LT8618/LT8618-3.3/LT8618C

High Efficiency 65V/100mA

Synchronous Bucks

DESCRIPTION

FEATURES

High Efficiency Synchronous Operation

n > 90% Efficiency at 30mA, 12V to 3.3V

IN

OUT

n Pin Selectable Forced Continuous or Burst Mode®

Operation (LT8618C Only)

n Ultralow Quiescent Current Burst Mode Operation

n < 2.5µA I Regulating 48V to 3.3V

Q

IN

OUT

n Output Ripple < 10mV

P-P

n 3.4V to 60V Input Operation Range (65V Max)

n Fast Minimum Switch-On Time: 35ns

n Adjustable (All) And Synchronizable (LT8618C

Only) Switching Frequency: 200kHz to 2.2MHz

n Fixed 3.3V Output Voltage Version (LT8618-3.3)

n Accurate 1V Enable Pin Threshold (All) with

Adjustable Hysteresis (LT8618C Only)

n Internal Compensation

n Output Soft-Start and Tracking

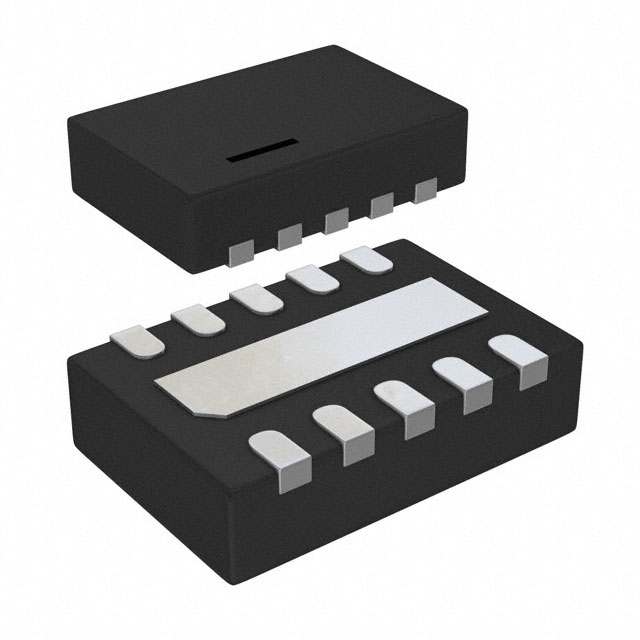

n Small 12-Lead 2mm × 2mm LQFN (LT8618C) and

10-Lead 3mm × 2mm DFN Packages

n AEC-Q100 Qualified for Automotive Applications

(LT8618/LT8618-3.3)

The LT®8618 family are compact, high speed synchronous monolithic step-down switching regulators that

deliver up to 100mA to the output with high efficiency at

a constant frequency, even up to 2.2MHz. They accept a

wide input voltage range up to 65V (transients only, 60V

for continuous operation), and consume only 2.5µA of

quiescent current when operating in Burst Mode. Top and

bottom power switches are included with all necessary

circuitry to minimize the need for external components.

n

The LT8618C includes BST and INTVCC ceramic capacitors for a more compact solution while having SYNC/

MODE and HYST pins. The SYNC/MODE pin selects the

regulator’s operation between forced continuous mode,

for predictive interference in sampling systems, Burst

Mode, for increased efficiency at light loads or spread

spectrum for Low EMI. It also allows synchronization to

an external clock to further increase signal to noise ratio

in high-resolution acquisition systems.

A PG flag signals when VOUT is within ±7.5% of the programmed output voltage and when in fault conditions.

Thermal shutdown provides additional protection.

APPLICATIONS

Industrial Sensors

n Industrial Internet of Things

n 4mA to 20mA Current Loops

n Flow Meters

n Automotive Housekeeping Supplies

n

PACKAGE

SYNC/

HYST

150°C

GRADE

INTERNAL

CAPS

FB

RESISTORS

DFN

No

Yes

No

External

LT8618

LT8618-3.3

DFN

No

Yes

No

Internal

LT8618C

LQFN

Yes

No

Yes

External

All registered trademarks and trademarks are the property of their respective owners.

TYPICAL APPLICATION

Efficiency at VOUT = 3.3V

100

3.3V, Step-Down Converter

OFF ON

VIN

1µF

1µF

10nF

95

BST

47nF

120µH

LT8618-3.3

EN/UV

SW

INTVCC

BIAS

TR/SS

110k

VOUT

3.3V

100mA

PG

RT

OUT

VIN = 24V

85

VIN = 48V

80

75

70

65

60

22µF

GND

VIN = 12V

90

EFFICIENCY (%)

VIN

4.2V TO 60V

8618 TA1a

55

50

fSW = 400kHz

fSW = 400kHz

0

10 20 30 40 50 60 70 80 90 100

OUTPUT CURRENT (mA)

8618 TA1b

Rev. A

Document Feedback

For more information www.analog.com

1

�LT8618/LT8618-3.3/LT8618C

ABSOLUTE MAXIMUM RATINGS

(Note 1)

VIN, EN/UV Voltage (Note 4)....................... –0.3V to 65V

PG Voltage.................................................. –0.3V to 42V

BIAS Voltage............................................... –0.3V to 25V

HYST Voltage (LT8618C Only).....................–0.3V to 12V

FB (LT8618/LT8618C), TR/SS Voltages......... –0.3V to 4V

OUT (LT8618-3.3)......................................... –0.3V to 6V

SYNC/MODE Voltage (LT8618C Only)........... –0.3V to 6V

Operating Junction Temperature Range (Note 2)

LT8618E/LT8618E-3.3/LT8618CA........... –40°C to 125°C

LT8618I/LT8618I-3.3............................... –40°C to 125°C

LT8618J/LT8618J-3.3............................. –40°C to 150°C

Storage Temperature Range................... –65°C to 150°C

PIN CONFIGURATION

LT8618C

1

SW

2

BIAS

3

INTVCC

4

RT

5

10 VIN

11

GND

9

EN/UV

8

PG

7

TR/SS

6

FB/OUT*

DDB PACKAGE

10-LEAD (3mm × 2mm) PLASTIC DFN

θJA = 76°C/W, θJC = 13.5°C/W

EXPOSED PAD (PIN 11) IS GND, MUST BE SOLDERED TO PCB

* FB FOR LT8618, OUT FOR LT8618-3.3

VIN

1

EN/UV

2

HYST

3

PG

4

DNC

BST

12

11

13

GND

5

6

TR/SS

TOP VIEW

GND

TOP VIEW

FB

LT8618/LT8618-3.3

10 SW

9

BIAS

8

RT

7

SYNC/MODE

LQFN PACKAGE

12-LEAD (2mm × 2mm × 0.74mm)

TJMAX = 125°C, θJA = 51°C/W

EXPOSED PAD (PIN 13) IS GND, MUST BE SOLDERED TO PCB

ORDER INFORMATION

TAPE AND REEL (MINI)

TAPE AND REEL

PART MARKING*

PACKAGE DESCRIPTION

TEMPERATURE RANGE

LT8618EDDB#TRMPBF

LT8618EDDB#TRPBF

LHHF

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 125°C

LT8618IDDB#TRMPBF

LT8618IDDB#TRPBF

LHHF

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 125°C

LT8618JDDB#TRMPBF

LT8618JDDB#TRPBF

LHHF

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 150°C

LT8618EDDB-3.3#TRMPBF

LT8618EDDB-3.3#TRPBF

LHHW

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 125°C

LT8618IDDB-3.3#TRMPBF

LT8618IDDB-3.3#TRPBF

LHHW

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 125°C

LT8618JDDB-3.3#TRMPBF

LT8618JDDB-3.3#TRPBF

LHHW

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 150°C

LT8618CAV#TRMPBF

LT8618CAV#TRPBF

LHNG

12-Lead (2mm × 2mm) LQFN (Laminate –40°C to 125°C

Package with QFN footprint)

2

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

ORDER INFORMATION

TAPE AND REEL (MINI)

TAPE AND REEL

PART MARKING*

PACKAGE DESCRIPTION

TEMPERATURE RANGE

LT8618EDDB#WTRMPBF

LT8618EDDB#WTRPBF

LHHF

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 125°C

LT8618IDDB#WTRMPBF

LT8618IDDB#WTRPBF

LHHF

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 125°C

LT8618JDDB#WTRMPBF

LT8618JDDB#WTRPBF

LHHF

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 150°C

LT8618EDDB-3.3#WTRMPBF

LT8618EDDB-3.3#WTRPBF

LHHW

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 125°C

LT8618IDDB-3.3#WTRMPBF

LT8618IDDB-3.3#WTRPBF

LHHW

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 125°C

LT8618JDDB-3.3#WTRMPBF

LT8618JDDB-3.3#WTRPBF

LHHW

10-Lead (3mm × 2mm) Plastic DFN

–40°C to 150°C

AUTOMOTIVE PRODUCTS**

Contact the factory for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

Tape and reel specifications. Some packages are available in 500 unit reels through designated sales channels with #TRMPBF suffix.

**Versions of this part are available with controlled manufacturing to support the quality and reliability requirements of automotive applications. These

models are designated with a #W suffix. Only the automotive grade products shown are available for use in automotive applications. Contact your

local Analog Devices account representative for specific product ordering information and to obtain the specific Automotive Reliability reports for

these models.

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C.

PARAMETER

CONDITIONS

Operating Input Voltage

Minimum Input Voltage

(Note 5)

VIN Quiescent Current

VEN/UV = 0V

VEN/UV = 2V, Not Switching

VIN Current in Regulation

MIN

l

TYP

3.4

MAX

60

UNITS

V

l

2.9

3.4

V

l

1

1.7

4

12

µA

µA

VIN = 12V, VOUT = 3.3V, ILOAD = 100µA

VIN = 12V, VOUT = 3.3V, ILOAD = 1mA

56

400

µA

µA

LT8618/LT8618C Feedback Reference Voltage

VIN = 12V, ILOAD = 100µA

l

0.762

0.778

0.798

V

LT8618-3.3 Output Voltage

VIN = 12V, ILOAD = 100µA

l

3.2

3.3

3.4

V

FB/OUT Voltage Line Regulation

VIN = 4V to 60V

l

±0.02

±0.06

LT8618/LT8618C FB Pin Input Current

VFB = 0.8V

l

BIAS Pin Current Consumption

VBIAS = 3.3V, ILOAD = 30mA, 700kHz

±20

0.8

%/V

nA

mA

Minimum On-Time

l

35

65

ns

Minimum Off-Time

l

90

120

ns

200

2.00

260

2.15

kHz

MHz

Oscillator Frequency

RT = 221k

RT = 18.2k

l

l

140

1.85

Top Power NMOS On-Resistance

3

Top Power NMOS Current Limit

l

150

Bottom Power NMOS On-Resistance

200

Ω

250

1.3

SW Leakage Current

VIN = 48V

l

EN/UV Pin Threshold

Pin Voltage Rising

l

Ω

15

0.98

EN/UV Pin Hysteresis

1.05

1.11

50

EN/UV Pin Current

VEN/UV = 2V

HYST Pull-Down Resistance

VHYST = 0.1V, VEN/UV < 0.9V, LT8618C Only

HYST Pin Leakage Current

VHYST = 1V, VEN/UV > 1.2V, LT8618C Only

PG Upper Threshold Offset from VFB/OUT

VFB/OUT Rising, LT8618/LT8618-3.3

VFB/OUT Rising, LT8618C

280

l

l

5.0

4.5

7.5

7.5

mA

µA

V

mV

±50

nA

500

Ω

±200

nA

10.0

10.0

%

%

Rev. A

For more information www.analog.com

3

�LT8618/LT8618-3.3/LT8618C

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C.

PARAMETER

CONDITIONS

PG Lower Threshold Offset from VFB/OUT

VFB/OUT Falling

l

MIN

TYP

MAX

UNITS

–10.0

–7.5

–5.0

%

PG Hysteresis

0.5

PG Leakage

VPG = 42V

PG Pull-Down Resistance

VPG = 0.1V

SYNC/MODE Threshold Voltage

LT8618C Only

TR/SS Source Current

VTR/SS = 0.1V, E- and I-Grades

VTR/SS = 0.1V, J- and A-Grades

±200

nA

550

1200

Ω

l

TR/SS Pull-Down Resistance

Fault Condition, VTR/SS = 0.1V

VIN to Disable Forced Continuous Mode

VIN Rising, LT8618C Only

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT8618E/LT8618E-3.3 is guaranteed to meet performance

specifications from 0°C to 125°C junction temperature. Specifications over

the –40°C to 125°C operating junction temperature range are assured by

design, characterization and correlation with statistical process controls.

The LT8618I/LT8618I-3.3 is guaranteed over the full –40°C to 125°C

operating junction temperature range. The LT8618J/LT8618J-3.3 is

guaranteed over the full –40°C to 150°C operating junction temperature

range. The LT8618CA is specified over the –40°C to 125°C operating

junction temperature range. High junction temperatures degrade operating

lifetimes. Operating lifetime is derated at junction temperatures greater

%

0.4

0.9

1.5

V

l

l

1

1

2

2

3.5

4

µA

µA

300

900

Ω

l

30

32

34

V

than 125°C. Note the maximum ambient temperature consistent with

these specifications is determined by specific operating conditions in

conjunction with board layout, the rated package thermal impedance and

other environmental factors.

Note 3: This IC includes overtemperature protection that is intended to

protect the device during overload conditions. Junction temperature will

exceed 125°C when overtemperature protection is active. Continuous

operation above the specified maximum operating junction temperature

will reduce lifetime

Note 4: Absolute maximum voltage at the VIN and EN/UV pins is 65V for

transients, and 60V for continuous operation.

Note 5: For the LT8618-3.3, minimum input voltage will be limited by

output voltage.

TYPICAL PERFORMANCE CHARACTERISTICS

LT8618:

Burst Mode Efficiency (5V Output)

LT8618:

Burst Mode Efficiency (5V Output)

VIN = 12V

VIN = 24V

80

VIN = 48V

70

60

4

100

90

90

80

80

70

VIN = 12V

60

VIN = 24V

50

VIN = 48V

40

30

L = 33µH

fSW = 2MHz

0

10 20 30 40 50 60 70 80 90 100

OUTPUT CURRENT (mA)

8618 G01

VIN = 12V

VIN = 24V

VIN = 48V

70

60

50

40

30

20

20

50

40

EFFICIENCY (%)

EFFICIENCY (%)

90

100

EFFICIENCY (%)

100

LT8618C: Forced Continuous

Mode Efficiency (5V Output)

L = 33µH

fSW = 2MHz

10

0

1μ

10μ

100μ

1m

10m

OUTPUT CURRENT (A)

100m

8618 G02

L = 47µH

fSW = 2MHz

10

0

0

10 20 30 40 50 60 70 80 90 100

OUTPUT CURRENT (mA)

8618 G31

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

TYPICAL PERFORMANCE CHARACTERISTICS

LT8618C:

Burst Mode Efficiency (5V Output)

LT8618C:

Burst Mode Efficiency (5V Output)

100

100

70

60

60

70

50

40

30

60

50

40

30

20

50

40

70

L = 47µH

fSW = 2MHz

0

20

L = 47µH

fSW = 2MHz

10

0

1μ

10 20 30 40 50 60 70 80 90 100

OUTPUT CURRENT (mA)

10μ

8618 G32

LT8618/LT8618C:

FB Voltage

100μ

1m

10m

OUTPUT CURRENT (A)

VIN = 48V

10

0

1μ

100m

10μ

8618 G33

VIN = 24V

100μ

1m

10m

OUTPUT CURRENT (A)

3.310

5.0

VO UT = 3.3V

R1 = 309kΩ

R2 = 1MΩ

778

777

776

3.305

4.2

INPUT CURRENT (µA)

OUT REGULATION VOLTAGE (V)

FB REGULATION VOLTAGE (mV)

4.6

779

3.300

3.295

3.290

3.8

3.4

3.0

2.6

LT8618

2.2

LT8618-3.3

1.8

3.285

LT8618C

1.4

0

3.280

−50 −25

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G05

LT8618/LT8618-3.3:

Burst Mode Efficiency (3.3V Output)

VIN = 24V

70

EFFICIENCY (%)

EFFICIENCY (%)

VIN = 12V

80

VIN = 48V

60

40

100

90

90

80

80

70

70

VIN = 12V

60

VIN = 24V

50

VIN = 48V

40

30

L = 33µH

fSW = 2MHz

0

10 20 30 40 50 60 70 80 90 100

OUTPUT CURRENT (mA)

8618 G03

0

10

20

30

40

INPUT VOLTAGE (V)

50

60

8618 G09

LT8618C: Forced Continuous

Mode Efficiency (3.3V Output)

100

VIN = 12V

VIN = 24V

VIN = 48V

60

50

40

30

20

20

50

1.0

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G06

LT8618/LT8618-3.3:

Burst Mode Efficiency (3.3V Output)

100

90

0

EFFICIENCY (%)

775

−50 −25

100m

8618 G34

No-Load Supply Current

In Burst Mode (3.3V Output)

LT8618-3.3:

OUT Voltage

780

VIN = 12V

80

VIN = 48V

EFFICIENCY (%)

EFFICIENCY (%)

EFFICIENCY (%)

VIN = 48V

80

L = 47µH

90 fSW = 2MHz

VIN = 24V

80

VIN = 24V

100

VIN = 12V

90

VIN = 12V

90

LT8618C: Forced Continuous

Mode Efficiency (5V Output)

L = 33µH

fSW = 2MHz

10

0

1μ

10μ

100μ

1m

10m

OUTPUT CURRENT (A)

100m

8618 G04

L = 33µH

fSW = 2MHz

10

0

0

10 20 30 40 50 60 70 80 90 100

OUTPUT CURRENT (mA)

8618 G35

Rev. A

For more information www.analog.com

5

�LT8618/LT8618-3.3/LT8618C

TYPICAL PERFORMANCE CHARACTERISTICS

LT8618C:

Burst Mode Efficiency (3.3V Output)

LT8618C:

Burst Mode Efficiency (3.3V Output)

100

100

100

80

VIN = 24V

70

VIN = 48V

70

60

VIN = 24V

60

50

40

30

20

50

L = 33µH

fSW = 2MHz

0

0

1μ

L = 33µH

fSW = 2MHz

10μ

8618 G36

Load Regulation

0.20

0.4

0.15

0.1

0

−0.1

−0.2

−0.3

−0.4

40

60

80

OUTPUT CURRENT (mA)

100

VIN = 24V

10μ

100μ

1m

10m

OUTPUT CURRENT (A)

2.25

L = 33µH

fSW = 2MHz

2.00

−0.05

−0.10

1.75

1.50

1.25

(FORCED

CONTINUOUS

MODE)

1.00

0.75

0.50

L = 120µH

fSW = 400kHz

0.25

0

10

100m

8618 G38

2.50

0

−0.20

VIN = 48V

LT8618C: No-Load Supply Current

In Forced Continuous Mode

(3.3V Output)

VOUT = 3.3V

IOUT = 100mA

8618 G07

20

30

40

INPUT VOLTAGE (V)

50

0

60

0

10

(PULSE SKIPPING)

20

30

40

INPUT VOLTAGE (V)

8618 G08

Top FET Current Limit

vs Duty Cycle

50

60

8618 G39

Top FET Current Limit

vs Temperature

220

200

VIN = 12V

VOUT = 5V

1.6 ILOAD = 100mA

215

1.4

1.2

1.0

VBIAS = 3.3V

VBIAS = 5V

0.6

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2

SWITCHING FREQUENCY (MHz)

8618 G40

190

SWITCH CURRENT (mA)

TOP FET CURRENT LIMIT (mA)

BIAS PIN CURRENT (mA)

30

8618 G37

0.05

1.8

6

40

0

1μ

100m

0.10

BIAS Current

0.8

100μ

1m

10m

OUTPUT CURRENT (A)

−0.15

20

50

10

INPUT CURRENT (mA)

0.2

CHANGE IN VOUT (%)

CHANGE IN VOUT (%)

0.3

0

60

Line Regulation

0.5

−0.5

70

20

10

10 20 30 40 50 60 70 80 90 100

OUTPUT CURRENT (mA)

VIN = 12V

80

VIN = 48V

EFFICIENCY (%)

EFFICIENCY (%)

80

VIN = 12V

EFFICIENCY (%)

90

L = 33µH

90 fSW = 2MHz

VIN = 12V

90

40

LT8618C: Forced Continuous

Mode Efficiency (3.3V Output)

180

170

210

205

200

195

190

185

160

0

20

40

60

DUTY CYCLE (%)

80

100

8618 G10

180

−50 −25

0

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G11

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

TYPICAL PERFORMANCE CHARACTERISTICS

600

Minimum On-Time

vs Temperature

Switch Drop vs Switch Current

Switch Drop vs Temperature

400

SWITCH CURRENT = 100mA

40

39

400

TOP SW

300

200

BOT SW

100

38

300

MINIMUM ON-TIME (ns)

SWITCH DROP (mV)

SWITCH DROP (mV)

500

200

TOP SW

100

37

36

35

34

33

32

BOT SW

31

0

−50 −25

0

0

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G12

Minimum Off-Time

vs Temperature

30

−50 −25

100

95

90

85

2030

2020

300

250

200

150

100

0

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G15

Burst Frequency vs Load Current

L = 33µH

VIN = 12V

VOUT = 3.3V

1750

1500

1250

1000

750

500

LT8618C

(SYNC = 0)

250

0

L = 47µH

VIN = 12V

VOUT = 5V

SWITCHING FREQUENCY (kHz)

LT8618/LT8618-3.3

2000

0

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

8618 G16

8618 G18

1980

1970

1950

−50 −25

1.0

2250

0.9

2000

0.8

1750

0.7

1500

1250

1000

0.5

0.4

0.3

500

0.2

0.1

RT = 18.2kΩ

0

0.1

0.2

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G17

0.6

750

0

RT = 18.2kΩ

0

Soft-Start Tracking

2500

250

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

1990

Frequency Foldback

2500

2250

2000

FB VOLTAGE (V)

0

2010

1960

50

80

−50 −25

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G14

Switching Frequency

vs Temperature

SWITCHING FREQUENCY (kHz)

100

0

8618 G13

L=MOS6020-333ML

350 VOUT = 3.3V

DROPOUT VOLTAGE (mV)

MINIMUM OFF-TIME (ns)

40

60

80

SWITCH CURRENT (mA)

400

105

SWITCHING FREQUENCY (kHz)

20

Dropout Voltage vs Load Current

110

0

0

0.3 0.4 0.5 0.6

FB VOLTAGE (V)

0.7

0.8

8618 G19

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

TR/SS VOLTAGE (V)

8618 G20

Rev. A

For more information www.analog.com

7

�LT8618/LT8618-3.3/LT8618C

TYPICAL PERFORMANCE CHARACTERISTICS

Soft-Start Current vs Temperature

VIN UVLO

3.2

3.1

2.4

3.0

VIN UVLO (V)

SOFT-START CURRENT (μA)

2.5

2.3

2.2

2.9

2.8

2.7

2.1

2.6

2.0

−50 −25

0

2.5

−50 −25

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G21

6

6

6

5

5

5

5

4

VIN

3

3

2

2

VOUT

0

0

1

2

3

4

5

INPUT VOLTAGE (V)

6

7

INPUT VOLTAGE (V)

INPUT VOLTAGE (V)

6

4

7

RLOAD = 50Ω

4

4

VIN

3

3

2

1

1

0

0

2

VOUT

0

8618 G23

1

2

3

4

5

INPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

7

OUTPUT VOLTAGE (V)

7

RLOAD = 500Ω

1

8

25 50 75 100 125 150

TEMPERATURE (°C)

8618 G22

Start-Up Dropout

Start-Up Dropout

7

0

1

6

7

0

8618 G24

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

TYPICAL PERFORMANCE CHARACTERISTICS

LT8618/LT8618-3.3:

Switching Waveforms

LT8618/LT8618-3.3:

Switching Waveforms

LT8618C: Forced Continuous

Mode Switching Waveforms

IL

20mA/DIV

IL

25mA/DIV

IL

10mA/DIV

SW

5V/DIV

SW

16V/DIV

SW

5V/DIV

12VIN TO 3.3VOUT AT 50mA

1µs/DIV

L = 100µH

48VIN TO 3.3VOUT AT 50mA

1µs/DIV

8618 G25

LT8618/LT8618-3.3:

Switching Waveforms

12VIN TO 5VOUT AT 5mA

L = 100µH

200ns/DIV

8618 G26

LT8618/LT8618-3.3:

Switching Waveforms

IL

20mA/DIV

IL

100mA/DIV

SW

4V/DIV

SW

16V/DIV

SW

4V/DIV

5µs/DIV

L = 100µH

48VIN TO 3.3VOUT AT 4mA

Transient Response

L = 47µH

500ns/DIV

8618 G28

8618 G42

LT8618C: Transition Between Burst

Mode And Forced Continuous Mode

Transient Response

100mA

ILOAD

25mA/DIV

12VIN TO 5VOUT AT 20mA

L = 100µH

5µs/DIV

8618 G27

8618 G41

LT8618C: Burst Mode

Switching Waveforms

IL

20mA/DIV

12VIN TO 3.3VOUT AT 3mA

L = 47µH

100mA

ILOAD

25mA/DIV

50mA

VSYNC

2V/DIV

50mA

ILOAD = 2mA

VOUT

20mV/DIV

ILOAD = 50mA

VOUT

20mV/DIV

VOUT

20mV/DIV

VOUT

20mV/DIV

VIN = 12V

COUT = 22µF

fSW = 400kHz

100µs/DIV

8618 G29

VIN = 48V

COUT = 22µF

fSW = 400kHz

100µs/DIV

8618 G30

ILOAD = 100mA

VOUT

20mV/DIV

VOUT = 3.3V, L = 120µH, COUT = 2 × 47µF

500µs/DIV

Rev. A

For more information www.analog.com

9

�LT8618/LT8618-3.3/LT8618C

PIN FUNCTIONS

LT8618/LT8618-3.3

BST (Pin 1): This pin is used to provide a drive voltage higher than the input voltage, to the topside power

switch. Place a 47nF boost capacitor as close as possible

to the IC. Do not put resistance in series with this pin.

SW (Pin 2): The SW pin is the output of the internal power

switches. Connect this pin to the inductor. This node

should be kept small on the PCB for good performance.

BIAS (Pin 3): The internal regulator will draw current from

BIAS instead of VIN when BIAS is tied to a voltage higher

than 3.2V. For output voltages of 3.3V to 25V this pin

should be tied to VOUT. If this pin is tied to a supply other

than VOUT, use a 1µF local bypass capacitor on this pin.

If no supply is available, tie this pin to GND.

INTVCC (Pin 4): Internal 3.4V Regulator Bypass Pin. The

internal power drivers and control circuits are powered

from this voltage. INTVCC maximum output current is

2mA. Do not load the INTVCC pin with external circuitry.

INTVCC current will be supplied from BIAS if BIAS >

3.2V, otherwise current will be drawn from VIN. Voltage

on INTVCC will vary between 2.8V and 3.4V when VBIAS

is between 3.0V and 3.6V. Decouple this pin to power

ground with a low ESR ceramic capacitor of at least 1μF

placed close to the IC.

RT (Pin 5): Tie a resistor between RT and ground to set

the switching frequency.

FB (Pin 6, LT8618 Only): The LT8618 regulates the FB

pin to 0.778V. Connect the feedback resistor divider tap

to this pin.

OUT (Pin 6, LT8618-3.3 Only): The LT8618-3.3 regulates

the OUT pin to 3.3V. This pin connects to the internal

feedback divider that programs the fixed output voltage.

Tie the output to this pin.

10

TR/SS (Pin 7): Output Tracking and Soft-Start Pin. This

pin allows user control of output voltage ramp rate during start-up. A TR/SS voltage below 0.778V forces the

LT8618 to regulate the FB pin to equal the TR/SS pin voltage. When TR/SS is above 0.778V, the tracking function is

disabled and the internal reference resumes control of the

error amplifier. An internal 2µA pull-up current on this pin

allows a capacitor to program output voltage slew rate.

This pin is pulled to ground with a 300Ω MOSFET during

shutdown and fault conditions; use a series resistor if

driving from a low impedance output.

PG (Pin 8): The PG pin is the open-drain output of an

internal comparator. PG remains low until the FB pin is

within ±7.5% of the final regulation voltage, and there are

no fault conditions. PG is valid when VIN is above 3.4V,

regardless of EN/UV pin state.

EN/UV (Pin 9): The LT8618 is shut down when this pin is

low and active when high. The hysteretic threshold voltage is 1.05V rising and 1.00V falling. Tie to VIN if the

shutdown feature is not used. An external resistor divider

from VIN can be used to program a VIN threshold below

which the LT8618 will shut down.

VIN (Pin 10): The VIN pin supplies current to the LT8618

internal circuitry and to the internal top side power switch.

This pin must be locally bypassed. Be sure to place the

positive terminal of the input capacitor as close as possible to the VIN pin, and the negative capacitor terminal

as close as possible to the GND pin.

GND (Exposed Pad Pin 11): Ground. The exposed pad

must be connected to the negative terminal of the input

capacitor and soldered to the PCB in order to lower the

thermal resistance.

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

PIN FUNCTIONS

LT8618C

VIN (Pin 1): The VIN pin supplies current to the LT8618C

internal circuitry and the internal top side power switch.

This pin must be locally bypassed. Place the positive terminal of the input capacitor as close as possible to the

VIN pin, and the negative capacitor terminal as close as

possible to the GND pin.

EN/UV (Pin 2): The LT8618C is shut down when this pin

is low and active when high. The hysteretic threshold

voltage is 1.05V rising and 1.00V falling. Tie to VIN if the

shutdown feature is not used. An external resistor divider

from VIN can program a VIN threshold below which the

LT8618C will shut down.

HYST (Pin 3): EN/UV Hysteresis Open-Drain Logic Output.

This pin is pulled to ground when EN/UV (Pin 2) is below

1V. This pin can be used to adjust the EN/UV pin hysteresis. See applications information.

PG (Pin 4): The PG pin is the open-drain output of an

internal comparator. PG remains low until the FB pin is

within ±7.5% of the final regulation voltage, and there are

no fault conditions. PG is valid when VIN is above 3.4V,

regardless of EN/UV pin state.

FB (Pin 5): The LT8618C regulates the FB pin to 0.778V.

Connect the feedback resistor divider tap to this pin.

TR/SS (Pin 6): Output Tracking and Soft-Start Pin. This

pin allows user control of output voltage ramp rate during start-up. A TR/SS voltage below 0.778V forces the

LT8618C to regulate the FB pin to equal the TR/SS pin

voltage. When TR/SS is above 0.778V, the tracking function is disabled, and the internal reference resumes control of the error amplifier. An internal 2µA pull-up current

on this pin allows a capacitor to program output voltage slew rate. This pin is pulled to ground with a 300Ω

MOSFET during shutdown and fault conditions; use a

series resistor if driving from a low impedance output.

SYNC/MODE (Pin 7): This pin programs four different operating modes: 1) Burst Mode operation. Tie this

pin to ground for Burst Mode operation at low output

loads—this will result in ultralow quiescent current. 2)

Forced Continuous mode (FCM). This mode offers fast

transient response and full frequency operation over a

wide load range. Float this pin for FCM. When floating, the

pin leakage current should be 3V for forced continuous mode with spread-spectrum modulation. 4)

Synchronization mode. Drive this pin with a clock source

to synchronize to an external frequency. During synchronization, the part will operate in forced continuous mode.

RT (Pin 8): Tie a resistor between RT and ground to set

the switching frequency.

BIAS (Pin 9): The internal regulator will draw current from

BIAS instead of VIN when BIAS is tied to a voltage higher

than 3.2V. For output voltages of 3.3V to 25V, this pin

should be tied to VOUT. If this pin is tied to a supply other

than VOUT, use a 1µF local bypass capacitor on this pin.

If no supply is available, tie to GND.

SW (Pin 10): The SW pin is the output of the internal

power switches. Connect this pin to the inductor. This node

should be kept small on the PCB for good performance.

DNC (Pin 11): Do not connect pin. This pin should be

left floating.

GND (Pin 12, Exposed Pad Pin 13): Ground. The exposed

pad must be connected to the input capacitor’s negative

terminal and soldered to the PCB to lower the thermal

resistance.

Rev. A

For more information www.analog.com

11

�LT8618/LT8618-3.3/LT8618C

BLOCK DIAGRAM

VIN

10

VIN

BIAS

CIN

R3

9

INTERNAL 0.778V REF

+

–

1V

EN/UV

–

+

SHDN

3

3.4V

REG

INTVCC

SLOPE COMP

4

R4

CINTVCC

RT

5

8

RT

ERROR

AMP

±7.5%

PG

+

+

–

CSS

VC

2µA

R1

LT8618

ONLY

CBST

SW

L

VOUT

2

COUT

M2

GND

SHDN

TSD

V IN UVLO

R2

1

M1

SWITCH

LOGIC

AND

ANTISHOOT

THROUGH

BURST

DETECT

SHDN

TSD

INTVCC UVLO

VIN UVLO

TR/SS

7

BST

OSCILLATOR

200kHz TO 2.2MHz

11

LT8618-3.3

OUT

ONLY*

FB

6

6

R2

R1

8618 BDa

* R1 = 1.5M, R2 = 4.6875M

LT8618/LT8618-3.3

VIN

1

CIN

R3

(OPT)

2

R4

(OPT)

VIN

BIAS

EN/UV

1V

3

–

+

–

+

INTERNAL 0.778V REF

OSCILLATOR

200kHz TO 2.2MHz

ERROR

AMP

PG

±7.5%

+

–

VC

SHDN

TSD

INTVCC UVLO

VIN UVLO

BST

BURST

DETECT

INTVCC

2µA

CSS

6

7

RT

INTVCC

SLOPE COMP

R5

(OPT)

4

3.5V

REG

SHDN

HYST

8

9

M1

SWITCH

LOGIC

AND

ANTISHOOT

THROUGH

SW

M2

GND

TR/SS

SHDN

TSD

VIN UVLO

RT

VOUT

COUT

60k

SYNC/MODE

L

10

GND

12

13

600k

FB

R2

5

R1

LT8618C

12

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

OPERATION

The LT8618 family is monolithic constant frequency current mode step-down DC/DC converters. Operation is best

understood by referring to the Block Diagrams. An internal oscillator turns on the integrated top power switch at

the beginning of each clock cycle. Current in the inductor

then increases until the top switch current comparator

trips and turns off the top power switch. The peak inductor current at which the top switch turns off is controlled

by the voltage on the internal VC node. The error amplifier servos the VC node by comparing the voltage on the

FB pin with an internal reference. When the load current

increases it causes a reduction in the feedback voltage

relative to the reference leading the error amplifier to raise

the VC voltage until the average inductor current matches

the new load current. When the top power switch turns

off, the synchronous power switch turns on until the next

clock cycle begins or the inductor current falls to zero.

If overload conditions result in excess current flowing

through the bottom switch, the next clock cycle will be

delayed until switch current returns to a safe level.

To optimize efficiency, the LT8618 enters Burst Mode

operation during light load situations. Between bursts,

all circuitry associated with controlling the output switch

is shut down, reducing the input supply current to 1.7µA.

In a typical application with a 48V input, 2.5µA will be

consumed from the input supply when regulating with

no load. The LT8618/LT8618-3.3 does not have a SYNC/

MODE pin and always operates in Burst Mode. The SYNC/

MODE pin (LT8618C only) is tied low to use Burst Mode

operation with a fixed burst current limit of 180mA for

improved efficiency at very light loads and can be floated

to use forced continuous mode (FCM). If a clock is applied

to the SYNC/MODE pin, the part will synchronize to an

external clock frequency and operate in FCM. The SYNC/

MODE pin may be tied high for spread spectrum modulation mode, and the LT8618C will operate like FCM but vary

the clock frequency to reduce EMI.

The LT8618C can operate in forced continuous mode

(FCM) for fast transient response and full frequency

operation over a wide load range. When in FCM, the

oscillator operates continuously, and positive SW transitions are aligned to the clock. Negative inductor current

is allowed. The LT8618C can sink current from the output

and return it to the input in this mode, improving load step

transient response.

To improve efficiency across all loads, supply current to

internal circuitry is drawn from the BIAS pin when biased

at 3.2V or above. Else, the internal circuitry will draw current from VIN. The BIAS pin should be connected to VOUT

if the output is programmed to a voltage between 3.3V

and 25V.

Comparators monitoring the FB (LT8618/LT8618C) or

OUT (LT8618-3.3) pin voltage will pull the PG pin low if

the output voltage varies more than ±7.5% (typical) from

the set point or if a fault condition is present.

In the LT8618 family, the oscillator reduces its operating

frequency when the voltage at the FB (LT8618/LT8618C)

or OUT (LT8618-3.3) pin is low. This frequency foldback

helps to control the inductor current when the output voltage is lower than the programmed value, which occurs

during start-up or overcurrent conditions. When a clock

is applied to the SYNC/MODE pin (LT8618C only), the

SYNC/MODE pin is floated or held DC high, the frequency

foldback is disabled, and the switching frequency will

slow down only during overcurrent conditions.

If the EN/UV pin is low, the LT8618 family is shut down

and draws 1µA from the input. When the EN/UV pin is

above 1.05V, the switching regulator becomes active.

The HYST pin (LT8618C only) provides an added degree

of flexibility for the EN/UV pin operation. This open-drain

output is pulled to ground whenever the EN/UV comparator is not tripped, signaling that the LT8618C is not in

normal operation. In applications where the EN/UV pin

is used to monitor the VIN voltage through an external

resistive divider, the HYST pin can be used to increase

the effective EN/UV comparator hysteresis.

Rev. A

For more information www.analog.com

13

�LT8618/LT8618-3.3/LT8618C

APPLICATIONS INFORMATION

Achieving Ultralow Quiescent Current

To enhance efficiency at light loads, the LT8618 family

enters into low ripple Burst Mode operation, which keeps

the output capacitor charged to the desired output voltage

while minimizing the input quiescent current and minimizing output voltage ripple. This is the default operation of

LT8618/LT8618-3.3. For the LT8618C, the SYNC/MODE

pin must be tied to ground. In Burst Mode operation, the

LT8618 family delivers single small pulses of current to

the output capacitor followed by sleep periods where the

output power is supplied by the output capacitor. While in

sleep mode the LT8618 family consumes 1.7μA.

As the output load decreases, the frequency of single current pulses decreases (see Figure 1) and the percentage of

time the LT8618 family is in sleep mode increases, resulting in much higher light load efficiency than for typical

converters. By maximizing the time between pulses, the

converter quiescent current approaches 2.5µA for a typical application when there is no output load. Therefore,

to optimize the quiescent current performance at light

loads, the current in the feedback resistor divider must

be minimized as it appears to the output as load current.

VOUT

5mV/DIV

SW

5V/DIV

IL

20mA/DIV

500µs/DIV

Figure 2. Burst Mode Operation (LT8618/LT8618-3.3)

VOUT

5mV/DIV

SW

5V/DIV

IL

100mA/DIV

500µs/DIV

2500

SWITCHING FREQUENCY (kHz)

2250

L = 33µH

VIN = 12V

VOUT = 3.3V

1750

1500

load at which the LT8618 family reaches the programmed

frequency varies based on input voltage, output voltage,

and inductor choice.

1250

1000

750

500

LT8618C

(SYNC = 0)

250

0

0

L = 47µH

VIN = 12V

VOUT = 5V

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

8618 F01

Figure 1. SW Burst Mode Frequency vs Load

While in Burst Mode operation, the current limit of the top

switch is approximately 40mA in the LT8618/LT8618-3.3

and 180mA in the LT8618C, resulting in output voltage

ripple shown in Figure 2 and Figure 3. As the load ramps

upward from zero the switching frequency will increase

but only up to the switching frequency programmed by

the resistor at the RT pin as shown in Figure 1. The output

14

8618 F03

Figure 3. Burst Mode Operation (LT8618C)

LT8618/LT8618-3.3

2000

8618 F02

Since the higher Burst Mode current limit of the LT8618C

leads to a higher inductor current ripple, its switching

frequency is reduced accordingly and will usually never

reach the frequency programmed by the resistor at the

RT pin over the entire load range. Use forced continuous

mode (see next section) for full frequency operation. The

LT8618C applies slope compensation even in Burst Mode

to ensure stable operation at higher load currents.

Forced Continuous Mode (LT8618C Only)

The LT8618C can operate in forced continuous mode

(FCM) for fast transient response and full frequency operation over a wide load range. When in FCM, the oscillator

operates continuously, and positive SW transitions are

aligned to the clock. Negative inductor current is allowed

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

APPLICATIONS INFORMATION

at light loads or under large transient conditions. The

LT8618C can sink current from the output and return it

to the input in this mode, improving load step transient

response. At light loads, FCM operation is less efficient

than Burst Mode operation or pulse-skipping mode. Still,

it may be desirable in applications where it is necessary

to keep switching harmonics out of the signal band. FCM

must be used if the output is required to sink current. To

enable FCM (LT8618C only), float the SYNC/MODE pin.

Leakage current on this pin should be 3V. In this mode, triangular frequency modulation

is used to vary the switching frequency between 100%

and approximately 120% of the value programmed by

RT. The modulation frequency is approximately 3kHz. For

example, when the LT8618C is programmed to 2MHz,

the frequency will vary from 2MHz to 2.4MHz at a 3kHz

rate. When spread-spectrum operation is selected, Burst

Mode operation is disabled, and the part will run in forced

continuous mode.

Synchronization (LT8618C only)

To synchronize the LT8618C oscillator to an external frequency, connect a square wave (with 20% to 80% duty

The LT8618C achieves very high efficiency at very light

loads when operating in Burst Mode due to its fixed top

switch current limit of 180mA in this mode. The internal VC node does not control peak inductor current but

instead the period between current pulses. Thus it does

not need to vary much to keep the output in regulation

over the entire load current range. In Forced Continuous

Mode, on the other hand, the VC node controls the peak

inductor current and thus varies widely with load current.

For a given load current, the VC node voltage required to

keep the output in regulation may differ between Burst

Mode and FCM. The error amplifier adjusts the VC node

to the new required level when switching between these

modes of operation. During this transition, the output may

experience a load current dependent transient with worstcase amplitude happening at full load. Applications that

transition between Burst Mode and FCM require a larger

output capacitor to keep output voltage transients below

acceptable limits at full load current.

Rev. A

For more information www.analog.com

15

�LT8618/LT8618-3.3/LT8618C

APPLICATIONS INFORMATION

FB Resistor Network (LT8618)

The output voltage is programmed with a resistor divider

between the output and the FB pin. Choose the resistor

values according to:

⎛ V

⎞

R2 = R1⎜ OUT – 1⎟

⎝ 0.778V ⎠

1% resistors are recommended to maintain output voltage accuracy.

range. The advantage of high frequency operation is that

smaller inductor and capacitor values may be used. The

disadvantages are lower efficiency and a smaller input

voltage range.

The highest switching frequency (fSW(MAX)) for a given

application can be calculated as follows:

fSW(MAX) =

(

VOUT + VSW(BOT)

t ON(MIN) VIN – VSW(TOP) + VSW(BOT)

)

Setting the Switching Frequency

where VIN is the typical input voltage, VOUT is the output

voltage, VSW(TOP) and VSW(BOT) are the internal switch

drops (~0.3V, ~0.13V, respectively at max load) and

tON(MIN) is the minimum top switch on-time (see Electrical

Characteristics). This equation shows that slower switching frequency is necessary to accommodate a high VIN/

VOUT ratio.

The LT8618 family uses a constant frequency PWM

architecture that can be programmed to switch from

200kHz to 2.2MHz by using a resistor tied from the RT

pin to ground. Table 1 shows the necessary RT value for

a desired switching frequency.

For transient operation VIN may go as high as the Abs Max

rating regardless of the RT value, however the LT8618

family will reduce switching frequency as necessary

to maintain control of inductor current to assure safe

operation.

Table 1. SW Frequency vs RT Value

The LT8618 family is capable of maximum duty cycle

approaching 100%, and the VIN to VOUT dropout is limited

by the RDS(ON) of the top switch. In this mode the LT8618

family skips switch cycles, resulting in a lower switching

frequency than programmed by RT.

The total resistance of the FB resistor divider should be

selected to be as large as possible when good low load

efficiency is desired: The resistor divider generates a

small load on the output, which should be minimized to

optimize the quiescent current at low loads.

fSW (MHz)

RT (kΩ)

0.2

221

0.3

143

0.4

110

0.5

86.6

0.6

71.5

0.7

60.4

0.8

52.3

0.9

46.4

1.0

40.2

1.2

33.2

1.4

27.4

1.6

23.7

1.8

20.5

2.0

18.2

2.2

16.2

For applications that cannot allow deviation from the programmed switching frequency at low VIN/VOUT ratios, use

the following formula to set switching frequency:

Operating Frequency Selection and Trade-Offs

Selection of the operating frequency is a trade-off

between efficiency, component size, and input voltage

16

VIN(MIN) =

VOUT + VSW(BOT)

1– fSW • t OFF(MIN)

– VSW(BOT) + VSW(TOP)

where VIN(MIN) is the minimum input voltage without

skipped cycles, VOUT is the output voltage, VSW(TOP) and

VSW(BOT) are the internal switch drops (~0.3V, ~0.13V,

respectively at max load), fSW is the switching frequency

(set by RT), and tOFF(MIN) is the minimum switch offtime. Note that higher switching frequency will increase

the minimum input voltage below which cycles will be

dropped to achieve higher duty cycle.

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

APPLICATIONS INFORMATION

Inductor Selection and Maximum Output Current

The LT8618 family is designed to minimize solution size

by allowing the inductor to be chosen based on the output

load requirements of the application. During overload or

short circuit conditions the LT8618 family safely tolerates

operation with a saturated inductor through the use of a

high speed peak-current mode architecture.

is a function of the switch current limit (ILIM) and the

ripple current:

VOUT + VSW(BOT)

fSW

• 19

where fSW is the switching frequency in MHz, VOUT is

the output voltage, VSW(BOT) is the bottom switch drop

(~0.13V) and L is the inductor value in μH. Using an

inductor value more than two times this calculated size

is not recommended.

To avoid overheating and poor efficiency, an inductor

must be chosen with an RMS current rating that is greater

than the maximum expected output load of the application. In addition, the saturation current (typically labeled

ISAT) rating of the inductor must be higher than the load

current plus 1/2 of the inductor ripple current:

∆IL

2

The peak-to-peak ripple current in the inductor can be

calculated as follows:

A good first choice for the inductor value is:

L=

IOUT(MAX) = ILIM –

ΔIL =

⎞

VOUT ⎛

V

1– OUT ⎟

⎜

L • fSW ⎝ VIN(MAX) ⎠

where fSW is the switching frequency, and L is the value

of the inductor. Therefore, the maximum output current

that the LT8618 family will deliver depends on the switch

current limit, the inductor value, and the input and output

voltages. The inductor value may have to be increased

if the inductor ripple current does not allow sufficient

maximum output current (IOUT(MAX)) given the switching frequency, and maximum input voltage used in the

desired application.

For more information about maximum output current and

discontinuous operation, see Analog Devices Application

Note 44.

Finally, for duty cycles greater than 50%, a minimum

inductance is required to avoid sub-harmonic oscillation:

1

IL(PEAK) = ILOAD(MAX) + ∆ L

2

where ∆IL is the inductor ripple current as calculated several paragraphs below and ILOAD(MAX) is the maximum

output load for a given application.

As a quick example, an application requiring 100mA output should use an inductor with an RMS rating of greater

than 100mA and an ISAT of greater than 160mA. To keep

the efficiency high, the series resistance (DCR) should be

less than 1Ω, and the core material should be intended

for high frequency applications.

The LT8618 family limits the peak switch current in order

to protect the switches and the system from overload

faults. The top switch current limit (ILIM) is at least 150mA

at low duty cycles and decreases linearly to 120mA at D =

0.8. The inductor value must then be sufficient to supply

the desired maximum output current (IOUT(MAX)), which

L MIN =

VOUT + VSW(BOT)

0.08 • fSW

where fSW is the switching frequency, VOUT is the output

voltage, VSW(BOT) is the bottom switch drop (~0.13V) and

LMIN is the inductor value.

Input Capacitor

Bypass the input of the LT8618 family circuit with a

ceramic capacitor of X7R or X5R type. Y5V types have

poor performance over temperature and applied voltage,

and should not be used. A 1μF to 2.2μF ceramic capacitor

is adequate to bypass the LT8618 family and will easily

handle the ripple current. If the input power source has

high impedance, or there is significant inductance due to

long wires or cables, additional bulk capacitance may be

necessary. This can be provided with a low performance

electrolytic capacitor.

Rev. A

For more information www.analog.com

17

�LT8618/LT8618-3.3/LT8618C

APPLICATIONS INFORMATION

Step-down regulators draw current from the input supply in pulses with very fast rise and fall times. The input

capacitor is required to reduce the resulting voltage ripple

at the LT8618 family and to force this very high frequency

switching current into a tight local loop, minimizing EMI.

A 1μF capacitor is capable of this task, but only if it is

placed close to the LT8618 family (see the PCB Layout

section). A second precaution regarding the ceramic input

capacitor concerns the maximum input voltage rating

of the LT8618 family. A ceramic input capacitor combined with trace or cable inductance forms a high quality

(under damped) tank circuit. If the LT8618 family circuit

is plugged into a live supply, the input voltage can ring to

twice its nominal value, possibly exceeding the LT8618

family’s voltage rating. This situation is easily avoided

(see Analog Devices Application Note 88).

Output Capacitor and Output Ripple

The output capacitor has two essential functions. Along

with the inductor, it filters the square wave generated by

the LT8618 family to produce the DC output. In this role

it determines the output ripple, thus low impedance at

the switching frequency is important. The second function is to store energy in order to satisfy transient loads

and stabilize the LT8618 family’s control loop. Ceramic

capacitors have very low equivalent series resistance

(ESR) and provide the best ripple performance. A good

starting value is:

C OUT =

50

VOUT • fSW

where fSW is the switching frequency in MHz, VOUT is

the output voltage, and COUT is the recommended output

capacitance in μF. Use X5R or X7R types. This choice will

provide low output ripple and good transient response.

Transient performance can be improved with a higher

value output capacitor and the addition of a feedforward

capacitor placed between VOUT and FB. Increasing the

output capacitance will also decrease the output voltage ripple. Due to its larger burst mode current limit, the

LT8618C requires a larger COUT for low output voltage ripple. A lower value of output capacitor can be used to save

space and cost but transient performance will suffer and

18

may cause loop instability. See the Typical Applications

in this data sheet for suggested capacitor values. The

LT8618‑3.3 has an internal feedforward capacitor and

therefore requires a minimum COUT of 22μF.

When choosing a capacitor, special attention should be

given to the data sheet to calculate the effective capacitance under the relevant operating conditions of voltage

bias and temperature. A physically larger capacitor or one

with a higher voltage rating may be required.

Ceramic Capacitors

Ceramic capacitors are small, robust and have very low

ESR. However, ceramic capacitors can cause problems

when used with the LT8618 family due to their piezoelectric nature. When in Burst Mode operation, the

LT8618 family’s switching frequency depends on the

load current, and at very light loads the LT8618 family can excite the ceramic capacitor at audio frequencies, generating audible noise. Since the LT8618 family operates at a lower current limit during Burst Mode

operation, the noise is typically very quiet. If this is unacceptable, use a high performance tantalum or electrolytic

capacitor at the output.

A final precaution regarding ceramic capacitors concerns

the maximum input voltage rating of the LT8618 family.

As previously mentioned, a ceramic input capacitor combined with trace or cable inductance forms a high quality

(under damped) tank circuit. If the LT8618 family circuit

is plugged into a live supply, the input voltage can ring to

twice its nominal value, possibly exceeding the LT8618

family’s rating. This situation is easily avoided (see Analog

Devices Application Note 88).

EN/UV Pin and Programmable Hysteresis of LT8618C

The LT8618 family is in shutdown when the EN/UV pin is

low and active when the pin is high. The rising threshold

of the EN/UV comparator is 1.05V, with 50mV of hysteresis. The EN/UV pin can be tied to VIN if the shutdown

feature is not used, or tied to a logic level if shutdown

control is required.

Adding a resistor divider from VIN to EN/UV programs

the LT8618 family to regulate the output only when VIN

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

APPLICATIONS INFORMATION

is above a desired voltage (see Block Diagram). Typically,

this threshold, VIN(EN/UV), is used in situations where the

input supply is current limited, or has a relatively high

source resistance. A switching regulator draws constant

power from the source, so source current increases as

source voltage drops. This looks like a negative resistance

load to the source and can cause the source to current

limit or latch low under low source voltage conditions. The

VIN(EN/UV) threshold prevents the regulator from operating

at source voltages where the problems might occur. This

threshold can be adjusted by setting the values R3 and

R4 such that they satisfy the following equation:

⎛ VIN(EN/UV) ⎞

R3 = ⎜

– 1⎟ •R4

⎝ 1.05V

⎠

where the LT8618 family will remain off until VIN is above

VIN(EN/UV). Due to the comparator’s hysteresis, switching

will not stop until the input falls slightly below VIN(EN/UV).

Additional hysteresis may be added with the use of the

HYST pin (LT8618C only). The HYST pin is an open-drain

output that is pulled to ground whenever the EN/UV pin

voltage is below the threshold that keeps the part in shutdown. As shown in the Block Diagram, a simple resistive

divider can be used to meet specific operating VIN voltage

requirements.

Specific values for these UVLO thresholds can be computed from the following equations:

⎛ R3 ⎞

VIN(EN/UV)↑ =1.05V ⎜ 1+ ⎟

⎝ R4 ⎠

R3 ⎞

⎛

VIN(EN/UV)↓ =1V ⎜ 1+

⎝ R4+R5 ⎟⎠

where VIN(EN/UV)↑ is the rising VIN UVLO threshold and

VIN(EN/UV)↓ is the falling VIN UVLO threshold. The hysteresis VIN(EN/UV)H = VIN(EN/UV)↑ – VIN(EN/UV)↓ is set by R5:

R5=

R3

VIN(EN/UV)H

R3

1.05 +0.05 –

R4

1V

– R4

The minimum value of these UVLO thresholds is limited to

the internal minimum VIN Voltage shown in the Electrical

Characteristics table. Be aware that the HYST pin cannot

be allowed to exceed its absolute maximum rating of 12V.

To keep the voltage on the HYST pin from exceeding 12V,

the following relation should be satisfied:

R5

⎛

⎞

VIN(MAX) • ⎜

≤ 12V

⎝ R3+R4+R5 ⎟⎠

When in Burst Mode operation for light-load currents,

the current through the VIN(EN/UV) resistor network can

easily be greater than the supply current consumed by the

LT8618 family. Therefore, the VIN(EN/UV) resistors should

be large to minimize their effect on efficiency at low loads.

INTVCC Regulator

An internal low dropout (LDO) regulator produces the

3.4V supply from VIN that powers the drivers and the

internal bias circuitry. INTVCC can supply enough current

for the LT8618 family’s circuitry. Good bypassing is necessary to supply the high transient currents required by

the power MOSFET gate drivers. Therefore, the INTVCC pin

of the LT8618/LT8618-3.3 must be bypassed to ground

with a ceramic capacitor of at least 1μF. The LT8618C

does not have an INTVCC pin but provides an on-package

capacitor as an internal bypass. To improve efficiency,

the internal LDO can also draw current from the BIAS

pin when the BIAS pin is at 3.2V or higher. Typically, the

BIAS pin can be tied to the output of the LT8618 or can

be tied to an external supply of 3.3V or above. If BIAS is

connected to a supply other than VOUT, be sure to bypass

with a local ceramic capacitor. If the BIAS pin is below

3.0V, the internal LDO will consume current from VIN.

Applications with high input voltage and high switching

frequency where the internal LDO pulls current from VIN

will increase die temperature because of the higher power

dissipation across the LDO. Do not connect an external

load to the INTVCC pin.

Output Voltage Tracking and Soft-Start

The LT8618 family allows the user to program its output

voltage ramp rate by means of the TR/SS pin. An internal

Rev. A

For more information www.analog.com

19

�LT8618/LT8618-3.3/LT8618C

APPLICATIONS INFORMATION

2μA pulls up the TR/SS pin to INTVCC. Putting an external capacitor on TR/SS enables soft-starting the output

to prevent current surge on the input supply. During the

soft-start ramp the output voltage will proportionally track

the TR/SS pin voltage. For output tracking applications,

TR/SS can be externally driven by another voltage source.

From 0V to 0.778V, the TR/SS voltage will override the

internal 0.778V reference input to the error amplifier, thus

regulating the FB pin voltage to that of TR/SS pin. When

TR/SS is above 0.778V, tracking is disabled and the feedback voltage will regulate to the internal reference voltage.

An active pull-down circuit is connected to the TR/SS pin

which will discharge the external soft-start capacitor in

the case of fault conditions and restart the ramp when the

faults are cleared. Fault conditions that clear the soft-start

capacitor are the EN/UV pin transitioning low, VIN voltage

falling too low, or thermal shutdown.

the LT8618 family to individual applications and limiting

thermal dissipation during short circuit conditions.

There is another situation to consider in systems where

the output will be held high when the input to the LT8618

family is absent. This may occur in battery charging applications or in battery backup systems where a battery or

some other supply is diode ORed with the LT8618 family’s

output. If the VIN pin is allowed to float and the EN/UV pin

is held high (either by a logic signal or because it is tied to

VIN), then the LT8618 family’s internal circuitry will pull its

quiescent current through its SW pin. This is acceptable

if the system can tolerate several μA in this state. If the

EN/UV pin is grounded the SW pin current will drop to

near 0.7µA. However, if the VIN pin is grounded while the

D1

VIN

LT8618

EN/UV

Output Power Good

GND

8618 F04

When the LT8618 family’s output voltage is within the

±7.5% window of the regulation point, which is a VFB

voltage in the range of 0.720V to 0.836V (typical), the

output voltage is considered good and the open-drain

PG pin goes high impedance and is typically pulled high

with an external resistor. Otherwise, the internal drain pulldown device will pull the PG pin low. To prevent glitching both the upper and lower thresholds include 0.5% of

hysteresis.

The PG pin is also actively pulled low during several fault

conditions: EN/UV pin is below 1V, INTVCC has fallen too

low, or thermal shutdown.

Shorted and Reversed Input Protection

The LT8618 family will tolerate a shorted output. Several

features are used for protection during output short-circuit and brownout conditions. The first is the switching

frequency will be folded back while the output is lower

than the set point to maintain inductor current control.

Second, the bottom switch current is monitored such that

if inductor current is beyond safe levels switching of the

top switch will be delayed until such time as the inductor current falls to safe levels. This allows for tailoring

20

VIN

Figure 4. Reverse VIN Protection

output is held high, regardless of EN/UV, parasitic body

diodes inside the LT8618 family can pull current from the

output through the SW pin and the VIN pin. Figure 4 shows

a connection of the VIN and EN/UV pins that will allow the

LT8618 family to run only when the input voltage is present and that protects against a shorted or reversed input.

PCB Layout

For proper operation and minimum EMI, care must be

taken during printed circuit board layout. Figure 5 shows

the recommended component placement with trace,

ground plane and via locations. Note that large, switched

currents flow in the LT8618 family’s VIN pins, GND pins,

and the input capacitor (CIN). The loop formed by the

input capacitor should be as small as possible by placing

the capacitor adjacent to the VIN and GND pins. When

using a physically large input capacitor the resulting loop

may become too large in which case using a small case/

value capacitor placed close to the VIN and GND pins plus

a larger capacitor further away is preferred. These components, along with the inductor and output capacitor,

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

APPLICATIONS INFORMATION

should be placed on the same side of the circuit board,

and their connections should be made on that layer. Place

a local, unbroken ground plane under the application circuit on the layer closest to the surface layer. The SW and

BOOST nodes should be as small as possible. In addition, keep the FB and RT nodes small so that the ground

traces will shield them from the SW and BOOST nodes.

Finally, route the LT8618C’s SYNC node below the ground

plane in order to minimize capacitive coupling to the FB

and TR/SS nodes. The exposed pad on the bottom of the

package must be soldered to ground so that the pad is

connected to ground electrically and also acts as a heat

sink thermally. To keep thermal resistance low, extend

the ground plane as much as possible, and add thermal

vias near the LT8618 family to additional ground planes

within the circuit board and on the bottom side. Figure 5

and Figure 6 show basic guidelines for layout examples

that can pass the CISPR25 radiated emission test with

class 5 limits.

COUT

VOUT

GND

COUT

VIN

VOUT

CIN

CBST

L

CIN

L

2

BIAS

3

INTVCC

10

9

EN/UV

8

PG

4

7

TR/SS

RT 5

6

FB

11

VIN

1

EN/UV 2

R1

8 RT

5

6

TR/SS

GND

10 SW

9 BIAS

13

HYST 3

PG 4

LT8618C

12 11

FB

GND

CINTVCC

1

GND

BST

SW

LT8618

7 SYNC

RT

R2

CPL

VOUT

VIAS

C PL

Figure 5. LT8618/LT8618-3.3, Recommended PCB Layout

R1

RT

GND

VOUT

8618 F05

R2

8618 F06

VIAS

Figure 6. LT8618C, Recommended PCB Layout

Rev. A

For more information www.analog.com

21

�LT8618/LT8618-3.3/LT8618C

TYPICAL APPLICATIONS

Typical Performance Minimum

Load to Full Frequency

3.3V Step-Down Converter

60

C1

47nF

VIN

C2

1µF

BST

EN/UV

50

L1

120µH

SW

R2

100k

LT8618-3.3

INTVCC

C3

1µF

C4

10nF

VOUT

3.3V

100mA

POWER

GOOD

PG

TR/SS

BIAS

RT

OUT

INPUT VOLTAGE (V)

VIN

4.2V TO 60V

40

30

FULL FREQUENCY

20

10

C5

22µF

X7R

1206

16V

GND

R1

110k

8618 TA03a

fSW = 400kHz

0

8618 TA03b

Typical Performance Minimum

Load to Full Frequency

60

C1

47nF

VIN

BST

EN/UV

SW

INTVCC

C4

10nF

VOUT

3.3V

100mA

R2

100k

LT8618-3.3

C3

1µF

50

L1

33µH

POWER

GOOD

PG

TR/SS

BIAS

INPUT VOLTAGE (V)

C2

1µF

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

L1: LPS5030-124MR

3.3V, 2MHz Step-Down Converter

VIN

4.2V TO 60V

0

40

30

FULL FREQUENCY

20

10

RT

OUT

C5

22µF

X7R

1206

16V

GND

R1

18.2k

8618 TA04a

fSW = 2MHz

0

0

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

8618 TA04b

L1: WE-LQS 3012

Typical Performance Minimum

Load to Full Frequency

5V, 2MHz Step-Down Converter

60

C1

47nF

C2

1µF

VIN

BST

EN/UV

SW

50

L1

47µH

R2

100k

LT8618

INTVCC

C3

1µF

C4

10nF

PG

TR/SS

fSW = 2MHz

22

POWER

GOOD

40

30

FULL FREQUENCY

20

BIAS

RT

R1

18.2k

VOUT

5V

100mA

INPUT VOLTAGE (V)

VIN

5.8V TO 60V

FB

GND

8618 TA05a

10

R3

1MΩ

C5

4.7µF

X7R

1210

16V

R4

187k

0

0

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

8618 TA05b

L1: LPS5030-473MR

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

TYPICAL APPLICATIONS

Typical Performance Minimum

Load to Full Frequency

1.8V Step-Down Converter

60

C1

47nF

VIN

C2

1µF

BST

EN/UV

50

L1

47µH

SW

R2

100k

LT8618

INTVCC

C3

1µF

PG

TR/SS

C4

10nF

R3

1MΩ

FB

VOUT

1.8V

100mA

INPUT VOLTAGE (V)

VIN

3.4V TO 60V

POWER

GOOD

40

30

FULL FREQUENCY

20

10

RT

R4

768k

BIAS

GND

R1

60.4k

C5

22µF

X7R

1210

16V

8618 TA06a

fSW = 700kHz

0

L1: WE-LQS 3012

Typical Performance Minimum

Load to Full Frequency

60

C1

47nF

R5

11MΩ

VIN

BST

EN/UV

SW

50

L1

220µH

R2

100k

LT8618

INTVCC

C3

1µF

C4

10nF

R6

500k

PG

TR/SS

POWER

GOOD

BIAS

RT

R1

40.2k

VOUT

12V

100mA

INPUT VOLTAGE (V)

C2

1µF

FB

GND

C5

2.2µF

X7R

1206

50V

R4

102k

8618 TA07a

40

30

FULL FREQUENCY

20

10

R3

1.47MΩ

fSW = 1MHz

0

60

C1

47nF

BST

EN/UV

SW

R2

100k

LT8618

INTVCC

C3

1µF

C4

10nF

PG

TR/SS

C6, 330pF

VOUT

1.8V

100mA

POWER

GOOD

FB

BIAS

GND

C5

200µF

X7R

1206

6.3V

R4

768k

8618 TA08a

fSW = 400kHz

40

30

FULL FREQUENCY

20

10

R3, 1MΩ

RT

R1

110k

50

L1

47µH

INPUT VOLTAGE (V)

VIN

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

Typical Performance Minimum

Load to Full Frequency

1.8V Step-Down Converter with Large Output Capacitor

C2

1µF

R5 SHORTED

0

8618 TA07b

L1: WE-LQS 4025

VIN

3.4V TO 60V

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

8618 TA06b

12V Step-Down Converter with Undervoltage Lockout

VIN

23V

TO 60V

0

0

0

10 20 30 40 50 60 70 80 90 100

LOAD CURRENT (mA)

8618 TA08b

L1: WE-LQS 3012

Rev. A

For more information www.analog.com

23

�LT8618/LT8618-3.3/LT8618C

TYPICAL APPLICATIONS

5V, 2MHz Step-Down Converter

VIN

5.8V TO 60V

L1

47µH

VIN

C1

1µF

R2

100k

EN/UV

SYNC

SYNC

POWER

GOOD

PG

LT8618C

TR/SS

C2

10nF

VOUT

5V

100mA

SW

BIAS

RT

R3

1M

FB

GND

R1

18.2k

C3

22µF

X7R

16V

R4

187k

fSW = 2MHz

L1: LPS5030-473MR

8618 TA09

3.3V, 400kHz Step-Down Converter

L1

120µH

VIN

4.2V TO 60V

VIN

C1

1µF

SW

R2

100k

EN/UV

SYNC

SYNC

TR/SS

C2

10nF

POWER

GOOD

PG

LT8618C

C3

1nF

BIAS

RT

FB

GND

R1

110k

VOUT

3.3V

100mA

R4

392k

R3

1.27M

fSW = 400kHz

C4

47µF

X5R

16V

L1: LPS5030-124MR

C5

47µF

X5R

16V

8618 TA10

24V, 2.2MHz Step-Down Converter

VIN

4.2V TO 60V

L1

220µH

D1

VIN

C1

1µF

EN/UV

SYNC

SYNC

C2

10nF

LT8618C

TR/SS

PG

C3

33pF

BIAS

RT

R1

16.2k

FB

GND

R4

187k

R3

5.62M

fSW = 2.2MHz

C4

10µF

50V

2220/X7R

C5

10µF

50V

2220/X7R

C6

10µF

50V

2220/X7R

(EFFECTIVE CAPACITANCE OF 22µF)

D1: OPTIONAL PROTECTION

AGAINST VIN TRANSIENTS

24

VOUT

24V

100mA

SW

L1: WE-LQFS 4828

8618 TA11

Rev. A

For more information www.analog.com

�LT8618/LT8618-3.3/LT8618C

PACKAGE DESCRIPTION

DDB Package

10-Lead Plastic DFN (3mm × 2mm)

(Reference LTC DWG # 05-08-1722 Rev Ø)

0.64 ±0.05

(2 SIDES)

0.70 ±0.05

2.55 ±0.05

1.15 ±0.05

PACKAGE

OUTLINE

0.25 ±0.05

0.50 BSC

2.39 ±0.05

(2 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

3.00 ±0.10

(2 SIDES)

R = 0.05

TYP

R = 0.115

TYP

6

0.40 ±0.10

10

2.00 ±0.10

(2 SIDES)

PIN 1 BAR

TOP MARK

(SEE NOTE 6)

0.200 REF

0.75 ±0.05

0 – 0.05

0.64 ±0.05

(2 SIDES)

5

0.25 ±0.05

PIN 1

R = 0.20 OR

0.25 × 45°

CHAMFER

1

(DDB10) DFN 0905 REV Ø

0.50 BSC

2.39 ±0.05

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

NOTE:

1. DRAWING CONFORMS TO VERSION (WECD-1) IN JEDEC PACKAGE OUTLINE M0-229

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS