LTC3623

15V, ±5A Rail-to-Rail

Synchronous Buck Regulator

Description

Features

Single Resistor Programmable VOUT: 0V to VIN – 0.5V

nn Silent Switcher® Architecture

nn I

ISET Accuracy: ±1%

nn Tight V

OUT Regulation Across VOUT Range

nn Output Current Monitor Accuracy: ±5%

nn Programmable Wire Drop Compensation

nn Easy to Parallel for Higher Current and Heat Spreading

nn Input Supply Voltage Regulation Loop

nn High Efficiency: Up to 96%

nn Output Current: ±5A

nn Integrated N-MOSFETs (60mΩ Top & 30mΩ Bottom)

nn Adjustable Switching Frequency: 400kHz to 4MHz

nn V Range: 4V to 15V

IN

nn Current Mode Operation for Excellent Line and Load

Transient Response

nn Shutdown Mode Draws Less Than 1µA Supply Current

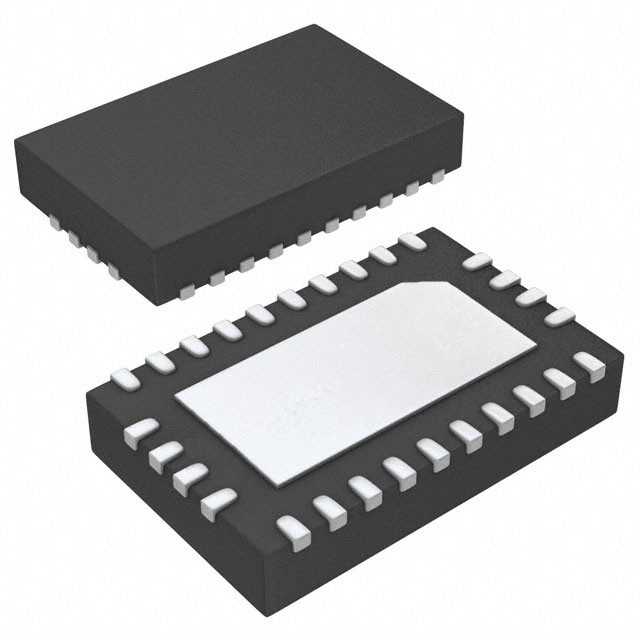

nn Low Profile 24-Lead 3mm × 5mm QFN Package

nn

Applications

Tracking Supply or DDR Memory Supply

ASIC Substrate Biasing

nn Point-of-Load (POL) Power Supply

nn Portable Instruments, Battery-Powered Equipment

nn Thermo Electric Cooler (TEC) Systems

nn

nn

The LTC®3623 is a high efficiency, monolithic synchronous buck regulator in which the output voltage is programmed with a single external resistor. The accurate

internally generated 50µA current source on the ISET pin

allows the user to program an output voltage from 0V

to 0.5V below VIN. The user can also directly drive the

ISET pin with an external voltage supply to program the

converter’s VOUT. The VOUT voltage is fed directly back

to the error amplifier to be regulated to the ISET voltage.

The operating supply voltage range for the SVIN pin is from

15V down to 4V, while the PVIN pin’s voltage range is 15V

down to 1.5V, making it suitable for dual Li-Ion batteries

and for taking power from a 12V or 5V rail.

The operating frequency is programmable from 400kHz

to 4MHz with an external RT resistor. Higher switching frequency allows the use of smaller surface mount inductors

while lower frequency allows for higher power efficiency.

The unique constant-frequency/controlled on-time

architecture is ideal for high step-down ratio applications

that are operating at high frequency while demanding fast

transient response.

L, LT, LTC, LTM, OPTI-LOOP, Silent Switcher, Linear Technology and the Linear logo are

registered trademarks of Analog Devices, Inc. All other trademarks are the property of their

respective owners. Protected by U.S. Patents, including 5481178, 5705919, 5847554, 6580258.

Typical Application

SVIN

90

0.1µF

22µF

ERROR

AMP

SW

80

1µH

VOUT

5V

5A

47µF

PGND

VOUT

70

50

40

POWER

LOSS

1.8

CCM

1.2

30

20

0

0.001

3623 TA01

2.4

DCM

60

10

PGOOD

ITH

PGFB

INTVCC

MODE/

SYNC

IMON

VIN_REG

ISET

IOUT/50k

VIN = 12V

VOUT = 5V

POWER LOSS (W)

PWM

CONTROL

AND

SWITCH

DRIVER

EFFICIENCY (%)

50µA

3.0

100

LTC3623EUD

LOAD

RUN

Efficiency and Power Loss

vs Load Current

BOOST

PVIN

RT

VIN

(5.5V TO 15V)

0.6

CCM

DCM

0.01

0.1

1

LOAD CURRENT (A)

10

0

3623 TA01a

100k

0.1µF

1µF

10k

10nF

3623fa

For more information www.linear.com/LTC3623

1

�LTC3623

Absolute Maximum Ratings

Pin Configuration

(Note 1)

IMON

VIN_REG

RT

TOP VIEW

ITH

PVIN, SVIN Voltage...................................... –0.3V to 17V

VOUT, ISET Voltage..........................................–0.3 to VIN

BOOST Voltage............................... SW –0.3V to SW+6V

RUN Voltage.............................................. –0.3V to SVIN

MODE/SYNC Voltage.................................... –0.3V to 6V

ITH, RT, VIN_REG Voltage..................... –0.3V to INTVCC

IMON, PGOOD, PGFB Voltage................ –0.3V to INTVCC

GSNS Voltage..............................................–0.3V to 12V

Operating Junction Temperature Range

(Notes 4, 5).............................................. –40°C to 125°C

24 23 22 21

ISET 1

20 PGFB

PGOOD 2

19 INTVCC

RUN 3

18 BOOST

GSNS 4

17 SVIN

25

PGND

PVIN 5

16 PVIN

SW 6

15 SW

NC 7

14 NC

MODE/SYNC 8

13 VOUT

PGND

PGND

PGND

PGND

9 10 11 12

UDD PACKAGE

24-LEAD (3mm × 5mm) PLASTIC QFN

TJMAX = 125°C, θJA = 36°C/W

EXPOSED PAD (PIN 25) IS GND, MUST BE SOLDERED TO PCB

Order Information

(http://www.linear.com/product/LTC3623#orderinfo)

LEAD FREE FINISH

TAPE AND REEL

PART MARKING

PACKAGE DESCRIPTION

TEMPERATURE RANGE

LTC3623EUDD#PBF

LTC3623EUDD#TRPBF

LGMW

24-Lead (3mm × 5mm) Plastic QFN

–40°C to 125°C

LTC3623IUDD#PBF

LTC3623IUDD#TRPBF

LGMW

24-Lead (3mm × 5mm) Plastic QFN

–40°C to 125°C

Consult LTC Marketing for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifications, go to: http://www.linear.com/tapeandreel/. Some packages are available in 500 unit reels through

designated sales channels with #TRMPBF suffix.

2

3623fa

For more information www.linear.com/LTC3623

�LTC3623

Electrical Characteristics

The l denotes the specifications which apply over the specified operating

junction temperature range, otherwise specifications are at TA = 25°C. (Note 4) VIN = 12V, unless otherwise noted.

SYMBOL PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

SVIN

Signal VIN Supply Range

4

15

V

PVIN

Power VIN Supply Range

1.5

15

V

VOUT

VOUT Range (Note 6)

VIN = 15V

0

14.5

V

IISET

Reference Current

25°C

25°C to 130°C

–45°C to 25°C

50.5

50.5

51.5

µA

µA

µA

ISET

ISET Dropout Voltage

VIN – ISET

ISET Line Regulation

VIN = 5V to 15V

l

l

49.5

49

49.5

50

50

50

360

l

–10

mV

10

nA/V

ISET Load Regulation (Note 6)

ILOAD = 0 to 5A

0.5

%

VOUT Load Regulation

ITH = 0.9V to 1.6V

0.05

%

EA’s Input Offset

ISET = 3V

–4.5

gm (EA)

Error Amplifier Transconductance

ITH = 1.2V

0.21

IQ

Input DC Supply Current (Note 2)

Shutdown

Discontinuous

RUN = 0

Mode = 0, RT = 33.2k

4.5

mV

0.28

0.35

mS

0

1.45

5

1.75

µA

mA

ton(min)

Minimum On Time (Note 6)

30

ns

toff(min)

Minimum Off Time (Note 6)

100

ns

ILIM

Current Limit

RTOP

Top Switch ON Resistance

RBOTTOM

Bottom Switch On Resistance

VINTVCC

Internal VCC Voltage

5.5V < VIN < 15V

VUVLO

INTVCC Undervoltage Lockout Threshold

INTVCC Rising

VRUN

Run Threshold

Run Hysteresis

RUN Rising

Run Leakage

RUN = 15V

INTVCC Load Regulation

ILOAD = 0 to 20mA

OV

Output Overvoltage

PGFB Upper Threshold

PGFB Rising

0.585

0.63

UV

Output Undervoltage

PGFB Lower Threshold

PGFB Falling

0.5

0.54

RPGOOD

PGOOD Pull-Down Resistance

fOSC

Frequency

RT = 33.2k

RT = INTVCC

MODE/SYNC Threshold

MODE VIL(MAX)

MODE VIH(MIN)

SYNC VIH(MIN)

SYNC VIL(MAX)

MODE/SYNC = 5V

l

Negative Current Limit

5.2

6.2

7.4

–5

–6.5

–9

60

mΩ

30

mΩ

5

V

3.6

3.8

1.2

UVLO Hysteresis

4

V

1.45

0.34

1.67

V

V

0

1

µA

0.36

l

%

0.67

15

PGFB UV Hysteresis

5mA Load

mV

0.575

VIN_REG Input Voltage Regulation Reference (Note 6)

0.94

0.75

V

15

mV

Ω

1

l

V

100

PGOOD Leakage

MODE/SYNC Pin Current

V

0.5

PGFB OV Hysteresis

A

1

1

4.5

2.5

10

1.45

µA

1.07

1.22

MHz

MHz

0.4

V

V

V

V

µA

0.4

V

3623fa

For more information www.linear.com/LTC3623

3

�LTC3623

Electrical Characteristics

The l denotes the specifications which apply over the specified operating

junction temperature range, otherwise specifications are at TA = 25°C. (Note 4) VIN = 12V, unless otherwise noted.

SYMBOL PARAMETER

CONDITIONS

MIN

VOUT Resistance to GND

VINOV

VIN Overvoltage Lockout

VIN Rising

15.5

IMON Current Limit Threshold

IMON Gain

ILOAD = 5A, Not Switching

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime. Absolute Maximum Ratings are those values

beyond which the life of a device may be impaired.

Note 2: Dynamic supply current is higher due to the internal gate charge

being delivered at the switching frequency.

Note 3: The LTC3623 is tested in a feedback loop that adjusts VOUT to

achieve a specified error amplifier output voltage (ITH).

Note 4: The LTC3623 is tested under pulsed load conditions such that

TJ ≈ TA. The LTC3623E is guaranteed to meet performance specifications

from 0°C to 85°C junction temperature. Specifications over the

–40°C to 125°C operating junction temperature range are assured by

design, characterization and correlation with statistical process controls.

The LTC3623I is guaranteed over the full –40°C to 125°C operating

4

MAX

600

VIN 0V Hystersis

IIMON

TYP

UNITS

kΩ

16.8

V

1.4

V

2.15

2.35

2.55

20

21

22

V

µA/A

junction temperature range. Note that the maximum ambient temperature

consistent with these specifications is determined by specific operating

conditions in conjunction with board layout, the rated package thermal

impedance and other environmental factors. The junction temperature

(TJ, in °C) is calculated from the ambient temperature (TA, in °C) and

power dissipation (PD, in watts) according to the formula:

TJ = TA + (PD • θJA), where θJA (in °C/W) is the package thermal

impedance.

Note 5: This IC includes overtemperature protection that is intended

protect the device during momentary overload conditions. Junction

temperature will exceed 125°C when overtemperature protection is active.

Continuous operation above the specified maximum operating junction

temperature may impair device reliability.

Note 6: Guaranteed by design.

3623fa

For more information www.linear.com/LTC3623

�LTC3623

Typical Performance Characteristics

Load Regulation

ISET Current vs. Temperature

50.0

49.5

0

VOUT

VISET

99

49

98

97

95

45

VIN = 12V

VOUT = 3.3V

0

1

2

3

LOAD CURRENT (A)

4

100

90

90

80

EFFICIENCY (%)

EFFICIENCY (%)

60

CCM

50

40

30

20

8

10

VIN (V)

12

14

16

0.01

0.1

1

LOAD CURRENT (A)

3623 G04

10

3623 G03

40

30

fSW = 1MHz

0.01

0.1

1

LOAD CURRENT (A)

10

Shutdown Current vs VIN

1.0

4

VRUN = 0

0.8

0.7

3

IQ (µA)

CCM

2

30

0.6

0.5

0.4

0.3

20

0

0.001

16

CCM

50

0.9

40

10

60

Quiescent Current vs VIN

DCM

14

3623 G06

5

IQ (mA)

EFFICIENCY (%)

50

12

DCM

70

0

0.001

90

60

8

10

VISET (V)

3623 G05

100

70

6

10

fSW = 1MHz

0

0.001

Efficiency vs Load Current

VOUT = 1.8V, VIN = 12V

80

4

20

10

VISET = 2.5V

6

2

80

DCM

70

49.9

4

0

Efficiency vs Load Current

VOUT = 3.3V, VIN = 12V

100

50.1

IISET (µA)

44

5

Efficiency vs Load Current

VOUT = 5V, VIN = 12V

50.2

2

47

3623 G02

ISET Current Line Regulation

0

48

46

96

25 50 75 100 125 150

TEMPERATURE (°C)

50.0

VIN = 16V

50

3623 G01

49.8

51

IISET (µA)

50.5

IISET (µA)

ISET Current vs VISET

100

NORMALIZED VISET AND VOUT (%)

51.0

49.0

–50 –25

TA = 25°C, unless otherwise noted.

1

fSW = 1MHz

0.01

0.1

1

LOAD CURRENT (A)

10

3623 G07

0.2

0.1

DCM

0

0

2

4

6

8

10

VIN (V)

12

14

16

3623 G08

0

0

2

4

6

8

10

VIN (V)

12

14

16

3623 G09

3623fa

For more information www.linear.com/LTC3623

5

�LTC3623

Typical Performance Characteristics

RDS(ON) vs VIN

150

80

VOUT(AC)

200mV/DIV

120

MTOP

RDS(ON) (mΩ)

RDS(ON) (mΩ)

Transient Response CCM

Operation, External Compensation

RDS(ON) vs Temperature

100

60

40

MBOT

20

0

TA = 25°C, unless otherwise noted.

90

MTOP

IL

5A/DIV

60

MBOT

30

0

3

6

9

VIN (V)

12

15

18

3623 G12

0

–50 –25

0

20µs/DIV

VIN = 12V

fSW = 1MHz

VOUT = 3.3V

RITH = 20kΩ, CITH = 470pF

IOUT = 0A TO 4A

MODE = INTVCC

L = 1.2µH

COUT = 47µF

25 50 75 100 125 150

TEMPERATURE (°C)

3623 G10

3623 G11

Transient Response CCM

Operation, Internal Compensation

Transient Response DCM

Operation, External Compensation

Transient Response DCM

Operation, Internal Compensation

VOUT(AC)

200mV/DIV

VOUT(AC)

200mV/DIV

VOUT(AC)

200mV/DIV

IL

5A/DIV

IL

5A/DIV

IL

5A/DIV

20µs/DIV

VIN = 12V

fSW = 1MHz

VOUT = 3.3V

ITH = INTVCC

IOUT = 0A TO 4A

MODE = INTVCC

L = 1.2µH

COUT = 47µF

3623 G14

3623 G13

Output Tracking

ISET

VOLTAGE

VOUT

2V/DIV

IL

2A/DIV

ISET

VOLTAGE

VOUT

1ms/DIV

6

3623 G16

20µs/DIV

VIN = 12V

fSW = 1MHz

VOUT = 3.3V

RITH = 20kΩ, CITH = 470pF

IOUT = 0.5A TO 4A

MODE = 0V

L = 1.2µH

COUT = 47µF

20µs/DIV

VIN = 12V

fSW = 1MHz

VOUT = 3.3V

ITH = INTVCC

IOUT = 0.5A TO 4A

MODE = 0V

L = 1.2µH

COUT = 47µF

Discontinuous Conduction Mode

(DCM) Operation

Continuous Conduction Mode

(CCM) Operation

VSW

10V/DIV

VSW

10V/DIV

IL

2A/DIV

IL

2A/DIV

VIN = 16V

VOUT=2.5V

MODE=0V

L=1.0µH

500ns/DIV

3623 G17

VIN = 16V

VOUT=2.5V

MODE=INTVCC

L=1.0µH

500ns/DIV

3623 G15

3623 G18

3623fa

For more information www.linear.com/LTC3623

�LTC3623

Typical Performance Characteristics

Switching Frequency/Period

vs RT

Switch Leakage Current

INTVCC Load Regulation

5.00

VIN = 15V

2.0

1.5

2

1.0

1

PERIOD (µs)

3

4.95

90

60

MBOT

MTOP

30

20

40

60

RT (kΩ)

0

100

80

4.90

4.85

4.80

0.5

0

INTVCC VOLTAGE (V)

TSW

fSW

LEAKAGE CURRENT (µA)

2.5

4

FREQUENCY (MHz)

120

3.0

5

0

TA = 25°C, unless otherwise noted.

0

–50 –25

0

25 50 75 100 125 150

TEMPERATURE (°C)

4.75

0

20

40

60

80

LOAD CURRENT (mA)

3623 G20

3623 G19

Rising RUN Threshold

vs Temperature

100

3623 G21

Start-up Waveform in CCM

Start-up Waveform in DCM

RUN THRESHOLD (V)

1.50

1.45

1.40

RUN

5V/DIV

RUN

5V/DIV

VOUT(DC)

2V/DIV

VOUT(DC)

2V/DIV

IL

2A/DIV

IL

2A/DIV

1.35

1ms/DIV

1.30

–50 –25

0

25 50 75 100 125 150

TEMPERATURE (°C)

3623 G23

1ms/DIV

MODE = INTVCC

NO PREBIASED VOUT

VIN = 12V

VOUT = 3.3V

MODE = OV

NO PREBIASED VOUT

VIN = 12V

VOUT = 3.3V

Prebiased Start-up Waveform

in DCM

VIN Overvoltage

3623 G24

3623 G22

Prebiased Start-up Waveform

in CCM

RUN

5V/DIV

RUN

5V/DIV

VIN

5V/DIV

VOUT(DC)

2V/DIV

VOUT(DC)

2V/DIV

VOUT

1V/DIV

IL

2A/DIV

IL

2A/DIV

1ms/DIV

MODE = INTVCC

VOUT IS PREBIASED TO 2V

VIN = 12V

VOUT = 3.3V

3623 G25

SW

10V/DIV

1ms/DIV

3623 G26

MODE = OV

VOUT IS PREBIASED TO 2V

VIN = 12V

VOUT = 3.3V

20ms/DIV

VIN = 12V TO 18V TO 12V

VOUT = 3.3V

IOUT = 1A

MODE = CCM

3623 G27

3623fa

For more information www.linear.com/LTC3623

7

�LTC3623

Pin Functions

ISET (Pin 1): Accurate 50µA Current Source. Positive

input to the error amplifier. Connect an external resistor

from this pin to signal GND to program the VOUT voltage.

Connecting an external capacitor from ISET to ground

will soft start the output voltage and reduce current

inrush at the input cap when turning on. VOUT can also

be programmed by driving ISET directly with an accurate

external voltage supply from 0 to VIN, in which case the

external supply would be sinking this 50µA. Do not drive

ISET above VIN or below GND.

PGOOD (Pin 2): Output Power Good with Open-Drain

Logic. PGOOD is pulled to ground when the PGFB pin

is more than 0.63V or less than 0.54V. If PGFB is tied

to INTVCC, the open drain logic on PGOOD is disabled.

PGOOD voltage is referred to GSNS.

RUN (Pin 3): Run Control Input. Enables chip operation by

tying RUN above 1.45V. Tying RUN below 1V shuts down

switching regulator. Tying RUN below 0.4V shuts off the

entire chip. RUN voltage is referred to GSNS.

GSNS (Pin 4): System Ground SENSE. Ground reference

for the RUN, PGOOD and MODE/SYNC pins. For positive

VOUT applications, connect GSNS to PGND. For negative

VOUT applications, connect GSNS to ground return of the

system board.

PVIN (Pins 5, 16): Power VIN. Input voltage connected

to the drain of the top power NMOS. Must be decoupled

to PGND with capacitor close to PVIN pin. PVIN operates

down to 1.5V as long as SVIN > 4V.

SW (Pins 6, 15): Switch Node Connection to External

Inductor. Voltage swing of SW is from a diode voltage

drop below ground to PVIN.

MODE/SYNC (Pin 8): Operation Mode Select. Tie this pin

to INTVCC to force continuous synchronous operation at

all output loads. Tying it to GSNS enables discontinuous

mode operation at light loads. Applying an external clock

signal to this pin will synchronize switching frequency

to the external clock. MODE/SYNC voltage is referred to

GSNS. During external clock synchronization, RT value

should be set up such that the free running frequency is

within ±30% of the external clock frequency.

8

PGND (Pins 9, 10, 11, 12, Exposed Pad Pin 25):

Power Ground. Return path of Internal Power MOSFETs.

Connect these pins to the negative terminals of the input

and output capacitors. The exposed pad must be soldered

to the PCB ground for electrical contact and rated thermal

performance.

VOUT (Pin 13): Output Voltage Pin. Negative input of the

error amplifier which is driven to be the same voltage as

ISET.

SVIN (Pin 17): Signal VIN. Input voltage to power internal

bias circuitry. SVIN must be above 4V.

BOOST (Pin 18): Boosted Floating Driver Supply for

Internal Top Power MOSFET. The (+) terminal of the bootstrap capacitor connects here. This pin swings from a

diode voltage drop below INTVCC up to PVIN + INTVCC.

INTVCC (Pin 19): Internal 5V Regulator Output. The internal power drivers and control circuits are powered from

this voltage. Decouple this pin to PGND with a minimum

of 1µF low ESR ceramic capacitor.

PGFB (Pin 20): Power Good Feedback. Place a resistor

divider on VOUT to detect power good level. If PGFB is

more than 0.63V or less than 0.54V, PGOOD will be pulled

down. Tie PGFB to INTVCC to disable PGOOD function.

Tying PGFB to a voltage between 0.67V and 4V will force

continuous synchronous operation regardless of the

MODE/SYNC state.

IMON (Pin 21): Current Monitor Pin. There will be a current equal to 21µA • IOUT coming out of the IMON pin.

Place a resistor in parallel with a filtering capacitor (10nF)

from IMON to GND to report IOUT. When the voltage on

IMON is above 2.35V, IOUT will be limited. IMON can also

be used to program VOUT to compensate for output voltage drop at the load due to wire resistance by injecting the

IMON current into a portion of the ISET resistor.

VIN_REG (Pin 22): Control Pin for VIN regulation. Tie this

pin to INTVCC for buck converter operation where VOUT is

regulated to ISET. Tie this pin to a resistor divider from VIN

to GND to enable input voltage regulation. When VIN_REG

drops below 1.45V, the system will reduce the inductor

current to keep VIN from dropping.

3623fa

For more information www.linear.com/LTC3623

�LTC3623

Pin Functions

RT (Pin 23): Switching Frequency Programming Pin.

Connect an external resistor (between 100k to 10k) from

RT to GND to program the frequency from 400kHz to

4MHz. Tying the RT pin to INTVCC programs 1MHz operation. Floating the RT pin shuts off the power switches.

ITH (Pin 24): Error Amplifier Output and Switching

Regulator Compensation Point. The internal current comparator’s trip threshold is linearly proportional to this

voltage, whose normal range is from 0.55V to 1.85V.

For external compensation, tie a resistor (RITH) in series

with a capacitor (CITH) to signal GND. A separate 10pF

high frequency filtering cap can also be placed from ITH

to signal GND. Tying ITH to INTVCC enables the default

internal compensation and removes the need for external

compensation components.

3623fa

For more information www.linear.com/LTC3623

9

�LTC3623

FUNCTIONAL Diagram

100k

GND

2pF

VON

200k

400k

0.2V

100pF

17

4V

PVIN

IION =

OSC

19

18

R

–

TG

ON

Q

SWITCH LOGIC

AND ANTISHOOT-THROUGH

+

ICMP

–

600k

CB

L1

6, 15

IREV

VOUT

SENSE+

COUT

BG

–6.7µA TO 3.3µA

RT

M1

SW

ENABLE

4 GSNS

CVCC

BOOST

20k

+

RT

23

CIN

INTVCC

S

8

5, 16

0.0122 • VIN

RT

V

tON = VON (1pF)

IION

V

! IN

INTVCC

VIN

5V

REG

VON

BUFFER

ION

PLL-SYNC

(±30%)

MODE/SYNC

SVIN

VOUT

M2

IOUT

50k

PGB

SENSE–

PGND

21

IMON

9-12, 25

PGOOD

2

6.7µA

0µA TO 10µA

VOUT

13

–

–

1

180k

+

0.63V

RPG2

OV

INTVCC

PGFB

+

50pF

RPG1

–

100k

20

UV

+

VIN

RUN

gm

RIN22

(OPT)

22

24 ITH

50µA

VIN

VIN_REG

RIN21

(OPT)

–

EA

+

+

1.45V

1

ISET

–

RITH

–

CITH 1.45V

0.54V

SVIN

+

RIN12

(OPT)

RUN

3

RIN11

(OPT)

RISET

3623 FD

10

3623fa

For more information www.linear.com/LTC3623

�LTC3623

Operation

Main Control Loop

The LTC3623 is a current mode monolithic step down regulator. The accurate 50µA current source on the ISET pin

allows the user to use just one external resistor to program

the output voltage in a unity gain buffer fashion. In normal

operation, the internal top power MOSFET is turned on for

a fixed interval determined by a fixed one-shot timer OST.

When the top power MOSFET turns off, the bottom power

MOSFET turns on until the current comparator ICMP trips,

restarting the one shot timer and initiating the next cycle.

Inductor current is determined by sensing the voltage

drop across the SW and PGND nodes of the bottom power

MOSFET. The voltage on the ITH pin sets the comparator

threshold corresponding to inductor valley current. The

error amplifier EA adjusts this ITH voltage by comparing

the VOUT voltage with the voltage on ISET. If the load current increases, it causes a drop in the VOUT voltage relative to VISET. The ITH voltage then rises until the average

inductor current matches that of the load current.

At low load current, the inductor current can drop to zero

and become negative. This is detected by current reversal

comparator IREV, which then shuts off the bottom power

MOSFET, resulting in discontinuous operation. Both power

MOSFETs will remain off with the output capacitor supplying

the load current until the ITH voltage rises above the zero

current level to initiate another cycle. Discontinuous mode

operation is disabled by tying the MODE pin to INTVCC,

which forces continuous synchronous operation regardless of output load.

The operating frequency is determined by the value of the

RT resistor, which programs the current for the internal

oscillator as well as the current for the internal one-shot

timer. An internal phase-lock loop servos the switching regulator on-time to track the internal oscillator to force constant

switching frequency. If an external synchronization clock is

present on the MODE/SYNC pin, the regulator on-time and

switching frequency would then track the external clock.

Overvoltage and under-voltage comparators OV and UV

pull the PGOOD output low if the output power-good

feedback voltage VPGFB exits a ±7.5% window around the

regulation point. Continuous operation is forced during

an OV condition. To defeat the PGOOD function, simply

tie PGFB to INTVCC.

Pulling the RUN pin to ground forces the LTC3623 into its

shutdown state, turning off both power MOSFETs as well

as all of its internal control circuitry. Bringing the RUN pin

above 0.7V turns on the internal reference only, while still

keeping the power MOSFETs off. Further increasing the

RUN voltage above 1.45V turns on the entire chip.

INTVCC Regulator

An internal low drop out (LDO) regulator produces the

5V supply that powers the drivers and the internal bias

circuitry. The INTVCC can supply up to 50mA RMS and

must be bypassed to ground with a minimum of 1µF

ceramic capacitor. Good bypassing is necessary to supply

the high transient currents required by the power MOSFET

gate drivers. Applications with high input voltage and high

switching frequency will increase die temperature because

of the higher power dissipation across the LDO. Connecting

a load to the INTVCC pin is not recommended since it will

further push the LDO into its RMS current rating while

increasing power dissipation and die temperature.

VIN Overvoltage Protection

In order to protect the internal power MOSFET devices

against transient voltage spikes, the LTC3623 constantly

monitors the VIN pin for an overvoltage condition. When

VIN rises above 16.8V, the regulator suspends operation by

shutting off both power MOSFETs and discharges the ISET

pin voltage to ground. Once VIN drops below 15.4V, the

regulator immediately resumes normal switching operation

by first charging up the ISET pin to its programmed voltage.

Programming Switching Frequency

Connecting a resistor from the RT pin to GND programs

the switching frequency from 400kHz to 4MHz according

to the following formula:

10

Frequency(Hz)= 3.32 •10

RT

For ease of use, the RT pin can be connected directly to

the INTVCC pin for 1MHz operation. The internal on-time

phase lock loop has a synchronization range of ±30%

around its programmed frequency. Therefore, during

external clock synchronization, the proper RT value should

For more information www.linear.com/LTC3623

3623fa

11

�LTC3623

Operation

be selected such that the external clock frequency is

within this ±30% range of the RT programmed frequency.

MODE/SYNC Operation

The MODE/SYNC pin is a multipurpose pin allowing both

mode selection and operating frequency synchronization.

Connecting it to ground enables Discontinuous Mode

operation for superior efficiency at low load currents at

the expense of slightly higher output voltage ripple. When

the MODE/SYNC pin is tied to INTVCC, forced continuous

mode operation is selected, creating the lowest fixed output ripple at the expense of lower light load efficiency. The

LTC3623 will detect the presence of an external clock signal on the MODE/SYNC pin and synchronize the switching

frequency to that of the incoming clock. The presence of

an external clock will place the part into forced continuous

mode operation.

Current Monitor and Programmable Output Current

Limit

The LTC3623 provides a 21µA scaled replica of the average output current at the IMON pin. Placing an external

resistor at the IMON pin will generate a corresponding

IMON voltage reflecting that of the output current. An

internal current limit amplifier with a threshold of 2.35V

is placed on the IMON pin, allowing the user to use an

appropriately valued resistor to program the output current limit:

RLIM =

2.35V

21µA •ILIM

Output Cable Drop Compensation

For applications where the actual load is far away from the

output of the LTC3623 converter and the resistance of the

connecting cable is affecting the output regulation voltage

at the load, the user can compensate for such cable drop

voltage by placing an additional resistor between IMON

and ISET. This resistor’s value should be (1/21µ) times

that of the measured cable resistance.

RISET2 = 2•RCABLE / 21µA

VOUT =IISET •(RISET1 +RISET2 )

VOUT,COMP =IISET •RISET1 +(IISET +IIMON )•RISET2

L

SW

LTC3623

ISET

VOUT,COMP

VOUT

RCABLE

COUT R

CABLE

IMON PGND

VOUT

ILOAD

RISET1

CISET

10nF

RISET2

3623 F01

Figure 1. Output Cable Drop Compensation

If there’s an equivalent cable resistance for the ground

return between the load and the converter, then the resistor’s value should be doubled. As a result, the ISET programming reference voltage would increase as the load

current increase, compensating for the VOUT cable drop

at the load.

Output Voltage Tracking and Soft Start

where ILIM is the programmable output current limit.

For instance, placing a 50k resistor between IMON and

ground would program an approximate 2.2A output

current limit.

When the programmable current limit feature is used, a

compensation capacitor (10nF typical) should be placed in

parallel with the chosen resistor. To disable output current

monitor or remove output current programmability, connect IMON to ground.

The LTC3623 allows the user to program its output voltage

ramp rate by means of the ISET pin. Since VOUT servos its

voltage to that of the ISET pin, placing an external capacitor CISET on the ISET pin will program the ramp-up rate of

the ISET pin and thus the VOUT voltage:

-t

⎡

⎤

⎢ (RISET •CISET ) ⎥

VOUT (t)=IISET •RISET ⎢1-e

⎥

⎢

⎥⎦

⎣

From 0 to 90% of VOUT

t SS = –RISET •CISET •ln(1-0.9)

12

t SS = 2.3 •RISET •CISET

For more information www.linear.com/LTC3623

3623fa

�LTC3623

Operation

The soft-start time tss (from 0% to 90% VOUT) is 2.3

times of time constant (RISET • CISET). The ISET pin can

also be driven by an external Voltage supply capable of

sinking the provided 50µA.

When starting up into a pre-biased VOUT, the LTC3623 will

stay in discontinuous mode and keep the power switches

off until the voltage on ISET has ramped up to be equal

to VOUT, at which point the switcher will begin switching

and VOUT will ramp up with ISET.

Input Voltage Regulation Loop for Backup Power Supply

The input voltage regulation loop circuit is used to hold

up and regulate the input voltage for backup power supply

applications when the input supply is removed or is very

resistive. An external resistor divider from VIN can be

used to sense the VIN voltage and feeds into the VIN_REG

pin of the LTC3623. When the voltage on the VIN_REG

pin is less than 1.45V, the part will dynamically reduce

the inductor current to prevent the input voltage from

drooping below the 1.45V threshold. If the VIN voltage and

the VIN_REG pin voltage continues to fall, charge will be

transferred from the VOUT capacitor to the VIN capacitor

in order to hold up the VIN voltage. Duration of the holdup

will depend on the amount of charge stored in the output

capacitor. Activation and termination of the input voltage

regulation loop can also be set using a separate resistor

divider from VIN to drive the RUN pin, which has a rising

threshold of 1.45V to enable the chip, and a falling threshold of 1.1V to disable the chip. If the VIN voltage regulation

feature is not used, connect the VIN_REG pin to INTVCC.

⎛R

⎞

+R

VINholdup = ⎜ DIR1 DIR2 ⎟ •1.45V

RDIR1

⎝

⎠

RRUN1

50K

RUN

RDIR2

10K

RRUN2

10K

When the LTC3623’s output voltage is within the ±7.5%

window of the regulation point, which is reflected back as

a VPGFB voltage in the range of 0.54V to 0.63V, the output

voltage is in regulation and the PGOOD pin is pulled high

with an external resistor. Otherwise, an internal open-drain

pull down device (100Ω) will pull the PGOOD pin low. To

prevent unwanted PGOOD glitches during transients or

dynamic VOUT changes, the LTC3623’s PGOOD falling

edge includes a blanking delay of approximately 20µsec.

Internal/External ITH Compensation

For ease of use, the user can simplify the loop compensation by tying the ITH pin to INTVCC to enable internal

compensation. This connects an internal 100k resistor in

series with a 50pF cap to the output of the error amplifier

(internal ITH compensation point). This is a trade-off for

simplicity instead of OPTI-LOOP® optimization, where ITH

components are external and are selected to optimize the

loop transient response with minimum output capacitance.

Minimum Off-Time Considerations

The minimum off-time tOFF(min) is the smallest amount of

time that the LTC3623 is capable of turning on the bottom

power MOSFET, tripping the current comparator and turning the power MOSFET back off. This time is generally

about 100ns. The minimum off-time limit imposes a maximum duty cycle of ton/(tON+tOFF(min)). If the maximum

duty cycle is reached, due to the input voltage dropping,

for example, then the output will drop out of regulation.

The minimum input voltage to avoid dropout is:

(

⎛ tON + tOFF(MIN)

V

=

V

•

IN(MIN) OUT ⎜⎜

tON

⎝

VIN

RDIR1

45K

Output Power Good

) ⎞⎟

⎟⎠

Conversely, the minimum on-time is the smallest duration of

time in which the top power MOSFET can be in its “on” state.

This time is typically 30ns. In continuous mode operation, the

minimum on-time limit imposes a minimum duty cycle of:

PVIN/SVIN

LTC3623

VIN_REG

PGND

DCMIN = f • tON(MIN)

3623 F02

Figure 2. Input Voltage Regulation

Where tON(MIN) is the minimum on-time. As the equation

shows, reducing the operating frequency will alleviate the

minimum duty cycle constraint.

3623fa

For more information www.linear.com/LTC3623

13

�LTC3623

Operation

In the rare cases where the minimum duty cycle is surpassed, the output voltage will still remain in regulation, but

the switching frequency will decrease from its programmed

value. This is an acceptable result in many applications, so

this constraint may not be of critical importance in most

cases. High switching frequencies may be used in the

design without any fear of severe consequences. As the

sections on inductor and capacitor selection show, high

switching frequencies allow the use of smaller board components, thus reducing the size of the application circuit.

CIN and COUT Selection

The input capacitance, CIN, is needed to filter the trapezoidal wave current at the drain of the top power MOSFET.

To prevent large voltage transients from occurring, a low

ESR input capacitor sized for the maximum RMS current

should be used. The maximum RMS current is given by:

⎞1/2

⎛ VOUT ⎞⎛ VIN

IRMS =IOUT(MAX) ⎜

–1⎟

⎟⎜

⎝ VIN ⎠⎝ VOUT ⎠

Using Ceramic Input and Output Capacitors

This formula has a maximum at VIN = 2VOUT, where

IRMS = IOUT/2. This simple worst case condition is commonly used for design because even significant deviations

do not offer much relief. Note that ripple current ratings

from capacitor manufacturers are often based on only

2000 hours of life which makes it advisable to further

de-rate the capacitor, or choose a capacitor rated at a

higher temperature than required.

Several capacitors may also be paralleled to meet size or

height requirements in the design. For low input voltage

applications, sufficient bulk input capacitance is needed

to minimize transient effects during output load changes.

The selection of COUT is determined by the effective series

resistance (ESR) that is required to minimize voltage ripple and load step transients as well as the amount of bulk

capacitance that is necessary to ensure that the control

loop is stable. Loop stability can be checked by viewing

the load transient response. The output ripple, ΔVOUT, is

determined by:

⎞

⎛

1

ΔVOUT < ΔIL ⎜⎜

+RESR ⎟⎟

⎠

⎝ 8 • fSW •COUT

14

The output ripple is highest at maximum input voltage since

ΔIL increases with input voltage. Multiple capacitors placed

in parallel may be needed to meet the ESR and RMS current handling requirements. Dry tantalum, special polymer, aluminum electrolytic, and ceramic capacitors are

all available in surface mount packages. Special polymer

capacitors are very low ESR but have lower capacitance

density than other types. Tantalum capacitors have the

highest capacitance density but it is important to only

use types that have been surge tested for use in switching

power supplies. Aluminum electrolytic capacitors have

significantly higher ESR, but can be used in cost-sensitive

applications provided that consideration is given to ripple

current ratings and long term reliability. Ceramic capacitors have excellent low ESR characteristics and small

footprints. Their relatively low value of bulk capacitance

may require multiples in parallel.

Higher values, lower cost ceramic capacitors are now

becoming available in smaller case sizes. Their high ripple

current, high voltage rating and low ESR make them ideal

for switching regulator applications. However, care must

be taken when these capacitors are used at the input and

output. When a ceramic capacitor is used at the input

and the power is supplied by a wall adapter through long

wires, a load step at the output can induce ringing at the

VIN input. At best, this ringing can couple to the output and

be mistaken as loop instability. At worst, a sudden inrush

of current through the long wires can potentially cause

a voltage spike at VIN large enough to damage the part.

When choosing the input and output ceramic capacitors,

choose the X5R and X7R dielectric formulations. These

dielectrics have the best temperature and voltage characteristics of all the ceramics for a given value and size.

Since the ESR of a ceramic capacitor is so low, the input

and output capacitor must instead fulfill a charge storage requirement. During a load step, the output capacitor must instantaneously supply the current to support

the load until the feedback loop raises the switch current

enough to support the load. The time required for the

feedback loop to respond is dependent on the compensation and the output capacitor size. Typically, 3 to 4 cycles

3623fa

For more information www.linear.com/LTC3623

�LTC3623

Operation

are required to respond to a load step, but only in the first

cycle does the output drop linearly. The output droop,

VDROOP, is usually about 2 to 3 times the linear drop of

the first cycle. Thus, a good place to start with the output

capacitor value is approximately:

⎛ ΔI

⎞

OUT

COUT ~ 2.5 • ⎜

⎟

⎝ f SW • VDROOP ⎠

More capacitance may be required depending on the duty

cycle and load step requirements.

In most applications, the input capacitor is merely required

to supply high frequency bypassing, since the impedance

to the supply is very low. A 22µF ceramic capacitor is usually enough for these conditions. Place this input capacitor as close to VIN pin as possible.

Inductor Selection

Given the desired input and output voltages, the inductor value and operating frequency determine the ripple

current:

⎛ V

⎞⎛ V ⎞

ΔIL = ⎜ OUT ⎟⎜1– OUT ⎟

VIN ⎠

⎝ fSW •L ⎠⎝

Lower ripple current reduces core losses in the inductor,

ESR losses in the output capacitors, and output voltage

ripple. Highest efficiency operation is obtained at low frequency with small ripple current. However, achieving this

requires a large inductor. There is a trade-off between

component size, efficiency, and operating frequency.

A reasonable starting point is to choose a ripple current

that is about 40% of IOUT(MAX). Note that the largest ripple

current occurs at the highest VIN. To guarantee that ripple

current does not exceed a specified maximum, the inductance should be chosen according to:

⎞⎛

⎞

⎛

V

VOUT

⎟⎟⎜⎜1– OUT ⎟⎟

L = ⎜⎜

⎝ fSW • ΔIL(MAX) ⎠⎝ VIN(MAX) ⎠

Once the value for L is known, the type of inductor must

be selected. Actual core loss is independent of core size

for a fixed inductor value, but is very dependent on the

inductance selected. As the inductance increases, core

losses decrease. Unfortunately, increased inductance

requires more turns of wire and therefore copper losses

will increase.

Ferrite designs have very low core losses and are preferred at high switching frequencies, so design goals can

concentrate on copper loss and preventing saturation.

Ferrite core material saturates “hard”, which means that

inductance collapses abruptly when the peak design current is exceeded. This results in an abrupt increase in

inductor ripple current and consequent output voltage

ripple. Do not allow the core to saturate!

Different core materials and shapes will change the size/

current and price/current relationship of an inductor.

Toroid or shielded pot cores in ferrite or permalloy materials are small and don’t radiate much energy, but generally

cost more than powdered iron core inductors with similar

characteristics. The choice of which style inductor to use

mainly depends on the price versus size requirements

and any radiated field/EMI requirements. New designs for

surface mount inductors are available from Toko, Vishay,

NEC/Tokin, Cooper, TDK, and Würth Elektronik. Refer to

Table 1 for more details

Checking Transient Response

The OPTI-LOOP compensation allows the transient

response to be optimized for a wide range of loads and

output capacitors. The availability of the ITH pin not

only allows optimization of the control loop behavior but

also provides a DC-coupled and AC-filtered closed-loop

response test point. The DC step, rise time and settling

at this test point truly reflects the closed-loop response.

Assuming a predominantly second order system, phase

margin and/or damping factor can be estimated using

the percentage of overshoot seen at this pin.

The ITH external components shown in Figure 5 circuit will

provide an adequate starting point for most applications.

The series R-C filter sets the dominant pole-zero loop compensation. The values can be modified slightly (from 0.5

to 2 times their suggested values) to optimize transient

response once the final PC layout is done and the particular output capacitor type and value have been determined.

The output capacitors need to be selected because their

3623fa

For more information www.linear.com/LTC3623

15

�LTC3623

Operation

Table 1. Inductor Selection Table

INDUCTANCE

DCR

MAX CURRENT

DIMENSIONS

HEIGHT

6.7mm × 7mm

3mm

Vishay IHLP-2525CZ-01 Series

0.33µH

4.1mW

18A

0.47µH

6.5mW

13.5A

0.68µH

9.4mW

11A

0.82µH

11.8mW

10A

1.0µH

14.2mW

9A

Vishay IHLP-1616BZ-11 Series

0.22µH

4.1mW

12A

0.47µH

15mW

7A

4.3mm × 4.7mm

2.0mm

7mm × 7.7mm

2.0mm

Toko FDV0620 Series

0.20µH

4.5mW

12.4A

0.47µH

8.3mW

9A

1µH

18.3mW

5.7A

NEC/Tokin MLC0730L Series

0.47µH

4.5mW

16.6A

0.75µH

7.5mW

12.2A

1µH

9mW

10.6A

6.9mm × 7.7mm

3.0mm

7mm × 7.3mm

3.0mm

6.9mm × 7.3mm

3.2mm

7mm × 7.7mm

3.8mm

Cooper HCP0703 Series

0.22µH

2.8mW

23A

0.47µH

4.2mW

17A

0.68µH

5.5mW

15A

0.82µH

8mW

13A

1µH

10mW

11A

1.5µH

14mW

9A

TDK RLF7030 Series

1µH

8.8mW

6.4A

1.5µH

9.6mW

6.1A

2.2µH

12mW

5.4A

Würth Elektronik WE-HC 744312 Series

0.25µH

2.5mW

18A

0.47µH

3.4mW

16A

0.72µH

7.5mW

12A

1µH

9.5mW

11A

1.5µH

10.5mW

9A

16

various types and values determine the loop feedback

factor gain and phase. An output current pulse of 20%

to 100% of full load current having a rise time of 1µs to

10µs will produce output voltage and ITH pin waveforms

that will give a sense of the overall loop stability without

breaking the feedback loop.

Switching regulators take several cycles to respond to

a step in load current. When a load step occurs, VOUT

immediately shifts by an amount equal to ΔILOAD • ESR,

where ESR is the effective series resistance of C OUT.

ΔILOAD also begins to charge or discharge COUT generating a feedback error signal used by the regulator to

return VOUT to its steady-state value. During this recovery time, VOUT can be monitored for overshoot or ringing

that would indicate a stability problem.

The initial output voltage step may not be within the

bandwidth of the feedback loop, so the standard second

order overshoot/DC ratio cannot be used to determine

phase margin. The gain of the loop increases with the R

and the bandwidth of the loop increases with decreasing

C. If R is increased by the same factor that C is decreased,

the zero frequency will be kept the same, thereby keeping

the phase the same in the most critical frequency range

of the feedback loop. In addition, a feed forward capacitor

CFF can be added to improve the high frequency response,

as shown in Figure 1. Capacitor CFF provides phase lead

by creating a high frequency zero with R2 which improves

the phase margin.

The output voltage settling behavior is related to the stability of the closed-loop system and will demonstrate the

actual overall supply performance. For a detailed explanation of optimizing the compensation components,

including a review of control loop theory, refer to Linear

Technology Application Note 76.

In some applications, a more severe transient can be caused

by switching in loads with large (>10µF) input capacitors.

The discharged input capacitors are effectively put in parallel with COUT, causing a rapid drop in VOUT. No regulator

can deliver enough current to prevent this problem, if the

switch connecting the load has low resistance and is driven

quickly. The solution is to limit the turn-on speed of the load

3623fa

For more information www.linear.com/LTC3623

�LTC3623

Operation

switch driver. A Hot Swap controller is designed specifically for this purpose and usually incorporates current limit,

short-circuit protection, and soft-start.

Efficiency Considerations

The percent efficiency of a switching regulator is equal to

the output power divided by the input power times 100%.

It is often useful to analyze individual losses to determine

what is limiting the efficiency and which change would

produce the most improvement. Percent efficiency can

be expressed as:

% Efficiency = 100%-(L1 + L2 + L3 +…)

where L1, L2, etc. are the individual losses as a percentage

of input power.

Although all dissipative elements in the circuit produce

losses, four main sources usually account for most of the

losses in LTC3623 circuits: 1) I2R losses, 2) Transition

losses, 3) switching losses, 4) other losses.

1. I2R losses are calculated from the DC resistances of

the internal switches, RSW, the external inductor, RL,

and board trace resistance, Rb. In continuous mode,

the average output current flows through inductor L

but is “chopped” between the internal top and bottom

power MOSFETs. Thus, the series resistance looking

into the SW pin is a function of both top and bottom

MOSFET RDS(ON) and the duty cycle (DC) as follows:

RSW = RDS(ON)(TOP)(DC) + RDS(ON)(BOT)(1-DC)

The RDS(ON) for both the top and bottom MOSFETs

can be obtained from the Typical Performance

Characteristics curves. Thus to obtain I2R losses:

I2R losses = IOUT2(RSW + RL + Rb)

2. Transition loss arises from the brief amount of time

the top power MOSFET spends in the saturated

region during switch node transitions. It depends

upon the input voltage, load current, internal power

MOSFET gate capacitance, internal driver strength, and

switching frequency.

3. The INTVCC current is the sum of the power MOSFET

driver and control currents. The power MOSFET driver

current results from switching the gate capacitance of

the power MOSFETs, Each time a power MOSFET gate

is switched from low to high to low again, a packet of

charge dQ moves from VIN to ground. The resulting

dQ/dt is a current out of INTVCC that is typically much

larger than the DC control bias current. In continuous

mode, IGATECHG = fSW(QT + QB), where QT and QB are

the gate charges of the internal top and bottom power

MOSFETs and fSW is the switching frequency. Since

INTVCC is a low drop out regulator output powered

by VIN, the INTVCC current also shows up as VIN current, unless a separate voltage supply (>5V and