Evaluation Board for ADP2114

EVAL-ADP2114

FEATURES

GENERAL DESCRIPTION

Full-featured demo board for the ADP2114

Standalone capability

Configurable dual synchronous step-down, dc-to-dc

switching regulator

Dual 2 A/2 A or 3 A/1 A output or single combined 4 A output

Input voltage VIN: 2.75 V to 5.5 V

Selectable fixed output: 0.8 V, 1.2 V, 1.5 V, 1.8 V, 2.5 V, 3.3 V or

adjustable output voltage to 0.6 V minimum

Selectable switching frequency: 300 kHz, 600 kHz, 1.2 MHz

or synchronized from 200 kHz to 2 MHz

Configurable SYNC input or CLOCKOUT output

Two independent enable inputs

Two power good outputs

Size: 3-7/16 inch × 2-5/8 inch

The ADP2114 evaluation (demo) board is a complete, dual,

step-down, dc-to-dc converter design based on the ADP2114,

a configurable, dual 2 A/single 4 A, synchronous step-down,

dc-to-dc regulator.

APPLICATIONS

Demonstrate features and configurability of ADP2114

Emulate functionality of ADP2114 in a user’s circuit

Evaluate ADP2114 performance

The ADP2114 is a versatile step-down switching regulator that

satisfies a wide range of user point-of-load requirements. The

two PWM channels are 180° phase shifted and provide ±1.5%

accurate regulated output voltages. For more details, see the

ADP2114 data sheet.

The ADP2114 evaluation board comes in two versions: the

ADP2114-EVALZ with 3.3 V at 2 A and 1.8 V at 2 A outputs,

switching frequency set to 600 kHz, and pulse skip enabled,

and the ADP2114-2PH-EVALZ with interleaved 1.2 V at 4 A

single output, switching frequency set to 1.2 MHz, and forced

PWM mode. If needed, the ADP2114 evaluation board output

voltages and configuration can be modified by changing the

values of the appropriate passive components and changing the

links. The ambient temperature operation range is from −40°C

to +85°C.

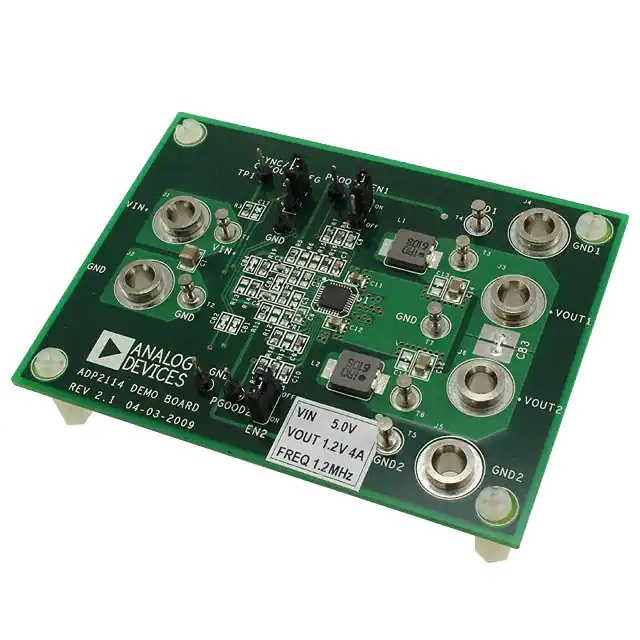

08366-001

ADP2114 EVALUATION BOARD

Figure 1. ADP2114-EVALZ—VOUT1: 3.3 V @ 2 A; VOUT2: 1.8 V @ 2 A; fSW = 600 kHz; Pulse Skip Enabled

Rev. 0

Evaluation boards are only intended for device evaluation and not for production purposes.

Evaluation boards are supplied “as is” and without warranties of any kind, express, implied, or

statutory including, but not limited to, any implied warranty of merchantability or fitness for a

particular purpose. No license is granted by implication or otherwise under any patents or other

intellectual property by application or use of evaluation boards. Information furnished by Analog

Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog

Devices for its use, nor for any infringements of patents or other rights of third parties that may result

from its use. Analog Devices reserves the right to change devices or specifications at any time

without notice. Trademarks and registered trademarks are the property of their respective owners.

Evaluation boards are not authorized to be used in life support devices or systems.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Fax: 781.461.3113

©2009 Analog Devices, Inc. All rights reserved.

�EVAL-ADP2114

TABLE OF CONTENTS

Features .............................................................................................. 1

Typical Performance Characteristics ..............................................6

Applications ....................................................................................... 1

Bode Plots .......................................................................................9

General Description ......................................................................... 1

Evaluation Board Schematics and Artwork ................................ 10

ADP2114 Evaluation Board ............................................................ 1

PCB Layout ................................................................................. 12

Revision History ............................................................................... 2

Ordering Information .................................................................... 16

Using the Evaluation (Demo) Board .............................................. 3

Bill of Materials ........................................................................... 16

Powering Up .................................................................................. 3

Ordering Guide .......................................................................... 17

Evaluating Performance of the DC-to-DC Converter ............ 4

ESD Caution................................................................................ 17

Modifying the Board .................................................................... 4

REVISION HISTORY

7/09—Revision 0: Initial Version

Rev. 0 | Page 2 of 20

�EVAL-ADP2114

USING THE EVALUATION (DEMO) BOARD

Input and Output Voltages

POWERING UP

The ADP2114 evaluation board is supplied fully assembled and

tested. Before applying power to the evaluation board, follow

the procedures in this section.

Input Power Source

The power source voltage must not exceed 5.5 V, the maximum

operation input voltage of the ADP2114.

Connect the negative terminal of the power source to the J2

(GND) jack of the evaluation board and the positive terminal of

the power source to the J1 (VIN+) jack of the evaluation board.

Output Load

Before connecting a load to the output of the demo board, make

sure that the output voltage does not exceed the maximum operating voltage range of the load. To connect a load to the output of

Channel 1, connect the negative terminal of the load to Jack J4

(GND1) on the evaluation board and connect the positive terminal of the load to Jack J3 (+VOUT1). To connect a load to the

output of Channel 2, connect the negative terminal of the load

to Jack J5 (GND2) of the evaluation board and connect the

positive terminal to Jack J6 (+VOUT2).

For the single interleaved output configuration, the outputs of

Channel 1 and Channel 2 are shorted together by soldering

Link CB3. To apply a load to the single interleaved dual-phase

output, connect the negative terminal of the load to either

Jack J4 (GND1) or Jack J5 (GND2) of the evaluation board

and connect the positive terminal of the load to either Jack J3

(+VOUT1) or Jack J6 (+VOUT2).

To measure the input voltage, VIN, connect the negative probe of

the voltmeter to Terminal T2 (GND) on the evaluation board

and connect the positive probe to Terminal T1 (VIN+).

To measure the output voltage of Channel 1, VOUT1, connect

the negative probe of the voltmeter to Terminal T4 (GND1)

and connect the positive probe to Terminal T3. To measure the

output voltage of Channel 2, VOUT2, connect the negative probe

to Terminal T5 (GND2) and connect the positive probe to

Terminal T6.

To measure the output voltage, VOUT, for the single interleaved

output configuration, connect the negative probe of the voltmeter

to Terminal T7 (GND) and connect the positive probe to either

Terminal T3 or Terminal T6.

External Synchronization

To synchronize the dc-to-dc converter to an external clock

signal,

1.

2.

fSYNC = 2 × fSW

HEADER3 EN1 is used to control Channel 1. Use one of the

following methods to enable or disable Channel 1:

•

To enable Channel 1, short the middle pin of HEADER3

EN1 to VIN+ by placing a shunt in the on position, or

apply a dc voltage from 2.0 V to 5.5 V to the middle pin.

To disable Channel 1, short the middle pin of HEADER3

EN1 to GND by placing a shunt in the off position or apply

a positive dc voltage below 0.8 V to the middle pin.

HEADER3 EN2 is used to control Channel 2. Use one of the

following methods to enable or disable Channel 2:

•

•

To enable Channel 2, short the middle pin of HEADER3

EN2 to VIN+ by placing a shunt in the on position, or

apply a dc voltage from 2.0 V to 5.5 V to the middle pin.

To disable Channel 2, short the middle pin of HEADER3

EN2 to GND by placing a shunt in the off position, or

apply a positive dc voltage below 0.8 V to the middle pin.

For the single interleaved output configuration, the EN1 and

EN2 signals are connected together at the Circuit Breaker CB1,

which is a solder link. Use either HEADER3 EN1 or EN2 to

enable and disable Channel 1 and Channel 2 simultaneously.

(1)

For reliable synchronization, the external clock frequency,

fSYNC, must be in the range from 800 kHz to 2 MHz for the

ADP2114-EVALZ board, which has the switching frequency

set to 600 kHz. When using the ADP2114-2PH-EVALZ

board, which has the switching frequency set point at

1.2 MHz, the external clock frequency fSYNC must be within

the range from 1.6 MHz to 4 MHz.

Enabling and Disabling the DC-to-DC Converter

•

Short the middle pin of HEADER3 SCFG to GND by

placing a shunt in the in position. This configures the

(SYNC/CLKOUT) pin of the ADP2114 as an input.

Apply an external clock signal to Test Point TP1

SYNC/CLKOUT. The clock signal must have a logic high

level from 2.0 V up to the voltage of the input power, VIN,

and a logic low level below 0.8 V. Set the external clock

pulse width to more than 100 ns and the frequency, fSYNC,

equal to double the target PWM switching frequency, fSW:

Internal Clock Out

Shorting the middle pin of HEADER3 SCFG to VIN+, performed

by placing the shunt in the out position, makes the ADP2114

internal clock available at Test Point TP1 (SYNC/CLKOUT).

The frequency of the internal clock, fCLKOUT, is twice that of the

switching frequency, fSW, of the converter and 90° phase-shifted.

PGOOD1 and PGOOD2 Signals

When Channel 1 is enabled and the output voltage, VOUT1, is in

regulation range, the logic signal at the Test Point PGOOD1 is

high. When Channel 2 is enabled and the output voltage, VOUT2,

is in regulation range, the logic signal at Test Point PGOOD2 is

also high. For the single dual-phase interleaved output configuration, the PGOOD1 and PGOOD2 signals are tied together at

the Circuit Breaker CB2, which is a solder link. Use either

Rev. 0 | Page 3 of 20

�EVAL-ADP2114

Test Point PGOOD1 or Test Point PGOOD2 to monitor whether

the converter output voltage, VOUT, is within regulation.

EVALUATING PERFORMANCE OF THE DC-TO-DC

CONVERTER

To observe the switching waveform with an oscilloscope, place

the probe tip at the end of Inductor L1 (or L2 for Channel 2)

that is connected to the SWx pin of the ADP2114. The probe

ground is connected to GND.

Output Voltage Ripple

To observe the output voltage ripple, place the oscilloscope

probe tip at Terminal T3 (or T6 for Channel 2), the converter

output, and connect the probe ground lead to Terminal T7

(GND). The oscilloscope input should be set to ac-coupled.

The efficiency, η, is calculated by comparing the measured

input power with the measured output power of the converter:

(2)

V IN × I IN

Measuring Line Regulation

Vary the input voltage and measure the change of the output

voltage.

Generate a step input voltage (VIN) change and observe the

behavior of the output voltage, VOUT1 (VOUT2 for Channel 2),

with an oscilloscope.

Load Transient Response

Generate a load current transient at the output, VOUT1 (VOUT2 for

Channel 2), and observe the output voltage response with an

oscilloscope. Use a current probe attached to the wire between

the output and the load to visualize the current transient.

MODIFYING THE BOARD

Measuring Efficiency

η=

Measure the load regulation by increasing the load current at

the output and measuring the change in output voltage.

Line Transient Response

Switching Waveforms

VOUT × I OUT

Measuring Load Regulation

To modify the converter configuration, unsolder and/or

replace/remove the appropriate passive components or links

on the board.

Changing the Operation Mode Settings

The operating mode of the ADP2114 dc-to-dc converter can

be changed by replacing the configuration resistor, R14, with a

different value, as shown in Table 1. This configuration sets the

current limit for each channel and enables or disables the transition to pulse skip mode at light loads.

Table 1. Setting the Operating Mode

R14 (Ω) ± 5%

0

4.7 k

8.2 k

15 k

VOUT1

2

2

3

3

Maximum DC Load Current (A)

VOUT2

2

2

1

1

VOUT1

3.3

3.3

4.5

4.5

Rev. 0 | Page 4 of 20

Peak Current Limit (A)

VOUT2

3.3

3.3

1.9

1.9

Pulse Skip

Enabled

Forced PWM

Enabled

Forced PWM

�EVAL-ADP2114

Changing the Output Voltages

Table 2. Setting the Switching Frequency, fSW

The output voltages set points of the converter can be changed

by replacing Resistor R15, Resistor R16, Resistor R17, and

Resistor R18 with the resistor values shown in Table 3.

R19 (Ω) ± 5%

0

8.2 k

27 k

In addition, when the adjustable output voltage version is used

for the ADP2114, the output voltage, VOUT1, is set by the resistive voltage divider R5/R6 and the output voltage, VOUT2, is set

by the resistive voltage divider R11/R12.

To calculate the desired resistor values, first determine the value

of the bottom divider string resistor, R6 (R12 for Channel 2),

by ensuring that the divider string current, ISTRING, is greater

than 20 μA.

For Channel 1,

R6 = 0.6 V/ISTRING

(3)

For Channel 2,

R12 = 0.6 V/ISTRING

(4)

Then calculate the value of the top resistor, R5 (R11 for Channel 2).

For Channel 1,

Switching Frequency, fSW (kHz)

300

600

1200

Note that when the switching frequency (fSW) is changed, to

ensure stable operation, the values of the Inductor L1 and

Inductor L2, the C13, C14, C15, and C16 output capacitors, and

the R2, C2, R4, and C4 compensation components must be

recalculated and changed (see the ADP2114 data sheet for

details on external component selection).

Changing the Soft Start Time

The soft start time of the ADP2114 on the evaluation board is

programmed to 1 ms.

To change the soft start time, tSS, replace Capacitor C7 (C9 for

Channel 2) with a different capacitor value using the following:

For Channel 1,

C7 [nF] = 10 × tSS [ms]

(7)

For Channel2,

V

0.6 V

R5 R6 OUT 1

0.6 V

C9 [nF] = 10× tSS [ms]

(5)

(8)

Combining the Two Channels into a Single Output

For Channel 2,

For a single, interleaved dual-phase output, make the following

modifications:

V

0.6 V

R11 R12 OUT 2

0.6 V

(6)

Note that when the output voltage of Channel 1, VOUT1, is changed,

to ensure stable operation, the values of Inductor L1, the C13

and C14 output capacitors, and the R2 and C2 compensation

components must be recalculated and changed (see the ADP2114

data sheet for details on external component selection). If the

output voltage of Channel 2, VOUT2, is changed, the values of the

Inductor L2, the C15 and C16 output capacitors, and the R4 and

C4 compensation components must be recalculated and changed.

Changing the Switching Frequency

The switching frequency (fSW) set point can be changed by replacing Resistor R19 with a different value, as shown in Table 2.

Short the outputs, +VOUT1 and +VOUT2, by soldering

the bridge on CB3

Tie the EN1 and EN2 signals by shorting CB1

Tie the PGOOD1 and PGOOD2 signals by shorting CB2

Tie the FB1 and FB2 signals by shorting CB4

Tie the COMP1 and COMP2 signals by shorting CB5

Set the same output voltages of both channels by choosing

R15 = R17 and R16 = R18

Choose and set the operating mode to 2 A/2 A, forced

PWM configuration, by setting R14 to 4.7 kΩ.

The evaluation board version ADP2114-2PH-EVALZ is already

configured for interleaved dual-phase single output, 1.2 V at

4 A, 1.2 MHz switching frequency, and forced PWM mode.

Table 3. Programming the Output Voltages

R15 (Ω) ± 5%

Open

Open

Open

Open

Open

Open

Open

0

R16 (Ω) ± 5%

0

4.7 k

8.2 k

15 k

27 k

47 k

82 k

Open

VOUT1 (V)

0.8

1.2

1.5

1.8

2.5

3.3

Adjustable 0.6 to