High Accuracy

Instrumentation Amplifier

AMP02

FEATURES

Low Offset Voltage: 100 V max

Low Drift: 2 V/ⴗC max

Wide Gain Range: 1 to 10,000

High Common-Mode Rejection: 115 dB min

High Bandwidth (G = 1000): 200 kHz typ

Gain Equation Accuracy: 0.5% max

Single Resistor Gain Set

Input Overvoltage Protection

Low Cost

Available in Die Form

APPLICATIONS

Differential Amplifier

Strain Gage Amplifier

Thermocouple Amplifier

RTD Amplifier

Programmable Gain Instrumentation Amplifier

Medical Instrumentation

Data Acquisition Systems

FUNCTIONAL BLOCK DIAGRAM

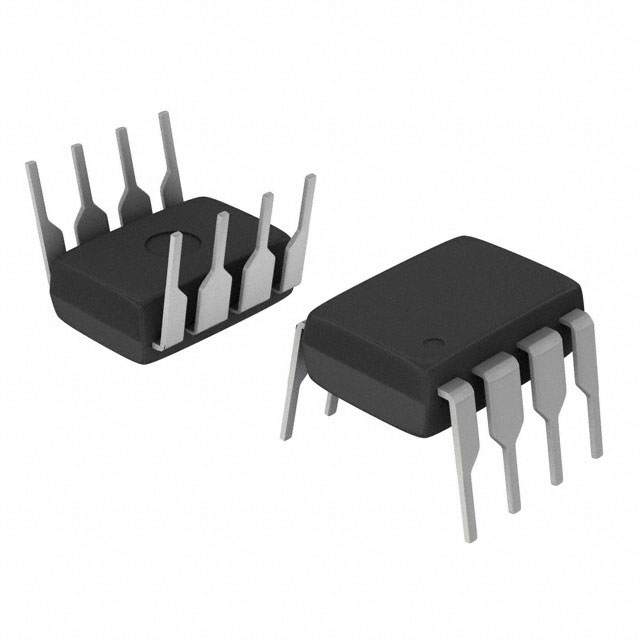

8-Lead PDIP and CERDIP

16-Lead SOIC

RG1 1

8

RG2

–IN 2

7

V+

+IN 3

6

OUT

NC 3

14 NC

V– 4

5

REFERENCE

–IN 4

13 V+

+IN 5

12 SENSE

16 NC

NC 1

RG1 2

15 RG2

NC 6

11 OUT

V– 7

10 REFERENCE

NC 8

9 NC

NC = NO CONNECT

V+

+IN

RG

–IN

G=

3

–

1

RG1

8

RG2

2 +

7

6

OUT

5

4

REFERENCE

V–

VOUT

50k⍀

=

(+IN) – (–IN)

RG

(

)

+1

FOR SOL CONNECT SENSE TO OUTPUT

Figure 1. Basic Circuit Connections

GENERAL DESCRIPTION

The AMP02 is the first precision instrumentation amplifier

available in an 8-lead package. Gain of the AMP02 is set by a

single external resistor and can range from 1 to 10,000. No

gain set resistor is required for unity gain. The AMP02 includes

an input protection network that allows the inputs to be taken

60 V beyond either supply rail without damaging the device.

Laser trimming reduces the input offset voltage to under 100 µV.

Output offset voltage is below 4 mV, and gain accuracy is better

than 0.5% for a gain of 1000. ADI’s proprietary thin-film resistor process keeps the gain temperature coefficient under 50 ppm/°C.

Due to the AMP02’s design, its bandwidth remains very high

over a wide range of gain. Slew rate is over 4 V/µs, making the

AMP02 ideal for fast data acquisition systems.

A reference pin is provided to allow the output to be referenced

to an external dc level. This pin may be used for offset correction or level shifting as required. In the 8-lead package, sense is

internally connected to the output.

For an instrumentation amplifier with the highest precision,

consult the AMP01 data sheet.

REV. E

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002. All rights reserved.

�AMP02–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

Parameter

OFFSET VOLTAGE

Input Offset Voltage

Input Offset Voltage Drift

Output Offset Voltage

(@ VS = ⴞ15 V, VCM = 0 V, TA = 25ⴗC, unless otherwise noted.)

Symbol

Conditions

VIOS

TA = 25°C

–40°C ≤ TA ≤ +85°C

–40°C ≤ TA ≤ +85°C

TA = 25°C

–40°C ≤ TA ≤ +85°C

–40°C ≤ TA ≤ +85°C

VS = ± 4.8 V to ± 18 V

G = 100, 1000

G = 10

G=1

VS = ± 4.8 V to ± 18 V

–40°C ≤ TA ≤ +85°C

G = 1000, 100

G = 10

G=1

TCVIOS

VOOS

Output Offset Voltage Drift TCVOOS

Power Supply Rejection

PSR

Min

AMP02E

Typ

Max

20

50

0.5

1

4

50

100

200

2

4

10

100

120

110

90

105

90

70

110

95

75

dB

dB

dB

Differential, G ≤ 1000

Common Mode, G = 1000

TA = 25°C1

VCM = ± 11 V

G = 1000, 100

G = 10

G=1

VCM = ± 11 V

–40°C ≤ TA ≤ +85°C

G = 100, 1000

G = 10

G=1

10

16.5

OUTPUT RATING

Output Voltage Swing

GTC

NOISE

Voltage Density, RTI

fO = 1 kHz

G = 1000

G = 100

G = 10

G=1

fO = 1 kHz, G = 1000

0.1 Hz to 10 Hz

G = 1000

G = 100

G = 10

Noise Current Density, RTI in

Input Noise Voltage

en p-p

DYNAMIC RESPONSE

Small-Signal Bandwidth

(–3 dB)

G = 100, 1000

Slew Rate

Settling Time

BW

G=1

G = 10

SR

tS

G = 10, RL = 1 kΩ

To 0.01% ± 10 V Step

G = 1 to 1000

5

± 11

20

10

nA

pA/°C

nA

pA/°C

10

16.5

GΩ

GΩ

V

110

95

75

115

110

90

dB

dB

dB

110

95

75

120

110

90

105

90

70

115

105

85

dB

dB

dB

0.50

0.30

0.25

0.02

10k

0.006

20

en

4

250

2

15

120

115

95

1

TA = 25°C, RL = 1 kΩ

RL = 1 kΩ, –40°C ≤ TA ≤ +85°C

Output-to-Ground Short

Output-to-Ground Short

10

115

100

80

G = 1 to 1000

1 ≤ G ≤ 10002, 3

VOUT

Positive Current Limit

Negative Current Limit

± 11

G = 1000

G = 100

G = 10

G=1

G

µV

µV

µV/°C

mV

mV

µV/°C

110

95

75

RIN

Gain Range

Nonlinearity

Temperature Coefficient

200

350

4

8

20

200

dB

dB

dB

INPUT

Input Resistance

50 kΩ

+1

RG

40

100

1

2

9

100

115

100

80

2

150

1.2

9

G=

Unit

110

95

75

TA = 25°C

–40°C ≤ TA ≤ +85°C

TA = 25°C

–40°C ≤ TA ≤ +85°C

GAIN

Gain Equation

Accuracy

Max

125

110

90

IB

TCIB

IOS

TCIOS

IVR

CMR

AMP02F

Typ

115

100

80

INPUT CURRENT

Input Bias Current

Input Bias Current Drift

Input Offset Current

Input Offset Current Drift

Input Voltage Range

Common-Mode Rejection

Min

± 12

± 11

4

± 13

± 12

22

32

0.70

0.50

0.40

0.05

10k

1

0.006

20

50

± 12

± 11

50

%

%

%

%

V/V

%

ppm/°C

±13

±12

22

32

V

V

mA

mA

9

10

18

120

0.4

9

10

18

120

0.4

nV/√Hz

nV/√Hz

nV/√Hz

nV/√Hz

pA/√Hz

0.4

0.5

1.2

0.4

0.5

1.2

µV p-p

µV p-p

µV p-p

1200

300

200

6

1200

300

200

6

kHz

kHz

kHz

V/µs

10

10

µs

4

SENSE INPUT

Input Resistance

Voltage Range

RIN

25

± 11

25

± 11

kΩ

V

REFERENCE INPUT

Input Resistance

Voltage Range

Gain to Output

RIN

50

± 11

1

50

± 11

1

kΩ

V

V/V

–2–

REV. E

�AMP02

Parameter

Symbol

POWER SUPPLY

Supply Voltage Range

Supply Current

VS

ISY

Conditions

Min

AMP02E

Typ

Max

Min

± 18

6

6

± 4.5

5

5

± 4.5

TA = 25°C

–40°C ≤ TA ≤ +85°C

AMP02F

Typ

5

5

Max

Unit

± 18

6

6

V

mA

mA

NOTES

1

Input voltage range guaranteed by common-mode rejection test.

2

Guaranteed by design.

3

Gain tempco does not include the effects of external component drift.

Specifications subject to change without notice.

ABSOLUTE MAXIMUM RATINGS 1, 2

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational sections

of this specifications is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

3

θJA is specified for worst case mounting conditions, i.e., θJA is specified for

device in socket for P-DIP package; θJA is specified for device soldered to

printed circuit board for SOIC package.

Supply Voltage

± 18 V

Common-Mode Input Voltage [(V–) – 60 V] to [(V+) + 60 V]

Differential Input Voltage

[(V–) – 60 V] to [(V+) + 60 V]

Output Short-Circuit Duration

Continuous

Operating Temperature Range

–40°C to +85°C

Storage Temperature Range

–65°C to +150°C

Function Temperature Range

–65°C to +150°C

Lead Temperature (Soldering, 10 sec)

300°C

Package Type

JA3

JC

Unit

8-Lead Plastic DIP (P)

16-Lead SOIC (S)

96

92

37

27

°C/W

°C/W

ORDERING GUIDE

Model

AMP02EP

AMP02FP

AMP02AZ/883C

AMP02FS

AMP02GBC

AMP02FS-REEL

VIOS max @ VOOS max @ Temperature

TA = 25ⴗC

TA = 25ⴗC

Range

Package

Description

100 µV

200 µV

200 µV

200 µV

4 mV

8 mV

10 mV

8 mV

–40°C to +85°C

–40°C to +85°C

–55°C to +125°C

–40°C to +85°C

200 µV

8 mV

–40°C to +85°C

8-Lead Plastic DIP

8-Lead Plastic DIP

8-Lead CERDIP

16-Lead SOIC

Die

16-Lead SOIC

V+

25k⍀

SENSE

25k⍀

OUT

25k⍀

25k⍀

REFERENCE

–IN

+IN

RG1 RG2

V–

Figure 2. Simplified Schematic

REV. E

–3–

�AMP02

8

1. RG1

2. –IN

3. +IN

4. V–

5. REFERENCE

6. OUT

7. V+

8. RG2

9. SENSE

CONNECT SUBSTRATE TO V–

1

DIE SIZE 0.103 inch ⴛ 0.116 inch, 11,948 sq. mils

(2.62 mm ⴛ 2.95 mm, 7.73 sq. mm)

NOTE: PINS 1 and 8 are KELVIN CONNECTED

Die Characteristics

WAFER TEST LIMITS* (@ V = ⴞ15 V, V

S

CM

= 0 V, TA = 25ⴗC, unless otherwise noted.)

AMP02 GBC

Limits

Unit

VIOS

200

µV max

VOOS

8

mV max

Parameter

Symbol

Input Offset Voltage

Output Offset Voltage

Conditions

VS = ± 4.8 V to ± 18 V

G = 1000

G = 100

G = 10

G=1

110

110

95

75

Power Supply

Rejection

PSR

Input Bias Current

IB

20

nA max

Input Offset Current

IOS

10

nA max

Input Voltage Range

IVR

Guaranteed by CMR Tests

± 11

V min

CMR

VCM = ± 11 V

G = 1000

G = 100

G = 10

G=1

110

110

95

75

Common-Mode

Rejection

G=

Gain Equation Accuracy

Output Voltage Swing

VOUT

Supply Current

ISY

50 kΩ

+ 1, G = 1000

RG

RL = 1 kΩ

dB

dB

0.7

% max

± 12

V min

6

mA max

*Electrical tests are performed at wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not

guaranteed for standard product dice. Consult factory to negotiate specifications based on dice lot qualifications through sample lot assembly and testing.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AMP02 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

–4–

REV. E

�Typical Performance Characteristics–AMP02

TA = 25ⴗC

1000 VS = ⴞ15V

160

3000 UNITS

FROM 3 RUNS

400 UNITS

FROM 3 RUNS

VS = ⴞ15V

140

800

NUMBER OF UNITS

700

600

500

400

300

120

100

80

60

40

200

0

–100 –80 –60 –40 –30 0 20 40 60 80 100

INPUT OFFSET VOLTAGE – V

0

TPC 1. Typical Distribution of

Input Offset Voltage

1100

TA = 25ⴗC

1000 VS = ⴞ15V

3000 UNITS

FROM 3 RUNS

0

NUMBER OF UNITS

NUMBER OF UNITS

700

600

500

400

300

–5

150

125

100

75

0

5

TPC 4. Typical Distribution of

Output Offset Voltage

20

40

32

VS = ⴞ15V

VCM = 0V

INPUT BIAS CURRENT – nA

2.0

1.5

1.0

0.5

25

0

50

TEMPERATURE – ⴗC

75

TPC 7. Input Offset Current

vs. Temperature

100

–1.0

6

24

20

16

12

8

0

–50

0

ⴞ5

ⴞ10

ⴞ15

POWER SUPPLY VOLTAGE – V

ⴞ20

TPC 6. Output Offset Voltage

Change vs. Supply Voltage

VS = ⴞ15V

VCM = 0V

5

4

3

2

1

4

–25

–0.5

VS = ⴞ15V

VCM = 0V

28

2.5

0

60

80 100 120 140 160

TCVOOS – V/ⴗC

TPC 5. Typical Distribution

of TCVOOS

TA = 25ⴗC

0.5

–1.5

0

ⴞ20

1.0

INPUT BIAS CURRENT – nA

3.0

ⴞ5

ⴞ10

ⴞ15

POWER SUPPLY VOLTAGE – V

1.5

400 UNITS

FROM 3 RUNS

VS = ⴞ15V

25

0

1

2

3

4

–5 –4 –3 –2 –1 0

OUTPUT OFFSET VOLTAGE – mV

0

200

50

100

INPUT OFFSET CURRENT – nA

0

TPC 3. Input Offset Voltage

Change vs. Supply Voltage

200

REV. E

5

TPC 2. Typical Distribution

of TCVIOS

900

0

–50

10

–10

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

TCVIOS – V/ⴗC

175

800

TA = 25ⴗC

15

20

100

INPUT OFFSET VOLTAGE – mV

NUMBER OF UNITS

900

20

INPUT OFFSET VOLTAGE – V

1100

–25

0

50

25

TEMPERATURE – ⴗC

75

TPC 8. Input Bias Current

vs. Temperature

–5–

100

0

0

ⴞ10

ⴞ15

ⴞ5

POWER SUPPLY VOLTAGE – V

TPC 9. Input Bias Current

vs. Supply Voltage

ⴞ20

�AMP02

G = 100

40

G = 10

20

G=1

0

–20

–40

1k

10k

100k

1M

FREQUENCY – Hz

10M

TPC 10. Closed-Loop Voltage

Gain vs. Frequency

G = 1000

120

G = 100

100

G = 10

80

60

G=1

40

TA = 25ⴗC

20 VS = ⴞ15V

VCM = 2V p-p

0

1

100

1k

10

FREQUENCY – Hz

POWER SUPPLY REJECTION – dB

G = 10

100

G=1

80

60

40

TA = 25ⴗC

VS = ⴞ15V

⌬VS = ⴞ1V

20

1

10

1k

100

FREQUENCY – Hz

10k

100k

TPC 13. Positive PSR vs. Frequency

G=1

80

60

40

TA = 25ⴗC

VS = ⴞ15V

⌬VS = ⴞ1V

20

1

1k

VOLTAGE NOISE – nV/ Hz

50

40

30

20

10

1k

100

FREQUENCY – Hz

10k

100k

1

10

1k

100

FREQUENCY – Hz

10k

TPC 16. Voltage Noise Density

vs. Frequency

100k

100

10

1

80

1

100

10

VOLTAGE GAIN – G

1k

TA = 25ⴗC

VS = ⴞ15V

RL = 600⍀

VOUT = 20V p-p

0.100

G = 100

0.010

G=1

G = 10

1k

100

FREQUENCY – Hz

10k

TPC 15. Total Harmonic Distortion

vs. Frequency

100mV

10

0

90

0.01

10

TA = 25ⴗC

VS = ⴞ15V

f = 1kHz

TA = 25ⴗC

VS = ⴞ15V

G = 1000

60

G = 100

G = 10

100

TPC 14. Negative PSR vs. Frequency

70

VOLTAGE NOISE DENSITY – nV/ Hz

120

0

100

1s

NOISE VOLTAGE – 200nV/DIV

POWER SUPPLY REJECTION – dB

120

110

1.000

G = 1000

G = 100

120

TPC 12. Common-Mode Rejection

vs. Voltage Gain

140

G = 1000

TA = 25ⴗC

VS = ⴞ15V

130

70

100k

TPC 11. Common-Mode Rejection

vs. Frequency

140

0

10k

TOTAL HARMONIC DISTORTION – %

VOLTAGE GAIN – dB

60

COMMON-MODE REJECTION – dB

G = 1000

140

140

TA = 25ⴗC

VS = ⴞ15V

COMMON-MODE REJECTION – dB

80

1

100

10

VOLTAGE GAIN – G

TPC 17. RTI Voltage Noise

Density vs. Gain

–6–

1k

TIME – S

TPC 18. 0.1 Hz to 10 Hz Noise

AV = 1000

REV. E

�AMP02

20

15

10

14

5

TA = 25ⴗC

VS = ⴞ15V

100 I

OUT = 20mA p-p

12

10

8

6

4

1k

10k

100k

FREQUENCY – Hz

0

10

1M

7

7

SLEW RATE – Vs

8

6

TA = –25ⴗC, +25ⴗC, +85ⴗC

5

1k

10k

100

LOAD RESISTANCE – ⍀

100k

TPC 20. Maximum Output Voltage

vs. Load Resistance

8

4

3

VS = ⴞ15V

TA = –40ⴗC, +25ⴗC, +85ⴗC

6

5

4

3

2

0

ⴞ10

ⴞ5

ⴞ15

SUPPLY VOLTAGE – V

TPC 22. Supply Current

vs. Supply Voltage

REV. E

ⴞ20

1

80

60

40

20

0

2

TPC 19. Maximum Output Swing

vs. Frequency

1

120

TA = 25ⴗC

VS = ⴞ15V

OUTPUT IMPEDANCE – ⍀

25

0

100

SUPPLY CURRENT – mA

16

TA = 25ⴗC

VS = ⴞ15V

RL = 1k⍀

OUTPUT VOLTAGE – V

PEAK- TO-PEAK AMPLITUDE – V

30

1

100

10

VOLTAGE GAIN – G

TPC 23. Slew Rate vs.

Voltage Gain

–7–

1k

–20

100

1k

100k

10k

FREQUENCY – Hz

1M

TPC 21. Closed Loop Output

Impedance vs. Frequency

10M

�AMP02

The voltage gain can range from 1 to 10,000. A gain set resistor is

not required for unity-gain applications. Metal-film or wirewound

resistors are recommended for best results.

APPLICATIONS INFORMATION

Input and Output Offset Voltages

Instrumentation amplifiers have independent offset voltages

associated with the input and output stages. The input offset

component is directly multiplied by the amplifier gain, whereas

output offset is independent of gain. Therefore at low gain,

output-offset errors dominate while at high gain, input-offset

errors dominate. Overall offset voltage, VOS, referred to the

output (RTO) is calculated as follows:

The total gain accuracy of the AMP02 is determined by the

tolerance of the external gain set resistor, RG, combined with the

gain equation accuracy of the AMP02. Total gain drift combines

the mismatch of the external gain set resistor drift with that of the

internal resistors (20 ppm/°C typ). Maximum gain drift of the

AMP02 independent of the external gain set resistor is 50 ppm/°C.

VOS ( RTO ) = (VIOS × G ) + VOOS

All instrumentation amplifiers require attention to layout so

thermocouple effects are minimized. Thermocouples formed

between copper and dissimilar metals can easily destroy the

TCVOS performance of the AMP02, which is typically 0.5 µV/°C.

Resistors themselves can generate thermoelectric EMFs when

mounted parallel to a thermal gradient.

where VIOS and VOOS are the input and output offset voltage

specifications and G is the amplifier gain.

The overall offset voltage drift TCVOS, referred to the output, is

a combination of input and output drift specifications. Input

offset voltage drift is multiplied by the amplifier gain, G, and

summed with the output offset drift:

The AMP02 uses the triple op amp instrumentation amplifier

configuration with the input stage consisting of two transimpedance amplifiers followed by a unity-gain differential amplifier.

The input stage and output buffer are laser-trimmed to increase

gain accuracy. The AMP02 maintains wide bandwidth at all

gains as shown in Figure 3. For voltage gains greater than 10,

the bandwidth is over 200 kHz. At unity gain, the bandwidth of

the AMP02 exceeds 1 MHz.

TCVOS ( RTO ) = (TCVIOS × G ) + TCVOOS

where TCVIOS is the input offset voltage drift, and TCVOOS is

the output offset voltage drift. Frequently, the amplifier drift is

referred back to the input (RTI), which is then equivalent to an

input signal change:

TCVOS ( RTI ) = TCVIOS +

TCVOOS

G

80

For example, the maximum input-referred drift of an

AMP02EP set to G = 1000 becomes:

VOLTAGE GAIN – dB

TCVOS ( RTI ) = 2 µV oC +

60

100 µV oC

= 2.1 µV oC

1000

Input Bias and Offset Currents

Input transistor bias currents are additional error sources that

can degrade the input signal. Bias currents flowing through the

signal source resistance appear as an additional offset voltage.

Equal source resistance on both inputs of an IA will minimize

offset changes due to bias current variations with signal voltage

and temperature; however, the difference between the two bias

currents (the input offset current) produces an error. The magnitude of the error is the offset current times the source resistance.

0

G = 100

G = 10

G=1

–40

1k

10k

100k

FREQUENCY – Hz

1M

10M

Figure 3. The AMP02 Keeps Its Bandwidth at

High Gains

Common-Mode Rejection

Ideally, an instrumentation amplifier responds only to the difference between the two input signals and rejects common-mode

voltages and noise. In practice, there is a small change in output

voltage when both inputs experience the same common-mode

voltage change; the ratio of these voltages is called the

common-mode gain. Common-mode rejection (CMR) is the

logarithm of the ratio of differential-mode gain to common-mode

gain, expressed in dB. Laser trimming is used to achieve the

high CMR of the AMP02.

Gain

The AMP02 only requires a single external resistor to set the

voltage gain. The voltage gain, G, is:

50 kΩ

+1

RG

and

RG =

20

G = 1000

–20

A current path must always be provided between the differential

inputs and analog ground to ensure correct amplifier operation.

Floating inputs such as thermocouples should be grounded

close to the signal source for best common-mode rejection.

G=

40

TA = 25ⴗC

VS = ⴞ15V

50 kΩ

G –1

–8–

REV. E

�AMP02

3

+IN

8

RG2

V1 25k⍀

25k⍀

R

25k⍀

RG

RG1

1

SENSE

(SOIC-16 ONLY)

6

OUT

R

25k⍀

25k⍀

–IN

2

25k⍀

5

REFERENCE

V2

Figure 4. Triple Op Amp Topology

Figure 4 shows the triple op amp configuration of the AMP02.

With all instrumentation amplifiers of this type, it is critical not

to exceed the dynamic range of the input amplifiers. The amplified differential input signal and the input common-mode voltage must not force the amplifier’s output voltage beyond ± 12 V

(VS = ± 15 V) or nonlinear operation will result.

Grounding

The majority of instruments and data acquisition systems have

separate grounds for analog and digital signals. Analog ground may

also be divided into two or more grounds that will be tied together

at one point, usually at the analog power supply ground. In

addition, the digital and analog grounds may be joined—normally

at the analog ground pin on the A/D converter. Following this

basic practice is essential for good circuit performance.

The input stage amplifier’s output voltages at V1 and V2 equal:

2R VD

V1 = – 1 +

+ VCM

RG 2

= –G

Mixing grounds causes interactions between digital circuits and the

analog signals. Since the ground returns have finite resistance

and inductance, hundreds of millivolts can be developed between

the system ground and the data acquisition components. Using

separate ground returns minimizes the current flow in the sensitive

analog return path to the system ground point. Consequently, noisy

ground currents from logic gates interact with the analog signals.

VD

+ VCM

2

2R VD

V2 = 1 +

+ VCM

RG 2

=G

Inevitably, two or more circuits will be joined together with

their grounds at differential potentials. In these situations, the

differential input of an instrumentation amplifier, with its high

CMR, can accurately transfer analog information from one

circuit to another.

VD

+ VCM

2

Sense and Reference Terminals

where:

VD

The sense terminal completes the feedback path for the instrumentation amplifier output stage and is internally connected directly

to the output. For SOIC devices, connect the sense terminal to

the output. The output signal is specified with respect to the reference terminal, which is normally connected to analog ground.

The reference may also be used for offset correction level shifting. A reference source resistance will reduce the common-mode

rejection by the ratio of 25 kΩ/RREF. If the reference source resistance is 1 Ω, the CMR will be reduced 88 dB (25 kΩ/1 Ω = 88 dB).

= Differential input voltage

= (+IN) – (–IN)

VCM = Common-mode input voltage

G

= Gain of instrumentation amplifier

If V1 and V2 can equal ± 12 V maximum, the common-mode

input voltage range is:

GVD

CMVR = ± 12 V −

2

REV. E

–9–

�AMP02

Overvoltage Protection

Power Supply Considerations

Instrumentation amplifiers invariably sit at the front end of

instrumentation systems where there is a high probability of

exposure to overloads. Voltage transients, failure of a transducer,

or removal of the amplifier power supply while the signal source is

connected may destroy or degrade the performance of an unprotected device. A common technique is to place limiting resistors in

series with each input, but this adds noise. The AMP02 includes

internal protection circuitry that limits the input current to ±4 mA

for a 60 V differential overload (see Figure 5) with power off,

± 2.5 mA with power on.

Achieving the rated performance of precision amplifiers in a

practical circuit requires careful attention to external influences.

For example, supply noise and changes in the nominal voltage

directly affect the input offset voltage. A PSR of 80 dB means

that a change of 100 mV on the supply (not an uncommon

value) will produce a 10 µV input offset change. Consequently,

care should be taken in choosing a power unit that has a low

output noise level, good line and load regulation, and good

temperature stability. In addition, each power supply should be

properly bypassed.

4

LEAKAGE CURRENT – mA

3

TA = 25ⴗC

VS = ⴞ15V

POWER OFF

2

POWER ON

1

0

–1

–2

–3

–4

–100

–80

–60

–40

–20

0

20

40

60

80

100

DIFFERENTIAL INPUT VOLTAGE

Figure 5. AMP02’s Input Protection Circuitry Limits Input

Current During Overvoltage Conditions

–10–

REV. E

�AMP02

OUTLINE DIMENSIONS

8-Lead Plastic Dual-in-Line Package [PDIP]

(N-8)

8-Lead Ceramic DIP - Glass Hermetic Seal [CERDIP]

(Q-8)

Dimensions shown in inches and (millimeters)

Dimensions shown in inches and (millimeters)

0.005 (0.13)

MIN

0.375 (9.53)

0.365 (9.27)

0.355 (9.02)

8

5

1

4

8

0.295 (7.49)

0.285 (7.24)

0.275 (6.98)

0.150 (3.81)

0.130 (3.30)

0.110 (2.79)

0.022 (0.56)

0.018 (0.46)

0.014 (0.36)

5

0.310 (7.87)

0.220 (5.59)

PIN 1

1

0.325 (8.26)

0.310 (7.87)

0.300 (7.62)

0.100 (2.54)

BSC

0.180

(4.57)

MAX

0.055 (1.40)

MAX

4

0.100 (2.54) BSC

0.150 (3.81)

0.135 (3.43)

0.120 (3.05)

0.015

(0.38)

MIN

0.200 (5.08)

MAX

0.150 (3.81)

MIN

0.200 (5.08)

0.125 (3.18)

0.015 (0.38)

0.010 (0.25)

0.008 (0.20)

SEATING

PLANE

0.060 (1.52)

0.050 (1.27)

0.045 (1.14)

0.060 (1.52)

0.015 (0.38)

0.023 (0.58)

0.014 (0.36)

SEATING

0.070 (1.78) PLANE

0.030 (0.76)

15

0

0.015 (0.38)

0.008 (0.20)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETERS DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

COMPLIANT TO JEDEC STANDARDS MO-095AA

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

16-Lead Standard Small Outline Package [SOIC]

Wide Body

(R-16)

Dimensions shown in millimeters and (inches)

10.50 (0.4134)

10.10 (0.3976)

9

16

7.60 (0.2992)

7.40 (0.2913)

1.27 (0.0500)

BSC

0.30 (0.0118)

0.10 (0.0039)

COPLANARITY

0.10

10.65 (0.4193)

10.00 (0.3937)

8

1

0.51 (0.0201)

0.33 (0.0130)

0.75 (0.0295)

ⴛ 45ⴗ

0.25 (0.0098)

2.65 (0.1043)

2.35 (0.0925)

SEATING

PLANE

0.32 (0.0126)

0.23 (0.0091)

8ⴗ

0ⴗ

1.27 (0.0500)

0.40 (0.0157)

COMPLIANT TO JEDEC STANDARDS MS-013AA

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

REV. E

0.320 (8.13)

0.290 (7.37)

0.405 (10.29) MAX

–11–

�AMP02

Revision History

Location

Page

1/03—Data Sheet changed from REV. D to REV. E.

Edits to Die Characteristics .............................................................................................................................................................4

PRINTED IN U.S.A.

Updated OUTLINE DIMENSIONS.............................................................................................................................................11

C00248–0–1/03(E)

Edits to Figure 2 .............................................................................................................................................................................3

–12–

REV. E

�