LTM4609

36VIN, 34VOUT High Efficiency

Buck-Boost DC/DC

µModule Regulator

Description

Features

Single Inductor Architecture Allows VIN Above,

Below or Equal to VOUT

n Wide V Range: 4.5V to 36V

IN

n Wide V

OUT Range: 0.8V to 34V

n I

OUT : 4A DC (10A DC in Buck Mode)

n Up to 98% Efficiency

n Current Mode Control

n Power Good Output Signal

n Phase-Lockable Fixed Frequency: 200kHz to 400kHz

n Ultrafast Transient Response

n Current Foldback Protection

n Output Overvoltage Protection

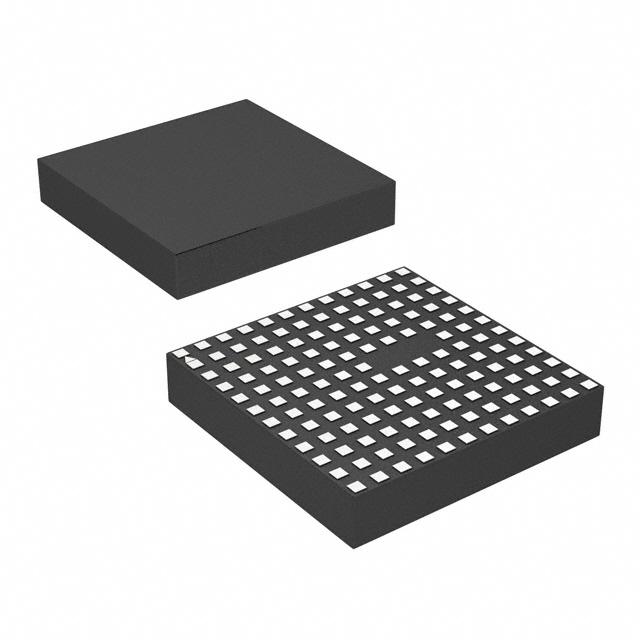

n Small Surface Mount Footprint, Low Profile

(15mm × 15mm × 2.82mm) LGA and

(15mm × 15mm × 3.42mm) BGA Packages

n SnPb (BGA) or RoHS Compliant (LGA and BGA)

Finish

The LTM®4609 is a high efficiency switching mode buckboost power supply. Included in the package are the

switching controller, power FETs and support components.

Operating over an input voltage range of 4.5V to 36V, the

LTM4609 supports an output voltage range of 0.8V to

34V, set by a resistor. This high efficiency design delivers

up to 4A continuous current in boost mode (10A in buck

mode). Only the inductor, sense resistor, bulk input and

output capacitors are needed to finish the design.

n

The low profile package enables utilization of unused space

on the bottom of PC boards for high density point of load

regulation. The high switching frequency and current

mode architecture enable a very fast transient response

to line and load changes without sacrificing stability. The

LTM4609 can be frequency synchronized with an external

clock to reduce undesirable frequency harmonics.

Fault protection features include overvoltage and foldback

current protection. The DC/DC µModule® regulator is offered in small 15mm × 15mm × 2.82mm LGA and 15mm

× 15mm × 3.42mm BGA packages. The LTM4609 is available with SnPb (BGA) or RoHS compliant terminal finish.

Applications

Telecom, Servers and Networking Equipment

Industrial and Automotive Equipment

n High Power Battery-Operated Devices

n

n

L, LT, LTC, LTM, Linear Technology, the Linear logo, µModule, Burst Mode and PolyPhase are

registered trademarks and No RSENSE is a trademark of Linear Technology Corporation. All other

trademarks are the property of their respective owners.

Typical Application

Efficiency and Power Loss

vs Input Voltage

30V/2A Buck-Boost DC/DC µModule Regulator with 6.5V to 36V Input

VIN

RUN

PLLIN V

OUT

FCB

LTM4609

10µF

50V

5.6µH

+

330µF

50V

VOUT

30V

2A

SW1

SW2

RSENSE

SENSE+

0.1µF

SS

SGND

SENSE–

PGND

R2

15mΩ

×2

VFB

98

4609 TA01a

5

97

4

96

95

3

94

2

93

92

91

2.74k

6

POWER LOSS (W)

ON/OFF

99

CLOCK SYNC

10µF

50V

EFFICIENCY (%)

VIN

6.5V TO 36V

EFFICIENCY

POWER LOSS

8

12

16

24

20

VIN (V)

28

32

36

1

0

4609 TA01b

4609ff

For more information www.linear.com/LTM4609

1

�LTM4609

Absolute Maximum Ratings

(Note 1)

VIN.............................................................. –0.3V to 36V

VOUT.............................................................. 0.8V to 36V

INTVCC, EXTVCC, RUN, SS, PGOOD............... –0.3V to 7V

SW1, SW2 (Note 7)....................................... –5V to 36V

VFB............................................................. –0.3V to 2.4V

COMP........................................................... –0.3V to 2V

FCB, STBYMD........................................ –0.3V to INTVCC

PLLIN......................................................... –0.3V to 5.5V

Pin Configuration

TOP VIEW

PLLFLTR..................................................... –0.3V to 2.7V

INTVCC................................................................. –40mA

Operating Temperature Range (Note 2)

E- and I-grades.....................................–40°C to 85°C

MP-grade............................................ –55°C to 125°C

Junction Temperature............................................ 125°C

Storage Temperature Range....................–55°C to 125°C

Solder Temperature (Note 3).................................. 245°C

(See Table 6 Pin Assignment)

TOP VIEW

SW2

(BANK 2)

M

M

L

L

SW1

(BANK 4)

VOUT

(BANK 5)

INTVCC

EXTVCC

PGND

(BANK 6)

PGOOD

VFB

SW2

(BANK 2)

VIN

(BANK 1)

K

SW1

(BANK 4)

J

J

H

H

VOUT

(BANK 5)

RSENSE

(BANK 3)

G

INTVCC

EXTVCC

F

F

E

E

D

PGND

(BANK 6)

B

COMP

PLLFLTR

PLLIN

SENSE – SS SGND RUN FCB

A

1

2

3

4

5

6

7

8

9

SENSE+

10

11

PGOOD

VFB

RSENSE

(BANK 3)

G

D

C

VIN

(BANK 1)

K

C

B

COMP

PLLFLTR

PLLIN

SENSE – SS SGND RUN FCB

A

1

12

2

3

4

5

6

7

8

SENSE+

STBYMD

9

10

11

12

STBYMD

BGA PACKAGE

141-LEAD (15mm × 15mm × 3.42mm)

LGA PACKAGE

141-LEAD (15mm × 15mm × 2.82mm)

TJMAX = 125°C, θJA = 11.4°C/W, θJCtop = 15°C/W, θJCbottom = 4°C/W, WEIGHT = 1.7g

TJMAX = 125°C, θJA = 11.4°C/W, θJCtop = 15°C/W, θJCbottom = 4°C/W, WEIGHT = 1.5g

Order Information

PART NUMBER

PAD OR BALL FINISH

PART MARKING*

DEVICE

FINISH CODE

PACKAGE

TYPE

MSL

RATING

TEMPERATURE RANGE

(Note 2)

LTM4609EV#PBF

Au (RoHS)

LTM4609V

e4

LGA

3

–40°C to 85°C

LTM4609IV#PBF

Au (RoHS)

LTM4609V

e4

LGA

3

–40°C to 85°C

LTM4609MPV#PBF

Au (RoHS)

LTM4609V

e4

LGA

3

–55°C to 125°C

LTM4609EY#PBF

SAC305 (RoHS)

LTM4609Y

e1

BGA

3

–40°C to 85°C

LTM4609IY#PBF

SAC305 (RoHS)

LTM4609Y

e1

BGA

3

–40°C to 85°C

LTM4609IY

SnPb (63/37)

LTM4609Y

e0

BGA

3

–40°C to 85°C

LTM4609MPY #PBF

SAC305 (RoHS)

LTM4609Y

e1

BGA

3

–55°C to 125°C

LTM4609MPY

SnPb (63/37)

LTM4609Y

e0

BGA

3

–55°C to 125°C

Consult Marketing for parts specified with wider operating temperature

ranges. *Device temperature grade is indicated by a label on the shipping

container. Pad or ball finish code is per IPC/JEDEC J-STD-609.

• Recommended LGA and BGA PCB Assembly and Manufacturing

Procedures:

www.linear.com/umodule/pcbassembly

• Pb-free and Non-Pb-free Part Markings:

www.linear.com/leadfree

• LGA and BGA Package and Tray Drawings:

www.linear.com/packaging

4609ff

2

For more information www.linear.com/LTM4609

�LTM4609

Electrical Characteristics

The l denotes the specifications which apply over the specified operating

temperature range (Note 2), otherwise specifications are at TA = 25°C, VIN = 12V, per typical application (front page) configuration.

SYMBOL

PARAMETER

Input Specifications

VIN(DC)

Input DC Voltage

VIN(UVLO)

Undervoltage Lockout Threshold

IQ(VIN)

CONDITIONS

l

VIN Falling (–40°C to 85°C)

VIN Falling (–55°C to 125°C)

Input Supply Bias Current

Normal

Standby

Shutdown Supply Current

Output Specifications

Output Continuous Current Range

IOUTDC

(Note 3)

Load Regulation Accuracy

VCOMP = 1.2V to 0.7V

VCOMP = 1.2V to 1.8V (Note 4)

Turn-On Time

M3 tf

Turn-Off Time

M2, M4 tr

Turn-On Time

M2, M4 tf

Turn-Off Time

t1d

M1 Off to M2 On Delay

t2d

M2 Off to M1 On Delay

t3d

M3 Off to M4 On Delay

t4d

M4 Off to M3 On Delay

Mode Transition 1

M2 Off to M4 On Delay

Mode Transition 2

M4 Off to M2 On Delay

M1 RDS(ON)

Static Drain-to-Source

On-Resistance

Static Drain-to-Source

M2 RDS(ON)

On-Resistance

Static Drain-to-Source

M3 RDS(ON)

On-Resistance

Static Drain-to-Source

M4 RDS(ON)

On-Resistance

Oscillator and Phase-Locked Loop

fNOM

Nominal Frequency

fLOW

Lowest Frequency

36

4

4.5

V

V

V

60

mA

mA

µA

10

4

ΔVFB/VFB(LOAD)

M3 tr

3.4

3.4

4.5

l

l

VIN = 32V, VOUT = 12V

VIN = 6V, VOUT = 12V

VIN = 4.5V to 36V, VCOMP = 1.2V (Note 4)

Turn-Off Time

MAX

2.8

1.6

35

Line Regulation Accuracy

M1 tf

TYP

VRUN = 0V, VSTBYMD > 2V

VRUN = 0V, VSTBYMD = Open

ΔVFB/VFB(NOM)

Switch Section (Note 5)

M1 tr

Turn-On Time

MIN

l

l

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Drain to Source Voltage VDS = 12V,

Bias Current ISW = 10mA

Bias Current ISW = 3A

UNITS

A

A

0.002

0.02

%/V

0.15

–0.15

0.5

–0.5

%

%

50

ns

40

ns

25

ns

20

ns

20

ns

20

ns

50

ns

50

ns

50

ns

50

ns

220

ns

220

ns

10

mΩ

Bias Current ISW = 3A

14

20

mΩ

Bias Current ISW = 3A

14

20

mΩ

Bias Current ISW = 3A

14

20

mΩ

300

200

330

220

kHz

kHz

VPLLFLTR = 1.2V

VPLLFLTR = 0V

260

170

4609ff

For more information www.linear.com/LTM4609

3

�LTM4609

Electrical

Characteristics

The

l denotes the specifications which apply over the specified operating

temperature range (Note 2), otherwise specifications are at TA = 25°C, VIN = 12V, per typical application (front page) configuration.

SYMBOL

fHIGH

RPLLIN

IPLLFLTR

PARAMETER

Highest Frequency

PLLIN Input Resistance

Phase Detector Output Current

CONDITIONS

VPLLFLTR = 2.4V

Control Section

VFB

Feedback Reference Voltage

VCOMP = 1.2V(–40°C to 85°C)

VCOMP = 1.2V (–55°C to 125°C)

TYP

400

50

–15

15

MAX

440

UNITS

kHz

kΩ

µA

µA

0.792

0.785

1

0.8

0.8

1.6

–1.7

0.7

1.25

0.8

–0.2

5.3

0.808

0.815

2.2

–1

0.84

–0.1

5.5

V

V

V

µA

V

V

V

µA

V

99

99

200

250

%

%

ns

99.5

100

100.5

kΩ

l

l

5.7

5.56

6.3

6.35

2

l

5.4

6

6

0.3

5.6

300

60

V

V

%

V

mV

mV

160

–130

–6

–380

190

–150

mV

mV

mV

µA

7.5

–7.5

2.5

0.2

10

–10

%

%

%

V

µA

fPLLIN < fOSC

fPLLIN > fOSC

RUN Pin ON/OFF Threshold

Soft-Start Charging Current

Start-Up Threshold

Keep-Active Power On Threshold

Forced Continuous Threshold

Forced Continuous Pin Current

Burst Inhibit (Constant Frequency)

Threshold

Maximum Duty Factor

DF(BOOST, MAX)

DF(BUCK, MAX)

Maximum Duty Factor

tON(MIN, BUCK)

Minimum On-Time for Synchronous

Switch in Buck Operation

RFBHI

Resistor Between VOUT and VFB Pins

Internal VCC Regulator

INTVCC

Internal VCC Voltage

VRUN

ISS

VSTBYMD(START)

VSTBYMD(KA)

VFCB

IFCB

VBURST

Internal VCC Load Regulation

ΔVLDO/VLDO

VEXTVCC

EXTVCC Switchover Voltage

EXTVCC Switchover Hysteresis

ΔVEXTVCC(HYS)

EXTVCC Switch Drop Voltage

ΔVEXTVCC

Current Sensing Section

VSENSE(MAX)

Maximum Current Sense Threshold

VSENSE(MIN, BUCK)

ISENSE

PGOOD

ΔVFBH

ΔVFBL

ΔVFB(HYS)

VPGL

IPGOOD

MIN

340

l

l

VRUN = 2.2V

VSTBYMD Rising

VSTBYMD Rising, VRUN = 0V

0.4

0.76

–0.3

VFCB = 0.85V

Measured at FCB Pin

% Switch M4 On

% Switch M1 On

Switch M1 (Note 6)

VIN = 12V, VEXTVCC = 5V

VIN = 7V, VEXTVCC = 5V

ICC = 0mA to 20mA, VEXTVCC = 5V

ICC = 20mA, VEXTVCC Rising

ICC = 20mA, VEXTVCC = 6V

Minimum Current Sense Threshold

Sense Pins Total Source Current

Boost Mode

Buck Mode

Discontinuous Mode

VSENSE– = VSENSE+ = 0V

PGOOD Upper Threshold

PGOOD Lower Threshold

PGOOD Hysteresis

PGOOD Low Voltage

PGOOD Leakage Current

VFB Rising

VFB Falling

VFB Returning

IPGOOD = 2mA

VPGOOD = 5V

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LTM4609 is tested under pulsed load conditions such that

TJ ≈ TA. The LTM4609E is guaranteed to meet performance specifications

from 0°C to 85°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls. The LTM4609I is guaranteed over

the –40°C to 85°C operating temperature range. The LTM4609MP is

guaranteed and tested over the –55°C to 125°C operating temperature

l

l

–95

5.5

–5.5

150

0.3

1

range. For output current derating at high temperature, please refer to

Thermal Considerations and Output Current Derating discussion.

Note 3: See output current derating curves for different VIN, VOUT, and TA.

Note 4: The LTM4609 is tested in a feedback loop that servos VCOMP to a

specified voltage and measures the resultant VFB.

Note 5: Turn-on and turn-off time are measured using 10% and 90%

levels. Transition delay time is measured using 50% levels.

Note 6: 100% test at wafer level only.

Note 7: Absolute Maximum Rating of –5V on SW1 and SW2 is under

transient condition only.

4609ff

4

For more information www.linear.com/LTM4609

�LTM4609

Typical Performance Characteristics

100

Efficiency vs Load Current

12VIN to 12VOUT

Efficiency vs Load Current

32VIN to 12VOUT

100

90

90

80

80

80

70

70

70

60

50

40

30

20

0

0.01

0.1

1

LOAD CURRENT (A)

60

50

40

30

0

0.01

0.1

1

LOAD CURRENT (A)

4609 G01

0

0.01

10

100

99

70

99

98

1

2

3 4 5 6 7

LOAD CURRENT (A)

8

9

96

95

94

93

28VIN to 20VOUT

32VIN to 20VOUT

36VIN to 20VOUT

91

10

90

0

1

2

4

5

3

6

LOAD CURRENT (A)

96

7

Efficiency vs Load Current

3.3µH Inductor

8

93

0

1

3

2

4

LOAD CURRENT (A)

100

6

5

4609 G06

Transient Response from

12VIN to 12VOUT

Transient Response from

6VIN to 12VOUT

95

30VIN to 30VOUT

32VIN to 30VOUT

36VIN to 30VOUT

94

4609 G05

4609 G04

EFFICIENCY (%)

97

95

92

12VIN TO 5VOUT

24VIN TO 5VOUT

32VIN TO 5VOUT

0

98

97

EFFICIENCY (%)

EFFICIENCY (%)

EFFICIENCY (%)

95

80

100

Efficiency vs Load Current

8µH Inductor

100

100

85

0.1

1

10

LOAD CURRENT (A)

4609 G03

Efficiency vs Load Current

5.6µH Inductor

90

SKIP CYCLE

DCM

CCM

10

4609 G02

Efficiency vs Load Current

3.3µH Inductor

75

50

40

20

BURST

DCM

CCM

10

10

60

30

20

BURST

DCM

CCM

10

EFFICIENCY (%)

90

EFFICIENCY (%)

EFFICIENCY (%)

100

Efficiency vs Load Current

6VIN to 12VOUT

(Refer to Figure 18)

IOUT

2A/DIV

IOUT

2A/DIV

VOUT

200mV/DIV

VOUT

200mV/DIV

90

85

80

200µs/DIV

70

LOAD STEP: 0A TO 3A AT CCM

OUTPUT CAPS: 4x 22µF CERAMIC CAPS AND

2x 180µF ELECTROLYTIC CAPS

2x 15mΩ SENSING RESISTORS

5VIN to 16VOUT

5VIN to 24VOUT

5VIN to 30VOUT

75

0

0.5

1.5

1

2

LOAD CURRENT (A)

2.5

4609 G08

200µs/DIV

4609 G09

LOAD STEP: 0A TO 3A AT CCM

OUTPUT CAPS: 4x 22µF CERAMIC CAPS AND

2x 180µF ELECTROLYTIC CAPS

2x 15mΩ SENSING RESISTORS

3

4609 G07

4609ff

For more information www.linear.com/LTM4609

5

�LTM4609

Typical Performance Characteristics

Transient Response from

32VIN to 12VOUT

Start-Up with 6VIN to 12VOUT at

IOUT = 4A

IOUT

2A/DIV

VOUT

100mV/DIV

200µs/DIV

Start-Up with 32VIN to 12VOUT at

IOUT = 5A

IL

5A/DIV

IL

5A/DIV

IIN

5A/DIV

IIN

2A/DIV

VOUT

10V/DIV

VOUT

10V/DIV

4609 G10

50ms/DIV

4609 G11

10ms/DIV

4609 G12

LOAD STEP: 0A TO 5A AT CCM

OUTPUT CAPS: 4x 22µF CERAMIC CAPS AND

2x 180µF ELECTROLYTIC CAPS

2x 12mΩ SENSING RESISTORS

0.1µF SOFT-START CAP

OUTPUT CAPS: 4x 22µF CERAMIC CAPS AND

2x 180µF ELECTROLYTIC CAPS

2x 12mΩ SENSING RESISTORS

0.1µF SOFT-START CAP

OUTPUT CAPS: 4x 22µF CERAMIC CAPS AND

2x 180µF ELECTROLYTIC CAPS

2x 12mΩ SENSING RESISTORS

Short Circuit with 6VIN to 12VOUT

at IOUT = 4A

Short Circuit with 32VIN to 12VOUT

at IOUT = 5A

Short Circuit with 12VIN to 34VOUT

at IOUT = 2A

VOUT

10V/DIV

VOUT

5V/DIV

IIN

2A/DIV

VOUT

5V/DIV

IIN

5A/DIV

50µs/DIV

4609 G13

OUTPUT CAPS: 4x 22µF CERAMIC CAPS AND

2x 180µF ELECTROLYTIC CAPS

2x 12mΩ SENSING RESISTORS

IIN

5A/DIV

50µs/DIV

4609 G14

OUTPUT CAPS: 4x 22µF CERAMIC CAPS AND

2x 180µF ELECTROLYTIC CAPS

2x 12mΩ SENSING RESISTORS

20µs/DIV

4607 G15

OUTPUT CAPS: 2x 10µF 50V CERAMIC CAPS AND

2x 47µF 50V ELECTROLYTIC CAPS

2x 15mΩ SENSING RESISTORS

4609ff

6

For more information www.linear.com/LTM4609

�LTM4609

Pin Functions

VIN (Bank 1): Power Input Pins. Apply input voltage between these pins and PGND pins. Recommend placing

input decoupling capacitance directly between VIN pins

and PGND pins.

VOUT (Bank 5): Power Output Pins. Apply output load

between these pins and PGND pins. Recommend placing

output decoupling capacitance directly between these pins

and PGND pins.

PGND (Bank 6): Power Ground Pins for Both Input and

Output Returns.

SW1, SW2 (Bank 4, Bank 2): Switch Nodes. The power

inductor is connected between SW1 and SW2.

RSENSE (Bank 3): Sensing Resistor Pin. The sensing resistor is connected from this pin to PGND.

SENSE+ (Pin A4): Positive Input to the Current Sense and

Reverse Current Detect Comparators.

SENSE– (Pin A5): Negative Input to the Current Sense and

Reverse Current Detect Comparators.

EXTVCC (Pin F6): External VCC Input. When EXTVCC exceeds

5.7V, an internal switch connects this pin to INTVCC and

shuts down the internal regulator so that the controller and

gate drive power is drawn from EXTVCC. Do not exceed

7V at this pin and ensure that EXTVCC < VIN

INTVCC (Pin F5): Internal 6V Regulator Output. This pin

is for additional decoupling of the 6V internal regulator.

Do not source more than 40mA from INTVCC.

PLLIN (Pin B9): External Clock Synchronization Input

to the Phase Detector. This pin is internally terminated

to SGND with a 50k resistor. The phase-locked loop will

force the rising bottom gate signal of the controller to be

synchronized with the rising edge of PLLIN signal.

PLLFLTR (Pin B8): The lowpass filter of the phase-locked

loop is tied to this pin. This pin can also be used to set the

frequency of the internal oscillator with an AC or DC voltage. See the Applications Information section for details.

SS (Pin A6): Soft-Start Pin. Soft-start reduces the input

surge current from the power source by gradually increasing the controller’s current limit.

STBYMD (Pin A10): LDO Control Pin. Determines whether

the internal LDO remains active when the controller is shut

down. See Operations section for details. If the STBYMD

pin is pulled to ground, the SS pin is internally pulled to

ground to disable start-up and thereby providing a single

control pin for turning off the controller. An internal decoupling capacitor is tied to this pin.

VFB (Pin B6): The Negative Input of the Error Amplifier.

Internally, this pin is connected to VOUT with a 100k precision resistor. Different output voltages can be programmed

with an additional resistor between VFB and SGND pins.

See the Applications Information section.

FCB (Pin A9): Forced Continuous Control Input. The voltage

applied to this pin sets the operating mode of the module.

When the applied voltage is less than 0.8V, the forced

continuous current mode is active in boost operation and

the skip cycle mode is active in buck operation. When the

pin is tied to INTVCC, the constant frequency discontinuous

current mode is active in buck or boost operation. See the

Applications Information section.

SGND (Pin A7): Signal Ground Pin. This pin connects to

PGND at output capacitor point.

COMP (Pin B7): Current Control Threshold and Error

Amplifier Compensation Point. The current comparator

threshold increases with this control voltage. The voltage

ranges from 0V to 2.4V.

PGOOD (Pin B5): Output Voltage Power Good Indicator.

Open drain logic output that is pulled to ground when the

output voltage is not within ±7.5% of the regulation point.

RUN (Pin A8): Run Control Pin. A voltage below 1.6V will

turn off the module. There is a 100k resistor between the

RUN pin and SGND in the module. Do not apply more than

6V to this pin. See the Applications Information section.

4609ff

For more information www.linear.com/LTM4609

7

�LTM4609

Simplified Block Diagram

VIN

4.5V TO 36V

EXTVCC

C1

CIN

M1

SW2

INTVCC

M2

PGOOD

L

SW1

RUN

ON/OFF

VOUT

100k

STBYMD

12V

4A

CO1

M3

COUT

0.1µF

100k

COMP

VFB

M4

CONTROLLER

INT

COMP

RFB

7.15k

RSENSE

SENSE+

SS

SS

0.1µF

PLLIN

INT

FILTER

PLLFLTR

RSENSE

SENSE–

PGND

INT

FILTER

FCB

SGND

1000pF

TO PGND PLANE AS

SHOWN IN FIGURE 15

4609 BD

Figure 1. Simplified LTM4609 Block Diagram

Decoupling Requirements

TA = 25°C. Use Figure 1 configuration.

SYMBOL

PARAMETER

CONDITIONS

CIN

External Input Capacitor Requirement

(VIN = 4.5V to 36V, VOUT = 12V)

IOUT = 4A

10

COUT

External Output Capacitor Requirement

(VIN = 4.5V to 36V, VOUT = 12V)

IOUT = 4A

200

MIN

TYP

MAX

UNITS

µF

300

µF

4609ff

8

For more information www.linear.com/LTM4609

�LTM4609

Operation

Power Module Description

The LTM4609 is a non-isolated buck-boost DC/DC power

supply. It can deliver a wide range output voltage from 0.8V

to 34V over a wide input range from 4.5V to 36V, by only

adding the sensing resistor, inductor and some external

input and output capacitors. It provides precisely regulated

output voltage programmable via one external resistor.

The typical application schematic is shown in Figure 18.

The LTM4609 has an integrated current mode buck-boost

controller, ultralow RDS(ON) FETs with fast switching speed

and integrated Schottky diodes. With current mode control

and internal feedback loop compensation, the LTM4609

module has sufficient stability margins and good transient

performance under a wide range of operating conditions

and with a wide range of output capacitors. The operating

frequency of the LTM4609 can be adjusted from 200kHz

to 400kHz by setting the voltage on the PLLFLTR pin.

Alternatively, its frequency can be synchronized by the

input clock signal from the PLLIN pin. The typical switching frequency is 400kHz.

The Burst Mode® and skip-cycle mode operations can be

enabled at light loads to improve efficiency, while the forced

continuous mode and discontinuous mode operations are

used for constant frequency applications. Foldback current

limiting is activated in an overcurrent condition as VFB

drops. Internal overvoltage and undervoltage comparators pull the open-drain PGOOD output low if the output

feedback voltage exits the ±7.5% window around the

regulation point. Pulling the RUN pin below 1.6V forces

the controller into its shutdown state.

If an external bias supply is applied on the EXTVCC pin, then

an efficiency improvement will occur due to the reduced

power loss in the internal linear regulator. This is especially

true at the higher end of the input voltage range.

Applications Information

The typical LTM4609 application circuit is shown in Figure 18. External component selection is primarily determined by the maximum load current and output voltage.

Refer to Table 3 for specific external capacitor requirements

for a particular application.

Output Voltage Programming

The PWM controller has an internal 0.8V reference voltage.

As shown in the Block Diagram, a 100k internal feedback

resistor connects VOUT and VFB pins together. Adding a

resistor RFB from the VFB pin to the SGND pin programs

the output voltage:

VOUT = 0.8V •

100k +RFB

RFB

Operation Frequency Selection

The LTM4609 uses current mode control architecture at

constant switching frequency, which is determined by the

internal oscillator’s capacitor. This internal capacitor is

charged by a fixed current plus an additional current that

is proportional to the voltage applied to the PLLFLTR pin.

The PLLFLTR pin can be grounded to lower the frequency

to 200kHz or tied to 2.4V to yield approximately 400kHz.

When PLLFLTR is left open, the PLLFLTR pin goes low,

forcing the oscillator to its minimum frequency.

A graph for the voltage applied to the PLLFLTR pin vs

frequency is given in Figure 2. As the operating frequency

increases, the gate charge losses will be higher, thus the

efficiency is lower. The maximum switching frequency is

approximately 400kHz.

Table 1. RFB Resistor (0.5%) vs Output Voltage

VOUT

0.8V

1.5V

2.5V

3.3V

5V

6V

8V

9V

RFB

Open

115k

47.5k

32.4k

19.1k

15.4k

11k

9.76k

VOUT

10V

12V

15V

16V

20V

24V

30V

34V

5.23k

4.12k

3.4k

2.74k

2.37k

RFB

8.66k 7.15k 5.62k

Frequency Synchronization

The LTM4609 can also be synchronized to an external

source via the PLLIN pin instead of adjusting the voltage

on the PLLFLTR pin directly. The power module has a

4609ff

For more information www.linear.com/LTM4609

9

�LTM4609

Applications Information

phase-locked loop comprised of an internal voltage controlled oscillator and a phase detector. This allows turning

on the internal top MOSFET for locking to the rising edge of

the external clock. A pulse detection circuit is used to detect

a clock on the PLLIN pin to turn on the phase-locked loop.

The input pulse width of the clock has to be at least 400ns,

and 2V in amplitude. The synchronized frequency ranges

from 200kHz to 400kHz, corresponding to a DC voltage

input from 0V to 2.4V at PLLFLTR. During the start-up of

the regulator, the phase-locked loop function is disabled.

450

OPERATING FREQUENCY (kHz)

400

350

300

250

200

150

100

50

0

0

1.0

1.5

2.0

0.5

PLLFLTR PIN VOLTAGE (V)

2.5

4609 F02

Figure 2. Frequency vs PLLFLTR Pin Voltage

Low Current Operation

To improve efficiency at low output current operation,

LTM4609 provides three modes for both buck and boost

operations by accepting a logic input on the FCB pin. Table

2 shows the different operation modes.

load current is lower than the preset minimum output

current level. The MOSFETs will turn on for several cycles,

followed by a variable “sleep” interval depending upon the

load current. During buck operation, skip-cycle mode sets

a minimum positive inductor current level. In this mode,

some cycles will be skipped when the output load current

drops below 1% of the maximum designed load in order

to maintain the output voltage.

When the FCB pin voltage is tied to the INTVCC pin, the

controller enters constant frequency discontinuous current

mode (DCM). For boost operation, if the output voltage is

high enough, the controller can enter the continuous current

buck mode for one cycle to discharge inductor current.

In the following cycle, the controller will resume DCM

boost operation. For buck operation, constant frequency

discontinuous current mode is turned on if the preset

minimum negative inductor current level is reached. At

very light loads, this constant frequency operation is not

as efficient as Burst Mode operation or skip-cycle, but

does provide low noise, constant frequency operation.

Input Capacitors

In boost mode, since the input current is continuous, only

minimum input capacitors are required. However, the input

current is discontinuous in buck mode. So the selection

of input capacitor CIN is driven by the need of filtering the

input square wave current.

For a buck converter, the switching duty-cycle can be

estimated as:

Table 2. Different Operating Modes (VINTVCC = 6V)

FCB PIN

BUCK

BOOST

0V to 0.75V

Force Continuous Mode

Force Continuous Mode

0.85V to

VINTVCC – 1V

Skip-Cycle Mode

Burst Mode Operation

>5.3V

DCM with Constant Freq

DCM with Constant Freq

When the FCB pin voltage is lower than 0.8V, the controller

behaves as a continuous, PWM current mode synchronous

switching regulator. When the FCB pin voltage is below

VINTVCC – 1V, but greater than 0.85V, where VINTVCC is 6V,

the controller enters Burst Mode operation in boost operation or enters skip-cycle mode in buck operation. During

boost operation, Burst Mode operation is activated if the

D=

VOUT

VIN

Without considering the inductor current ripple, the RMS

current of the input capacitor can be estimated as:

ICIN(RMS) =

IOUT(MAX)

η

• D•(1-D)

In the above equation, η is the estimated efficiency of the

power module. CIN can be a switcher-rated electrolytic

aluminum capacitor, OS-CON capacitor or high volume

ceramic capacitors. Note the capacitor ripple current

ratings are often based on temperature and hours of life.

4609ff

10

For more information www.linear.com/LTM4609

�LTM4609

Applications Information

This makes it advisable to properly derate the input capacitor, or choose a capacitor rated at a higher temperature

than required. Always contact the capacitor manufacturer

for derating requirements.

LBOOST ≥

Output Capacitors

In boost mode, the discontinuous current shifts from the

input to the output, so the output capacitor COUT must be

capable of reducing the output voltage ripple.

For boost and buck modes, the steady ripple due to charging and discharging the bulk capacitance is given by:

VRIPPLE,BOOST =

VRIPPLE,BUCK =

ripple ΔIL is typically set to 20% to 40% of the maximum

inductor current. In the inductor design, the worst cases

in continuous mode are considered as follows:

(

IOUT(MAX) • VOUT – VIN(MIN)

COUT • VOUT • ƒ

(

VOUT • VIN(MAX) – VOUT

)

)

8 •L •COUT • VIN(MAX) • ƒ 2

The steady ripple due to the voltage drop across the ESR

(effective series resistance) is given by:

VESR,BUCK = ∆IL(MAX) •ESR

VESR,BOOST =IL(MAX) •ESR

The LTM4609 is designed for low output voltage ripple.

The bulk output capacitors defined as COUT are chosen

with low enough ESR to meet the output voltage ripple and

transient requirements. COUT can be the low ESR tantalum

capacitor, the low ESR polymer capacitor or the ceramic

capacitor. Multiple capacitors can be placed in parallel to

meet the ESR and RMS current handling requirements. The

typical capacitance is 300µF. Additional output filtering may

be required by the system designer, if further reduction of

output ripple or dynamic transient spike is required. Table 3

shows a matrix of different output voltages and output

capacitors to minimize the voltage droop and overshoot

at a current transient.

)

V 2OUT(MAX) • ƒ •IOUT(MAX) •Ripple%

(

VOUT • VIN(MAX) – VOUT

)

VIN(MAX) • ƒ •IOUT(MAX) •Ripple%

where:

ƒ is operating frequency, Hz

Ripple% is allowable inductor current ripple, %

VOUT(MAX) is maximum output voltage, V

VIN(MAX) is maximum input voltage, V

VOUT is output voltage, V

IOUT(MAX) is maximum output load current, A

The inductor should have low DC resistance to reduce the

I2R losses, and must be able to handle the peak inductor

current without saturation. To minimize radiated noise,

use a toroid, pot core or shielded bobbin inductor. Please

refer to Table 3 for the recommended inductors for different cases.

RSENSE Selection and Maximum Output Current

RSENSE is chosen based on the required inductor current.

Since the maximum inductor valley current at buck mode

is much lower than the inductor peak current at boost

mode, different sensing resistors are suggested to use

in buck and boost modes.

The current comparator threshold sets the peak of the

inductor current in boost mode and the maximum inductor

valley current in buck mode. In boost mode, the allowed

maximum average load current is:

Inductor Selection

The inductor is chiefly decided by the required ripple current and the operating frequency. The inductor current

LBUCK ≥

(

V 2IN • VOUT(MAX) – VIN

160mV ∆IL VIN

IOUT(MAX,BOOST) =

–

•

2 VOUT

RSENSE

where ΔIL is peak-to-peak inductor ripple current.

4609ff

For more information www.linear.com/LTM4609

11

�LTM4609

Applications Information

In buck mode, the allowed maximum average load current is:

130mV ∆IL

IOUT(MAX,BUCK) =

+

R

2

SENSE

The maximum current sensing RSENSE value for the boost

mode is:

RSENSE(MAX,BOOST) =

2 •130mV

2 •IOUT(MAX,BUCK) – ∆IL

A 20% to 30% margin on the calculated sensing resistor

is usually recommended. Please refer to Table 3 for the

recommended sensing resistors for different applications.

Soft-Start

The SS pin provides a means to soft-start the regulator.

A capacitor on this pin will program the ramp rate of the

output voltage. A 1.7µA current source will charge up the

external soft-start capacitor. This will control the ramp of

the internal reference and the output voltage. The total

soft-start time can be calculated as:

tSOFTSTART =

The RUN pin can also be used as an undervoltage lockout

(UVLO) function by connecting a resistor from the input

supply to the RUN pin. The equation:

V_UVLO=

R1+R2

•1.6V

R2

Power Good

The maximum current sensing RSENSE value for the buck

mode is:

The RUN pin is used to enable the power module. The pin

can be driven with a logic input, not to exceed 6V.

2 •160mV • VIN

2 •IOUT(MAX,BOOST) • VOUT + ∆IL • VIN

RSENSE(MAX,BUCK) =

Run Enable

2.4V •CSS

1.7µA

When the RUN pin falls below 1.6V, then the soft-start

pin is reset to allow for proper soft-start control when

the regulator is enabled again. Current foldback and force

continuous mode are disabled during the soft-start process.

Do not apply more than 6V to the SS pin.

The PGOOD pin is an open drain pin that can be used to

monitor valid output voltage regulation. This pin monitors

a ±7.5% window around the regulation point.

COMP Pin

This pin is the external compensation pin. The module

has already been internally compensated for most output

voltages. A spice model is available for other control loop

optimization.

Fault Conditions: Current Limit and Overcurrent

Foldback

LTM4609 has a current mode controller, which inherently

limits the cycle-by-cycle inductor current not only in steady

state operation, but also in transient. Refer to Table 3.

To further limit current in the event of an overload condition, the LTM4609 provides foldback current limiting. If the

output voltage falls by more than 70%, then the maximum

output current is progressively lowered to about 30% of

its full current limit value for boost mode and about 40%

for buck mode.

Standby Mode (STBYMD)

The standby mode (STBYMD) pin provides several choices

for start-up and standby operational modes. If the pin is

pulled to ground, the SS pin is internally pulled to ground,

preventing start-up and thereby providing a single control

4609ff

12

For more information www.linear.com/LTM4609

�LTM4609

Applications Information

pin for turning off the controller. If the pin is left open or

decoupled with a capacitor to ground, the SS pin is internally

provided with a starting current, permitting external control

for turning on the controller. If the pin is connected to a

voltage greater than 1.25V, the internal regulator (INTVCC)

will be on even when the controller is shut down (RUN

pin voltage