[AK09918]

AK09918

3-axis Electronic Compass

1. General Description

AK09918 is 3-axis electronic compass IC with high sensitive Hall sensor technology.

Small package of AK09918 incorporates magnetic sensors for detecting terrestrial magnetism in the X-axis,

Y-axis, and Z-axis, a sensor driving circuit, signal amplifier chain, and an arithmetic circuit for processing

the signal from each sensor. Self-test function is also incorporated. From its compact foot print and thin

package feature, it is suitable for map heading up purpose in Smart phone to realize pedestrian navigation

function.

2. Features

Functions:

3-axis magnetometer device suitable for compass application

Built-in A to D Converter for magnetometer data out

16-bit data out for each 3-axis magnetic component

Sensitivity: 0.15 µT/LSB (typ.)

Serial interface

I2C bus interface

Standard and Fast modes compliant with Philips I2C specification Ver.2.1

Operation mode

Power-down, Single measurement, Continuous measurement and Self-test

DRDY function for measurement data ready

Magnetic sensor overflow monitor function

Built-in oscillator for internal clock source

Power on Reset circuit

Self-test function with internal magnetic source

Built-in magnetic sensitivity adjustment circuit

Operating temperatures:

-30˚C to +85˚C

Operating supply voltage:

+1.65V to +1.95V

Current consumption:

Power-down:

1 µA (typ.)

Measurement:

Average current consumption at 100 Hz repetition rate: 1.1mA (typ.)

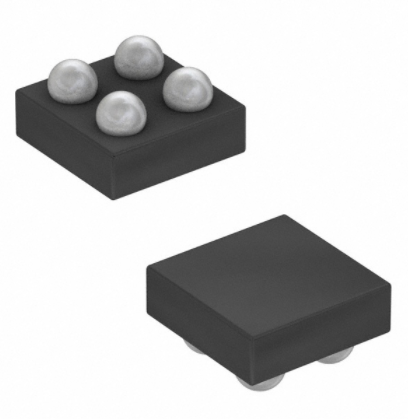

Package:

AK09918C

4-pin WL-CSP (BGA):

0.8 mm 0.8 mm 0.5mm

016014242-E-00

2016/11

-1-

�[AK09918]

3. Table of Contents

1. General Description .................................................................................................................. 1

2. Features ..................................................................................................................................... 1

3. Table of Contents ...................................................................................................................... 2

4. Block Diagram and Functions ................................................................................................... 3

5. Pin Configurations and Functions ............................................................................................. 4

6. Absolute Maximum Ratings ...................................................................................................... 4

7. Recommended Operating Conditions ....................................................................................... 4

8. Electrical Characteristics ........................................................................................................... 5

8.1. DC Characteristics.............................................................................................................. 5

8.2. AC Characteristics .............................................................................................................. 6

8.3. Analog Circuit Characteristics............................................................................................ 6

8.4. I2C Bus Interface ................................................................................................................ 7

9. Function Descriptions ............................................................................................................... 8

9.1. Power States ....................................................................................................................... 8

9.2. Reset Functions .................................................................................................................. 8

9.3. Operation Modes ................................................................................................................ 9

9.4. Description of Each Operation Mode ............................................................................... 10

9.4.1. Power-down Mode .................................................................................................... 10

9.4.2. Single Measurement Mode ........................................................................................ 10

9.4.3. Continuous Measurement Mode 1, 2, 3 and 4 ........................................................... 11

9.4.4. Self-test Mode............................................................................................................ 15

10. Serial Interface ...................................................................................................................... 16

10.1. I2C Bus Interface ............................................................................................................ 16

10.1.1. Data Transfer ........................................................................................................... 16

10.1.2. WRITE Instruction .................................................................................................. 18

10.1.3. READ Instruction .................................................................................................... 19

11. Registers ................................................................................................................................ 20

11.1. Description of Registers ................................................................................................. 20

11.2. Register Map .................................................................................................................. 21

11.3. Detailed Description of Register .................................................................................... 22

11.3.1. WIA: Who I Am ...................................................................................................... 22

11.3.2. RSV: Reserved register ............................................................................................ 22

11.3.3. ST1: Status 1 ............................................................................................................ 22

11.3.4. HXL to HZH: Measurement data ............................................................................ 23

11.3.5. TMPS: Dummy register ........................................................................................... 23

11.3.6. ST2: Status 2 ............................................................................................................ 24

11.3.7. CNTL1: Dummy register ......................................................................................... 24

11.3.8. CNTL2: Control 2.................................................................................................... 24

11.3.9. CNTL3: Control 3.................................................................................................... 25

11.3.10. TS1, TS2: Test register........................................................................................... 25

12. Example of Recommended External Connection ................................................................. 26

13. Package ................................................................................................................................. 27

13.1. Marking .......................................................................................................................... 27

13.2. Pin Assignment ............................................................................................................... 27

13.3. Outline Dimensions ........................................................................................................ 28

13.4. Recommended Foot Print Pattern................................................................................... 28

14. Relationship between the Magnetic Field and Output Code ................................................. 29

IMPORTANT NOTICE .............................................................................................................. 30

016014242-E-00

2016/11

-2-

�[AK09918]

4. Block Diagram and Functions

3-axis

Hall

sensor

Chopper

SW

PreAMP

Integrator&ADC

MUX

OSC

HE-Drive

SCL

Timing

Control

VREF

Interface Logic

& Register

SDA

Magnetic source

POR

VSS

Block

3-axis Hall sensor

MUX

Chopper SW

HE-Drive

Pre-AMP

Integrator & ADC

OSC

POR

VREF

Interface Logic

&

Register

Timing Control

Magnetic Source

VDD

Function

Monolithic Hall elements.

Multiplexer for selecting Hall elements.

Performs chopping.

Magnetic sensor drive circuit.

Fixed-gain differential amplifier used to amplify the magnetic sensor signal.

Integrates and amplifies Pre-AMP output and performs analog-to-digital

conversion.

Generates an operating clock for sensor measurement.

Power On Reset circuit. Generates reset signal on rising edge of VDD.

Generates reference voltage and current.

Exchanges data with an external CPU.

I2C bus interface using two pins, namely, SCL and SDA. Standard and Fast modes

are supported.

Generates a timing signal required for internal operation from a clock generated by

the OSC.

Generates magnetic field for Self-test of magnetic sensor.

016014242-E-00

2016/11

-3-

�[AK09918]

5. Pin Configurations and Functions

Pin No.

A1

Pin name

VSS

I/O

-

Type

-

A2

SCL

I

CMOS

B1

VDD

-

Power

B2

SDA

I/O

CMOS

Function

Ground pin.

Control data clock input pin.

Input: Schmidt trigger

Positive power supply pin.

Control data input/output pin.

Input: Schmidt trigger, Output: Open-drain

6. Absolute Maximum Ratings

Vss = 0V

Parameter

Power supply voltage

Input voltage

(except for power supply pin)

Input current

(except for power supply pin)

Storage temperature

Symbol

Vdd

VIN

Min.

-0.3

-0.3

Max.

+2.5

+2.5

Unit

V

V

IIN

-

±10

mA

Tst

-40

+125

˚C

If the device is used in conditions exceeding these values, the device may be destroyed. Normal operations are not

guaranteed in such exceeding conditions.

7. Recommended Operating Conditions

Vss = 0V

Parameter

Operating temperature

Power supply voltage

Symbol

Ta

Vdd

Min.

-30

1.65

016014242-E-00

Typ.

1.8

Max.

+85

1.95

Unit

˚C

V

2016/11

-4-

�[AK09918]

8. Electrical Characteristics

The following conditions apply unless otherwise noted:

Vdd = 1.65V to 1.95V, Temperature range = -30˚C to +85˚C.

8.1. DC Characteristics

Parameter

High level input voltage

Symbol

VIH

Low level input voltage

VIL

Input current

IIN

Hysteresis input voltage

(Note 1)

VHS

SCL

SDA

Low level output voltage

(Note 2)

VOL

SDA

IOL ≤ +3mA

Current consumption

(Note 3)

IDD1

VDD

Power-down mode

Vdd = 1.95V

When magnetic sensor

is driven

Self-test mode

IDD2

IDD3

(Note 1)

(Note 2)

(Note 3)

Pin

SCL

SDA

SCL

SDA

SCL

SDA

Condition

VIN = Vss or Vdd

Min.

70%Vdd

Typ.

Max.

Unit

V

-0.3

30%Vdd

V

-10

+10

µA

10%Vdd

V

20%Vdd

V

1

3

µA

1.5

3

mA

2.5

4

mA

Schmitt trigger input (reference value for design)

Output is Open-drain. Connect a pull-up resistor externally. Maximum capacitive load: 400pF

(Capacitive load of each bus line for I2C bus interface).

Without any resistance load. It does not include the current consumed by external loads

(pull-down resister, etc.). SDA = SCL = Vdd or 0V.

016014242-E-00

2016/11

-5-

�[AK09918]

8.2. AC Characteristics

Parameter

Power supply rise time

(Note 4)

POR completion time

(Note 4)

Power supply turn off

voltage (Note 4)

Power supply turn on

interval (Note 4)

Symbol

PSUP

Wait time before mode

setting

Twait

(Note 4)

(Note 5)

Pin

VDD

PORT

SDV

VDD

PSINT

VDD

Condition

Period of time that VDD changes

from 0.2V to Vdd.

Period of time after PSUP to

Power-down mode (Note 5)

Turn off voltage to enable POR to

restart (Note 5)

Period of time that voltage lower

than SDV needed to be kept to

enable POR to restart (Note 5)

Min.

Typ.

Max.

50

Unit

ms

100

µs

0.2

V

100

µs

100

µs

Reference value for design.

When POR circuit detects the rise of VDD voltage, it resets internal circuits and initializes the

registers. After reset, AK09918 transits to Power-down mode.

Power-down mode

Power-down mode

VDD

PORT

SDV

0V

PSUP

PSINT

8.3. Analog Circuit Characteristics

Parameter

Measurement data output bit

Time for measurement

Magnetic sensor sensitivity

Magnetic sensor measurement range

(Note 6)

Magnetic sensor initial offset

(Note 7)

(Note 6)

(Note 7)

Symbol

DBIT

TSM

BSE

BRG

Condition

Min.

-

Single measurement mode

Ta = 25 ˚C

Ta = 25 ˚C

0.1425

±4670

BIO

Ta = 25 ˚C

-2000

Typ.

16

7.2

0.15

±4912

Max.

Unit

bit

8.2

ms

0.1575 µT/LSB

±5160

µT

+2000

LSB

Reference value for design

Value of measurement data register on shipment test without applying magnetic field on purpose.

016014242-E-00

2016/11

-6-

�[AK09918]

8.4. I2C Bus Interface

I2C bus interface is compliant with Standard mode and Fast mode. Standard/Fast mode is selected

automatically by fSCL.

Standard mode

fSCL ≤ 100kHz

Symbol

fSCL

tHIGH

tLOW

tR

tF

tHD:STA

tSU:STA

tHD:DAT

tSU:DAT

tSU:STO

tBUF

Parameter

SCL clock frequency

SCL clock “High” time

SCL clock “Low” time

SDA and SCL rise time

SDA and SCL fall time

Start Condition hold time

Start Condition setup time

SDA hold time (vs. SCL falling edge)

SDA setup time (vs. SCL rising edge)

Stop Condition setup time

Bus free time

Min.

Typ.

Max.

100

Unit

kHz

s

s

s

s

s

s

s

ns

s

s

4.0

4.7

1.0

0.3

4.0

4.7

0

250

4.0

4.7

Fast mode

100kHz ≤ fSCL ≤ 400kHz

Symbol

fSCL

tHIGH

tLOW

tR

tF

tHD:STA

tSU:STA

tHD:DAT

tSU:DAT

tSU:STO

tBUF

tSP

Parameter

SCL clock frequency

SCL clock “High” time

SCL clock “Low” time

SDA and SCL rise time

SDA and SCL fall time

Start Condition hold time

Start Condition setup time

SDA hold time (vs. SCL falling edge)

SDA setup time (vs. SCL rising edge)

Stop Condition setup time

Bus free time

Noise suppression pulse width

Min.

Typ.

Max.

400

Unit

kHz

s

s

s

s

s

s

s

ns

s

s

ns

0.6

1.3

0.3

0.3

0.6

0.6

0

100

0.6

1.3

50

[I2C bus interface timing]

1/fSCL

VIH

SCL

VIL

VIH

SDA

VIL

tLOW

tBUF

tR

tHIGH

tF

tSP

VIH

SCL

VIL

tHD:STA

Stop

Start

tHD:DAT

tSU:DAT

tSU:STA

tSU:STO

Start

Stop

016014242-E-00

2016/11

-7-

�[AK09918]

9. Function Descriptions

9.1. Power States

When VDD is turned on from Vdd = OFF (0V), all registers in AK09918 are initialized by POR circuit and

AK09918 transits to Power-down mode.

Table 9.1. Power state

State

1

VDD

OFF (0V)

2

1.65V to 1.95V

Power state

OFF

It doesn’t affect external interface.

ON

9.2. Reset Functions

Power on Reset (POR) works until Vdd reaches to the operation effective voltage (about 1.1V: reference

value for design) on power-on sequence. After POR is completed, all registers are initialized and AK09918

transits to Power-down mode.

When Vdd = 1.65 to 1.95V, POR circuit is active.

AK09918 has two types of reset;

(1) Power on Reset (POR)

When Vdd rise is detected, POR circuit operates, and AK09918 is reset.

(2) Soft reset

AK09918 is reset by setting SRST bit. When AK09918 is reset, all registers are initialized and

AK09918 transits to Power-down mode.

016014242-E-00

2016/11

-8-

�[AK09918]

9.3. Operation Modes

AK09918 has following seven operation modes:

(1) Power-down mode

(2) Single measurement mode

(3) Continuous measurement mode 1

(4) Continuous measurement mode 2

(5) Continuous measurement mode 3

(6) Continuous measurement mode 4

(7) Self-test mode

By setting CNTL2 register MODE[4:0] bits, the operation set for each mode is started.

A transition from one mode to another is shown below.

MODE[4:0] = “00001”

Power-down

MODE[4:0] = “00000”

mode

Transits automatically

MODE[4:0] = “00010”

MODE[4:0] = “00000”

MODE[4:0] = “00100”

MODE[4:0] = “00000”

MODE[4:0] = “00110”

MODE[4:0] = “00000”

MODE[4:0] = “01000”

MODE[4:0] = “00000”

MODE[4:0] = “10000”

MODE[4:0] = “00000”

Single measurement mode

Sensor is measured for one time and data is output.

Transits to Power-down mode automatically after

measurement ended.

Continuous measurement mode 1

Sensor is measured periodically in 10Hz.

Transits to Power-down mode by writing

MODE[4:0] = “00000”.

Continuous measurement mode 2

Sensor is measured periodically in 20Hz.

Transits to Power-down mode by writing

MODE[4:0] =“00000”.

Continuous measurement mode 3

Sensor is measured periodically in 50Hz.

Transits to Power-down mode by writing

MODE[4:0] = “00000”.

Continuous measurement mode 4

Sensor is measured periodically in 100Hz.

Transits to Power-down mode by writing

MODE[4:0] = “00000”.

Self-test mode

Sensor is self-tested and the result is output.

Transits to Power-down mode automatically.

Transits automatically

Figure 9.1. Operation mode

When power is turned ON, AK09918 is in Power-down mode. When a specified value is set to MODE[4:0]

bits, AK09918 transits to the specified mode and starts operation. When user wants to change operation

mode, transit to Power-down mode first and then transit to other modes. After Power-down mode is set, at

least 100 s (Twait) is needed before setting another mode

016014242-E-00

2016/11

-9-

�[AK09918]

9.4. Description of Each Operation Mode

9.4.1. Power-down Mode

Power to almost all internal circuits is turned off. All registers are accessible in Power-down mode. Data

stored in read/write registers are remained. They can be reset by soft reset.

9.4.2. Single Measurement Mode

When Single measurement mode (MODE[4:0] bits = “00001”) is set, magnetic sensor measurement is

started. After magnetic sensor measurement and signal processing is finished, measurement magnetic data is

stored to measurement data registers (HXL to HZH), then AK09918 transits to Power-down mode

automatically. On transition to Power-down mode, MODE[4:0] bits turns to “00000”. At the same time,

DRDY bit in ST1 register turns to “1”. This is called “Data Ready”. When any of measurement data register

(HXL to TMPS) or ST2 register is read, DRDY bit turns to “0”. It remains “1” on transition from

Power-down mode to another mode. (Figure 9.2. )

When sensor is measuring (Measurement period), measurement data registers (HXL to TMPS) keep the

previous data. Therefore, it is possible to read out data even in measurement period. Data read out in

measurement period are previous data.(Figure 9.3. )

Operation Mode:

Power-down

Single measuremnet

(1)

(2)

(3)

Measurement period

Internal Buffer

Last Data

Measurement Data (1)

Measurement Data Register

Last Data

Data(2)

Data(3)

Measurement Data (1)

Data(3)

Data(1)

Data(3)

DRDY

Data read

Register Write

MODE[4:0]="00001"

MODE[4:0]="00001" MODE[4:0]="00001"

Figure 9.2. Single measurement mode when data is read out of measurement period

Operation Mode:

Power-down

Single measuremnet

(1)

(2)

(3)

Measurement period

Internal Buffer

Last Data

Measurement Data (1)

Measurement Data Register

Last Data

Data(2)

Data(3)

Measurement Data (1)

DRDY

Data read

Register Write

Data(1)

MODE[4:0]="00001"

MODE[4:0]="00001" MODE[4:0]="00001"

Figure 9.3. Single measurement mode when data read started during measurement period

016014242-E-00

2016/11

- 10 -

�[AK09918]

9.4.3. Continuous Measurement Mode 1, 2, 3 and 4

When Continuous measurement mode 1 (MODE[4:0] bits = “00010”), 2 (MODE[4:0] bits = “00100”), 3

(MODE[4:0] bits = “00110”) or 4 (MODE[4:0] bits = “01000”) is set, magnetic sensor measurement is

started periodically at 10 Hz, 20 Hz, 50 Hz or 100 Hz respectively. After magnetic sensor measurement and

signal processing is finished, measurement magnetic data is stored to measurement data registers (HXL to

HZH) and all circuits except for the minimum circuit required for counting cycle length are turned off (PD).

When the next measurement timing comes, AK09918 wakes up automatically from PD and starts

measurement again.

Continuous measurement mode ends when Power-down mode (MODE[4:0] bits = “00000”) is set. It repeats

measurement until Power-down mode is set.

When Continuous measurement mode 1 (MODE[4:0] bits = “00010”), 2 (MODE[4:0] bits = “00100”), 3

(MODE[4:0] bits = “00110”) or 4 (MODE[4:0] bits = “01000”) is set again while AK09918 is already in

Continuous measurement mode, a new measurement starts. ST1, ST2 and measurement data registers (HXL

to TMPS) will not be initialized by this.

(N-1)th

PD

Nth

Measurement

(N+1)th

Measurement

PD

PD

10Hz,20Hz,50Hz or 100Hz

Figure 9.4. Continuous measurement mode

9.4.3.1. Data Ready

When measurement data is stored and ready to be read, DRDY bit in ST1 register turns to “1”. This is called

“Data Ready”. When measurement is performed correctly, AK09918 becomes Data Ready on transition to

PD after measurement.

016014242-E-00

2016/11

- 11 -

�[AK09918]

9.4.3.2. Normal Read Sequence

(1) Check Data Ready or not by polling DRDY bit of ST1 register

DRDY: Shows Data Ready or not. Not when “0”, Data Ready when “1”.

DOR: Shows if any data has been skipped before the current data or not. There are no skipped

data when “0”, there are skipped data when “1”.

(2) Read measurement data

When any of measurement data register (HXL to TMPS) or ST2 register is read, AK09918 judges

that data reading is started. When data reading is started, DRDY bit and DOR bit turns to “0”.

(3) Read ST2 register (required)

HOFL: Shows if magnetic sensor is overflowed or not. “0” means not overflowed, “1” means

overflowed.

When ST2 register is read, AK09918 judges that data reading is finished. Stored measurement data is

protected during data reading and data is not updated. By reading ST2 register, this protection is

released. It is required to read ST2 register after data reading.

(N-1)th

PD

Nth

Measurement

Internal Buffer

(N-1)th

(N+1)th

Measurement

PD

Nth

Measurement Data Register

(N-1)th

PD

(N+1)th

Nth

(N+1)th

DRDY

Data read

ST1 Data(N)

ST2

ST1 Data(N+1)

ST2

Figure 9.5. Normal read sequence

9.4.3.3. Data Read Start during Measurement

When sensor is measuring (Measurement period), measurement data registers (HXL to TMPS) keep the

previous data. Therefore, it is possible to read out data even in measurement period. If data is started to be

read during measurement period, previous data is read.

(N-1)th

PD

Nth

Measurement

Internal Buffer

(N-1)th

(N+1)th

Measurement

PD

Nth

Measurement Data Register

(N-1)th

PD

(N+1)th

Nth

DRDY changes to "1"

because read-out becomes possible.

DRDY

Data read

ST1 Data(N)

ST2

ST1 Data(N)

ST2

Figure 9.6. Data read start during measurement

016014242-E-00

2016/11

- 12 -

�[AK09918]

9.4.3.4. Data Skip

When Nth data was not read before (N+1)th measurement ends, Data Ready remains until data is read. In

this case, a set of measurement data is skipped so that DOR bit turns to “1”.

When data reading started after Nth measurement ended and did not finish reading before (N+1)th

measurement ended, Nth measurement data is protected to keep correct data. In this case, a set of

measurement data is skipped and not stored so that DOR bit turns to “1”.

In both case, DOR bit turns to “0” at the next start of data reading.

(N-1)th

PD

Nth

Measurement

Internal Buffer

(N-1)th

(N+1)th

Measurement

PD

Nth

PD

(N+1)th

Measurement Data Register

(N-1)th

(N+1)th

DRDY

DOR

Data read

ST1 Data(N+1)

ST2

Figure 9.7. Data Skip: When data is not read

(N-1)th

PD

Nth

(N+1)th

PD

Measurement

Internal Buffer

(N-1)th

Nth

Measurement Data Register

(N-1)th

(N+2)th

PD

Measurement

PD

Measurement

(N+1)th

(N+2)th

Nth

(N+2)th

Data register is protected

because data is being read

DRDY changes to "1"

because read-out becomes possible.

DRDY

(N+1)th data is skipped

DOR

Data read

ST1 Data(N)

ST2

ST1 Data(N+2)

Figure 9.8. Data Skip: When data read has not been finished before the next measurement end

016014242-E-00

2016/11

- 13 -

�[AK09918]

Although Nth data is read out when it is performed during (N+1)th measurement period, (N+1)th data is obtained by

reading out again before completion of (N+2)th measurement.

(N-1)th

PD

Nth

(N+1)th

PD

Measurement

Internal Buffer

(N-1)th

Nth

Measurement Data Register

(N-1)th

(N+2)th

PD

Measurement

PD

Measurement

(N+1)th

(N+2)th

Nth

(N+1)th

Data register is protected

because data is being read

DRDY changes to "1"

because read-out becomes possible.

DRDY

DOR

Data read

ST1 Data(N)

ST2

ST1 Data(N+1)

Figure 9.9. Read-out is performed before completion of the next measurement after data protection.

9.4.3.5. End Operation

Set Power-down mode (MODE[4:0] bits = “00000”) to end Continuous measurement mode.

9.4.3.6. Magnetic Sensor Overflow

AK09918 has the limitation for measurement range that the sum of absolute values of each axis should be

smaller than 4912 μT. (Note 8)

|X|+|Y|+|Z| < 4912 μT

When the magnetic field exceeded this limitation, data stored at measurement data are not correct. This is

called Magnetic Sensor Overflow.

When magnetic sensor overflow occurs, HOFL bit turns to “1”.

When measurement data register (HXL to HZH) is updated, HOFL bit is updated.

(Note 8) BRG: 0.15μT/LSB

016014242-E-00

2016/11

- 14 -

�[AK09918]

9.4.4. Self-test Mode

Self-test mode is used to check if the magnetic sensor is working normally.

When Self-test mode (MODE[4:0] bits = “10000”) is set, magnetic field is generated by the internal

magnetic source and magnetic sensor is measured. Measurement data is stored to measurement data registers

(HXL to HZH), then AK09918 transits to Power-down mode automatically.

Data read sequence and functions of read-only registers in Self-test mode is the same as Single measurement

mode.

9.4.4.1. Self-test Sequence

(1) Set Power-down mode. (MODE[4:0] bits = “00000”)

(2) Set Self-test mode. (MODE[4:0] bits = “10000”)

(3) Check Data Ready or not by polling DRDY bit of ST1 register.

When Data Ready, proceed to the next step.

(4) Read measurement data. (HXL to HZH)

9.4.4.2. Self-test Judgment

When measurement data read by the above sequence is in the range of following table, AK09918 is working

normally.

Criteria

HX[15:0] bits

-200 ≤ HX ≤ 200

HY[15:0] bits

-200 ≤ HY ≤ 200

016014242-E-00

HZ[15:0] bits

-1000 ≤ HZ ≤ -150

2016/11

- 15 -

�[AK09918]

10. Serial Interface

10.1. I2C Bus Interface

The I2C bus interface of AK09918 supports the Standard mode (100 kHz max.) and the Fast mode (400 kHz

max.).

10.1.1. Data Transfer

To access AK09918 on the bus, generate a start condition first.

Next, transmit a one-byte slave address including a device address. At this time, AK09918 compares the

slave address with its own address. If these addresses match, AK09918 generates an acknowledgement, and

then executes READ or WRITE instruction. At the end of instruction execution, generate a stop condition.

10.1.1.1. Change of Data

A change of data on the SDA line must be made during “Low” period of the clock on the SCL line. When

the clock signal on the SCL line is “High”, the state of the SDA line must be stable. (Data on the SDA line

can be changed only when the clock signal on the SCL line is “Low”.)

During the SCL line is “High”, the state of data on the SDA line is changed only when a start condition or a

stop condition is generated.

SCL

SDA

DATA LINE

STABLE :

DATA VALID

CHANGE

OF DATA

ALLOWED

Figure 10.1. Data Change

10.1.1.2. Start/Stop Condition

If the SDA line is driven to “Low” from “High” when the SCL line is “High”, a start condition is generated.

Every instruction starts with a start condition.

If the SDA line is driven to “High” from “Low” when the SCL line is “High”, a stop condition is generated.

Every instruction stops with a stop condition.

SCL

SDA

START CONDITION

STOP CONDITION

Figure 10.2. Start and Stop Condition

016014242-E-00

2016/11

- 16 -

�[AK09918]

10.1.1.3. Acknowledge

The IC that is transmitting data releases the SDA line (in the “High” state) after sending 1-byte data.

The IC that receives the data drives the SDA line to “Low” on the next clock pulse. This operation is referred

as acknowledge. With this operation, whether data has been transferred successfully can be checked.

AK09918 generates an acknowledge after reception of a start condition and slave address.

When a WRITE instruction is executed, AK09918 generates an acknowledge after every byte is received.

When a READ instruction is executed, AK09918 generates an acknowledge then transfers the data stored at

the specified address. Next, AK09918 releases the SDA line then monitors the SDA line. If a master IC

generates an acknowledge instead of a stop condition, AK09918 transmits the 8bit data stored at the next

address. If no acknowledge is generated, AK09918 stops data transmission.

Clock pulse

for acknowledge

SCL FROM

MASTER

1

8

9

DATA

OUTPUT BY

TRANSMITTER

not acknowledge

DATA

OUTPUT BY

RECEIVER

START

CONDITION

acknowledge

Figure 10.3. Generation of Acknowledge

10.1.1.4. Slave Address

The slave address of AK09918 is 0Ch.

MSB

0

LSB

0

0

1

1

0

0

R/W

Figure 10.4. Slave Address

The first byte including a slave address is transmitted after a start condition, and an IC to be accessed is

selected from the ICs on the bus according to the slave address.

When a slave address is transferred, the IC whose device address matches the transferred slave address

generates an acknowledge then executes an instruction. The 8th bit (least significant bit) of the first byte is a

R/W bit.

When the R/W bit is set to “1”, READ instruction is executed. When the R/W bit is set to “0”, WRITE

instruction is executed.

016014242-E-00

2016/11

- 17 -

�[AK09918]

10.1.2. WRITE Instruction

When the R/W bit is set to “0”, AK09918 performs write operation.

In write operation, AK09918 generates an acknowledge after receiving a start condition and the first byte

(slave address) then receives the second byte. The second byte is used to specify the address of an internal

control register and is based on the MSB-first configuration.

MSB

A7

LSB

A6

A5

A4

A3

A2

A1

A0

Figure 10.5. Register Address

After receiving the second byte (register address), AK09918 generates an acknowledge then receives the

third byte.

The third and the following bytes represent control data. Control data consists of 8 bits and is based on the

MSB-first configuration. AK09918 generates an acknowledge after every byte is received. Data transfer

always stops with a stop condition generated by the master.

MSB

D7

LSB

D6

D5

D4

D3

D2

D1

D0

Figure 10.6. Control Data

AK09918 can write multiple bytes of data at a time.

After reception of the third byte (control data), AK09918 generates an acknowledge then receives the next

data. If additional data is received instead of a stop condition after receiving one byte of data, the address

counter inside the LSI chip is automatically incremented and the data is written at the next address.

The address is incremented from 00h to 18h, from 30h to 32h. When the address is 00h to 18h, the address is

incremented 00h 01h 02h 03h 10h 11h ... 18h,and the address goes back to 00h after

18H. When the address is 30h to 32h, the address goes back to 30h after 32h.

Actual data is written only to Read/Write registers (Table 11.2. ).

S

T

A

R

T

SDA

S

S

T

O

P

R/W="0"

Slave

Address

Register

Address(n)

A

C

K

Data(n)

A

C

K

Data(n+1)

A

C

K

Data(n+x)

A

C

K

A

C

K

P

A

C

K

Figure 10.7. WRITE Instruction

016014242-E-00

2016/11

- 18 -

�[AK09918]

10.1.3. READ Instruction

When the R/W bit is set to “1”, AK09918 performs read operation.

If a master IC generates an acknowledge instead of a stop condition after AK09918 transfers the data at a

specified address, the data at the next address can be read.

Address can be 00h to 18h, 30h to 32h. When the address is 00h to 18h, the address is incremented 00h

01h 02h 03h 10h 11h ... 18h, and the address goes back to 00h after 18h. When the address

is 30h to 32h, the address goes back to 30h after 32h. AK09918 supports current address read and random

address read.

10.1.3.1. Current Address READ

AK09918 has an address counter inside the LSI chip. In current address read operation, the data at an address

specified by this counter is read.

The internal address counter holds the next address of the most recently accessed address.

For example, if the address most recently accessed (for READ instruction) is address “n”, and a current

address read operation is attempted, the data at address “n+1” is read.

In current address read operation, AK09918 generates an acknowledge after receiving a slave address for the

READ instruction (R/W bit = “1”). Next, AK09918 transfers the data specified by the internal address

counter starting with the next clock pulse, then increments the internal counter by one. If the master IC

generates a stop condition instead of an acknowledge after AK09918 transmits one byte of data, the read

operation stops.

S

T

A

R

T

SDA

S

S

T

O

P

R/W="1"

Slave

Address

Data(n+1)

A

C

K

Data(n+2)

A

C

K

Data(n+3)

A

C

K

Data(n+x)

A

C

K

P

A

C

K

Figure 10.8. Current Address READ

10.1.3.2. Random Address READ

By random address read operation, data at an arbitrary address can be read.

The random address read operation requires to execute WRITE instruction as dummy before a slave address

for the READ instruction (R/W bit = “1”) is transmitted. In random read operation, a start condition is first

generated then a slave address for the WRITE instruction (R/W bit = “0”) and a read address are transmitted

sequentially.

After AK09918 generates an acknowledge in response to this address transmission, a start condition and a

slave address for the READ instruction (R/W bit = “1”) are generated again. AK09918 generates an

acknowledge in response to this slave address transmission. Next, AK09918 transfers the data at the

specified address then increments the internal address counter by one. If the master IC generates a stop

condition instead of an acknowledge after data is transferred, the read operation stops.

S

T

A

R

T

SDA

S

S

T

A

R

T

R/W="0"

Slave

Address

Register

Address(n)

A

C

K

S

A

C

K

S

T

O

P

R/W="1"

Slave

Address

Data(n)

A

C

K

Data(n+1)

A

C

K

Data(n+x)

A

C

K

P

A

C

K

Figure 10.9. Random Address READ

016014242-E-00

2016/11

- 19 -

�[AK09918]

11. Registers

11.1. Description of Registers

AK09918 has registers of 18 addresses as indicated in Table 11.1. . Every address consists of 8 bits data.

Data is transferred to or received from the external CPU via the serial interface described previously.

Table 11.1. Register Table

00h

READ/

WRITE

READ

Company ID

Bit

width

8

WIA2

01h

READ

Device ID

8

RSV1

02h

READ

Reserved 1

8

RSV2

03h

READ

Reserved 2

8

ST1

10h

READ

Status 1

8

Data status

HXL

11h

READ

Measurement Magnetic Data

8

X-axis data

HXH

12h

READ

8

HYL

13h

READ

8

HYH

14h

READ

8

HZL

15h

READ

8

Name

Address

WIA1

Description

Remarks

Y-axis data

Z-axis data

HZH

16h

READ

TMPS

17h

READ

Dummy

8

8

Dummy

ST2

18h

READ

Status 2

8

Data status

CNTL1

30h

Dummy

8

Dummy

CNTL2

31h

Control 2

8

Control settings

CNTL3

32h

Control 3

8

Control settings

TS1

33h

Test

8

DO NOT ACCESS

TS2

34h

READ/

WRITE

READ/

WRITE

READ/

WRITE

READ/

WRITE

READ/

WRITE

Test

8

DO NOT ACCESS

Addresses 00h to 18h, 30h to 32h are compliant with automatic increment function of serial interface

respectively. In other modes, read data is not correct. When the address is in 00h to 18h, the address is

incremented 00h 01h 02h 03h 10h 11h ... 18h, and the address goes back to 00h after

18h. When the address is in 30h to 32h, the address goes back to 30h after 32h.

016014242-E-00

2016/11

- 20 -

�[AK09918]

11.2. Register Map

Table 11.2. Register Map

Addr.

Register

name

D7

D6

D5

D4

Read-only register

0

0

0

0

RSV15

RSV14

RSV25

RSV24

0

0

HX5

HX4

HX13

HX12

HY5

HY4

HY13

HY12

HZ5

HZ4

HZ13

HZ12

0

0

RSV30

RSV29

Read/Write register

0

0

D3

D2

D1

D0

1

1

RSV13

RSV23

0

HX3

HX11

HY3

HY11

HZ3

HZ11

0

HOFL

0

1

RSV12

RSV22

0

HX2

HX10

HY2

HY10

HZ2

HZ10

0

RSV28

0

0

RSV11

RSV21

DOR

HX1

HX9

HY1

HY9

HZ1

HZ9

0

0

0

0

RSV10

RSV20

DRDY

HX0

HX8

HY0

HY8

HZ0

HZ8

0

0

00h

01h

02h

03h

10h

11h

12h

13h

14h

15h

16h

17h

18h

WIA1

WIA2

RSV1

RSV2

ST1

HXL

HXH

HYL

HYH

HZL

HZH

TMPS

ST2

0

0

RSV17

RSV27

0

HX7

HX15

HY7

HY15

HZ7

HZ15

0

0

1

0

RSV16

RSV26

0

HX6

HX14

HY6

HY14

HZ6

HZ14

0

RSV31

30h

CNTL1

0

0

0

0

0

0

31h

CNTL2

0

0

0

MODE4

MODE3

MODE2

MODE1

MODE0

32h

CNTL3

0

0

0

0

0

0

0

SRST

33h

TS1

-

-

-

-

-

-

-

-

34h

TS2

-

-

-

-

-

-

-

-

When VDD is turned ON, POR function works and all registers of AK09918 are initialized.

TS1 and TS2 are test registers for shipment test. Do not access these registers.

016014242-E-00

2016/11

- 21 -

�[AK09918]

11.3. Detailed Description of Register

11.3.1. WIA: Who I Am

Addr.

Register

name

D7

D6

00h

01h

WIA1

WIA2

0

0

1

0

D5

D4

Read-only register

0

0

0

0

D3

D2

D1

D0

1

1

0

1

0

0

0

0

WIA1[7:0] bits: Company ID of AKM. It is described in one byte and fixed value.

48h: fixed

WIA2[7:0] bits: Device ID of AK09918. It is described in one byte and fixed value.

0Ch: fixed

11.3.2. RSV: Reserved

Addr.

Register

name

02h

03h

RSV1

RSV2

D7

RSV17

RSV27

D6

D5

D4

Read-only register

RSV16 RSV15 RSV14

RSV26 RSV25 RSV24

D3

D2

D1

D0

RSV13

RSV23

RSV12

RSV22

RSV11

RSV21

RSV10

RSV20

D3

D2

D1

D0

0

0

0

0

DOR

0

DRDY

0

RSV1[7:0] bits/ RSV2[7:0] bits: Reserved register for AKM.

11.3.3. ST1: Status 1

Addr.

10h

Register

name

ST1

Reset

D7

D6

0

0

0

0

D5

D4

Read-only register

0

0

0

0

DRDY: Data Ready

“0”: Normal

“1”: Data is ready

DRDY bit turns to “1” when data is ready in Single measurement mode, Continuous measurement mode 1, 2,

3, 4 or Self-test mode. It returns to “0” when any one of ST2 register or measurement data register (HXL to

TMPS) is read.

DOR: Data Overrun

“0”: Normal

“1”: Data overrun

DOR bit turns to “1” when data has been skipped in Continuous measurement mode 1, 2, 3, 4. It returns to “0”

when any one of ST2 register or measurement data register (HXL to TMPS) is read.

016014242-E-00

2016/11

- 22 -

�[AK09918]

11.3.4. HXL to HZH: Measurement Magnetic data

Addr.

11h

12h

13h

14h

15h

16h

Register

name

HXL

HXH

HYL

HYH

HZL

HZH

Reset

D7

D6

HX7

HX15

HY7

HY15

HZ7

HZ15

0

HX6

HX14

HY6

HY14

HZ6

HZ14

0

D5

D4

Read-only register

HX5

HX4

HX13

HX12

HY5

HY4

HY13

HY12

HZ5

HZ4

HZ13

HZ12

0

0

D3

D2

D1

D0

HX3

HX11

HY3

HY11

HZ3

HZ11

0

HX2

HX10

HY2

HY10

HZ2

HZ10

0

HX1

HX9

HY1

HY9

HZ1

HZ9

0

HX0

HX8

HY0

HY8

HZ0

HZ8

0

Measurement data of magnetic sensor X-axis/Y-axis/Z-axis

HXL[7:0] bits: X-axis measurement data lower 8-bit

HXH[15:8] bits: X-axis measurement data higher 8-bit

HYL[7:0] bits: Y-axis measurement data lower 8-bit

HYH[15:8] bits: Y-axis measurement data higher 8-bit

HZL[7:0] bits: Z-axis measurement data lower 8-bit

HZH[15:8] bits: Z-axis measurement data higher 8-bit

Measurement data is stored in two’s complement and Little Endian format. Measurement range of each axis

is -32752 to 32752 in 16-bit output.

Table 11.3. Measurement magnetic data format

Measurement data (each axis) [15:0] bits

Magnetic flux

density [µT]

Two’s complement

Hex

Decimal

0111 1111 1111 0000

7FF0

32752

4912(max.)

|

|

|

|

0000 0000 0000 0001

0001

1

0.15

0000 0000 0000 0000

0000

0

0

1111 1111 1111 1111

FFFF

-1

-0.15

|

|

|

|

1000 0000 0001 0000

8010

-32752

-4912(min.)

11.3.5. TMPS: Dummy

Addr.

17h

Register

name

TMPS

Reset

D7

D6

0

0

0

0

D5

D4

Read-only register

0

0

0

0

D3

D2

D1

D0

0

0

0

0

0

0

0

0

TMPS[7:0] bits: Dummy register.

016014242-E-00

2016/11

- 23 -

�[AK09918]

11.3.6. ST2: Status 2

Addr.

18h

Register

name

ST2

Reset

D7

D6

0

0

RSV31

0

D5

D4

Read-only register

RSV30

RSV29

0

0

D3

D2

D1

D0

HOFL

0

RSV28

1

0

0

0

0

ST2[6:4] bits: Reserved register for AKM.

HOFL: Magnetic sensor overflow

“0”: Normal

“1”: Magnetic sensor overflow occurred

In Single measurement mode, Continuous measurement mode 1, 2, 3, 4, and Self-test mode, magnetic sensor

may overflow even though measurement data register is not saturated. In this case, measurement data is not

correct and HOFL bit turns to “1”. When measurement data register is updated, HOFL bit is updated. Refer

to 9.4.3.6 for detailed information.

ST2 register has a role as data reading end register, also. When any of measurement data register (HXL to

TMPS) is read in Continuous measurement mode 1, 2, 3, 4, it means data reading start and taken as data

reading until ST2 register is read. Therefore, when any of measurement data is read, be sure to read ST2

register at the end.

11.3.7. CNTL1: Dummy

Addr.

30h

Register

name

CNTL1

Reset

D7

D6

0

0

0

0

D5

D4

Read/Write register

0

0

0

0

D3

D2

D1

D0

0

0

0

0

0

0

0

0

D3

D2

D1

D0

CNTL1[7:0] bits: Dummy register.

11.3.8. CNTL2: Control 2

Addr.

31h

Register

name

CNTL2

Reset

D7

0

0

D6

0

0

D5

D4

Read/Write register

0

MODE4 MODE3

0

0

0

MODE2

0

MODE1 MODE0

0

0

MODE[4:0] bits: Operation mode setting

“00000”: Power-down mode

“00001”: Single measurement mode

“00010”: Continuous measurement mode 1

“00100”: Continuous measurement mode 2

“00110”: Continuous measurement mode 3

“01000”: Continuous measurement mode 4

“10000”: Self-test mode

Other code settings are prohibited

.

When each mode is set, AK09918 transits to the set mode. Refer to 9.3 for detailed information.

016014242-E-00

2016/11

- 24 -

�[AK09918]

11.3.9. CNTL3: Control 3

Addr.

32h

Register

name

CNTL3

Reset

D7

D6

0

0

0

0

D5

D4

Read/Write register

0

0

0

0

D3

D2

D1

D0

0

0

0

0

0

0

SRST

0

SRST: Soft reset

“0”: Normal

“1”: Reset

When “1” is set, all registers are initialized. After reset, SRST bit turns to “0” automatically.

11.3.10. TS1, TS2: Test

Addr.

33h

34h

Register

name

TS1

TS2

Reset

D7

0

D6

0

D5

D4

Read/Write register

0

0

D3

D2

D1

D0

0

0

0

0

TS1 and TS2 registers are AKM internal test register. Do not access these registers.

016014242-E-00

2016/11

- 25 -

�[AK09918]

12. Example of Recommended External Connection

VDD

POWER 1.65V to 1.95V

Host CPU

Power for I/F

B

SDA

VDD

SCL

VSS

I2C I/F

0.1µF

2

A

1

AK09918C

(Top view)

016014242-E-00

2016/11

- 26 -

�[AK09918]

13. Package

13.1. Marking

Date code:

X1X2 X3X4X5

X1 = ID

X2 = Year code

X3 =Month code

X4X5 =Lot

X1X2X3

X4X5

13.2. Pin Assignment

B

A

2

SDA

SCL

1

VDD

VSS

016014242-E-00

2016/11

- 27 -

�[AK09918]

13.3. Outline Dimensions

[mm]

0.760.03

1

1

2

B

B

0.4

0.760.03

2

0.4

A

A

+0.03

0.22-0.01

0.40

0.583 max.

0.147

0.03 C

C

13.4. Recommended Foot Print Pattern

[mm]

0.4

B

2

1

0.4

A

0.21

016014242-E-00

2016/11

- 28 -

�[AK09918]

14. Relationship between the Magnetic Field and Output Code

The measurement data increases as the magnetic flux density increases in the arrow directions.

016014242-E-00

2016/11

- 29 -

�[AK09918]

IMPORTANT NOTICE

0. Asahi Kasei Microdevices Corporation (“AKM”) reserves the right to make changes to the information contained in

this document without notice. When you consider any use or application of AKM product stipulated in this

document (“Product”), please make inquiries the sales office of AKM or authorized distributors as to current status

of the Products.

1. All information included in this document are provided only to illustrate the operation and application examples of

AKM Products. AKM neither makes warranties or representations with respect to the accuracy or completeness of

the information contained in this document nor grants any license to any intellectual property rights or any other

rights of AKM or any third party with respect to the information in this document. You are fully responsible for use

of such information contained in this document in your product design or applications. AKM ASSUMES NO

LIABILITY FOR ANY LOSSES INCURRED BY YOU OR THIRD PARTIES ARISING FROM THE USE OF

SUCH INFORMATION IN YOUR PRODUCT DESIGN OR APPLICATIONS.

2. The Product is neither intended nor warranted for use in equipment or systems that require extraordinarily high

levels of quality and/or reliability and/or a malfunction or failure of which may cause loss of human life, bodily

injury, serious property damage or serious public impact, including but not limited to, equipment used in nuclear

facilities, equipment used in the aerospace industry, medical equipment, equipment used for automobiles, trains,

ships and other transportation, traffic signaling equipment, equipment used to control combustions or explosions,

safety devices, elevators and escalators, devices related to electric power, and equipment used in finance-related

fields. Do not use Product for the above use unless specifically agreed by AKM in writing.

3. Though AKM works continually to improve the Product’s quality and reliability, you are responsible for complying

with safety standards and for providing adequate designs and safeguards for your hardware, software and systems

which minimize risk and avoid situations in which a malfunction or failure of the Product could cause loss of human

life, bodily injury or damage to property, including data loss or corruption.

4. Do not use or otherwise make available the Product or related technology or any information contained in this

document for any military purposes, including without limitation, for the design, development, use, stockpiling or

manufacturing of nuclear, chemical, or biological weapons or missile technology products (mass destruction

weapons). When exporting the Products or related technology or any information contained in this document, you

should comply with the applicable export control laws and regulations and follow the procedures required by such

laws and regulations. The Products and related technology may not be used for or incorporated into any products or

systems whose manufacture, use, or sale is prohibited under any applicable domestic or foreign laws or regulations.

5. Please contact AKM sales representative for details as to environmental matters such as the RoHS compatibility of

the Product. Please use the Product in compliance with all applicable laws and regulations that regulate the inclusion

or use of controlled substances, including without limitation, the EU RoHS Directive. AKM assumes no liability for

damages or losses occurring as a result of noncompliance with applicable laws and regulations.

6. Resale of the Product with provisions different from the statement and/or technical features set forth in this

document shall immediately void any warranty granted by AKM for the Product and shall not create or extend in

any manner whatsoever, any liability of AKM.

7. This document may not be reproduced or duplicated, in any form, in whole or in part, without prior written consent

of AKM.

Rev.1

016014242-E-00

2016/11

- 30 -

�