Circuit Note

CN-0342

Devices Connected/Referenced

Circuits from the Lab® reference designs are engineered and

tested for quick and easy system integration to help solve today’s

analog, mixed-signal, and RF design challenges. For more

information and/or support, visit www.analog.com/CN0342.

ADuM3190

2.5 kV rms Isolated Error Amplifier

ADP1621

Constant-Frequency, Current-Mode

Step-Up DC-to-DC Controller

Flyback Power Supply Using a High Stability Isolated Error Amplifier

EVALUATION AND DESIGN SUPPORT

The entire circuit operates from 5 V to 24 V, allowing it to be

used with standard industrial and automotive power supplies.

The output capability of the circuit is up to 1 A with a 5 V input

and 5 V output configuration.

Circuit Evaluation Board

CN-0342 Circuit Evaluation Board (EVAL-CN0342-EB1Z)

Design and Integration Files

Schematics, Layout Files, Bill of Materials

This solution can be adapted for use in applications where higher

dc input voltages are used to create lower voltage isolated supplies

with good efficiency and a small form factor. Examples include

10 W to 20 W telecommunication and server power supplies,

where power efficiency and printed circuit board (PCB) density

are important, and −48 V supplies are common.

CIRCUIT FUNCTION AND BENEFITS

The circuit shown in Figure 1 is an isolated, flyback power

supply that uses a linear isolated error amplifier to supply the

feedback signal from the secondary side to the primary side.

Unlike optocoupler-based solutions, which have a nonlinear

transfer function that changes over time and temperature, the

linear transfer function of the isolated amplifier is stable and

minimizes offset and gain errors when transferring the feedback

signal across the isolation barrier.

VOUT

5V TO 24V

T1

C26

C25

C14

47µF

47µF

100µF

R12

820Ω

C21

220nF

D1

R19

390Ω

C23

C24

C3

47µF

47µF

100µF

5V

R4

100kΩ

Q2

R18

0Ω

IN

SDSN

CS

GND

COMP PIN

GATE

FB

FREQ PGND

ADP1621

R3

51kΩ

R5

82Ω

D2

Q3

R16

0Ω

R6

100kΩ

C17

0.1µF

R2

47kΩ

R1

2kΩ

R20

0Ω

VDD1

VDD2

ADuM3190

REF

REFOUT

+IN

EAOUT

–IN

C10

1nF

COMP

GND1

GND2

R19

15kΩ

C9

2.2nF

11763-001

VIN

Figure 1. Simplified Schematic of Flyback Power Supply Circuit

Rev. 0

Circuits from the Lab reference designs from Analog Devices have been designed and built by Analog

Devices engineers. Standard engineering practices have been employed in the design and

construction of each circuit, and their function and performance have been tested and verified in a lab

environment at room temperature. However, you are solely responsible for testing the circuit and

determining its suitability and applicability for your use and application. Accordingly, in no event shall

Analog Devices be liable for direct, indirect, special, incidental, consequential or punitive damages due

toanycausewhatsoeverconnectedtotheuseofanyCircuitsfromtheLabcircuits. (Continuedonlastpage)

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Fax: 781.461.3113

©2014 Analog Devices, Inc. All rights reserved.

�CN-0342

Circuit Note

CIRCUIT DESCRIPTION

The average transformer primary side current, ILAVG, is given by

The isolation amplifier is the ADuM3190, which includes a

1.225 V voltage reference and an error amplifier with 10 MHz

unity-gain bandwidth product. An external resistive divider

(R1, R2, R3, and R4) and compensation network (R9, C9, and

C10) complete the analog feedback loop.

The input supply range of the ADuM3190 is 3.0 V to 20 V on

both sides, and internal low dropout regulators provide stable

supplies for the voltage reference, error amplifier, and analog

isolator. The ADuM3190 is compatible with the Distributedpower Open Standards Alliance (DOSA) output voltage trim

method.

The ADP1621 provides pulse-width modulation (PWM)

control for the flyback power supply. The internal 5.5 V shunt

regulator provides the capability of high supply input voltage

with the addition of an external NPN transistor (Q2). The

ADP1621 also provides lossless current sensing for current

mode operation, providing excellent line and load transient

response.

Setting the Output Voltage

The output voltage is set through a voltage divider from VOUT to

the −IN pin of ADuM3190. The feedback resistor ratio sets the

output voltage of the system. Using the internal voltage reference in

the ADuM3190, the regulation voltage at the −IN pin is 1.225 V.

VOUT

I LAVG =

where:

ILOAD is the load current.

D is the duty cycle under maximum load current.

NS/NP is the turn ratio of the transformer.

The output voltage is

VOUT × (1 − D) ×

The peak-to-peak primary inductor ripple current is inversely

proportional to the inductor value.

∆I L =

The ADuM3190 provides an internal 1.225 V voltage reference

specified for ±1% accuracy over the −40°C to +125°C temperature

range. The reference voltage output pin (REFOUT) can be connected

to the +IN pin of the error amplifier to set the output voltage.

When higher accuracy or a special output voltage is required, and

a different reference voltage must be used, the +IN pin can also

be connected to an external reference

For this design example, the following parameters were used:

•

•

•

•

•

VIN = 5 V

VOUT = 5 V

IOUTMAX = 1 A

fSW = 200 kHz

Transformer turn ratio = 1:1

f SW × L

where:

fSW is the switching frequency.

L is the primary inductor value.

Assuming continuous conduction mode (CCM) operation, the

primary inductor current is given by

Voltage Reference

The transformer choice is important because it dictates the

primary inductor current ripple.

VIN × D

VIN × D

I LOAD N S

×

+

1 − D N P 2 × f SW × L

Assuming the primary ripple current is 50% of the average current

on the transformer primary side, a reasonable choice for the

inductor value is

For a 5 V output configuration, the resistor divider values are

R1 = 2 kΩ, R2 = 47 kΩ, R3 = 51 kΩ, and R4 = 100 kΩ.

Transformer Selection

NP

= VIN × D

NS

The duty cycle (D) is 50% because the output and input are both

5 V, and the transformer turn ratio is 1:1.

I LPK =

R4 + R3

= 1.225 V × 1 +

R1

+

R2

I LOAD N S

×

1 − D NP

L=

VIN × D × (1 − D)

0.5 × f SW × I LOAD

×

5 V × 0.5 (1 − 0.5)

NP

=

= 12.5 μH

N S 0.5 × 200 kHz × 1 A

The transformer used in this design is a 1:1 turn ratio transformer

with 16 µH primary side inductance (Halo Electronics, Inc.,

TGB01-P099EP13LF).

Compensation Network

In a flyback topology power supply, the output load resistance, the

output capacitor, and its effective series resistance (ESR) add a zero

and a pole at frequencies that are dependent on the component

type and values. There is also a right half plane (RHP) zero in

the control-to-output transfer function. Because the RHP zero

reduces the phase by 90°, the frequency of 0 dB gain (crossover

frequency) is lower than the RHP zero.

With the ADuM3190 providing the error amplifier, a Type II

compensation network can be provided from the −IN pin to the

COMP pin to compensate for the control loop for stability. The

compensation network values depend on the selected components.

Rev. 0 | Page 2 of 5

�Circuit Note

CN-0342

Insulation and Safety

The zeros and poles of a Type II compensation network are

derived as follows:

f ZERO

The ADuM3190 is packaged in a small, 16-lead QSOP package

for a 2.5 kV rms isolation voltage rating.

1

2 R9 C9

f POLE

Safety specifications for the ADuM3190 are shown in Table 1.

C10 C9

Table 1. Safety Specifications for the ADuM3190

2 R9 C10 C9

In this particular design, the compensation network is set by

R9 = 15 kΩ, C9 = 2.2 nF, and C10 = 1 nF.

The zero and the pole provided by this compensation network

are fZERO = 4.8 kHz and fPOLE = 15.4 kHz. Increasing the zero and

pole frequency improves the load transient response but decreases

the phase margin of the feedback loop and can cause instability

in the power supply.

Parameter

Rated Dielectric Insulation Voltage

Minimum External Air Gap (Clearance)

Minimum External Tracking (Creepage)

Minimum Internal Gap (Internal Clearance)

Tracking Resistance (Comparative Tracking

Index)

Isolation Material Group

Value

2500

3.8 min

3.1 min

0.017 min

>400

Unit

V rms

mm

mm

mm

V

II

COMMON VARIATIONS

Snubber Network

When the power MOSFET (Q3) is turned off, there is a high

voltage spike on the drain due to the transformer leakage

inductance. This excessive voltage can overstress the power

MOSFET and lead to a reliability issue or damage. Therefore, it

is necessary to use an additional network to clamp the voltage.

The resistor, capacitor, and diode (R19, C21, and D2) snubber

network absorbs the current in the leakage inductance by turning

on the snubber diode when the MOSFET drain voltage exceeds

the cathode voltage of D2.

The ADP1621 operates in lossless mode with the drain of the

power MOSFET connected to the CS pin. In a practical design,

limit the voltage at the CS pin to an absolute maximum of 33 V, and

a practical maximum of 30 V to maintain accuracy. If the measured

peak voltage exceeds 30 V, or if a more accurate current limit is

desired, connect the CS pin to an external current sense resistor

in the source of the MOSFET.

Primary Side Power Supply

The ADP1621 supply voltage range is 2.9 V to 5.5 V, and the

ADuM3190 supply voltage range is 3.0 V to 20 V. To work

with a 5 V to 12 V input voltage supply, a small-signal NPN

transistor (Q2) can be used as a voltage regulator.

For higher input voltages, the current sense resistor must be used

with a current control loop. Change the R20 resistor from 0 Ω

to the value required by the application. For the 1 A output

configuration, choose a sense resistor value of 50 mΩ. According to

the internal current feedback loop in the ADP1621, the maximum

PWM duty cycle of switching is reduced when the current sensing

voltage rises. If the sense resistor value is too high, the duty cycle of

the switching is limited; the maximum output current is then

also limited under the specific output voltage. The ADP1621

compensation pin (COMP) has a 0 V to 2 V effective input voltage

range. It is recommended to limit the voltage on the CS pin to

less than 0.1 V to guarantee an adequate switching duty cycle.

When working with an input voltage less than 5 V, bypass the

input regulation transistor by shorting the jumper between the

collector and the emitter.

For applications such as telecommunication or server power

supplies with a −48 V input, regulate the supply voltage for the

primary side controller to +5 V. The NPN transistor Q2 needs a

higher VCE breakdown voltage, and the power MOSFET Q3 needs

a higher VDS (100 V, VDSMAX). In addition, change the diode in

the RCD snubber circuit, D2, to a 70 V reverse voltage rating.

To reduce the current on the internal regulator in the ADP1621,

increase R12 to 1.5 kΩ.

The IN pin of ADP1621 has a 5.5 V internal voltage regulator

and is connected to the base node of the NPN transistor Q2.

This connection biases Q2 so that the emitter node can be

regulated to 5.5 V − 0.7 V = 4.8 V, which can be used as the

power supply voltage for the ADP1621 (PIN) and the

ADuM3190 (VDD1).

Table 2 summarizes the alternative components selected for

different input voltage configurations.

Table 2. Component Values for Different Configurations

Secondary Side Power Supply

The ADuM3190 has a 3.0 V to 20 V supply voltage range on the

secondary side (VDD2), with an internal regulator providing a

3.0 V operating voltage. If VOUT is set higher than 20 V, add an

external voltage regulator to provide the specified VDD2 voltage.

Input Voltage

Q2

Q3

D2

R12

5 V to 7 V

PMST2369

NTD18N06L

MBR0540T1

390 Ω

7 V to 24 V

PMST2369

NTD18N06L

MBR0540T1

820 Ω

24 V to 48 V

BC846

NVD6824NL

MMSD701T1

1.5 kΩ

A complete design support package, including the schematics,

layouts, and bill of materials, is available at

www.analog.com/CN0342-DesignSupport.

Rev. 0 | Page 3 of 5

�CN-0342

Circuit Note

Performance Results

Figure 2 shows the measured efficiency with three different

input voltages: 5 V, 12 V, and 24 V.

Figure 4. 100 mA to 900 mA Load Transient Response

Figure 2. Flyback Circuit Output Efficiency vs. Load Current for

Input Voltages of 5 V, 12 V, and 24 V

Figure 3 shows the output voltage over a temperature range

from −40°C to +125°C. The total output voltage error over this

range is less than ±20 mV (±0.4%).

Figure 5. 900 mA to 100 mA Load Transient Response

Figure 3. Flyback Circuit Output Voltage vs. Temperature

Figure 4 and Figure 5 show the transient response for increasing

and decreasing load current. The transient response time is

32 µs for a load current increase from 100 mA to 900 mA, and

45 µs for a load current decrease from 900 mA to 100 mA.

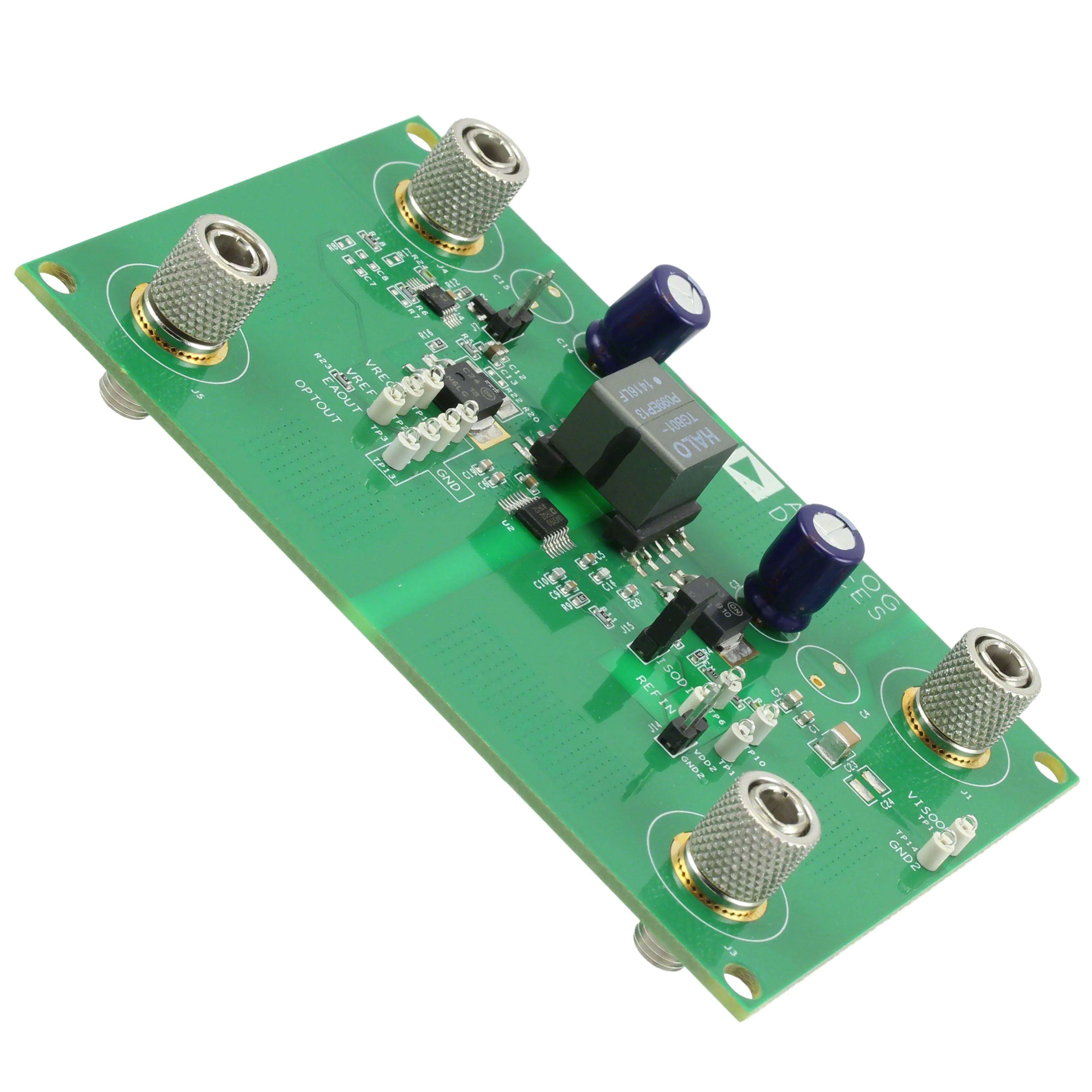

A photograph of the EVAL-CN0342-EB1Z evaluation board is

shown in Figure 6.

Figure 6. EVAL-CN0342-EB1Z Evaluation Board Photo

Rev. 0 | Page 4 of 5

�Circuit Note

CN-0342

CIRCUIT EVALUATION AND TEST

LEARN MORE

The circuit is tested using a dc power supply and a source/

measurement unit for efficiency and load regulation. Load

transient response and output ripple are measured with an

oscilloscope and current probe.

CN0342 Design Support Package.

Equipment Needed

Brown, Marty. Practical Switching Power Supply Design.

Academic Press, 1990.

Gottlieb, Irving M. Power Supplies, Switching Regulators,

Inverters, and Converters. Second Edition, McGraw Hill

(TAB Books), 1994.

The following equipment is required:

A 30 V power supply with 3 A current output capability

and current measurement function

A source/measurement unit with 1 A load current capability

An oscilloscope with >300 MHz bandwidth and a current

probe with >1 A input range

Getting Started

The circuit does not require software support for evaluation.

Connect the power supply, and the output is regulated based

on the configuration.

Brown, Marty. Power Supply Cookbook. ButterworthHeinemann, 1994.

Lenk, John D. Simplified Design of Switching Power Supplies.

Butterworth-Heinemann, 1995.

Billings, Keith. Switchmode Power Supply Handbook.

McGraw-Hill, 1989.

Chryssis, George. High-Frequency Switching Power Supplies:

Theory and Design. Second Edition, McGraw-Hill, 1989.

Setup and Test

Pressman, Abraham I. Switching Power Supply Design.

McGraw-Hill, 1991.

Connect the 5 V power supply to the primary side input

connector (J4), and connect ground to J5.

ADIsimPower Power Management Design Tool.

Analog Devices, Inc.

Connect the source meter to the secondary side, where J1 is the

5 V output, and J3 is the output ground.

Data Sheets and Evaluation Boards

Place a jumper on J15 to use the internal 1.225 V voltage

reference of the ADuM3190.

ADP1621 Data Sheet

ADuM3190 Data Sheet

REVISION HISTORY

11/14—Revision 0: Initial Version

(Continued from first page) Circuits from the Lab reference designs are intended only for use with Analog Devices products and are the intellectual property of Analog Devices or its

licensors. While you may use the Circuits from the Lab reference designs in the design of your product, no other license is granted by implication or otherwise under any patents or

other intellectual property by application or use of the Circuits from the Lab reference designs. Information furnished by Analog Devices is believed to be accurate and reliable.

However, Circuits from the Lab reference designs are supplied "as is" and without warranties of any kind, express, implied, or statutory including, but not limited to, any implied

warranty of merchantability, noninfringement or fitness for a particular purpose and no responsibility is assumed by Analog Devices for their use, nor for any infringements of

patents or other rights of third parties that may result from their use. Analog Devices reserves the right to change any Circuits from the Lab reference designs at any time without

notice but is under no obligation to do so.

©2014 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

CN11763-0-11/14(0)

Rev. 0 | Page 5 of 5

�