Customer: ALPS ELECTRONICS HONG KONG

No. : KK-2016-2024

LTD

Date: Aug. 29, 2016

Attention:

Your ref. No.:

Your Part No.: M/EM11B16140AD

SPECIFICATIONS

ALPS Model

: EM11B16140AD

ALPS Spec. No .:

ALPS Sample No.: 0022702490

RECEIPT STATUS

RECEIVED

By. Date

Signature

Name

Title

DSG'D

APP'D

ENG. DEPT.

Sales

Head Office

1-7, Yukigaya-otsuka-machi, Ota-ku, Tokyo, 145-8501 Japan

Phone,+81(3)3726-1211

E318Y

ACY04-G03A

(EA)

�No. KK-2016-2024

S P E C I F I C A T I O N S

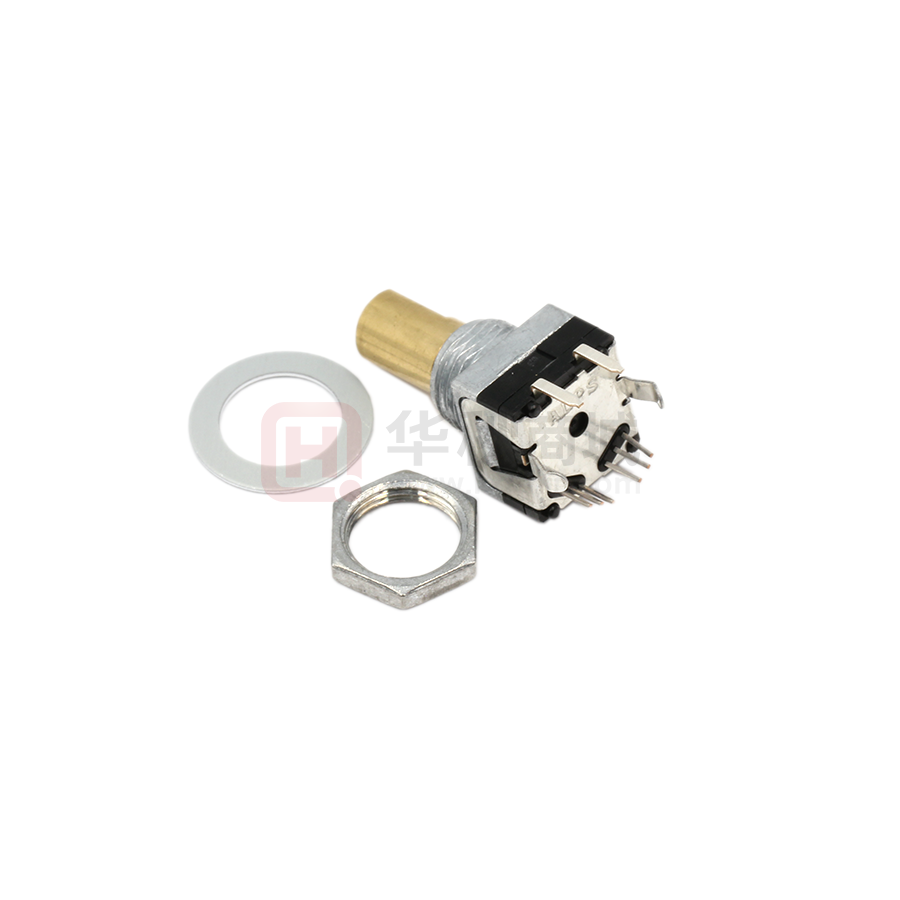

1.THIS SPECIFICATIONS APPLY TO EM11B16140AD ROTARY ENCODERS.

2.CONTENTS OF THIS SPECIFICATIONS.

5LM211-01, 4LE-37

C-2, C-4, C-5

LM211401F

3.MARKING

・MARKING ON ALL UNITS

DATE CODE

4.REMARKS

・FURNISH PACKAGE

NUT:1 WASHER:1

・CAUTION

1.For the export of products which are controlled items subject to foreign and domestic export

laws and regulations, you must obtain approval and/or follow the formalities of such laws and

regulations.

2.Products must not be used for military and/or antisocial purposes such as terrorism, and shall

not be supplied to any party intending to use the products for such purposes.

3.Unless provided otherwise, the products have been designed and manufactured for application to

equipment and devices which are sold to end-users in the market, such as AV (audio visual)

equipment, home electric equipment, office and commercial electronic equipment, information and

communication equipment or amusement equipment. The products are not intended for use in, and

must not be used for, any application of nuclear equipment, driving control equipment for

aerospace or any other unauthorized use.

With the exception of the above mentioned banned applications, for applications involving high

levels of safety and liability such as medical equipment, burglar alarm equipment, disaster

prevention equipment and undersea equipment, please contact an Alps sales representative and/or

evaluate the total system on the applicability. Also, implement a fail-safe design, protection

circuit, redundant circuit, malfunction protection and/or fire protection into the complete

system for safety and reliability of the total system.

4.Before using products which were not specifically designed for use in automotive applications,

please contact an Alps sales representative.

5.Please store the product without open package, keep same condition as delivery, under normal

temperature and humidity, prevent direct sunlight, and corrosive gas exposure then use product

as soon as you can within about six months after delivery. Once you opend package, please use

plastic bag which is used for packaging and prevent product from exposure of outside air then

store the product under same condition as above.

6.About characteristics and conditions for test or measurement are not mentiond in this document

should be examined by each product specification in order to specify them.

���������1.

はんだ付けに関するその他注意事項

Other precautions for Soldering

1)

図のようにP.W.Bの上面にはんだ付けをする配線は、お避け下さい。

Please avoid soldering on upper surface of P.W.B. as shown below.

2)

基板に挿入される金属足ははんだ付けしてご使用願います。

Please solder all inserted metal terminals and bracket to a P.W.B.

3)

はんだ付け後、溶剤などで製品を洗浄しないで下さい。

After soldering , please not to wash or clean products by liquid such as solvent or any similar.

4)

Selective solderingの場合は、Dip solderingと条件が異なりますので、

事前に貴社設備で充分確認の上条件設定をお願いします。

Please thoroughly test and decide appropriate parameters for soldering by your soldering equipment

under actual condition of production.

(for example , parameters for selective soldering can be different from for wave soldering.)

5)

Spray flaxerの場合は、製品の実装側からflaxが浸入しないようにして下さい。

If you use spray fluxer equipment , please prevent the flux from entering the inside of product from

mounting side.

APPD.

CHKD,

DSGD.

Oct.22.2015 Oct.22.2015 Oct.22.2015

S. Urushihara

SYMB.

DATE

APPD. CHKD. DSGD.

K. Sasaki

Y. Ashida

TITLE

その他注意事項 (DIP/手はんだ)

Other precautions (DIP/Manual soldering)

DOCUMENT No.

C-2

(1/1)

�1.

ご使用上の注意 precautions in use

1)

当製品は密閉構造ではありませんので、使用環境によって外部ガスが製品内部に侵入し接点障害を起こす

場合があります。 同一セット内に以下の様な部材を使用しないで下さい。

・硫化、酸化ガスを発生する部材(例:ゴム材,接着材,合板,潤滑剤,梱包材)

・低分子シロキサンガスを発生する部材(例:シリコン系ゴム,潤滑剤,接着剤)

・低分子シロキサンガスを発生する部材(例:シリコン系ゴム 潤滑剤 接着剤)

As this product does not have hermetical structure , it is possible gas from outside get inside of product

and may cause contact failure depends on using environment. Please avoid using following materials.

If you have to use any of material in parentheses , please pay special attention and confirm it does not

influence to products through tests under actual using conditions.

-materials which may generate sulfide gas or oxidized gas.

(rubber, glue , adhesive , plywood , packaging material)

-materials which may generate low-molecular-weight siloxane gas.

(silicone base rubber , lubricant ,glue)

glue)

2)

高湿度環境下,又は結露する環境下,液体が製品にかかる環境下では、端子間の電流リークが発生する

恐れがありますのでご使用にならないで下さい。

Please not to use this product under the atmosphere with high humidity , with possibility of dew

condensation or of direct splash of liquid. Because it may cause leak between terminals.

3)

ツマミを挿入する際に、軸に規定荷重以上の力や衝撃荷重が加わると製品が破壊する場合があります。

ツマミの寸法や 挿入治具の圧力管理は、規定荷重以下で挿入できる設定の配慮をお願いします。

ツマミの寸法や

挿入治具の圧力管理は 規定荷重以下で挿入できる設定の配慮をお願いします

The product may have malfunction if excessive stress or impact than specified value is applied when

insert knob to the shaft.

Please fix appropriate dimension for knob or fix insertion force of knob of mounting equipment which

can avoid excessive stress to the product than specified value.

4)

使用温度範囲の上限、下限付近で長期間の連続使用はできません。

動作寿命の規定は常温15℃~35℃、常温25%~85%の環境条件に限ります。

使用温度範囲の上限 下限付近で長期間の連続動作を行う場合は 機種毎に仕様規定が可能かどうか

使用温度範囲の上限、下限付近で長期間の連続動作を行う場合は、機種毎に仕様規定が可能かどうか

確認が必要になります。

This product can't be continuously used under high operating temperature or low operating temperature

specified in this document. Unless otherwise specified , the durability is specified only under normal

conditions , temperature 15 to 35 degree Celsius and related humidity 25 to 85%.

When this product is operated at temperature near from upper or lower limit of operating temperature range ,

feasibility must be examined by each product specification.

5)

製品本体を規定の取付面まで挿入して水平になるように取付けて下さい

製品本体を規定の取付面まで挿入して水平になるように取付けて下さい。

水平にならないまま取付けますと、動作不良の要因となります。

Insert these switches to the specified mounting surface and mount them horizontally.

If not mounted norizontally, these switches will malfunction.

6)

塵埃が多い環境で使用されますと塵埃が開口部から入り出力不良や動作不良の原因と

なることがありますのでセット設計時に予めご配慮ください。

If this product is used under dusty conditions , dust or debris may get inside of product from openings and

possible to ca

cause

output

failure

malfunction.

se o

tp t fail

re or malf

nction

Please consider protections against dust when surrounding parts of the product are designed.

APPD.

CHKD,

DSGD.

Oct.15.2015 Oct.15.2015 Oct.15.2015

S. Urushihara

SYMB.

DATE

KV,SV,EC,JSX

APPD. CHKD. DSGD.

K. Sasaki

Y. Ashida

ご使用上の注意 (共通)

TITLE

Precautions in use (Common)

DOCUMENT No.

C-4

(1/1)

�1. ご使用上の注意

precautions in use

1)

プッシュスイッチ付きの製品は、軸が押されたままの状態で梱包や保管をされますと

スイッチ部に支障をきたす恐れがありますのでご配慮下さい。

F product

For

d t variety

i t with

ith push

h switch

it h , please

l

pay attention

tt ti tto storage

t

condition

diti b

because if shaft

h ft is

i b

being

i

pushed for long time during storage or after built in final products , the switch function may have malfunction.

2)

プッシュスイッチ付きの製品は、軸をプッシュした状態で軸を回転するとスイッチ部に支障をきたす恐れがあります。

For product variety with push switch , if shaft is rotated while shaft is pushed , it may cause deterioration to

push switch functions.

3)

プッシュスイッチ付きの製品は、軸に挿入したツマミの中心を押すようにして下さい。

直径が大き 場合

縁を押すと感触が変

た 作動力が 大 強くなる れがあ ます

ツマミの直径が大きい場合、ツマミの縁を押すと感触が変化したり、作動力が過大に強くなる恐れがあります。

For product variety with push switch , please design knob to encourage end-user to push center of knob

which is fixed to the shaft of product. Because if the area near from edge of knob is pushed ,

it may bring a bad influence , such as unexpected heavy operating force to switch operation feeling

especially knob has large diameter.

APPD.

CHKD,

DSGD.

Oct.22.2015 Oct.22.2015 Oct.22.2015

S.Urushihara

SYMB.

DATE

APPD. CHKD. DSGD.

J.Yashiro H.Miura

TITLE

ご使用上の注意 (プッシュスイッチ付き)

Precautions in use (with push switch)

DOCUMENT No.

C-5

(1/1)

��