A80601 and A80601-1

High Power LED Driver with Pre-Emptive Boost

for Ultra-High Dimming Ratio and Low Output Ripple

FEATURES AND BENEFITS

DESCRIPTION

• Automotive AEC-Q100 qualified

• Enhanced fault handling for ASIL B system compliance

• Wide input voltage range of 4.5 to 40 V for start/stop,

cold crank, and load dump requirements

• Operate in Boost or SEPIC mode for flexible output

• Gate driver for external NMOS to deliver higher output power

• Four integrated LED current sinks, up to 210 mA each

• Boost switching frequency synced externally or

programmed from 200 kHz to 2.3 MHz

• Programmable boost frequency dithering to reduce EMI

• Advanced control allows minimum PWM on-time down

to 0.3 µs, and avoids MLCC audible noises

• LED contrast ratio: 15,000:1 at 200 Hz using PWM

dimming alone, 150,000:1 when combining PWM and

analog dimming

• Excellent input voltage transient response even at lowest

PWM duty cycle

• Gate driver for optional PMOS input disconnect switch

• Extensive fault protection features

The A80601 is a multi-output LED driver for automotive

applications such as exterior lighting, heads-up display, and midsize LCD backlighting. It implements a current-mode boost/

SEPIC converter with gate driver for external N-MOSFET. This

allows greater output power even at minimum supply voltage.

The A80601 provides four integrated current sinks driving up

to 210 mA per string. Multiple sinks can be paralleled together

to achieve higher LED currents up to 840 mA. The IC operates

from single power supply from 4.5 to 40 V; once started, it can

continue to operate down to 4 V. This allows it to withstand

stop/start, cold crank, and load dump conditions encountered

in automotive systems.

The A80601 can control LED brightness through external PWM

signal. By using the patented Pre-Emptive Boost control, an LED

brightness contrast ratio of 15,000:1 can be achieved using PWM

dimming at 200 Hz. A higher ratio of 150,000:1 is possible when

using a combination of PWM and analog dimming.

Continued on next page...

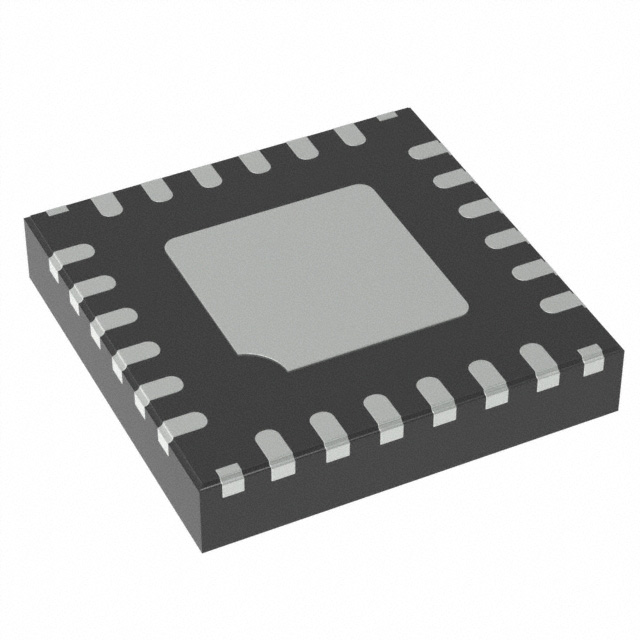

PACKAGE:

APPLICATIONS

24-Pin 4 mm × 4 mm QFN

with Wettable Flank

• Automotive infotainment backlighting

• Automotive heads-up display

• Automotive interior and exterior lighting

Not to scale

VIN

L1

RSENSE

Cin

VOUT

*optional

D1

Q1

RADJ

ROVP

CDRV

RGDRV

RCS

COUT

GATE

Vsense

Vc

CVDD

RPU

VDRV GDRV

CS

VIN

OVP

VDD

LED1

FAULT

A80601

LED3

PWM

PWM tON ≥ 0.3 µs

100%

LED4

ADIM

CLKOUT

iLED

AGND

ADIM

APWM 100 kHz 0-90%

Up to 11 WLEDs in series

Up to 210 mA/channel

Combine to drive up to 840 mA total

LED2

EN

Enable

PGND

ISET

FSET

DITH

COMP

PEB

CP

PEB = Pre-Emptive Boost

(RD controls the delay time)

DITH = Dithering Control

(Modulation frequency and range)

RISET

RFSET

RM

CM

RD

RZ

CZ

Figure 1: A80601 in Boost configuration where VOUT is higher than VIN

A80601-DS

MCO-0000618

March 4, 2019

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

DESCRIPTION (continued)

Switching frequency can be externally synchronized or programmed

between 200 kHz and 2.3 MHz. This allows operation either above

or below the AM band. A programmable dithering feature further

reduces EMI. A Clock-Out is provided for other converters to sync

to the A80601.

The A80601 provides protection against output short, overvoltage,

open- or shorted-LED pin, and overtemperature. A cycle-by-cycle

current limit protects the external boost switch against high current

overloads. An external P-MOSFET can optionally be used to

disconnect input supply in case of output to ground short fault. The

A80601-1 is similar to A80601 except it adopts ‘One-Out-All-Out’

fault handling (See Fault Table section for details).

SELECTION GUIDE [1]

Part Number

Fault Handling

A80601KESJSR

One-Out-Continue

A80601KESJSR-1

One-Out-All-Out

[1] Contact Allegro

LED Driver

Package

Packing

4 × 210 mA

24-pin 4 × 4 mm wettable flank QFN

with exposed thermal pad and sidewall plating

6000 pieces per reel

for additional packing options.

ABSOLUTE MAXIMUM RATINGS [2]

Characteristic

Symbol

LEDx Pin

VLEDx

OVP pin

VOVP

VIN

VSENSE, GATE

VDRV, GDRV

CS

Notes

Rating

–0.3 to 40

V

–0.3 to 40

V

VIN

–0.3 to 40

V

VSENSE,

VGATE

Higher of –0.3

and (VIN – 7.4) to

VIN +0.4

V

VDRV, VGDRV

–1.0 to 7.5

V

VCS

–0.3 to 7

V

External input signals must not be higher than VIN + 0.4 V

–0.3 to 5.5

V

Range K

–40 to 125

°C

EN, PWM, FAULT, ADIM, CLKOUT,

COMP, DITH, PEB, FSET, ISET, VDD

x = 1..4

Unit

Operating Ambient Temperature

TA

Maximum Junction Temperature

TJ(max)

150

°C

Tstg

–55 to 150

°C

Storage Temperature

[2]

Stresses beyond those listed in this table may cause permanent damage to the device. The absolute maximum ratings are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated in the Electrical Characteristics table is not implied.

Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

THERMAL CHARACTERISTICS: May require derating at maximum conditions; see application information

Characteristic

Package Thermal Resistance

[4] Additional

Symbol

RθJA

Test Conditions [4]

Value

Unit

37

°C/W

ES package measured on 4-layer PCB based on JEDEC standard

thermal information available on the Allegro website.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

2

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

Table of Contents

LED Current Setting......................................................... 18

PWM Dimming................................................................ 18

Pre-Emptive Boost (PEB).................................................. 19

Analog Dimming.............................................................. 20

ADIM Mode................................................................. 20

APWM Mode............................................................... 21

Extending LED Dimming Ratio.......................................... 22

Analog Dimming with External Voltage............................... 23

VDD............................................................................... 24

VDRV............................................................................. 24

Shutdown....................................................................... 24

Fault Detection and Protection.............................................. 25

FAULT Status.................................................................. 25

LED String Partial-Short Detect......................................... 27

Overvoltage Protection..................................................... 28

Boost Switch Overcurrent Protection.................................. 29

Input Overcurrent Protection and Disconnect Switch............ 30

Setting the Input Current Sense Resistor............................ 31

Input UVLO..................................................................... 31

Fault Protection During Operation...................................... 31

Package Outline Drawing..................................................... 34

Appendix: External MOSFET Selection Guide........................ 35

Features and Benefits............................................................ 1

Description........................................................................... 1

Applications.......................................................................... 1

Package.............................................................................. 1

Selection Guide.................................................................... 2

Absolute Maximum Ratings.................................................... 2

Thermal Characteristics......................................................... 2

Typical Application – SEPIC................................................... 3

Functional Block Diagram...................................................... 4

Pinout Diagram and Terminal List............................................ 5

Electrical Characteristics........................................................ 6

Functional Description..........................................................11

Enabling the IC.................................................................11

Powering Up: LED Detection Phase................................... 12

Powering Up: Boost Output Undervoltage........................... 14

Soft Start Function........................................................... 14

Frequency Selection......................................................... 15

Synchronization............................................................... 15

Loss of External Sync Signal............................................. 16

Switching Frequency Dithering.......................................... 17

Clock Out Function.......................................................... 17

L2

Breakdown voltage of Q1 and

D1 must be > VIN + VOUT

VIN

D1

L1

CC

CIN

Q1

ROVP

COUT1

CDRV

VC

RPU

GATE

Vsense

CVDD

VDRV GDRV CS

VIN

A80601

LED1

LED3

LED4

ADIM

CLKOUT

iLED

ADIM

APWM 100kHz 0-90%

Up to 11 WLEDs in series

Up to 210 mA/ch. Combine

to drive up to 840 mA total

LED2

PWM

100%

PGND

OVP

EN

PWM t on ≥ 0.3 µs

COUT2

VDD

FAULT

Enable

VOUT ≤ 40 V

AGND

ISET

FSET

DITH

COMP

PEB

CP

RISET

RFSET

RDITH

CDITH

RPEB

RZ

CZ

Figure 2: A80601 in SEPIC configuration where VOUT can be either higher or lower than VIN

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

3

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

External

SYNC

RFSET

Oscillator

CLKOUT active as

long as EN=H

CDRV

GATE

VDRV

Enable

fSW

Boost

Enable

COMP

Comparator

COMP

NMOS

Gate

Drive

VDD

PGND

1 MHz

4 MHz

OCP2

System

oscillator

TSD

VOUT

FSET or ISET

pin Open/Short

Internal VDD

(4.25 V)

CVDD

VIN

Regulator

UVLO Block

ROVP

1.235 V

REF

OVP

sense

Vref

Enable

Open/Short

LED Detect

+

VSENSE

iADJ

Input current

sense amp

Chopping

freq = 4 MHz

VIN

On/Off

GATE

GATE

OFF

Boost

Enable

PMOS

Driver

Current

level

LED1

LED

Driver

Block

LED2

LED3

LED4

AGND

Enable

Clock

detector

Vref

100 kΩ

1 MHz

Keep-Alive

Timer

ISET

Block

PWM

LED Enable

100k

start

Pre-Emptive

Boost

Internal FAULT

delay

A80601

External

FAULT

ADIM

50k

Int VDD

EN

OVP

Fault Block

AGND

RSENSE

RPEB

RCS

÷4

LED1

.

.

LED4

Multi-input

Error Amp

PEB

CS

Current

sense

Soft Start

Ramp

(8 ms)

VLED

ref

External PWM

100 Hz – 20 KHz

GDRV

PGND

CCOMP

VOUT

Gate Driver

LDO (6.5 V)

VIN

Frequency

dithering

Clock Out

Buffer

SW

L1

DITH

FSET/SYNC

CLKOUT

VSENSE

CDITH

RDITH

ISET

RISET

VDD

RPU

FAULT

AGND

Figure 3: Functional Block Diagram

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

4

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

20 CS

19 VDRV

21 GDRV

22 GATE

23 VSENSE

24 VIN

PINOUT DIAGRAM AND TERMINAL LIST

FAULT

1

18 PGND

VDD

2

17 OVP

AGND

3

16 LED1

PAD

15 LED2

EN 11

CLKOUT 12

PWM 10

13 LED4

9

6

ADIM

PEB

8

14 LED3

7

5

DITH

4

ISET

FSET

COMP

Package ES, 24-Pin QFN Pinouts

Terminal List Table

Number

1

Name

FAULT

Function

This pin is an open drain type configuration that will be pulled low when a fault occurs. Connect a pull-up resistor between this pin and

desired logic level voltage.

Output of internal LDO (bias regulator). Connect a 1 µF decoupling capacitor between this pin and AGND. VDD is regulated at ~4.25 V.

2

VDD

3

AGND

LED current Ground. Also serves as ‘quiet’ ground for analog signals.

4

COMP

Output of the error amplifier and compensation node. Connect a series RZ-CZ network from this pin to AGND for control loop compensation.

5

ISET

Connect RISET resistor between this pin and AGND to set the 100% LED current.

6

PEB

Pre-Emptive Boost control: Connect resistor from PEB pin to AGND to fine-tune the delay between boost switch and LED current sinks.

Leave pin open for minimum PEB delay of 1 μs.

7

DITH

Dithering control: connect a capacitor to AGND to set the dithering modulation frequency (1 to 22 kHz). Connect a resistor between DITH and

FSET pins to set the dithering range (such as ±5% of fSW).

8

FSET

Frequency/Synchronization pin. A resistor RFSET from this pin to AGND sets the switching frequency fSW (with dithering superimposed)

between 200 kHz and 2.3 MHz. It can also be used to synchronize fSW to an external frequency between 260 kHz and 2.3 MHz (frequency

dithering is disabled in this case).

9

ADIM

Analog dimming. Apply a PWM clock (40 to 1000 kHz) to pin and the duty cycle of this clock determines the LED current. Alternatively, apply

DC level between 0.2 and 2 V to vary LED current between 10% and 100%. If unused, pull pin above 2 V for 100%.

10

PWM

Controls the on/off state of LED current sinks to reduce the light intensity by using pulse-width modulation. Typical PWM dimming frequency

is in the range of 200 Hz to 2 kHz. EN and PWM pins may be tied together to allow single-wire dimming control.

11

EN

12

CLKOUT

13-16

LED4..LED1

17

OVP

18

PGND

19

VDRV

20

CS

21

GDRV

22

GATE

Enables the IC when this pin is pulled high. If EN goes low, the IC remains in standby mode for up to 16 ms, then shuts down completely.

Logic output representing the switching frequency of internal boost oscillator. This allows other converters to be synchronized to the same fSW

with the same dithering modulation, if applicable. Output is active as long as IC is enabled.

LED current sinks #4 to #1. Connect the cathode of each LED string to pin. Unused LED pin must be terminated to AGND through a 2.37 kΩ resistor.

Overvoltage Protection. Connect external resistor from VOUT to this pin to adjust the overvoltage protection threshold.

Power Ground for internal Gate Driver. Connect pin to external power GND with shortest path.

Gate driver supply voltage (~6.5 V). Connect a 2.2 µF MLCC to PGND for buffer.

Current Sense for peak current control of power switch. Connect to sense resistor at the Source terminal of external power MOSFET.

Gate driver for power switch. Connect to Gate of external power MOSFET. (External FET must be fully enhanced at VGS = 5 V).

Output gate driver pin for external P-channel MOSFET (input disconnect switch).

Connect this pin to the negative sense side of the input current sense resistor RSC. The threshold voltage is measured as VIN – VSENSE. There

is also fixed iADJ current sink to allow for trip threshold adjustment.

23

VSENSE

24

VIN

Input power to the IC as well as the positive side of input current sense resistor.

–

PAD

Exposed pad of the package providing enhanced thermal dissipation. Must be connected to the ground plane(s) of the PCB with at least 8

vias, directly in the pad.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

5

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

ELECTRICAL CHARACTERISTICS [1]: Unless otherwise noted, specifications are valid at VIN = 12 V, TJ = 25°C, • indicates specifications guaranteed over the full operating temperature range with TJ = –40°C to 125°C, typical specifications are at TJ = 25°C

Characteristics

Symbol

Test Conditions

Min.

Typ.

Max.

Unit

INPUT VOLTAGE SPECIFICATIONS

●

4.5

−

40

V

VUVLO(rise)

VIN

VIN rising

●

−

–

4.45

V

VIN UVLO Stop Threshold

VUVLO(fall)

VIN falling

●

UVLO Hysteresis [2]

VUVLO_HYS

Operating Input Voltage Range [3]

VIN UVLO Start Threshold

−

–

4.05

V

300

400

500

mV

INPUT CURRENTS

VIN Pin Operating Current

VIN Pin Quiescent Current

VIN Pin Sleep Current

IOP

EN and PWM = H, CGATE = 1 nF from GDRV to

PGND, fSW = 2 MHz

●

−

22

32

mA

IQ

EN = H and PWM = L, fCLKOUT = 2 MHz

●

−

4

6

mA

VIN = 16 V, VEN / VPWM = VSYNC = 0 V

●

−

1

5

µA

●

−

−

0.4

V

●

ISLEEP

INPUT LOGIC LEVELS (EN/PWM, ADIM)

Input Logic Level-Low

Input Logic Level-High

Input Pull-Down Resistor

VIL

VIH

1.5

−

−

V

REN, RPWM

Input = 5 V

60

100

140

kΩ

RADIM

Input = 5 V

30

50

70

kΩ

−

0.3

V

OUTPUT LOGIC LEVELS (CLKOUT)

Output Logic Level-Low

Output Logic Level-High

VOL

5 V < VIN < 40 V, iLOAD = 1 mA

●

−

VOH

5 V < VIN < 40 V, iLOAD = 1 mA

●

1.8

−

−

V

CLKOUT Duty Cycle

DCLKOUT

fSW = 2 MHz, no external sync

●

33

50

67

%

CLKOUT Negative Pulse Width

tCLKNPW

External sync = 260 kHz to 2.3 MHz

−

200

−

ns

ANALOG DIMMING (ADIM)

iADIM50

DC 1.0 V applied to ADIM pin

−

50

−

%

iADIM25

DC 0.5 V applied to ADIM pin

23

25

27

%

APWM Frequency Range [2]

fAPWM

Clock signal applied to ADIM pin

●

40

−

1000

kHz

APWM Duty Cycle Range [2]

DAPWM

Clock signal applied to ADIM pin

●

0

−

90

%

Analog Dimming Current Level

(shown as % of full-scale current)

VDD REGULATOR

Regulator Output Voltage

VDD

4.05

4.25

4.45

V

VDD UVLO Start Threshold

VDDUVLOrise

VIN > 6 V, iLOAD < 1 mA

VDD rising, no external load

−

3.2

−

V

VDD UVLO Stop Threshold

VDDUVLOfall

VDD falling, no external load

−

2.65

−

V

ERROR AMPLIFIER

Amplifier Gain [2]

gm

VCOMP = 1.5 V

−

900

−

μA/V

VCOMP = 1.5 V, A80601 (symm COMP)

−

–500

−

μA

Source Current

IEA(SRC)

VCOMP = 1.5 V, A80601-1 (asymm COMP)

−

–700

−

μA

Sink Current

IEA(SINK)

VCOMP = 1.5 V

−

+500

−

μA

COMP Pin Pull Down Resistance

RCOMP

FAULT = 0, VCOMP = 1.5 V

−

1.4

−

kΩ

Continued on the next page…

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

6

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

ELECTRICAL CHARACTERISTICS [1] (continued): Unless otherwise noted, specifications are valid at VIN = 12 V, TJ = 25°C, • indicates specifications guaranteed over the full operating temperature range with TJ = –40°C to 125°C, typical specifications are at TJ = 25°C

Characteristics

Symbol

Test Conditions

Min.

Typ.

Max.

Unit

OVERVOLTAGE PROTECTION

OVP Pin Voltage Threshold

VOVP(th)

OVP pin connected to VOUT

OVP Pin Sense Current Threshold

iOVP(th)

OVP Sense Current Temperature

Coefficient [2]

∆iOVP

Current into OVP pin

IOVPLKG

VOUT = 16 V, EN = L

OVP Pin Leakage Current

OVP Variation at Output

Undervoltage Detection Threshold

ΔOVP

VUVP(th)

●

Current into OVP pin at 125ºC

Measured over temperature

Measured at VOUT when ROVP = 188 kΩ

●

●

●

2.2

2.5

2.8

V

140

146.5

153

µA

140

150

160

µA

−

−36

−

nA/ºC

−

0.1

1

µA

−

−

4

%

−

−

7

%

Measured at VOUT when ROVP = 188 kΩ [2]

2.4

2.55

2.7

V

Measured at VOUT when ROVP = 0 Ω

0.13

0.20

0.25

V

Measured at VIN > 7.5 V

−

6.5

−

V

Measured at iGDRV = 100 mA

−

2.5

−

Ω

EN = L, VIN = 0 V

−

100

−

kΩ

BOOST SWITCH GATE DRIVER

Gate Driver Supply Voltage

Gate Driver Pull-Up and Pull-Down

Gate Pull-Down When Disabled

Peak Sink Current

[2]

VDRV

RGDRV

RGDRV_OFF

iSINK

Peak Source Current [2]

iSOURCE

Gate Rise / Fall Time [2]

tRISE, tFALL

Measured at VGDRV = VDRV

−

2

−

A

Measured at VGDRV = 0 V

−

2

−

A

Measured with CLOAD = 1.5 nF;

VGDRV between 10% and 90% of VDRV

−

7

−

ns

Minimum Gate Driver On-Time

tSW(ON)

●

−

−

100

ns

Minimum Gate Driver Off-Time

tSW(OFF)

●

−

−

100

ns

●

175

210

245

mV

BOOST SWITCH CURRENT SENSE

Primary Current Sense Limit

iCS(LIM1)

Exceeding iCS(LIM1) causes gate driver to

truncate existing cycle, but does not shut down

Secondary Current Sense Limit

iCS(LIM2)

Exceeding iCS(LIM2) causes gate driver to shut

down and latch off

−

300

−

mV

Secondary Current Sense Limit

Propagation delay [2]

tCSDELAY

Overdrive CS threshold by 10%, excluding

leading edge blanking

−

32

−

ns

1.95

2.15

2.35

MHz

OSCILLATOR FREQUENCY

Oscillator Frequency

FSET Pin Voltage

fSW

RFSET = 10 kΩ

●

RFSET = 110 kΩ

−

200

−

kHz

VFSET

RFSET = 10 kΩ

−

1.00

−

V

VSYNCL

FSET/SYNC pin logic Low

●

−

−

0.4

V

VSYNCH

FSET/SYNC pin logic High

●

1.5

−

−

V

SYNCHRONIZATION

Sync Input Logic Level

Synchronized PWM Frequency

fSWSYNC

●

260

−

2300

kHz

Synchronization Input Min Off-Time

tPWSYNCOFF

●

150

−

−

ns

Synchronization Input Min On-Time

tPWSYNCON

●

150

−

−

ns

Continued on the next page…

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

7

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

ELECTRICAL CHARACTERISTICS [1] (continued): Unless otherwise noted, specifications are valid at VIN = 12 V, TJ = 25°C, • indicates specifications guaranteed over the full operating temperature range with TJ = –40°C to 125°C, typical specifications are at TJ = 25°C

Characteristics

Symbol

Test Conditions

LEDx Accuracy [4]

ErrLED

iISET = 120 µA (RISET = 8.33 kΩ)

LEDx Matching

ΔLEDx

iISET = 120 µA

LEDx Regulation Voltage

VLED

Measured individually with all

other LED pins tied to ≥1 V,

iISET = 120 µA, VADIM > 2.1 V

IISET to ILEDx Current Gain

AISET

iISET = 120 µA

ISET Pin Voltage

VISET

VADIM > 2.1 V

Allowable ISET Current

iISET

VADIM > 2.1 V

Min.

Typ.

Max.

Unit

●

−

0.7

3

%

●

−

0.8

2

%

A80601

●

650

750

850

mV

A80601-1

●

760

860

960

mV

LED CURRENT SINKS

LED String Partial-Short Detect

VLEDSD

Sensed from each LED pin to GND while its current

sink is in regulation; all other LED pins tied to 1 V

LED Pin Shorted-to-GND Test

Duration [2]

tLEDSTG

Wait time before proceeding with Soft-Start (if

no LED pin is shorted to GND)

Soft-Start Ramp-Up Time [2]

tSSRU

Enable Pin Shut Down Delay

tEN(OFF)

Minimum PWM On-Time

●

1432

1466

1500

A/A

0.955

0.985

1.015

V

●

20

−

144

µA

●

4.9

5.5

6.1

V

−

1.5

−

ms

6.6

8.2

9.8

ms

Maximum time duration before all LED

channels come into regulation, or OVP is

tripped, whichever comes first

EN goes from High to Low; exceeding tEN(OFF)

results in IC shutdown

●

10

16

22

ms

tPWMH

First and subsequent PWM pulses

●

−

0.3

0.4

µs

IGSINK

INPUT DISCONNECT GATE PIN

Gate Pin Sink Current

VGS = VIN, no input OCP fault

−

−113

−

µA

Gate Pin Source Current

IGSOURCE

VGS = VIN – 6 V, input OCP fault tripped

−

6

−

mA

Gate Shutdown Delay When OverCurrent Fault Is Tripped [2]

tGATEFAULT

VIN – VSENSE = 200 mV; monitored at FAULT pin

−

−

3

µs

VGS

PMOS Gate to source voltage measured when

gate is on

−

−6.7

−

V

Gate Voltage

VSENSE PIN

VSENSE Pin Sink Current

VSENSE Trip Point

iADJ

●

16

20

24

µA

Measured between VIN and VSENSE, RADJ = 0 Ω ●

88

98

108

mV

VFAULT

iFAULT = 1 mA

−

−

0.5

V

IFAULT-LKG

VFAULT = 5 V

VSENSETRIP

FAULT PIN

FAULT Output Pull-Down Voltage

FAULT Pin Leakage Current

−

−

1

µA

External FAULT Input Low

VFIL

No internal faults; FAULT pin externally pulled down

●

−

−

0.8

V

External FAULT Input High

VFIH

No internal faults

●

1.5

−

−

V

tFIL

No internal faults; delay (in fSW cycles) from

FAULT pin externally pulled L to LED off;

ignored if FAULT returns to H before that

−

8

−

cycles

Thermal Shutdown Threshold [2]

TSD

Temperature rising

155

170

−

°C

Thermal Shutdown Hysteresis [2]

TSDHYS

−

20

−

°C

External FAULT Deglitch Timer

THERMAL PROTECTION (TSD)

For input and output current specifications, negative current is defined as coming out of the node or pin (sourcing);

positive current is defined as going into the node or pin (sinking).

[2] Ensured by design and characterization; not production tested.

[3] Minimum V = 4.5 V is only required at startup. After startup is completed, IC can continue to operate down to V = 4 V.

IN

IN

[4] LED current is trimmed to cancel variations in both Gain and ISET voltage.

[1]

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

8

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

APPLICATION EXAMPLES

VIN

VOUT > 40 V

D1

*optional

L1

RSENSE

CIN

Q2

Q1

ROVP

COUT

CVDRV

GATE

VSENSE

VC

RPU

VDRV GDRV CS

OVP

VIN

CVDD

A80601

LED1

LED2

EN

100%

iLED

APWM 100 kHz 0-90%

AGND

Q3..Q6

LED4

ADIM

CLKOUT

ADIM

Cascode

Transistors

LED3

PWM

PWM ton ≥ 0.3 µs

VDRV

VT

VDD

FAULT

Enable

PGND

ISET

RISET

FSET

RFSET

DITH

CP

RM

CM

Max. LEDx pin voltage

limited to VDRV - VT

COMP

PEB

RD

RZ

CZ

Figure 4: Cascode transistors can be used in case VOUT needs to be higher than 40 V

To drive an output load with more than 11 white LEDs in series, the above application circuit can be

used. The cascode transistors Q3..Q6 limits LED1-4 pin voltages to VDRV – VT, even in case of LED

string direct short. (VT = threshold voltage of transistor, typically under 3 V).

The cascode transistors can be any small-signal N-channel MOSFET, rated for the maximum output

voltage and LED current per channel. As an example: consider T2N7002BK in SOT23 package. It is

rated for 60 V breakdown and 400 mA continuous current.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

9

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

VIN

D1

VOUT ≤ 40 V

L1

Q1

CIN

COUT

ROVP1

ROVP2

CVDRV

VIN

GDRV

CS

VDRV

GATE

VSENSE

VC

RPU

CVDRV

PGND

OVP

VIN

VDD

A80601-1

(MASTER)

FAULT

CVDD

LED1

LED4

PWM

LED1

LED2

LED3

EN

Up to 210 mA × 4

ADIM

LED4

PWM

ADIM

CLKOUT

AGND

A80601-1

(SLAVE)

FAULT

LED3

PGND

OVP

VIN

VDD

LED2

EN

GDRV

CS

VDRV

GATE

VSENSE

ISET

FSET

DITH

COMP

CLKOUT

PEB

AGND

CP

RISET

RFSET

RDITH

CDITH

RPEB1

RZ

CZ

RISET

Up to 210 mA × 4

COMP

ISET

FSET

RFSET

DITH

PEB

RPEB

Figure 5: Two A80601-1 connected in Master/Slave Configuration to drive 210 mA × 8 LED strings

Remarks on Master-Slave configuration:

• Only one Slave to a Master.

• Master-Slave operation requires asymmetrical COMP (for example: source = –700 µA and

sink = 500 µA). This is available in A80601-1 only.

• Also requires bidirectional FAULT pin of A80601-1, so that the slave can halt the switching of master.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

10

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

FUNCTIONAL DESCRIPTION

The A80601 is a multi-string LED regulator with four precision current sinks and a gate driver for external boost MOSFET

switch. It incorporates a patented Pre-Emptive Boost (PEB)

control algorithm to achieve PWM dimming ratio over 15,000:1

at 200 Hz. PEB control also minimizes output ripple to avoid

audible noise from output ceramic capacitors.

The switching frequency can be either synchronized to an

external clock or generated internally. Spread-spectrum technique (with user-programmable dithering range and modulation

frequency) is provided to reduce EMI. A clock-out signal (CLKOUT) allows other converters to be synchronized to the switching

frequency of A80601.

Only if no faults were detected, then the IC can proceed to start

switching.

As long as EN = H, the PWM pin can be toggled to control the

brightness of LED channels by using PWM dimming. Alternatively, EN and PWM can be tied together to allow single-wire

control for both power on/off and PWM dimming. If EN is pulled

low for longer than 16 ms, the IC shuts off.

Enabling the IC

The A80601 wakes up when EN pin is pulled above logic high

level, provided that VIN pin voltage is over the VIN_UVLO

threshold. The boost stage and LED channels are enabled separately by PWM = H signal after the IC powers up.

The IC performs a series of safety checks at power up, to determine if there are possible fault conditions that might prevent the

system from functioning correctly. Power-up checks include:

• VOUT shorted to GND

• LED pin shorted to GND

• FSET pin open/shorted

Figure 6: Startup showing EN, VDD, CLKOUT, and ISET (PWM = L).

Note that CLKOUT is available as soon as VDD ramps up, even though

Boost stage and LED drivers are not yet enabled.

• ISET pin open/shorted to GND, etc.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

11

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

Powering Up: LED Detection Phase

The VIN pin has an undervoltage lockout (UVLO) function that

prevents the A80601 from powering up until the UVLO threshold is

reached. Once the VIN pin goes above UVLO and a high signal is

present on the EN pin, the IC proceeds to power up. At this point, the

A80601 is going to enable the disconnect switch and will try to check

if any LED pins are shorted to GND and/or are not used. The LED

detection phase starts when PWM = H and the GATE voltage of the

input disconnect PMOS switch is pulled down to 3.3 V below VIN.

Unused LED pin should be terminated with a 2.37 kΩ

resistor to GND. At the end of LED detection phase,

any channel with pull down resistor is then disabled

and will not contribute to the boost regulation loop.

VOUT

VOUT

Using all LED

Channels

Using LED

Channels 1-3

LED1

LED1

LED2

LED2

LED3

LED3

GND

LED4

GND

LED4

2.37 kΩ

Figure 8: How to signal an unused LED channel

during startup LED detection phase

Table 1: LED Detection phase voltage threshold levels

Figure 7: Startup showing EN+PWM, GATE, LED1, and ISET. Note

that LED Detection Phase starts as soon as GATE pin is pulled

down to 3.3 V below VIN (provided that PWM = H).

LED Pin

Voltage Measured

Interpretation

Outcome

< 120 mV

LED pin shorted to

GND fault

Cannot proceed with

soft-start unless fault

is removed

~ 230 mV

LED channel not in

use

LED channel is

removed from

operation

> 340 mV

LED channel in use

Proceed with soft-start

Once the voltage threshold on VLED pins exceeds ~120 mV, a

delay of approximately 1.5 ms is used to determine the status of

the pins.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

12

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

If an LED pin is shorted to ground, the A80601 will not proceed

with soft start until the short is removed from the LED pin. This

prevents the A80601 from ramping up the output voltage and putting an uncontrolled amount of current through the LEDs.

The FAULT pin is pulled low in case of LED pin shorted-to-GND

fault, but the IC continues to retry. Once the fault is removed, the

soft-start process will continue. The same applies in case of FSET

or ISET pin is shorted to GND.

Figure 9: Normal startup showing all channels passed LED Detection phase (only LED1 and LED2 pin voltages are shown). Total

LED current = 100 mA × 4.

Figure 11: LED1 is shorted-to-GND initially, then released. After the

fault is removed, the IC auto-recovers and proceeds with soft-start.

FAULT is released at the end of LED detection phase.

Figure 10: Normal startup showing LED1 channel is disabled with

a 2.37 kΩ resistor to GND. Total LED current = 100 mA × 3.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

13

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

Power Up: Boost Output Undervoltage

During startup, after the input disconnect switch has been

enabled, the output voltage is checked through the OVP (overvoltage protection) pin. If the sensed voltage does not rise above

VUVP(th), the output is assumed to be at fault and the IC will not

proceed with soft start. Output UVP level is linked to the OVP

level programmed according to the equation:

VUVP = VOVP / 12

Undervoltage protection may be caused by one of the following

faults:

• Output capacitor shorted to GND

• Boost inductor or diode open

• OVP sense resistor open

After an UVP (undervoltage protection) fault, the A80601 is

immediately shutdown and latched off. To enable the IC again,

the latched fault must be cleared. This can be achieved by

powering-cycling the IC, which means either:

• VIN falls below falling UVLO threshold, or

• EN = L for >16 ms.

This is illustrated by the following startup timing diagram (not to

scale):

EN

PWM

VIN

3.3 V

GATE

6.7 V

0

1V

LEDx

0

LED detection

phase

93% OVP

1.5 ms

OVP

VOUT

VIN

0

tSSRU

i LED

0

A B

C

D

Soft-Start

E

Regulation

Figure 12: Complete startup process of A80601

Alternatively, latched fault can be cleared by keeping EN = H but

pulling PWM = L for >16 ms. This method has the advantage that

it does not interrupt the CLKOUT signal.

Explanation of Events:

Soft Start Function

B: When GATE is pulled down to 3.3 V below VIN, ISET becomes

enabled. IC is now waiting for PWM = H to startup.

During startup, the A80601 ramps up its boost output voltage

following a fixed slope, as determined by OVP set point and SoftStart Timer. This technique limits the input inrush current, and

ensures consistent startup time regardless of the PWM dimming

duty cycle.

The soft-start process is completed when any one of the following conditions is met:

• All enabled LED channels have reached their regulation

current,

• Output voltage has reached 93% of its OVP threshold, or

• Soft-start ramp time (tSS) has expired.

A: EN = H wakes up the IC. VDD ramps up and CLKOUT

becomes available. IC starts to pull down GATE slowly.

C: Once PWM = H, the IC checks each LEDx pins to determine

if it is in use, disabled, or shorted to GND.

D: Soft-Start begins at the completion of LED pin short-detect

phase of ~1.5 ms. VOUT ramps up following a fixed slope set by

OVP and soft-start timer of ~8 ms.

E: Soft-start terminates when all LED currents reached regulation, VOUT reached 93% OVP, or soft-start timer expired.

To summarize, the complete startup process of A80601 consists

of:

•

•

•

•

Power-up error checking

Enabling input disconnect switch

LED pin open/short detection

Soft-start ramp

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

14

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

Frequency Selection

t PWSYNCON

The switching frequency of the boost regulator is programmed

by a resistor connected to FSET pin. The switching frequency

can be selected anywhere from 200 kHz to 2.3 MHz. The chart

below shows the typical switching frequency verses FSET resistor value.

154 ns

150 ns

150 ns

t PWSYNCOFF

t = 454 ns

Figure 14: Pulse width requirements

for an External Sync clock at 2.2 MHz

Based on the above, any clock with a duty cycle between 33%

and 66% at 2.2 MHz can be used. The table below summarizes

the allowable duty cycle range at various synchronization frequencies.

Table 2: Acceptable Duty Cycle range for External Sync

clock at various frequencies

Sync. Pulse Frequency

Duty Cycle Range

2.2 MHz

33% to 66%

2 MHz

30% to 70%

1 MHz

15% to 85%

Figure 13: Switching Frequency

as a function of FSET Resistance

Alternatively, the following empirical formula can be used:

Equation 1:

fSW = 21.5 / (RFSET + 0.2)

where fSW is in MHz and RFSET is in kΩ.

If a fault occurs during operation that will increase the switching frequency, the internal oscillator frequency is clamped to a

maximum of 3.5 MHz. If the FSET pin is shorted to GND, the

part will shut down. For more details, refer to the Fault Mode

Table section.

Synchronization

The A80601 can also be synchronized using an external clock.

At power up, if the FSET pin is held low, the IC will not start.

Only when the FSET pin is tristated to allow for the pin to rise to

about 1 V, or when a sync clock is detected, the A80601 will then

try to power up.

The basic requirement of the external sync signal is 150 ns

minimum on-time and 150 ns minimum off time. The diagram

below shows the timing restrictions for a synchronization clock at

2.2 MHz.

600 kHz

9% to 91%

300 kHz

4.5% to 95.5%

If it is necessary to switch over between internal oscillator and

external sync during operation, ensure the transition takes place

at least 500 ns after the previous PWM = H rising edge. Alternatively, execute the switchover during PWM = L only. This restriction does not apply if PWM dimming is not being used.

EN

PWM

500 ns

Ext_Sync

/ FSET 1 V

CLKOUT

Internal oscillator

External Sync

Figure 15: Avoid switching over between Internal

Oscillator and External Sync in highlighted region

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

15

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

Loss of External Sync Signal

Suppose the A80601 started up with a valid external SYNC signal, but the SYNC signal is lost during normal operation. In that

case, one of the following happens:

• If the external SYNC signal is high impedance (open), the

IC continues normal operation after approximately 5 μs, at

the switching frequency set by RFSET. No FAULT flag is

generated.

• If the external SYNC signal is stuck low (shorted to ground),

the IC will detect an FSET-shorted-to-GND fault. FAULT

pin is pulled low after approximately 10 μs, and switching is

disabled. Once the FSET pin is released or SYNC signal is

detected again, the IC will proceed to soft-start.

To prevent generating a fault when the external SYNC signal

is stuck at low, the circuit shown below can be used. When the

external SYNC signal goes low, the IC will continue to operate

normally at the switching frequency set by the RFSET. No FAULT

flag is generated.

External

Sychronization

220 pF

Signal

Schottky

Barrier

Diode

FSET/SYNC

RFSET

10 kΩ

Figure 16: Countermeasure for

External Sync Stuck-at-Low Fault

It is important to use a small capacitance for the AC-coupling

capacitor (220 pF in the above example). If the capacitance is too

large, the IC may incorrectly declare a FSET-shorted-to-GND

fault and restart.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

16

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

Switching Frequency Dithering

To minimize the peak EMI spikes at switching frequency harmonics, the A80601 offers the option of frequency dithering, or

spread-spectrum clocking. This feature simplifies the input filters

needed to meet the automotive CISPR 25 conducted and radiated

emission limits.

There are no hard limits on dithering range and modulation

frequency. As a general guideline, pick a dithering range between

±5% and 10%, with the modulation frequency between 1 kHz and

3 kHz. In practice, using a larger dithering range and/or higher

modulation frequency do not generate any noticeable benefits.

For maximum flexibility, the A80601 allows both dithering range

and modulation frequency to be independently programmable

using two external components.

If dithering function is not desired, it can be disabled by disconnecting the RDITH between DITH and FSET pins. Connect DITH

pin to VDD if CDITH is not populated. Dithering is always disabled when fSW is controlled by external sync. RDITH and CDITH

have no effects in this case even if they were populated.

The Dithering Modulation Frequency is given by the approximate

equation:

Clock Out Function

Equation 2:

fDM (kHz) = 25 / CDITH (nF)

where CDITH is the value of capacitor connected from DITH

pin to GND.

The dithering Range is given by the approximate equation:

Equation 3:

Range (±%) = 20 × RFSET / RDITH

where RFSET is the resistor from FSET pin to GND, RDITH is

the resistor between DITH and FSET pins.

As an example, by using RFSET = 10 kΩ, RDITH = 40.1 kΩ,

and CDITH = 22 nF, the resulted switching frequency is fSW =

2.15 MHz ±5% modulated at 1.1 kHz. This is illustrated by the

following diagram.

FSET

RFSET

10 kΩ

iFSET = 100 µA

±5 µA

RDITH

40.1 kΩ

DITH

The CLKOUT signal is available as soon as the IC is enabled

(EN = H), even when the boost stage is not active (PWM = L).

Its frequency is the same as that of the internal oscillator. Its

duty cycle, however, depends on how the switching frequency is

generated:

• If fSW is programmed by FSET resistor, the CLKOUT duty

cycles is approximately 50%.

• If fSW is controlled by external sync, the output signal has a

fixed 150 ns negative pulse width (CLKOUT = L), regardless

of the external sync frequency.

This is illustrated by the following waveforms:

VDITH

1.2 V

iDITH = ±20 µA

The A80601 allows other ICs to be synchronized to its internal

switching frequency through the CLKOUT pin.

VFSET

1.0 V

0.8 V

CDITH

22 nF

Dithering Range =

±5%

iDITH

20 µA

0

Modulation

frequency

= 1.1 kHz

–20 µA

Per iod = 0.8 × C / i

(0.88 ms when C = 22 nF)

fSW (MHz)

2.25

2.15

2.05

Time (ms)

0

0.88

Figure 17: How to Program Switching Frequency

Dithering Range and Modulation Frequency

Figure 18: Without external sync, the CLKOUT signal has a fixed

duty cycle of 50%. Delay from CLKOUT falling edge to SW falling

edge is approximately 50 ns.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

17

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

PWM Dimming

When both EN and PWM pins are pulled high, the A80601 turns

on all enabled LED current sinks. When either EN or PWM is

pulled low, all LED current sinks are turned off. The compensation (COMP) pin is floated, and critical internal circuits are kept

active.

Figure 19: With external sync, the CLKOUT signal has a fixed

negative pulse width of 200 ns. Delay from SYNC rising edge to

CLKOUT falling edge is approximately 60 ns.

LED Current Setting

The maximum LED current can be up to 210 mA per channel,

and is set through the ISET pin. Connect a resistor RISET between

this pin and GND. The relation between ILED and RISET is given

below:

Equation 4:

By using the patented Pre-Emptive Boost (PEB) control algorithm, the A80601 is able to achieve minimum PWM dimming

on-time down to 300 ns. This translates to PWM dimming ratio

up to 15,000:1 at the PWM dimming frequency of 200 Hz. Technical details on PEB will be explained in the next section.

ILED = ISET × AISET

ISET = VISET / RISET

Therefore RISET = (VISET × AISET ) / ILED

Figure 20: PWM dimming operation at 20% 1 kHz. CH1 = PWM (5 V/

div), CH2 = SW (20 V/div), CH3 = VOUT, CH4 = iLED (200 mA/div).

= 1444 / ILED

where ILED current is in mA and RISET is in kΩ.

This sets the maximum current through the LEDs, referred to

as the ‘100% current’. The average LED current can be reduced

from the 100% current level by using either PWM dimming or

analog dimming.

Table 3: ISET resistor values vs. LED current. Resistances

are rounded to the nearest E-96 (1%) resistor value.

Standard Closest RISET

Resistor Value

LED current per channel

7.15 kΩ

200 mA

9.53 kΩ

150 mA

14.3 kΩ

100 mA

19.1 kΩ

75 mA

28.7 kΩ

50 mA

Figure 21: Zoom in view for PWM on-time = 10 µs. Notice that the

LED current is shifted with respect to PWM signal. Ripple at VOUT

is ~0.2 V when using 2 × 4.7 µF MLCC as output capacitors.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

18

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

CH1 (Yellow) = PWM (5 V/div); CH2 (Red) = Inductor current

(500 mA/div); CH3 (Blue) = VOUT (1 V/div); CH4 (Green) =

LED current (200 mA/div); time scale = 2 µs/div.

Figure 22: Zoom-in view showing A80601 is able to regulate LED

current at PWM on-time down to 300 ns.

The typical PWM dimming frequencies fall between 200 Hz and

1 kHz. There is no hard limit on the highest PWM dimming frequency that can be used. However at higher PWM frequency, the

maximum PWM dimming ratio will be reduced. This is shown in

the following table:

Table 4: Maximum PWM Dimming Ratio that can be achieved

when operating at different PWM Dimming Frequency

PWM Frequency

PWM Period

Maximum PWM

Dimming Ratio

200 Hz

5 ms

15,000:1

1 kHz

1 ms

3,000:1

3.3 kHz

300 µs

1,000:1

20 kHz

50 µs

150:1

Figure 23: Traditional PWM Dimming operation where boost switch

and LED current are enabled at the same time. Note that VOUT

shows overall ripple of ~0.5 V

When PWM signal goes high, a conventional LED driver turns

on its boost switching at the time with LED current sinks. The

problem is that the inductor current takes several switching cycles

to ramp up to its steady-state value before it can deliver full

power to the output load. During the first few cycles, energy to

the LED load is mainly supplied by the output capacitor, which

results in noticeable dip in output voltage.

Pre-Emptive Boost

The basic principle of pre-emptive boost (PEB) can be best

explained by the following two waveforms. The first one shows

how a conventional LED driver operates during PWM dimming

operation. The second one shows that of the A80601.

Common test conditions for both cases:

PWM = 1% at 1 kHz (on-time = 10 µs), fSW = 2.15 MHz,

L = 10 µH, VIN = 12 V, LED load = 8 series (VOUT = ~25 V)

at 100 mA × 4. COUT = 2 × 4.7 µF 50 V 1210 MLCC.

COMP: RZ = 280 Ω, CZ = 68 nF.

Common scope settings:

Figure 24: A80601 PWM dimming operation with PEB delay set to

3 µs. Note that VOUT ripple is reduced to ~0.2 V.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

19

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

In the A80601, the boost switch is also enabled when PWM goes

high. However, the LED current is not turned on until after a

short delay of tPEB. This allows the inductor current to build up

before it starts to deliver the full power to LED load. During the

pre-boost period, VOUT actually bumps up very slightly, while

the following dip is essentially eliminated. When PWM goes low,

both boost switching and LED remains active for the same delay

of tPEB. Therefore the PWM on-time is preserved in LED current.

Analog Dimming

PEB delay can be programmed using an external resistor, RPEB,

from PEB pin to GND. Their relationship is shown in the following chart:

2. In APWM mode: apply a clock signal with duty cycle between 90% and 0% at the pin.

PEB Delay (µs) vs. PEB Resistor value (kΩ)

10

The peak (100%) level of LED current is set by the RISET resistor.

The actual peak LED current may also be adjusted continuously

from approximately 10% up to 100%, by using the ADIM pin.

There are two methods to do so:

1. In ADIM mode: apply a DC voltage between 0.2 V and 2 V

at the pin.

ADIM MODE

An analog voltage is applied at the ADIM/APMW pin. This DC

voltage linearly controls the peak LED current, as illustrated by

the chart below:

9

8

Normalized LED Current vs. ADIM Voltage

6

100%

5

90%

4

80%

3

70%

2

60%

1

0

LED Current

tPEB (µs)

7

50%

6

8

10

12

14

16

RPEB (kΩ)

18

20

22

24

Figure 25: How PEB delay time varies with value of PEB pin resistor to GND.

Ideally, tPEB is equal to the inductor current ramp up time. But the

latter is affected by many external parameters, such as switching

frequency, inductance, VIN and VOUT ratio, etc. Therefore, some

experimentation is required to optimize the PEB delay time. In

general for switching frequency at 2 MHz, tPEB = 2.5 to 4 µs is a

good starting point.

The advantage of PEB is that even a non-optimized delay time

can significantly reduce the output ripple voltage compared to a

conventional LED driver.

40%

ADIM Decreasing

30%

ADIM Increasing

20%

10%

0%

0

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8

ADIM Voltage (V)

2

2.2

Figure 26: In analog dimming mode, the LED current is linearly proportional to ADIM voltage between 0.2 V and 2 V approximately

There is an internal pull-down resistor (50 kΩ typical) from

ADIM pin to GND. When this pin is left floating, LED current

is actually being dimmed down to ~10%. Therefore, if analog

dimming is not required, the ADIM pin should be pulled to over

2 V (but below VDD) to ensure 100% LED current. One simple

technique is to pull up ADIM to VDD through a 30 kΩ resistor.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

20

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

APWM MODE

When a clock signal is detected at ADIM pin, the A80601 goes

into APWM mode. The typical APWM signal frequency is

between 40 kHz and 1 MHz. The duty cycle of this signal is

inversely proportional to the percentage of current delivered to

the LED. The relationship is shown below:

Normalized LED Current vs. APWM Duty Cycle

100%

80%

LED Current

Measured

60%

Theore�cal

Figure 28: PWM = H. Total LED current drops from 400 mA (4 ×

100 mA/ch) to 300 mA when APWM of 25% duty cycle is applied.

Note that LED current takes ~0.5 ms to settle after change in APWM.

40%

20%

0%

0%

20%

40%

60%

APWM Duty Cycle

80%

100%

Figure 27: Showing LED current is inversely proportional to the

APWM duty cycle. Test conditions: VIN = 12 V, VOUT = 25 V (8 ×

WLED), total LED current = 100 mA × 4, APWM frequency = 100 kHz

As an example, a system that delivers a full LED current of

100 mA per channel would deliver 75 mA when an APWM signal

with a duty-cycle of 25% is applied (because analog dimming

level is 100% – 25% = 75%). This is demonstrated by the following waveforms.

Figure 29: PWM = 25% at 1 kHz. Peak LED current drops from

400 mA (4 × 100 mA/ch) to 300 mA when APWM of 25% duty cycle

is applied

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

21

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

To use ADIM pin as a trim function, the user should first set the

100% current based on efficacy of LED from the lowest bin.

When using LED with higher efficacy, the required current is then

trimmed down to the appropriate level using APWM duty cycle.

As an example, assume that:

• LED from lowest bin has an efficacy of 80 lm/W

• LED highest bin has an efficacy of 120 lm/W

Suppose the maximum LED current was set at 100 mA based

on LEDs from lowest bin. When using LEDs from highest bin,

the current should then be reduces to 67% (80/120). This can be

achieved by sending APWM clock with 33% duty cycle.

Extending LED Dimming Ratio

The dynamic range of LED brightness can be further extended,

by using a combination of PWM duty cycle, APWM duty cycle,

and analog dimming method.

For example, the following approach can be used to achieve a

100,000:1 dimming ratio at 200 Hz:

• Vary PWM duty cycle from 100% down to 0.01% to give

10,000:1 dimming. This requires PWM dimming on-time be

reduced down to 0.5 µs.

• With PWM dimming on-time fixed at 0.5µs, vary APWM duty

from 0% to 90% to reduce peak LED current from 100% down

to 10%. This gives a net effect of 100,000:1 dimming.

100

Normalized LED Current (%)

One popular application of analog dimming is for LED brightness

calibration, commonly known as ‘LED Binning’. LEDs from

the same manufacturer and series are often grouped into different ‘bins’ according to their light efficacy (lumens per watt). It is

therefore necessary to calibrate the ‘100% current’ for each LED

bin, in order to achieve uniform luminosity.

Average LED Current vs. PWM Dimming Duty Cycle

10

1

0.1

PWM Dimming

0.01

APWM + PWM

Ideal

0.001

0.001

0.01

0.1

1

10

PWM Dimming Duty Cycle (%)

100

Figure 30: How to achieve 100,000:1 dimming ratio by using both

PWM and APWM. Test conditions: VIN = 12 V, VOUT = 25 V (8 ×

WLED), total LED current = 400 mA, PWM frequency = 200 Hz,

APWM frequency = 100 kHz.

Note that the A80601 is capable of providing analog dimming

range greater than 10:1. By applying APWM with 96% duty

cycle, for example, an analog dimming range of 25:1 can be

achieved. However, this requires the external APWM signal

source to have very fine pulse-width resolution. At 200 kHz

APWM frequency, a resolution of 50 ns is required to adjust its

duty cycle by 1%.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

22

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

Analog Dimming with External Voltage

Besides using ADIM pin, the LED current can also be reduced

by using an external voltage source applied through a resistor

to the ISET pin. The dynamic range of this type of dimming is

dependent on the ISET pin current. The recommended iSET range

is from 20 µA to 144 µA for the A80601. Note that the IC will

continue to work at iSET below 20 µA, but the relative error in

LED current becomes larger at lower dimming level.

Below is a typical application circuit using a DAC (digital-analog

converter) to control the LED current. The ISET current (which

directly controls the LED current) is normally set as VISET/RISET.

The DAC voltage can be higher or lower than VISET, thus adjusting the LED current to a lower or higher value.

A80601

R2

VDAC

In the following application example, the thermistor used is NTCS0805E3684JXT (680 kΩ @ 25°C). R1 = 336 kΩ, R2 = 20 kΩ,

and R3 = 8.45 kΩ. The LED current per channel is reduced from

97 mA at 25°C to 34 mA at 125°C.

VDD

(4.25 V)

NTC

R2

R1

A80601

ISET

(1.0 V)

R3

GND

Figure 32: Thermal foldback of

LED current using NTC thermistor

ISET

RISET

GND

Figure 31: Adjusting LED current

with an external voltage source

Equation 5:

iISET =

VISET VDAC − VISET

−

R2

RISET

where VISET is the ISET pin voltage (typically 1.0 V), and

VDAC is the DAC output voltage.

When VDAC is higher than 1.00 V, the LED current is reduced.

When VDAC is lower than 1.00 V, the LED current is increased.

Figure 33: LED current varies with temperature

when using thermistor NTCS0805E3684JXT

for thermal foldback

Some common applications for the above scheme include:

• LED binning

• Thermal fold-back using external NTC (negative temperature

coefficient) thermistor

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

23

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

VDD

The VDD pin provides regulated bias supply for internal circuits.

Connect a CVDD capacitor with a value of 1 μF or greater to this

pin. The internal LDO can deliver up to 2 mA of current externally with a typical VDD voltage of about 4.25 V. This allows it

to serve as the pull up voltage for FAULT pin.

There is an alternative way to reset the internal fault status registers. By keeping EN = H and PWM = L for longer than 16 ms,

the A80601 clears all internal fault registers but does not go into

sleep mode. The next time PWM pin goes high, the IC will still

go through soft start process. The difference is that VDD voltage

and CLKOUT signal are always available as long as EN = H.

VDRV

The VDRV pin provides a regulated gate driver supply for

external boost power MOSFET. Connect a CVDRV capacitor with

a typical value of 2.2 μF to this pin. The gate driver can deliver

up to 2 A of peak sink and source current, with a typical VDRV

voltage of 6.5 V. However, its average output current is limited to

approximately 36 mA. Note that average gate driver current is:

Equation 6:

iVDRV = fSW × QG

where fSW is the switching frequency and QG is the total gate

charge of the power MOSFET for VGS = 0 to 6.5 V.

At higher switching frequency, it is important to select a power

MOSFET with low QG to limit the average gate driver current.

Refer to the appendix section for details on MOSFET selection.

Shutdown

Figure 35: As long as EN = H, the IC does not shut down VDD and

CLKOUT. But internal latched faults are cleared by PWM = L for

~16 ms.

If EN pin is pulled low for longer than tEN(OFF) (~16 ms), the

A80601 enters shutdown (sleep mode). The next time EN pin

goes high, all internal fault registers are cleared. The IC needs to

go through a complete soft start process after PWM goes high.

Figure 34: After EN = L for ~16 ms, the IC completely shuts down

so VDD (Blue) decays.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

24

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

FAULT DETECTION AND PROTECTION

FAULT Status

The FAULT pin is an open-drain output that will be pulled low

when a fault occurs. A pull-up resistor (typically around 10 kΩ) is

required between this pin and desired logic level voltage (typically 3.3 to 5 V). Multiple devices with open-drain FAULT pins

can be connected in parallel to form a wired-AND configuration.

This way, when any device reports a fault, the system FAULT

signal is pulled low.

The A80601-1 (One-Out-All-Out option) has a bidirectional

FAULT pin. This means the same pin also serves as an input to

monitor the status of system FAULT signal. When the FAULT

pin is pulled low externally for >8 fSW cycles by another device,

the A80601-1 disables its own boost switch and all LED current

sinks in response. This feature is required in Master/Slave configuration, for example.

The following two simplified flow charts demonstrate the difference between A80601 (unidirectional FAULT pin) and A80601-1

(bidirectional FAULT pin).

IC Off

EN=H &

VIN>UVLO

EN=L

Power up

(VCC, BG ready; GATE

pulled L; Fault checking)

FAULT State

(FAULT pulled L )

Any Fault

detected?

Yes

No

EN=L

IC Ready

(CLKOUT active,

FAULT pulled L )

EN=H &

PWM=L

EN=H & PWM=H

Pin shorted

to GND fault

FAULT =L

LED Pin Check

(In Use, Disabled, or

Shorted to GND)

Time-out without faults

FAULT released

Soft Start

(enable boost SW and

LED current sinks)

Any Fault

detected?

PWM Dimming

Yes

No

LED=on

Clear 16ms timer

EN && PWM =H

EN && PWM =L

LED=off

Start 16ms timer

Timer expired

Figure 36: Simplified A80601 Startup Flowchart

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

25

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

IC Off

EN=H &

VIN>UVLO

EN=L

Power up

(VCC, BG ready; GATE

pulled L; Fault checking)

FAULT State

(FAULT pulled L)

Any Internal

Fault detected?

Yes

No

EN=L

IC Ready

(CLKOUT active,

FAULT pulled L)

EN=H &

PWM=L

EN=H & PWM=H

Pin shorted

to GND fault

FAULT=L

LED Pin Check

(In Use, Disabled, or

Shorted to GND)

Time-out without faults

FAULT released

Any External

detected?

Yes

Fault

(FAULT pulled L

externally)

No

(FAULT=H)

Soft Start

(enable boost SW and

LED current sinks)

Any Internal

Fault detected?

Yes

No

Any External

detected?

Yes

Fault

(FAULT pulled L

externally)

No

PWM Dimming

LED=on

Clear 16ms timer

EN && PWM =H

EN && PWM =L

LED=off

Start 16ms timer

Timer expired

Figure 37: Simplified startup flow chart for A80601-1, showing responses to both Internal

and External FAULT signals

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

26

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

LED String Partial-Short Detect

All LED current sink pins (LED1 to LED4) are designed to withstand the maximum output voltage, as specified in the Absolute

Maximum Ratings table. This prevents the IC from being damaged if VOUT is directly applied to an LED pin due to an output

connector short.

In case of direct-short or partial-shorted fault in any LED string during operation, the LED pin with voltage exceeding VLEDSD will be

removed from regulation. This prevents the IC from dissipating too

much power due to large voltage drop across the LED current sink.

For A80601, the FAULT pin is pulled low in case any LED

string is directly or partially shorted. The suspect LED string is

disabled, while the rest of the LED strings continue to operate.

FAULT pin is latched at low until it is reset by either EN = L or

PWM = L for >16 ms

For A80601-1, all LED strings are turned off in case any LED

string has detected a partial short. FAULT pin is latched at low

until the IC is reset.

Figure 40: A80601-1 startup sequence when LED string#2 has a

partial-short fault (6 × WLED instead of 8). As soon as LED2 pin rises

above VLEDSD (~5 V), the channel is disabled but FAULT remains High.

Figure 38: A80601 Normal startup sequence showing voltage at LED1 and

LED2 pins. VIN = 6 V, output = 8 × WLED in series, current = 4 × 100 mA

At least one LED pin must be at regulation voltage (below

~1.2 V) for the LED string partial-short detection to activate.

In case all of the LED pins are above regulation voltage (this

could happen when the input voltage rises too high for the LED

strings), they will continue to operate normally.

Figure 39: A80601 startup sequence when LED string#2 has a partialshort fault (6 × WLED instead of 8). As soon as LED2 pin rises above

VLEDSC (~5 V), the channel is disabled and FAULT = Low.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

27

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

Overvoltage Protection

The A80601 offers a programmable output overvoltage protection

(OVP). The OVP pin has a threshold level of 2.5 V typical. Overvoltage protection is tripped when current into this pin exceeds ~150 µA.

A resistor can be used to set the OVP threshold up to 40 V approximately. This is sufficient for driving 11 white LEDs in series.

The formula for calculating the OVP resistor is shown below:

Equation 7:

ROVP = (VOVP – VOVP(th)) / iOVP(th)

where VOVP is the desired OVP threshold, VOVP(th) = 2.5 V

typical, iOVP(th) = 150 µA typical.

To determine the desired OVP threshold, take the maximum LED

string voltage at cold and add ~10% margin on top of it.

The OVP event is not a latched fault and, by itself, does not pull

the FAULT pin to low. If the OVP condition occurs during a load

dump, for example, the IC will stop switching but not shut down.

OVP condition is typically caused by an open LED fault, or disconnected output connector. It may be detected either at startup or

during normal operation. This is explained separately below.

Figure 41: A80601 startup with LED2 string open. VOUT hits OVP at

~28 V and LED2 is removed from regulation. FAULT pin goes Low

but remaining LED strings continue to operate.

For A80601-1, all LED strings are disabled in case any string is

not in regulation when VOUT hits OVP. FAULT pin is pulled low

and switching is stopped. The IC remains in latched off state until

it is reset.

CASE 1: OVP AT STARTUP

During soft start period, the A80601 tries to boost VOUT until it

becomes high enough for all LED string to come into regulation.

But if any LED string is open, VOUT will eventually hit OVP. At

this point, the A80601 will disable any LED string that is still not

in regulation. The FAULT pin is pulled low and boost switching

is stopped to allow VOUT to fall. Once VOUT falls below ~97%

OVP, switching resumes to power the remaining LED strings.

Figure 42: A80601-1 startup with LED2 string open. VOUT hits

OVP and all LED string are disabled. FAULT pin goes Low and IC

remains latched off until reset.

Allegro MicroSystems, LLC

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

28

�A80601 and

High Power LED Driver with Pre-Emptive Boost

A80601-1 for Ultra-High Dimming Ratio and Low Output Ripple

CASE 2: OVP DURING NORMAL OPERATION

Boost Switch Overcurrent Protection

When one LED string becomes open during operation, current

through its LED driver drops to zero. The A80601 responds by

boosting the output voltage higher. When output reaches OVP

threshold, the LED string without current is removed from

regulation. The rest of LED strings continue to draw current and

drain down VOUT. Once VOUT falls below ~97% OVP, boost will

resume switching to power the remaining LED strings.

The external boost switch is protected with a cycle-by-cycle

primary current limit. When the voltage sensed at CS pin exceeds

VCS(LIM1) (typically 210mV), the existing switching cycle is

truncated. That means the peak switching current is limited to:

Equation 8: iSW(LIM1) = VCS(LIM1) / RCS

where RCS is the sense resistor connected from source of boost

MOSFET to power ground.

As an example, if RCS = 39 mΩ, then iSW(LIM1) = 5.4 A approximately.