LTC4162-F

35V/3.2A Multicell

LiFePO4 Step-Down Battery Charger

with PowerPath and I2C Telemetry

DESCRIPTION

FEATURES

LiFePO4 Battery Charger with Termination

nn Wide Charging Input Voltage Range: 4.5V to 35V

nn High Efficiency Synchronous Operation

nn 16-Bit Digital Telemetry System Monitors V

BAT,

IBAT, RBAT, TBAT, TDIE, VIN, IIN, VOUT

nn Charges 1-9 Lithium Iron Phosphate Cells

nn Input Undervoltage Charge Current Limit Loop

nn Input MPPT for Solar Panel Inputs

nn Input Current Limit Prioritizes System Load Output

nn Low Loss PowerPath™

nn Instant-On Operation with Discharged or Missing

Battery

nn JEITA Temperature Controlled Charging

nn Pin Compatible with Li-Ion and SLA Versions

nn

APPLICATIONS

The LTC®4162-F is an advanced monolithic synchronous

step-down switching battery charger and PowerPath™

manager that seamlessly manages power distribution

between input sources such as wall adapters, backplanes,

solar panels, etc., and a rechargeable lithium iron phosphate battery.

A high resolution measurement system provides extensive telemetry information for circuit voltages, currents,

battery resistance and temperature which can all be read

back over the I2C port. The I2C port can also be used to

configure many charging parameters including charging

voltages and currents, termination algorithms and numerous system status alerts.

The LTC4162-F can charge LiFePO4 cell stacks from 1 cell

to 9 cells with as much as 3.2A of charge current.

The power path topology decouples the output voltage

from the battery allowing a portable product to start up

instantly under very low battery voltage conditions.

Medical Instruments

USB-C Power Delivery

nn Industrial Handhelds

nn Ruggedized Notebooks

nn Tablet Computers

nn

nn

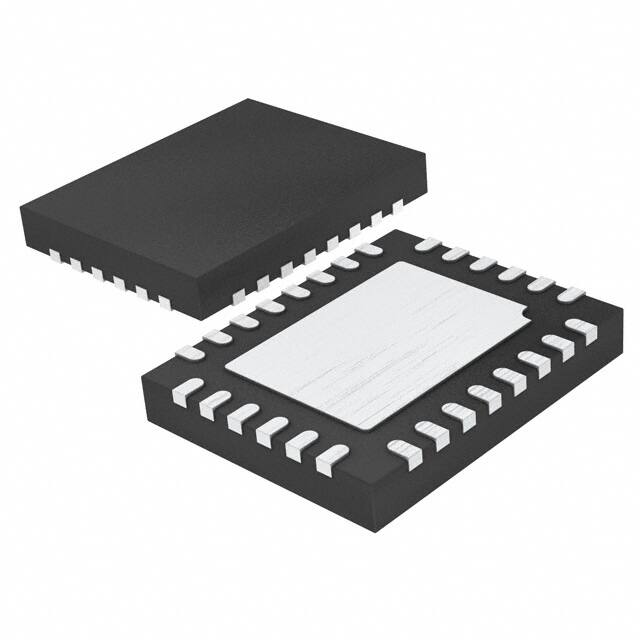

The LTC4162-F is available in a thermally enhanced 28pin 4mm × 5mm × 0.75mm QFN surface mount package.

All registered trademarks and trademarks are the property of their respective owners.

TYPICAL APPLICATION

1-9 Cell, 3.2A Step-Down Switching Battery Charger with PowerPath

VIN

Charging Efficiency vs Input Voltage by Cell Count

VOUT

VIN INFET CLP

CLN VOUT

SW

CSP

LTC4162-F

CSN

BATSENS+

NTCBIAS

NTC

CELL

COUNT

GND

ICHARGE = 2.5A

95

BATFET

2C

EFFICIENCY (%)

I

100

90

85

1 CELL

2 CELLS

3 CELLS

4 CELLS

5 CELLS

6 CELLS

80

75

T

5

10

15

7 CELLS

8 CELLS

9 CELLS

20

25

30

35

INPUT VOLTAGE (V)

4162F TA01a

4162F TA01b

Rev A

Document Feedback

For more information www.analog.com

1

�LTC4162-F

TABLE OF CONTENTS

Features............................................................................................................................. 1

Applications........................................................................................................................ 1

Typical Application ................................................................................................................ 1

Description......................................................................................................................... 1

Absolute Maximum Ratings...................................................................................................... 3

Order Information.................................................................................................................. 3

Pin Configuration.................................................................................................................. 3

Electrical Characteristics......................................................................................................... 4

Typical Performance Characteristics........................................................................................... 7

Pin Functions......................................................................................................................10

Block Diagram.....................................................................................................................12

ESD Diagram......................................................................................................................13

Timing Diagram...................................................................................................................14

Operation..........................................................................................................................15

Applications Information........................................................................................................29

Register Descriptions............................................................................................................36

Typical Applications..............................................................................................................48

Package Description.............................................................................................................50

Revision History..................................................................................................................51

Typical Application...............................................................................................................52

Related Parts......................................................................................................................52

Rev A

2

For more information www.analog.com

�LTC4162-F

ABSOLUTE MAXIMUM RATINGS

PIN CONFIGURATION

(Note 1)

BATSENS+, VIN, CSP, CSN, CLP,

CLN, VOUT, VOUTA................................... −0.3V to 36V

CSP to CSN, CLP to CLN.........................................±0.3V

CELLSO, CELLS1, SYNC ...................... −0.3V to INTVCC

DVCC.......................................................... −0.3V to 5.5V

SDA, SCL, SMBALERT.............................. −0.3V to DVCC

ISW ........................................................................ ±3.5A

Operating Junction Temperature Range

(Notes 2, 4)............................................. −40 to 125°C

Storage Temperature Range....................... −65 to 150°C

PGND

PGND

SW

SW

VOUT

VOUT

TOP VIEW

28 27 26 25 24 23

BOOST 1

22 BATFET

INTVCC 2

21 CSP

VOUTA 3

20 CSN

CLN 4

19 BATSENS+

AGND

29

CLP 5

18 CELLS1

INFET 6

17 CELLS0

VIN 7

16 SYNC

VCC2P5 8

15 DVCC

SDA

SCL

SMBALERT

RT

NTC

NTCBIAS

9 10 11 12 13 14

UFD PACKAGE

28-LEAD (4mm × 5mm) PLASTIC QFN

TJMAX = 125°C, θJA = 43°C/W, θJC = 3.4°C/W

EXPOSED PAD (PIN 29) IS GND, MUST BE SOLDERED TO PCB

ORDER INFORMATION

DESCRIPTION

TEMPERATURE

RANGE

E

I2C Adjustable Voltage

–40°C to 125°C

4162G

E

3.6V Fixed Voltage

–40°C to 125°C

LTC4162EUFD-FFS#PBF

4162F

E

3.8V Rapid Charge

–40°C to 125°C

LTC4162EUFD-FADM#PBF

4162P

E

I2C Adjustable Voltage MPPT ON

–40°C to 125°C

LTC4162EUFD-FSTM#PBF

4162S

E

3.6V Fixed Voltage MPPT ON

–40°C to 125°C

LTC4162EUFD-FFSM#PBF

4162R

E

3.8V Rapid Charge MPPT ON

–40°C to 125°C

–40°C to 125°C

PART NUMBER

PART

MARKING*

LTC4162EUFD-FAD#PBF

4162E

LTC4162EUFD-FST#PBF

TAPE AND

REEL

TEMP

GRADE

LTC4162EUFD-FAD#TRPBF

4162E

✓

E

I2C Adjustable Voltage

LTC4162EUFD-FST#TRPBF

4162G

✓

E

3.6V Fixed Voltage

–40°C to 125°C

LTC4162EUFD-FFS#TRPBF

4162F

✓

E

3.8V Rapid Charge

–40°C to 125°C

–40°C to 125°C

LTC4162EUFD-FADM#TRPBF

4162P

✓

E

I2C Adjustable Voltage MPPT ON

LTC4162EUFD-FSTM#TRPBF

4162S

✓

E

3.6V Fixed Voltage MPPT ON

–40°C to 125°C

LTC4162EUFD-FFSM#TRPBF

4162R

✓

E

3.8V Rapid Charge MPPT ON

–40°C to 125°C

–40°C to 125°C

LTC4162IUFD-FAD#PBF

4162E

I

I2C Adjustable Voltage

LTC4162IUFD-FST#PBF

4162G

I

3.6V Fixed Voltage

–40°C to 125°C

LTC4162IUFD-FFS#PBF

4162F

I

3.8V Rapid Charge

–40°C to 125°C

I

I2C Adjustable Voltage MPPT ON

–40°C to 125°C

LTC4162IUFD-FADM#PBF

4162P

Rev A

For more information www.analog.com

3

�LTC4162-F

ORDER INFORMATION

PART NUMBER

PART

MARKING*

LTC4162IUFD-FSTM#PBF

4162S

LTC4162IUFD-FFSM#PBF

4162R

TAPE AND

REEL

DESCRIPTION

TEMPERATURE

RANGE

I

3.6V Fixed Voltage MPPT ON

–40°C to 125°C

I

3.8V Rapid Charge MPPT ON

–40°C to 125°C

–40°C to 125°C

TEMP

GRADE

LTC4162IUFD-FAD#TRPBF

4162E

✓

I

I2C Adjustable Voltage

LTC4162IUFD-FST#TRPBF

4162G

✓

I

3.6V Fixed Voltage

–40°C to 125°C

LTC4162IUFD-FFS#TRPBF

4162F

✓

I

3.8V Rapid Charge

–40°C to 125°C

LTC4162IUFD-FADM#TRPBF

4162P

✓

I

I2C Adjustable Voltage MPPT ON

–40°C to 125°C

LTC4162IUFD-FSTM#TRPBF

4162S

✓

I

3.6V Fixed Voltage MPPT ON

–40°C to 125°C

LTC4162IUFD-FFSM#TRPBF

4162R

✓

I

3.8V Rapid Charge MPPT ON

–40°C to 125°C

Contact the factory for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

Tape and reel specifications. Some packages are available in 500 unit reels through designated sales channels with #TRMPBF suffix.

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full specified

operating junction temperature range, otherwise specifications are at TA = 25°C (Note 4). VIN = 18V, DVCC = 3.3V, RSNSI = 10mΩ,

RSNSB = 10mΩ unless otherwise noted.

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

System Voltages and Currents

VIN

Input Supply Voltage

l

4.5

l

2.7

35

V

VBAT

Battery Voltage

35

V

IBATSENS+

Battery Drain Current

VIN – VBATSENS+ > VIN_DUVLO, Terminated

VIN – VBATSENS+ < VIN_DUVLO

VIN = 0, SHIPMODE Activated

0.5

54

2.8

1

100

5

µA

µA

µA

IVIN

VIN Drain Current

VIN – VBATSENS+ > VIN_DUVLO, Terminated

115

200

µA

0.5

1.5

V

mV

%

%

0.25

0.75

mV

mV

mV

mV

0.2

mV

mV

mV

1

V

mV

%

Switching Battery Charger

VCHARGE

Range

Resolution (5 Bits)

Accuracy

Per cell_count

l

ICHARGE

Servo Voltage

(VCSP – VCSN)

Range

Resolution (5 Bits)

Accuracy

ICHARGE = (VCSP – VCSN)/RSNSB

Note 5

l

IINLIM

Servo Voltage

(VCLP – VCLN)

Range

Resolution (6 Bits)

Accuracy

VINLIM

Range

Resolution (8 Bits)

Full Scale Accuracy

IIN = (VCLP – VCLN)/RSNSI

Note 6

–0.5

–1.5

–0.25

–0.75

–0.2

–1

3.4125–3.8

12.5

1–32

1

0.5–32

0.5

0.14–36

140.625

Rev A

4

For more information www.analog.com

�LTC4162-F

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full specified

operating junction temperature range, otherwise specifications are at TA = 25°C (Note 4). VIN = 18V, DVCC = 3.3V, RSNSI = 10mΩ,

RSNSB = 10mΩ unless otherwise noted.

SYMBOL

PARAMETER

CONDITIONS

fOSC

Switching Frequency

RT = 63.4k

DMAX

Maximum Duty Cycle

RSWITCH

Primary Switch On-Resistance

RRECT

Rectifier Switch On-Resistance

IPEAK

Peak Inductor Current Limit

Note 3

VIN_UVLO

VIN Charger Enable

Input Undervoltage Lockout

Rising Threshold

Hysteresis

4.2

4.4

0.2

4.6

V

V

VIN_DUVLO

VIN to BATSENS+ Charger Enable

Differential Undervoltage Lockout

Rising Threshold

Hysteresis

100

150

170

200

mV

mV

VIN_OVLO

VIN Charger Disable

Overvoltage Lockout

Rising Threshold

Hysteresis

37.6

38.6

1.4

40

V

V

VINTVCC_UVLO

INTVCC Telemetry Enable

Undervoltage Lockout

Rising Threshold

Hysteresis

2.75

2.85

0.12

2.95

V

V

l

MIN

TYP

MAX

1.4

1.5

1.6

99.5

UNITS

MHz

%

90

mΩ

90

mΩ

45mV/RSNSB

A

System Controls

Telemetry A/D Measurement Subsystem

IBAT

(VCSP – VCSN)

Resolution

Offset Error

Span Error

IBAT = (VCSP – VCSN)/RSNSB

0.32mV < VCSP – VCSN < 32mV

IIN

(VCLP – VCLN)

Resolution

Offset Error

Span Error

IIN = (VCLP – VCLN)/RSNSI

0.32mV < VCLP – VCLN < 32mV

VIN

Resolution

Offset Error

Span Error

3V < VIN < 35V

–25

–1

VBATSENS+

(Per cell_count)

Resolution

Offset Error

Span Error

2V < VBATSENS+ < 3.8V

–10

–1

VOUT

Resolution

Offset Error

Span Error

3V < VOUT < 35V

–25

–1

VNTC/VNTCBIAS

Resolution

Offset Error

Span Error

0 < VNTC/VNTCBIAS < 1

–1

–1

T_die

Resolution

Offset

–0.15

–1

–0.15

–1

1.466

1.466

1.649

192.4

1.653

45.833

0.15

1

µV /LSB

mV

%rdng

0.15

1

µV/LSB

mV

%rdng

25

1

mV/LSB

mV

%rdng

10

1

µV/LSB

mV

%rdng

25

1

mV/LSB

mV

%rdng

1

1

µV/V/LSB

mV/V

%rdng

°C/LSB

°C

0.0215

–264.4

Serial Port, SDA, SCL, SMBALERT

DVCC

Logic Reference Level

IDVCCQ

DVCC Current

ADDRESS

I2C Address

VIHI2C

Input High Threshold

VILI2C

Input Low Threshold

VOLI2C

Digital Output Low (SDA/SMBALERT)

FSCL

SCL Clock Frequency

l

1.8

SCL/SDA = DVCC, 0kHz

5.5

0

V

µA

0b1101000[R/W]

70

ISDA/SMBALERT = 3mA

% DVCC

30

% DVCC

400

mV

400

kHz

Rev A

For more information www.analog.com

5

�LTC4162-F

ELECTRICAL CHARACTERISTICS

The l denotes the specifications which apply over the full specified

operating junction temperature range, otherwise specifications are at TA = 25°C (Note 4). VIN = 18V, DVCC = 3.3V, RSNSI = 10mΩ,

RSNSB = 10mΩ unless otherwise noted.

SYMBOL

PARAMETER

tLOW

LOW Period of SCL Clock

1.3

µs

tHIGH

HIGH Period of SCL Clock

0.6

µs

tBUF

Bus Free Time Between Start and Stop

Conditions

1.3

µs

tHD,STA

Hold Time, After (Repeated) Start

Condition

0.6

µs

tSU,STA

Setup Time after a Repeated Start

Condition

0.6

µs

tSU,STO

Stop Condition Set-Up Time

0.6

tHD,DAT(OUT)

Output Data Hold Time

tHD,DAT(IN)

Input Data Hold Time

tSU,DAT

Data Set-Up Time

tSP

Input Spike Suppression Pulse Width

CONDITIONS

MIN

0

TYP

MAX

UNITS

µs

900

ns

0

ns

100

ns

50

ns

SYNC Pin

VIHSYNC

Input High Threshold

l

VILSYNC

Input Low Threshold

l

1.5

V

0.2

V

50

nA

Pin Leakages (NTC, CELLS0, CELLS1, SDA, SCL, SYNC, SMBALERT)

Pin Current

–50

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LTC4162 includes over-temperature protection that is

intended to protect the device during momentary overload conditions.

The maximum rated junction temperature will be exceeded when this

protection is active. Continuous operation above the specified absolute

maximum operating junction temperature may impair device reliability or

permanently damage the device.

Note 3: The safety current limit features of this part are intended to

protect the IC from short term or intermittent fault conditions. Continuous

operation above the maximum specified pin current may result in device

degradation or failure.

Note 4: The E-grade is tested under pulsed load conditions such that

TJ ≈ TA. The E-grade is guaranteed to meet specifications from 0°C

to 85°C junction temperature. Specifications over the –40°C to 125°C

operating junction temperature range are assured by design,

characterization, and correlation with statistical process controls. The

I-grade is guaranteed over the full –40°C to 125°C operating junction

temperature range. The junction temperature (TJ) is calculated from the

ambient temperature (TA) and power dissipation (PD) according to the

formula TJ = TA + (PD • θJA). Note that the maximum ambient temperature

consistent with these specifications is determined by specific operating

conditions in conjunction with board layout, the rated package thermal

resistance and other environmental factors.

Note 5: Charge Current is given by the charger servo voltage, VCSP-CSN,

divided by the charge current setting resistor RSNSB. Errors in the value of

the external resistor contribute directly to the total charge current error.

Note 6: Input Current is given by the VCLP-CLN servo voltage divided by

the input current setting resistor RSNSI. Errors in the value of the external

resistor contribute directly to the total input current error.

Rev A

6

For more information www.analog.com

�LTC4162-F

TYPICAL PERFORMANCE CHARACTERISTICS

Input Current and Charge Current

vs Load Current

3.6

3.2

3.2

2.8

2.8

3.6

CHARGE

CURRENT

2.4

CURRENT (A)

2.4

2.0

1.6

1.2

2.0

INPUT

CURRENT

1.6

1.2

0.8

0.8

0.4

0.4 VIN = 12V

CELL COUNT = 2

0.0

4.8

5.4

6.0

0.0

6.6

7.2

VIN = 18V

VBAT = 3.7V

iin_limit_target = 1.2A

−0.4

0.0

7.8

0.2

0.4

BATTERY VOLTAGE (V)

0.6

0.8

20

CHARGE

CURRENT

3.2

CHARGE CURRENT (A)

3.6

Resistive Source Input Voltage and

Charge Current vs Load Current

1.0

1.2

1.4

1.6

18

2.8

16

2.4

14

2.0

12

1.6

10

INPUT

VOLTAGE

1.2

8

0.8

6

0.4

4

SOURCE IMPEDANCE = 5Ω

0.0 input_undervoltage_setting = 7V

cell_count = 1

−0.4

0.0

0.5

1.0

1.5

2.0

LOAD CURRENT (A)

4162F G03

No Input Battery Drain Current vs

Battery Voltage

Ship Mode Battery Drain Current

vs Battery Voltage

100

4

12.1

12.0

VBAT

VIN

11.9

−0.05

0.00

0.05

0.10

0.15

80

25°C

60

–50°C

40

20

0

0.20

125°C

BATTERY DRAIN CURRENT (µA)

BATTERY DRAIN CURRENT (µA)

VOUT VOLTAGE (V)

12.2

VIN = 0V

0

5

10

VIN − VBAT VOLTAGE (V)

15

20

25

30

75°C

25°C

1.2

1.7

2.2

2.7

3.2

SWITCH PIN CURRENT (A)

22.0

28.5

VBAT = 6.6V

ICHARGE = 2.5A

cell_count = 2

90

90

85

75

35.0

Efficiency vs Switching Frequency

95

1 CELL

2 CELLS

3 CELLS

4 CELLS

5 CELLS

6 CELLS

5

10

15

85

80

7 CELLS

8 CELLS

9 CELLS

20

25

30

35

INPUT VOLTAGE (V)

4162F G07

15.5

4162F G06

ICHARGE = 2.5A

80

−50°C

0.7

9.0

BATTERY VOLTAGE (V)

EFFICIENCY (%)

EFFICIENCY (%)

SWITCH RESISTANCE (mΩ)

130

50

0.2

1

0

2.5

35

95

125°C

70

2

Efficiency vs Input Voltage

100

150

90

–50°C

4162F G05

Top and Bottom Switch RDS(ON)

110

25°C

3

BATTERY VOLTAGE (V)

4162F G04

170

0

3.0

2.5

4162F G02

125°C

VOUT

2

LOAD CURRENT (A)

4162F G01

VOUT vs VIN Power Path Controller

INPUT VOLTAGE (V)

CHARGE CURRENT (A)

Charge Current vs Battery Voltage

12.3

TA = 25°C, unless otherwise noted.

75

1.0

VIN = 12V

VIN = 18V

VIN = 24V

VIN = 30V

1.5

2.0

2.5

3.0

3.5

4.0

SWITCHING FREQUENCY (MHz)

4162F G08

4162F G09

Rev A

For more information www.analog.com

7

�LTC4162-F

TYPICAL PERFORMANCE CHARACTERISTICS

3.3Ah 2-Cell Battery Charge

Current and Voltage vs Time

TA = 25°C, unless otherwise noted.

400mAh 2-Cell Battery Rapid

Charge Current and Voltage vs Time

4.0

7.5

1.8

7.5

15 MINUTE ABSORB

TERMINATION

2.4

6.5

CHARGE

CURRENT

1.6

6.0

1 HOUR CV TIMER

TERMINATION

0.8

VIN = 18V

0.0

0.0

0.5

1.0

1.5

CHARGE CURRENT (A)

7.0

5.5

1.5

1.2

6.9

CHARGE

CURRENT

0.9

6.6

0.6

6.3

1 HOUR CV TIMER

TERMINATION

0.3

5.0

2.0

0.0

0.0

6.0

VIN = 12V

0.5

TIME (H)

1.0

1.5

4162F G11

Charge Current During BSR

Measurement Cycle

Example Power Path Handover

5

BATFET

20

INFET

4

CHARGE CURRENT (A)

INFET / BATFET VOLTAGE (V)

25

15

10

5

VBATSENS+ = 15V

VIN = 15V TO 15.5V

QGS = 6nC

0

20

40

60

80

3

OPEN CIRCUIT BATTERY

VOLTAGE MEASUREMENT

ca. THIS TIME POINT

2

1

0

−1

100

0

10

20

30

40

4162F G13

4162F G12

Solar Panel Global Sweep

Light to Dark Solar Panel Tracking

1 CELL

PANEL

CURRENT

1.0

20

0.8

15

0.6

10

0.4

5

0.2

200

300

400

0.0

500

18

1.20

1.05

PANEL

VOLTAGE

0.90

15

0.75

12

9

0.60

PANEL

CURRENT

0.45

6

0.30

3

0.15

0

0.0

0.6

1.2

1.8

2.4

PANEL CURRENT (A)

25 PANEL

VOLTAGE

100

21

1.2

PANEL CURRENT (A)

PANEL VOLTAGE (V)

30

0

24

1.4

PANEL VOLTAGE (V)

35

50

TIME (ms)

TIME (µs)

0

5.7

2.0

TIME (H)

4162F G10

0

7.2

BATTERY

VOLTAGE

BATTERY VOLTAGE (V)

3.2

BATTERY VOLTAGE (V)

CHARGE CURRENT (A)

BATTERY VOLTAGE

0.00

3.0

TIME (s)

TIME (s)

4162F G14

4162F G15

Rev A

8

For more information www.analog.com

�LTC4162-F

TYPICAL PERFORMANCE CHARACTERISTICS

Charge Current and Die Temperature

Using Thermal Regulation

Multi-Peak Solar Panel

Acquisition

30

1.2

1.0

20

0.8

15

0.6

10

0.4

PANEL

CURRENT

5

0

1

2

3

5

3.2

90

2.4

80

1.6

70

DIE

TEMP

0.8

0.2

4

100

THERMAL START = 70°C

THERMAL END = 80°C

60

CHARGE

CURRENT

0.0

0.0

25

40

TIME (s)

55

70

85

Histogram of vbat Readings

4162F G17

10000

8000

σ = 576µV

σ = 3.48mV

2000

6000

6000

FREQUENCY

FREQUENCY

FREQUENCY

σ = 21.3m°C

8000

6000

4000

3.303

3.305

3.307

0

11.95

3.309

11.96

11.97

11.98

11.99

0

25.0

12.00

OUTPUT VOLTAGE (V)

4162F G18

Histogram of bsr Readings

Histogram of die_temp Readings

σ = 419µA

8000

FREQUENCY

FREQUENCY

1500

1000

500

0

198.5 199.0 199.5 200.0 200.5 201.0 201.5

bsr (mΩ)

0

24.8

25.4

Histogram of ibat Readings

σ = 28m°C

2000

500

25.3

10000

σ = 250µΩ

1000

25.2

4162F G20

2000

1500

25.1

THERMISTOR TEMPERATURE (°C)

4162F G19

2500

RSNSI=10mΩ

4000

2000

2000

BATTERY VOLTAGE (V)

FREQUENCY

Histogram of thermistor_voltage

Readings

Histogram of vout Readings

8000

0

3.301

50

100

AMBIENT TEMPERATURE (°C)

4162F G16

4000

DIE TEMPERATURE (°C)

25

0

4.0

PANEL CURRENT (A)

PANEL VOLTAGE (V)

1.4

PANEL

VOLTAGE

CHARGE CURRENT (A)

35

TA = 25°C, unless otherwise noted.

6000

4000

2000

24.9

25.0

25.1

25.2

die_temp (°C)

4162F G21

0

3.195

3.196

3.197

3.198

3.199

3.200

BATTERY CURRENT (A)

4162F G22

4162F G23

Rev A

For more information www.analog.com

9

�LTC4162-F

TYPICAL PERFORMANCE CHARACTERISTICS

Histogram of iin Readings

TA = 25°C, unless otherwise noted.

Histogram of vin Readings

4000

10000

σ = 1.62mA

σ = 3.57mV

7500

FREQUENCY

FREQUENCY

3000

2000

1000

0

1.035

5000

2500

1.040

1.045

1.050

1.055

1.060

0

12.00

INPUT CURRENT (A)

12.01

12.02

12.03

12.04

INPUT VOLTAGE (V)

4162F G24

4162F G25

PIN FUNCTIONS

BOOST (Pin 1): Gate-Drive bias for the high side switch in

the switching regulator. This pin provides a pumped bias

voltage relative to SW. The voltage on this pin is charged

up through an internal diode from INTVCC. A 22nF multilayer ceramic capacitor is required from SW to BOOST.

INTVCC (Pin 2): Bypass pin for the internal 5V regulator.

This regulator provides power to the internal analog circuitry. A 4.7µF multilayer ceramic capacitor is required

from INTVCC to GND.

VOUTA (Pin 3): Analog system power pin. VOUTA powers

the majority of circuits on the LTC4162. A 0.1µF multilayer

ceramic capacitor is required from VOUTA to GND.

CLN (Pin 4): Connection point for the negative terminal

of the sense resistor that measures and regulates input

current by limiting charge current.

CLP (Pin 5): Connection point for the positive terminal

of the sense resistor that measures and regulates input

current by limiting charge current.

INFET (Pin 6): Gate control output pin for an input reverse

blocking external N-channel MOSFET between VIN and

VOUT.

VIN (Pin 7): Supply voltage detection and INFET charge

pump supply for the INFET/BATFET PowerPath. When

voltage at VIN is detected as being high enough to charge a

battery, the INFET charge-pump is activated and the BATFET

charge-pump is deactivated thereby powering VOUTA from

the input supply through an external NMOS transistor and

also starting a charge cycle. A 0.1µF multilayer ceramic

capacitor is required from VIN to GND.

VCC2P5 (Pin 8): Bypass pin for the internal 2.5V regulator. This regulator provides power to the internal logic

circuitry. A 1µF multilayer ceramic capacitor is required

from VCC2P5 to GND.

NTCBIAS (Pin 9): NTC thermistor bias output. Connect a

low temperature coefficient bias resistor between NTCBIAS

and NTC, and a thermistor between NTC and GND. The

bias resistor should be equal in value to the nominal value

of the thermistor. The LTC4162 applies 1.2V to this pin

during NTC measurement and expects a thermistor β

value of 3490K. Higher β value thermistors can be used

with simple circuit modifications.

Rev A

10

For more information www.analog.com

�LTC4162-F

PIN FUNCTIONS

NTC (Pin 10): Thermistor input. The NTC pin connects to

a negative temperature coefficient thermistor to monitor

the temperature of the battery. The voltage on this pin

is digitized by the analog to digital converter to qualify

battery charging and is available for readout via the I2C

port. A low drift bias resistor is required from NTCBIAS

to NTC and a thermistor is required from NTC to ground.

RT (Pin 11): Switching regulator frequency control pin.

The RT pin controls the switching regulator's internal

oscillator frequency by placing a resistor from RT to GND.

SMBALERT (Pin 12): Interrupt output. This open drain

output pulls low when one or more of the programmable

alerts is triggered.

SCL (Pin 13): Open drain clock input for the I2C port. The

I2C port input levels are scaled with respect to DVCC for

I2C compliance.

SDA (Pin 14): Open drain data input/output for the I2C

port. The I2C port input levels are scaled with respect to

DVCC for I2C compliance.

DVCC (Pin 15): Logic supply for the I2C port. DVCC sets the

reference level of the SDA and SCL pins for I2C compliance. It should be connected to the same power supply

as the SDA and SCL pull up resistors.

SYNC (Pin 16): Optional external clock input for the switching battery charger. The switching battery charger will

lock to a square wave or pulse on this pin that is close to

the frequency programmed by the RT pin. Ground SYNC

if this feature is not needed.

CELLS0 (Pin 17): Cell count selection pin. Used in combination with CELLS1, this pin sets the total number of

series cells to be charged. The pin should be strapped to

either INTVCC, VCC2P5 or GND to represent one of three

possible states. See Table 5.

CELLS1 (Pin 18): Cell count selection pin. Used in combination with CELLS0, this pin sets the total number of

series cells to be charged. The pin should be strapped to

either INTVCC, VCC2P5 or GND to represent one of three

possible states. See Table 5.

BATSENS+ (Pin 19): Positive terminal battery sense pin.

BATSENS+ should Kelvin sense the positive terminal of the

battery for optimized charging. A 10µF multilayer ceramic

capacitor is required from BATSENS+ to ground.

CSN (Pin 20): Connection point for the negative terminal

of the current sense resistor used to measure and limit

charge current.

CSP (Pin 21): Connection point for the positive terminal

of the current sense resistor used to measure and limit

charge current.

BATFET (Pin 22): Gate control pin for a reverse blocking

external N-channel MOSFET between the battery and VOUT.

PGND (Pins 23,24): Power ground pins. These pins should

be connected to a copper pour that forms the return for

the VOUT bypass capacitor on the top layer of the printed

circuit board.

SW (Pin 25, 26): Switching regulator power transmission

pins. The SW pins deliver power from the VOUT pins to the

battery via the step-down switching regulator. An inductor

should be connected from SW to a sense resistor at CSP.

See the Applications Information section for a discussion

of inductor value and current rating.

VOUT (Pin 27, 28): Switching regulator input pins. The

VOUT pins deliver power to the switching charger. Having

extremely high frequency current pulses, bypassing of

the VOUT pins should take precedence over all other PCB

layout considerations. A bypass capacitor of 10µF is a

good starting point.

AGND (Exposed PAD, Pin 29): Analog ground pin. This

is the ground pin used to return all of the analog circuitry

inside the LTC4162 and should be connected to an analog

ground pour that is common with PGND (pins 23 and 24).

It should also be connected to a ground plane on layer 2

of the PCB to which all of the analog components return

such as the RT resistor and the INTVCC and VCC2P5 bypass capacitors.

Rev A

For more information www.analog.com

11

�LTC4162-F

BLOCK DIAGRAM

7

6

INTVCC

VIN

INFET

29R

CHARGE

PUMP

R

4

5

20

21

22

19

15

12

13

14

17

18

9

10

VINDIV

D/A

INTVCC

+

+

––

BOOST

VOUT

–

CLN

+

CLP

37.5

I_IN

D/A

CSN

VOUT

–

+

+–

SW

SWITCHING

REGULATOR

–

+

CSP

37.5

I_BAT

D/A

BATFET

INTVCC

–

+

SW

PGND

CHARGE

PUMP

PGND

BATSENS+

VBATDIV

–

PRESCALER

D/A

DVCC

OSCILLATOR

+

RT

SYNC

SMBALERT

1

28

27

26

25

24

23

11

16

I2C

SCL

SDA

CELLS0

VOUTA

LOGIC

CELLS1

29R

NTCBIAS

R

NTC

VBATDIV

INTVCC

2

2.5V LDO

VCC2P5

VREF

AGND

VOUTDIV

VINDIV

INTVCC LDO

VOUTDIV

1.2V

3

8

29

A/D

I_BAT

I_IN

T_DIE

4162F BD

Rev A

12

For more information www.analog.com

�LTC4162-F

ESD DIAGRAM

6

7

INFET

DVCC

SCL

VIN

SDA

3

4

5

VOUTA

SMBALERT

20

27

28

NTC

BATSENS+

26

23

24

1

8

9

10

11

CSP

CSN

VOUT

VOUT

SYNC

25

12

BATFET

RT

21

14

CLP

NTCBIAS

19

13

CLN

VCC2P5

22

15

SW

CELLS0

SW

CELLS1

PGND

INTVCC

16

17

18

2

PGND

BOOST

AGND

29

4162F ESD

Rev A

For more information www.analog.com

13

�LTC4162-F

TIMING DIAGRAM

SDA

tSU(DAT)

tSU(STA)

tHD(DAT)

tLOW

tBUF

tSU(STO)

tHD(STA)

SCL

tHD(STA)

tf

tf

tHIGH

START

CONDITION

tSP

REPEATED START

CONDITION

STOP

CONDITION

START

CONDITION

4162F TD

I2C SMBus Legend

S

Sr

Rd

Wr

A

N

P

PEC*

START CONDITION

REPEATED START CONDITION

READ (BIT VALUE OF 1)

WRITE (BIT VALUE OF 0)

ACKNOWLEDGE

NACK

STOP CONDITION

PACKET ERROR CODE

MASTER TO SLAVE

SLAVE TO MASTER

SMBus WRITE WORD PROTOCOL

S

SLAVE ADDRESS

Wr

A

COMMAND CODE

A

DATA BYTE LOW

A

DATA BYTE HIGH

A

DATA BYTE LOW

A

DATA BYTE HIGH

A

P

SMBus WRITE WORD WITH PEC PROTOCOL

S

SLAVE ADDRESS

Wr

A

COMMAND CODE

A

PEC*

A

P

SMBus READ WORD PROTOCOL

S

SLAVE ADDRESS

Wr

A

COMMAND CODE

A

Sr

SLAVE ADDRESS

Rd

A

DATA BYTE LOW

A

DATA BYTE HIGH

N

A

Sr

SLAVE ADDRESS

Rd

A

DATA BYTE LOW

A

DATA BYTE HIGH

A

P

SMBus READ WORD WITH PEC PROTOCOL

S

SLAVE ADDRESS

Wr

A

COMMAND CODE

PEC*

N

P

SMBus ALERT RESPONSE ADDRESS PROTOCOL

S

ALERT RESPONSE ADDRESS Rd

A

DEVICE ADDRESS

Rd

N

P

SMBus ALERT RESPONSE ADDRESS PROTOCOL WITH PEC

S

ALERT RESPONSE ADDRESS Rd

A

DEVICE ADDRESS

Rd

A

PEC*

N

P

*USE OF PACKET ERROR CHECKING IS OPTIONAL

Rev A

14

For more information www.analog.com

�LTC4162-F

OPERATION

Introduction

The LTC4162 is an advanced power manager and switching battery charger utilizing a high efficiency synchronous

step-down switching regulator.

Using multiple feedback control signals, power is delivered from the input to the battery by a 1.5MHz constantfrequency step-down switching regulator. The switching

regulator reduces output power in response to one of its

four regulation loops including battery voltage, battery

charge current, input current and input voltage.

The switching regulator is designed to efficiently transfer

power from a variety of possible sources, such as USB

ports, wall adapters and solar panels, to a battery while

minimizing power dissipation and easing thermal budgeting constraints. Since a switching regulator conserves

power, the LTC4162 allows the charge current to exceed

the source's output current, making maximum use of the

allowable power for battery charging without exceeding

the source's delivery specifications. By incorporating input

voltage and system current measurement and control

systems, the switching charger ports seamlessly to these

sources without requiring application software to monitor

and adjust system loads. By decoupling the system load

from the battery and prioritizing power to the system,

the instant-on PowerPath architecture ensures that the

system is powered upon input power arrival, even with a

completely dead battery.

Two low power charge pumps drive external MOSFETs to

provide low loss power paths from the input supply and

battery to the system load while preventing the system

node from back-driving the input supply or overcharging

the battery. The power path from the battery to the system

load guarantees that power is available to the system even

if there is insufficient or absent power from VIN. A wide

range of input current settings as well as battery charge

current settings are available by software control and by

choosing the values of input and charge current sense

resistors RSNSI and RSNSB.

A measurement subsystem periodically monitors and

reports on a large collection of system parameters via the

I2C port. An interrupt subsystem can be enabled to alert

the host microprocessor of various status change events

so that system parameters can be varied as needed. All

of the status change events are maskable for maximum

flexibility. For example, features such as battery presence

detection and battery impedance measurement are easily

enabled.

To eliminate battery drain between manufacture and sale,

a ship-and-store feature reduces the already low battery

drain current even further.

The input undervoltage control loop can be engaged to

keep the input voltage from decreasing beyond a minimum

level when a resistive cable or power limited supply such

as a solar panel is providing input power. A maximum

power point tracking algorithm using this control loop

can be deployed to maximize power extraction from solar

panels and other resistive sources.

Finally, the LTC4162 has a digital subsystem that provides

substantial adjustability so that power levels and status

information can be controlled and monitored via the

conventional I2C port.

LTC4162 Digital System Overview

The LTC4162 contains an advanced digital system which

can be accessed using the I2C port. Use of the I2C port

is optional, it can be used extensively in the application

or not at all, as dictated by the application requirements.

Cell count, charge current, input current regulation and

switching charger frequency are all externally configurable

without using the I2C port. For applications requiring the

LTC4162's advanced digital features, the I2C port provides

a means to use status and A/D telemetry data from the

measurement system, monitor charger operation, configure charger settings (e.g. charge voltage, charge current,

temperature response, termination algorithm, etc), enable,

disable, read and clear alerts, activate the low power ship

mode, and enable/disable the battery charger.

Power Path Controller

The LTC4162 features input and output N-channel MOSFET charge pump gate drivers. These drivers make up a

dual unidirectional power path system that allows power

to be delivered to the system load by either the input

supply or the battery, whichever is greater. Only one of

Rev A

For more information www.analog.com

15

�LTC4162-F

OPERATION

the external MOSFETs will be enabled at a time. If VIN is

more than 150mV above BATSENS+, the MOSFET from

the input to the system load will be enabled and the one

from the system load to BATSENS+ will block conduction

preventing overcharging of the battery. If VIN falls more

than 20mV below BATSENS+ the MOSFET from the input

supply to the system load will be disabled preventing

reverse conduction and the MOSFET from BATSENS+ to

the system load will be enabled powering downstream

circuitry from the battery. It is important not to back drive

VOUT as one or the other of the power path MOSFETs will

always be enabled.

Step Down Switching Battery Charger

The LTC4162’s battery charger is based on a very efficient

synchronous step down switching regulator. As with any

modern battery charger, the LTC4162 incorporates both

constant-current and constant-voltage feedback control

loops to prevent overcharging. The switching charger can

charge either a single cell or a battery of up to nine series

lithium iron phosphate cells.

Normal charging begins with a constant current until the

battery reaches its target voltage. The charge current is

determined by the combination of the sense resistor,

RSNSB, placed in series with the inductor and the servo

control voltage set by either icharge_jeita_2 through

icharge_jeita_6 with en_jeita set or just charge_current_setting if en_jeita is cleared. An internal soft-start

algorithm ramps up the charge current setting from zero

to its present setting. Once the battery voltage reaches the

programmed voltage limit the constant-current control

loop hands off to the constant-voltage control loop. The

final battery voltage is set with the combination of either

vcharge_jeita_2 through vcharge_jeita_6 with en_jeita

set or with just vcharge_setting if en_jeita is cleared. The

cell_count, controlled by the CELLS0 and CELLS1 pins,

is a charge voltage multiplier so that multiple series cells

can be charged.

If en_jeita is set, the charge current is given by the expression:

ICHARGE = (ich arg e _ jeita _ x + 1)

1mV

R SNSB

where icharge_jeita_2 through icharge_jeita_6 each range

from 0 to 31.

If en_jeita is not set:

ICHARGE = (ch arg e _ current _ setting + 1)

1mV

R SNSB

where charge_current_setting ranges from 0 to 31.

If en_jeita is set, the charge voltage is given by the expression:

VCHARGE = (3.4125V + 12.5mV • vcharge_jeita_x) •

cell_count

where vcharge_jeita_2 through vcharge_jeita_6 each

range from 0 to 31.

If en_jeita is not set:

VCHARGE = (3.4125V + 12.5mV • vcharge_setting) •

cell_count

where vcharge_setting ranges from 0 to 31.

Beyond the conventional constant-current and constantvoltage control loops, the LTC4162 also has the ability to

monitor and control both input current and input voltage,

regulating battery charge power based on any one of these

four control loops. Power limit is prioritized based on the

lowest set-point of the group. For example, if the combined

system load plus battery charge current is large enough

to cause the switching charger to reach the programmed

input current limit, the input current limit will reduce charge

current to limit the voltage across the input sense resistor,

RSNSI, to the iin_limit_target. Even if the charge current

is programmed to exceed the allowable input current, the

input current due to charge current will not be violated;

the charger will reduce its current as needed. Similarly,

the input voltage limit loop, controlled by input_undervoltage_setting, can be used to prevent resistive power

sources such as a solar panel from dragging the input

voltage down below its under-voltage lockout level.

Only target values can be programmed with the I2C port.

The LTC4162 uses the target values as a starting point from

which the charging algorithms calculate the actual values

to be applied to the DACs to support functions such as

Rev A

16

For more information www.analog.com

�LTC4162-F

OPERATION

temperature compensated charge voltages and currents,

maximum power point tracking, charger soft starting,

etc. The target value registers are read/write whereas the

actual DAC value registers, icharge_dac, vcharge_dac,

iin_limit_dac and input_undervoltage_dac are read only.

Due to its all NMOS switch design, a small charge pump

capacitor is required from SW to BOOST to provide high

side boosted drive for the top switch.

Input Current Regulation

Input current control limits loading on the input source

during periods of high system demand by sacrificing charge

current. Note that the LTC4162 only has the authority to

reduce charge current to zero and cannot further reduce

input current below the system load current. The input

current limit is controlled by a combination of the sense

resistor, RSNSI, from CLP to CLN and either the default

32mV servo voltage or a lower value set by iin_limit_target.

The servo voltage across the sense resistor divided by the

resistor's value determines the input current regulation

set point. A 10mΩ resistor, for example, would have an

upper input current limit of 3.2A using the default 32mV

servo voltage. iin_limit_target has 6 bit resolution giving

adjustable values from 500µV to 32mV in 500µV steps and

can be calculated in Amperes, by the following expression:

IINLIM = (iin _ limit _ t arg et + 1)

500μV

R SNSI

where iin_limit_target ranges from integer values of 0 to 63.

Input Undervoltage Regulation and Solar Panel

Maximum Power Point Tracking (MPPT)

The LTC4162 also contains an undervoltage control loop

that allows it to tolerate a resistive connection to the input

power source by automatically reducing charge current

as the VIN pin drops to input_undervoltage_setting. This

circuit helps prevent UVLO oscillations by linearly regulating the input voltage above the LTC4162's undervoltage

lockout level.

Optionally, the LTC4162 includes a maximum power

point tracking (MPPT) algorithm to find and track the

input_undervoltage_dac value that delivers the maximum

charge current to the battery. If mppt_en is set, the MPPT

algorithm performs a global sweep of input_undervoltage_dac values, measuring battery charge current at each

setting. Once the sweep is complete, the LTC4162 applies

the input_undervoltage_dac value corresponding to the

maximum battery charge current ibat (i.e. the maximum

power point). The LTC4162 then tracks small changes

in the maximum power point by slowly dithering the

input_undervoltage_dac. The LTC4162 performs a new

global sweep of input_undervoltage_dac values every

15 minutes, applies the new maximum power point, and

resumes dithering at that point. Alternatively, the global

sweep will run immediately, bypassing the 15 minute wait,

if ibat changes by more that 25%. With mppt_en, a solar

panel can be used as a suitable power source for charging a battery and powering a load. The MPPT algorithm

may not work for all solar panel applications and does not

have to be used. Alternatively a solar panel can be used

without the MPPT algorithm by setting the input_undervoltage_setting value to match the optimum loaded solar

panel voltage, but significant shadows or drops in light

will likely result in suboptimum power delivery.

Note that, due to the Power Path topology, current can flow

from the input to the system load without being controlled

by the LTC4162's switching charger. Therefore, the MPPT

algorithm does not have full authority to track and find

the maximum power point under all conditions. To obtain

complete Maximum Power Point operation, it may be

necessary to forgo the Power Path feature of the LTC4162

and connect the system load directly to the battery pack. In

this configuration, the LTC4162 has full authority to track

the maximum power point of the solar panel.

The input under voltage value, in Volts, will be given by

the following expression:

VINLIM = (input_undervoltage_setting + 1) • 140.625mV

where input_undervoltage_setting ranges from integer

values of 0 to 255.

Rev A

For more information www.analog.com

17

�LTC4162-F

OPERATION

System Controls

The switching battery charger can be disabled by setting

suspend_charger. This might be necessary, for instance, to

pass USB Suspend compliance testing. suspend_charger

should be used with caution as a low battery situation

could prevent the system processor from being able to

clear it and may require a factory service call to remove

and replace the battery.

its 16-bit signed two's complement results are stored in

registers accessible via the I2C port. The seven channels

measured by the ADC each take approximately 1.6ms to

convert. The maximum range of the 16 bit ΔΣ A/D converter is ±1.8V and it has an internal span term of 18191

counts per Volt. It measures each of the above parameters

through different paths giving different sensitivity terms

for each measurement as summarized in Table 1.

Battery Voltage Measurement

Input Overvoltage Protection

The LTC4162 has over-voltage detection on its input. If

VIN exceeds approximately 38.6V as indicated by vin_ovlo,

the switching charger will stop delivering power. The

charger will resume switching if VIN falls below roughly

37.2V. The overvoltage detection cutoff circuit provides

only modest over voltage protection and is not intended

to prevent damage in all circumstances.

Measurement Subsystem

The LTC4162 includes a 16-bit ΔΣ A/D converter and signal

multiplexer to monitor numerous analog parameters. It

can measure the voltages at vin, vbat and vout, the input

current (voltage between CLP and CLN), iin, the battery

charge current (voltage between CSP and CSN), ibat, the

battery pack thermistor_voltage, its own internal die_temp

and, once a charge cycle begins, the series resistance of

the battery, bsr. To save battery current, the measurement system is disabled if the battery is the only source

of power (vin_gt_vbat = 0). This can be overridden with

force_telemetry_on. The A/D converter is automatically

multiplexed between all of the measured channels and

Battery voltage is measured through a resistive voltage

divider whose attenuation ratio is based on the cell_count.

The result is reported in vbat. The divider ratio is BATSENS+/(3.5 • cell_count) making the A/D span term

3.5 • cell_count/18191 or 192.4µV • cell_count per LSB

where cell_count varies from 1 to 9. An alert may be

set on battery voltage by setting the vbat based value

vbat_lo_alert_limit or vbat_hi_alert_limit and setting

en_vbat_lo_alert or en_vbat_hi_alert. These alerts are

indicated by vbat_lo_alert or vbat_hi_alert and are cleared

by writing them to 0.

Input Voltage Measurement

Input voltage is measured through a 30:1 resistive voltage divider making the A/D span term for input voltage

measurements 30/18191 or 1.649mV/LSB and is digitized

to vin. An alert may be set on input voltage by setting the

value vin_lo_alert_limit or vin_hi_alert_limit and setting

en_vin_lo_alert or en_vin_hi_alert. These alerts are indicated by vin_lo_alert and vin_hi_alert and are cleared by

writing them to 0.

Table 1. Measurement Subsystem LSB Sizes

MEASUREMENT

UNITS

REGISTER SYMBOL

LSB SIZE

BATTERY VOLTAGE

V

vbat

192.4µV • cell_count

INPUT VOLTAGE

V

vin

1.649mV

OUTPUT VOLTAGE

V

vout

INPUT CURRENT

A

iin

1.466µV/RSNSI

BATTERY CURRENT

A

ibat

1.466µV/RSNSB

DIE TEMPERATURE

°C

die_temp

BATTERY IMPEDANCE

Ω

bsr

THERMISTOR VOLTAGE

V

thermistor_voltage

OFFSET

1.653mV

0.0215°C

264.4°C

RSNSB • cell_count/500

45.833µV/V

Rev A

18

For more information www.analog.com

�LTC4162-F

OPERATION

VOUT Voltage Measurement

Output voltage is measured through a 30.07:1 resistive

voltage divider making the A/D span term for system voltage measurements 30.07/18191 or 1.653mV/LSB and is

digitized to vout. An alert may be set on output voltage by

setting the value vout_lo_alert_limit or vout_hi_alert_limit

and setting en_vout_lo_alert or en_vout_hi_alert. These

alerts are indicated by vout_lo_alert and vout_hi_alert and

are cleared by writing them to 0.

Battery Current Measurement

Battery current is measured with a current sense resistor

between the CSP and CSN pins. An amplifier with a gain of

37.5 amplifies this signal and refers it to ground internally

so that the A/D converter can measure it. The sensed battery current is therefore given by IBAT • RSNSB • 37.5. For

a 10mΩ RSNSB current sense resistor, the A/D sensitivity

is 1/(18191 • 10mΩ • 37.5) or 146.6µA/LSB. The battery

current measurement system has a built in commutator.

While charging a battery, two's complement number ibat

will be positive representing current into the battery. When

the battery charger is disabled or terminated, as detected

by charger_suspended, the commutator is activated and

ibat will be negative, representing current out of the battery. An alert may be set on the ibat measurement by

setting the desired value in ibat_lo_alert_limit and setting

en_ibat_lo_alert. While charging, ibat_lo_alert_limit can

be used to detect when the charge current has dropped

below a given threshold. When charger_suspended, if set

to a negative number, ibat_lo_alert_limit can be used to

detect if the battery load has exceeded a given threshold.

This alert is indicated by ibat_lo_alert and is cleared by

writing it to 0.

Input Current Measurement

Input current is measured with a current sense resistor

between the CLP and CLN pins. An amplifier with a gain of

37.5 amplifies this signal and refers it to ground internally

so that the A/D converter can measure it. The sensed

input current is therefore given by IIN • RSNSI • 37.5. For

a 10mΩ RSNSI current sense resistor, the A/D sensitivity

is 1/(18191 • 10mΩ • 37.5) or 146.6µA/LSB. The input

current is digitized to iin. An upper limit alert may be set

on input current by setting the value iin_hi_alert_limit

and setting the en_iin_hi_alert. This alert is indicated by

iin_hi_alert and is cleared by writing it to 0.

Battery Series Resistance (BSR) Measurement

The LTC4162 can optionally measure the series resistance

of the battery stack or cell. If run_bsr is set, the LTC4162

momentarily suspends the battery charger and calculates

the battery series resistance by dividing the voltage change

(charging vs not charging) by the measured charge current

(bsr_charge_current).

The per-cell resistance value is reported in bsr and the

charge current observed during the measurement is reported in bsr_charge_current. The LTC4162 automatically

resets run_bsr after the bsr measurement is complete.

The total battery series resistance value is proportional to

the charge current sense resistor, RSNSB, as well as the

cell_count, and can be computed in Ω from the expression:

RBAT (Ω) =

bsr • cell _ count • R SNSB

500

Higher bsr_charge_current during a bsr measurement

results in a more accurate bsr measurement. Very low

values of bsr_charge_current may adversely impact the

accuracy of the bsr measurement. If charge current is

less than C/10 (bsr_charge_current < icharge_over_10),

bsr_questionable will be set indicating that bsr_charge_

current during the bsr test was less than optimum for an

accurate reading. Recall that full charge current typically

flows at the beginning of a charge cycle (presuming the

battery is more deeply depleted) and will diminish when

the charger enters the constant voltage phase of charging.

If run_bsr is set to 1 and the battery charger is not currently

running, then the LTC4162 will be queued to perform the

bsr measurement only after the start of the next charge

cycle. An alert can be set with en_bsr_done_alert to

generate a bsr_done_alert interrupt indicating that a bsr

measurement is complete and that the result is available. A

bsr_hi_alert may also be set on battery series impedance

by writing a bsr_hi_alert_limit and setting en_bsr_hi_alert.

Again, the bsr reading is the per-cell battery resistance

and should be scaled by cell_count or, consequently, the

Rev A

For more information www.analog.com

19

�LTC4162-F

OPERATION

target total resistance threshold for bsr_hi_alert_limit

should be divided by cell_count before being written to

bsr_hi_alert_limit.

bsr_done_alert and bsr_hi_alert are cleared by writing

them to 0.

Die Temperature Measurement

The LTC4162 has an integrated die temperature sensor

that is monitored by the A/D converter and is digitized to

die_temp. The die temperature is derived from an internal

circuit and follows the equation:

TDIE(°C) = die_temp • 0.0215°C/LSB – 264.4°C

An alert may be set on die temperature by setting the value

die_temp_hi_alert_limit and setting en_die_temp_hi_alert.

This alert is indicated by die_temp_hi_alert and is cleared

by writing it to 0.

To set the die_temp_hi_alert_limit, compute the threshold

value from:

T (°C ) +264.4°C

die _ temp _ hi _ alert _ limit = DIE

0.0215°C/LSB

either during the battery detection test or during charging, charger_state will switch to bat_missing_fault and

charging will halt. Either a thermistor_voltage_lo_alert or

thermistor_voltage_hi_alert may be set with en_thermistor_voltage_lo_alert or en_thermistor_voltage_hi_alert,

both of which are cleared by writing them to 0.

The temperature vs resistance curve of a thermistor can

be obtained from thermistor manufacturers in either table

form or estimated by applying the modified Steinhart-Hart

equation:

(A+

RNTC = R 25 • e

Where R25 is the thermistor's resistance at 25°C and A,

B, C and D are provided by the thermistor manufacturer

and TC is the temperature in °C.

The temperature of the thermistor is computed from its

resistance value by the complementary Steinhart-Hart

expression where A1, B1, C1 and D1 are also provided

by the thermistor manufacturer.

TC =

Battery Temperature (NTC Thermistor) Measurement

To measure the battery temperature using a thermistor,

connect the thermistor, RNTC, normally being located in

the battery pack, between the NTC pin and ground, and a

low drift bias resistor, RNTCBIAS, between NTCBIAS and

NTC. RNTCBIAS should be a 1% or better resistor with a

value equal to the value of the chosen thermistor at 25°C

(R25). The LTC4162 applies an excitation voltage of 1.2V to

RNTCBIAS to measure the thermistor value. The thermistor

measurement result is available at thermistor_voltage. To

minimize battery stress due to charging at temperature

extremes, the LTC4162 has both a simple and a more

advanced JEITA (Japan Electronics and Information

Technology Industries Association) temperature qualified

charging algorithm. If the application does not require temperature controlled charging, then the thermistor should be

replaced with a resistor of equal value to the bias resistor

RNTCBIAS to continuously simulate 25°C. If the thermistor is

found to be open (thermistor_voltage > open_thermistor)

B

C

D

+

+

)

TC +273.15 (T +273.15)2 (T +273.15)3

C

C

1

A 1 +B1 ln(

RNTC

R 25

2

) + C1 ln (

RNTC

R 25

3

) + D1 ln (

RNTC

R 25

−273.15o C

(1)

)

Alternatively, the more common but less accurate condensed version of Steinhart-Hart using the ubiquitous β

parameter may be employed:

RNTC = R 25 • e

−β25/85 (

1

1

−

)

o

298.15 C TC +273.15 o C

Where again, R25 is the thermistor's resistance at 25°C

and several β values are provided by the thermistor manufacturer, one for each of a number of temperature ranges.

The inverse β form is:

TC =

β 25/85

– 273.15o C

RNTC

β 25/85

ln(

)+

R 25

298.15 o C

(2)

Rev A

20

For more information www.analog.com

�LTC4162-F

OPERATION

The LTC4162 thermistor measurement system is designed

specifically for a thermistor with a β25/85 value of 3490K

and returns thermistor_voltage where:

thermistor _ voltage = 18191• 1.2 •

RNTC

RNTC +RNTCBIAS

where typically RNTCBIAS is set equal to R25, the 25°C value

of the thermistor. To arrive at the thermistor's temperature

in °C from thermistor_voltage substitute RNTC from:

RNTC = RNTCBIAS •

thermistor_ voltage

18191• 1.2 − thermistor_ voltage

into Equation 1 or Equation 2.

For thermistors with a β25/85 value higher than 3490K

see Alternate Thermistors and Biasing in the Applications

section.

Output Current Measurement

There is no sense resistor dedicated to measuring output

current but its value can be obtained nonetheless. Output

current is delivered from the input supply if vin_gt_vbat

is true and from the battery if it is false.

If vin_gt_vbat is true and the battery charger is enabled

(en_chg is true) then the input current measurement will

be the sum of current to the switching charger and the

output load. In this instance the switching charger will

need to be disabled with suspend_charger to obtain an

output current reading. It's also possible that the charger

may already be terminated. If en_chg is false then set

telemetry_speed to tel_high_speed, wait 20ms or more,

and record iin as output current. If en_chg is true then set

both suspend_charger and force_telemetry_on to 1 and

telemetry_speed to tel_high_speed, wait 20ms or more

for at least one telemetry cycle, and again record iin as

output current. suspend_charger should then be cleared.

Note that suspending the charger resets the tchargetimer

and tcvtimer termination timers to 0.

On the other hand if vin_gt_vbat is false then the output

current will be delivered from the battery and its value can be

obtained from –ibat. Since vin_gt_vbat is low, the telemetry

system will be disabled and the ibat reading will be stale.

To enable the telemetry system, set force_telemetry_on to

1 and telemetry_speed to tel_high_speed. telemetry_valid

indicates when fresh telemetry readings are available. To

avoid polling for telemetry_valid a telemetry_valid_alert

can be set with en_telemetry_valid_alert. Once the reading is obtained, force_telemetry_on can be cleared or

telemetry_speed set to tel_low_speed for power savings.

Low Power Telemetry

If input power is available (vin_gt_vbat = 1), and the battery

is being charged, the telemetry system will be in its high

speed mode returning results at a rate of roughly once

per 11ms. If, on the other hand, charging has terminated

normally or paused due to battery temperature out of

range, the telemetry system will drop back to a rate of

about once every 5 seconds to save power. When input

power is not available (vin_gt_vbat = 0) it is still possible

to collect telemetry data by setting force_telemetry_on. To

save power in this mode the telemetry system will default

to the lower speed 5 second mode. To force the higher

telemetry rate, and suffer the higher quiescent current

of roughly 2.5mA, the telemetry_speed can be set to the

higher ~11ms rate by setting it to tel_high_speed.

Configurable Limit Alert Subsystem

The I2C port also supports the SMBus SMBALERT protocol, including the Alert Response Address. An alert can

optionally be generated if a monitored parameter exceeds

a programmed limit or if a selected battery charger_state

or any of a wide number of other charge_status change or

fault events occur. This off-loads much of the continuous

monitoring from the system's microcontroller and onto the

LTC4162; reducing bus traffic and microprocessor load.

The SMBALERT pin is asserted (pulled low) whenever

an enabled alert occurs. After asserting an interrupt, the

LTC4162 responds to the host's Alert Response Address

(ARA = 0b0001100[1]) with its own read address. If another part with a pending alert and a lower address also

responds, that part wins the arbitration and the LTC4162

will stop responding to this ARA, keeping its SMBALERT

pin asserted. Only a response of the LTC4162's complete

read address will clear the LTC4162's SMBALERT signal.

Rev A

For more information www.analog.com

21

�LTC4162-F

OPERATION

Table 2. Summary of Limit Alerts Registers

ALERT VALUE SETTING (0x01 – 0x0C)

EN_LIMIT_ALERTS_REG

LIMIT_ALERTS_REG

vin_hi_alert_limit

en_vin_hi_alert

vin_hi_alert

vin_lo_alert_limit

en_vin_lo_alert

vin_lo_alert

thermistor_voltage_hi_alert_limit

en_thermistor_voltage_hi_alert

thermistor_voltage_hi_alert

thermistor_voltage_lo_alert_limit

en_thermistor_voltage_lo_alert

thermistor_voltage_lo_alert

bsr_hi_alert_limit

en_bsr_hi_alert

bsr_hi_alert

die_temp_hi_alert_limit

en_die_temp_hi_alert

die_temp_hi_alert

ibat_lo_alert_limit

en_ibat_lo_alert

ibat_lo_alert

iin_hi_alert_limit

en_iin_hi_alert

iin_hi_alert

vout_hi_alert_limit

en_vout_hi_alert

vout_hi_alert

vout_lo_alert_limit

en_vout_lo_alert

vout_lo_alert

vbat_hi_alert_limit

en_vbat_hi_alert

vbat_hi_alert

vbat_lo_alert_limit

en_vbat_lo_alert

vbat_lo_alert

NA

en_bsr_done_alert

bsr_done_alert

NA

en_telemetry_valid_alert

telemetry_valid_alert

CHARGER_STATE_REG

EN_CHARGER_STATE_ALERTS_REG

CHARGER_STATE_ALERTS_REG

bat_detect_failed_fault

en_bat_detect_failed_fault_alert

bat_detect_failed_fault_alert

Table 3. Summary of Charger State Alerts

battery_detection

en_battery_detection_alert

battery_detection_alert

charger_suspended

en_charger_suspended_alert

charger_suspended_alert

cc_cv_charge

en_cc_cv_charge_alert

cc_cv_charge_alert

ntc_pause

en_ntc_pause_alert

ntc_pause_alert

timer_term

en_timer_term_alert

timer_term_alert

c_over_x_term

en_c_over_x_term_alert

c_over_x_term_alert

max_charge_time_fault

en_max_charge_time_alert

max_charge_time_fault_alert

bat_missing_fault

en_bat_missing_fault_alert

bat_missing_fault_alert

bat_short_fault

en_bat_short_fault_alert

bat_short_fault_alert

CHARGE_STATUS_REG

EN_CHARGE_STATUS_ALERTS_REG

CHARGE_STATUS_ALERTS_REG

constant_voltage

en_constant_voltage_alert

constant_voltage_alert

Table 4. Summary of Charger Status Alerts

constant_current

en_constant_current_alert

constant_current_alert

iin_limit_active

en_iin_limit_active_alert

iin_limit_active_alert

vin_uvcl_active

en_vin_uvcl_active_alert

vin_uvcl_active_alert

thermal_reg_active

en_thermal_reg_active_alert

thermal_reg_active_alert

ilim_reg_active

en_ilim_reg_active_alert

ilim_reg_active_alert

Rev A

22

For more information www.analog.com

�LTC4162-F

OPERATION

This allows the system to have many parts share a common

interrupt line. If multiple parts are asserting the SMBALERT

signal then multiple reads from the ARA are needed. For

more information refer to the SMBus specification.

After the ARA process is complete, alert bits can be cleared

by individually writing them to 0 and writing the remaining

bits in the register to 1. This preserves any other pending

alert bits as writing 1s to the alert registers are ignored.

Series Cell Count Selection

Cell count selection of up to eight series cells is made via

the CELLS1 and CELLS0 pins. CELLS1 and CELLS0 should

be pin strapped to either GND, VCC2P5, or INTVCC to make

the cell_count selection (see Table 5). For added safety,

cell_count can be read back from the I2C port. The GND/

GND combination will result in a cell_count_err and will

inhibit charging. Note that the number of cells multiplied

by their expected maximum cell voltage during charging

cannot exceed VIN – VIN_DUVLO.

Table 5. CELLS0 and CELLS1 Pin Mapping to Series Cell Count

CELLS1

CELLS0

cell_count

INTVCC

INTVCC

1

INTVCC

VCC2P5

2

INTVCC

GND

3

VCC2P5

INTVCC

4

VCC2P5

VCC2P5

5

VCC2P5

GND

6

GND

INTVCC

7

GND

VCC2P5

8

GND

GND

9

When charging stacks of two or more cells in series it is

important to consult with the battery manufacturer to ascertain requirements pertaining to cell balancing. Repeatedly

charging series stacks of cells without balancing is usually

degenerative and typically leads to increased mismatch

accompanied with shorter battery life. For high reliability

applications an auxiliary battery balancer is recommended.

Battery Detection

The LTC4162 begins a charging cycle by performing a 2-4

second battery detection test, during which a 1mA load is

drawn from the battery followed by a small charge current

being sent to the battery. If the battery voltage remains

stable during the battery detection test, the LTC4162

proceeds with battery charger soft-start. If the battery

voltage does not remain stable, the LTC4162 proceeds

with a battery open/short test. The battery is charged at

minimum charge current for one to two seconds. Abnormal results from the battery detection test result in charger_state becoming bat_missing_fault, bat_short_fault or

bat_detect_failed_fault and will prevent further charging.

A charger_state of bat_missing_fault will also occur if

the thermistor is open or has a very high value (thermistor_voltage > open_thermistor). Programmable interrupts

en_bat_short_fault_alert, en_bat_missing_fault_alert and

en_bat_detect_failed_fault_alert can be set to generate an

SMBALERT if one of these cases occurs. In the event of a

battery detection fault, the battery detection test will retry

every 30 seconds.

Battery Charger Soft-Start

The LTC4162 soft starts charge current by ramping icharge_dac from 0 to its target charge current setting at a

nominal rate of 400µS per icharge_dac LSB. This results

in a maximum charge current soft start time of 31 • 400µs

or 12.4ms. Any time the battery charger needs to change

its charge current setting up or down, the ramp routine is

invoked. The charge current target is derived from either

charge_current_setting or the JEITA temperature qualified

charging system, icharge_jeita_2 through icharge_jeita_6

(See Advanced JEITA Temperature Controlled Charging).

Low Battery

If the BATSENS+ pin voltage is lower than about 2.5V,

the battery charger delivers roughly 10mA directly from

INTVCC. This operating mode is mainly used to pull a

pack protected battery out of protection mode. When the

BATSENS+ pin voltage reaches 2.5V, charging hands over

to the switching battery charger and proceeds to the full

constant-current/constant-voltage charging phase reporting cc_cv_charge.

Rev A

For more information www.analog.com

23

�LTC4162-F

OPERATION

Constant-Current Charging

Constant-Voltage Charging

The charger will attempt to deliver either (icharge_

jeita_x + 1) • 1mV/RSNSB with en_jeita or (charge_current_setting + 1) • 1mV/RSNSB without en_jeita in constantcurrent mode where icharge_jeita_x or charge_current_

setting ranges from 0 to 31. For example, A 10mΩ resistor

between CPS and CSN would give an upper limit charge

current of 3.2A. Depending on available input power and

external load conditions, the battery charger may not be

able to charge at the full programmed rate. An alternate

control loop such as the input current limit loop or input

voltage limit loop may be in force and only partial power

will be available to charge the battery. If input current limit

is reached, for instance, the system load will be prioritized

over the battery charge current. When system loads are

light, battery charge current will be maximized and could

be as high as the value programmed by icharge_jeita_x