APS13295

Precision Hall-Effect Switch

for Consumer and Industrial Applications

FEATURES AND BENEFITS

DESCRIPTION

•

•

•

•

•

•

•

•

•

•

•

•

The APS13295 Hall-effect switch is a three-wire, planar

Hall-effect sensor integrated circuit (IC) especially suited for

operation over extended temperature ranges (up to 125°C).

Unipolar switch points

Superior ruggedness and fault tolerance

Reverse-polarity and transient protection

Operation from –40°C to 175°C junction temperature

Output short-circuit and overvoltage protection

Superior temperature stability

Resistant to physical stress

High EMC immunity, ±12 kV HBM ESD

Operation from unregulated supplies, 2.8 to 24 V

Chopper stabilization

Solid-state reliability

Industry-standard packages and pinouts

PACKAGES:

Not to scale

3-pin SIP

(suffix UA)

This Hall-effect switch IC is ideal for industrial and consumer

applications and features performance enhancements permitting

high-temperature operation up to 175°C junction temperatures.

In addition, the APS13295 includes a number of features

designed specifically to maximize system robustness such as

reverse-polarity protection, output current limiter, overvoltage,

and EMC protection.

The single silicon chip includes: a voltage regulator, a Hall

plate, small signal amplifier, chopper stabilization, Schmitt

trigger, and a short-circuit-protected open-drain output. A

south pole of sufficient strength turns the output on. Removal

of the magnetic field—or a north pole—turns the output off.

The devices include on-board transient protection for all pins,

permitting operation directly from unregulated or regulated

supplies from 2.8 to 24 V.

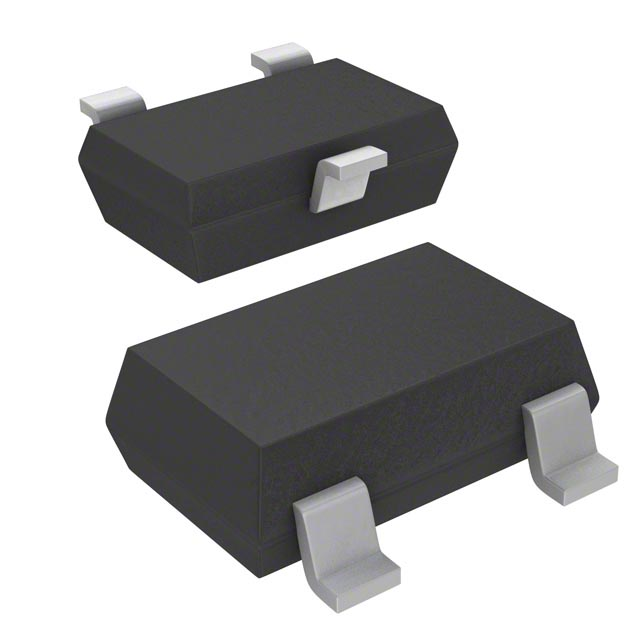

Two package styles provide a choice of through-hole or surface

mounting. Package type LH is a modified SOT23W, surfacemount package, while UA is a three-lead ultra-mini SIP for

through-hole mounting. Both packages are lead (Pb) free and

RoHs compliant with 100% matte-tin leadframe plating.

3-pin SOT23W

(suffix LH)

Functional Block Diagram

VCC

REGULATOR

Hall

Element

DYNAMIC OFFSET

CANCELLATION

TO ALL SUBCIRCUITS

LOW-PASS

FILTER

HALL

AMP.

SAMPLE, HOLD &

AVERAGING

SCHMITT

TRIGGER

VOUT

CONTROL

CURRENT

LIMIT

GND

APS13295-DS, Rev. 3

MCO-0000386

October 4, 2021

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

SELECTION GUIDE

Part Number

Packing [1]

Mounting

Branding

APS13295KLHALX

13-in. reel, 10000 pieces/reel

3-pin SOT23W surface mount

A33

APS13295KLHALT [2]

7-in. reel, 3000 pieces/reel

3-pin SOT23W surface mount

A33

APS13295KUAA

Bulk, 500 pieces/bag

3-pin SIP through hole

A34

Ambient Temperature,

TA

–40°C to 125°C

Switch

Points (Typ.)

BOP

BRP

35 G

25 G

[1] Contact Allegro

[2] Available

for additional packing options.

through authorized Allegro distributors only.

RoHS

COMPLIANT

VSUPPLY

RPULL-UP =

1 kΩ

APS13295

1

CBYP =

0.1 µF

VCC

VOUT

2

VOUT

GND

3

Figure 1: Typical Application Circuit

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

2

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

ABSOLUTE MAXIMUM RATINGS

Characteristic

Voltage [1]

Forward Supply

Reverse Supply Voltage [1]

Output Off

Voltage [1]

Symbol

Notes

Rating

Units

VCC

30

V

VRCC

–18

V

VOUT

30

V

Output Current [2]

IOUT

60

mA

Reverse Output Current

IROUT

–50

mA

Magnetic Flux Density [3]

B

Unlimited

–

165

°C

175

°C

Maximum Junction Temperature

Storage Temperature

TJ(max)

For 500 hours

Tstg

ESD Voltage

–65 to 170

°C

VESD(HBM)

Human Body Model according to AEC-Q100-002

±12

kV

VESD(CDM)

Charged Device Model according to AEC-Q100-011

±1

kV

This rating does not apply to extremely short voltage transients such as load dump and/or ESD. Those events have individual ratings,

specific to the respective transient voltage event.

[2] Through short-circuit current limiting device.

[3] Guaranteed by design.

[1]

GND

PINOUT DIAGRAMS AND TERMINAL LIST

3

Terminal List

Name

1

VOUT

VCC

3-pin SOT23W

(suffix LH)

2

3

VOUT

2

GND

1

VCC

VCC

Description

Number

LH

UA

Connects power supply to chip

1

1

VOUT

Output from circuit

2

3

GND

Ground

3

2

3-pin SIP

(suffix UA)

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

3

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

ELECTRICAL CHARACTERISTICS: Valid over full operating voltage, ambient temperature range TA = –40°C to 125°C,

and with CBYP = 0.1 µF, unless otherwise specified

Characteristics

Symbol

Test Conditions

Min.

Typ.[1]

Max.

Unit [2]

2.8

–

24

V

1

2

3

mA

ELECTRICAL CHARACTERISTICS

Forward Supply Voltage

VCC

Supply Current

ICC

Output Leakage Current

VOUTOFF = 24 V, B < BRP

–

–

10

µA

Output Saturation Voltage

VOUT(SAT)

IOUT = 20 mA, B > BOP

–

200

500

mV

Output Off Voltage

VOUTOFF

B < BRP

–

–

24

V

VCC ≥ VCC(min), B < BRP(min) – 10 G,

B > BOP(max) + 10 G

–

–

25

µs

Power-On Time [3]

Power-On State, Output [3]

IOUTOFF

Operating, TJ < 175°C

tON

POS

Chopping Frequency

fC

Output Rise Time [4]

tr

Output Fall Time [4]

tf

VCC ≥ VCC(min), t < tON

Low

–

–

800

–

kHz

RPULL-UP = 1 kΩ, CL = 20 pF

–

0.2

2

µs

RPULL-UP = 1 kΩ, CL = 20 pF

–

0.1

2

µs

30

–

60

mA

IOUTOFF = 3 mA; TA = 25°C, Output Off

30

–

–

V

VRCC = –18 V, TA = 25°C

–

–

–5

mA

ICC = ICC(max) + 3 mA, TA = 25°C

30

–

–

V

TRANSIENT PROTECTION CHARACTERISTICS

Output Short-Circuit Current Limit

Output Zener Clamp Voltage

Reverse Battery Current

Supply Zener Clamp Voltage

IOM

VZoutput

IRCC

VZ

MAGNETIC CHARACTERISTICS

Operate Point

BOP

–

35

50

G

Release Point

BRP

5

25

–

G

Hysteresis

BHYS

7

10

20

G

(BOP – BRP)

[1] Typical

data are at TA = 25°C and VCC = 12 V.

G (gauss) = 0.1 mT (millitesla).

[3] Guaranteed by device design and characterization.

[4] C = oscilloscope probe capacitance.

L

[2] 1

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

4

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

THERMAL CHARACTERISTICS: May require derating at maximum conditions; see application information

Characteristic

Symbol

Test Conditions

RθJA

Package Thermal Resistance

Value

Units

Package LH, 1-layer PCB with copper limited to solder pads

228

°C/W

Package LH, 2-layer PCB with 0.463 in.2 of copper area each side

connected by thermal vias

110

°C/W

Package UA, 1-layer PCB with copper limited to solder pads

165

°C/W

Power Derating Curve

Maximum Allowable VCC (V)

TJ(max) = 175°C; ICC = ICC(max), IOUT = 0 mA (Output Off)

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

VCC(max)

Package LH, 2-layer PCB

(RθJA = 110 °C/W)

Package UA, 1-layer PCB

(RθJA = 165 °C/W)

Package LH, 1-layer PCB

(RθJA = 228 °C/W)

VCC(min)

25

45

65

85 105 125 145

Temperature (°C)

165

185

TJ(max)

Power Dissipation, PD (mW)

Power Dissipation versus Ambient Temperature

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

0

Package LH, 2-layer PCB

(RθJA = 110°C/W)

Package UA, 1-layer PCB

(RθJA = 165°C/W)

Package LH, 1-layer PCB

(RθJA = 228°C/W)

25

45

65

85

105

125

145

165

185

Temperature (°C)

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

5

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

CHARACTERISTIC PERFORMANCE DATA

Average Supply Current versus Supply Voltage

Average Supply Current versus Ambient Temperature

4.0

4.0

3.5

3.5

TA (°C)

2.5

-40

2.0

25

1.5

3.0

ICC (mA)

ICC (mA)

3.0

125

1.0

12

1.5

24

0.5

2

6

10

14

VCC (V)

18

22

0.0

26

TA (°C)

TA (°C)

-40

-40

25

25

125

125

6

6

10

10

14

VCC14(V)

VCC

(V)

18

18

22

22

26

26

VOUT(SAT)

VOUT(SAT)(mV)

(mV)

500

500

450

450

400

400

350

350

300

300

250

250

200

200

150

150

100

100

50

50

0

0 2

2

-60

-40

-20

0

20

40

TA (°C)

60

80

100

120

140

Average Low Output Voltage versus Ambient Temperature for IOUT = 20 mA

Average Low Output Voltage versus Ambient Temperature for IOUT = 20 mA

Average Low Output Voltage versus Supply Voltage for IOUT = 20 mA

Average Low Output Voltage versus Supply Voltage for IOUT = 20 mA

VOUT(SAT)

VOUT(SAT)(mV)

(mV)

2.8

2.0

1.0

0.5

0.0

VCC (V)

2.5

500

500

450

450

400

400

350

350

300

300

250

250

200

200

150

150

100

100

50

50

0

0 -60

-60

VCC (V)

VCC (V)

2.8

2.8

12

12

24

24

-40

-40

-20

-20

0

0

20

20

40

40

T (°C)

TAA (°C)

60

60

80

80

100

100

120

120

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

140

140

6

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

CHARACTERISTIC PERFORMANCE DATA (continued)

Average Operate Point versus Ambient Temperature

Average Operate Point versus Supply Voltage

60

60

55

55

50

-40

40

35

25

30

25

45

BOP (G)

45

BOP (G)

50

TA (°C)

125

2.8

35

30

12

25

24

20

20

15

15

10

VCC (V)

40

10

2

6

10

14

VCC (V)

18

22

26

-60

50

45

45

-40

30

25

25

BRP (G)

BRP (G)

35

20

20

40

TA (°C)

60

80

100

120

140

VCC (V)

35

30

2.8

25

12

20

125

15

24

15

10

10

5

2

6

10

14

VCC (V)

18

22

26

-60

Average Switchpoint Hysteresis versus Supply Voltage

-40

-20

0

20

40

TA (°C)

60

80

100

120

140

Average Switchpoint Hysteresis versus Ambient Temperature

25

25

23

23

21

TA (°C)

19

17

-40

15

13

25

11

125

9

VCC (V)

19

BHYS (G)

21

BHYS (G)

0

40

TA (°C)

40

17

2.8

15

12

13

24

11

9

7

7

5

-20

Average Release Point versus Ambient Temperature

Average Release Point versus Supply Voltage

50

5

-40

5

2

6

10

14

VCC (V)

18

22

26

-60

-40

-20

0

20

40

TA (°C)

60

80

100

120

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

140

7

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

FUNCTIONAL DESCRIPTION

OPERATION

The output of the APS13295 switches low (turns on) when a

south-polarity magnetic field perpendicular to the Hall element

exceeds the operate point threshold, BOP (see Figure 2). After

turn-on, the output voltage is VOUT(SAT). The output transistor is

capable of continuously sinking up to 30 mA. When the magnetic

field is reduced below the release point, BRP, the device output

goes high (turns off) to VOUTOFF.

V+

VOUT(OFF)

BRP

VOUT

VOUT

0

Key

POS

B > BOP

B < BRP, BRP < B < BOP

V

VOUT(SAT)

BOP

0

Powering-on the device in the hysteresis range (less than BOP and

higher than BRP) will give an output state of VOUTOFF. The correct state is attained after the first excursion beyond BOP or BRP .

Switch to Low

Switch to High

VOUTOFF

POWER-ON BEHAVIOR

Device power-on occurs once tON has elapsed. During the

time prior to tON, and after VCC ≥ VCC(min), the output state is

VOUT(SAT). After tON has elapsed, the output will correspond with

the applied magnetic field for B > BOP or B < BRP. See Figure 3

for an example.

VOUT (SAT)

B+

(south)

V

The difference in the magnetic operate and release points is the

hysteresis, BHYS , of the device. This built-in hysteresis allows

clean switching of the output even in the presence of external

mechanical vibration and electrical noise.

VCC

On the horizontal axis, the B+ direction indicates increasing

south polarity magnetic field strength.

POS

t

BHYS

Figure 2: Device Switching Behavior

Output State

Undefined for

VCC< VCC (min)

VCC (min)

0

t ON

t

Figure 3: Power-On Sequence and Timing

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

8

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

Applications

It is strongly recommended that an external bypass capacitor be

connected (in close proximity to the Hall element) between the

supply and ground of the device to guarantee correct performance

under harsh environmental conditions and to reduce noise from

internal circuitry. As is shown in Figure 1: Typical Application

Circuit, a 0.1 µF capacitor is required. In applications where maximum robustness is required, additional measures may be taken.

In Figure 4: Enhanced Protection Circuit, a resistor in series with

the VCC pin and a capacitor on the VOUT pin enhance the EMC

immunity of the device. It is up to the user to fully qualify the

Allegro sensor IC in their end system to ensure they achieve their

system requirements.

These devices are sensitive in the direction perpendicular to the

branded package face, and may be configured to sense magnetic

fields in a variety of orientations, such as the ones shown in

Figure 5.

VPULL-UP

VSUPPLY

RPULL-UP =

1 kΩ

A

RS =

100 Ω

CBYP =

0.1 µF

A

APS13295

1

VCC

VOUT

VOUT

2

GND

3

A

COUT =

4.7 nF

RS and C OUT are recommended for maximum

robustness in an automotive environment.

Figure 4: Enhanced Protection Circuit

Extensive applications information for Hall-effect devices is

available in:

• Hall-Effect IC Applications Guide, AN27701,

• Hall-Effect Devices: Guidelines for Designing Subassemblies

Using Hall-Effect Devices AN27703.1

• Soldering Methods for Allegro’s Products – SMD and

Through-Hole, AN26009

All are provided on the Allegro website:

www.allegromicro.com

N

S

N

S

B

PC

Figure 5: Sensing Configurations

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

9

�APS13295

Precision Hall-Effect Switch

for Consumer and Industrial Applications

CHOPPER STABILIZATION

A limiting factor for switch point accuracy when using Halleffect technology is the small-signal voltage developed across

the Hall plate. This voltage is proportionally small relative to the

offset that can be produced at the output of the Hall sensor. This

makes it difficult to process the signal and maintain an accurate,

reliable output over the specified temperature and voltage range.

Chopper stabilization is a proven approach used to minimize Hall

offset.

The Allegro technique, dynamic quadrature offset cancellation,

removes key sources of the output drift induced by temperature

and package stress. This offset reduction technique is based on

a signal modulation-demodulation process. Figure 6: Model of

Chopper Stabilization Circuit (Dynamic Offset Cancellation)

illustrates how it is implemented.

The undesired offset signal is separated from the magnetically

induced signal in the frequency domain through modulation.

The subsequent demodulation acts as a modulation process for

the offset causing the magnetically induced signal to recover its

original spectrum at baseband while the DC offset becomes a

high-frequency signal. Then, using a low-pass filter, the signal

passes while the modulated DC offset is suppressed. Allegro’s

innovative chopper stabilization technique uses a high-frequency

clock. The high-frequency operation allows a greater sampling

rate that produces higher accuracy, reduced jitter, and faster signal processing. Additionally, filtering is more effective and results

in a lower noise analog signal at the sensor output. Devices such

as the APS13295 that use this approach have an extremely stable

quiescent Hall output voltage, are immune to thermal stress,

and have precise recoverability after temperature cycling. This

technique is made possible through the use of a BiCMOS process

which allows the use of low-offset and low-noise amplifiers

in combination with high-density logic and sample-and-hold

circuits.

Regulator

Hall Element

Amp

Sample and

Hold

Clock/Logic

Low-Pass

Filter

Figure 6: Model of Chopper Stabilization Circuit

(Dynamic Offset Cancellation)

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

10

�APS13295

Precision Hall-Effect Switch

for Consumer and Industrial Applications

POWER DERATING

The device must be operated below the maximum junction temperature of the device, TJ(max). Under certain combinations of

peak conditions, reliable operation may require derating supplied

power or improving the heat dissipation properties of the application. This section presents a procedure for correlating factors

affecting operating TJ. (Thermal data is also available on the

Allegro MicroSystems website.)

The Package Thermal Resistance, RθJA, is a figure of merit summarizing the ability of the application and the device to dissipate

heat from the junction (die), through all paths to the ambient air.

Its primary component is the Effective Thermal Conductivity, K,

of the printed circuit board, including adjacent devices and traces.

Radiation from the die through the device case, RθJC, is relatively

small component of RθJA. Ambient air temperature, TA, and air

motion are significant external factors, damped by overmolding.

The resulting power dissipation capability directly reflects upon

the ability of the device to withstand extreme operating conditions. The junction temperature mission profile specified in the

Absolute Maximum Ratings table designates a total operating life

capability based on qualification for the most extreme conditions,

where TJ may reach 175°C.

The silicon IC is heated internally when current is flowing into

the VCC terminal. When the output is on, current sinking into the

VOUT terminal generates additional heat. This may increase the

junction temperature, TJ, above the surrounding ambient temperature. The APS13295 is permitted to operate up to TJ = 175°C. As

mentioned above, an operating device will increase TJ according

to equations 1, 2, and 3 below. This allows an estimation of the

maximum ambient operating temperature.

For example, given common conditions such as: TA= 25°C,

VCC = 12 V, ICC = 2 mA, VOUT = 185 mV, IOUT = 20 mA (output

on), and RθJA = 165°C/W, then:

PD = (VCC × ICC) + (VOUT × IOUT) =

(12 V × 2 mA) + (185 mV × 20 mA) =

24 mW + 3.7 mW = 27.7 mW

ΔT = PD × RθJA = 27.7 mW × 165°C/W = 4.6°C

TJ = TA + ΔT = 25°C + 4.6°C = 29.6°C

A worst-case estimate, PD(max), represents the maximum allowable power level (VCC(max), ICC(max)), without exceeding

TJ(max), at a selected RθJA.

For example, given the conditions RθJA = 228°C/W, TJ(max) =

175°C, VCC(max) = 24 V, ICC(max) = 4 mA, VOUT = 500 mV,

and IOUT = 25 mA (output on), the maximum allowable operating

ambient temperature can be determined.

The power dissipation required for the output is shown below:

PD(VOUT) = VOUT × IOUT = 500 mV × 25 mA = 12.5 mW

The power dissipation required for the IC supply is shown below:

PD(VCC) = VCC × ICC = 24 V × 4 mA = 96 mW

Next, by inverting using equation 2:

ΔT = PD × RθJA = [PD(VOUT) + PD(VCC)] × 228°C/W =

(12.5 mW + 96 mW) × 228°C/W =

108.5 mW × 228°C/W = 24.7°C

Finally, by inverting equation 3 with respect to voltage:

TA(est) = TJ(max) – ΔT = 175°C – 24.7°C = 150.3°C

(1) In the above case, there is sufficient power dissipation capability

to operate up to TA(est).The example indicates that TA(max) can

ΔT = PD × RθJA

(2) be as high as 150.3°C without exceeding TJ(max). However, the

TA(max) rating of the device is 125°C; the APS13295 perforTJ = TA + ΔT (3) mance

is not guaranteed above TA = 125°C.

PD = VIN × IIN

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

11

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

Package LH, 3-Pin (SOT-23W)

For Reference Only – Not for Tooling Use

(Reference Allegro DWG-0000628, Rev. 1)

NOT TO SCALE

Dimensions in millimeters

Dimensions exclusive of mold flash, gate burrs, and dambar protrusions

Exact case and lead configuration at supplier discretion within limits shown

+0.125

2.975 –0.075

1.49

4°±4°

Active Area Depth

0.28 ±0.04 mm

3

Die Rotation

Error 4° Max

+0.020

0.180–0.053

0.96

+0.10

2.90 –0.20

+0.19

1.91 –0.06

Hall Element

(not to scale)

0.25 MIN

0.38 NOM

Package Centerline

to Die Centerline ±0.20

8× 10° ±5°

0.55 REF

0.25 BSC

Seating Plane

Gauge Plane

0.95 BSC

Lead Foot Centerline

To Package Centerline ±0.18

All pads a minimum of 0.20 mm from all adjacent pads; adjust as necessary

to meet application process requirements and PCB layout tolerances

Branded Face

0.41 ±0.04

C

0.95

PCB Layout Reference View

0.57 ±0.04

3×

1.00

Package Centerline

to Die Centerline ±0.15

2

1

0.10

2.40

0.70

+0.10

0.05 –0.05

0.40 ±0.10

1.00 ±0.13

SEATING

PLANE

C

A33

1

Standard Branding Reference View

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

12

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

Package UA, 3-Pin SIP

For Reference Only – Not For Tooling Use

(Reference DWG-0000404, Rev. 1)

NOT TO SCALE

Dimensions in millimeters

Exact case and lead configuration at supplier discretion within limits shown

Mold gate and tie bar

protrusion zone

Ejector pin flash

protrusion

R0.25 MAX (2×)

5° (2×)

0.56 MAX

A34

45° (2×)

0.10 MAX

1.52 ±0.05

1.68 MAX

5° (2×)

1

Standard Branding Reference View

+0.08

4.09 –0.05

3.00 ±0.05

2.04

Mold gate and tie bar

protrusion zone

0.15 MAX

Ejector pin

(far side)

Including gate and

tie bar burrs

+0.08

3.02 –0.05

3.10 MAX

Sensor element location tolerance

Standard ±0.20

+0.05

0.08 –0.00

0.50 ±0.08 Active Area Depth

Ejector pin flash

protrusion

Sensor element location tolerance

Standard ±0.20

1.44

Hall Element

(not to scale)

45°

10° (3×)

1.02 MAX

0.79 REF

0.51 REF

0.05 NOM

0.05 NOM

14.99 ±0.25

+0.03

0.41 –0.06

0.10 MAX

0.10 MAX

Dambar Trim Detail

1.27 NOM (2×)

+0.05

0.43 –0.07 (3×)

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

13

�Precision Hall-Effect Switch

for Consumer and Industrial Applications

APS13295

Revision History

Number

Date

Description

–

February 26, 2018

Initial release

1

May 10, 2018

Corrected part numbers in selection guide (page 2); renamed RLOAD to RPULL-UP (page 2, 4, 9).

2

August 2, 2019

Minor editorial updates

3

October 4, 2021

Updated package drawings (pages 12-13)

Copyright 2021, Allegro MicroSystems.

Allegro MicroSystems reserves the right to make, from time to time, such departures from the detail specifications as may be required to permit

improvements in the performance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that the

information being relied upon is current.

Allegro’s products are not to be used in any devices or systems, including but not limited to life support devices or systems, in which a failure of

Allegro’s product can reasonably be expected to cause bodily harm.

The information included herein is believed to be accurate and reliable. However, Allegro MicroSystems assumes no responsibility for its use; nor

for any infringement of patents or other rights of third parties which may result from its use.

Copies of this document are considered uncontrolled documents.

For the latest version of this document, visit our website:

www.allegromicro.com

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

14

�