak

measurements. Note that if more than one bit is set, the VPEAK

and IPEAK registers can hold values from two different phases,

that is, the voltage and current peak are independently

processed (see the Peak Current Detection section).

Rev. E | Page 21 of 72

�ADE7758

Data Sheet

PHASE

CALIBRATION

VAP

VA

TO ACTIVE AND

REACTIVE ENERGY

CALCULATION

Φ

GAIN[6:5]

×1, ×2, ×4

+

PGA

–

PHCAL[6:0]

TO VOLTAGE RMS

CALCULATION AND

WAVEFORM SAMPLING

ADC

LPF1

VN

f3dB = 260Hz

50Hz

LPF OUTPUT

WORD RANGE

0x2797

VA

0V

ANALOG INPUT

RANGE

0.5V

GAIN

0x0

0x2852

0xD869

0x0

60Hz

0xD7AE

LPF OUTPUT

WORD RANGE

0x2748

04443-049

0x0

0xD8B8

Figure 49. ADC and Signal Processing in Voltage Channel

0

VOLTAGE CHANNEL ADC

Voltage Channel Sampling

The waveform samples on the voltage channels can also be

routed to the WFORM register. However, before passing to the

WFORM register, the ADC outputs pass through a single-pole,

low-pass filter (LPF1) with a cutoff frequency at 260 Hz.

Figure 50 shows the magnitude and phase response of LPF1.

This filter attenuates the signal slightly. For example, if the line

frequency is 60 Hz, the signal at the output of LPF1 is

attenuated by 3.575%. The waveform samples are 16-bit, twos

complement data ranging between 0x2748 (+10,056d) and

0xD8B8 (−10,056d). The data is sign extended to 24-bit in the

WFORM register.

H(f )=

1

⎛ 60 Hz ⎞

⎟

1+ ⎜

⎜ 260 Hz ⎟

⎝

⎠

2

= 0.974 = −0.225 dB

(3)

–20

(60Hz; –13°)

–40

–20

–60

–30

–80

10

100

FREQUENCY (Hz)

–40

1k

GAIN (dB)

–10

04443-050

For active and reactive energy measurements, the output of the

ADC passes to the multipliers directly and is not filtered. This

solution avoids the much larger multibit multiplier and does not

affect the accuracy of the measurement. An HPF is not

implemented on the voltage channel to remove the dc offset

because the HPF on the current channel alone should be

sufficient to eliminate error due to ADC offsets in the power

calculation. However, ADC offset in the voltage channels

produces large errors in the voltage rms calculation and affects

the accuracy of the apparent energy calculation.

(60Hz; –0.2dB)

PHASE (Degrees)

Figure 49 shows the ADC and signal processing chain for the

input VA in the voltage channel. The VB and VC channels have

similar processing chains.

0

Figure 50. Magnitude and Phase Response of LPF1

Note that LPF1 does not affect the active and reactive energy

calculation because it is only used in the waveform sampling

signal path. However, waveform samples are used for the

voltage rms calculation and the subsequent apparent energy

accumulation.

The WAVSEL[2:0] bits in the WAVMODE register should be set

to 001 (binary) to start the voltage waveform sampling. The

PHSEL[1:0] bits control the phase from which the samples are

routed. In waveform sampling mode, one of four output sample

rates can be chosen by changing Bit 5 and Bit 6 of the WAVMODE

register (see Table 20). The available output sample rates are

26.0 kSPS, 13.5 kSPS, 6.5 kSPS, or 3.3 kSPS. By setting the WFSM

bit in the interrupt mask register to Logic 1, the interrupt request

output IRQ goes active low when a sample is available. The 24bit waveform samples are transferred from the ADE7758 one byte

(8 bits) at a time, with the most significant byte shifted out first.

The sign of the register is extended in the upper 8 bits. The

timing is the same as for the current channels, as seen in Figure 40.

Rev. E | Page 22 of 72

�Data Sheet

ADE7758

every time a zero crossing is detected on its associated input.

The default value of ZXTOUT is 0xFFFF. If the internal register

decrements to 0 before a zero crossing at the corresponding

input is detected, it indicates an absence of a zero crossing in

the time determined by the ZXTOUT[15:0]. The ZXTOx

detection bit of the corresponding phase in the interrupt status

register is then switched on (Bit 6 to Bit 8). An active low on the

IRQ output also appears if the ZXTOx mask bit for the

corresponding phase in the interrupt mask register is set to

Logic 1. Figure 52 shows the mechanism of the zero-crossing

timeout detection when the Line Voltage A stays at a fixed dc

level for more than 384/CLKIN × ZXTOUT[15:0] seconds.

ZERO-CROSSING DETECTION

The ADE7758 has zero-crossing detection circuits for each of

the voltage channels (VAN, VBN, and VCN). Figure 51 shows

how the zero-cross signal is generated from the output of the

ADC of the voltage channel.

GAIN[6:5]

×1, ×2, ×4

VAN,

VBN,

VCN

PGA

REFERENCE

ZEROCROSSING

DETECTOR

ADC

LPF1

f–3dB = 260Hz

24.8° @ 60Hz

1.0

0.908

ANALOG VOLTAGE

WAVEFORM

(VAN, VBN, OR VCN)

16-BIT INTERNAL

REGISTER VALUE

LPF1

OUTPUT

ZXTOUT[15:0]

IRQ

04443-051

VOLTAGE

CHANNEL A

READ RSTATUS

The zero-crossing interrupt is generated from the output of

LPF1. LPF1 has a single pole at 260 Hz (CLKIN = 10 MHz). As

a result, there is a phase lag between the analog input signal of

the voltage channel and the output of LPF1. The phase response

of this filter is shown in the Voltage Channel Sampling section.

The phase lag response of LPF1 results in a time delay of

approximately 1.1 ms (at 60 Hz) between the zero crossing on

the voltage inputs and the resulting zero-crossing signal. Note

that the zero-crossing signal is used for the line cycle

accumulation mode, zero-crossing interrupt, and line

period/frequency measurement.

When one phase crosses from negative to positive, the

corresponding flag in the interrupt status register (Bit 9 to

Bit 11) is set to Logic 1. An active low in the IRQ output also

appears if the corresponding ZX bit in the interrupt mask

register is set to Logic 1. Note that only zero crossing from

negative to positive generates an interrupt.

The flag in the interrupt status register is reset to 0 when the

interrupt status register with reset (RSTATUS) is read. Each

phase has its own interrupt flag and mask bit in the interrupt

register.

Zero-Crossing Timeout

Each zero-crossing detection has an associated internal timeout

register (not accessible to the user). This unsigned, 16-bit

register is decreased by 1 every 384/CLKIN seconds. The

registers are reset to a common user-programmed value, that is,

the zero-crossing timeout register (ZXTOUT[15:0], Address 0x1B),

READ

RSTATUS

04443-052

ZXTOA

DETECTION BIT

Figure 51. Zero-Crossing Detection on Voltage Channels

Figure 52. Zero-Crossing Timeout Detection

PHASE COMPENSATION

When the HPF in the current channel is disabled, the phase

error between the current channel (IA, IB, or IC) and the

corresponding voltage channel (VA, VB, or VC) is negligible.

When the HPF is enabled, the current channels have phase

response (see Figure 53 through Figure 55). The phase response

is almost 0 from 45 Hz to 1 kHz. The frequency band is sufficient

for the requirements of typical energy measurement applications.

However, despite being internally phase compensated, the

ADE7758 must work with transducers that may have inherent

phase errors. For example, a current transformer (CT) with a

phase error of 0.1° to 0.3° is not uncommon. These phase errors

can vary from part to part, and they must be corrected to

perform accurate power calculations.

The errors associated with phase mismatch are particularly

noticeable at low power factors. The ADE7758 provides a

means of digitally calibrating these small phase errors. The

ADE7758 allows a small time delay or time advance to be

introduced into the signal processing chain to compensate for

the small phase errors.

The phase calibration registers (APHCAL, BPHCAL, and

CPHCAL) are twos complement, 7-bit sign-extended registers

that can vary the time advance in the voltage channel signal

path from +153.6 μs to −75.6 μs (CLKIN = 10 MHz),

Rev. E | Page 23 of 72

�ADE7758

Data Sheet

0.20

0.15

PHASE (Degrees)

Figure 56 illustrates how the phase compensation is used to

remove a 0.1° phase lead in IA of the current channel from the

external current transducer. To cancel the lead (0.1°) in the

current channel of Phase A, a phase lead must be introduced

into the corresponding voltage channel. The resolution of the

phase adjustment allows the introduction of a phase lead of

0.104°. The phase lead is achieved by introducing a time

advance into VA. A time advance of 4.8 μs is made by writing

−2 (0x7E) to the time delay block (APHCAL[6:0]), thus

reducing the amount of time delay by 4.8 μs or equivalently,

360° × 4.8 μs × 60 Hz = 0.104° at 60 Hz.

80

60

0

–0.10

40

45

50

55

60

FREQUENCY (Hz)

65

70

Figure 54. Phase Response of the HPF and Phase Compensation

(40 Hz to 70 Hz)

0.10

0.08

50

0.06

0.04

0.02

0

40

04443-055

PHASE (Degrees)

70

0.05

–0.05

PHASE (Degrees)

90

0.10

04443-054

respectively. Negative values written to the PHCAL registers

represent a time advance, and positive values represent a time

delay. One LSB is equivalent to 1.2 μs of time delay or 2.4 μs of

time advance with a CLKIN of 10 MHz. With a line frequency

of 60 Hz, this gives a phase resolution of 0.026° (360° × 1.2 μs ×

60 Hz) at the fundamental in the positive direction (delay) and

0.052° in the negative direction (advance). This corresponds to

a total correction range of −3.32° to +1.63° at 60 Hz.

–0.02

30

44

20

0

0

100

200

300

400 500 600

FREQUENCY (Hz)

700

800

900

48

50

52

FREQUENCY (Hz)

54

56