LT8391A

60V 2MHz Synchronous 4-Switch

Buck-Boost LED Driver Controller

FEATURES

DESCRIPTION

4-Switch Single Inductor Architecture Allows VIN

Above, Below or Equal to VOUT

n Up to 95% Efficiency at 2MHz

n Proprietary Peak-Buck Peak-Boost Current Mode

n Wide V Range: 4V to 60V

IN

n Wide V

OUT Range: 0V to 60V (51V LED)

n ±3% LED Current Accuracy

n 2000:1 External and 128:1 Internal PWM Dimming

n High Side PMOS PWM Switch Driver

n No Top MOSFET Refresh Noise in Buck or Boost

n Adjustable and Synchronizable: 600kHz to 2MHz

n Flicker-Free Spread Spectrum for Low EMI

n Open and Short LED Protection with Fault Reporting

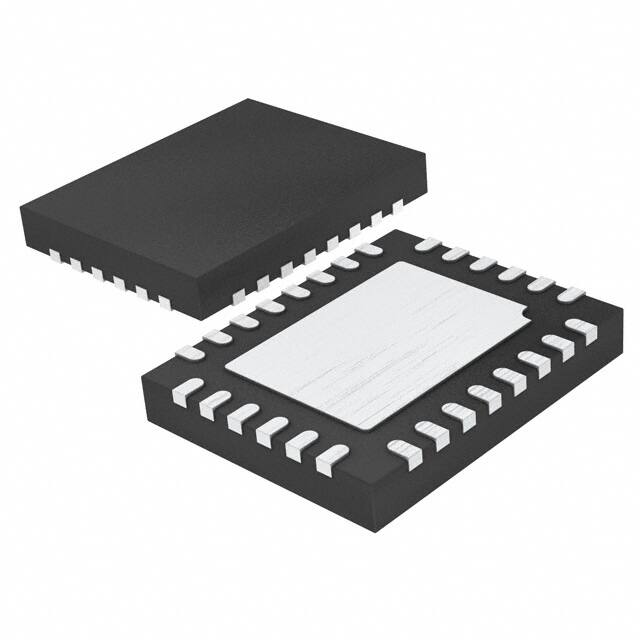

n Available in 28-Lead TSSOP with Exposed Pad and

28-Lead QFN (4mm × 5mm)

n AEC-Q100 Qualified for Automotive Applications

The LT®8391A is a synchronous 4-switch buck-boost LED

controller that regulates LED current from input voltage

above, below, or equal to the output voltage. The proprietary peak-buck peak-boost current mode control scheme

allows adjustable and synchronizable 600kHz to 2MHz

fixed frequency operation, or internal 25% triangle spread

spectrum operation for low EMI. With 4V to 60V input,

0V to 60V output, and seamless low noise transitions

between operation regions, the LT8391A is ideal for LED

driver and battery charger applications in automotive,

industrial, and battery-powered systems.

n

The LT8391A provides both internal (up to 128:1) and

external (up to 2000:1) LED current PWM dimming with

a high-side PMOS switch. Two CTRL pins provide flexible

20:1 analog dimming with ±3% LED current accuracy at

100mV full scale. Fault protection is provided to detect an

open or short LED condition, during which the LT8391A

retries, latches off, or keeps running.

APPLICATIONS

n

n

Automotive Head Lamps/Running Lamps

High Frequency LED Lighting

All registered trademarks and trademarks are the property of their respective owners.

TYPICAL APPLICATION

94% Efficient 24W (16V, 1.5A) 2MHz Buck-Boost LED Driver

VIN

6V TO 32V CONTINUOUS

4V TO 56V TRANSIENT

2.2µH

6mΩ

22µF

63V

4.7µF

100V

×2

0.1µF

SW1 LSP

BST1

INTVCC

LSN

BG1

BG2

10µF

25V

×2

0.1µF

SW2

BST2

Efficiency vs VIN

100

INTVCC

95

GND

165k

100k

FAULT

ANALOG DIM

90.9k

113k

48.7k

56mΩ

INTVCC

ISN

PWM

22nF

80

75

70

60

PWM DIM

VREF

CTRL2

SS

85

65

PWMTG

FAULT

CTRL1

0.47µF

1M

ISP

4.7µF

100k

1µF

FB

SYNC/SPRD

INTVCC

90

TG2

VOUT

EN/UVLO

SSFM OFF

SSFM ON

LT8391A

EFFICIENCY (%)

1µF

383k

TG1

VIN

0

5

10

15 20 25 30 35

INPUT VOLTAGE (V)

40

45

8391a TA01b

RP

VC

RT

4.7k

3.3nF

PWM SETTING

EXT

59.0k

2MHz

INT

16V

1.5A

LEDs

300k

488Hz

8391a TA01a

Rev. A

Document Feedback

For more information www.analog.com

1

�LT8391A

ABSOLUTE MAXIMUM RATINGS

(Note 1)

VIN, EN/UVLO, VOUT, ISP, ISN....................................60V

(ISP-ISN)..........................................................–1V to 1V

BST1, BST2................................................................66V

SW1, SW2, LSP, LSN..................................... –6V to 60V

INTVCC, (BST1-SW1), (BST2-SW2)..............................6V

(BST1-LSP), (BST1-LSN).............................................6V

FB, PWM, SYNC/SPRD, CTRL1, CTRL2, FAULT............6V

Operating Junction Temperature Range (Notes 2, 3)

LT8391AE........................................... –40°C to 125°C

LT8391AI............................................ –40°C to 125°C

LT8391AH........................................... –40°C to 150°C

LT8391AJ............................................ –40°C to 150°C

Storage Temperature Range................... –65°C to 150°C

PIN CONFIGURATION

TOP VIEW

SW1

26 SW2

TG1

4

25 TG2

LSP

5

LSN

6

VIN

7

INTVCC

8

EN/UVLO

29

GND

28 27 26 25 24 23

24 VOUT

TG1 1

22 TG2

LSP 2

23 PWMTG

21 VOUT

LSN 3

22 SYNC/SPRD

20 PWMTG

29

GND

VIN 4

19 SYNC/SPRD

21 RT

INTVCC 5

9

20 VC

EN/UVLO 6

RP 10

19 FB

RP 7

16 FB

PWM 11

18 SS

PWM 8

15 SS

VREF 12

17 FAULT

CTRL1 13

16 CTRL2

18 RT

17 VC

FE PACKAGE

28-LEAD PLASTIC TSSOP

θJA = 30°C/W, θJC = 5°C/W

EXPOSED PAD (PIN 29) IS GND, MUST BE SOLDERED TO PCB

FAULT

ISN

CTRL2

15 ISN

ISP

VREF

9 10 11 12 13 14

CTRL1

ISP 14

2

SW2

27 BST2

3

BST2

2

BG2

BST1

TOP VIEW

BG1

28 BG2

BST1

1

SW1

BG1

UFD PACKAGE

28-LEAD (4mm × 5mm) PLASTIC QFN

θJA = 43°C/W, θJC = 3.4°C/W

EXPOSED PAD (PIN 29) IS GND, MUST BE SOLDERED TO PCB

Rev. A

For more information www.analog.com

�LT8391A

ORDER INFORMATION

LEAD FREE FINISH

TAPE AND REEL

PART MARKING*

PACKAGE DESCRIPTION

TEMPERATURE RANGE

LT8391AEFE#PBF

LT8391AEFE#TRPBF

LT8391AFE

28-Lead Plastic TSSOP

–40°C to 125°C

LT8391AIFE#PBF

LT8391AIFE#TRPBF

LT8391AFE

28-Lead Plastic TSSOP

–40°C to 125°C

LT8391AHFE#PBF

LT8391AHFE#TRPBF

LT8391AFE

28-Lead Plastic TSSOP

–40°C to 150°C

LT8391AEUFD#PBF

LT8391AEUFD#TRPBF

8391A

28-Lead (4mm × 5mm) Plastic QFN

–40°C to 125°C

LT8391AIUFD#PBF

LT8391AIUFD#TRPBF

8391A

28-Lead (4mm × 5mm) Plastic QFN

–40°C to 125°C

LT8391AHUFD#PBF

LT8391AHUFD#TRPBF

8391A

28-Lead (4mm × 5mm) Plastic QFN

–40°C to 150°C

LT8391AJFE#WPBF

LT8391AJFE#WTRPBF

LT8391AFE

28-Lead Plastic TSSOP

–40°C to 150°C

LT8391AHFE#WPBF

LT8391AHFE#WTRPBF

LT8391AFE

28-Lead Plastic TSSOP

–40°C to 150°C

AUTOMOTIVE PRODUCTS**

Contact the factory for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

Tape and reel specifications. Some packages are available in 500 unit reels through designated sales channels with #TRMPBF suffix.

**Versions of this part are available with controlled manufacturing to support the quality and reliability requirements of automotive applications. These

models are designated with a #W suffix. Only the automotive grade products shown are available for use in automotive applications. Contact your

local Analog Devices account representative for specific product ordering information and to obtain the specific Automotive Reliability reports for

these models.

Rev. A

For more information www.analog.com

3

�LT8391A

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 2). VIN = 12V, VEN/UVLO = 1.5V unless otherwise noted.

SYMBOL PARAMETER

CONDITIONS

VIN Operating Voltage Range

VIN Quiescent Current

l

VEN/UVLO = 0.3V, VOUT = 12V

VEN/UVLO = 1.1V, VOUT = 12V

Not Switching, VOUT = 12V

TYP

4

VEN/UVLO = 0.3V

VEN/UVLO = 1.1V

Not Switching

VOUT Voltage Range

VOUT Quiescent Current

MIN

l

MAX

UNITS

60

V

2

µA

µA

mA

1

270

2.1

2.8

60

V

20

0.1

0.1

40

0.5

0.5

60

µA

µA

µA

4.85

0

Linear Regulators

INTVCC Regulation Voltage

IINTVCC = 20mA

5.0

5.15

V

INTVCC Load Regulation

IINTVCC = 0mA to 80mA

1

4

%

INTVCC Line Regulation

IINTVCC = 20mA, VIN = 6V to 60V

1

4

%

145

190

INTVCC Current Limit

VINTVCC = 4.5V

INTVCC Dropout Voltage (VIN – INTVCC)

IINTVCC = 20mA, VIN = 4V

INTVCC Undervoltage Lockout Threshold

Falling

110

160

3.44

INTVCC Undervoltage Lockout Hysteresis

VREF Regulation Voltage

3.54

3.64

0.24

IVREF = 100µA

l

1.97

2.00

mA

mV

V

V

2.03

V

VREF Load Regulation

IVREF = 0mA to 1mA

0.4

1

%

VREF Line Regulation

IVREF = 100µA, VIN = 4V to 60V

0.1

0.2

%

VREF Current Limit

VREF = 1.8V

2

2.5

3.2

mA

VREF Undervoltage Lockout Threshold

Falling

1.78

1.84

1.90

VREF Undervoltage Lockout Hysteresis

50

V

mV

Control Inputs/Outputs

EN/UVLO Shutdown Threshold

EN/UVLO Enable Threshold

Falling

l

0.3

0.6

1.0

V

l

1.196

1.220

1.244

V

EN/UVLO Enable Hysteresis

13

EN/UVLO Hysteresis Current

VEN/UVLO = 0.3V

VEN/UVLO = 1.1V

VEN/UVLO = 1.3V

CTRL1, CTRL2 Input Bias Current

VCTRL1/2 = 0.75V (Note 4), Current out of

Pin

CTRL1, CTRL2 Dim-Off Threshold

Falling

l

mV

–0.1

2.2

–0.1

0

2.5

0

0.1

2.8

0.1

µA

µA

µA

0

20

50

nA

190

200

210

mV

CTRL1, CTRL2 Dim-Off Hysteresis

28

mV

PWM Dimming

4

External PWM Dimming Threshold

Rising, RP = 30k

External PWM Dimming Hysteresis

RP = 30k

Internal PWM Dimming Duty Cycle

VPWM = 1V, RP ≥ 51k

VPWM = 1.5V, RP ≥ 51k

VPWM = 2V, RP ≥ 51k

Switching Frequency to Internal PWM Dimming

Frequency Ratio

RP = 51k

RP = 82k

RP = 130k

RP = 200k

RP = 300k

l

1.3

1.4

1.5

220

3

53

47

97

V

mV

%

%

%

256

512

1024

2048

4096

Rev. A

For more information www.analog.com

�LT8391A

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 2). VIN = 12V, VEN/UVLO = 1.5V unless otherwise noted.

SYMBOL PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

RP Pin Current Limit

VRP = 0V, Current out of Pin

40

µA

Minimum VOUT for PWMTG to be On

PWM dimming on

2.4

PWMTG On Voltage V(VOUT-PWMTG)

VOUT = 12V

4.5

5

5.5

V

PWMTG Off Voltage V(VOUT-PWMTG)

VOUT = 12V

–0.1

0

0.1

V

3

V

PWM to PWMTG Turn On Propagation Delay

CPWMTG = 3.3nF to VOUT, 50% to 50%

90

ns

PWM to PWMTG Turn Off Propagation Delay

CPWMTG = 3.3nF to VOUT, 50% to 50%

40

ns

PWMTG Turn On Fall Time

PWMTG Turn Off Rise Time

CPWMTG = 3.3nF to VOUT, 10% to 90%

CPWMTG = 3.3nF to VOUT, 90% to 10%

300

10

ns

ns

Error Amplifier

Full Scale LED Current Regulation V(ISP-ISN)

VCTRL1/2 ≥ 1.35V (Note 4), VISP = 12V

VCTRL1/2 ≥ 1.35V (Note 4), VISP = 0V

l

l

97

97

100

100

103

103

mV

mV

9/10th LED Current Regulation V(ISP-ISN)

VCTRL1/2 = 1.15V (Note 4), VISP = 12V

VCTRL1/2 = 1.15V (Note 4), VISP = 0V

l

l

87

87

90

90

93

93

mV

mV

1/2 LED Current Regulation V(ISP-ISN)

VCTRL1/2 = 0.75V (Note 4), VISP = 12V

VCTRL1/2 = 0.75V (Note 4), VISP = 0V

l

l

47.5

47.5

50

50

52.5

52.5

mV

mV

1/20th LED Current Regulation V(ISP-ISN)

VCTRL1/2 = 0.30V (Note 4), VISP = 12V

VCTRL1/2 = 0.30V (Note 4), VISP = 0V

l

l

3

3

5

5

7

7

mV

mV

Zero Scale LED Current Regulation V(ISP-ISN)

VCTRL1/2 = 0.25V (Note 4), VISP = 12V

VCTRL1/2 = 0.25V (Note 4), VISP = 0V

l

l

–2

–2

0

0

2

2

mV

mV

l

0

60

V

ISP/ISN Input Common Mode Range

ISP/ISN Low Side to High Side Switchover

Voltage

VISP = VISN

1.8

V

ISP/ISN High Side to Low Side Switchover

Voltage

VISP = VISN

1.7

V

ISP Input Bias Current

VPWM = 5V, VISP = VISN = 12V

VPWM = 5V, VISP = VISN = 0V

VEN/UVLO = 0V, VISP = VISN = 12V or 0V

23

–10

0

µA

µA

µA

ISN Input Bias Current

VPWM = 5V, VISP = VISN = 12V

VPWM = 5V, VISP = VISN = 0V

VEN/UVLO = 0V, VISP = VISN = 12V or 0V

23

–10

0

µA

µA

µA

2000

µS

LED Current Regulation Amplifier gm

FB Regulation Voltage

VC = 1.2V

FB Line Regulation

VIN = 4V to 60V

l

0.98

FB Load Regulation

FB in Regulation, Current Out of Pin

V

0.2

0.5

%

0.2

0.8

%

10

VC Output Impedance

VC Standby Leakage Current

1.02

660

FB Voltage Regulation Amplifier gm

FB Input Bias Current

1.00

µS

40

10

VC = 1.2V, PWM Dimming Off

–10

0

nA

MΩ

10

nA

Rev. A

For more information www.analog.com

5

�LT8391A

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 2). VIN = 12V, VEN/UVLO = 1.5V unless otherwise noted.

SYMBOL PARAMETER

CONDITIONS

MIN

TYP

MAX

35

40

50

50

65

60

UNITS

Current Comparator

Maximum Current Sense Threshold V(LSP-LSN)

Buck, VFB = 0.8V

Boost, VFB = 0.8V

LSP Pin Bias Current

VLSP = VLSN = 12V

60

µA

LSN Pin Bias Current

VLSP = VLSN = 12V

60

µA

FB Overvoltage Threshold (VFB)

Rising

l

l

mV

mV

Fault

l

1.03

1.05

1.07

l

15

25

35

Rising, V(ISP-ISN) = 0V

l

0.93

0.95

0.97

FB Open LED Hysteresis

V(ISP-ISN) = 0V

l

35

50

65

FB Short LED Threshold (VFB)

Falling

l

0.24

0.25

0.26

FB Short LED Hysteresis

Hysteresis

l

35

50

65

FB Overvoltage Hysteresis

FB Open LED Threshold (VFB)

ISP/ISN Over Current Threshold V(ISP-ISN)

VISP = 12V

ISP/ISN Open LED Threshold V(ISP-ISN)

Falling, VFB = 1.0V

l

8

750

ISP/ISN Open LED Hysteresis

VFB = 1.0V

l

3

FAULT Pull-Down Resistance

10

V

mV

V

mV

V

mV

mV

12

mV

5

7

mV

100

200

Ω

100

200

Ω

SS Hard Pull-Down Resistance

VEN/UVLO = 1.1V

SS Pull-Up Current

VFB = 0.8V, VSS = 0V

10.5

12.5

14.5

µA

SS Pull-Down Current

VFB = 1.0V, VSS = 2V

1.05

1.25

1.45

µA

SS Fault Latch-Off Threshold

Falling

1.7

V

SS Fault Latch-Off Hysteresis

50

mV

SS Fault Reset Threshold

0.2

V

1.00

V

Oscillator

RT Pin Voltage

RT = 100kΩ

Switching Frequency

VSYNC/SPRD = 0V, RT = 226k

VSYNC/SPRD = 0V, RT = 100k

VSYNC/SPRD = 0V, RT = 59.0k

SYNC Frequency

SYNC/SPRD Input Bias Current

6

685

1360

2000

600

VSYNC/SPRD = 5V

SYNC/SPRD Threshold Voltage

Highest Spread Spectrum Above Oscillator

Frequency

l

645

1290

1900

–0.1

0

0.4

VSYNC/SPRD = 5V

21

23

725

1430

2100

kHz

kHz

kHz

2100

kHz

0.1

µA

1.5

V

25

%

Rev. A

For more information www.analog.com

�LT8391A

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 2). VIN = 12V, VEN/UVLO = 1.5V unless otherwise noted.

SYMBOL PARAMETER

CONDITIONS

MIN

TYP

MAX

0.73

0.75

0.77

UNITS

Region Transition

Buck-Boost to Boost (VIN/VOUT)

Boost to Buck-Boost (VIN/VOUT)

0.83

0.85

0.87

Buck to Buck-Boost (VIN/VOUT)

1.23

1.25

1.27

Buck-Boost to Buck (VIN/VOUT)

1.31

1.33

1.35

Peak-Buck to Peak-Boost (VIN/VOUT)

0.96

0.98

1.00

Peak-Boost to Peak-Buck (VIN/VOUT)

1.00

1.02

1.04

NMOS Drivers

TG1, TG2 Gate Driver On-Resistance

Gate Pull-Up

Gate Pull-Down

V(BST-SW) = 5V

BG1, BG2 Gate Driver On-Resistance

Gate Pull-Up

Gate Pull-Down

VINTVCC = 5V

TG1, TG2 Rise Time

TG1, TG2 Fall Time

2.6

1.4

Ω

Ω

3.2

1.2

Ω

Ω

CL = 3.3nF, 10% to 90%

CL = 3.3nF, 90% to 10%

25

20

ns

ns

BG1, BG2 Rise Time

BG1, BG2 Fall Time

CL = 3.3nF, 10% to 90%

CL = 3.3nF, 90% to 10%

25

20

ns

ns

TG Off to BG On Delay

CL = 3.3nF

25

ns

BG Off to TG On Delay

CL = 3.3nF

25

ns

TG1 Minimum Duty Cycle in Buck Region

Peak-Buck Current Mode

10

%

TG1 Maximum Duty Cycle in Buck Region

Peak-Buck Current Mode

90

%

TG1 Fixed Duty Cycle in Buck-Boost Region

Peak-Boost Current Mode

80

%

BG2 Fixed Duty Cycle in Buck-Boost Region

Peak-Buck Current Mode

20

%

BG2 Minimum Duty Cycle in Boost Region

Peak-Boost Current Mode

10

%

BG2 Maximum Duty Cycle in Boost Region

Peak-Boost Current Mode

90

%

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT8391AE is guaranteed to meet performance specifications

from 0°C to 125°C operating junction temperature. Specifications over

the –40°C to 125°C operating junction temperature range are assured by

design, characterization and correlation with statistical process controls.

The LT8391AI is guaranteed over the –40°C to 125°C operating junction

temperature range. The LT8391AH is guaranteed over the –40°C to 150°C

operating junction temperature range. The LT8391AJ specifications over

the –40°C to 150°C operating junction temperature range are assured by

design, characterization and correlation with statistical process controls.

High junction temperatures degrade operating lifetimes. Operating lifetime

is derated at junction temperatures greater than 125°C.

Note 3: The LT8391A includes overtemperature protection that is intended

to protect the device during momentary overload conditions. Junction

temperature will exceed 150°C when overtemperature protection is active.

Continuous operation above the specified absolute maximum operating

junction temperature may impair device reliability.

Note 4: VCTRL1/2 represents the condition of CTRL1 when CTRL2 is equal

to 2V or the condition of CTRL2 when CTRL1 is equal to 2V.

Rev. A

For more information www.analog.com

7

�LT8391A

TYPICAL PERFORMANCE CHARACTERISTICS

Efficiency vs LED Current

(Buck Region)

Efficiency vs LED Current

(Buck-Boost Region)

Efficiency vs LED Current

(Boost Region)

90

90

90

80

80

80

70

60

0

0.2

0.4

0.6 0.8 1 1.2

LED CURRENT (A)

1.4

70

60

50

FRONT PAGE APPLICATION

VIN = 32V, VLED = 16V, fSW = 2MHz

40

1.6

0

0.2

0.4

0.6 0.8 1 1.2

LED CURRENT (A)

Switching Waveforms

(Buck Region)

VSW2

20V/DIV

VSW1

20V/DIV

VSW2

20V/DIV

VSW2

20V/DIV

3.0

2.5

1.6

2.0

IQ (µA)

1.7

1.0

1.3

0.5

10

15 20 25 30

INPUT VOLTAGE (V)

35

40

8391a G05

0.4

0.6 0.8 1 1.2

LED CURRENT (A)

500ns/DIV

FRONT PAGE APPLICATION

VIN = 8V, ILED = 1.5A

VIN Shutdown Current

2.8

1.4

1.6

0.0

–50 –25

8391a G06

VIN Quiescent Current

2.6

VIN = 60V

1.5

1.4

5

0.2

IL

2A/DIV

500ns/DIV

FRONT PAGE APPLICATION

VIN = 18V, ILED = 1.5A

LED Current vs VIN

0

0

8391a G03

VSW1

20V/DIV

8391a G04

1.5

FRONT PAGE APPLICATION

VIN = 8V, VLED = 16V, fSW = 2MHz

Switching Waveforms

(Boost Region)

IL

2A/DIV

IL

2A/DIV

1.2

40

1.6

Switching Waveforms

(Buck-Boost Region)

VSW1

20V/DIV

500ns/DIV

FRONT PAGE APPLICATION

VIN = 32V, ILED = 1.5A

60

8391a G02

8391a G01

1.8

1.4

70

50

FRONT PAGE APPLICATION

VIN = 18V, VLED = 16V, fSW = 2MHz

IQ (mA)

40

EFFICIENCY (%)

100

EFFICIENCY (%)

100

EFFICIENCY (%)

100

50

LED CURRENT (A)

TA = 25°C, unless otherwise noted.

VIN = 12V

VIN = 60V

2.4

VIN = 12V

2.2

VIN = 4V

2.0

VIN = 4V

0

25 50 75 100 125 150

TEMPERATURE (°C)

1.8

–50 –25

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G07

8391a G08

8

8391a G09

Rev. A

For more information www.analog.com

�LT8391A

TYPICAL PERFORMANCE CHARACTERISTICS

5.15

INTVCC Voltage vs Temperature

5.15

5.10

5.10

5.05

5.05

TA = 25°C, unless otherwise noted.

INTVCC Voltage vs VIN

4.0

INTVCC UVLO Threshold

3.9

IINTVCC = 0mA

5.00

IINTVCC = 80mA

IINTVCC = 20mA

VINTVCC (V)

VINTVCC (V)

VINTVCC (V )

3.8

5.00

4.95

4.95

4.90

4.90

RISING

3.7

3.6

FALLING

3.5

3.4

4.85

–50 –25

0

4.85

25 50 75 100 125 150

TEMPERATURE (°C)

3.3

0

10

20

30

VIN (V)

40

50

8391a G10

2.04

2.03

2.03

2.02

2.02

VREF (V)

VREF (V)

VREF Voltage vs VIN

VREF UVLO Threshold

2.00

1.95

2.01

2.00

IVREF = 100µA

2.00

1.99

1.99

IVREF = 1mA

1.98

RISING

1.85

FALLING

1.80

1.75

1.97

0

1.90

1.98

1.97

1.96

–50 –25

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G12

VREF (V)

VREF Voltage vs Temperature

IVREF = 0mA

0

8391a G11

2.04

2.01

3.2

–50 –25

60

1.96

25 50 75 100 125 150

TEMPERATURE (°C)

0

10

20

30

VIN (V)

40

50

1.70

–50 –25

60

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G14

8391a G13

EN/UVLO Enable Threshold

8391a G15

EN/UVLO Hysteresis Current

CTRL1/CTRL2 Dim-Off Threshold

3.0

1.240

0.30

1.235

2.8

1.230

0.25

RISING

1.220

FALLING

1.215

1.210

2.6

VCTRL (V)

IHYS (µA)

VEN/UVLO (V)

1.225

2.4

RISING

0.20

FALLING

0.15

2.2

1.205

1.200

–50 –25

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G16

2.0

–50 –25

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G17

0.10

–50 –25

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G18

Rev. A

For more information www.analog.com

9

�LT8391A

TYPICAL PERFORMANCE CHARACTERISTICS

106

75

50

25

104

104

102

102

100

98

96

0

0.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00

VCTRL (V)

94

0

10

20

30

VISP (V)

40

0.99

20

0.98

0

0.96 0.97 0.98 0.99 1.00 1.01 1.02 1.03 1.04

VFB (V)

0.97

–50 –25

VIN = 4V

VIN = 12V

VIN = 60V

0

60

55

50

45

40

35

30

–50 –25

25 50 75 100 125 150

TEMPERATURE (°C)

BUCK

BOOST

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G23

FB Overvoltage Threshold

8391a G24

FB Open LED Threshold

1.10

RISING

FB Short LED Threshold

1.10

0.40

1.05

0.35

1.00

0.30

RISING

FALLING

VFB (V)

VFB (V)

Maximum Current Sense

vs Temperature

65

8391a G22

0.95

0.90

0.85

0.85

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G25

RISING

0.95

0.90

10

25 50 75 100 125 150

TEMPERATURE (°C)

70

1.00

40

0

0

8391a G21

CURRENT LIMIT (mV)

1.01

VFB (V)

V(ISP-ISN) (mV)

80

60

ISP = 0V

ISP = 12V

ISP = 60V

94

–50 –25

60

1.03

1.02

0.80

–50 –25

50

FB Regulation vs Temperature

100

1.00

98

8391a G20

V(ISP-ISN) Regulation vs VFB

1.05

100

96

8391a G19

120

106

V(ISP-ISN) (mV)

V(ISP-ISN) (mV)

V(ISP-ISN) (mV)

100

V(ISP-ISN) Regulation

vs Temperature

V(ISP-ISN) Regulation vs VISP

0.80

–50 –25

VFB (V)

125

V(ISP-ISN) Regulation vs VCTRL

TA = 25°C, unless otherwise noted.

FALLING

FALLING

0.25

0.20

0.15

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G26

0.10

–50 –25

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G27

Rev. A

For more information www.analog.com

�LT8391A

TYPICAL PERFORMANCE CHARACTERISTICS

15.0

25

12.5

20

10.0

RISING

FALLING

10

PULL-UP

7.5

5.0

2.5

5

0

–50 –25

2.5

0

SWITCHING FREQUENCY (MHz)

30

15

Oscillator Frequency

vs Temperature

SS Current vs Temperature

ISS (µA)

V(ISP-ISN) (mV)

ISP/ISN Open LED Threshold

TA = 25°C, unless otherwise noted.

25 50 75 100 125 150

TEMPERATURE (°C)

0.0

–50 –25

PULL-DOWN

0

25 50 75 100 125 150

TEMPERATURE (°C)

RT = 59.0k

2.0

RT = 100k

1.5

1.0

RT = 226k

0.5

0

–50 –25

0

25 50 75 100 125 150

TEMPERATURE (°C)

8391a G30

8391a G28

8391a G29

Rev. A

For more information www.analog.com

11

�LT8391A

PIN FUNCTIONS

BG1: Buck Side Bottom Gate Drive. Drives the gate of

buck side bottom N-channel MOSFET with a voltage swing

from ground to INTVCC.

BST1: Buck Side Bootstrap Floating Driver Supply. The

BST1 pin has an integrated bootstrap Schottky diode from

the INTVCC pin and requires an external bootstrap capacitor to the SW1 pin. The BST1 pin swings from a diode

voltage drop below INTVCC to (VIN + INTVCC).

SW1: Buck Side Switch Node. The SW1 pin swings from

a Schottky diode voltage drop below ground up to VIN.

TG1: Buck Side Top Gate Drive. Drives the gate of buck

side top N-channel MOSFET with a voltage swing from

SW1 to BST1.

LSP: Positive Terminal of the Buck Side Inductor Current

Sense Resistor (RSENSE). Ensure accurate current sense

with Kelvin connection.

LSN: Negative Terminal of the Buck Side Inductor Current

Sense Resistor (RSENSE). Ensure accurate current sense

with Kelvin connection.

VIN: Input Supply. The VIN pin must be tied to the power

input to determine the buck, buck-boost, or boost operation regions. Locally bypass this pin to ground with a

minimum 1µF ceramic capacitor.

INTVCC: Internal 5V Linear Regulator Output. The INTVCC

linear regulator is supplied from the VIN pin, and powers the internal control circuitry and gate drivers. Locally

bypass this pin to ground with a minimum 4.7µF ceramic

capacitor.

EN/UVLO: Enable and Undervoltage Lockout. Force the

pin below 0.3V to shut down the part and reduce VIN quiescent current below 2µA. Force the pin above 1.233V for

normal operation. The accurate 1.220V falling threshold

can be used to program an undervoltage lockout (UVLO)

threshold with a resistor divider from VIN to ground. An

accurate 2.5µA pull-down current allows the programming of VIN UVLO hysteresis. If neither function is used,

tie this pin directly to VIN.

RP: Internal PWM Dimming Frequency Setting. The RP pin

is used to set the internal PWM dimming frequency with a

resistor to ground. Do not use a resistor larger than 1MΩ

and do not leave this pin open. If an external PWM dimming

pulse is available at the PWM pin, tie this pin to ground.

PWM: PWM Dimming Input. The PWM pin can be used

in two ways: external PWM dimming and internal PWM

dimming. For external PWM dimming, drive this pin with

a digital pulse from 0V to a voltage higher than 1.5V to

control PWM dimming of the LED string. Make sure the

RP pin is tied to ground in this case. For internal PWM

dimming, apply an analog voltage between 1V and 2V to

generate an internal digital pulse by comparing with the

internal ramp. If PWM dimming is not used, tie this pin to

INTVCC. Forcing the pin low turns off TG1 and TG2, turns

on BG1 and BG2, disconnects the VC pin from all internal

loads, and turns off PWMTG.

VREF: Voltage Reference Output. The VREF pin provides an

accurate 2V reference capable of supplying 1mA current.

Locally bypass this pin to ground with a 0.47µF ceramic

capacitor.

CTRL1: Control Input for LED Current Sense Threshold. The

CTRL1 pin is used to program the LED regulation current:

ILED =

Min ( VCTRL1 – 0.25V,VCTRL2 – 0.25,1V )

10 •RLED

The VCTRL1 can be set by an external voltage reference

or a resistor divider from VREF to ground. For 0.25V ≤

VCTRL1 ≤ 1.15V, the current sense threshold linearly goes

up from 0mV to 90mV. For VCTRL1 ≥ 1.35V, the current

sense threshold is constant at 100mV full scale value.

For 1.15V ≤ VCTRL1 ≤ 1.35V, the current sense threshold

smoothly transitions from the linear function of VCTRL1

to the 100mV constant value. Tie CTRL1 to VREF for the

100mV full scale threshold. Force the pin below 0.2V to

stop switching.

ISP: Positive Terminal of the LED Current Sense Resistor

(RLED). Ensure accurate current sense with Kelvin

connection.

ISN: Negative Terminal of the LED Current Sense Resistor

(RLED). Ensure accurate current sense with Kelvin

connection.

12

Rev. A

For more information www.analog.com

�LT8391A

PIN FUNCTIONS

CTRL2: Thermal Control Input for LED Current Sense

Threshold. The CTRL2 pin is used to program LED current

derating versus temperature. The VCTRL2 with a negative

temperature coefficient can be set by an external temperature dependent resistor divider from VREF to ground.

For 0.25V ≤ VCTRL2 ≤ 1.15V, the current sense threshold

linearly goes up from 0mV to 90mV. For VCTRL2 ≥ 1.35V,

the current sense threshold is constant at 100mV full

scale value. For 1.15V ≤ VCTRL2 ≤ 1.35V, the current sense

threshold smoothly transitions from the linear function of

VCTRL2 to the 100mV constant value. Tie CTRL2 to VREF

for the 100mV full scale threshold. Force the pin below

0.2V to stop switching.

FAULT: LED Fault Open Drain Output. The FAULT pin is

pulled low when any of the following conditions happens:

1. Open LED (VFB > 0.95V & V(ISP-ISN) < 10mV)

2. Short LED (VFB < 0.25V)

To function, the pin requires an external pull-up resistor.

The FAULT status is updated only during PWM high state

and latched during PWM low state.

SS: Soft-Start Timer Setting. The SS pin is used to set

soft-start timer by connecting a capacitor to ground. An

internal 12.5µA pull-up current charging the external SS

capacitor gradually ramps up FB regulation voltage. A

22nF capacitor is recommended on this pin. Any UVLO or

thermal shutdown immediately pulls SS pin to ground and

stops switching. Using a single resistor from SS to VREF,

the LT8391A can be set in three different fault protection

modes during open or short LED fault conditions: hiccup

(no resistor), latchoff (499k), and keep-running (100k).

See more details in the Applications Information section.

FB: Voltage Loop Feedback Input. The FB pin is used for

constant-voltage regulation and LED fault protection. The

internal error amplifier with its output VC regulates VFB

to 1.00V through the DC/DC converter. During open LED

(VFB > 0.95V & V(ISP-ISN) < 10mV) or short LED (VFB <

0.25V) fault conditions, the part pulls the FAULT pin low

and gets into one fault mode per customer setting. During

an overvoltage (VFB > 1.05V) condition, the part turns off

all TG1, BG1, TG2, BG2, and PWMTG.

VC: Error Amplifier Output to Set Inductor Current

Comparator Threshold. The VC pin is used to compensate the control loop with an external RC network. During

PWM low state, the VC pin is disconnected from all internal loads to store its voltage information for the highest

PWM dimming performance.

RT: Switching Frequency Setting. Connect a resistor from

this pin to ground to set the internal oscillator frequency

from 600kHz to 2MHz.

SYNC/SPRD: Switching Frequency Synchronization or

Spread Spectrum. Ground this pin for switching at internal oscillator frequency. Apply a clock signal for external

frequency synchronization. Tie to INTVCC for 25% triangle

spread spectrum above internal oscillator frequency.

PWMTG: PWM Dimming Top Gate Drive. A buffered and

inverted version of the PWM input signal, the PWMTG

pin drives an external high side PMOS PWM switch with

a voltage swing from the higher voltage of (VOUT –5V)

and 1.2V to VOUT. Leave this pin unconnected if not used.

VOUT: Output Supply. The VOUT pin must be tied to the

power output to determine the buck, buck-boost, or boost

operation regions. The VOUT pin also serves as positive rail

for the PWMTG drive. Locally bypass this pin to ground

with a minimum 1µF ceramic capacitor.

TG2: Boost Side Top Gate Drive. Drives the gate of boost

side top N-Channel MOSFET with a voltage swing from

SW2 to BST2.

SW2: Boost Side Switch Node. The SW2 pin swings from

a Schottky diode voltage drop below ground to VOUT.

BST2: Boost Side Bootstrap Floating Driver Supply. The

BST2 pin has an integrated bootstrap Schottky diode from

the INTVCC pin and requires an external bootstrap capacitor to the SW2 pin. The BST2 pin swings from a diode

voltage drop below INTVCC to (VOUT + INTVCC).

BG2: Boost Side Bottom Gate Drive. Drives the gate of

boost side bottom N-Channel MOSFET with a voltage

swing from ground to INTVCC.

GND (Exposed Pad): Ground. Solder the exposed pad

directly to the ground plane.

Rev. A

For more information www.analog.com

13

�LT8391A

BLOCK DIAGRAM

LSN

VIN

INTVCC

LSP

INTVCC

+

5V LDO

–

VREF

+

A1

–

2V REF

BST1

A3

TG1

PEAK_BUCK

SW1

BUCK

LOGIC

INTVCC

PWMON

RT

OSC

SYNC/SPRD

0.2V

CTRL1

0.2V

CTRL2

EN/UVLO

1.220V

BG1

VOS

GND

+

–

+

–

+

–

FBOV

VOUT/BST2

VIN/BST1

CHARGE

CONTROL

FB

GND

1.05V

INHIBIT

SWITCH

–

+

BG2

+

–

ISOC

2.5µA

PWMON

VISP-ISN

0.75V

PEAK_BOOST

BOOST

LOGIC

INTVCC

SW2

TG2

+

PWM

RP

VOUT

PWMTG

–

INT/EXT

PWM

VIS

FB

FAULT

+

–

+

–

0.25V

FB

10µA

LED

FAULT

LOGIC

+

–

INTVCC

EA1

OPEN

VOUT –5V 0.95V

BST2

VREF

12.5µA

PWMON

0.1V

A4

1.25µA

+

+

–

EA2

SHORT

PWMON

1V

FB

+

+

+

CTRL1

CTRL2

1.25V

–

+

+

A2=10

VIS

SS

VC

GND

–

ISP

ISN

0.25V

8391a BD

14

Rev. A

For more information www.analog.com

�LT8391A

OPERATION

The LT8391A is a current mode LED controller that can

regulate LED current from input voltage above, below, or

equal to the LED string voltage. The ADI proprietary peakbuck peak-boost current mode control scheme uses a single inductor current sense resistor and provides smooth

transition between buck region, buck-boost region, and

boost region. Its operation is best understood by referring

to the Block Diagram.

PEAK-BUCK

PEAK-BOOST

Power Switch Control

Figure 1 shows a simplified diagram of how the four

power switches A, B, C, and D are connected to the inductor L, the current sense resistor RSENSE, power input VIN,

power output VOUT, and ground. The current sense resistor RSENSE connected to the LSP and LSN pins provides

inductor current information for both peak current mode

control and reverse current detection in buck region,

buck-boost region, and boost region. Figure 2 shows the

current mode control as a function of VIN/VOUT ratio and

Figure 3 shows the operation region as a function of VIN/

VOUT ratio. The power switches are properly controlled

to smoothly transition between modes and regions.

Hysteresis is added to prevent chattering between modes

and regions.

VIN

TG1

VOUT

A

SW1

BG1

B

RSENSE

L

D

8391a F02

Figure 2. Current Mode vs VIN/VOUT Ratio

(1)

BUCK

(3)

(2)

BUCK-BOOST

(2)

BOOST

(4)

0.75

0.85

1.00

1.25

1.33

VIN/VOUT

8391a F03

Figure 3. Operation Region vs VIN/VOUT Ratio

TG2

SW2

C

0.98 1.00 1.02

VIN/VOUT

BG2

8391a F01

Figure 1. Simplified Diagram of the Power Switches

There are total four states: (1) peak-buck current mode

control in buck region, (2) peak-buck current mode control in buck-boost region, (3) peak-boost current mode

control in buck-boost region, and (4) peak-boost current

mode control in boost region. The following sections

give detailed description for each state with waveforms,

in which the shoot-through protection dead time between

switches A and B, between switches C and D are ignored

for simplification.

Peak-Buck in Buck Region (VIN >> VOUT)

When VIN is much higher than VOUT, the LT8391A uses

peak-buck current mode control in buck region (Figure 4).

Switch C is always off and switch D is always on. At the

beginning of every cycle, switch A is turned on and the

inductor current ramps up. When the inductor current hits

the peak buck current threshold commanded by VC voltage at buck current comparator A3 during (A+D) phase,

switch A is turned off and switch B is turned on for the

rest of the cycle. Switches A and B will alternate, behaving

like a typical synchronous buck regulator.

Rev. A

For more information www.analog.com

15

�LT8391A

OPERATION

A

A

B

B

C

100% OFF

C

D

100% ON

D

20%

80%

IL

IL

A+D

B+D

B+D

A+D

20%

80%

A+D

A+C

A+D

B+D

A+C

B+D

8391a F05

8391a F04

Figure 4. Peak-Buck in Buck Region (VIN >> VOUT)

Figure 5. Peak-Buck in Buck-Boost Region (VIN ~> VOUT)

Peak-Buck in Buck-Boost Region (VIN ~> VOUT)

When VIN is slightly higher than VOUT, the LT8391A uses

peak-buck current mode control in buck-boost region

(Figure 5). Switch C is always turned on for the beginning 20% cycle and switch D is always turned on for the

remaining 80% cycle. At the beginning of every cycle,

switches A and C are turned on and the inductor current

ramps up. After 20% cycle, switch C is turned off and

switch D is turned on, and the inductor keeps ramping

up. When the inductor current hits the peak buck current

threshold commanded by VC voltage at buck current comparator A3 during (A+D) phase, switch A is turned off and

switch B is turned on for the rest of the cycle.

Peak-Boost in Buck-Boost Region (VIN

LBOOST >

0

–10

0.1

Figure 9. CISPR 25 Average Conducted EMI

PEAK CONDUCTED EMI (dBµV)

The rising edge of the synchronization clock represents

the beginning of a switching cycle, turning on switches A

and C, or switches A and D.

L>

10• VOUT •RSENSE

f

For high efficiency, choose an inductor with low core loss,

such as ferrite. Also, the inductor should have low DC

resistance to reduce the I2R losses, and must be able to

handle the peak inductor current without saturating. To

minimize radiated noise, use a shielded inductor.

Rev. A

For more information www.analog.com

�LT8391A

APPLICATIONS INFORMATION

RSENSE Selection and Maximum Output Current

Power MOSFET Selection

RSENSE is chosen based on the required output current.

The duty cycle independent maximum current sense

thresholds (50mV in peak-buck and 50mV in peak-boost)

set the maximum inductor peak current in buck region,

buck-boost region, and boost region.

The LT8391A requires four external N-channel power

MOSFETs, two for the top switches (switches A and D

shown in Figure 1) and two for the bottom switches

(switches B and C shown in Figure 1). Important parameters for the power MOSFETs are the breakdown voltage VBR(DSS), threshold voltage VGS(TH), on-resistance

RDS(ON), reverse transfer capacitance CRSS and maximum

current IDS(MAX).

In boost region, the lowest maximum average load current happens at VIN(MIN) and can be calculated as:

⎛ 50mV ΔIL(BOOST) ⎞ VIN(MIN)

IOUT(MAX_BOOST) = ⎜

−

⎟⎠ • V

2

⎝ RSENSE

OUT

where ∆IL(BOOST) is peak-to-peak inductor ripple current

in boost region and can be calculated as:

ΔIL(BOOST) =

VIN(MIN)•(VOUT − VIN(MIN) )

f•L• VOUT

In buck region, the lowest maximum average load current

happens at VIN(MAX) and can be calculated as:

To achieve 2MHz operation, the power MOSFET selection is critical. With typical 25ns shoot-through protection

dead time, high performance power MOSFETs with low

Qg and low RDS(ON) must be used.

Since the gate drive voltage is set by the 5V INTVCC

supply, logic-level threshold MOSFETs must be used in

LT8391A applications. Switching four MOSFETs at higher

frequency like 2MHz, the substantial gate charge current

from INTVCC can be estimated as:

(

IINTVCC = f • QgA + QgB + QgC + QgD

⎛ 50mV ΔIL(BUCK) ⎞

IOUT(MAX_BUCK) = ⎜

−

⎟⎠

2

⎝ RSENSE

where ∆IL(BUCK) is peak-to-peak inductor ripple current in

buck region and can be calculated as:

f is the switching frequency

ΔIL(BUCK) =

where:

VOUT •(VIN(MAX) − VOUT )

f•L• VIN(MAX)

The maximum current sense RSENSE in boost region is:

RSENSE(BOOST) =

2•50mV• VIN(MIN)

2•ILED(MAX)• VOUT + ΔIL(BOOST)• VIN(MIN)

The maximum current sense RSENSE in buck region is

RSENSE(BUCK) =

)

2•50mV

2•ILED(MAX) + ΔIL(BUCK)

The final RSENSE value should be lower than the calculated

RSENSE in both buck and boost regions. A 20% to 30%

margin is usually recommended.

QgA, QgB, QgC, QgD are the total gate charges of

MOSFETs A, B, C, D at 5V VGS.

Make sure the total required INTVCC current not exceeding the INTVCC current limit in the data sheet. Typically,

MOSFETs with less than 15nC Qg are recommended.

The LT8391A uses the VIN/VOUT ratio to transition between

modes and regions. Bigger IR drop in the power path caused

by improper MOSFET and inductor selection may prevent the

LT8391A from smooth transition. Make sure that low RDS(ON)

MOSFETs and low DCR inductor are used to satisfy:

ILED(MAX) ≤

0.025 • VOUT

R A,B +RC,D +RSENSE +RL

where:

RA,B is the maximum RDS(ON) of MOSFETs A or B at 25°C

RC,D is the maximum RDS(ON) of MOSFETs C or D at 25°C

RL is the maximum DCR resistor of inductor at 25°C

Rev. A

For more information www.analog.com

21

�LT8391A

APPLICATIONS INFORMATION

The RDS(ON) and DCR increase at higher junction temperatures and the process variation have been included

in the calculation above.

In order to select the power MOSFETs, the power dissipated by the device must be known. For switch A, the

maximum power dissipation happens in boost region,

when it remains on all the time. Its maximum power dissipation at maximum output current is given by:

⎛ ILED(MAX)•VOUT ⎞2

PA(BOOST) = ⎜

⎟ •ρ T •RDS(ON)

VIN

⎝

⎠

where ρT is a normalization factor (unity at 25°C) accounting for the significant variation in on-resistance with temperature, typically 0.4%/°C as shown in Figure 11. For a

maximum junction temperature of 125°C, using a value

of ρT = 1.5 is reasonable.

ρT NORMALIZED ON-RESISTANCE (Ω)

2.0

0.5

50

100

0

JUNCTION TEMPERATURE (°C)

150

Figure 11. Normalized RDS(ON) vs Temperature

Switch B operates in buck region as the synchronous

rectifier. Its power dissipation at maximum output current

is given by:

VIN − VOUT

•ILED(MAX)2•ρ T •RDS(ON)

VIN

Switch C operates in boost region as the control switch.

Its power dissipation at maximum current is given by:

PC(BOOST) =

(VOUT − VIN )•VOUT

VIN

•RDS(ON)+k•VOUT 3•

22

PD(BOOST) =

VOUT

•ILED(MAX)2•ρ T •RDS(ON)

VIN

For the same output voltage and current, typically switch

A has the highest power dissipation in buck region at

VIN(MAX) and switch C has the highest power dissipation

in boost region at VIN(MIN).

From a known power dissipated in the power MOSFET, its

junction temperature can be obtained using the following

formula:

The junction-to-ambient thermal resistance RTH(JA)

includes the junction-to-case thermal resistance RTH(JC)

and the case-to-ambient thermal resistance RTH(CA). This

value of TJ can then be compared to the original, assumed

value used in the iterative calculation process.

1.0

8391a F11

PB(BUCK) =

For switch D, the maximum power dissipation happens in

boost region, when its duty cycle is higher than 50%. Its

maximum power dissipation at maximum output current

is given by:

TJ = TA + P • RTH(JA)

1.5

0

–50

where CRSS is usually specified by the MOSFET manufacturers. The constant k, which accounts for the loss caused

by reverse recovery current, is inversely proportional to

the gate drive current and has an empirical value of 1.7.

2

ILED(MAX)

VIN

•ILED(MAX)2•ρ T

•CRSS•f

Optional Schottky Diode (DB, DD) Selection

The optional Schottky diodes DB (in parallel with switch B)

and DD (in parallel with switch D) conduct during the

dead time between the conduction of the power MOSFET

switches. They are intended to prevent the body diode

of synchronous switches B and D from turning on and

storing charge during the dead time. In particular, DB

significantly reduces reverse recovery current between

switch B turn-off and switch A turn-on, and DD significantly reduces reverse recovery current between switch

D turn-off and switch C turn-on. They improve converter

efficiency and reduce switch voltage stress. In order for

the diode to be effective, the inductance between it and

the synchronous switch must be as small as possible,

mandating that these components be placed adjacently.

Rev. A

For more information www.analog.com

�LT8391A

APPLICATIONS INFORMATION

CIN and COUT Selection

Input and output capacitance is necessary to suppress

voltage ripple caused by discontinuous current moving

in and out the regulator. A parallel combination of capacitors is typically used to achieve high capacitance and low

equivalent series resistance (ESR). Dry tantalum, special

polymer, aluminum electrolytic and ceramic capacitors are

all available in surface mount packages. Capacitors with

low ESR and high ripple current ratings, such as OS-CON

and POSCAP are also available.

Ceramic capacitors should be placed near the regulator

input and output to suppress high frequency switching

spikes. Ceramic capacitors, of at least 1µF, should also

be placed from VIN to GND and VOUT to GND as close to

the LT8391A pins as possible. Due to their excellent low

ESR characteristics, ceramic capacitors can significantly

reduce input ripple voltage and help reduce power loss

in the higher ESR bulk capacitors. X5R or X7R dielectrics

are preferred, as these materials retain their capacitance

over wide voltage and temperature ranges. Many ceramic

capacitors, particularly 0805 or 0603 case sizes, have

greatly reduced capacitance at the desired operating

voltage.

Discontinuous input current is highest in buck region due

to the switch A toggling on and off. Make sure that the

CIN capacitor network has low enough ESR and is sized

to handle the maximum RMS current. In buck region, the

input RMS current is given by:

Δ VCAP(BOOST) =

ΔVCAP(BUCK) =

ILED •(VOUT − VIN(MIN) )

C OUT • VOUT • f

⎛

⎞

V

VOUT • ⎜ 1– OUT ⎟

⎝ VIN(MAX) ⎠

8 • L • f2 • C OUT

The maximum steady ripple due to the voltage drop

across the ESR is given by:

Δ VESR(BOOST) =

VOUT •ILED(MAX)

VIN(MIN)

•ESR

⎛

⎞

V

VOUT • ⎜ 1– OUT ⎟

⎝ VIN(MAX) ⎠

ΔVESR(BUCK) =

• ESR

L•f

INTVCC Regulator

Input Capacitance CIN

IRMS ≈ILED(MAX)•

The effects of ESR and the bulk capacitance must be considered when choosing the right capacitor for a given

output ripple voltage. The maximum steady state ripple

due to charging and discharging the bulk capacitance is

given by:

VOUT

VIN

•

−1

VIN

VOUT

The formula has a maximum at VIN = 2VOUT, where IRMS

= ILED(MAX)/2. This simple worst-case condition is commonly used for design because even significant deviations

do not offer much relief.

Output Capacitance COUT

Discontinuous current shifts from the input to the output

in the boost region. Make sure that the COUT capacitor

network is capable of reducing the output voltage ripple.

An internal P-channel low dropout regulator produces 5V

at the INTVCC pin from the VIN supply pin. The INTVCC powers internal circuitry and gate drivers in the LT8391A. The

INTVCC regulator can supply a peak current of 145mA and

must be bypassed to ground with a minimum of 4.7µF

ceramic capacitor. Good local bypass is necessary to supply

the high transient current required by MOSFET gate drivers.

Higher input voltage applications with large MOSFETs

being driven at higher switching frequencies may cause

the maximum junction temperature rating for the LT8391A

to be exceeded. The system supply current is normally

dominated by the gate charge current. Additional external

loading of the INTVCC also needs to be taken into account

for the power dissipation calculation. The total LT8391A

power dissipation in this case is VIN • IINTVCC, and overall

efficiency is lowered. The junction temperature can be

estimated by using the equation:

TJ = TA + PD • θJA

Rev. A

For more information www.analog.com

23

�LT8391A

APPLICATIONS INFORMATION

where θJA (in °C/W) is the package thermal resistance.

VIN

To prevent maximum junction temperature from being

exceeded, the input supply current must be checked operating in continuous mode at maximum VIN.

R1

EN/UVLO

Top Gate MOSFET Driver Supply (CBST1, CBST2)

The top MOSFET drivers, TG1 and TG2, are driven between

their respective SW and BST pin voltages. The boost voltages are biased from floating bootstrap capacitors CBST1

and CBST2, which are normally recharged through both the

external and internal bootstrap diodes when the respective

top MOSFET is turned off. External bootstrap diodes are recommended because the internal bootstrap diodes are not

always strong enough to refresh top MOSFETs at 2MHz. Both

capacitors are charged to the same voltage as the INTVCC

voltage. The bootstrap capacitors CBST1 and CBST2, need to

store about 100 times the gate charge required by the top

switches A and D. In most applications, a 0.1µF to 0.47µF,

X5R or X7R dielectric capacitor is adequate.

Programming VIN UVLO

A resistor divider from VIN to the EN/UVLO pin implements VIN undervoltage lockout (UVLO). The EN/UVLO

enable falling threshold is set at 1.214V with 10mV hysteresis. In addition, the EN/UVLO pin sinks 2.5µA when the

voltage on the pin is below 1.214V. This current provides

user programmable hysteresis based on the value of R1.

The programmable UVLO thresholds are:

R1+R2

VIN(UVLO+) =1.233V•

+2.5µA•R1

R2

RUN/STOP

CONTROL

(OPTIONAL)

R2

LT8391A

GND

8391a F12

Figure 12. VIN Undervoltage Lockout (UVLO)

string. The voltage drop across RLED is (Kelvin) sensed by

the ISP and ISN pins. The CTRL1 and CTRL2 pins should

be tied to a voltage higher than 1.35V to get the full-scale

100mV (typical) threshold across the sense resistor. Either

the CTRL1 or CTRL2 pin can be used to dim the LED current to zero, although relative accuracy decreases with the

decreasing sense threshold. When either the CTRL1 or

CTRL2 pin voltage is less than 1.15V, the LED current is:

ILED =

Min(VCTRL1,VCTRL2 )− 250mV

10•RLED

where Min(VCTRL1, VCTRL2) is the minimum value of CTRL1

and CTRL2 pin voltages. When Min(VCTRL1, VCTRL2) is

between 1.15V and 1.35V, the LED current varies with the

Min(VCTRL1, VCTRL2), but departs from the equation above

by an increasing amount as Min(VCTRL1, VCTRL2) increases.

Ultimately, when Min(VCTRL1, VCTRL2) > 1.35V, the LED

current no longer varies. The typical V(ISP-ISN) threshold

vs Min(VCTRL1, VCTRL2) is listed in Table 2.

Table 2. V(ISP-ISN) Threshold vs Min(VCTRL1, VCTRL2)

Min(VCTRL1, VCTRL2) (V)

V(ISP-ISN) (mV)

1.15

90

R1+R2

R2

1.20

94.5

Figure 12 shows the implementation of external shutdown control while still using the UVLO function. The

NMOS grounds the EN/UVLO pin when turned on, and

puts the LT8391A in shutdown with quiescent current

less than 2µA.

When Min(VCTRL1, VCTRL2) is higher than 1.35V, the LED

current is regulated to:

Programming LED Current

The LED current is programmed by placing an appropriate

value current sense resistor, RLED, in series with the LED

The CTRL1/CTRL2 pin should not be left open (tie to VREF

if not used). The CTRL1/CTRL2 pin can also be used in

VIN(UVLO−) =1.220V•

24

ILED =

1.25

98

1.30

99.5

1.35

100

100mV

RLED

Rev. A

For more information www.analog.com

�LT8391A

APPLICATIONS INFORMATION

conjunction with a thermistor to provide overtemperature

protection for the LED load, or with a resistor divider to

VIN to reduce output power and switching current when

VIN is low. The presence of a time varying differential

voltage ripple signal across ISP and ISN at the switching frequency is expected. The amplitude of this signal

is increased by higher LED load current, lower switching

frequency, or smaller value output filter capacitor. Some

level of ripple signal is acceptable, and the compensation capacitor on the VC pin filters the signal so the average difference between ISP and ISN is regulated to the

user-programmed value. The ripple voltage amplitude

(peak-to-peak) in excess of 20mV should not cause misoperation, but may lead to noticeable offset between the

average value and the user-programmed value.

Dimming Control

There are two methods to control the LED current for dimming using the LT8391A. One method uses the CTRL1 or

CTRL2 pin to adjust the current regulated in the LEDs. A

second method uses the PWM pin to modulate the LED

current between zero and full current to achieve a precisely programmed average current.

Compared to the analog dimming method, the PWM dimming method offers much higher dimming ratio without

any color shift. To make PWM dimming more accurate, the

switch demand current is stored on the VC node when the

PWM signal is low. This feature minimizes recovery time

when the PWM signal goes high. To further improve the

recovery time, a high side PMOS PWM switch should be

used in the LED current path to prevent the output capacitor

from discharging during the PWM signal low phase.

The choice of switching frequency, inductor value, and

loop compensation affects the minimum PWM on time,

below which the LT8391A loses the LED current regulation. For the same application, the LT8391A achieves

the highest PWM dimming ratio (up to 2000:1) in buck

region, the medium PWM dimming ratio (up to 2000:1)

in buck-boost region, and the lowest PWM dimming ratio

(up to 1000:1) in boost region.

In either fixed frequency operation set by RT resistor or

spread spectrum frequency operation, the internal oscillator is synchronized to the PWM signal rising edge, thereby

providing flicker-free PWM dimming performance. In

external frequency synchronization operation, both SYNC

and PWM signals must have synchronized rising edges to

achieve flicker-free PWM dimming performance.

The LT8391A provides both external PWM dimming and

internal PWM dimming. For external PWM dimming,

choose RP resistor less than 30k and apply external PWM

clock signal on the PWM pin. For internal PWM dimming,

choose RP resistor to one of the five resistor values in

Table 3 and apply analog DC voltage or a resistor divider

from VREF to the PWM pin. The RP resistor sets the internal PWM dimming frequency, and the analog DC voltage

on the PWM pin from 1V to 2V sets the internal PWM

dimming duty ratio from 0% to 100% with a discrete

1/128 step size in Figure 13. A 1µF ceramic capacitor on

the PWM pin is recommended to minimize the internal

PWM dimming duty ratio jitter caused by switching noise.

Table 3. Internal PWM Dimming Frequency vs RP Value

(5% Resistor)

RP (k)

fSW

fSW = 1MHz

fSW = 1.5MHz

fSW = 2MHz

≤ 30

External

External

External

External

51

fSW/256

3.9kHz

5.9kHz

7.8kHz

82

fSW/512

2.0kHz

2.9kHz

3.9kHz

130

fSW/1024

1.0kHz

1.5kHz

2.0kHz

200

fSW/2048

0.49kHz

0.73kHz

0.98kHz

300

fSW/4096

0.24kHz

0.37kHz

0.49kHz

PWMTG DUTY RATIO (%)

100

PWMTG DUTY

RATIO (%)

ALWAYS

ON

50

ALWAYS

OFF

0

0.0

0.5

1.0

1.5

2.0

PWM (V)

2.5

3.0

8391 F13

Figure 13. Internal PWM Dimming Duty Ratio vs PWM Voltage

High Side PMOS PWM Switch Selection

A high side PMOS PWM switch is recommended in most

LT8391A applications to maximize the PWM dimming

ratio and protect the LED string during fault conditions.

Compared to a low side NMOS PWM switch, the high side

PMOS PWM switch allows a single wire to the LED string

Rev. A

For more information www.analog.com

25

�LT8391A

APPLICATIONS INFORMATION

and ground return path through chassis. The high side

PMOS PWM switch is typically selected for drain-source

voltage VDS, gate-source threshold voltage VGS(TH), and

continuous drain current ID. For proper operations, VDS

rating should exceed the open LED regulation voltage set

by the FB pin, the absolute value of VGS(TH) should be less

than 3V, and ID rating should be above ILED(MAX).

Programming Output Voltage and Thresholds

The LT8391A has a voltage feedback pin FB that can be

used to program a constant-voltage output. The output

voltage can be set by selecting the values of R3 and R4

(Figure 14) according to the following equation:

VOUT = 1.00 V•

R3+R4

R4

VOUT

R3

LT8391A

FB

R4

8391a F14

Figure 14. Feedback Resistor Connection

In addition, the FB pin also sets output overvoltage threshold, open LED threshold, and short LED threshold. For an

LED driver application with small output capacitors, the

output voltage usually overshoots a lot during an open

LED event. Although the 1.00V FB regulation loop tries to

regulate the output, the loop is usually too slow to prevent

the output from overshooting. Once the FB pin hits its

overvoltage threshold 1.05V, the LT8391A stops switching by turning off TG1, BG1, TG2, and BG2, and also turns

off PWMTG to disconnect the LED string for protection.

The output overvoltage threshold can be set as:

VOUT(OVP) = 1.05V•

R3+R4

R4

Make sure the expected VFB during normal operation

stays between the short LED rising threshold 0.3V and

the open LED falling threshold 0.9V:

0.3V ≤ VLED •

26

R4

≤ 0.9 V

R3+R4

These equations set the maximum LED string voltage with

full open LED protection for the LT8391A to be 51V.

FAULT Pin

The LT8391A provides an open-drain status pin, FAULT,

which is pulled low during either open LED or short LED

conditions. The open LED condition happens when the FB

pin is above 0.95V and the voltage across V(ISP-ISN) is less

than 10mV. The short LED condition happens when the

FB pin is below 0.25V. The FAULT status is updated when

the SS pin is above 1.75V and the PWM signal is high.

Soft-Start and Fault Protection

As shown in Figure 8 and explained in the Operation section, the SS pin can be used to program soft-start by connecting an external capacitor from the SS pin to ground.

The internal 12.5µA pull-up current charges up the capacitor, creating a voltage ramp on the SS pin. As the SS pin

voltage rises linearly from 0.25V to 1V (and beyond), the

output voltage rises smoothly and transitions into LED

current regulation. The soft-start range is defined to be

the voltage range from 0V to the FB voltage in LED current regulation. The soft-start time can be calculated as:

t SS = VLED •

C

R4

• SS

R3+R4 12.5µA

Make sure the CSS is at least five to ten times larger than

the compensation capacitor on the VC pin. A 22nF ceramic

capacitor is a good starting point.

The SS pin is also used as a fault timer. Once an open

LED or a short LED fault is detected, a 1.25µA pull-down

current source is activated. Using a single resistor from

the SS pin to the VREF pin, the LT8391A can be set to

three different fault protection modes: hiccup (no resistor), latch-off (499k), and keep-running (100k).

With a 100k resistor in keep-running mode, the LT8391A

continues switching normally, either regulating the programmed VOUT during open LED fault or regulating the

current during short LED fault. With a 499k resistor in

latch-off mode, the LT8391A stops switching until the

EN/UVLO pin is pulled low and high to restart. With no

resistor in hiccup mode, the LT8391A enters low duty

Rev. A

For more information www.analog.com

�LT8391A

APPLICATIONS INFORMATION

cycle auto-retry operation. The 1.25µA pull-down current

discharges the SS pin to 0.2V and then 12.5µA pull-up

current charges the SS pin up. If the fault condition has

not been removed when the SS pin reaches 1.75V, the

1.25µA pull-down current turns on again, initiating a new

hiccup cycle. This will continue until the fault is removed.

Loop Compensation

The LT8391A uses an internal transconductance error

amplifier, the output of which, VC, compensates the control loop. The external inductor, output capacitor, and the

compensation resistor and capacitor determine the loop

stability.

The inductor and output capacitor are chosen based on

performance, size and cost. The compensation resistor

and capacitor on the VC pin are set to optimize control

loop response and stability. For a typical LED application,

a 2.2nF compensation capacitor on the VC pin is adequate,

and a series resistor should always be used to increase

the slew rate on the VC pin to maintain tighter regulation

of LED current during fast transients on the input supply

of the converter.

3. INTVCC current. This is the sum of the MOSFET driver

and control currents.

4. CIN and COUT loss. The input capacitor has the difficult job of filtering the large RMS input current to the

regulator in buck region. The output capacitor has the

difficult job of filtering the large RMS output current in

boost region. Both CIN and COUT are required to have

low ESR to minimize the AC I2R loss and sufficient

capacitance to prevent the RMS current from causing

additional upstream losses in fuses or batteries.

5. Other losses. Schottky diode DB and DD are responsible for conduction losses during dead time and light

load conduction periods. Inductor core loss occurs

predominately at light loads. Switch A causes reverse

recovery current loss in buck region, and switch C

causes reverse recovery current loss in boost region.

When making adjustments to improve efficiency, the input

current is the best indicator of changes in efficiency. If you

make a change and the input current decreases, then the

efficiency has increased. If there is no change in the input

current, then there is no change in efficiency.

PC Board Layout Checklist

Efficiency Considerations

The power efficiency of a switching regulator is equal to

the output power divided by the input power times 100%.

It is often useful to analyze individual losses to determine

what is limiting the efficiency and which change would

produce the most improvement. Although all dissipative

elements in circuits produce losses, four main sources

account for most of the losses in LT8391A circuits:

1. DC I2R losses. These arise from the resistances of the

MOSFETs, sensing resistor, inductor and PC board

traces and cause the efficiency to drop at high output

currents.

2. Transition loss. This loss arises from the brief amount

of time switch A or switch C spends in the saturated

region during switch node transitions. It depends upon

the input voltage, load current, driver strength and

MOSFET capacitance, among other factors.

The basic PC board layout requires a dedicated ground

plane layer. Also, for high current, a multilayer board provides heat sinking for power components.

The ground plane layer should not have any traces

and it should be as close as possible to the layer with

power MOSFETs.

n Place C , switch A, switch B and D in one comIN

B

pact area. Place COUT, switch C, switch D and DD in

one compact area.

n Use immediate vias to connect the components to

the ground plane. Use several large vias for each

power component.

n Use planes for V and V

IN

OUT to maintain good voltage

filtering and to keep power losses low.

n

Rev. A

For more information www.analog.com

27

�LT8391A

APPLICATIONS INFORMATION

Flood all unused areas on all layers with copper.

Flooding with copper will reduce the temperature rise

of power components. Connect the copper areas to

any DC net (VIN or GND).

n Separate the signal and power grounds. All smallsignal components should return to the exposed

GND pad from the bottom, which is then tied to the

power GND close to the sources of switch B and

switch C.

n Place switch A and switch C as close to the controller as possible, keeping the power GND, BG and SW

traces short.

n Keep the high dV/dT SW1, SW2, BST1, BST2, TG1

and TG2 nodes away from sensitive small-signal

nodes.

n The path formed by switch A, switch B, D and the

B

CIN capacitor should have short leads and PCB trace

lengths. The path formed by switch C, switch D, DD

and the COUT capacitor also should have short leads

and PCB trace lengths.

n The output capacitor (–) terminals should be connected as close as possible to the (–) terminals of the

input capacitor.

n

28

Connect the top driver bootstrap capacitor CBST1

closely to the BST1 and SW1 pins. Connect the top

driver bootstrap capacitor CBST2 closely to the BST2

and SW2 pins.

n Connect the input capacitors C and output capaciIN

tors COUT closely to the power MOSFETs. These

capacitors carry the MOSFET AC current.

n Route LSP and LSN traces together with minimum

PCB trace spacing. Avoid sense lines pass through

noisy areas, such as switch nodes. The filter capacitor between LSP and LSN should be as close as possible to the IC. Ensure accurate current sensing with

Kelvin connections at the RSENSE resistor. A low ESL

sense resistor is recommended.

n Connect the V pin compensation network close to

C

the IC, between VC and the signal ground. The capacitor helps to filter the effects of PCB noise and output

voltage ripple voltage from the compensation loop.

n Connect the INTV

CC bypass capacitor, CINTVCC,

close to the IC, between the INTVCC and the power

ground. This capacitor carries the MOSFET drivers’

current peaks.

n

Rev. A

For more information www.analog.com

�LT8391A

TYPICAL APPLICATIONS

94% Efficient 24W (16V 1.5A) 2MHz Buck-Boost LED Driver with Fault Protection

VIN

6V TO 32V CONTINUOUS

4V TO 56V TRANSIENT

22µF

63V

L1

2.2µH

R1

6mΩ

M1

4.7µF

100V

×2

0.1µF

SW1 LSP

BST1

LSN

M4

D2

D1

INTVCC

M2

10µF

25V

×2

0.1µF

SW2

BST2

BG1

BG2

INTVCC

M3

GND

1µF

383k

165k

100k

FAULT

ANALOG DIM

L1: COILCRAFT XAL5030-222MEB 2.2µH

M1, M2: NXP BUK9M42-60E

M3, M4: INFINEON IPZ40N04S5L-7R4

M5: VISHAY Si2343CDS

D1, D2: NXP BAT46WJ

D3: NXP PMEG3010EB

R1: SUSUMU KRL3216D-C-R006-F

113k

TG2

VOUT

4.7µF

1µF

1M

FB

48.7k

ISP

SYNC/SPRD

INTVCC

56mΩ

INTVCC

ISN

M5

PWMTG

FAULT

CTRL1

100k

90.9k

LT8391A

EN/UVLO

SSFM OFF

SSFM ON

TG1

VIN

PWM

PWM DIM

D3

VREF

0.47µF

CTRL2

SS

22nF

RP

VC

RT

4.7k

3.3nF

59.0k

2MHz

PWM SETTING

EXT

INT

16V

1.5A

LEDs

300k

488Hz

8391a TA02a

Rev. A

For more information www.analog.com

29

�LT8391A

TYPICAL APPLICATIONS

100Hz 2000:1 External PWM

Dimming (VIN = 32V)

100Hz 2000:1 External PWM

Dimming (VIN = 18V)

100Hz 800:1 External PWM

Dimming (VIN = 8V)

VPWM

5V/DIV

VPWM

5V/DIV

VPWM

5V/DIV

IL

2A/DIV

IL

2A/DIV

IL

2A/DIV

ILED

1A/DIV

ILED

1A/DIV

ILED

1A/DIV

8391 TA02b

2µs/DIV

2µs/DIV

OPEN LED Protection: Hiccup

Mode (RSS = Open)

OPEN

8391 TA02c

2µs/DIV

OPEN LED Protection: Latch-Off

Mode (RSS = 499k)

RECONNECT

OPEN

RECONNECT

OPEN LED Protection:

Keep-Running Mode (RSS = 100k)

VOUT

20V/DIV

VSS

2V/DIV

VSS

2V/DIV

VOUT

20V/DIV

VSS

2V/DIV

VFAULT

5V/DIV

VFAULT

5V/DIV

VFAULT

5V/DIV

ILED

2A/DIV

ILED

2A/DIV

ILED

4A/DIV

VOUT

20V/DIV

20ms/DIV

30

8391a TA02e

20ms/DIV

8391a TA02f

8391 TA02d

OPEN

RECONNECT

20ms/DIV

8391a TA02g

Rev. A

For more information www.analog.com

�LT8391A

PACKAGE DESCRIPTION

FE Package

28-Lead Plastic TSSOP (4.4mm)

(Reference LTC DWG # 05-08-1663 Rev L)

Exposed Pad Variation EB

9.60 – 9.80*

(.378 – .386)

4.75

(.187)

4.75

(.187)

28 27 26 2524 23 22 21 20 1918 17 16 15

6.60 ±0.10

4.50 ±0.10

2.74

(.108)

SEE NOTE 4

0.45 ±0.05

EXPOSED

PAD HEAT SINK

ON BOTTOM OF

PACKAGE

6.40

2.74

(.252)

(.108)

BSC

1.05 ±0.10