EVALUATION KIT AVAILABLE

MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

General Description

The MAX8513/MAX8514 integrate a voltage-mode PWM

step-down DC-DC controller and two LDO controllers, a

voltage monitor, and a power-on reset for the lowest-cost

power-supply and monitoring solution for xDSL modems,

routers, gateways, and set-top boxes.

The DC-DC controller switching frequency can be set with

an external resistor from 300kHz to 1.4MHz, to allow for

the optimization of cost, size, and efficiency. For noisesensitive applications, the DC-DC controller can also

be synchronized to an external clock, minimizing noise

interference. Operation above 1.1MHz reduces noise

for high data-rate xDSL applications. An adjustable softstart and adjustable foldback current limit provide reliable

startup and fault protection. The DC-DC controller output

voltage can be set externally to a voltage from 1.25V to

5.5V. Current limiting is accomplished by inductor current

sensing for improved efficiency, or by an external sense

resistor for better accuracy.

The MAX8513/MAX8514s’ first LDO controller is designed

to provide a low-cost, high-current regulated output from

0.8V to 5.5V using an N-channel MOSFET or a lowcurrent output using a low-cost NPN transistor. The

MAX8513’s second regulator can be used to generate

0.8V to 27V output with a low-cost PNP transistor. Both

LDO regulators can operate either from the DC-DC controller output or from a higher voltage derived with a flyback overwinding on the DC-DC converter inductor. The

MAX8514’s second LDO regulator is designed to provide

a negative output with an NPN transistor.

A sequence input allows the outputs to either power up

together, or for the DC-DC regulator to power up first and

each LDO controller to power up in sequence. An input

power-fail output (PFO) is provided for input power-fail

warning, such as in dying-gasp applications. A power-on

reset circuit with a 140ms delay is also included to indicate

when all outputs have achieved regulation and stabilized.

Applications

●● xDSL, Cable, ISDN Modems, and Routers

●● Wireless Routers

●● Set-Top Boxes

Pin Configurations appear at end of data sheet.

19-3178; Rev 1; 4/14

Features

●● Low-Cost DC-DC Controller with Two LDOs

●● Wide Input Range: 4.5V to 28V

●● 300kHz to 1.4MHz Adjustable Switching Frequency

●● Low Noise for High Data-Rate xDSL Applications

●● Synchronizable to External Clock

●● Adjustable Soft-Start

●● Lossless Adjustable Foldback Current Limit

●● Power-On Reset with 140ms Delay

●● Adjustable Input Power-Fail Warning for Dying Gasp

●● Selectable Output-Voltage Sequencing or

Output-Voltage Tracking

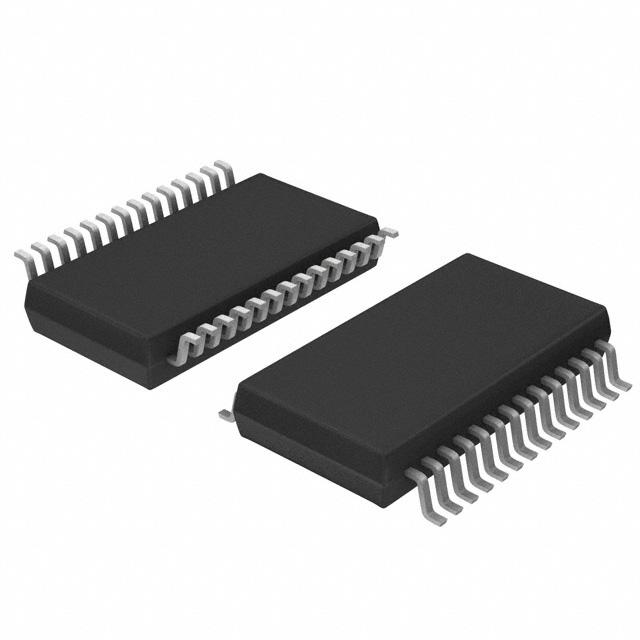

Ordering Information

PART

TEMP RANGE

PIN-PACKAGE

MAX8513EEI

-40°C to +85°C

28 QSOP

MAX8514EEI

-40°C to +85°C

28 QSOP

MAX8514AEI

-40°C to +125°C

28 QSOP

Functional Diagram

VIN

(4.5V TO 28V)

OFF

ON

SYNC

OUTPUT

POWER-ON RESET

INPUT POWERFAIL MONITOR

MAX8513

STEPDOWN

CONTROLLER

LDO

CONTROLLER 1

VOUT1

(1.25V TO 5.5V)

VOUT2

(0.8V TO VOUT1)

LDO

CONTROLLER 2

VOUT3

(0.8V TO 27V)

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Absolute Maximum Ratings

IN, DRV3P, SUP2 to GND......................................-0.3V to +30V

DRV2 to GND........................................ -0.3V to (VSUP2 + 0.3V)

DRV3N to GND...................(VSUP3N - 28V) to (VSUP3N + 0.3V)

FREQ, PFI, PFO, POR, SUP3N, SYNC/EN,

CSP, CSN to GND................................................-0.3V to +6V

VL to GND..................-0.3V to the lesser of (VIN + 0.3V) or +6V

COMP1, FB1, FB2, FB3P, FB3N, REF, ILIM,

SS, SEQ to GND....................................-0.3V to (VVL + 0.3V)

PVL to PGND...........................................................-0.3V to +6V

DL to PGND.............................................-0.3V to (VPVL + 0.3V)

BST to LX.................................................................-0.3V to +6V

DH to LX...................................................-0.3V to (VBST + 0.3V)

PGND to GND.......................................................-0.3V to +0.3V

VL Short Circuit to GND.............................................Continuous

Continuous Power Dissipation

28-Pin QSOP (derate 10.8mW/°C above +70°C)........860mW

Operating Temperature Range

MAX8513EEI, MAX8514EEI........................... -40°C to +85°C

MAX8514AEI................................................. -40°C to +125°C

Junction Temperature.......................................................+150°C

Storage Temperature Range............................. -65°C to +150°C

Lead Temperature (soldering, 10s).................................. +300°C

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may affect

device reliability.

Electrical Characteristics

(VIN = VLX = VSUP2 = 12V, VPVL = VBST - VLX = VDRV3P = 5V, VSUP3N = 3.3V, VDRV3N = -5V, CVL = 4.7µF, CREF = 0.22µF, RFREQ =

15.0kΩ, TA = 0°C to +85°C, unless otherwise noted. Typical values are at TA = +25°C.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

GENERAL

IN Operating Range

IN = VL

5.5

28.0

4.5

5.5

V

IN Supply Current

VFB1 = 1.3V, VFB2 = VFB3 = 1.0V, does

not include switching current to PVL and

BST, SYNC/EN = VL

2.6

3.2

mA

IN Shutdown Current

VSYNC/EN = 0, RFREQ = 50kΩ

200

300

µA

5

5.25

V

560

mV

VL REGULATOR

VL Output Voltage

VIN = 6V to 28V, IVL = 0.1mA to 40mA

4.75

VL Dropout Voltage

From IN to VL, VIN = 5V, IVL = 40mA

VL Line Regulation

VIN = 6V to 28V, IVL = 5mA

VL Undervoltage Threshold

VL rising, VHYST = 675mV (typ)

3.6

4.2

V

(Note 1)

1.25

5.50

V

1.259

V

0.05

%

OUT1 (BUCK CONVERTER)

Output Voltage Range

VOUT1

FB1 Regulation Threshold

VFB1

1.234

1.25

Error-Amplifier Open-Loop

Voltage Gain

AVOL

65

90

-200

+10

FB1 Input Bias Current

IFB1_BIAS

VFB1 = 1.3V

Error-Amplifier Gain Bandwidth

dB

+200

25

nA

MHz

DH Output-Resistance High

RDH_HIGH

1.5

2.55

Ω

DH Output-Resistance Low

RDH_LOW

1.2

2.1

Ω

DL Output-Resistance High

RDL_HIGH

2.5

5

Ω

DL Output-Resistance Low

RDL_LOW

0.7

1.3

Ω

Driver Dead Time

www.maximintegrated.com

tdt

Starts from VDL = 1V or (VDH - VLX) = 1V

50

ns

Maxim Integrated │ 2

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Electrical Characteristics (continued)

(VIN = VLX = VSUP2 = 12V, VPVL = VBST - VLX = VDRV3P = 5V, VSUP3N = 3.3V, VDRV3N = -5V, CVL = 4.7µF, CREF = 0.22µF, RFREQ =

15.0kΩ, TA = 0°C to +85°C, unless otherwise noted. Typical values are at TA = +25°C.)

PARAMETER

SYMBOL

CONDITIONS

VILIM = 2.00V, VCSN = 0 to 5.5V

Current-Limit Threshold (Positive)

Current-Limit Threshold

(Negative)

VCS

VCS

MIN

TYP

MAX

246

275

300

VILIM = 0.50V, VCSN = 0 to 5.5V

50

67

81

VILIM = VVL, VCSN = 0 to 5.5V

151

170

188

VILIM = 2.00V, VCSN = 0 to 5.5V

-333

-272

-199

UNITS

mV

VILIM = 0.50V, VCSN = 0 to 5.5V

-90

-67

-42

VILIM = VVL, VCSN = 0 to 5.5V

-210

-166

-122

CSP and CSN Bias Current

VCSP = VCSN = 0 to 5.5V

-120

+135

µA

ILIM Bias Current

VILIM = 1.25V

-5.3

-5

-4.7

µA

SS Soft-Start Charge Current

VSS = 0.6V

15

25

35

µA

100

200

Ω

0.03

20

µA

1.125

1.20

V

Soft-Start Discharge Resistance

VLX = VIN = 28V, VBST = 33V, VPVL = 5V,

VSYNC/EN = 0

LX, BST, PVL Leakage Current

FB1 Power-On Reset Threshold

1.08

mV

OUT2 (POSITIVE LDO)

SUP2 Operating Range

VSUP2

(Note 1)

4.5

28.0

V

DRV2 Clamp Voltage

VDRV2

VFB2 = 0.75V

7.75

9.00

V

300

µA

SUP2 Supply Current

160

SUP2 Shutdown Supply Current

VSYNC/EN = 0

FB2 Regulation Voltage

VFB2

FB2 Input Bias Current

IFB2_BIAS

0.784

VFB2 = 0.75V

3

10

µA

0.80

0.808

V

0.01

100

nA

DRV2 Output Current Limit

VIN = 5V, VDRV2 = 5V, VFB2 = 0.77V

15

30

DRV2 Output Current Limit

During Soft-Start

VIN = 6V, VDRV2 = 5V, VFB2 = 0.70V

8

10

12

mA

0.690

0.720

0.742

V

0.12

0.2

0.36

S

FB2 Power-On Reset Threshold

FB2 to DRV2 Transconductance

GC2

IDRV2 = +250µA, -250µA

mA

OUT3P (POSITIVE PNP LDO) (MAX8513 ONLY)

DRV3P Operating Range

VDRV3P

FB3P Regulation Voltage

FB3P to DRV3P Large-Signal

Transconductance

GC3P

28

V

VDRV3P = 5V, IDRV3P = 1mA

0.790

1

0.803

0.816

V

VDRV3P = 5V, IDRV3P = 0.5mA to 5mA

0.38

0.6

1.1

S

0.01

100

nA

Feedback Input Bias Current

VFB3P = 0.75V

Driver Sink Current

VFB3P = 0.75V

FB3P POR Threshold

FB3P Soft-Start Period

www.maximintegrated.com

DRV3P = 2.5V

15

DRV3P = 4.0V

35

mA

40

0.690

0.720

1312

0.742

V

Clock

Cycles

Maxim Integrated │ 3

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Electrical Characteristics (continued)

(VIN = VLX = VSUP2 = 12V, VPVL = VBST - VLX = VDRV3P = 5V, VSUP3N = 3.3V, VDRV3N = -5V, CVL = 4.7µF, CREF = 0.22µF, RFREQ =

15.0kΩ, TA = 0°C to +85°C, unless otherwise noted. Typical values are at TA = +25°C.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

OUT3N (NEGATIVE NPN LDO CONTROLLER) (MAX8514 ONLY)

SUP3N Operating Range

(Note 1)

1.5

5.5

V

DRV3N Operating Range

(Note 1)

VSUP3N

- 21V

VSUP3N

- 1.5V

V

SUP3N Supply Current

VDRV3N = 1.5V, VSUP3N = 3.5V,

IDRV3N = -1mA (source)

1.1

2

mA

FB3N Regulation Voltage

VDRV3N = 1.5V, VSUP3N = 3.5V,

IDRV3N = -1mA (source)

-20

-5

+10

mV

0.225

0.36

0.550

S

60

1000

nA

FB3N to DRV3N Large-Signal

Transconductance

GC3N

VDRV3N = 0, IDRV3N = -0.5mA to -5mA

(source)

Feedback Input Bias Current

VFB3N = -100mV

Driver Source Current

VFB3N = 200mV, VDRV3N = 0,

VSUP3N = 3.5V

FB3N POR Threshold

13

25

450

500

FB3N Soft-Start Period

mA

550

mV

Clock

Cycles

2048

REFERENCE

REF Output Voltage

VREF

-2µA < IREF < +50µA

1.231

1.25

1.269

RFREQ = 10.7kΩ ±1% from FREQ to GND

1300

1390

1460

RFREQ = 15.0kΩ ±1% from FREQ to GND

933

985

1040

RFREQ = 50.0kΩ ±1% from FREQ to GND

260

290

324

V

OSCILLATOR

Frequency

fS

FREQ Resistance-Frequency

Product

MHz

x kΩ

15.0

RFREQ = 10.7kΩ ±1% from FREQ to GND

77

83

91

Maximum Duty Cycle

(Measured at DH Pin)

RFREQ = 15.0kΩ ±1% from FREQ to GND

80

87

95

RFREQ = 50.0kΩ ±1% from FREQ to

GND

93

96

99

Minimum On-Time

(Measured at DH Pin)

RFREQ = 10.7kW ±1% from FREQ to GND

20

62

SYNC/EN Pulse Width

Low or high (Note 1)

200

SYNC/EN Frequency Range

SYNC/EN input frequency needs to be

within ±30% of the value set at the FREQ

pin (Note 1)

200

SYNC/EN Input Voltage, High

SYNC/EN Input Current

www.maximintegrated.com

VSYNC/EN = 0 to 5.5V

-1

%

ns

ns

1850

2.4

SYNC/EN Input Voltage, Low

kHz

kHz

V

0.8

V

+1

µA

Maxim Integrated │ 4

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Electrical Characteristics (continued)

(VIN = VLX = VSUP2 = 12V, VPVL = VBST - VLX = VDRV3P = 5V, VSUP3N = 3.3V, VDRV3N = -5V, CVL = 4.7µF, CREF = 0.22µF, RFREQ =

15.0kΩ, TA = 0°C to +85°C, unless otherwise noted. Typical values are at TA = +25°C.)

PARAMETER

SEQ, PFI, PFO, POR

SYMBOL

CONDITIONS

SEQ Input-Voltage High

MIN

TYP

MAX

2.4

UNITS

V

SEQ Input-Voltage Low

0.8

V

1

10

µA

IPOR = 1.6mA

10

200

IPOR = 0.1mA,

VIN = 1.0V

20

200

0.001

1

µA

ms

SEQ Input Current

VSEQ = 0 to VVL

POR Output-Voltage Low

VFB1, VFB2, VFB3P,

VFB3N, out-of-regulation

POR Output Leakage Current

VFB1, VFB2, and VFB3P or VFB3N,

in-regulation

POR Power-Ready Delay Time

From VFB1, VFB2, and VFB3P or VFB3N,

in-regulation to POR = high impedance

140

315

560

PFI Input Threshold

Falling, VHYST = 20mV

1.20

1.22

1.25

V

PFI Input Bias Current

VPFI = 1.0V

0.1

100

nA

20

200

PFI = 1.1V

IPFO = 1.6mA

PFO Output-Voltage Low

IPFO = 0.1mA,

VIN = 1.0V

10

200

PFO Output Leakage Current

PFI = 1.4V, PFO = 5V

0.001

1

Junction temperature rising

+170

°C

25

°C

mV

mV

µA

THERMAL PROTECTION

Thermal Shutdown

Thermal-Shutdown Hysteresis

Electrical Characteristics

(VIN = VLX = VSUP2 = 12V, VPVL = VBST - VLX = VDRV3P = 5V, VSUP3N = 3.3V, VDRV3N = -5V, CVL = 4.7µF, CREF = 0.22µF, RFREQ =

15.0kΩ, TA = -40°C to +125°C (Note 2), unless otherwise noted.)

PARAMETER

SYMBOL

CONDITIONS

MIN

MAX

5.5

28.0

4.5

5.5

UNITS

GENERAL

IN Operating Range

IN = VL

V

IN Supply Current

VFB1 = 1.3V, VFB2 = VFB3 = 1.0V, does not

include switching current to PVL and BST,

SYNC/EN = VL

3.2

mA

IN Shutdown Current

VSYNC/EN = 0, RFREQ = 50kΩ

300

µA

5.25

V

610

mV

4.2

V

VL REGULATOR

VL Output Voltage

VIN = 6V to 28V, IVL = 0.1mA to 40mA

VL Dropout Voltage

From IN to VL, VIN = 5V, IVL = 40mA

VL Undervoltage Threshold

VL rising, VHYST = 675mV (typ)

www.maximintegrated.com

4.75

3.6

Maxim Integrated │ 5

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Electrical Characteristics (continued)

(VIN = VLX = VSUP2 = 12V, VPVL = VBST - VLX = VDRV3P = 5V, VSUP3N = 3.3V, VDRV3N = -5V, CVL = 4.7µF, CREF = 0.22µF, RFREQ =

15.0kΩ, TA = -40°C to +125°C (Note 2), unless otherwise noted.)

PARAMETER

SYMBOL

CONDITIONS

MIN

MAX

UNITS

OUT1 (BUCK CONVERTER)

Output Voltage Range

VOUT1

1.25

5.50

V

FB1 Regulation Threshold

VFB1

(Note 1)

1.225

1.265

V

Error-Amplifier Open-Loop

Voltage Gain

AVOL

65

dB

FB1 Input Bias Current

IFB1_BIAS

+200

nA

DH Output-Resistance High

RDH_HIGH

2.55

Ω

DH Output-Resistance Low

RDH_LOW

2.1

Ω

DL Output-Resistance High

RDL_HIGH

5

Ω

DL Output-Resistance Low

RDL_LOW

1.3

Ω

Current-Limit Threshold (pos)

Current-Limit Threshold (neg)

VCS

VCS

VFB1 = 1.3V

-200

VILIM = 2.00V, VCSN = 0 to 5.5V

243

303

VILIM = 0.50V, VCSN = 0 to 5.5V

49

83

VILIM = VVL, VCSN = 0 to 5.5V

147

190

VILIM = 2.00V, VCSN = 0 to 5.5V

-333

-199

VILIM = 0.50V, VCSN = 0 to 5.5V

-90

-42

mV

mV

VILIM = VVL, VCSN = 0 to 5.5V

-210

-122

CSP and CSN Bias Current

VCSP = VCSN = 0 to 5.5V

-120

+135

µA

ILIM Bias Current

VILIM = 1.25V

-5.7

-4.3

µA

SS Soft-Start Charge Current

VSS = 0.6V

15

35

µA

200

Ω

Soft-Start Discharge Resistance

VLX = VIN = 28V, VBST = 33V, VPVL = 5V,

VSYNC/EN = 0

LX, BST, PVL Leakage Current

FB1 Power-On Reset Threshold

20

µA

1.08

1.20

V

V

OUT2 (POSITIVE LDO)

SUP2 Operating Range

VSUP2

(Note 1)

4.5

28.0

DRV2 Clamp Voltage

VDRV2

VFB2 = 0.75V

7.75

9.00

V

300

µA

10

µA

SUP2 Supply Current

VSYNC/EN = 0

SUP2 Shutdown Supply Current

FB2 Regulation Voltage

VFB2

FB2 Input Bias Current

IFB2_BIAS

0.775

VFB2 = 0.75V

0.816

V

150

nA

DRV2 Output Current Limit

VIN = 5V, VDRV2 = 5V, VFB2 = 0.77V

12

DRV2 Output Current Limit

During Soft-Start

VIN = 6V, VDRV2 = 5V, VFB2 = 0.70V

8

12

mA

0.690

0.742

V

0.11

0.41

S

FB2 Power-On Reset Threshold

FB2 to DRV2 Transconductance

www.maximintegrated.com

GC2

IDRV2 = +250µA, -250µA

mA

Maxim Integrated │ 6

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Electrical Characteristics (continued)

(VIN = VLX = VSUP2 = 12V, VPVL = VBST - VLX = VDRV3P = 5V, VSUP3N = 3.3V, VDRV3N = -5V, CVL = 4.7µF, CREF = 0.22µF, RFREQ =

15.0kΩ, TA = -40°C to +125°C (Note 2), unless otherwise noted.)

PARAMETER

SYMBOL

CONDITIONS

MIN

MAX

UNITS

OUT3P (POSITIVE PNP LDO) (MAX8513 ONLY)

DRV3P Operating Range

VDRV3P

FB3P Regulation Voltage

FB3P to DRV3P Large-Signal

Transconductance

VDRV3P = 5V, IDRV3P = 1mA

GC3P

VDRV3P = 5V, IDRV3P = 0.5mA to 5mA

Feedback Input Bias Current

VFB3P = 0.75V

Driver Sink Current

VFB3P = 0.75V

1

28

V

0.780

0.820

V

0.3

1.4

S

100

DRV3P = 2.5V

FB3P POR Threshold

15

nA

mA

0.690

0.742

V

OUT3N (NEGATIVE NPN LDO CONTROLLER) (MAX8514 ONLY)

SUP3N Operating Range

(Note 1)

1.5

5.5

V

DRV3N Operating Range

(Note 1)

VSUP3N

-21V

VSUP3N

-15V

V

SUP3N Supply Current

VDRV3N = 1.5V, VSUP3N = 3.5V,

IDRV3N = -1mA (source)

2

mA

FB3N Regulation Voltage

VDRV3N = 1.5V, VSUP3N = 3.5V,

IDRV3N = -1mA (source)

-20

+10

mV

0.225

0.550

S

1500

nA

FB3N to DRV3N Large-Signal

Transconductance

GC3N

VDRV3N = 0, IDRV3N = -0.5mA to -5mA

(source)

Feedback Input Bias Current

VFB3N = -100mV

Driver Source Current

VFB3N = 200mV, VDRV3N = 0,

VSUP3N = 3.5V

FB3N POR Threshold

13

mA

450

550

mV

-2µA < IREF < +50µA

1.22

1.27

V

RFREQ = 10.7kΩ ±1% from FREQ to GND

1300

1500

RFREQ = 15.0kΩ ±1% from FREQ to GND

917

1070

RFREQ = 50.0kΩ ±1% from FREQ to GND

250

335

RFREQ = 10.7kΩ ±1% from FREQ to GND

77

91

RFREQ = 15.0kΩ ±1% from FREQ to GND

80

95

RFREQ = 50.0kΩ ±1% from FREQ to GND

93

99

REFERENCE

REF Output Voltage

VREF

OSCILLATOR

Frequency

Maximum Duty Cycle

(Measured at DH Pin)

fS

Minimum On-Time

(Measured at DH Pin)

RFREQ = 10.7kΩ ±1% from FREQ to GND

SYNC/EN Pulse Width

Low or high (Note 1)

200

SYNC/EN Frequency Range

SYNC/EN input frequency needs to be

within ±30% of the value set at the FREQ

pin (Note 1)

200

www.maximintegrated.com

62

kHz

%

ns

ns

1850

kHz

Maxim Integrated │ 7

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Electrical Characteristics (continued)

(VIN = VLX = VSUP2 = 12V, VPVL = VBST - VLX = VDRV3P = 5V, VSUP3N = 3.3V, VDRV3N = -5V, CVL = 4.7µF, CREF = 0.22µF, RFREQ =

15.0kΩ, TA = -40°C to +125°C (Note 2), unless otherwise noted.)

PARAMETER

SYMBOL

CONDITIONS

SYNC/EN Input Voltage, High

MIN

SYNC/EN Input Voltage, Low

SYNC/EN Input Current

SEQ, PFI, PFO, POR

SEQ Input Voltage, High

MAX

2.4

VSYNC/EN = 0 to 5.5V

-1

V

0.8

V

+1

µA

2.4

SEQ Input Voltage, Low

UNITS

V

0.8

V

10

µA

IPOR = 1.6mA

200

mV

IPOR = 0.1mA,

VIN = 1.0V

200

mV

1

µA

ms

SEQ Input Current

VSEQ = 0 to VVL

POR Output Voltage, Low

VFB1, VFB2, VFB3P,

VFB3N out-of-regulation

POR Output Leakage Current

VFB1, VFB2, and VFB3P or VFB3N,

in- regulation

POR Power-Ready Delay Time

From VFB1, VFB2, and VFB3P or VFB3N,

in- regulation to POR = high impedance

140

560

PFI Input Threshold

Falling, VHYST = 20mV

1.20

1.25

V

PFI Input Bias Current

VPFI = 1.0V

300

nA

IPFO = 1.6mA

200

mV

PFO Output Voltage, Low

PFI = 1.1V

IPFO = 0.1mA,

VIN = 1.0V

200

mV

PFO Output Leakage Current

PFI = 1.4V, PFO = 5V

1

µA

Note 1: Guaranteed by design, not production tested.

Note 2: Specifications to -40°C are guaranteed by design, not production tested.

www.maximintegrated.com

Maxim Integrated │ 8

�(TA = +25°C, unless otherwise noted.)

MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Typical Operating Characteristics

(Circuit of MAX8513 evaluation kit, VIN = 12V, TA = +25°C, fS = 1.4MHz, unless otherwise noted.)

50

40

30

VOUT1 = 3.3V, IOUT1 = 2A

VOUT2 = 2.5V, IOUT2 = 1.5A

VOUT3 = 12V, IOUT3 = 50mA

20

10

7

8

60

VIN = 12V

50

40

VIN = 16V

30

3.27

3.26

0.1

0.6

1.1

1.6

2.1

2.6

3.1

3.6

3.25

4.1

VOUT3 vs. IOUT3

12.20

12.15

3.33

3.31

2.50

12.00

2.49

11.95

2.48

11.90

2.47

11.85

2.46

11.80

2.45

11.75

0.8

0.6

1.0

1.4

3.30

3.29

IOUT1 = 3A

3.27

VOUT1 = 3.3V AT 1A

VOUT2 = 2.5V AT 0.75A

0

5

3.26

3.25

10 15 20 25 30 35 40 45 50

7

8

9 10 11 12 13 14 15 16 17 18

VOUT1 = 3.3V AT 1A

VOUT2 = 2.5V AT 0.75A

12.30

12.25

12.20

IOUT3 = 0

12.15

12.10

12.05

12.00

2.47

11.95

2.46

11.90

9 10 11 12 13 14 15 16 17 18

VIN (V)

www.maximintegrated.com

11.85

IOUT3 = 50mA

7

8

9 10 11 12 13 14 15 16 17 18

VIN (V)

1.43

OSCILLATOR FREQUENCY (MHz)

12.35

MAX8513/14 toc08

OSCILLATOR FREQUENCY

vs. INPUT VOLTAGE

2.48

4.0

IOUT1 = 0

VOUT3 vs. VIN

2.49

8

3.5

VOUT2 vs. VIN

2.50

7

3.0

VIN (V)

IOUT2 = 1.5A

2.51

2.5

IOUT3 (mA)

IOUT2 = 0

2.52

1.2

2.0

3.28

VOUT3 (V)

2.53

1.5

IOUT2 (A)

VOUT1 = 3.3V AT 1A

VOUT3 = 12V AT 25mA

2.54

2.45

VOUT1 (V)

VOUT3 (V)

3.32

0.4

1.0

VOUT2 = 2.5V AT 0.75A

VOUT3 = 12V AT 25mA

3.34

12.05

0.2

0.5

VOUT1 vs. VIN

3.35

MAX8513/14 toc05

12.25

2.51

0

0

IOUT1 (A)

12.10

MAX8513/14 toc07

VOUT2 (V)

3.28

2.52

2.55

VOUT2 (V)

MAX8513/14 toc04

VOUT1 = 3.3V AT 1A

VOUT3 = 12V AT 25mA

2.53

3.29

IOUT1 (A)

VOUT2 vs. IOUT2

2.54

3.30

10

VIN (V)

2.55

3.31

20

0

9 10 11 12 13 14 15 16 17 18

3.32

MAX8513/14 toc06

60

3.33

VIN = 9V

70

MAX8513/14 toc03

80

VOUT2 = 2.5V AT 0.75A

VOUT3 = 12V AT 25mA

3.34

VOUT1 (V)

70

EFFICIENCY (%)

EFFICIENCY (%)

80

90

VOUT1 vs. IOUT1

3.35

MAX8513/14 toc02

90

0

100

MAX8513/14 toc01

100

EFFICIENCY vs. IOUT1

(IOUT2 = 0, IOUT3 = 0)

RFREQ = 10.7kΩ

1.42

1.41

TA = -40°C

TA = +25°C

MAX8513/14 toc09

EFFICIENCY vs. VIN

1.40

1.39

1.38

1.37

TA = +85°C

1.36

1.35

7

8

9 10 11 12 13 14 15 16 17 18

VIN (V)

Maxim Integrated │ 9

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Typical Operating Characteristics (continued)

(Circuit of MAX8513 evaluation kit, VIN = 12V, TA = +25°C, fS = 1.4MHz, unless otherwise noted.)

OUTPUT1 LOAD-TRANSIENT RESPONSE

OUTPUT3 LOAD-TRANSIENT RESPONSE

MAX8513/14 toc10

50mV/div

MAX8513/14 toc11

IOUT2 = 0.75A, IOUT3 = 25mA

IOUT1 = 1A, IOUT2 = 0.75A

VOUT1

AC-COUPLED

50mV/div

VOUT2

AC-COUPLED

VOUT1

AC-COUPLED

VOUT2

AC-COUPLED

50mV/div

50mV/div

50mV/div

VOUT3

AC-COUPLED

VOUT3

AC-COUPLED

100mV/div

IOUT1

1A/div

0A

IOUT3

50mA/div

5mA

40µs/div

40µs/div

SWITCHING WAVEFORMS

(ALL OUTPUTS AT FULL LOAD)

SYNCHRONIZATION

MAX8513/14 toc12

MAX8513/14 toc13

VDH

10V/div

0V

VDL

5V/div

0V

VLX

10V/div

0V

VD2

(ANODE)

20V/div

0V

VDL

10V/div

0V

PFO RESPONSE

1µs/div

POR RESPONSE

MAX8513/14 toc14

PFO

2V/div

0V

VIN

5V/div

0V

VOUT1

2V/div

IOUT1 = 2A, IOUT2 = 1.5A, IOUT3 = 50mA

2ms/div

www.maximintegrated.com

SYNC/EN

5V/div

0V

200ns/div

0V

VDH

5V/div

0V

MAX8513/14 toc15

POR

5V/div

0V

VOUT1

2V/div

0V

0V

VOUT2

5V/div

0V

VOUT3

10V/div

100ms/div

Maxim Integrated │ 10

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Typical Operating Characteristics (continued)

(Circuit of MAX8513 evaluation kit, VIN = 12V, TA = +25°C, fS = 1.4MHz, unless otherwise noted.)

STAGGERED SEQUENCE (SEQ = GND)

TRACKING SEQUENCE (SEQ = VL)

MAX8513/14 toc16

MAX8513/14 toc17

SYNC/EN

5V/div

0V

SYNC/EN

5V/div

0V

VOUT3

5V/div

VOUT1

2V/div

VOUT2

2V/div

VOUT3

5V/div

VOUT1

2V/div

VOUT2

2V/div

0V

0V

2ms/div

4ms/div

OUTPUT1 SHORT CIRCUIT

(ALL OUTPUTS AT FULL LOAD)

OUTPUT1 SHORT CIRCUIT

(ALL OUTPUTS AT NO LOAD)

MAX8513/14 toc19

MAX8513/14 toc18

VOUT1

2V/div

VOUT1

2V/div

0V

0V

VLX

10V/div

VLX

10V/div

0V

0V

1L

2A/div

IL

2A/div

0A

0A

20µs/div

20µs/div

1.5

VIN = 12V

VOUT1 = 3.3V AT 2A

VOUT2 = 2.5V AT 1.5A

VOUT3 = 12V AT 50mA

1.3

1.1

NOISE (mV)

0.9

MAX8513/14 toc20

OUTPUT RIPPLE AND HARMONICS

(MEASURED AT OUT1)

0.7

0.5

0.3

0.1

-0.1

-0.3

-0.5

100

1100

2100

3100

4100

5100

FREQUENCY (kHz)

www.maximintegrated.com

Maxim Integrated │ 11

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Pin Description

PIN

NAME

MAX8513

MAX8514

PFI

1

1

Power-Fail Input. Connect PFI to an external resistive-divider between IN, PFI, and GND.

PFI senses VIN to detect voltage failure. Trip falling threshold at this input is 1.22V, with

20mV of hysteresis.

PFO

2

2

Power-Fail Output. Open-drain output that goes low if VPFI < 1.22V.

DH

3

3

OUT1 High-Side Gate-Drive Output. DH drives the high-side N-channel MOSFET (Q1 in the

Typical Applications Circuits). DH is a floating driver output that swings from LX to BST.

LX

4

4

OUT1 High-Side Driver Return Path. The high-side FET driver uses BST and LX for its

respective high and low-side supplies.

BST

5

5

OUT1 Boost Capacitor Connection for High-Side Gate Drive. Connect a 0.1µF ceramic

capacitor from BST to LX with a less than 5mm trace length.

DL

6

6

OUT1 Low-Side Gate-Drive Output. DL drives the low-side N-channel MOSFET (Q2 in the

Typical Applications Circuits). DL swings from 0 to VPVL.

PVL

7

7

OUT1 Gate-Drive Supply Bypass Connection. Connect PVL to VL through a 10Ω resistor

(R15), and bypass PVL to PGND with a minimum 1µF capacitor (C1).

PGND

8

8

Power-Ground Connection and Low-Side Supply for Dl Driver

VL

9

9

Internal +5V Linear-Regulator Bypass Pin. Bypass VL to GND with a minimum 2.2µF

ceramic capacitor (C10) and 5mm or less of trace length. VL should be connected to IN

when VIN < 5.5V.

COMP1

10

10

OUT1 Compensation Node. See the OUT1 Compensation section.

FB1

11

11

OUT1 Feedback Input. Connect a resistive-divider (R1, R2) from OUT1 to FB1 to GND to

regulate FB1 at 1.25V.

FUNCTION

FREQ

12

12

Oscillator Frequency-Set Input. A resistor from FREQ to GND sets the oscillator frequency

from 300kHz to 1.4MHz (f = 15MHz x kΩ / RFREQ). RFREQ is still required if an external

clock is used at SYNC/EN, and the SYNC/EN input frequency should be within ±30% of the

frequency set by RFREQ.

REF

13

13

1.25V Reference Output. Connect a 0.1µF or larger ceramic capacitor (C9) from REF to

GND.

GND

14

14

Analog/Signal Ground

FB2

15

15

OUT2 Feedback Input. Connect a resistive-divider (R5, R6) from OUT2 to FB2 to GND to

regulate FB2 to 0.8V.

DRV2

16

16

OUT2 Gate Drive. DRV2 connects to the gate of an external N-channel MOSFET to form a

positive linear voltage regulator.

SUP2

17

17

Supply Input for DRV2. Connect to a voltage source of at least 1V above the maximum

desired DRV2 gate voltage.

www.maximintegrated.com

Maxim Integrated │ 12

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Pin Description (continued)

PIN

NAME

MAX8513

MAX8514

SEQ

18

18

Connect to VL for output tracking. Connect to GND for output staggered sequence.

Staggered sequence ramps up VOUT2 and VOUT3 softly to avoid glitches on the previous

voltage due to charging of the LDO’s output capacitors.

FUNCTION

SYNC/EN

19

19

Shutdown Control and Synchronization Input. There are three operating modes:

• When SYNC/EN is low, the controller is off but the VL regulator is still running.

• When SYNC/EN is high, the controller is enabled with the switching frequency set by

RFREQ.

• When SYNC/EN is driven by an external clock, the controller is enabled and switches at

the external clock frequency.

N.C.

20

—

No Connection. Not internally connected. Connect to GND or leave floating.

SUP3N

—

20

OUT3N Base-Drive Supply. Connect SUP3N to any positive voltage between 1.5V and 5.5V

to provide power for the negative linear-regulator transistor driver.

DRV3P

21

—

OUT3P Base Drive. Connect DRV3P to the base of an external PNP pass transistor to form

a positive linear voltage regulator.

DRV3N

—

21

OUT3N Base Drive. Connect DRV3N to the base of an external NPN pass transistor to form

a negative linear voltage regulator.

IN

22

22

Main Voltage Input (4.5V to 28V). Bypass IN to GND, close to the IC, with a minimum 1µF

ceramic capacitor (C2). IN powers the linear regulator whose output is VL.

POR

23

23

Power-On Reset. Open-drain output that goes high after all outputs reach the regulation limit

and a 315ms delay time has elapsed.

FB3P

24

—

OUT3P Feedback Input. FB3P is referenced to 0.8V and connects to a resistive-divider

(R13, R14) to control a positive linear voltage regulator.

FB3N

—

24

OUT3N Feedback Input. Connect a resistive-divider (R13, R14) from OUT1 to FB3N to

OUT3N to regulate FB3N to 0V.

ILIM

25

25

ILIM Set Input. Connect a resistive-divider (R17, R18) from OUT1 to ILIM to GND. See the

Current Limit section.

CSP

26

26

Positive Current-Sense Input. Used to detect OUT1 current limit.

CSN

27

27

Negative Current-Sense Input. Used to detect OUT1 current limit.

28

Analog Soft-Start Control Input. This pin goes into the positive input of the VOUT1’s error

amplifier. When the MAX8513/MAX8514 are turned on, SS is at GND and charges up to

1.25V with a constant 25µA. Connect a capacitor (C13) from SS to GND for the desired

soft-start time.

SS

28

www.maximintegrated.com

Maxim Integrated │ 13

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

IN

SS

BST

SYNC/EN

S

Q

DH

R

Q

LX

PVL

VL

BIAS

1/7.5

DL

5µA

GND

PGND

CSP

FREQ

PWM

COMP.

SEQ

CSN

1VP-P

FB1

ERROR

AMP

PFI

COMP

1.25V

PFO

N

ILIM

SUP2

0.8V

POR

DRV2

GC2

N

FB2

0.8V

REF

REFERENCE

MAX8513

GC3P

N

DRV3P

N

FB3P

Figure 1. MAX8513 Functional Diagram

www.maximintegrated.com

Maxim Integrated │ 14

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

IN

SS

BST

SYNC/EN

S

Q

DH

R

Q

LX

PVL

VL

BIAS

DL

5µA

1/7.5

PGND

GND

CSP

FREQ

PWM

COMP.

SEQ

CSN

1VP-P

FB1

ERROR

AMP

PFI

COMP

1.25V

PFO

N

ILIM

SUP2

REFERENCE

0.8V

POR

DRV2

GC2

N

FB2

SUP3N

REF

GC3N

P

P

DRV3N

MAX8514

FB3N

Figure 2. MAX8514 Functional Diagram

www.maximintegrated.com

Maxim Integrated │ 15

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Detailed Description

The MAX8513/MAX8514 combine a step-down DC-DC

converter and two LDOs, providing three output voltages for xDSL modem and set-top box applications. The

switching frequency is set with an external resistor connected from the FREQ pin to GND, and is adjustable from

300kHz to 1.4MHz. The main step-down DC-DC controller operates in a voltage-mode, pulse-width-modulation

(PWM) control scheme. The MAX8513/MAX8514 include

two low-cost LDO controllers capable of delivering current

from the DC-DC main output, an extra winding, the input,

or from an alternate supply voltage. The first LDO controller drives an external NMOS or NPN with a maximum

drive of 7.75V. The second LDO controller provides either

a positive 0.8V to 27V output using an external PNP pass

device, or a negative -1V to -18V output with an external

NPN pass device.

DC-DC Controller

The MAX8513/MAX8514 step-down DC-DC converters

use a PWM voltage-mode control scheme. An internal

high-bandwidth (25MHz) operational amplifier is used

as an error amplifier to regulate the output voltage. The

output voltage is sensed and compared with an internal

1.25V reference to generate an error signal. The error

signal is then compared with a fixed-frequency ramp by

a PWM comparator to give the appropriate duty cycle to

maintain output-voltage regulation. At the rising edge of

the internal clock and when DL (the low-side MOSFET

gate drive) is at 0V, the high-side MOSFET turns on.

When the ramp voltage reaches the error-amplifier output

voltage, the high-side MOSFET latches off until the next

clock pulse. During the high-side MOSFET on-time, current flows from the input through the inductor to the output

capacitor and load. At the moment the high-side MOSFET

turns off, the energy stored in the inductor during the ontime is released to support the load. The inductor current

ramps down through the low-side MOSFET body diode.

After a fixed delay, the low-side MOSFET turns on to

shunt the current from its body diode for a lower voltage

drop to increase the efficiency. The low-side MOSFET

turns off at the rising edge of the next clock pulse, and

when its gate voltage discharges to zero, the high-side

MOSFET turns on after an additional fixed delay and

another cycle starts.

The MAX8513/MAX8514 operate in forced-PWM mode,

so even under light load the controller maintains a constant switching frequency to minimize noise and possible

interference with system circuitry.

www.maximintegrated.com

Current Limit

The MAX8513/MAX8514s’ switching regulator senses

the inductor current either through the DC resistance of

the inductor itself for lossless sensing, or through a series

resistor for more accurate sensing. When using the DC

resistance of the inductor, an RC filter circuit is needed

(see R19, R20, and C14 of the Typical Applications

Circuits and the Current-Limit Setting section). When

peak voltage across the sensing circuit (which occurs at

the peak of the inductor current) exceeds the current-limit

threshold set by ILIM, the controller turns off the highside MOSFET and turns on the low-side MOSFET. The

inductor current ramps down and DH turns on again if

the inductor current is below the current-limit threshold

at the next clock pulse. The MAX8513/MAX8514 currentlimit threshold can be set by two external resistors to be

proportional to the output voltage with an adjustable offset

level, providing foldback current-limit and short-circuit

protection. This feature greatly reduces power dissipation

and prevents overheating of external components during

an indefinite short-circuit at the output. See the Foldback

Current Limit section for how to set ILIM with external

resistors. The current-limit threshold defaults to 170mV

when ILIM is connected to VL, and in this case, the current limit functions as a constant current limit only. The

LDO controllers do not have current limit and rely on input

current limit for protection.

Synchronous-Rectifier Driver (DL)

Synchronous rectification reduces the conduction loss in

the rectifier by replacing the normal Schottky catch diode

with a low-on-resistance MOSFET switch. The MAX8513/

MAX8514 also use the synchronous rectifier to ensure

proper startup of the boost gate-drive circuit.

High-Side Gate-Drive Supply (BST)

A flying-capacitor boost circuit (see D1 and C3 in the

Typical Applications Circuits) generates the gate-drive

voltage for the high-side N-channel MOSFET. On startup,

the synchronous rectifier (low-side MOSFET, Q2) forces

LX to ground and charges the boost capacitor (C3) to

VVL - VDIODE. On the second half-cycle, the controller

turns on the high-side MOSFET by closing an internal

switch between BST and DH. This boosts the voltage

at BST to VVL - VDIODE + VIN, providing the necessary

gate-to-source voltage to turn on the high-side N-channel

MOSFET.

Maxim Integrated │ 16

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Internal 5V Linear Regulator

All MAX8513/MAX8514 functions (except for the positive

output LDO with an NFET or NPN, and the negative LDO

on the MAX8514) are powered from the on-chip low-dropout 5V regulator with its input connected to IN. Bypass the

regulator’s output (VL) with a 2.2µF or greater ceramic

capacitor. The VIN to VVL dropout voltage is typically

350mV, so when VIN is greater than 5.5V, VVL is typically

5V. If VIN is between 4.5V and 5.5V, short VL to IN.

Undervoltage Lockout

If VVL drops below 3.8V, the MAX8513/MAX8514 assume

that the supply voltage is too low to make valid decisions.

When this happens, the undervoltage lockout (UVLO)

circuitry inhibits switching, forces POR and PFO low,

and forces DL and DH gate drivers low. After VVL rises

above 3.9V, the controller powers up the outputs (see the

Startup section).

Startup

The MAX8513/MAX8514 start switching when VVL rises

above the 3.9V UVLO threshold. However, the controller

is not enabled unless all three of the following conditions

are met:

1) VVL exceeds the 3.9V UVLO threshold.

2) The internal reference exceeds 90% of its nominal

value.

3) The thermal limit is not exceeded.

Once the MAX8513/MAX8514 assert the internal enable

signal, the step-down controller starts switching and

enables soft-start. The soft-start circuitry gradually ramps

up to the reference voltage to control the rate-of-rise of

the step-down controller and reduce input surge currents.

The soft-start period is determined by the value of the

capacitor from SS to GND (C13 in the Typical Applications

Circuits). SS sources a constant 25µA to charge the softstart capacitor to 1.25V.

Output-Voltage Sequencing

The MAX8513/MAX8514 can power up in either staggered-output sequencing or output tracking. For staggered-output sequencing, connect SEQ to GND. In this

configuration, VOUT1 comes up first. When it reaches

90% of the nominal regulated value, VOUT2 is softly

turned on. Once VOUT2 reaches 90% of its nominal regulated value, VOUT3 is softly turned on. Individual soft-start

www.maximintegrated.com

on OUT2 and OUT3 eliminates glitches on the previous

stages due to the charging of output capacitors. See the

Typical Operating Characteristics section for the startup

and staggered-output-sequence waveforms.

Output-Voltage Tracking

When SEQ is connected to VL, all outputs rise up at the

same time and the external series pass transistors are

driven fully on until reaching the respective regulation

limits. Since the LDOs are powered from the main DC-DC

step-down converter, either directly or through a coupled

winding on the inductor, their outputs track the DC-DC

step-down output (OUT1). See the Typical Operating

Characteristics section for the startup output- tracking

waveforms.

Power-On Reset

The MAX8513/MAX8514 provide a power-on-reset (POR)

signal, which goes high 315ms after all outputs reach

90% of their nominal regulated value. Therefore, by the

time POR goes high, all outputs are already stabilized at

nominal regulated voltages. See the Typical Operating

Characteristics section for the POR waveforms.

Input Power-Fail (PFI and PFO)

The MAX8513/MAX8514 have a built-in comparator to

detect the input voltage with an external resistive- divider

at PFI, with a threshold of 1.22V. When the input voltage

drops and trips this comparator, the power-fail output

(PFO) goes low, while all outputs are still within regulation

limits. This is typically used for input power-fail warning

for orderly system shutdown. The amount of warning

time depends on the input storage capacitor, the input

PFI trip voltage level, the main step-down output voltage,

the total output power, and the efficiency. See the Design

Procedure section for how to calculate the input capacitor

to meet the required warning time.

Enable and Synchronization

The MAX8513/MAX8514 can be turned on with logic high,

and off with logic low at SYNC/EN. When SYNC/EN is

driven with an external clock, the internal oscillator synchronizes the rising edge of the clock at SYNC/EN to DH

going high. When being driven by a synchronization clock

signal at SYNC/EN, the controller synchronizes to the

external clock within two cycles. The frequency at SYNC/

EN needs to be within ±30% of the value set by RFREQ.

See the Switching-Frequency Setting section.

Maxim Integrated │ 17

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Thermal-Overload Protection

Thermal-overload protection limits the total power dissipation in the MAX8513/MAX8514. When the junction temperature exceeds TJ = +170°C, a thermal sensor shuts

down the device, forcing DL and DH low and allowing the

IC to cool. The thermal sensor turns the part on again

after the junction temperature cools by 25°C, resulting

in a pulsed output during continuous thermal-overload

conditions. During a thermal event, the main step-down

converter and the linear regulators are turned off, POR

and PFO go low, and soft-start is reset.

Design Procedure

OUT1 Voltage Setting

The output voltage is set by a resistive-divider network

from OUT1 to FB1 to GND (see R1 and R2 in the Typical

Applications Circuits). Select R2 between 5kΩ and 15kΩ.

Then R1 can be calculated by:

V

= R2 × OUT1 - 1

R1

1.25V

Input Power-Fail Setting

The PFI input can monitor VIN to determine if it is falling.

When the voltage at PFI crosses 1.22V, the output (PFO)

goes low. The input voltage value at the PFI trip threshold,

VPFI, is set by a resistive-divider network from IN to PFI to

GND (see the Typical Applications Circuits). Select R11,

the resistor from PFI to GND between 10kΩ and 40kΩ.

Then R10, the resistor from PFI to IN, is calculated by:

V

= R11× PFI - 1

R10

1.22V

Switching-Frequency Setting

The resistor connected from FREQ to GND, RFREQ (R7

in the Typical Applications Circuits), sets the switching

frequency, fS, as shown by the equation below:

15 × 10 9

=

fS

Hz × W

R FREQ

where RFREQ is in ohms.

Inductor Value

There are several parameters that must be examined

when determining which inductor to use: input voltage,

output voltage, load current, switching frequency, and LIR.

LIR is the ratio of peak-to-peak inductor ripple current to

www.maximintegrated.com

the maximum DC load current. A higher LIR value allows

for a smaller inductor but results in higher losses and

higher output ripple. A good compromise between size

and efficiency is a 30% LIR. Once all of the parameters

are chosen, the inductor value is determined as follows:

L=

VOUT1 × (VIN - VOUT1)

VIN × f S × I OUT1_MAX × LIR

where VOUT1 is the main switching regulator output and

fS is the switching frequency.

Choose a standard value close to the calculated value.

The exact inductor value is not critical and can be adjusted

to make tradeoffs between size, cost, and efficiency. Lower

inductor values minimize size and cost, but also increase

the output ripple and reduce the efficiency due to higher

peak currents. On the other hand, higher inductor values

increase efficiency, but eventually resistive losses due to

extra turns of wire exceed the benefit gained from lower

AC current levels. Find a low-loss inductor with the lowest

possible DC resistance that fits the allotted dimensions.

Ferrite cores are often the best choice, although powdered

iron is inexpensive and can work well up to 300kHz. The

chosen inductor’s saturation current rating must exceed

the peak inductor current as calculated below:

=

IPEAK I OUT1_MAX +

(VIN - VOUT1) × VOUT1

2 × L × f S × VIN

This peak value should be smaller than the value set at

ILIM when VOUT1 is at its nominal regulated voltage (see

the Current Limit and Current-Limit Setting sections).

In applications where a multiple winding inductor (coupled

inductor) is used to generate the supply voltages for the

LDOs, the inductance value calculated above is for the

winding connected to the DC-DC step-down (primary windings) inductance. The inductance seen from the other windings (secondary windings) is proportional to the square of

the turns ratio with respect to the primary winding.

The turns ratio is important since it sets the LDOs’ supply

voltage values. The voltage generated by the secondary

winding (VSEC) together with the rectifier diode and output capacitor is calculated as follows:

VSEC=

n

(VOUT1 + VQ2 ) × n2 - VD2

1

where VQ2 and VD2 are the voltage drops across the

low-side MOSFET on the primary side and the rectifier

Maxim Integrated │ 18

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

diode on the secondary side (Q2 and D2 in the Typical

Applications Circuits). n2 and n1 are the number of

turns of the secondary winding and the primary winding,

respectively.

It is important to have the secondary winding tightly

coupled with the primary winding to minimize leakage

inductance for higher efficiency. The positive voltage generated by the secondary winding can also be stacked with

the main DC-DC step-down converter output to further

improve efficiency and reduce winding cost. In this case,

the secondary-side voltage:

VSEC=

n

1

VPFI and VDROOP can be calculated as:

Input Capacitor

The input-filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage ripple on the input caused by the AC-RMS current

through the ESR of the input capacitor (C2 in the Typical

Applications Circuits). The input capacitor must meet

the ripple-current requirement (IIN_RMS) imposed by the

switching currents defined by the following equation:

I OUT1 × VOUT1 × (VIN - VOUT1)

VIN

IIN_RMS has a maximum value when the input voltage

equals twice the output voltage (VIN = 2 x VOUT1), so

IIN_RMS(MAX) = IOUT1 / 2. Ceramic capacitors are recommended due to their low ESR and ESL at high frequency,

with relatively low cost. Choose a capacitor that exhibits

less than 10°C temperature rise at the maximum operating RMS current for optimum long-term reliability.

For applications that require input power-fail warning,

such as dying gasp, add a large-value electrolytic capacitor (CS) to the input as a local energy storage device to

provide the power to the converter in case of input powerfail. The capacitor value must be high enough to meet the

desired power-fail warning time, tWARN, where tWARN is

the time from when PFI trips the PFO output to when the

www.maximintegrated.com

POUT1 1

1

CS =

0.5 ×

×

V

V

η

PFI

DROOP

t WARN

×

(VPFI - VDROOP )

where POUT1 is the total output power, η is the total

converter efficiency, VPFI is the input voltage value at the

input power-fail (PFI) trip threshold, and VDROOP is the

input voltage value where VOUT1 starts dropping out of

regulation.

(VOUT1 + VQ2 ) × n2 +VOUT1 - VD2

IIN_RMS =

main output (OUT1) starts dropping out of regulation. The

value of the storage capacitor, CS, can be calculated as:

R10

VPFI

= 1.22V × 1 +

R11

where R10 and R11 are the resistive-dividers from IN to

PFI to GND in the Typical Applications Circuits.

VDROOP =

VOUT1

D MAX

where DMAX is the maximum duty cycle.

To ensure for worst-case component tolerances such

as capacitance of CS, converter efficiency, VPFI, and

VDROOP’s threshold over the operating temperature

range, it is recommended to select CS at least 1.5 times

the calculated value above.

Output Capacitor

The key selection parameters for the output capacitor

are the actual capacitance value, the equivalent series

resistance (ESR), the equivalent series inductance (ESL),

and the voltage-rating requirements. All of these affect

the overall stability, output ripple voltage, and transient

response.

The output ripple is composed of three components:

variations in the charge stored in the output capacitor,

the voltage drop across the capacitor’s equivalent series

resistance (ESR), and equivalent series inductance (ESL)

caused by the current into and out of the capacitor.

Maxim Integrated │ 19

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

The peak-to-peak output voltage ripple as a consequence

of the ESR, ESL, and output capacitance is:

VRIPPLE(ESR)

= IP-P × R ESR

VRIPPLE(C) =

IP-P

8 × C OUT × f S

where COUT is C4 in the Typical Applications Circuits.

VIN × ESL

L1A + ESL

V -V

V

and IP-P = IN OUT1 OUT1

f

L

V

S

IN

VRIPPLE(ESL) =

where IP-P is the peak-to-peak inductor current (see the

Inductor Selection section). An approximation of the overall voltage ripple at the output is:

VRIPPLE =

VRIPPLE(C) + VRIPPLE(ESR) + VRIPPLE(ESL)

While these equations are suitable for initial capacitor

selection to meet the ripple requirement, final values may

also depend on the relationship between the LC doublepole frequency and the capacitor ESR zero. Generally,

the ESR zero is higher than the LC double pole (see the

Compensation Design section). Solid polymer electrolytic

or ceramic capacitors are recommended due to their low

ESR and ESL at higher frequencies. Higher output current

may require paralleling multiple capacitors to meet the

output voltage ripple.

The MAX8513/MAX8514s’ response to a load transient

depends on the selected output capacitor. After a load

transient, the output instantly changes by (ESR x ∆IOUT1)

+ (ESL x dIOUT1 / dt). Before the controller can respond,

the output deviates further depending on the inductor

and output capacitor values. After a short period of time

(see the Typical Operating Characteristics), the controller responds by regulating the output voltage back to its

nominal state. The controller response time depends on

the closed-loop bandwidth. With a higher bandwidth the

response time is faster, preventing the output capacitor

from further deviation from its regulating value. Be sure

not to exceed the capacitor’s voltage or current ratings.

MOSFET Selection

The MAX8513/MAX8514 drive two external, logic-level,

N-channel MOSFETs as the circuit switch elements. The

key selection parameters are:

www.maximintegrated.com

• For on-resistance (RDS_ON), the lower the better.

• Maximum drain-to-source voltage (VDS) should be at

least 20% higher than the input supply rail at the highside MOSFET’s drain.

• For gate charges (QGS, QGD, QDS), the lower the

better.

Choose the MOSFETs with rated RDS_ON at VGS =

4.5V. For a good compromise between efficiency and

cost, choose the high-side MOSFET (Q1 in the Typical

Applications Circuits) that has conduction loss equal to

switching loss at nominal input voltage and maximum

output current. For the low-side MOSFET (Q2 in the

Typical Applications Circuits), make sure that it does not

spuriously turn on due to dV/dt caused by Q1 turning on

as this results in shoot-through current degrading the

efficiency. MOSFETs with a lower QGD / QGS ratio have

higher immunity to dV/dt.

For proper thermal management, the power dissipation

must be calculated at the desired maximum operating

junction temperature, maximum output current, and worstcase input voltage. For Q2, the worst case is at VIN_MAX.

For Q1, it could be either at VIN_MIN or VIN_MAX. Q1

and Q2 have different loss components due to the circuit

operation. Q2 operates as a zero voltage switch, where

major losses are the channel conduction loss (PQ2CC)

and the body-diode conduction loss (PQ2DC).

V

PQ2CC

= 1 - OUT1 × I

× R DS_ON

OUT12

V

IN

PQ2DC =

2 × I OUT1 × VF × t dt × f S

where VF is the body-diode forward voltage drop, tdt =

50ns is the dead time between Q1 and Q2 switching transitions, and fS is the switching frequency.

The total losses for Q2 are:

PQ2_TOTAL

= PQ2CC + PQ2DC

Q1 operates as a duty-cycle control switch and has the

following major losses: the channel conduction loss

(PQ1CC), the V I overlapping switching loss (PQ1SW), and

the drive loss (PQ1DR). Q1 does not have body-diode conduction loss because the diode never conducts current.

PQ1CC =

VOUT1

×I

× R DS_ON

OUT12

VIN

where RDS_ON is at the maximum operating junction

tempeure.

Maxim Integrated │ 20

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

PQ1SW = VIN × I OUT1 × f S ×

1) Connect a scope probe to measure VLX to GND, and

observe the ringing frequency, fR.

(Q GS + Q GD )

I GATE

where IGATE is the average DH high driver output-current

capability determined by:

I GATE =

2.5V

(R DH + R GATE )

where RDH is the high-side MOSFET driver’s on-resistance (1.5Ω typ) and RGATE is the internal gate resistance

of the MOSFET (≈2Ω).

PQ1DR= Q GS × VGS × f S ×

R GATE

(R GATE + R DH

)

where VGS ≈ VVL = 5V.

The total power loss in Q1 is:

PQ1 =PQ1CC + PQ1SW + PQ1DR

In addition to the losses above, allow approximately 20%

more for additional losses due to MOSFET output capacitances and Q2 body-diode reverse recovery charge dissipated in Q1. This is not typically well-defined in MOSFET

data sheets. Refer to the MOSFET data sheet for the

thermal-resistance specification to calculate the PC board

area needed to maintain the desired maximum operating

junction temperature with the above calculated power

dissipations.

To reduce EMI caused by switching noise, add a 0.1µF

or larger ceramic capacitor from the high-side MOSFET

drain to the low-side MOSFET source or add resistors in

series with DH and DL to slow down the switching transitions. However, adding series resistors with DH and DL

increases the power dissipation in the MOSFET when it

switches, so be sure this does not overheat the MOSFET.

The minimum load current must exceed the high-side

MOSFET’s maximum leakage current over temperature if

fault conditions are expected.

MOSFET Snubber Circuit

Fast switching transitions cause ringing because of resonating circuit parasitic inductance and capacitance at the

switching nodes. This high-frequency ringing occurs at

LX’s rising and falling transitions and can interfere with

circuit performance and generate EMI. To dampen this

ringing, a series-RC snubber circuit is added across each

switch. The following is the procedure for selecting the

value of the series-RC circuit:

www.maximintegrated.com

2) Find the capacitor value (connected from LX to GND)

that reduces the ringing frequency by half.

The circuit parasitic capacitance (CPAR) at LX is then

equal to 1/3rd the value of the added capacitance above.

The circuit parasitic inductance (LPAR) is calculated by:

L PAR =

1

(2π × fR ) 2 × C PAR

The resistor for critical dampening (RSNUB) is equal to

(2π x fR x LPAR). Adjust the resistor value up or down to

tailor the desired damping and the peak voltage excursion. The capacitor (CSNUB) should be at least 2 to 4

times the value of the CPAR to be effective. The power

loss of the snubber circuit is dissipated in the resistor

(PRSNUB) and can be calculated as:

2

PRSNUB = C SNUB × (VIN ) × f S

where VIN is the input voltage and fS is the switching

frequency. Choose an RSNUB power rating that meets

the specific application’s derating rule for the power dissipation calculated.

Current-Limit Setting

The MAX8513/MAX8514 can provide foldback current limit

or constant current limit. Unless constant current-limit operation is required, such as when driving a constant current

load, foldback current limit should be implemented. Foldback

current limit reduces the power dissipation of external components under overload or short-circuit conditions.

Foldback Current Limit

For foldback current limit, the current-limit threshold

is set by an external resistive-divider from VOUT1 to

ILIM to GND (R17 and R18 of the Typical Applications

Circuits). This makes the voltage at ILIM a function of

the internal 5µA current source and VOUT1. The currentlimit comparator threshold is equal to VILIM / 7.5. This

threshold is compared with VSENSE. VSENSE is either

the voltage across the current-sense resistor or, for

lossless sensing, the voltage across the inductor. When

VSENSE exceeds the current-limit threshold, the high-side

MOSFET turns off and the low-side MOSFET turns on.

This allows for a current foldback feature that reduces the

current-limit threshold during a short circuit. This makes

the current threshold limit, when VOUT = 0V, a percentage of the current-limit threshold, when VOUT1 is at its

nominal regulated value.

Maxim Integrated │ 21

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

To set the current limit and the current-limit foldback

thresholds, first select the foldback current-limit ratio

(PFB). This ratio is the foldback current limit (ILIMIT@0V)

divided by the current limit when VOUT1 equals its nominal regulated voltage ILIMIT).

PFB =

ILIMIT@0V

ILIMIT

PFB is typically set to 0.5. To calculate the values of R17

and R18 (in the Typical Applications Circuits), use the following equations:

(P × VOUT1)

R17 = FB

4.7µA × (1-PFB )

R18 =

(7.5 × R CS_MAX × ILIMIT × (1-PFB )) × R17

VOUT1-(7.5 × R CS_MAX × ILIMIT × (1-PFB ))

RCS_MAX is the maximum sensing resistance at the

high operating temperature. RCS can either be the series

resistance of the inductor or a discrete current-sense

resistor value. ILIMIT is the peak inductor current at maximum load, which equals:

1+ LIR

I OUT1_MAX ×

2

If R18 results in a negative resistance, then decrease

RCS. This can be done by choosing an inductor with a

lower DC resistance or a lower value discrete currentsense resistor.

Constant Current Limit

For constant current-limit operation, connect ILIM to VL

for a default current-limit threshold of 170mV (typ). The

sensing resistor value must then be chosen so that:

RCS_MAX x ILIMIT < 151mV

the minimum value of the default threshold.

Alternately, the constant current-limit threshold can also

be set by using only R18, in which case R18 is calculated

as follows:

I

R18 =

7.5 × R CS_MAX × LIMIT

4.7µA

of the Typical Applications Circuits). Pick the value of the

filter capacitor, C14, from 0.22µF to 1µF (ceramic X7R).

Then calculate the value of R19 as follows:

R19 =

L1A

(

)

2 × R L_DC × C14

RL_DC is the nominal value of the inductor’s DC resistance. Additionally, R20 (in the Typical Applications

Circuits) is added in series with the CSN input to cancel

the drop due to input bias current into CSP that develops

across R19. R20 should be set equal to R19.

Compensation Design

The MAX8513/MAX8514 use a voltage-mode control

scheme that regulates the output voltage by comparing the

error-amplifier output (COMP) with a fixed internal ramp to

produce the required duty cycle. The output lowpass LC

filter creates a double pole at the resonant frequency,

which has a gain drop of -40dB/decade and a phase shift

of approximately -180°/decade. The error amplifier must

compensate for this gain drop and phase shift to achieve

a stable high-bandwidth closed-loop system.

The basic regulator loop consists of a power modulator, an

output feedback divider, and an error amplifier. The power

modulator has a DC gain set by VIN / VRAMP (VRAMP =

1V pk-pk), with a double pole and a single zero set by the

output inductance (L), the output capacitance (COUT) (C4

in the Typical Applications Circuits), and its equivalent

series resistance (RESR). VRAMP is the peak of the sawtoothed waveform at the input of the PWM comparator

(see the Functional Diagrams in Figures 1 and 2). Below

are equations that define the power modulator:

G MOD(DC) =

f PMOD =

VIN

VRAMP

1

2π L × C OUT

where L is L1A and COUT is C4 in the Typical Application

circuits.

f ZESR =

1

2π × C OUT × R ESR

When using the DC resistance of the inductor as a current-sense resistor, an RC filter is needed (R19 and C14

www.maximintegrated.com

Maxim Integrated │ 22

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

When the output capacitance is comprised of paralleling n

number of identical capacitors whose values are CEACH

with ESR of RESR_EACH, then:

C OUT= n × C EACH and

R ESR =

R ESR_EACH

decade slope of the LC double pole, and the resultant

compensated loop crosses over at the desired -20dB/

decade slope. The error amplifier has a dominant pole

at very low frequency (≈0Hz), and two separate zeros at:

=

f Z1

n

1

1

=

and f Z2

2π × R3 × C5

2π × (R1 + R4) × C11

and poles at:

Thus the resulting fZESR is the same as that of each

capacitor.

1

1

=

f P2 =

and f P3

C5 × C12

2π × R4 × C11

The crossover frequency (fC), which is the frequency

2π × R3 ×

when the closed-loop gain is equal to unity, should be the

C5 + C12

smaller of 1/5th the switching frequency or 100kHz (see

The error-amplifier equivalent circuit and its gain vs. frethe Switching-Frequency Setting section):

quency plot are shown below in Figure 3.

f

f C ≤ S or 100kHz

5

The loop-gain equation at the crossover frequency is:

In this case, fZ2 and fP1 are selected to have the converters’ closed-loop crossover frequency, fC, occur when the

error-amplifier gain has a +20dB/decade slope between

fZ2 and fP2. The error-amplifier gain at fC is:

G EA(fc)G MOD(fc) = 1

G EA(fc) =

where GEA(fc) is the error-amplifier gain at fC, and

GMOD(fc) is the power modular gain at fC.

The loop compensation is affected by the choice of

output-filter capacitor used, due to the position of its ESR

zero frequency with respect to the desired closed-loop

crossover frequency. Ceramic capacitors are used for

higher switching frequencies (above 750kHz) because

of low capacitance and low ESR; therefore, the ESR

zero frequency is higher than the closed-loop crossover

frequency. While electrolytic capacitors (e.g., tantalum,

solid polymer, oscon, etc.) are needed for lower switching

frequencies, because of high capacitance and ESR, the

ESR zero frequency is typically lower than the closedloop crossover frequency. Thus the compensation design

procedure is separated into two cases:

Case 1: Ceramic Output Capacitor (operating

at high switching frequencies, fZESR > fC)

The modulator gain fC is:

f

G MOD(fc) = G MOD(DC) PMOD

fC

G MOD(fc)

The gain of the error amplifier between fZ1 and fZ2 is:

f Z2

f Z2

G=

EA(fZ1-fZ2) G=

EA(fc)

f C f CG MOD(fc)

C12

C11

C5

R3

R4

VOUT1

R1

GAIN

(dB)

EA

R2

COMP

REF

CLOSED-LOOP GAIN

EA GAIN

2

Since the crossover frequency is lower than the output

capacitors’ ESR zero frequency and higher than the LC

double-pole frequency, the error-amplifier gain must have

a +20dB/decade slope at fC. This +20dB/decade slope of

the error amplifier at crossover then adds to the -40dB/

www.maximintegrated.com

1

fZ1

fZ2

fC

fP2

fP3

FREQUENCY

Figure 3. Case 1: Error-Amplifier Compensation Circuit (ClosedLoop and Error-Amplifier Gain Plot)

Maxim Integrated │ 23

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

This gain is also set by the ratio of R3/R1 where R1 is

calculated in the OUT1 Voltage Setting section. Thus:

R3 =

R1× f Z2

f C × G MOD(fc)

Due to the underdamped (Q > 1) nature of the output LC

double pole, the error-amplifier zero frequencies must be

set less than the LC double-pole frequency to provide

adequate phase boost. Set the error-amplifier first zero,

fZ1, at 1/4th the LC double-pole frequency and the second

zero, fZ2, at the LC double-pole frequency. Hence:

C5 =

2

π × R3 × f PMOD

Set the error-amplifier fP2 at fZESR, and fP3 to 1/2 the

switching frequency, if fZESR < 1/2 fS. If fZESR > 1/2 fS,

then set fP2 at 1/2 fS and fP3 at fZESR.

The gain of the error amplifier between fP2 and fP3 is set

by the ratio of R3/RI and equal to:

f

R3

= G EA(fZ1-fZ2) P2

RI

f PMOD

where RI is the parallel combination of R1 and R4 and is

equal to:

R1× R4

RI =

R1 + R4

Therefore:

RI =

R3 × f PMOD

and

f P2 × G EA(fZ1-fZ2)

R1× R I

R4 =

R1 - R I

C11 can then be calculated as:

1

C11 =

2π × R4 × f P2

and C12 as:

C12 =

C5

(2π × C5 × R3 × fP3 -1)

Below is a numerical example to calculate the error-amplifier compensation values used in the Typical Applications

Circuit of Figure 5:

VIN = 12V (nomimal input voltage)

VRAMP = 1V

VOUT1 = 3.3V

VFB1 = 1.25V

L1A = 1.8µH

C4 = 47µF/ 6.3V ceramic, with RESR = 0.008Ω

fS = 1.4MHz

The LC double-pole frequency is calculated as:

=

f PMOD

1

=

2π L1A × C4

1

2π 1.8 × 10 -6 × 47 × 10 -6

= 17.3kHz

1

=

2π × R ESR × C4

=

f ZESR

1

2π × 0.008 × 47 × 10 -6

= 423kHz

Pick R2 = 8.06kΩ.

3.3V

=

R1 8.06kW ×

=

-1 13.3kW

1.25V

The modulator gain at DC is:

G MOD(DC)

=

VIN

=

12

VRAMP

Pick fC = 100kHz.

2

17.4kHz

G MOD(fc) =

12 ×

0.363

=

100kHz

f PMOD

G EA(fZ1− fZ2) =

f CG MOD(fC)

17.4kHz

= 0.479

100kHz × 0.363

R3

= R1× G EA(fZ1− fZ2)

=

= 13.3kW × 0.479

= 6.37kW

www.maximintegrated.com

Maxim Integrated │ 24

�MAX8513/MAX8514

Wide-Input, High-Frequency Triple-Output Supplies

with Voltage Monitor and Power-On Reset

Use 6.8kΩ.

C12

2

2

=

C5 =

= 5.38nF

π × R3 × f PMOD π × 6.8kW × 17.4kHz

Use 4.7nF.

=

RI

C11

C5

R3

R4

VOUT1

R1

R3 × f PMOD

6.8kW × 17.4kHz

=

= 583W

f P2 × G EA(fZ1-fZ2) 423kHz × 0.479

R4

=

R1× R I 13.3kW × 583W

=

= 609W

R1 - R I 13.3kW - 583W

EA

R2

GAIN

(dB)

VCOMP

VREF

CLOSED-LOOP GAIN

Use 620Ω.

EA GAIN

1

1

=

C11 =

= 607pF

2π × R4 × f P2 2π × 620W × 423kHz

Use 680pF.

Pick fP3 = 700kHz, which is the midpoint between fZESR

and 1/2 the switching frequency.

C12 =

C5

(2π × C5 × R3 × f P3 )-1

4.7nF

= 33.7pF

(2π × 4.7nF × 6.8kW × 700kHz)-1

Use 33pF.

Case 2: Electrolytic Output Capacitor (operating at lower switching frequencies, fZESR < fC )

The modulator gain at fC is:

2

f

G MOD(fc) = G MOD(DC) PMOD

f ZESR f C

The output capacitor’s ESR zero frequency is higher than

the LC double-pole frequency but lower than the closedloop crossover frequency. Here the modulator already has

a -20dB/decade slope; therefore, the error-amplifier gain

must have a 0dB/decade slope at fC, so the loop crosses

over at the desired -20dB/decade slope. The error-amplifier circuit configuration is the same as Case 1; however,

the closed-loop crossover frequency is now between fP2

and fP3, as illustrated in Figure 4.

www.maximintegrated.com

fZ1