Circuit Note

CN-0509

Devices Connected/Referenced

Circuits from the Lab® reference designs are engineered and

tested for quick and easy system integration to help solve today’s

analog, mixed-signal, and RF design challenges. For more

information and/or support, visit www.analog.com/CN0509.

LTC7103

105 V, 2.3 A Low EMI Synchronous StepDown Regulator

LT8302

42 VIN Micropower No Opto Isolated

Flyback Converter with 65 V/3.6 A Switch

Wide Input Voltage Range, Dual USB Port Charger

EVALUATION AND DESIGN SUPPORT

supplies, random stacks of alkaline battery cells, motors hacked

to run as generators, and wind turbines. The CN-0509 includes

two USB charging ports that can provide 2 A at 5 V. One port

includes a dedicated charging port (DCP) controller that enables

the fast charging modes for devices from most manufacturers.

Circuit Evaluation Boards

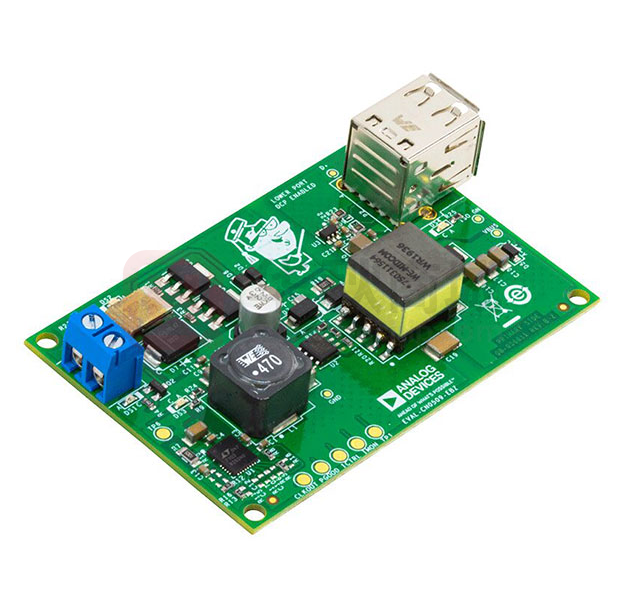

CN-0509 Circuit Evaluation Board (EVAL-CN0509-EBZ)

Design and Integration Files

Schematics, Layout Files, Bill of Materials

CIRCUIT FUNCTION AND BENEFITS

Finding a power source to charge cell phones or other USB

communication devices can be difficult during emergency

situations, such as natural disasters or extended power outages.

Chargers operating from ac mains are ubiquitous, but when a

power grid is unavailable, and the last USB battery backup charger

systems are depleted, how else can critical USB powered devices

be charged?

The circuit shown in Figure 1 is a wide input voltage range USB

device charger capable of providing 2 A at 5 V for a wide range of

dc power sources, including solar panels, fully charged or half

discharged car batteries, −48 V telecommunications backup

This circuit accepts any dc voltage from 5 V to 100 V and

produces an isolated 5 V supply via a standard USB, Type A

connector. Isolation prevents faults in situations in which the

relationship of the power source to Earth ground is unknown

because the outer case of many cell phones and other portable

electronics are often electrically connected to USB ground.

The circuit shown in Figure 1 is also protected from reverse

voltage conditions. Because the polarity of a makeshift power

supply may not be known, the circuit can survive reverse

connection to the dc power source. This design contains light

emitting diodes (LEDs) that indicate whether the voltage source

is connected properly or must be swapped.

INPUT POLARITY INDICATOR

GREEN LED

DRIVER

(TRANSISTOR)

RED LED

DRIVER

(TRANSISTOR)

USB2

LTC7103

(BUCK REGULATOR)

2.5A

FUSE

LTC8302

SW

FLYBACK

RFB

CONVERTER

USB CHARGE DM1

PORT

CONTROLLER DP1

USB1

20199-001

VIN

Figure 1. CN0509 Wide Range Isolated Device Charger Simplified Schematic

Rev. 0

Circuits from the Lab® reference designs from Analog Devices have been designed and built by Analog

Devices engineers. Standard engineering practices have been employed in the design and

construction of each circuit, and their function and performance have been tested and verified in a lab

environment at room temperature. However, you are solely responsible for testing the circuit and

determining its suitability and applicability for your use and application. Accordingly, in no event shall

Analog Devices be liable for direct, indirect, special, incidental, consequential or punitive damages due

toanycausewhatsoeverconnectedtotheuseofanyCircuitsfromtheLabcircuits. (Continuedonlastpage)

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Fax: 781.461.3113

©2020 Analog Devices, Inc. All rights reserved.

�CN-0509

Circuit Note

CIRCUIT DESCRIPTION

R1

270kΩ

The CN-0509 converts a wide array of dc power sources from

5 V to 100 V into a regulated 5 V, 2 A supply capable of charging

USB charged devices through a dual USB, Type A receptacle.

This design uses a combination of a high efficiency, step-down

(buck) dc to dc converter (LTC7103), capable of passthrough

operation, and an isolated flyback converter (LT8302). This

configuration combines the high power efficiency and wide

operating range of a buck converter with the isolation and

excellent regulation of a flyback converter.

Input Voltage Protection and LED Driver

The CN-0509 power entry stage is shown in Figure 2. A high

voltage Schottky diode and fuse protect the circuit from reverse

supply connection and overcurrent conditions.

INPUT POLARITY INDICATOR

B

DZTA42-13

3E

DSS120UTR

DSS120UTR

DS2

REVERSED

DS1

CORRECT

Q1

Q2

SML-P11MTT86R

SML-P11VTT86

MBT3904DW1T1G

MBT3904DW1T1G

R4

240Ω

R2

240Ω

GND

VIN

Figure 3. Polarity Indication

When power is applied, current flows through R1, which turns

on Transistor Q3. Current then flows through the emitter of Q3,

the LED, and R2. As the current increases through R2, the voltage

across R2 increases as well. Once the voltage drop across R2 reaches

the base to emitter voltage (VBE) of transistor Q1 (approximately

0.7 V), Q1 begins to turn on. The resulting current through R1

reduces the base drive to Q1, effectively limiting current to the

LED. This feedback loop maintains the green LED and the red

LED current at approximately 2.41 mA and 2.432 mA, respectively,

over a voltage range of 11 V to 100 V.

The power entry circuit is followed by an LTC7103 synchronous

buck converter. A buck converter, or step-down switch mode

power supply, efficiently reduces a higher dc voltage to a lower

voltage with low power dissipation and high power density in

a small package relative to a linear regulator of similar current

capability.

20199-002

LTC7103

VIN

D6

3E

LTC7103 Buck Converter

RED LED

DRIVER

(TRANSISTOR)

2.5A

FUSE

D2

Q4

4 2

C

1

Figure 2. Input Voltage Protection Circuit

Two LEDs indicate the input power, green indicates correct

polarity and red indicates a reversed connection. If the red LED

appears, the input connections must be reversed for the circuit

to operate. While a bridge rectifier could be used to allow operation

in either polarity, the additional 400 mV drop increases the

minimum operating voltage, which can be an issue when charging

from lower voltage sources, such as solar panels or alkaline

battery cells.

The dc input is filtered and bypassed by a total of 4.8 µF before

going into the input of the buck converter. The LTC7103 then

efficiently steps down the wide input voltage range of 12 V to

105 V to a regulated output voltage (VOUT) of 12 V while

delivering up to 2.3 A of output current at a 300 kHz switching

frequency (fSW).

An active, constant current driver circuit maintains LED

current over the entire operating range of the circuit, with

minimal variation in brightness. Two circuits are connected

in series, however, with opposite polarity (see Figure 3).

100

95

90

85

80

75

70

65

fSW = 300kHz

VIN = 100V

VIN = 72V

VIN = 48V

VIN = 24V

60

55

50

0.1

1

10

100

LOAD CURRENT (mA)

1000

20199-004

VIN

DZTA42-13

B

EFFICIENCY (%)

GREEN LED

DRIVER

(TRANSISTOR)

R3

270kΩ

20199-003

Two output ports are provided, one that leaves the USB D+

and D− signals open for general-purpose charging and one that

includes a USB DCP controller that enables the high current

charging modes for devices from most manufacturers. Both ports

can be used simultaneously. However, the maximum total load

current is 2 A.

Q3

4 2

C

1

Figure 4. Efficiency at 12 V VOUT and Various Input Voltage Conditions

Rev. 0 | Page 2 of 7

�Circuit Note

CN-0509

The LTC7103 includes a selectable precision internal feedback

divider, eliminating the need for external precision resistors.

The digital state of the VPRG1 and VPRG2 pins sets the output

voltage to one of the nine fixed options between 1.0 V and 15 V.

Note that the CN-0509 sets the output to 12 V by tying the

VPRG1 pin to the INTVCC pin and leaving the VPRG2 pin open.

5

VPRG1 = GND

VPRG2 = OPEN

OUTPUT VOLTAGE (V)

4

The CN-0509 takes advantage of the ability of the LTC7103 to

operate in passthrough mode when the input voltage is between

4.4 V and 12 V (see Figure 5). The isolated flyback stage following

the LTC7103 is optimized for 12 V but continues to operate

down to voltages as low as 5 V with a reduced output current

capability. Passthrough operation allows the circuit to continue to

operate as long as possible, even as the voltages of the emergency

power source begins to drop.

2

0

1

0

2

3

LOAD CURRENT (A)

20199-006

1

Figure 6. Typical LTC7103 Current-Limit Operation

13

LT8302 Flyback Converter

12

The buck stage is followed by an LT8302 micropower, no opto,

isolated flyback converter. The LT8302 maintains regulation by

indirectly sensing the output voltage by sampling the primary

side flyback waveform, eliminating the need for optocouplers or

a third sense winding on the coupled inductor.

11

10

9

8

Isolation is essential in this application because the polarity and

ground connections of a makeshift power source may not be

known or may inherently be incorrect for a charging application

by design. A −48 V telecommunications supply is a common

example (see Figure 7).

7

6

4

0

10

20

30

40

50

60

70

80

90

INPUT VOLTAGE (V)

100

20199-005

5

TELECOM

SUPPLY

Figure 5. Passthrough Operation for 4.4 V < VIN < 12 V

NONISOLATED

BUCK SUPPLY

VIN

The architecture of the LTC7103 provides inherent protection

against short-circuit conditions without the need for folding

back the output current or the oscillator frequency. This

protection is made possible because the pulse-width modulation

(PWM) comparator is continuously receiving inductor current

information from the average current amplifier. This results in

automatic cycle skipping under short-circuit conditions if the

minimum on time of the top switch is too long to maintain

control of the inductor current at the full switching frequency.

Typical current-limit operation is shown in Figure 6.

5V

SW

CASE AT

–48V

GND

+

48V

USB

CELLPHONE

–

–48V

HAZARD!

EARTH

Figure 7. Ground Fault Condition

Telecommunication supplies are negative with respect to Earth

ground to prevent galvanic corrosion of wires. Therefore, a

charger based on a nonisolated buck converter ties the outer

case of a cell phone to −48 V, posing a hazard if the case comes

into contact with a grounded object. Similar situations can

occur with improperly wired solar panels or generators.

Rev. 0 | Page 3 of 7

20199-007

OUTPUT VOLTAGE (V)

3

�Circuit Note

RREF × N PS × (VOUT + VF (T0))

VREF

Figure 8 shows the typical maximum output power at 5 V VOUT

for common winding ratio values at various input voltages. The

CN-0509 transformer has a 3:1 turns ratio for a maximum VOUT

of approximately 10 W.

20

OUTPUT POWER (W)

U3

5V, 2A

SUPPLY

where:

RFB is the LT8302 feedback resistor.

RREF is the LT8302 reference resistor.

NPS is the transformer effective primary to secondary turns ratio.

VOUT is the output voltage.

VF(T0) is the output diode forward voltage at 25°C = ~0.3 V.

VREF is the LT8302 internal voltage reference.

MAXIMUM OUTPUT POWER

N = 4:1

N = 3:1

N = 2:1

N = 1:1

15

GND

IN

DM

GND

VBUS

DP

D–

D+

GND

GND

20199-009

RFB =

VBUS

VBUS

USB CONNECTOR 2

(BOTTOM)

In addition to providing isolation, the LT8302 further steps

down the 12 V output from the buck converter to 5 V. VOUT is

programmed using two external resistors and a third optional

temperature compensation resistor as follows:

USB CONNECTOR 1

(TOP)

CN-0509

Figure 9. USB Dedicated Charging Port Controller

U3 is a DCP controller that monitors the USB data line voltages

(D+ and D−) and provides signatures for enabling fast charging

modes for several common device manufacturers (see Figure 9).

While both ports can be used simultaneously up to a maximum

total load current of 2 A, when using the DCP port, leaving the

other port disconnected is recommended.

Note that the quality of USB cables varies significantly. Long,

small gauge cables can result in significant voltage drop at the load.

System Performance

CN-0509 operation is nearly constant for any input voltage between

12 V and 100 V because the input to the isolated converter is at

a constant 12 V. Lower input voltage reduces the available

charging current according to Figure 10.

10

5

10

20

30

INPUT VOLTAGE (V)

40

Figure 8. Typical Maximum Output Power at 5 V VOUT

Fast Charging Up to 2 A

USBs have become a defacto standard for device charging, and

typical chargers can deliver more than the minimum 500 mA

USB 2.0 specification. Chargers must provide a special voltage

signature on USB data lines to let the device recognize itself and

to determine the maximum charging current it can draw from

the power source, which can be higher than the 500 mA

minimum standard.

Rev. 0 | Page 4 of 7

2.0

1.5

1.0

0.5

0

0

10

20

30

40

50

60

70

80

90

INPUT VOLTAGE (V)

Figure 10. Maximum Load Current vs. Input Voltage

100

20199-010

0

MAXIMUM LOAD CURRENT (A)

0

20199-008

2.5

�Circuit Note

CN-0509

Reverse Input Survival

Load Connection Transient

The CN-0509 is able to survive reverse input connections up to

100 V. Figure 11 shows the reverse input to the CN-0509 vs. the

LTC7103VIN.

Figure 13 and Figure 14 show the CN-0509 turn on transient

curves for the current and USB data lines for a cell phone

(Phone A) and USB power bank (Power Bank B), respectively.

20

LTC7103 V IN (mV)

15

10

1V/DIV

1V/DIV

5

0

500mA/DIV

C3

–10

0

–20

–40

–60

–80

–100

VIN (V)

20199-011

C2

20199-013

ILOAD

D–

D+

–5

TIME (1s/DIV)

Figure 13. ILOAD, D+, and D− Voltages of Phone A Charging

Figure 11. LTC7103 VIN vs. VIN

Load Regulation

Figure 12 shows that the load regulation of the CN-0509 across

input voltages above 12 V is within 65 mV because the load

increases from 0.1 A to 2 A, corresponding to an output

impedance of approximately 32.3 mΩ.

1V/DIV

1V/DIV

5.19

C3

5.18

50mV/DIV

5.17

5.15

TIME (1ms/DIV)

Figure 14. Bus Voltage (VBUS), D+, and D− Voltages of Power Bank B

5.14

5.13

5.12

5.11

5.10

0

0.5

1.0

1.5

ILOAD (A)

2.0

20199-012

VOUT (V)

5.16

20199-014

VBUS

D–

D+

C2

Figure 12. VOUT vs. Load Current (ILOAD)

Rev. 0 | Page 5 of 7

�CN-0509

Circuit Note

Test Setup and Functional Block Diagram

Figure 15 displays the thermal response of CN-0509 while

charging a load at 5.62 V, 2 A for one hour with the board

positioned horizontally above a workbench in still air at 25°C

ambient. The maximum temperature on the EVAL-CN0509EBZ board occurs on the D3 diode at 83.8°C, well below the

maximum operating temperature of 150°C.

A functional block diagram of the test setup is shown in Figure 16.

DC

SUPPLY

EVAL-CN0509-EBZ

USB

MULTIMETER

TESTER

WIRES/

WIRED OUT

USB CABLE

DEVICE/

LOAD

20199-016

Thermal Performance

Figure 16. Functional Block Diagram of the Test Setup

Setup and Test

Take the following steps for test setup:

1.

20199-015

2.

Figure 15. Thermal Image of EVAL-CN0509-EBZ at 5.62 V, 2 A Output

Charging a Load for One Hour

3.

4.

COMMON VARIATIONS

If mains supplies are available, the EVAL-CN0509-EBZ can turn

a wide variety of random offline power supplies into a USB charger.

Such supplies include laptop chargers, game console chargers,

and computer peripheral power supplies.

Using a Schottky bridge rectifier at power entry allows operation

regardless of input polarity. However, this input configuration

is at the expense of a 0.4 V increase in minimum operating

voltage over using a single protection diode. For example, a

VIN of 12.4 V is required for the full 2 A output current.

5.

6.

7.

Connect the input dc supply to P1 on the CN-0509. Use

caution when connecting high input voltages.

Upon turning on the dc input, the CN-0509 turns on. The

circuit determines if the input connection is in correct polarity

through lighting DS1 or DS2.

a. If DS1 (green LED) illuminates, the correct polarity is

on the input, and the circuit delivers up to 10 W on P2,

the USB output ports.

b. If DS2 (red LED) illuminates, turn off the input supply,

disconnect the power inputs, swap the power leads,

reconnect the supply outputs to P1, then repeat Step 2.

Connect the USB cable from the ET910 USB multimeter

tester to the lower USB port on the EVAL-CN0509-EBZ.

Connect a fast charge capable device from the ET910 USB

multimeter tester using the charging cable of the device.

Look at the ET910 USB multimeter tester and verify that

the device is pulling more than 500 mA but less than 2 A

(see Figure 17).

Swap the USB port on the EVAL-CN0509-EBZ from the

lower (DCP) port to the upper USB port.

Look at the ET910 USB multimeter tester and verify that the

device is pulling approximately 500 mA (see Figure 17).

CIRCUIT EVALUATION AND TEST

20199-017

For complete setup details and additional information on the

CN-0509, see the CN0509 User Guide.

Figure 17. ET910 USB Multimeter Tester Screenshot of Phone A Charging from the

Top USB Port (Left) vs. the Lower Port with the DCP Controller (Right)

Equipment Needed

The following equipment is needed :

•

•

•

•

•

A dc power supply (any voltage, 5 V to 100 V)

The EVAL-CN0509-EBZ evaluation board

A Klein Tools® ET910 USB multimeter tester (or equivalent)

A MicroUSB to USB Type A cable

A device with USB charging capability (cell phone, tablet,

or portable power pack) and a USB charging cable for the

device

Rev. 0 | Page 6 of 7

�Circuit Note

CN-0509

LEARN MORE

Data Sheets and Evaluation Boards

CN0509 Design Support Package:

https://www.analog.com/CN0509-DesignSupport

LTC7103 Data Sheet

CN0509 User Guide

DC2317A Demonstration Circuit

Triggs, Robert. (June 30, 2019). How fast charging really works.

Android Authority.

DC2014A Demonstration Circuit

Sengupta, Anirban. (January 14, 2016). Introduction to USB

Power Delivery. ElectronicDesign.

11/2020—Revision 0: Initial Version

LT8302 Data Sheet

REVISION HISTORY

(Continued from first page) Circuits from the Lab reference designs are intended only for use with Analog Devices products and are the intellectual property of Analog Devices or its licensors.

While you may use the Circuits from the Lab reference designs in the design of your product, no other license is granted by implication or otherwise under any patents or other intellectual

property by application or use of the Circuits from the Lab reference designs. Information furnished by Analog Devices is believed to be accurate and reliable. However, Circuits from the

Lab reference designs are supplied "as is" and without warranties of any kind, express, implied, or statutory including, but not limited to, any implied warranty of merchantability,

noninfringement or fitness for a particular purpose and no responsibility is assumed by Analog Devices for their use, nor for any infringements of patents or other rights of third parties

that may result from their use. Analog Devices reserves the right to change any Circuits from the Lab reference designs at any time without notice but is under no obligation to do so.

©2020 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

CN20199-11/20(0)

Rev. 0 | Page 7 of 7

�